Abstract

Betel vine (Piper betle L.) is a root climber with deep green heart shaped leaves. It belongs to the Piperaceae family. There is a huge wastage of the leaves during glut season and it can be reduced by various means including extraction of medicinal essential oil which can be considered as GRAS (generally recognized as safe) materials. Therefore, attempts were made to develop a novel cup cake by incorporating essential oil of betel leaf. The textural properties of the cakes were measured by texture analyzer instrument; whereas the organoleptic properties were adjudged by human preferences using sensory tables containing 9-point hedonic scale. Price estimation was done considering all costs and charges. Finally, all parameters of the developed cake were compared with different cup cakes available in the market for ascertaining consumer acceptability of the newly developed product in terms of quality and market price. Results revealed that the Novel cup cake developed with 0.005 % (v/w) essential oil of betel leaf occupied the 1st place among the four developed novel cup cakes. However, it occupied 4th place among the nine cup cakes in the overall preference list prepared based on the textural and organoleptic qualities, though its market price was calculated to be comparable to all the leading cupcakes available in the market. This indicates that manufacturing of novel cup cake with essential oil of betel leaf would be a profitable and self-sustaining entrepreneurship.

Keywords: Betel leaf, Essential oil, Cup cake, Textural properties, Sensory analysis, Price estimation

Introduction

There are a large number of ready to eat snack foods available in the markets worldwide, among which cakes occupy a predominant position as far as consumers’ preference is concerned. A cup cake is a small cake that has a cup like shape, flat top with narrow bottom and is intended to be consumed by an individual in a single sitting. Such cakes are made more attractive, flavored, tasty and consumer appealing by incorporating various additional ingredients into it like cashew nuts, resins, dry fruits, vanilla etc. but so far essential oil of betel leaf (Piper betle L.) has not yet been explored in this context (Guha 2007a). The betel vine is a medicinal plant bearing deep green heart shaped leaves with attractive unique flavor and taste. Therefore, the vine is cultivated in many Asian countries (Chattopadhyay and Maity 1967). The leaves are consumes in raw state with various ingredients mainly for digestive, stimulating and mouth refreshing effects. However, a huge amount of the leaves remain unsold during glut season every year contributing to a loss of about Rs. 90 crores in West Bengal alone (Guha 2007b). These unsold leaves can be used as a good and cheap source of medicinal essential oil. The different local varieties like Mitha, Bangla and Sanchi yields about 2.0 %, 1.7 % and 0.8 % essential oil (v/w) respectively, on dry weight basis (Guha 2006), which can be considered as a GRAS material (Burdock and Carabin 2004). This essential oil can be extracted from fresh or stale or de-chlorophylled or even partially decayed betel leaves by an apparatus called “Betel leaf oil extractor” designed and developed at IIT, Kharagpur (Guha 2006).

Essential oil of betel leaf of the most common variety “Bangla” was found to be constituted by a mixture of about twenty-one different compounds of which eugenol was the chief ingredient constituting about 29.5 % of the oil, whereas in some other varieties terpenyl acetate was the chief constituent (Guha and Jain 1997). These constituents are the main sources of the medicinal, aromatic, stimulant, tonic and various other useful properties found in the leaves (Guha 2006), which can be explored for development of novel commercial products (Guha 2007a). In view of the above, the present study was planned and executed with the following objectives: to examine suitability of essential oil of betel leaf as an unique ingredient for manufacturing cup cake; to examine, analyze and compare the organoleptic and textural properties of the developed cup cakes with the market available leading cup cakes, and finally, to examine the economic feasibility of production of the novel cup cake in commercial scale.

Materials and methods

Collection of raw materials

Five leading brands of cup cakes namely 1. Cream Delight; 2. Kup Keyk; 3. Choco Cup; 4. Take 2 and 5. Jig Jag, were randomly selected from the cup cakes available in the local market and sufficient number of cakes were collected for the present experiment. The other raw materials for production of the novel cup cake were also collected from the local markets. Betel leaves for oil extraction were collected from the local market as well as wholesale betel leaf market of Mecheda, Purba Medinipur, West Bengal, India.

