Abstract

A retrospective exposure assessment was performed for use in a health outcomes study of a facility manufacturing circuit boards, business machines, and other equipment during the years 1969–2002. A matrix was developed identifying chemical use by department-year based on company-provided information. Use of six chemical agents (fiberglass, lead, methylene chloride, methyl chloroform, perchloroethylene, and trichloroethylene) and six chemical classes (acid-base, aromatic hydrocarbons, chlorinated hydrocarbons, other hydrocarbons, chlorofluorocarbons, and metals), and general (including unspecified) chemicals was identified. The matrix also contained an assignment for each department-year categorizing the potential for use of chemicals as negligible, intermittent/incidental, or routine. These department-based exposure matrix data were combined with work history data to provide duration of potential chemical use for workers. Negligible, intermittent/incidental or routine extent-of-chemical-use categories comprised 42.6%, 39.4%, and 17.9%, respectively, of total person-years of employment. Cumulative exposure scores were also developed, representing a relative measure of the cumulative extent of potential exposure to the six chemical agents, six chemical classes, and general (including unspecified) chemicals. Additionally, the study period was divided into manufacturing eras showing trends in chemical use, and showing that process use of trichloroethylene and methylene chloride ended in the mid-1980s and the mid-1990s, respectively. This approach may be useful in other assessments addressing a variety of chemicals, and with data constraints common to retrospective chemical exposure studies.

Keywords: occupational exposure, circuit board manufacture, substrate production, exposure matrix, exposure score, chlorinated solvents, trichloroethylene, perchloroethylene

INTRODUCTION

The chemical exposure assessment described in this article was developed for use in a NIOSH cohort mortality study and testicular cancer incidence study involving 34,494 workers employed at a microelectronics and business machine manufacturing facility during the period 1969–2002.(1) The principal product manufactured initially was time recorders, and in subsequent years a wide variety of devices were produced including business-related tabulating, accounting, calculating, computing, typing, and other machines. By 1965 a new microelectronics manufacturing building had been constructed, and increasingly the facility was occupied in the manufacture of printed circuit boards as well as bank machines, printers, and other business machines.

Circuit board manufacture required increased use of chemicals at wet processing lines, and this work continued until that portion of the business was sold in 2001. Table I illustrates some of the common manufacturing steps used in printed circuit board manufacture at the facility and some of the chemicals used during the study period.(2) Steps varied with the specific product being manufactured and could include combinations of process tasks and a variety of chemicals depending on the specifications of the particular circuit board or other item produced. Integrated circuits (i.e., computer chips) were not manufactured at this facility.

TABLE I.

Common Process Step Order in Circuit Board Manufacture at the FacilityA

| Process | Description | Typical Chemicals Used Historically |

|---|---|---|

| Treater | Manufacture of prepreg from resin-impregnated fiberglass cloth | Epoxy resin; methyl ethyl ketone; ethylene glycol monomethyl ether; fiberglass; methylimidizole, dicyandiamide |

| Core lamination | Prepreg and copper sheets are layered, laminated and trimmed to form raw boards (cores). | NAB |

| Apply resist | After pre-cleaning core, sheets containing photoresist are applied and fixed using heat and pressure (start of internal circuitize steps). | Pumice, dry film resist |

| Expose | Glass artwork of the desired circuitry is cleaned and placed over the core which is exposed to ultraviolet light. | Isopropyl alcohol, trichlorotrifluoroethane, methanol, methyl ethyl ketone |

| Develop resist | Unexposed resist is removed. | Potassium carbonate, sodium carbonate, methyl chloroform, trichloroethylene |

| Etch | Unprotected copper is removed. | Cupric chloride, hydrochloric acid |

| Strip resist | Exposed resist is removed uncovering the remaining copper circuit. | Sodium hydroxide, potassium permanganate, sulfuric acid, methanol, methylene chloride |

| Drill | Holes are drilled in board. | NA |

| Surface prep | Hole surface is prepared for plating and burrs and debris removed. | Sodium hydroxide, sulfuric acid, benzotriazole, dimethyl aminoborane, hydrochloric acid, sodium carbonate |

| Copper plating | Holes are plated to create electrical connections through the board. | Sodium carbonate, sodium permanganate, sulfuric acid, cupric chloride, hydrochloric acid, copper sulfate, dimethylaminoborane, formaldehyde, sodium hydroxide, acetic acid, methanol, phosphoric acid, potassium hydroxide |

| Composite lamination | Circuitized cores are laminated together to form multi-layered boards. | NA |

| External circuitize | Previous process steps are repeated to create circuitry on the exterior and through the board. | (Same chemicals as above in process steps apply resist through copper plating) |

| Component placement | Components are mounted and soldered. | Isopropyl alcohol, perchloroethylene, flux, lead, tin |

| Inspection, testing and repair | Inspection is conducted at various points in the process and hand soldering is performed for repairs. | Isopropyl alcohol, flux, lead, tin |

Adapted from Pinkerton(2).

NA = Chemical use not identified.

In the early 1970s a product line was added, producing metalized ceramic substrates having microelectronic circuitry. The process steps used in the application of circuitry to substrates were similar to those used in circuit board manufacture, but the materials and process chemistry differed. Research and development was an ongoing function at the facility, such that product improvements and new products were frequently introduced as the years progressed. As the associated process improvements were implemented, changes in process chemistry requirements and chemicals were also made. Some limited chemical work was also involved in the manufacture of printers and bank machines during the study period. Machine manufacturing operations primarily involved metalworking and related activities, along with associated assembly and inspection. Solvents were historically used to clean metal parts manufactured for various types of data processing machines.

This article describes how a retrospective exposure assessment was developed for use in a health outcomes study of the manufacturing facility. The exposure assessment was used to categorize workers into groups exposed to various solvents and other chemicals.

METHODS

Overview

This exposure assessment method employed the available source data to identify departments that used chemicals over time. These assignments were used with work history data to determine duration of potential exposure. Professional judgment was used to categorize departments into exposure groups by type of chemical work activity (e.g., routine use), and to assign categorical ratings of exposure as in Brophy(3) and Labreche.(4) Cumulative exposure scores for chemicals were also calculated for each worker, and are defined in this assessment as duration employed in departments using chemicals, modified by two factors considering: 1) the extent of general chemical use based on department function, and 2) the position factor for the worker’s position title. This chemical exposure score represents a relative measure of the cumulative extent of potential exposure to a chemical for a worker, for comparison with other facility workers’ scores. Since there were insufficient data available to conduct a quantitative chemical exposure assessment, semi-quantitative methods were used to calculate these exposure scores. Semi-quantitative methods are preferred to methods based solely on duration of exposure or employment when data are not sufficient for use of quantitative methods.(5) Additionally, manufacturing eras were developed as part of this assessment to allow the timing of major process changes involving chemical use to be considered in the health outcomes study, as suggested by Axelson and Soderkvist.(6)

