Abstract

Tortilla is the most popular type of bread both in South and Central America. Since the demand for this bread among different classes of society is significant, improving its nutrient content could be important. Distillers dried grains with solubles is good source of fiber and protein, and can be used in the fortification of tortilla. In this study, three levels of DDGS (0, 10 and 20 %) were substituted for wheat flour and the physical and chemical properties of the resulting products were evaluated. Results showed that for the 20 % DDGS level, minimum force was required to rupture the tortilla. The color of the tortillas substituted with 10 and 20 % DDGS were darker, being 64.11 and 59.99, respectively (P < 0.05). As for chemical properties, the samples fortified with 10 and 20 % DDGS had higher protein (9.35 and 10.78 % dried basis), fiber (2.21 and 2.33 % dried basis) and fat (23.60 and 24.65 % dried basis) values at P < 0.05. Thus, it appeared that using DDGS in wheat tortillas can improve some of the nutritional values such as protein and fiber as well as the textural properties of these breads. Further work should examine consumer acceptability of these products.

Keywords: All-purpose flour, DDGS, Wheat tortillas

Introduction

Tortillas are unfermented flat breads made mainly from corn, wheat or barley (Guo et al. 2003). In general, tortillas can be made using three basic methods: hot pressing, die cutting, or hand stretching. The hot pressing method will result in tortillas with soft texture; however, the die cutting method is more efficient, often yielding a lower cost product. Tortillas made with the hand-stretch method are usually larger and thinner (Anton 2008).

Tortillas, especially corn tortillas, have historically been pride-inspiring symbols to Mexicans and Latin Americans to whom they are sacred (Gabel and Boller 2003). This flat bread provides a connection between modern-day people and their ancestors; however, it has lost much of its sacred nature as it has been globalized and consumed in other countries, especially the United States (Gabel and Boller 2003). Tortillas provide an inexpensive source of energy for all socio-economic levels in Mexico, with an annual consumption rate of nearly 120 kg per capita or approximately 328 g tortilla/person/day (Figuerou et al. 2003). During the past several years, consumption of tortillas has increased in other countries; tortillas are reported to be the second most popular type of bread in the U.S., with Americans consuming approximately 85 billion tortillas in 2000 (Toma et al. 2008). It has been predicted that this amount will increase by up to 10 % in the next few years (Steinberg 2005).

A flour tortilla can be defined as a flat, circular, light color bread with a thickness of less than 0.25 in and a diameter ranging from 6 to 13 in (Anton 2008).Tortilla in Spanish means “omelet”, and it was first introduced to Mexico by clerics centuries ago (Arreola 2002). At that time, corn was predominantly used for the production of tortillas (and still is even today), but the use of wheat for tortillas has become commonplace in recent years (Arreola 2002).

In the US, wheat tortillas are the most popular of all ethnic breads. Basic ingredients for making wheat tortillas include wheat flour, water, salt, shortening or oil. Wheat flour accounts for 80–95 % of the ingredient in tortillas. Thus flour quality has a significant influence on the quality of final product. Typically, the flour used for hot-press wheat tortillas is milled from hard red winter wheat and contains 9.5 to 11.5 % protein (Guo et al. 2003). Good quality flour tortillas should be soft, flexible, easy to fold, light color and well puffed (Pascut et al. 2004). In addition to quality and physical attributes of tortillas, the nutritional value of this type of bread is also important, as it can account for a large proportion of daily dietary intake for many people. Thus, adding value and enhancing the nutritional content of this bread can be beneficial in making healthier diets for all types of consumers (Pourafshar et al. 2010). Many studies have reported on fortification of tortilla with different flours. For example, the effect of different wheat classes on the textural properties of tortilla was investigated by Wang and Flores (1999). Toma et al. (2008) incorporated whole barley flour into tortilla and investigated the effect of flour particle size on acceptability of whole grain, soluble fiber-enriched tortillas by consumers. Saldivar et al. (2004) substituted triticale flour into wheat flour tortilla (hybrid of wheat and rye), and Figuerou et al. (2003) fortified tortillas by adding vitamin and soy protein to the flour. Other materials can also be used to fortify tortilla; one of them may be distillers dried grains with solubles (DDGS), which is produced as a coproduct from the production of ethanol.