Tools, equipments and instruments

Different instruments and equipments used for different unit operations like oil extraction, measuring, mixing, product development etc. were Betel leaf oil extractor, Weight measuring device, Volume measuring cylinder, Electrical hand mixer, Mixing bowl, Spoons, Baking pan, Baking oven, micro pipette and Texture analyzer instrument loaded with a software known as “Texture Expert”.

Methodology

Betel leaf oil was extracted from a sweet and attractive flavored “Mitha” variety of betel leaf with the help of ‘betel leaf oil extractor’ (Guha 2007b) and the extracted oil was used in its original state as chief flavoring ingredient for developing a novel cup cake. The formulation (Yogambal 2009) of ingredients used for manufacturing commercially successful cup cakes is mentioned below, which was taken up for the present experiment with only exception that essential oil of betel leaf was added in different proportions along with control (no essential oil added) to obtain the required flavor, taste and other desirable properties in the novel cup cake.

Formulation:

- Flour:

‘Maida’

- Vegetable Oil:

Soybean oil 75 % of flour (v/w)

- Eggs:

2 piece/100 g flour

- Sugar:

85 % of flour (w/w)

- Baking powder:

1 % of flour (w/w)

- Milk:

15 % of flour (v/w)

- Essential oil:

Betel leaf oil 0.01 %, 0.005 % & 0.001 % of flour (v/w).