Information Sources

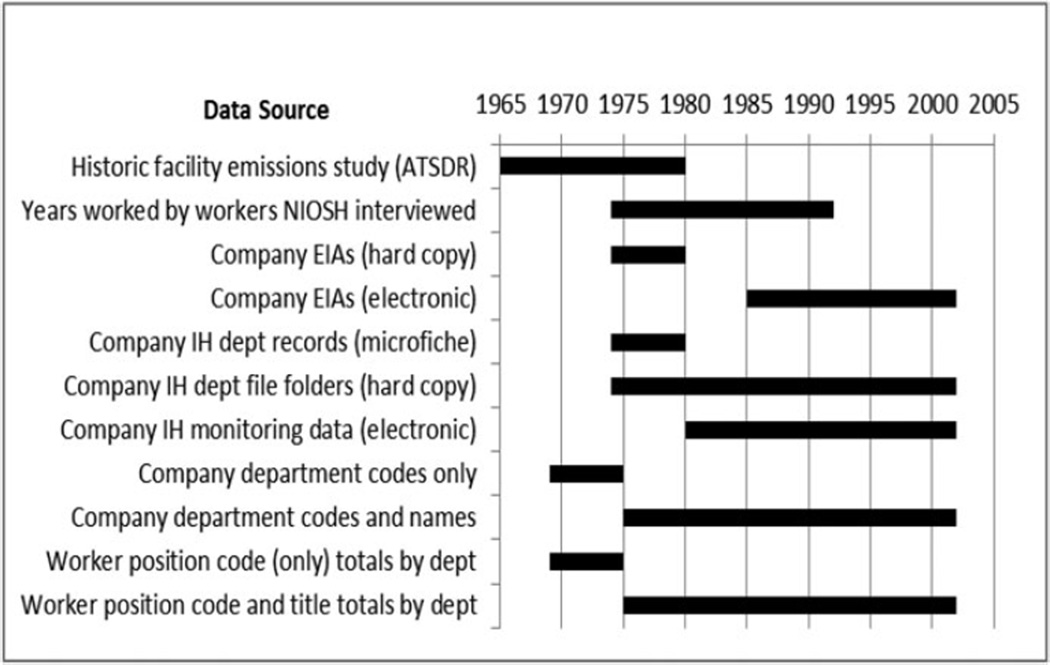

The majority of the chemical use and exposure information was obtained from company industrial hygiene (IH) department records. Information was also obtained from company environmental impact assessments (EIAs). Some additional information and clarification concerning manufacturing process steps and chemicals, changes in process equipment and buildings over time, department functions, job title responsibilities, and worker locations were also obtained during meetings with company employees who formerly worked at the facility in the functional areas of manufacturing, engineering, inspection, human resources, and emergency services. Company chemical use and exposure data were limited for the 1969–1973 period, so estimates of quantities of volatile organic compounds used at the facility for several years during the period 1969–1980 were obtained from an Agency for Toxic Substances and Disease Registry (ATSDR) study(7) evaluating historical outdoor chemical air emissions in the community near the facility. Figure 1 shows the information sources and their date ranges.

FIGURE 1.

Exposure assessment data sources and time periods (Department name and position data were obtained from company employment records for 1969–2002. Company chemical data from industrial hygiene (IH) sources and from environmental impact assessments (EIAs), clarified during meetings with employees, were supplemented with Agency for Toxic Substances and Disease Registry (ATSDR) information < 1980).

Rationale for Approach

While some industrial hygiene measurement data were available in the company database for the chemical agents (see Supplemental Table SI), it was not possible to link these data to the individual workers. There were two variables in the company employment database potentially of use for exposure assessment—department and position code. Unfortunately, the company-provided industrial hygiene database included only the former. Efforts to find alternative information sources to identify groups of workers exposed to similar levels of chemical agents were not successful. For example, position descriptions were examined in an effort to group position codes by similar chemical exposure tasks, but position descriptions varied greatly in content and were largely developed for administrative purposes. Therefore, these were not adequate for determination of tasks performed or for creating exposure groups across departments. Moreover, company representatives stated that position code did not necessarily reflect the tasks an employee performed, and employees in a given department with the same position code may have had significantly different exposures. In addition, there were numerous departments (n = 2986) and multiple position codes in many departments (see Supplemental Table SI). Initial evaluation of the company industrial hygiene data reviewed during the feasibility study(2) had indicated that inadequate data were present for a quantitative chemical exposure assessment. Evaluation of the data obtained for this study confirmed that conclusion.

Of particular interest was characterization of the exposure levels for trichloroethylene because exposures to this chemical were of particular concern to community stakeholders, and because it was known that significant quantities of this chemical had been used at this facility in the late 1960s and early 1970s.(7) Beginning in the early 1970s, the facility made significant efforts to reduce the volume of trichloroethylene used by various measures including substitution, process line changes, improved environmental controls, and workplace engineering controls. Unfortunately, no industrial hygiene air sample data for trichloroethylene were available in the database prior to 1980, and the exposure level data available for later years (n = 20 sampling results) were not representative of the prior processes, and were not suitable for estimation of earlier exposure levels (see Supplemental Figure SI).

Additionally, for all chemicals of interest the following impediments to exposure assessment development existed:

No airborne concentration level data were available for many departments which used chemicals during the study period (see Supplemental Table SI)

Data concerning processes and associated engineering controls were insufficient to develop estimates of exposure

No position code data were present in the company-provided industrial hygiene database so chemical concentration levels could not be categorized by jobs, precluding the development of similar exposure groups across the facility

It was not always possible to distinguish sampling performed in response to issues from routine sampling, and

The large number of departments and years (n = 27807 department-years) made obtaining quantifiable exposure information from former employees infeasible and beyond the scope of this assessment.

Exposure Matrix Development

In the approach taken, the industrial hygiene air sample database and other company information sources (e.g., the environmental impact assessment database, various hardcopy industrial hygiene inspection reports, memoranda, and similar documents) were used to identify departments in which the chemical agents were used over time. Work history data from the company employment database allowed the time worked by an individual in each department to be accumulated.

Personnel data obtained from the company were used to identify department codes and titles for department-years. Similarly, personnel data were used to identify the position codes and titles, and their frequencies for department-years. For years prior to 1975, these personnel data included department and position codes, but were incomplete with respect to department names and position titles.

A National Institute of Occupational Safety and Health (NIOSH) exposure assessment database was developed containing records coded by NIOSH from various hardcopy forms, documents, surveys, reports, and memos found in company industrial hygiene files and from early hardcopy EIAs, as well as data from electronic air sample database files and electronic EIA files. Records were created for each data variable (or group of data variables), from the source material that could be related to a department-year combination. The main data variables of interest were process, equipment, building, floor, and chemicals.