Since use of biofuels has dramatically increased in recent years, production of coproducts such as DDGS has increased as well. In 2005, for example, 87 manufacturing plants in US produced about 13.5 billion L/y of corn-based ethanol (Rosentrater and Krishnan 2006). According to RFA (2013), nearly 50 billion L/y of ethanol were produced in 2010, from which 32.5 million metric tons of distillers grains were produced (RFA 2013). DDGS is good source of protein (30–40 % db) and fiber (30–40 %), and thus has the potential to enhance the nutritional value of many foods, especially baked products (Rasco et al. 1987). Also, DDGS is a good source of essential amino acids such as lysine, methionine, valine, isoleucine, arginine, phenylalanine, tyrosine, and tryptophan which can vary in different DDGS depending on the method through which DDGS has been processed (Spiehs et al. 2002). A variety of methods can be used to produce DDGS, but the processes used also affect the physiochemical properties, appearance and composition of the DDGS (Cromwell et al. 1993). Variation in the composition of corn can also influence the compositional variation of final DDGS (Belyea et al. 2004). This coproduct has been used in some baked products. For example, Tsen et al. (1982, 1983) used DDG in breads and cookies. Pourafshar et al. (2011a) used DDGS in traditional Iranian breads. Brewer’s spent grains were also used in bread (Finely and Hanamoto 1980). Blended foods for overseas distribution have been examined as well (Wu et al. 1987).

The objective of this study was to understand the impact of substitution of DDGS on the physical and chemical attributes of tortillas. In this study, DDGS was added to wheat tortillas to fortify this bread in order to improve its protein and fiber content. Three levels of DDGS substitution were used (0, 10 and 20 %), and the physical and chemical properties of final tortillas were measured.

Materials and methods

Experimental design

Distillers dried grains with solubles (DDGS) was obtained from a commercial dry grind ethanol plant in South Dakota. Prior to the experiment, the DDGS was ground into a fine particle size using a Retsch Mill (GmbH & Co.KG, 5657 HAAN1, Germany) operated at 20,000 rpm using a 0.5 mm sieve. All-purpose wheat flour was purchased from a local market, table one shows the protein, fiber and fat content of for the all-purpose flour and the DDGS. Three levels of DDGS substitution (0, 10 and 20 % db) for the flour were used. Thus, this study was comprised of a one factor experimental design with three levels. Control tortillas were made using 500 g of all-purpose flour; other ingredients were 5.0 g baking powder, 5.5 g salt, 27.0 g vegetable shortening and 354.0 mL of warm water (40 ° C). For experimental tortillas, 500.0 g of all-purpose flour was substituted with 10 or 20 % DDGS (all-purpose flour was reduced to 450 and 400 g, respectively), the amount of all other ingredients remained the same. In order to obtain fine, well-distributed blends, the ground DDGS was mixed with the all-purpose flour using a blender (Blend Master, Patterson-Kelly, Harsco, East Stroudsburg, PA, USA) for 10 min. Two tortillas for each level of substitution were baked. All properties for each of the resulting tortillas were analyzed using three replications each, thus n = 6 measurements for each property, for each treatment combination.

Tortilla production

The raw ingredients were mixed together with a mixer at low speed for 2 min, then 27 g of shortening was added and mixing continued, after which 354 mL of water was slowly added to the mixture. Mixing was continued for an additional 5 min. The dough was allowed to rest in a plastic container for 10 min, and then was divided into 40 g dough balls. These were put aside for a rest time of 30 min. After that, a tortilla dough press (Dual Heat DoughPro, Propress Corp., Paramount, CA, USA) was used to form the balls into a specific thickness (0.2 cm). The temperatures of the top and bottom platens of the press were both at 80 °C, and the press time was 15 s at the “thin” setting. The tortillas were then baked on a heated flat metal surface in an oven at 173 °C for 35 s, flipped, cooked for an additional 35 s, and then allowed to cool for 5 min on metal baking racks.

Physical and chemical property analysis

After each tortilla was made, it was subjected to extensive chemical and physical analyses. Chemical properties included moisture content, protein, fat, fiber and ash content. Physical properties included texture (firmness and extensibility), water activity, and color (L*, a*, b*).

Moisture content was determined using method 44–19 (AACC 2000), oven drying at 135 °C (Model Labline, Inc. Chicago, IL, U.S.A). Protein was measured using method 46–30 (AACC 2000) with a combustion analyzer (CE Elantech Flash EA 1112, ThermoFinnigan, Italia S.p.A., Rodano (MI) Italy). Percentage nitrogen was converted into protein percentage using a conversion factor of 5.7. Fat content was determined using method 920.39 (AOAC 2003) on an automated soxhlet (CH-9230, Buchi Laborotechnik AG, Flawil, Switzerland) using petroleum ether. For determination of neutral detergent fiber (NDF), method 2002.04 (AOAC 2003) was used. Ash content was measured following method 08–03 (AACC 2000) using a muffle furnace (Lindberg/Blue 1100 °C Box furnace BF 51800 Series, Ashville, NC, USA), at 600 °C for 2 h.