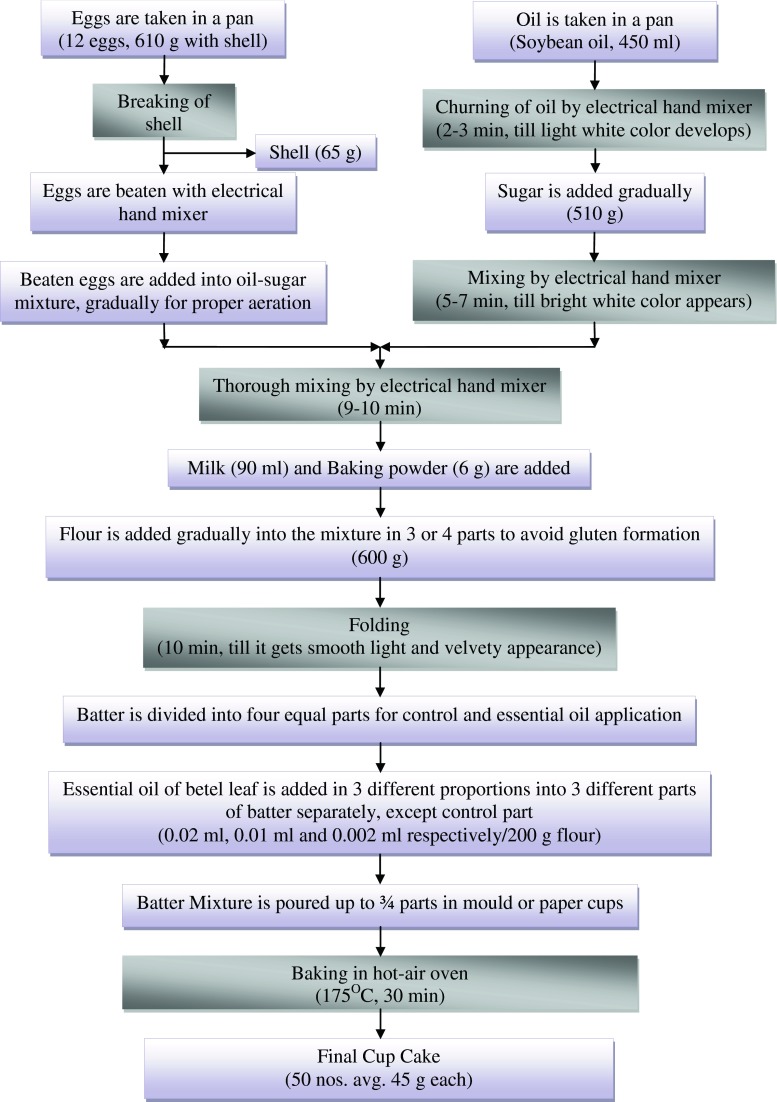

The material and process flow chart for manufacturing of the present cup cake has been shown in Fig 1. The cakes were baked in paper cups encased in aluminium cups which were separated out after completion of baking. The developed cakes along with the control (no essential oil added) and market available leading cup cakes were then examined for their textural as well as organoleptic properties and all these cakes were compared with each other for their consumer acceptability and preference.

Fig 1.

Material and Process flow chart for manufacturing novel cup cake

Analysis of organoleptic properties

Organoleptic or sensory properties are those properties of food which can be observed by a human being with the help of different sensory organs. Different sensory properties like colour, taste, aroma and mouth feel were measured by consumption of the food items by different peoples. During the test, cakes were distributed among 20 judges and sensory table was given to them for recording their preference about the cup cakes. All the judges consumed all the cakes one by one after cleaning their mouths each time with water and put the marks on the sensory tables (Tables 1 and 2). The table consisted of 9-point hedonic scale (Lawless et al. 2010) to find out the best product for different sensory properties. The same table was used for sensory evaluation of different market available cakes as well as the novel products developed using different amount of essential oil during this study. The data pertaining to organoleptic properties were collected and placed in tables and in each table an order of preference list was prepared using the foregoing Eqs. Error! Reference source not found.and 2 and placed in the last column of the tables for each of the examined properties, like colour, taste, aroma and mouth feel.

Table 1.

Sensory analysis of market available cup cakes

| Choice* | Cream DELITE | Kup Keyk | Choco Cup | Take 2 | Jig Jag Cake | Order of consumer preference |

|---|---|---|---|---|---|---|

| COLOUR | ||||||

| Like extremely (9) | 2 | 2 | 3 | 2 | 4 | Jig Jag Cake Kup Keyk Cream Delight Choco Cup Take 2 |

| Like very much (8) | 6 | 10 | 7 | 7 | ||

| Like moderately (7) | 9 | 3 | 2 | 12 | 7 | |

| Like slightly (6) | 3 | 3 | 4 | 4 | 2 | |

| Neither like nor dislike (5) | 2 | 1 | 2 | |||

| Dislike slightly (4) | 3 | |||||

| Dislike moderately (3) | ||||||

| Dislike very much (2) | ||||||

| Dislike extremely (1) | ||||||

| TASTE | ||||||

| Like extremely (9) | 4 | 2 | 4 | Cream Delight Jig Jag Cake Kup Keyk Take 2 Choco Cup |

||

| Like very much (8) | 10 | 5 | 6 | 5 | 6 | |

| Like moderately (7) | 4 | 9 | 4 | 3 | 7 | |

| Like slightly (6) | 1 | 3 | 2 | 9 | 2 | |

| Neither like nor dislike (5) | 3 | 2 | ||||

| Dislike slightly (4) | 1 | 1 | 5 | 1 | ||

| Dislike moderately (3) | ||||||

| Dislike very much (2) | 1 | |||||

| Dislike extremely (1) | ||||||

| AROMA | ||||||

| Like extremely (9) | 1 | 1 | 1 | 5 | Jig Jag Cake Cream Delight Kup Keyk Take 2 Choco Cup |

|

| Like very much (8) | 6 | 5 | 2 | 2 | 5 | |

| Like moderately (7) | 4 | 3 | 5 | 2 | 8 | |

| Like slightly (6) | 7 | 9 | 5 | 9 | 1 | |

| Neither like nor dislike (5) | 1 | 7 | 5 | 1 | ||

| Dislike slightly (4) | 1 | 1 | 1 | 1 | ||

| Dislike moderately (3) | 1 | 1 | ||||

| Dislike very much (2) | ||||||

| Dislike extremely (1) | ||||||

| MOUTHFEEL | ||||||

| Like extremely (9) | 4 | 1 | 1 | 1 | 2 | Cream Delight Jig Jag Cake Kup Keyk Take 2 Choco cup |