The exposure assessment approach and the methods used to create the department-exposure matrix were developed for this facility by three industrial hygienists experienced in retrospective exposure assessment. All three of these industrial hygienists also traveled to two company sites, met with company representatives, and conducted interviews with workers formerly employed at the facility under study. Two of these industrial hygienists subsequently carried out the review of the data in the exposure database and jointly made consensus assignments of department-year chemical use in the spreadsheets from which all exposure matrix data resulted. Chemical agents (fiberglass, lead, methyl chloroform, methylene chloride, perchloroethylene, and trichloroethylene) historically used at the facility in major process activities, and of interest from an occupational health standpoint, were selected for assessment. Use of chemical classes (acid-base, aromatic hydrocarbons, chlorinated hydrocarbons, other hydrocarbons, chlorofluorocarbons, and metals), and use of general (including unspecified) chemicals were also assessed. For all departments, the department name and department position title frequencies were obtained from available employment data by other study team members; exposure assessors were blinded to all individual employee identification and health outcome data.

For 750 departments, chemical use or other supplemental chemical-related information was found in company-supplied records for at least one year. The starting point for the chemical exposure matrix for these 750 departments was a spreadsheet to record yearly chemical use data, related supplemental information (building, floor, process, equipment, and comments) department name, and aggregate data on worker position titles and frequencies. Department name and position titles were not available for pre-1975 years; however, these were determined using department number and position code data available for the entire study period. If pre- and post-1975 position code and position code frequency data were consistent for a continuing department number, the pre-1975 department function was assumed to be similar to the post-1975 function.

The identification of chemical use by department-year was performed by a team of two NIOSH exposure assessors. A “D” was entered in the department spreadsheet cell when data (D) naming the chemical of interest (i.e., named in survey reports, office correspondence, industrial hygiene monitoring data, process descriptions, and environmental impact documents, and so on) were present for a department-year. Frequently, data showing use of a chemical by name were available in spreadsheet cells for non-consecutive years. Sometimes supplemental information was available in years without named chemicals. Exposure assessors examined all spreadsheet data in nearby department-years and assigned chemical use as probable (P) when departments with similar department name and worker position titles (and frequencies), as well as consistent supplemental data for building, floor, process, and/or equipment, were within 1 to 3 years of matrix cells containing chemical monitoring or use data. Similarly, “L” (likely) was assigned if the matrix cell in question was 4 or more years from a cell containing chemical monitoring or use data, and if the supplemental data were consistent in the judgment of the exposure assessors. While not used in this exposure assessment, the relative confidence in the chemical usage assignment (i.e., D, P, or L) is available for possible use in the current or future associated epidemiology studies. When the spreadsheet evaluation of the department was completed a value of 1 ( = yes) was entered in the chemical exposure matrix for the specific chemical agent or class if use was identified (i.e., C = 1); alternatively, a value of 0 was entered for chemical agents and classes for which no use was identified.

The remaining departments (n = 2236) lacked any chemical use or supplemental information so determinations as to use of specific chemical agents or classes were not possible. However, some of these remaining departments had department names (e.g., test, assembly, laboratory, process, service, and so on) and associated position titles and frequencies indicating that these departments may also have used chemicals. To address the potential for chemical use for every department-year in the matrix, a separate exposure metric was developed. Each department-year was categorized into a general chemical use exposure group by consensus of two NIOSH exposure assessors, based on exposure characteristics associated with department name and department position titles as shown in Table II.

TABLE II.

Categorization of Facility Department-years into Exposure Groups

| EXP_GRP | EXP_GRP Chemical Use Potential |

Department Name Characteristics & Functions |

Position Title ExamplesA |

Chemical Process/ Activity Characteristics |

|---|---|---|---|---|

| 0 | Negligible | Administrative, programming, sales, accounting, advisory, human resources, or other non-manufacturing- related department name | Manager, secretary, clerk, financial analyst, computer oper, programmer, accountant, cafeteria helper, buyer | No chemical processes |

| 1A | Intermittent/incidental-general | Assembly, circuit board drilling, inspection and testing, bench work and repair, maintenance of facilities and equipment, lab and development work, regulatory oversight, engineering and other manufacturing support. | Assembler, assembly test & repair spec, analyzer & repairer, facility maint spec, equipment maint spec, engineer/scientist, expediter, inspector, materials attendant | Small quantity and/or infrequent chemical use. Tasks in plant or lab environment. |

| 1B | Intermittent/ incidental - manufacturing engineering | Manufacturing engineering for chemical processes | Engineer /scientist, mfg methods specialist, prod tech, technical specialist | Small quantity and/or infrequent chemical use. Tasks in plant or lab environment. |

| 2A | Routine use-chemical process | Circuit board and substrate manufacturing work, and other hands-on chemical work | Mfg operator, process equip operator, assm. mach. operator, mfg attendant, auto equip specialist, metal plater, solution maintenance specialist | Routine hands-on work with process equipment involving chemicals. |

| 2B | Routine use - metal machining | Metal working including machining, grinding, milling, and degreasing and so on | Milling mach operator, grinding mach oper, tool/model maker, lathe oper | Routine hands-on work with machining equipment involving chemicals. |

Abbreviations reflect examples of raw data available in the company work history records. Other documentation including company job descriptions and memos include these explanations: assm - assembly; auto - automated; equip - equipment; mach - machine; maint - maintenance; mfg - manufacturing; oper - operator; prod - production; spec - specialist; tech - technician.

General chemical use exposure group 0 (Exp_Grp 0) included departments with no chemical processes and negligible potential for chemical use or exposure (e.g., administration, sales, and accounting). General chemical use exposure group 1 (sub-grouped into Exp_Grp 1A and 1B) included departments characterized by the potential for small quantity and/or infrequent chemical use. Exp_Grp 1B was a relatively small group comprising chemical manufacturing engineering departments, while Exp_Grp 1A contained all other departments having intermittent /incidental chemical use potential (e.g., assembly, inspection and testing, lab work, research and development). General chemical use exposure group 2 comprised departments characterized by routine use of chemicals and included Exp_Grp 2A departments operating process equipment involving chemicals (e.g., circuit board manufacturing, substrate manufacturing), and Exp_Grp 2B departments operating metal machining equipment using chemicals (e.g., grinding, tooling, and modeling).

The completed exposure matrix included a record for each department-year with a cell containing an exposure group assignment (i.e., 0, 1A, 1B, 2A, or 2B), as well as six cells for chemical agent determinations, six cells for chemical class determinations, and one cell for the general chemical determination (i.e., 0, 1). These matrix data were combined with work history data to determine the duration of potential chemical exposure for each worker.

