Abstract

Oil in water emulsions were produced by the mixture of culled banana resistant starch (CBRS) & soy protein isolate (SPI), mixture of Hylon VII & SPI and SPI with 7.5 and 5 % (w/w) Menhaden fish oil. The emulsions were further freeze- dried obtaining 33 and 50 % oil load microcapsules. The range of particles diameter was 4.11 to 7.25 μm and viscosity was 34.6 to 146.48 cP of the emulsions. Compressibility index (CI), Hasner ratio (HR) and angle of repose (AR) was significantly (p < 0.01) lower of the microcapsules made with starch and protein (CBRS & SPI and Hylon VII & SPI) than that made with protein (SPI) only. Microcapsules composed of CBRS & SPI with 33 % oil load had maximum microencapsulation efficiency (82.49 %) and highest oxidative stability. Muffin made with emulsions containing mixture of CBRS & SPI exhibited less fishy flavour than that containing mixture of Hylon VII & SPI.

Keywords: Culled banana resistant starch, Fish oil microcapsule, Encapsulation efficiency, Oxidative stability, Functional muffin

Introduction

Fish oil contains long-chain omega-3 fatty acids, eicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) that have the ability to prevent cardio-vascular disease, inflammations, hypertension, thrombosis, allergies, cancer, and also helps to improve early child hood development and cognition (Augustin et al. 2011). These health promoting properties have sparked a wide interest for incorporating fish oil into foods. However, the extreme susceptibility of these oils to oxidation and thus development of undesirable rancid odour and taste create difficulties to incorporate into food products. Encapsulation of oils in convenient emulsion or powder formats allows incorporation into food maintaining oxidative stability, control release and masking its unpleasant taste and smell. Protein and reducing sugars heated at certain elevated temperature can form the Maillard reaction products (MRP) with improved emulsifying properties (Shepherd et al. 2000) and enhanced oxidative stability of fish oil emulsions and microcapsules (Augustin et al. 2006; Drusch et al. 2009). Augustin et al. (2006) reported that the heat treatment of protein and carbohydrate in maximum temperature and time combination (100 °C for 90 min) produced the most stable fish oil powder to oxidation. On the other hand, Madene et al. (2006) reported that freeze dried microencapsulated fish oil had better oxidative stability than that by hot air drying process.

Most research has focused on the use of low molecular weight carbohydrates (for example, sugars, maltodextrins) in combination with proteins for encapsulation (Sheu and Rosenberg 1998; Kagami et al. 2003). Resistant starch (RS) has some specific advantages such as less solubility, higher crystalinity and stability in high processing temperatures. Moreover it is considered as dietary fibres (soluble and insoluble) and prebiotics. RS has been used in combination with milk protein for preparation of fish oil capsules for in vitro lipolysis and their oxidative stability (Chung et al. 2010). Oxidation of oils promotes the generation of free radicals leads to formation of unpleasant tastes and odours and reduces the shelf life of foodstuffs (Huang et al. 2012). At first, fatty acids react with oxygen; produce odourless compounds, usually determined by PV test. During the second phase of complex oxidation reactions, the peroxide degrades into many substances as volatile aldehydes, responsible for rancid odour and flavour (Anal et al. 2012). Anisidine value represents the level of non-volatile aldehydes, primarily 2-alkenals present in the fat. The permissible limit of PV is 5 meq/kg and 20 for AV in marine oils or omega-3 fatty acids derived from marine oils to ensure their oxidative stability (Nasrin and Anal 2013).

Omega-3 fatty acids from marine oil containing EPA and DAH fortified foods are the significant among the growing classes of functional foods. However, such fortification greatly affects the smell and taste of the fortified foods that largely depend on the amount of fish oil added and the types of fortified food (Kolanowski et al. 1999). Recommended intake levels for EPA and DHA is from 160 mg to 1.6 g per day (Barrow et al. 2009).