A texture analyzer (TX.XT- plus, Texture Technologies Corp., Scarsdale, New York, USA) was used to study firmness and extensibility using two different probes, the SMS/Chen-Hoseney Dough stickiness RIG and the Pizza Tensile RIG. Water activity was determined using a water activity meter (AquaLab CX-2, Decagon Devices, Inc., Pullman, WA, USA). Color was measured by spectrophotometer (Minolta CM-508d, Ramsey, NJ, USA) using the L*-a*-b* opposable color scales, in which L* is measure of lightness, a* is measure of greenness to redness, and b* is a measure of blueness to yellowness.

Data analysis

All collected data were analyzed with Microsoft Excel v.2007 (Redmond, WA, USA) and SAS v.9.0 (Cary, NC, USA) software, using a Type I error rate (α) of 0.05 by analysis of variance (ANOVA) to determine if there were significant differences between treatments. If significant differences were found, then post-hoc LSD tests were used to determine where the differences occurred.

Results and discussion

Chemical properties

Moisture content

Even though they were baked for the same length of time, the control tortilla had the highest moisture content (Tables 1 and 2), while the tortilla made with 20 % DDGS substitution had the lowest amount, and the differences were significant. These results were similar to those obtained for Barbari bread, in which DDGS was substituted at three different levels (0, 10 and 20 %) for flour (Pourafshar et al. 2011b). Water plays a major role in bread making; it affects starch gelatinization, protein distribution, flavor and color development, and baking quality. As the amount of fiber increases, the flour-water adsorption in the bread changes. This also depends on the particle size of the fiber (Sabanis et al. 2009). Generally, the moisture content of a fresh tortilla is about 38–45 % (Figuerou et al. 2003). However the addition of DDGS affected the moisture content of the tortillas in this study, and all tortillas were lower than that. The reason for the decrease in the moisture content, although the fiber was increased, was probably due to the lower content of gluten in the dough matrix in which the DDGS had been incorporated. Since the gluten content was decreased, it could not make a sufficient network and bind with water molecules in comparison to the control tortilla.

Table 1.

Protein, fiber and fat content of all-purpose flour (g/100 g) and DDGS (g/100 g dry matter)

| All-purpose flour | DDGS | |

|---|---|---|

| Protein | 10 | 31.3 |

| Crude fiber | 3.33 | 10.2 |

| Crude fat | 1.66 | 11.9 |

Table 2.

Chemical properties of resulting tortillas.

| DDGS Substitution (%) | |||

|---|---|---|---|

| Properties | 0 | 10 | 20 |

| MC | 42.0 a | 30.0 b | 29.0 b |

| (% db) | (0.02) | (0.01) | (0.02) |

| Protein | 9.18 c | 9.73 b | 10.78 a |

| (% db) | (0.10) | (0.02) | (0.10) |

| Fat | 19.15 c | 23.60 b | 24.65 a |

| (% db) | (0.21) | (0.00) | (0.07) |

| Fibera | 1.68 b | 2.21 a | 2.33 a |

| (% db) | (0.26) | (0.05) | (0.08) |

| Ash | 3.07 b | 3.83 a | 3.92 a |

| (% db) | (0.01) | (0.73) | (0.03) |

Means followed by similar letters for a given dependent variable are not significantly different at P < 0.05, LSD. Values in parentheses are standard deviation. MC is moisture content.

aFiber was measured as neutral detergent fiber (NDF).

Protein content

The higher quantity of protein in DDGS compared to flour resulted in higher protein in the final tortilla products (Table 2). The 20 % tortilla had the highest protein, which was significantly higher than the control. These results were similar to previous work done on muffins, in which muffins with 20 % DDG had a higher protein content in comparison to that made with 0 % DDG (Reddy et al. 1986). In a study done on spaghetti, incorporation of 10 % corn distillers grains resulted in 12–14 % higher protein in final spaghettis (Wu et al. 1987).

Protein quantity, quality, the amount of gluten, and the type of high molecular weight glutenins present can influence the quality of the dough and that of the final baked product (Saxena et al. 1997). Protein and fiber are the major constituents of DDGS, suggesting that DDGS can be a potential ingredient for fortification of bread products (Brochetti et al. 1991). In fact, a study done by Satterlee et al. (1976) concluded that protein concentrate obtained from fermented corn had an apparent digestibility of 78 %. DDGS protein may be similar to that.