Chemical Exposure Score

The chemical exposure score developed in this assessment represents a relative measure of the cumulative extent of potential exposure to a chemical for a worker, for comparison with other facility workers’ scores. While it is possible to use duration of exposure alone to provide a measure of cumulative chemical exposure potential, data available for this study allowed a modification to that approach. This approach modified the duration worked in departments using a specific chemical agent or class with the extent of general chemical use by the department, and limited consideration of the individual worker’s extent of exposure based on position title. A worker’s cumulative exposure score to a chemical agent or class was calculated using the equation below. Since chemical exposure matrix values of C and G were associated with each year, calculation of cumulative exposure scores required summation across all years (y) within each work history period, and summation across all work history periods (p) of employment for a worker.

| (1) |

Where:

C = chemical class / agent usage in the time period (Yes/No values = 1 or 0)

G = extent of general chemical use based on department function (Exp_Grp values = 0, 1, or 2)

D = duration of a worker’s tenure in a department in the time period (in days)

FP = the position factor for worker’s position title (values = 0.1 or 1)

The chemical class/agent variable (C) reflects whether a particular chemical agent (fiberglass, lead, methyl chloroform, methylene chloride, perchloroethylene, or trichloroethylene) or chemical class (acid-base, aromatic hydrocarbons, chlorinated hydrocarbons, other hydrocarbons, chlorofluorocarbons, or metals) was assigned as used (C = 1) in a department in a particular year, or not used (C = 0).

The variable G is used to rank the extent of chemical use for each department-year combination in the underlying department-based exposure groups: G = 0 for negligible chemical use potential, Exp_Grp 0; G = 1 for intermittent/incidental chemical use potential, Exp_Grp 1A or 1B; G = 2 for routine chemical use potential, Exp_Grp 2A or 2B. A value of 2 does not mean that a routine chemical use department-year has time-weighted-average (TWA) airborne chemical exposure concentrations twice the numeric value of an intermittent/incidental use department-year, but rather serves as a ranking factor to represent an increase in potential for chemical use and exposure when the functions of the department and its personnel are considered. A similar 0, 1, 2 weighting scheme has been used previously(3) to estimate occupational exposure to chemicals among worker groups rated in low, medium, and high potential exposure categories by experts using professional judgment.

While the company-provided industrial hygiene air sample database did not include position code data in the chemical monitoring level records, position code data were available for each employee in the company-provided employment history data. To account for major within-department differences in potential for exposure to chemicals, position codes were used to distinguish minimally exposed administrative and clerical workers from other workers who carried out the processing functions of the department that resulted in potential exposure to the targeted chemicals. It was not feasible to create factors to differentiate all within-department exposures, except for the expected extent of exposure difference between, 1) administrative and clerical personnel judged minimally exposed to chemicals, and 2) all other workers.

NIOSH developed a list of codes for positions judged to be minimally exposed to chemicals and provided this to a small group of company employees with facility experience and to a stakeholder group representative with facility experience for review, and received concurrence from both. Minimally exposed position codes included position titles such as “clerk” and “secretary.” The position factor (FP) for these minimally exposed position codes was given a non-zero value (0.1) since these office workers supporting manufacturing, testing, and development were often located nearby in the building and floor to their department work area, and they may have had occasion to visit or pass through the area occupied by fellow department members. All other position codes were assigned an FP value of 1. As an illustration, the exposure score associated with being a member of a chemical process department using methylene chloride for one year was reduced by multiplication by a position factor of 0.1 for a position code associated with a clerk. This order of magnitude weighting factor has been used previously(3) where data are lacking and categorical exposure levels are expected to vary widely.

Calculation of a worker’s cumulative exposure score presumes that the specific chemical agent/class has been identified, however this was not always possible, particularly in the intermittent/incidental chemical use groups. Use of the above equation results in a cumulative exposure score of zero for work history years where there is no chemical agent or class known (since C = 0), even though the corresponding exposure group assignment may indicate that the potential for intermittent/incidental or routine chemical exposure existed. To address this and to allow calculation of a score representing the potential for cumulative exposure to unspecified chemicals in addition to identified chemicals (thereby identifying all potentially exposed workers in the cohort) a separate cumulative exposure score calculation method was developed which does not consider the chemical agent or class. A worker’s score for cumulative exposure to general (including unspecified) chemicals was calculated using the following equation summed over all years within each work history period, and summed over all work history periods employed.

| (2) |

Where:

G = extent of general chemical use based on department function (Exp_Grp values = 0, 1, or 2)

D = duration of a worker’s tenure in a department in the time period (in days)

FP = the position factor for worker’s position title (values = 0.1 or 1)

Manufacturing Eras

In industrial settings, chemical exposure levels commonly change over time (e.g., may be reduced as hazards are recognized and addressed, and may be increased or decreased as process methods, products, and production levels change). Since it was not feasible to include estimates of exposure levels in this assessment, the timing of a worker’s accumulated exposure score for a chemical was considered. For example, if two workers have identical trichloroethylene exposure scores, but one individual worked in the first five years of an era of manufacturing when trichloroethylene was in use, and the second worked in the last five years of the era, subgrouping these workers for analysis of health effects may be informative.

The 1969–2002 study period was divided into segments (i.e., manufacturing eras) which best reflect exposure assessor knowledge of changes in workforce exposure potential based on the major chemicals used. Manufacturing eras have been developed for other retrospective exposure assessment studies.(8) Sources of information for development of manufacturing eras in this study included process information contained in the company industrial hygiene documents and EIAs, an ATSDR study(7) of outdoor emissions, and discussions with employees formerly employed at the facility. Information was reviewed to identify the history of major process changes in manufacturing activities involving the use of chemicals.

Major products manufactured were also considered. The key items identified in manufacturing which may have affected changes in major chemicals used during the study period included: the introduction of substrate-MC cermet manufacturing operations in 1974; elimination of trichloroethylene use and conversion of many solvent-based circuit board processes to aqueous-based processes by 1986; elimination of chlorinated solvents in panel degreasing by 1994; and ending of substrate-MC cermet manufacturing operations by 2000, with circuit board manufacturing operations continuing throughout the entire study period until 2002.

RESULTS

The chemical exposure matrix which was created contained a general chemical use exposure group assignment (Exp_Grp) for each department-year record (n = 27807) for the entire study cohort during the period 1969–2002. The chemical exposure matrix also identified those department-years associated with use of chemical classes and chemical agents (specific C = 0/1 scores). The matrix assignment data and the resulting person-year data are summarized in Table III.

TABLE III.