| Like very much (8) | 5 | 6 | 3 | 5 | 5 | |

| Like moderately (7) | 6 | 8 | 6 | 1 | 5 | |

| Like slightly (6) | 2 | 3 | 5 | 8 | 6 | |

| Neither like nor dislike (5) | 1 | 3 | 4 | 2 | ||

| Dislike slightly (4) | 2 | 2 | 2 | 1 | ||

| Dislike moderately (3) | ||||||

| Dislike very much (2) | ||||||

| Dislike extremely (1) | ||||||

*Numerical values of each type of choices are given in the parenthesis

Table 2.

Sensory analysis of developed novel cup cakes

| Choice* | Control | 0.01 % (v/w) | 0.005 % (v/w) | 0.001 % (v/w) | Order of consumer preference |

|---|---|---|---|---|---|

| COLOUR | |||||

| Like extremely (9) | 1 | 1 | 0.005 % Control 0.01 % 0.001 % |

||

| Like very much (8) | 9 | 6 | 10 | 4 | |

| Like moderately (7) | 5 | 12 | 7 | 9 | |

| Like slightly (6) | 4 | 2 | 2 | 7 | |

| Neither like nor dislike (5) | 1 | ||||

| Dislike slightly (4) | |||||

| Dislike moderately (3) | |||||

| Dislike very much (2) | |||||

| Dislike extremely (1) | |||||

| TASTE | |||||

| Like extremely (9) | 1 | 0.005 % 0.01 % 0.001 % Control |

|||

| Like very much (8) | 5 | 7 | 3 | ||

| Like Moderately (7) | 7 | 7 | 10 | 7 | |

| Like slightly (6) | 12 | 4 | 2 | 10 | |

| Neither like nor dislike (5) | 1 | 3 | 1 | ||

| Dislike slightly (4) | |||||

| Dislike moderately (3) | |||||

| Dislike very much (2) | |||||

| Dislike extremely (1) | |||||

| AROMA | |||||

| Like extremely (9) | 1 | 1 | 1 | 0.001 % 0.005 % 0.01 % Control |

|

| Like very much (8) | 1 | 1 | 3 | 4 | |

| Like moderately (7) | 1 | 6 | 6 | 7 | |

| Like slightly (6) | 5 | 3 | 7 | 4 | |

| Neither like nor dislike (5) | 13 | 1 | 2 | 4 | |

| Dislike slightly (4) | 7 | 1 | |||

| Dislike moderately (3) | 1 | ||||

| Dislike very much (2) | |||||

| Dislike extremely (1) | |||||

| MOUTHFEEL | |||||

| Like extremely (9) | Control 0.01 % 0.001 % 0.005 % |

||||

| Like very much (8) | 4 | 3 | 1 | 1 | |

| Like moderately (7) | 9 | 7 | 8 | ||

| Like slightly (6) | 7 | 10 | 13 | 9 | |

| Neither like nor dislike (5) | 6 | 1 | |||

| Dislike slightly (4) | 1 | ||||

| Dislike moderately (3) | |||||

| Dislike very much (2) | |||||

| Dislike extremely (1) | |||||

*Numerical values of each type of choices are given in the parenthesis

Comparison of organoleptic properties among the market available cup cakes and novel cup cakes

After tabulation of all the data obtained from the preferences of different judges on different sensory properties for all the market available cup cakes and developed novel cup cakes with control the order of consumer preferences were obtained by calculating the specific values for each of the properties for each sample using the following equation:

| 1 |

e. g.: color value of cream delight cup cake was = (9*2 + 8*6 + 7*9 + 6*3 + 5*0 + 4*0 + 3*0 + 2*0 + 1*0) / 20 = 7.35, like this, values of other sensory properties were also calculated, whereas, overall consumer preference values were calculated by taking the average of the above said specific values of different sensory properties using the following equation:

| 2 |

Using Eqs. Error! Reference source not found. and 2 all the values were calculated and shown in Table 3.