Fat content

Results from the fat measurements (Table 2) showed that the highest value of fat content, not surprisingly, was found in the tortilla made with 20 % DDGS substitution, while the lowest value was measured in the control tortilla. There were significant differences between fat content of the tortillas. This was due, in part, to the fat level in the DDGS itself. However, in a study done on muffins, no change in fat content was found in muffins made with 10 % DDG compared to control (0 % DDG) (Reddy et al. 1986). Another study showed that the fat content of control bread samples made with whole wheat flour was the same as those made with 10 % DDG (Tsen et al. 1983). Perhaps these behaviors occurred because of the lower level of gluten in the dough network, which led to fewer interactions between proteins and lipids in the dough compared to that of the control sample.

Fat is an important factor in the quality of final tortillas and their resulting texture. During preparation of tortillas, shortening is one of the ingredients which is added to the tortilla dough, but only up to a certain level before the product becomes greasy. This may be the only part of the added lipid that becomes an integral part of the dough matrix. Addition of shortening to flour tortilla at a 5 % level can improve the rheological properties for the heating, pressing, or sheeting of the dough balls into flat tortillas (Fu et al. 1997).

Fiber content

In this study, the highest value of fiber was found in the tortillas made with 20 % DDGS, while the lowest was measured in the control tortillas (Table 2). There were significant differences in the fiber content of the control and both the tortillas made with 10 and 20 % DDGS. This behavior was expected due to the fiber in the DDGS. Similar results occurred in a study on Barbari bread which incorporated three levels (0, 10 and 20 %) of DDGS (Pourafshar et al. 2011b). Tsen et al. (1983) also determined that breads supplemented with 10 % DDG had a higher amount of fiber compared to bread made with flour.

DDGS has a high fiber content. One study concluded that the NDF (neutral detergent fiber) level of DDGS was significantly greater than that of the starting grain. It was also determined that DDGS can contain 30–55 % NDF, 7–9 % crude fiber and 10–14 % acid detergent fiber (Dong and Rasco 1987). Dietary fiber is an important factor in food. It increases the nutritional value of bread, and potentially alters the sensory, rheological, and textural properties of the bread as well. Dietary fiber is the remaining components after consumption of the edible part of the plant; it is resistant to digestion and absorption in the human small intestine (Gomez et al. 2003). It can affect human health in many positive ways, such as decreasing the risk of cardiovascular diseases or cancer. Fiber has the ability to absorb water in baked products. When it absorbs a high amount of water, other particles may not be fully integrated into the starch/gluten matrix, which can lead to lower loaf volume and harder texture (Gould et al. 1989).

Ash content

The highest amount of ash was obtained in the sample made with 20 % DDGS (Table 2), while the lowest was measured in the control sample. There was no significant difference between the tortilla made with 10 and 20 % DDGS, however. The reason for the increase in the amount of ash was probably the soluble solids in the DDGS which were added to the distillers grains during processing. These soluble solids are a source of various vitamins and minerals (Davis 2001). Rasco et al. (1990) concluded that incorporation of DDG resulted in a higher amount of ash in cookies; however, the amount of ash varied due to DDGS processing conditions. Also, supplementation of 10 % DDG into bread resulted in a higher amount of ash compared to white (control) bread (Tsen et al. 1983).

Physical properties

Texture

Physical characteristics which result from structural elements are observed as textural properties (Mao et al. 2002). The texture of tortillas plays a major role in consumer acceptability (Toma et al. 2008). In this study, two different texture properties were evaluated, extensibility and firmness (Table 3). The highest value for extensibility was measured in the control tortilla. This was significantly different compared to the tortillas made with 10 and 20 % DDGS, which were not significantly different from each other. Tortilla stretchability, extensibility, and rupture distance are related to flour protein content as well as protein type, as they all impact texture (Wang and Flores 1999). Gluten content in the flour is thus an important factor in textural properties. In a study by Gujral and Pathak (2002), when whole wheat flour was replaced with rice flour, chapathi extensibility decreased significantly at higher levels of replacement, due to the absence of gluten protein in the rice flour.

Table 3.