Summary of Chemical Matrix and Person Exposure Data

| Exposure Group - Chemical Use Potential |

||||||

|---|---|---|---|---|---|---|

| Intermittent-Incidental Use |

Routine Use |

|||||

| Item | Negligible Use Exp_Grp 0A |

General Exp Grp 1A |

Mfg Engineering Exp Grp 1B |

Chemical Process Exp Grp 2A |

Metal Machining Exp Grp 2B |

TotalsB |

| Overall | ||||||

| Number of matrix department-yearsC | 16824 | 8602 | 717 | 1171 | 493 | 27807 |

| % of department-yearsD | 60.50% | 30.90% | 2.60% | 4.20% | 1.80% | 100.00% |

| Number of personsE | 18266 | 17810 | 1856 | 11195 | 1773 | 34494 |

| Person-years employed at facility | 113369 | 97496 | 7566 | 38100 | 9624 | 266309 |

| % of person-yrs employed at facility | 42.60% | 36.60% | 2.80% | 14.30% | 3.60% | 99.90% |

| Chemicals, GeneralF | ||||||

| Number of persons | 0 | 17810 | 1856 | 11195 | 1773 | 24290 |

| Person-years | 0 | 97496 | 7566 | 38100 | 9624 | 152786 |

| % of person-yrs. employed at facility | 0.00% | 36.61% | 2.84% | 14.31% | 3.61% | 57.37% |

| Acid-Base | ||||||

| Number of matrix department-years | 7 | 513 | 103 | 820 | 26 | 1469 |

| % of department-years | 0.00% | 1.80% | 0.40% | 2.90% | 0.10% | 5.30% |

| Number of persons | 214 | 3135 | 496 | 9125 | 260 | 11387 |

| Number of person-years | 168 | 7737 | 1115 | 28072 | 465 | 37556 |

| % of person-yrs. employed at facility | 0.06% | 2.91% | 0.42% | 10.54% | 0.17% | 14.10% |

| Aromatic Hydrocarbons | ||||||

| Number of matrix department-years | 3 | 168 | 41 | 288 | 2 | 502 |

| % of department-years | 0.00% | 0.60% | 0.10% | 1.00% | 0.00% | 1.80% |

| Number of persons | 47 | 1128 | 208 | 4316 | 34 | 5481 |

| Number of person-years | 15 | 2435 | 483 | 9010 | 27 | 11970 |

| % of person-yrs. employed at facility | 0.01% | 0.91% | 0.18% | 3.38% | 0.01% | 4.49% |

| Chlorinated Hydrocarbons | ||||||

| Number of matrix department-years | 25 | 564 | 89 | 706 | 217 | 1601 |

| % of department-years | 0.10% | 2.00% | 0.30% | 2.50% | 0.80% | 5.80% |

| Number of persons | 401 | 3720 | 473 | 7045 | 1133 | 10426 |

| Number of person-years | 923 | 9558 | 1070 | 21811 | 3928 | 37291 |

| % of person-yrs. employed at facility | 0.35% | 3.59% | 0.40% | 8.19% | 1.48% | 14.00% |

| Hydrocarbons, Other | ||||||

| Number of matrix department-years | 18 | 1316 | 126 | 968 | 384 | 2812 |

| % of department-years | 0.10% | 4.70% | 0.50% | 3.50% | 1.40% | 10.10% |

| Number of persons | 346 | 7171 | 667 | 10426 | 1531 | 15788 |

| Number of person-years | 467 | 21003 | 1511 | 34191 | 7971 | 65144 |

| % of person-yrs. employed at facility | 0.18% | 7.89% | 0.57% | 12.84% | 2.99% | 24.46% |

| Chlorofluorocarbons | ||||||

| Number of matrix department-years | 15 | 328 | 29 | 510 | 90 | 972 |

| % of department-years | 0.10% | 1.20% | 0.10% | 1.80% | 0.30% | 3.50% |

| Number of persons | 216 | 2566 | 155 | 6977 | 424 | 8977 |

| Number of person-years | 475 | 6143 | 328 | 18023 | 964 | 25933 |

| % of person-yrs. employed at facility | 0.18% | 2.31% | 0.12% | 6.77% | 0.36% | 9.74% |

| Metals | ||||||

| Number of matrix department-years | 9 | 976 | 139 | 726 | 47 | 1897 |

| % of department-years | 0.00% | 3.50% | 0.50% | 2.60% | 0.20% | 6.80% |

| Number of persons | 117 | 4675 | 566 | 8217 | 319 | 11720 |

| Number of person-years | 207 | 14353 | 1495 | 22247 | 775 | 39077 |

| % of person-yrs. employed at facility | 0.08% | 5.39% | 0.56% | 8.35% | 0.29% | 14.67% |

| Fiberglass | ||||||

| Number of matrix department-years | 0 | 126 | 0 | 150 | 2 | 278 |

| % of department-years | 0.00% | 0.50% | 0.00% | 0.50% | 0.00% | 1.00% |

| Number of persons | 0 | 2245 | 0 | 3836 | 50 | 5334 |

| Number of person-years | 0 | 4150 | 0 | 7191 | 28 | 11369 |

| % of person-yrs. employed at facility | 0.00% | 1.56% | 0.00% | 2.70% | 0.01% | 4.27% |

| Lead | ||||||

| Number of matrix department-years | 8 | 927 | 86 | 439 | 7 | 1467 |

| % of department-years | 0.00% | 3.30% | 0.30% | 1.60% | 0.00% | 5.30% |

| Number of persons | 114 | 4456 | 353 | 6550 | 131 | 9986 |

| Number of person-years | 206 | 13796 | 931 | 14471 | 128 | 29532 |

| % of person-yrs. employed at facility | 0.08% | 5.18% | 0.35% | 5.43% | 0.05% | 11.09% |

| Methylene Chloride | ||||||

| Number of matrix department-years | 1 | 105 | 25 | 363 | 11 | 505 |

| % of department-years | 0.00% | 0.40% | 0.10% | 1.30% | 0.00% | 1.80% |

| Number of persons | 18 | 897 | 143 | 4250 | 80 | 5028 |

| Number of person-years | 14 | 1504 | 301 | 11335 | 150 | 13304 |

| % of person-yrs. employed at facility | 0.01% | 0.56% | 0.11% | 4.26% | 0.06% | 5.00% |

| Methyl Chloroform | ||||||

| Number of matrix department-years | 20 | 383 | 42 | 471 | 151 | 1067 |

| % of department-years | 0.10% | 1.40% | 0.20% | 1.70% | 0.50% | 3.80% |

| Number of persons | 301 | 2602 | 275 | 5561 | 881 | 8239 |

| Number of person-years | 875 | 6764 | 504 | 14747 | 2844 | 25733 |

| % of person-yrs. employed at facility | 0.33% | 2.54% | 0.19% | 5.54% | 1.07% | 9.66% |

| Perchloroethylene | ||||||

| Number of matrix department-years | 3 | 80 | 44 | 265 | 0 | 392 |

| % of department-years | 0.00% | 0.30% | 0.20% | 1.00% | 0.00% | 1.40% |

| Number of persons | 59 | 538 | 247 | 3401 | 0 | 4075 |

| Number of person-years | 19 | 1042 | 543 | 7829 | 0 | 9433 |

| % of person-yrs. employed at facility | 0.01% | 0.39% | 0.20% | 2.94% | 0.00% | 3.54% |

| Trichloroethylene | ||||||

| Number of matrix department-years | 1 | 66 | 15 | 154 | 35 | 271 |

| % of department-years | 0.00% | 0.20% | 0.10% | 0.60% | 0.10% | 1.00% |

| Number of persons | 23 | 540 | 109 | 2390 | 252 | 3135 |

| Number of person-years | 15 | 846 | 184 | 5238 | 633 | 6916 |

| % of person-yrs. employed at facility | 0.01% | 0.32% | 0.07% | 1.97% | 0.24% | 2.60% |

A small number of department-years (and associated persons) in Exp_Grp 0 were identified with chemical classes and agents in the exposure matrix. Examination of the source data revealed chemical use was not representative of the entire department-year in any of these cases.