Approximately 20 % (w/w) of all harvested bananas become culls (Zhang et al. 2005) since these are undersized or partially injured. These culled bananas are the good source of starch. About 82 % of the total banana production in Thailand is Kluai Namwa (Musa ABB group) (Boonyanuphap et al. 2004) and contains high amount of amylose and granular RS that makes it suitable raw materials to produce retrogated RS. In previous paper, CBRS was produced and found that it had less solubility, swelling power, water holding capacity, freeze thaw stability than the raw starch (Nasrin and Anal 2013). Fish oil emulsion containing CBRS with SPI was produced and compared to that containing Hylon VII & SPI and only SPI with 7.5 and 5 % (w/w) Menhaden fish oil in that paper. Hence the purpose of this study was to produce 33 and 50 % (w/w) oil load microcapsules by freeze drying the previous emulsions to enhance their shelf life, sensory properties and ease-handling. Moreover, the muffins were produced using emulsions containing CBRS & SPI and Hylon VII & SPI with 7.5 % fish oil load to find out their suitable uses in food products.

Materials and methods

Materials

Fish oil from Menhaden and SPI were purchased from Sigma Aldrich. High amylose-resistant starch (Hylon VII) was obtained from National starch, Thailand. All other chemicals were of analytical grade. The retrogated resistant starch from culled banana of Kluai Namwa variety was produced in Bioprocess laboratory, Asian Institute of Technology (AIT), Thailand.

Preparation of RS from culled banana

Kluai Namwa banana of aged 100–110 days (full green stage of maturity) after anthesis was collected from a local market (Pathumthani, Thailand). The last two clusters of banana (under sized, called cull) having green peel and sharp edges were selected. Starch was extracted from peeled pulp by simple wet milling method using 0.05 % (w/w) NaOH solution. Extracted wet starch was dried at 40 °C in hot air oven overnight, cooled and then ground. Culled banana starch was suspended in water (1:10, w/w) and gelatinized at 85 °C for 30 min followed by autoclaving at 135 °C for 30 min, cooling and storing at 4 °C for 24 h. This autoclaving and storing process was repeated three times at same temperature and time (total 72 h storing) for each sample. The product was then dried at 50 °C in hot air oven, ground by grinder (Princess, model No-2194, China) and sieved through 100 meshes. Dried CBRS products were packed into high density polyethylene pouch (HDPP) by vacuum sealing and stored into desiccators for further use.

Preparation of encapsulant materials

Mixture of CBRS & SPI (1:1 ratio, w/w), mixture of Hylon VII & SPI (1:1 ratio, w/w) and only SPI were hydrated separately in warm water (60 °C) and to get aqueous suspensions (10 % total solids w/w). The mixture was first heated at 100 °C for 90 min to produce MRP. After cooling down, the mixtures were frozen and lyophilized using Labonco Freeze Dryer Model AF-1036. The freeze-dried encapsulant materials were stored in a freezer (−20 °C) prior to further use.

Preparation of microencapsulated fish oil

Fish oil emulsions were prepared following the method of Chung et al. (2010) with slight modifications. Three types of freeze-dried encapsulant materials i) mixture of CBRS & SPI, ii) mixture of Hylon VII & SPI and iii) only SPI were mixed with warm (60 °C) water to get three mixtures of 7.5 % (w/w) total solid and three mixtures of 10 % (w/w) total solids. Fish oil was added to these six types of mixtures to obtain 15 % (w/w) total solid emulsions (2:1:1 ratio of oil: protein: RS, or 1:1 ratio of oil: protein). The final pH of all six emulsions was 7.5 ± 0.2. The oil encapsulant mixture was pre emulsified with blender (National, MX-31GN) for 2 min followed by high pressure homogenizer (IKA Labor-pilot, 2000/4) at 1,000 bar and two passages. Each emulsion type was analysed for its size, viscosity and colour values. On the other hand, homogenized emulsions were frozen prior to lyophilize using Labonco Freeze Dryer Model AF-1036. The freeze-dried microcapsules of 33 and 50 % oil load were stored in amber glass bottle at room (20 °C) and refrigeration (4 °C) temperatures. During storage, fish oil microcapsules were subjected to PV and AV test analysis. Three independent trials were carried out.