Physical properties of resulting tortillas

| DDGS Substitution (%) | |||

|---|---|---|---|

| Properties | 0 | 10 | 20 |

| Extensibility a | 3.73 a | 2.03 b | 2.33 b |

| (N) | (0.51) | (0.42) | (0.39) |

| Firmness b | 3.41 a | 1.91 b | 2.42 b |

| (N) | (0.54) | (0.26) | (0.25) |

| aw | 0.93 a | 0.91 b | 0.89 c |

| (−) | (0.00) | (0.00) | (0.00) |

| L* | 75.15 a | 64.11 b | 59.92 b |

| (−) | (4.40) | (1.52) | (1.76) |

| a* | 0.38 c | 5.68 b | 8.38 a |

| (−) | (0.11) | (1.15) | (0.73) |

| b* | 15.51 b | 23.80 a | 22.91 a |

| (−) | (2.27) | (1.77) | (1.25) |

Means followed by similar letters for a given dependent variable (i.e., row) are not significantly different at P < 0.05, LSD. Values in parentheses are standard deviation. aw is water activity. L*, a* and b* are color parameters.

aExtensibility was measured as force versus distance.

bFirmness was measured as force versus time.

As for firmness, the highest value was determined in the control tortilla as well. Tortillas made with 10c and 20 % DDGS showed no significant difference from each other in firmness, but they were significantly lower than the control. Fiber content of the tortillas made with 10 and 20 % DDGS were higher than the control, which probably led to a harder texture. High quality tortillas should be firm and have a good flexibility (Mao et al. 2002).

Gluten content has an important role in both firmness and extensibility of tortillas. Improvement in the quality of gluten, as far as its extensibility and stretch-ability, can lead to a better network in the dough matrix and more effective gas production during baking. In one study, triticale flour, which is considerably lower in gluten content than wheat, was used in the production of tortillas. Results showed that when vital gluten was added to triticale-rich tortillas, the rupture force to distance increased in comparison to the triticale tortillas themselves (Saldivar et al. 2004). According to Pascut et al. (2004), the elasticity of bread can be improved by the glutenin content. Dough extensibility increase may be improved from lower amount of glutenin and more gliadin functionality in dough.

Water activity

The results from water activity measurement (Table 3) showed that the lowest value occurred in the tortilla made with 20 % DDGS, while the control had the highest value of water activity. Water activity was significantly different in each of the tortillas. All tortillas had high water activity values (>0.89), and were all too high for safe storage. Water activity depends on both the chemical characteristics and the physical properties of the materials. Particle size is an important factor; it influences water activity and water binding capacity. Wheat fiber has a small particle size, which could lead to high water binding capacity, compared to DDGS properties. The extent of increase in flour-water absorption depends on the structure of the fiber, and can be influenced by the hydroxyl groups in the fiber molecules. These groups allow more water interaction through hydrogen binding (Sabanis et al. 2009).