Totals are the row sum for all items except:

Total number of persons is the number of unique workers ever included. Some individuals worked in more than one exposure group. NOTE: See Table IV for the total number of persons ever exposed as determined after cumulative exposure scores were calculated.

Overall person-years employed at the facility total (n = 266309) includes person-years with no department identified.

Total number of departments: 2986.

Among the 39.5% of department-years with chemical use potential, 12.7% were associated with chemical agents and/or classes, and 26.8% were associated with unspecified chemical use.

Total number of workers: 34494.

By metric definition, Exp_Grp 0 contained no department-years (and thus no persons) exposed to Chemicals, General.

The largest number of department-year combinations (n = 16824) were assigned to the negligible general chemical use group (Exp_Grp 0), representing 60.5% of the total department-years, and 42.6% of total person-years in the study. The combined intermittent/incidental general exposure groups (Exp Grps 1A and 1B) represented 33.5% of total department-years, and 39.4% of total person-years. The combined general chemical routine use groups (Exp Grps 2A and 2B) represented 6% of total department-years and 17.9% of total person-years. The potential for use of acids and bases, aromatic hydrocarbons, chlorinated hydrocarbons, chlorofluorocarbons, methylene chloride, methyl chloroform, perchloroethylene, and trichloroethylene was most frequently identified for routine chemical processing departments (general chemical use Exp_Grp 2A), which included many departments associated with circuit board and substrate manufacture.

The potential for use of other hydrocarbons, metals, and lead was most frequently identified for the intermittent/incidental general chemical use exposure group Exp Grp 1A, which included many departments associated with circuit board and substrate assembly, inspection, testing, and repair activities as well as various research and development activities. The relatively small number of department-years in Exp_Grp 2B resulted in this routine-use group comprising a small percentage of person-years exposed among the cohort for the chemical categories in Table III. To provide some perspective, Exp_Grp 2B included 633 person-years exposed to trichloroethylene or 9.2% (633/6916) of total TCE-exposed person-years, compared with Exp_Grp 1A which included 846 person-years exposed to trichloroethylene or 12.2% (846/6916) of total TCE-exposed person-years.

A small number (0.3%) of the department-years assigned to Exp_Grp 0 had chemical monitoring data in the source files, and so were associated with use of chemical agents and classes in the exposure matrix. Totals presented in Table III (including number of persons in Exp_Grp 0) are based on these chemical exposure matrix data. Evaluation of source data showed that the monitoring or use of chemicals identified in these departments involved situations with limited exposure potential, not applicable to most workers associated with that department-year. For example, review of industrial hygiene monitoring source data showed that for a number of years members of a large data processing department occasionally performed solvent cleaning of tape-drive heads on third shift when only a few employees were present. This exposure was judged not representative of typical workers in this department since the task was performed infrequently and was limited to only a few unidentified workers within the department. Thus the calculation methods were designed so that a cumulative exposure score calculated for a worker in this, and the other Exp_Grp 0 department-years, accumulated no exposure score points.

With regard to the specific chemical agents, the largest percentage (11.09%) of the total person-years of employment at the facility were identified with exposure potential for lead (C = 1 for lead), and the smallest percentage (2.6%) were identified with exposure potential for trichloroethylene (C = 1 for trichloroethylene), with the remaining specific chemical agents in the range between these values (Table III). With regard to the general chemical use exposure potential of the cohort, 57.37% of total person-years were identified as having the potential for some (i.e., non-zero) chemical exposure (including both unspecified and identified chemicals) during their work tenure at the facility (Table III).

For the general chemical use exposure subgroups Exp Grp 1A, 1B, 2A, and 2B, one or more of the target chemical agents and/or classes were identified as used in 20.9%, 31.2%, 94.5%, and 83.8% of the department-years, respectively. This is consistent with expectations since company industrial hygiene surveillance and availability of historic data would be anticipated to be highest for departments with routine chemical use. The relatively low percentages for Exp Grp 1A and 1B indicate the lack of specific chemical associations for intermittent/incidental general chemical use department-years, and suggests that the application of the general chemical cumulative exposure score, which does not rely on specific chemical identification, may also be informative.

The potentially exposed workers’ cumulative exposure scores, calculated after matching the chemical exposure values from the exposure matrix with each worker’s work history, are summarized in Table IV. The cumulative exposure score data for all exposure metrics were highly skewed, with relatively low cumulative exposure scores predominating. Considering ever/never worker chemical exposure potential, lead and trichloroethylene were the most and least frequent chemical agents, respectively; and considering ever/never worker chemical exposure potential, other hydrocarbons and aromatic hydrocarbons were the most and least frequent chemical classes, respectively.

TABLE IV.

Cumulative Exposure Scores for Chemical Agents and Classes among Potentially Exposed Workers

| Cumulative Exposure ScoreA |

||||||

|---|---|---|---|---|---|---|

| Exposure metric | Number of workers ever exposed |

25th Percentile | Median | 75th Percentile |

95th Percentile |

Maximum |

| Chemical Agents | ||||||

| Fiberglass | 5334 | 206 | 488 | 1272 | 5404 | 17104 |

| Lead | 9894 | 276 | 718 | 1900 | 6350 | 17726 |

| Methyl chloroform | 8035 | 342 | 880 | 2498 | 6964 | 17016 |

| Methylene chloride | 5017 | 322 | 810 | 2370 | 6430 | 14672 |

| Perchloroethylene | 4041 | 301 | 668 | 1596 | 6604 | 14804 |

| Trichloroethylene | 3113 | 362 | 794 | 1946 | 5112 | 13878 |

| Chemical Classes | ||||||

| Acid-base | 11252 | 328 | 774 | 2520 | 8834 | 20628 |

| Aromatic | 5448 | 279 | 668 | 1640 | 5456 | 16320 |

| hydrocarbons | ||||||

| Chlorinated | 10197 | 354 | 974 | 2974 | 8084 | 17226 |

| hydrocarbons | ||||||

| Chlorofluorocarbons | 8832 | 304 | 726 | 2161 | 7346 | 18290 |

| Hydrocarbons, other | 15598 | 362 | 920 | 3068 | 9984 | 24106 |

| Metals | 11633 | 310 | 748 | 2268 | 7728 | 17726 |

| Exposure Groups | ||||||

| Chemicals (general) | 24290 | 376 | 1230 | 4196 | 10544 | 24106 |

The number of workers ever exposed to each agent and class are summarized. The total number of workers in the study was 34,494.