Table 3.

Comparison of organoleptic properties and market price of the cup cakes

| Samples showing organoleptic scores as per Eqs. No 1 & 2 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Market available products | Developed products | |||||||||

| Cream Delight | Kup Keyk | Choco Cup | Take 2 | Jig Jag Cake | Control | 0.01 % | 0.005 % | 0.001 % | ||

| Sensory properties | Colour | 7.35 | 7.35 | 6.90 | 6.80 | 7.65 | 7.25 | 7.20 | 7.50 | 6.85 |

| Taste | 7.70 | 7.15 | 5.60 | 6.35 | 7.45 | 6.30 | 6.85 | 7.15 | 6.65 | |

| Aroma | 6.80 | 6.55 | 6.00 | 6.10 | 7.60 | 5.50 | 5.65 | 6.55 | 6.70 | |

| Mouthfeel | 7.15 | 6.95 | 6.40 | 6.40 | 6.95 | 6.85 | 6.65 | 5.80 | 6.35 | |

| Overall Score | 7.25 | 7.00 | 6.23 | 6.41 | 7.41 | 6.48 | 6.59 | 6.75 | 6.64 | |

| Overall preference rank | 2nd | 3rd | 9th | 8th | 1st | 7th | 6th | 4th | 5th | |

| Market price (Rs.) | 6.00 | 5.00 | 6.00 | 5.00 | 5.00 | 6.00* | 6.00* | 6.00* | 6.00* | |

*Calculated market price, calculations shown in Table 5

Analysis of textural properties

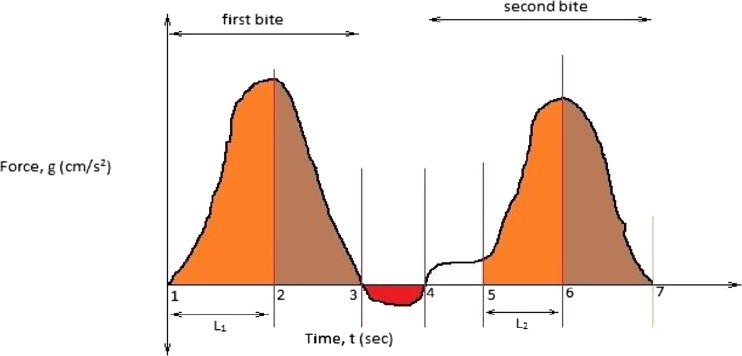

The textural properties of the cup cakes measured were ‘hardness’, ‘cohesiveness’, ‘adhesiveness’, ‘springiness’, ‘gumminess’ and ‘chewiness’. The measurements were done by the instrument named “Texture analyzer” using Eqs. 3, 4, 5, 6, 7 and 8 as shown below. The properties were worked out from a graphical representation generated through computer software named “Texture Expert” during the test (Bourne 1982). A model graphical representation has been shown in Fig 2.

Fig 2.

A typical diagram of graph generated during the test by ‘Texture Analyzer’.

From Fig 2 the different textural properties were measured using the following formulae:

3 4 5 6 7 8

Economic feasibility test

After conclusion of all the experiments and processes, finally the economic feasibility of this study was carried out (Table 5). It helped to decide the selling price of the developed product to examine whether the product would be marketable with reasonable price and the manufacturing unit would be economically viable and self sustainable.

Table 5.