Color

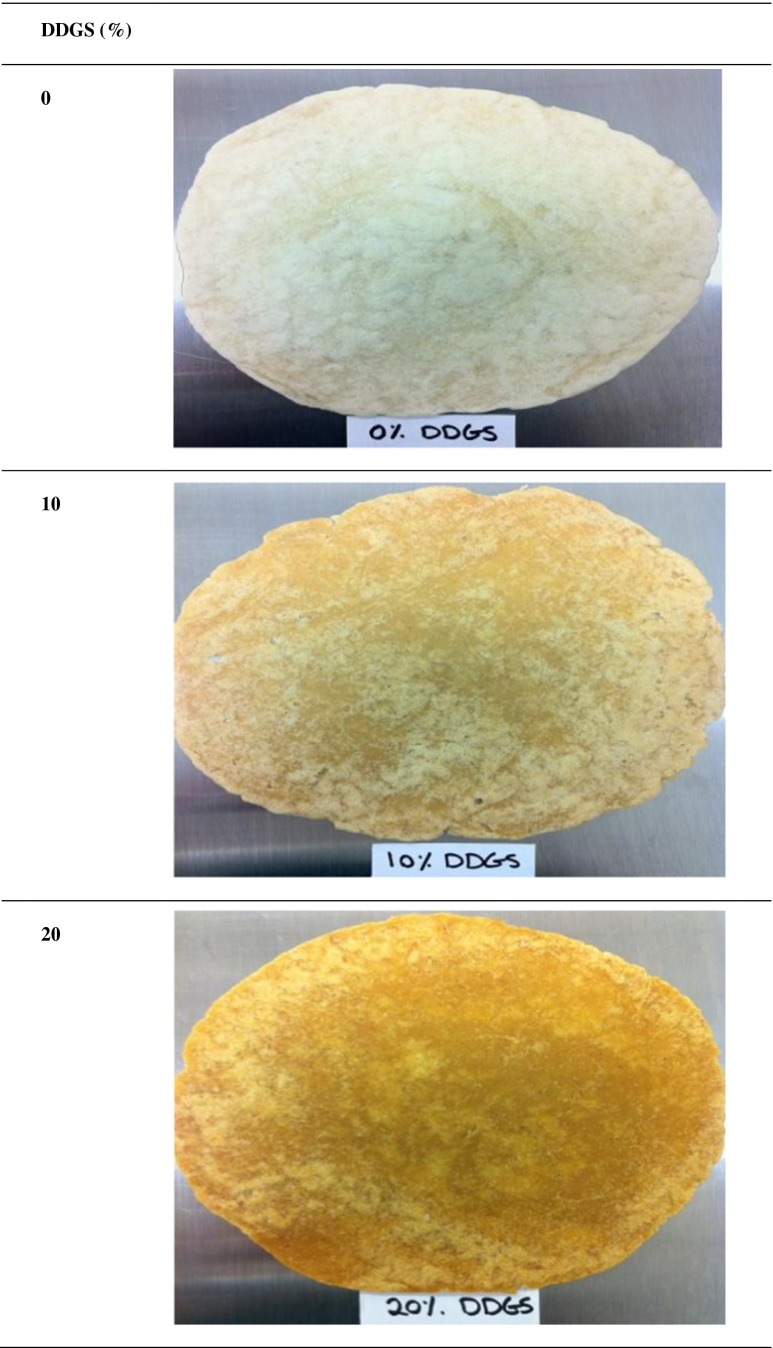

In this study, the L*, a* and b* values of the resulting tortillas changed according to DDGS level (Table 3). For the L* value, the control tortilla was the highest, and was significantly different compared to all other tortillas; 20 % DDGS was darker than the 10 % DDGS tortilla, but this was not significant. The highest value of a* was measured in the tortilla made with 20 % DDGS, while the lowest was measured in the control. Similarly, the highest value of b* occurred in the tortilla made with 20 % DDGS, but the lowest was for the control. Overall, these color results indicate that as the level of DDGS increased, the tortillas became darker, redder and yellower (Fig. 1). This was not surprising, as the DDGS was yellowish-brown in color. In another study, the crumb color of the breads became darker as DDG level increased (Brochetti et al. 1991). Rasco et al. (1990) incorporated DDG into breads and cookies, which led to darker, redder, and yellower color of final products. In another study, 30 % DDGS was incorporated into all-purpose flour for a variety of baked goods, which resulted in darker, redder, and yellower products (Rasco et al. 1987).

Fig. 1.

Resulting tortillas with DDGS substitutions of 0, 10 and 20 %.

Color is an important factor in consumer perception and together with aroma and texture can have a major role in bread acceptability (Toma et al. 2008). Color depends on the physiochemical characteristics of the dough and also processing of the bread. Chemical reactions can affect the color of baked products, including browning reactions such as the Maillard reaction, which is affected by the moisture content, temperature, and pH (Esteller and Lannes 2008).

Conclusions

Tortillas have been made and widely consumed in Mexico and Latin American for centuries. Today in the United States, tortillas have become very popular and highly consumed as well. Adding nutrients to this bread, especially fiber and protein, could help improve its nutritional content. For this purpose, DDGS which is high in both fiber and protein was used in this study. Incorporation of DDGS into wheat tortillas resulted in better textural properties. It appears that, substitution of flour with DDGS can be an effective way to produce this bread with a better nutritional value. Protein and fiber of the tortillas made with DDGS were significantly higher than the control sample at all levels of substitution (10 and 20 %). Thus, as far as the chemical and physical properties of tortillas, substitution of both 10 and 20 % DDGS improved the protein and fiber content as well as texture, and thus could be the recommended concentration of DDGS in these breads. However, since this study focused on the technical applicability of partially substituting DDGS for wheat flour into tortillas, future work should be done on sensory evaluation of these products in order to investigate the best dose at which DDGS can improve the chemical, physical, and sensory properties of tortillas. Because of the high amount of fiber and protein in DDGS, it is important to more fully characterize these new products, and consumer acceptability and sensory properties will thus be important.

Acknowledgments

The authors would like to thank the USDA-ARS and the South Dakota Agricultural Experiment Station for funding this project. The authors declare that they have no conflicts of interest.