While the validity of the calculated scores produced by this method could not be evaluated, a check was made on a sample of these results to ensure that they were consistent with assessor expectations. For the 25 workers with the highest cumulative exposure scores for trichloroethylene, the most frequent department names (based on person-time) were associated with: 1) service work on process equipment; 2) chemical service work (addition of chemicals to process equipment); and 3) core circuitizing. For the 25 workers with the highest cumulative exposure scores to perchloroethylene, the most frequent department names were associated with: 1) metalized ceramic substrate pinning; 2) maintenance service on metalized ceramic substrate process equipment; and 3) specialized work on metalized ceramic substrates. Position titles of these workers were also examined. The departments and position titles of the 25 workers with the highest cumulative exposure scores for both chemicals were consistent with information obtained during meetings between NIOSH assessors and company workers formerly employed at the facility, and with assessor expectations.

Five manufacturing eras (Table V) were developed. Circuit board manufacture occurred throughout the 1969–2002 period, but various manufacturing changes occurred associated with changes in types of chemicals used (i.e., start and end of substrate manufacture, and solvent-related process changes in circuit board manufacture) which allowed development of eras.

TABLE V.

Major Manufacturing Eras at the Facility (1969–2002)

| Era | Major Chemical Processes | Key Process Changes |

|---|---|---|

| 1969–1973 | Raw circuit board manufacture, internal circuitize, external circuitize | NAA |

| 1974–1985 | Raw circuit board manufacture, internal circuitize, external circuitize, substrates-MC/cermet resistor operations | Start of substrate manufacture in 1974. Use of trichloroethylene was reduced during the era, with manufacturing use ending in 1985. Conversion to aqueous processing systems for advanced panel circuitize by 1986. |

| 1986–1993 | Raw circuit board manufacture, internal circuitize, external circuitize, substrates-MC/cermet resistor operations | Process use of chlorinated solvents including perchlorooethylene continued to be reduced during the era. Use of trichlorotrifluoroethane and methylene chloride was eliminated in panel solvent degreasing by 1994. |

| 1994–1999 | Raw circuit board manufacture, internal circuitize, external circuitize, substrates-MC/cermet resistor operations | Substrates-MC/cermet resistor operations and accompanying use of aromatic hydrocarbons gradually reduced, ending by 2000. |

| 2000–2002 | Raw circuit board manufacture, internal circuitize, external circuitize | NAA |

NA = No key process changes applicable.

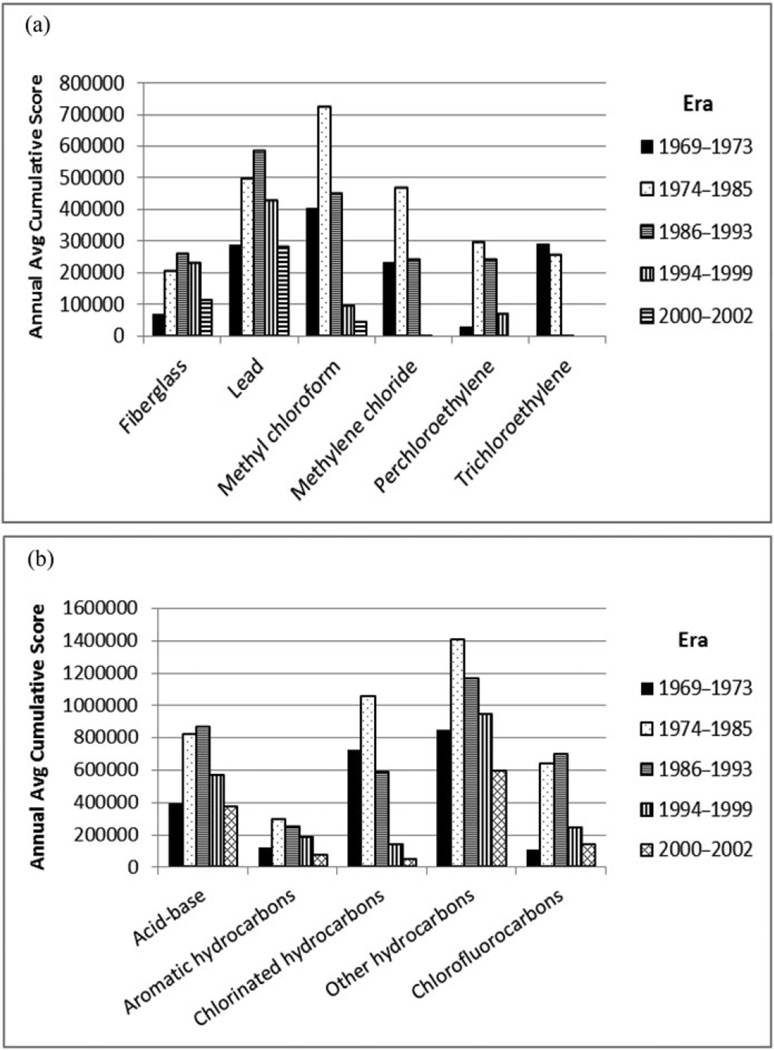

The presentation of cumulative exposure score data in Figure 2a shows that the maximum annual average score for trichloroethylene occurred during the first manufacturing era studied. Another report(7) indicates that trichloroethylene use at this facility may have already been in decline during this 1969–1973 manufacturing era, suggesting that the potential for trichloroethylene exposure may have been higher in the years preceding this study (i.e., 1965–1968).

FIGURE 2.

(a) Annual average cumulative exposure scores for chemical agents by manufacturing era. The annual average of the aggregate of all associated worker scores within a manufacturing era provides a relative measure of chemical agent use by the work force over time. (b) Annual average cumulative exposure scores for chemical classes by manufacturing era. The annual average of the aggregate of all associated worker cumulative scores within a manufacturing era provides a relative measure of chemical class use by the work force over time.

Figure 2b shows that the maximum annual average of the aggregate workforce cumulative exposure scores for the acid-base and chlorofluorocarbon chemical classes occurred during the 1986–1993 manufacturing era, following a pattern similar to fiberglass and lead. Acids evaluated were mineral acids, most commonly hydrochloric acid. The maximum annual average score for chlorinated hydrocarbons reflected the findings for the underlying agents. The maximum annual average score for aromatic hydrocarbons (most frequently xylene) occurred in the 1974–1985 era, and overall scores were lower compared to the other chemical classes. The maximum annual average score for other hydrocarbons also occurred in the 1974–1985 era, and was somewhat higher than other classes due to the common use through the years of isopropyl alcohol as a circuit board cleaner, as well as the inclusion of a wide variety of other chemicals in this class (e.g., alcohols, ketones, aldehydes, glycol ethers, oils, and so on).

DISCUSSION

The data available for this facility were not sufficient for development of a quantitative cumulative exposure metric. Rather, in addition to providing a matrix for determination of a simple duration of exposure and ever/never exposed options for health outcome analysis, cumulative exposure scores were developed. The exposure score metric provides cumulative extent of potential exposure for a worker to chemical agents, classes, and general (including unspecified) chemicals, but its limitations must be considered. The quantities of each chemical used by department or process task, and the engineering controls in place for each department, as well as the use of personal protective equipment and work practices could not be determined and were beyond the scope of this assessment. Therefore the ability of this method to accurately estimate the extent of worker exposure was limited. Exposure scores were calculated based on several factors, one of which is categorization of the extent of chemical use for each department-year as reflected in assignment of a ranking (G = 0, 1, or 2); and so the resulting exposure scores are also rankings. Sufficient company data were not available to evaluate how well these department-year rankings correlate with quantitative levels of chemical exposure. Within an exposure group, the actual levels of chemical exposure could not be determined, and would have varied among departments and individuals over time.