Cost of materials and processing charges for the best developed cup cake (0.005 % essential oil)

| Item | Quantity/batch | Rate (Rs.) | Market Price (Rs.) approx. |

|---|---|---|---|

| Flour | 600 g | 20/kg | 12.00 |

| Vegetable oil | 450 g | 85/kg | 38.25 |

| Sugar | 510 g | 32/kg | 16.30 |

| Egg | 12 pieces | 4/piece | 48.00 |

| Milk | 90 ml | 30/lt. | 2.70 |

| Baking powder | 6 g | 25/100 g | 1.50 |

| Betel leaf oil | 0.03 ml | 35/ml | 1.05 |

| Manual labour | – | – | 50.00 |

| Electricity | – | – | 20.00 |

| Rent for utensils | – | – | 2.50 |

| Rent for baking oven | – | – | 5.00 |

| Rent for hand mixer | – | – | 0.25 |

| Subtotal= | 197.55 | ||

| Bank interest (@12 % over subtotal) | – | – | 0.01 |

| Miscellaneous | – | – | 1.50 |

| Total= | 199.06 ≈ 200.00 (approx) | ||

| Nos. of cake produced | 50 pieces/ batch | ||

| Production Cost | Rs. 200/50 = Rs. 4.00/cake | ||

| Commission for vendor | Rs. 0.50/cake | ||

| Sell price (Cost + 20 % profit + commission to vendor) | Rs. 5.30 ≈ Rs. 6.00/cake | ||

| Net profit | Rs. 6.00 – (0.50 + 4.00) = Rs. 1.50/cake | ||

| Total net income | Rs. 50*1.50 = Rs. 75.00/batch |

Results

Organoleptic properties

The analysis of sensory properties was done by 20 different judges for market available cup cakes and also the developed novel cup cakes along with control (no essential oil added) (Tables 1, 2 and 3).

The data presented in Table 3 clearly point out that ‘Jig Jag Cake’ occupied 1st place in the consumer preference list for colour and aroma and 2nd place for taste and mouth feel while ‘Cream Delight’ occupied 1st place for taste and mouth feel and 2nd & 3rd place for aroma and colour. However ‘Choco Cup’ cake occupied last place for taste, aroma and mouth feel but 2nd last in colour. The Table clearly indicates that ‘Jig Jag Cake’ was the best cup cake available in the market while, ‘Cream Delight’ was the second best product in the group.

The data presented in Table 3 also show the result of examination of the sensory properties of cup cakes developed with incorporation of different amount of essential oil of betel leaf, i.e. 0.01 %, 0.005 % and 0.001 % (v/w) of the flour. The results show that novel cup cake developed with 0.005 % oil occupied first place for colour and taste but second and forth places respectively, for aroma and mouth feel, while the control cakes occupied forth place for taste and aroma and first and second places for mouth feel and colour respectively. A fair comparison therefore, clearly indicates that the developed cup cake (0.005 % oil) was the best and control cup cakes were the least preferred cakes while the other two cakes (0.01 % and 0.001 % oil) occupied intermediate positions, which was also confirmed by overall scores (Table 3).

Data pertaining to organoleptic scores of the cup cakes including overall organoleptic scores have been placed together in Table 3 for proper comparison among all the cup cakes. However, to make this comparison more focused, an overall preference rank list with market prices was also prepared (Table 3) which clearly shows that the ‘Jig Jag cake’ occupied the first place in the overall preference list while ‘Choco cup’ cake occupied the last place (9th place) whereas the best of the novel cup cakes (0.005 % essential oil) occupied the 4th place. This indicates that the quality and consumer preference of the developed cup cake is good enough for easy commercialization. Such indications were also given by Guha (2007a) recommending industrialization of products developed from betel leaf and essential oil extracted from it.