References

- American Association of Cereal Chemists (AACC) (2000) Approved Methods of the American Association of Cereal Chemists, 10th Ed. St. Paul, MN, USA

- Anton AA. Improving the nutritional and textural properties of wheat flour tortillas. Cereal Res Commun. 2008;36:301–311. doi: 10.1556/CRC.36.2008.2.10. [DOI] [Google Scholar]

- AOAC International (AOAC) Official Methods of Analysis of the Association of Analytical Chemists. 17. Gaithersburg: The Association; 2003. [Google Scholar]

- Arreola DD. A Mexican American cultural province, Tejano South Texas. Austin: University of Texas Press; 2002. [Google Scholar]

- Belyea RL, Rausch KD, Tumbleson ME. Composition of corn and distillers dried grains with soluble from dry grind ethanol processing. Bioresour Technol. 2004;94:293–298. doi: 10.1016/j.biortech.2004.01.001. [DOI] [PubMed] [Google Scholar]

- Brochetti D, Penfield MP, Edelman MF. Yeast bread containing distillers dried grain. J Food Qual. 1991;14:331–344. doi: 10.1111/j.1745-4557.1991.tb00074.x. [DOI] [Google Scholar]

- Cromwell GL, Herkelman KL, Stahly TS. Physical, chemical and nutritional characteristics of DDGS for chicks and pigs. J Anim Sci. 1993;71:679–686. doi: 10.2527/1993.713679x. [DOI] [PubMed] [Google Scholar]

- Davis, K. (2001) Corn milling, processing and generation of co-products. Presented at the 62nd Minnesota Nutrition Conference and Minnesota Corn Growers Association Technical Symposium, Bloomington, MN

- Dong FM, Rasco BA. The neutral detergent fiber, acid detergent fiber, crude fiber and lignin contents of distiller’s dried grains with solubles. J Food Sci. 1987;52:403–405. doi: 10.1111/j.1365-2621.1987.tb06624.x. [DOI] [Google Scholar]

- Esteller MS, Lannes SCS. Production of sponge-dough bread using scaled rye. J Texture Stud. 2008;39:56–67. doi: 10.1111/j.1745-4603.2007.00130.x. [DOI] [Google Scholar]

- Figuerou DJ, Godinez MGA, Mendez NLV, Guzman AL, Acosta LMF. Nutritional quality of nixtamal tortillas fortified with vitamin and soy protein. Int J Food Sci Nutr. 2003;3:189–200. doi: 10.1080/09637480120091991. [DOI] [PubMed] [Google Scholar]

- Finely JW, Hanamoto MM. Milling and baking properties of dried brewer’s spent grains. Cereal Chem. 1980;57:166–168. [Google Scholar]

- Fu J, Mulvaney SJ, Cohen C. Effect of added fat on the rheological properties of wheat flour dough. Cereal Chem. 1997;74:304–311. doi: 10.1094/CCHEM.1997.74.3.304. [DOI] [Google Scholar]

- RFA (Renewable Fuels Association) (2013) Industry Resources. Washington, D.C.: Renewable Fuels Association. Available at: www.ethanolrfa.org. Accessed on July 30, 2013

- Gabel TG, Boller GW. A preliminary look at the globalization of the tortilla in Mexico. Adv Cust Res. 2003;30:135–141. [Google Scholar]

- Gomez M, Ronda F, Blanco CA, Caballero PA, Apesteguia A. Effect of dietary fiber on dough rheology and bread quality. Eur Food Res Technol. 2003;216:51–56. [Google Scholar]

- Gould JM, Jasberg KB, Dexter LB, Hsu JT, Lewis M, Fahey GC. High-fiber, noncaloric flour substitute for baked foods, properties of alkaline peroxide-treated lignocelluloses. Cereal Chem. 1989;66:201–205. [Google Scholar]

- Gujral HS, Pathak A. Effect of composite flours and additives on the texture of chapathi. J Food Eng. 2002;55:173–179. doi: 10.1016/S0260-8774(02)00061-4. [DOI] [Google Scholar]

- Guo G, Jackson DS, Graybosch RA, Parkhurst AM. Wheat quality, impact of amylase content adjustment using waxy wheat flour. Cereal Chem. 2003;80:427–436. doi: 10.1094/CCHEM.2003.80.4.427. [DOI] [Google Scholar]

- Mao Y, Flores RA, Loughin TM. Objective texture measurement of commercial wheat flour tortillas. Cereal Chem. 2002;79:648–653. doi: 10.1094/CCHEM.2002.79.5.648. [DOI] [Google Scholar]

- Pascut S, Kelekci N, Waniska RD. Effect of wheat protein functions on tortilla quality. Cereal Chem. 2004;81:38–43. doi: 10.1094/CCHEM.2004.81.1.38. [DOI] [Google Scholar]