The completeness of available company-provided industrial hygiene site records and EIA documents cannot be assured. Known data gaps include: 1969–1974 (industrial hygiene and environmental paper records were extremely limited); 1969–1979 (no electronic industrial hygiene monitoring data available); and 1981–1984 (no EIA documents available) (Figure 1). Beginning in 1974, identification of potential chemical use for matrix years missing explicit data naming a chemical was performed if sufficient process or other supplemental data were available. Prior to 1974 the ability to assign chemical use likelihood was further limited, since fewer data were available and some early departments ceased to exist before 1974. The results of duration of chemical exposure determinations and cumulative exposure score calculations also depend on the accuracy and completeness of the available company employment records that NIOSH used to develop individual work histories. Sources of possible exposure misclassification included incomplete and contradictory company data on employment dates and department assignments in the employment records.

A significant difficulty for the exposure assessment process was the large number of departments (n = 2986) that existed at the facility during the study period. Since position title was not available in the company air sample database and could not be used to develop similar exposure groups or to link the exposure level data to the work history data, the association of department with chemical use was of primary importance for the assessment. Examination of department records showed that exposure assignments would be required for each department-year combination because basic department functions sometimes changed over time, sometimes department numbers were reassigned to a different function when there was a break in existence, and sometimes an existing department would be assigned a new number.

The need to assign chemical use at the department level was a limitation of this study. Some departments used numerous chemicals, so assignment of all department workers with potential for use of all department chemicals may result in misclassification.

Data for evaluation of between-department and within-department position title variability in chemical usage, and hence exposure potential, were not available. As stated previously, workers with the same position title in different departments did not necessarily have similar potential for exposure, so position title could not be used to categorize potential for exposure between departments. However, assessors determined that it was important and possible to address the exposure potential variability between the two major position title subgroups within departments, i.e., clerical / administrative workers and the remaining workers who carried out the specific function of the department (e.g., manufacturing tasks, test and repair bench work, laboratory work, and so on). Therefore, to partially address the exposure assessment limitation concerning within-department variability, a position factor (FP) was developed.

CONCLUSION

This exposure assessment produced metrics which allow the potential for chemical exposures among facility workers to be categorized in five ways for use in analysis of health outcomes. First, for workers potentially exposed to chemical agents or classes, exposure scores provide a relative ranking of cumulative extent of potential exposure. Second, for all workers, cumulative general chemical exposure scores provide a relative ranking of cumulative extent of potential exposure to general (including unspecified) chemicals. Third, workers with potential for use of chemical agents, classes, or general chemicals may be grouped by duration of exposure. Fourth, workers may be grouped for comparison by type of chemical use which took place in their department(s) (e.g., routine use - chemical process; routine use - metal machining; and so on). Fifth, workers never associated with chemical use (i.e., always in departments with negligible potential) may be grouped for comparison with other groups for possible never/ever exposed analyses.

These worker categorizations may also be sub-grouped for health outcome analysis by the manufacturing eras developed or by other time periods. Results showing numbers of persons potentially exposed to chemicals and cumulative exposure score distributions are presented for the period 1969–2002 at this microelectronics and business machine manufacturing facility. These methods may be useful for similar studies where historic industrial hygiene data are insufficient to quantify exposures for all workers and relative exposure metrics are needed for a variety of chemical agents.

Supplementary Material

ACKNOWLEDGMENTS

The authors wish to acknowledge the assistance of numerous members of the NIOSH Industry-wide Studies Branch who were instrumental in the planning and conduct of the site visits to collect company data; to organize, review, and store records; and to facilitate this work. In particular we wish to recognize Chris Gersic, Jean Geiman, Denise Giglio, Delores Montgomery, Surprese Watts, Faith Armstrong, Bill Ehling, and Kim Jenkins for data capture and coding. Kevin L. Dunn assisted in the document reviews, Steve Allee provided programming assistance, and Lynne Pinkerton provided consulting on the overall study and objectives. Funding for this research was provided by the National Institute for Occupational Safety and Health.

Footnotes

[Supplementary materials are available for this article. Go to the publisher’s online edition of Journal of Occupational and Environmental Hygiene for the following free supplemental resource: the availability of chemical agent industrial hygiene sampling results by department-year compared with all identified use of chemical agents by department-year at the facility for the study period, and number of departments identified as using trichloroethylene by year, compared to the number of departments in which industrial hygiene sampling data were available.]

REFERENCES

- 1.Silver SR, Pinkerton LE, Fleming DA, et al. Retrospective cohort study of a microelectronics and business machine facility. Am. J. Ind. Med. 2013 doi: 10.1002/ajim.22288. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 2.Pinkerton LE. An assessment of the feasibility of a study of cancer among former employees of the IBM facility in Endicott, New York. [accessed May 8, 2013];National Institute for Occupational Safety and Health. 2007 Jan 30; Available at http://www.cdc.gov/niosh/docket/archive/docket103.html.

- 3.Brophy JT, Keith MM, Watterson A, et al. Breast cancer risk in relation to occupations with exposure to carcinogens and endocrine disruptors: A Canadian case-control study. [accessed May 8, 2013];Environ. Health. 2012 11:87. doi: 10.1186/1476-069X-11-87. Available at http://www.ehjournal.net/content/11/1/87. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Labreche F, Goldberg MS, Valois M-F, Nadon L. Postmenopausal breast cancer and occupational exposures. Occup. Environ. Med. 2010;67:263–269. doi: 10.1136/oem.2009.049817. [DOI] [PubMed] [Google Scholar]

- 5.Stewart PA, Herrick RF. Issues in performing retrospective exposure assessment. Appl. Occup. Environ. Hyg. 1991;6:421–427. [Google Scholar]

- 6.Axelson O, Soderkvist P. Characteristics of disease and some exposure considerations. Appl. Occup. Environ. Hyg. 1991;6:428–435. [Google Scholar]

- 7.Agency for Toxic Substances and Disease Registry (ATSDR): Health Consultation: Historical Outdoor Air Emissions in the Endicott Area. International Business Machines Corporation (IBM). Village of Endicott, Broome County, New York. Atlanta: U.S. Department of Health and Human Services; 2006. Nov 17, [Google Scholar]

- 8.Herrick RF, Stewart JH, Blicharz D, et al. Exposure assessment for retrospective follow-up studies of semiconductor- and storage device-manufacturing workers. J. Occup. Environ. Med. 2005;47(10):983–995. doi: 10.1097/01.jom.0000177128.50822.01. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.