Textural properties

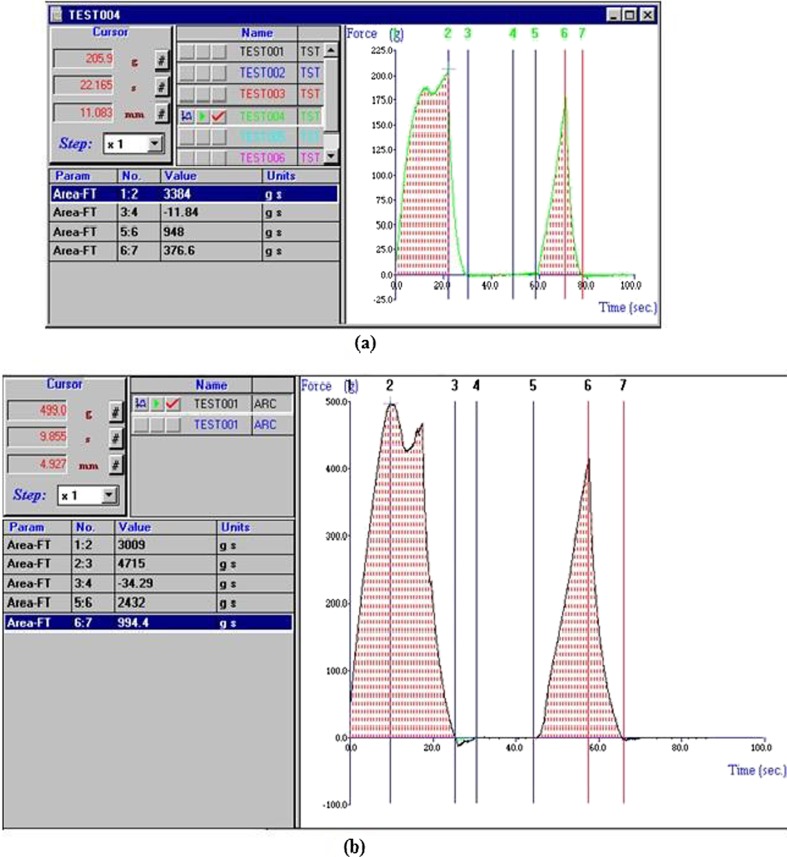

A total of nine textural graphs were obtained by the “Texture Analyzer” instrument for examining the textural properties of the different types of cup cakes including the newly developed ones and the control. Sample graphs of two cup cakes (best developed product and control) are presented in Fig 3.

Fig 3.

Textural graph obtained for developed products: (a) Control, (b) Cup cake with

The numerical data worked out from the relevant graphs representing different texture properties have been placed in Table 4 for comparison among the cup cakes.

Table 4.

Comparison of textural properties of the cup cakes

| Textural properties | Samples | ||||||

|---|---|---|---|---|---|---|---|

| Cream Delight | Kup Keyk | Choco Cup | Take 2 | Jig Jag Cake | Control | Developed product (0.005 % oil) | |

| Hardness (g) | 127.50 | 248.80 | 147.90 | 219.40 | 425.30 | 205.90 | 499 |

| Cohesiveness | 0.26 | 0.52 | 0.30 | 0.33 | 0.29 | 0.39 | 0.44 |

| Adhesiveness (g-s) | 41.77 | 31.81 | 61.09 | 25.32 | 42.39 | 11.84 | 34.29 |

| Springiness | 1.58 | 1.20 | 1.78 | 0.91 | 0.69 | 0.55 | 1.44 |

| Gumminess (g) | 33.15 | 129.38 | 44.37 | 72.40 | 123.38 | 80.30 | 219.56 |

| Chewiness (g) | 52.38 | 155.25 | 78.98 | 65.89 | 85.10 | 44.17 | 316.17 |

It is observed from the Table 4 that the hardness of betel leaf oil cake was highest among all the cup cakes but it resembled slightly with the ‘Jig Jag Cake’, while the least/minimum hardness was found in ‘Cream Delight’. Such hardness leads the new product towards a greater gumminess, which is much higher than all the other cakes but it did not impart any undesirability as would be evident from the overall values of organoleptic quality of the developed product. The value of gumminess is more as it is a product of hardness and cohesiveness. As far as springiness is concerned, out of the seven cakes mentioned above, the value of springiness in the novel developed product was 1.44, whereas it was 0.55 for the control cake. The material constituents of control and the novel developed product were exactly same except that in the later case 0.005 % essential oil of betel leaf was added up. Therefore, higher springiness in case of novel developed product compared to the control cake may be attributed to the addition of essential oil of betel leaf. Moreover, the values of all the textural properties had improved due to addition of essential oil of betel leaf in the developed product (with 0.005 % oil) compared to the control (Table 4). These higher values in turn contributed to better organoleptic properties which is clear from the higher overall value of the developed product (with 0.005 % oil) compared to the control (Table 4), making the developed product comparable to the leading cup cakes in the market in terms of quality and consumer preference.