- Pourafshar, S., Rosentrater, K. A., Krishnan, P. (2010) A review of alternatives to wheat flour. Paper No. 1008668. 2010 ASABE Annual International Meeting, Pittsburgh, PA. Presented June, 2010

- Pourafshar, S., Krishnan, P., Rosentrater, K. A. (2011a) Using alternative flours in production of Barbari bread, traditional Iranian bread. Paper 1111013. St. Joseph, MI. ASABE

- Pourafshar, S., Rosentrater, K. A., Krishnan, P. (2011b) Production of Barbari bread, traditional Iranian bread, using different levels of distiller’s dried grains with solubles (DDGS) and sodium sterol lactate (SSL). Poster 05525. New Orleans, LA. IFT [DOI] [PMC free article] [PubMed]

- Rasco BA, Downey SE, Dony FM. Consumer acceptability of baked goods containing distillers dried grains with solubles from soft white winter wheat. Cereal Chem. 1987;64:139–143. [Google Scholar]

- Rasco BA, Rubenthaler G, Borhan M, Dong FM. Baking properties of bread and cookies incorporating distillers’ or brewers’ grain from wheat or barley. J Food Sci. 1990;55:424–429. doi: 10.1111/j.1365-2621.1990.tb06778.x. [DOI] [Google Scholar]

- Reddy NR, Pierson MD, Cooler FW. Supplementation of wheat muffins with dried distillers grain flour. J Food Qual. 1986;9:243–249. doi: 10.1111/j.1745-4557.1986.tb00794.x. [DOI] [Google Scholar]

- Rosentrater KA, Krishnan PG. Incorporating distillers grains in food products. Cereal Foods World. 2006;51:52–60. [Google Scholar]

- Sabanis D, Lebesi D, Tzia C. Effect of dietary fiber enrichment on selected properties of gluten-free bread. Food SciTech. 2009;42:1380–1389. [Google Scholar]

- Saldivar SO, Flores SG, Rios RV. Potential of triticale as a substitute for wheat in flour tortilla production. Cereal Chem. 2004;81:220–225. doi: 10.1094/CCHEM.2004.81.2.220. [DOI] [Google Scholar]

- Satterlee LD, Vavak DM, Abdel-Kadir R, Kendrick JG. The chemical, functional and nutritional characterization of protein concentrates from distiller’s grains. Cereal Chem. 1976;55:739–749. [Google Scholar]

- Saxena DC, Rao UJP, Rao PH. Indian wheat cultivars: correlation between quality of gluten protein, rheological characteristics of dough and tandoori roti quality. J Sci Food Agric. 1997;74:265–272. doi: 10.1002/(SICI)1097-0010(199706)74:2<265::AID-JSFA795>3.0.CO;2-1. [DOI] [Google Scholar]

- Spiehs MJ, Whitney MH, Shurson GC. Nutrient database for distiller’s dried grains with solubles produced from new ethanol plants in Minnesota and South Dakota. J Anim Sci. 2002;80:2639–2645. doi: 10.2527/2002.80102639x. [DOI] [PubMed] [Google Scholar]

- Steinberg, I. I. (2005) Continued growth for the tortilla industry, Snack Food and Wholesale Bakery. Available at: www.snackandbakery.com. Accessed on July 30, 2013

- Toma A, Omary MB, Rosentrater KA, Arndt EA, Prasposunwaltana N, Chongcham S, Flores RA, Lee SP. Understanding consumer preference for functional barley tortillas through sensory, demographic and behavioral data. Cereal Chem. 2008;85:721–729. doi: 10.1094/CCHEM-85-6-0721. [DOI] [Google Scholar]

- Tsen CC, Eyestone W, Weber JL. Evaluation of the quality of cookies supplemented with distiller’s dried grains flours. J Food Sci. 1982;74:684–685. doi: 10.1111/j.1365-2621.1982.tb10156.x. [DOI] [Google Scholar]

- Tsen CC, Weber JL, Eyestone W. Evaluation of distillers dried grain flour as bread ingredient. Cereal Chem. 1983;60:295–297. [Google Scholar]

- Wang L, Flores RA. Effect of different wheat classes and their flour milling streams on textural properties of flour tortillas. Cereal Chem. 1999;76:496–502. doi: 10.1094/CCHEM.1999.76.4.496. [DOI] [Google Scholar]

- Wu YV, Youngers VL, Warner K, Bookwalter GN. Evaluation of spaghetti supplementation with corn distiller’s dried grains. Cereal Chem. 1987;64:434–436. [Google Scholar]