Economic feasibility

To determine the feasibility of manufacturing of a novel cup cake with essential oil of betel leaf (0.005 %) all the input costs (Table 5) were taken into consideration to estimate the selling price in order to earn a good profit (≥20 %) and maintain a self-sustainable manufacturing unit in a competitive market where many other cup cakes have already achieved a good foot hold and good will.

This economic feasibility test confirmed that this novel cup cake with 0.005 % essential oil of betel leaf can be commercially exploited with a sell price of Rs. 6.00 per cake. It was found (Table 5) that this novel cup cake occupied 4th place in the sensory preference list where the prices of the 1st, 2nd and 3rd cakes were Rs. 5.00, Rs. 6.00 and Rs. 5.00 respectively, therefore, selling of this novel product @ Rs. 6.00 per cake would be economically feasible and competitive with the market available leading cup cakes. It may therefore, be concluded that commercialization of the developed product would be economically viable and self sustainable.

Conclusions

Essential oil of betel leaf can be used as an ingredient for production of good quality cup cakes. Among the different concentrations of essential oil of betel leaf used for production of novel cup cakes, 0.005 % (v/w) concentration was found to be the best. The cup cakes developed with incorporation of essential oil of betel leaf (0.005 % v/w) was found to be comparable to the leading cup cakes available in the market in terms of overall consumer preference examined through textural and organoleptic properties of the cakes. Manufacturing of novel cup cakes with unique properties of essential oil of betel leaf was envisaged to be a profitable and self-sustainable entrepreneurship in view of its cost of production and quality compared to those of the leading cup cakes available in the market.

Acknowledgments

The authors are grateful to Indian Institute of Technology, Kharagpur, Indian Council of Agricultural Research, New Delhi and Ministry of Human Resource Development, Govt. of India, for providing funds and facilities for this work.

Contributor Information

Arnab Roy, Phone: +919836796805, Email: arnab.bckv@gmail.com.

Proshanta Guha, Phone: +913222283124, Email: pguha@agfe.iitkgp.ernet.in.

References

- Bourne MC (1982) Food Texture and Viscosity: Concept and Measurement. Academic Press

- Burdock GA, Carabin IG. Generally recognized as safe (GRAS): history and description. Toxicol Lett. 2004;150:3–18. doi: 10.1016/j.toxlet.2003.07.004. [DOI] [PubMed] [Google Scholar]

- Chattopadhyay SB, Maity S. Diseases of betelvine and spices. New Delhi: ICAR; 1967. [Google Scholar]

- Guha P. Betel leaf: the neglected green gold of India. J Hum Ecol. 2006;19(2):87–93. [Google Scholar]

- Guha P (2007a) Extraction of essential oil from betel leaf for manufacturing of food, medicinal and cosmetic products. In Proc. Indian convention of food scientist and technologist, pp. 44

- Guha P. Extraction of essential Oil: an appropriate rural technology for minimizing wastage of surplus betel leaves. Agric Mechanization in Asia, Afr and Latin Am. 2007;38(4):47–50. [Google Scholar]

- Guha P, Jain RK. Status report on production, processing and marketing of betel leaf (Piper betle L.) Kharagpur, India: Agricultural and Food Engineering Department, IIT; 1997. [Google Scholar]

- Lawless HT, Popper R, Kroll BJ. A comparison of the labeled magnitude (LAM) scale, an 11-point category scale and the traditional 9 point hedonic scale. Food Qual Prefer. 2010;21:4–12. doi: 10.1016/j.foodqual.2009.06.009. [DOI] [Google Scholar]

- Yogambal A K (2009) Theory of bakery and confectionery. PHI learning private limited