Optical microscopy and emulsion droplet size

The microstructure of the emulsions was determined according to (Klaypradit and Huang 2008) by light microscope (FDX-35, Nikon, Japan). Emulsion was diluted to avoid the particles clumping. Droplet size was measured by the calibrated scales. The volume-surface mean diameter (d32) was calculated from 100 droplets by the following Eq. (1).

| 1 |

Where ni is the number of droplets with diameter di.

Viscosity of emulsion

The viscosities of the emulsions were determined at 25 °C within 2 h of their preparation using Brookfeild viscometer (model No-LV DV-II + PX, USA). Emulsion was transferred to a 100 ml beaker and levelled up to the brim. The spindle number 61 was used for all emulsions at the speed of 5 rpm.

FTIR analysis

Infrared spectra of freeze dried SPI, mixture of CBRS & SPI and Hylon VII & SPI were measured on an Attenuated Total Reflectance (ATR) FTIR (Nicolet Avatar 360) with spectra-Tech HATR accessory. Powdered samples were used directly for measuring the spectra from 500 to 4,000 cm−1 wave numbers. All measurements were conducted under ambient conditions.

Colour spectra analysis of fish oil emulsions

Colour spectra of each emulsion were measured by a Hunter Lab Spectrocolorimeter (Model TC-P III A, Tokyo Denshoku Co., Ltd., Japan). The samples were kept into the glass jar and placed over the slit. The spectra were observed and analysed by CIE Lab system. L* (L* =0 means black and L* =100 means white), a* (−a* = greenness and + a* = redness) and b* (−b* = blueness and + b* = yellowness) values were measured.

Flow properties of microcapsules

Flowability of the fish oil freeze dried microcapsules was analysed by determining bulk density (BD), tapped density (TD), CI, HR, and AR. BD was measured by weighing 2 g of sample and placing it in a 50 mL graduated cylinder. The cylinder was tapped five times and the BD was calculated by dividing the mass of the powder by the volume occupied in the cylinder (Goula and Adamopoulos 2004).

TD was calculated from the height of powder inside the cylinder after being tapped for 50 times from a height of 10 cm (Goula and Adamopoulos 2004).

| 2 |

| 3 |

To measure AR, fish oil microcapsules were dropped from the summit on a level surface to make a moderately circular pile. The height (h) of the pile from the peak to the ground was measured. The horizontal distance (d) from the middle of the pile to the edge was also measured to calculate angle of repose by using the well known formula (4):

| 4 |

Free fat content and encapsulation efficiency of fish oil powder

The free fat in the microcapsules was estimated based on the method by Pisecky (1997) except that petroleum ether was used instead of carbon tetrachloride. Sample (one g) was dispersed into 10 mL petroleum ether into a flask, shaken for 15 min and filtered. The remaining fat residue was dried at 100 ± 2 °C for 1 h in hot air oven and weighed. The percentage of free fat in microcapsules was measured using the following formula:

| 5 |

The total fat of the microcapsules was estimated according to IUPAC (1987).

Encapsulation efficiency (EE) was calculated from the following equations:

| 6 |

Peroxide value (PV) analysis

Peroxide value of tested samples was determined according to IUPAC (1987). Oil samples (2 g) were dissolved into 20 ml acetic acid- chloroform (3:2) solution. Saturated potassium iodide (0.25 ml) solution was added with occasional swirling for 1 min and 12 ml distilled water was added. It was titrated with 0.01 N sodium thiosulphate solution with 1 ml of 1 % soluble starch indicator until blue color just disappeared. PV was determined by the following formula:

| 7 |

Where: S = ml of sodium thiosulphate

M = 0.01, concentration of sodium thiosulphate.

Anisidine value (AV) analysis

Anisidine value of tested samples was analyzed according to the method of IUPAC (1987). Para- anisidine was dissolved in glacial acetic acid to make a 0.25 g/100 ml solution. Samples (0.5 g) were accurately weighed in 25 ml volumetric flasks and diluted to volume with isooctane. The absorbance (Ab) of the resulting solutions at 350 nm was measured using isooctane as the reagent blank. 5 ml of the solution was then pipetted into a test tube and 5 ml of isooctane into another test tube. 1 ml of the para-anisidine solution was added to both and the solutions were mixed. After 10 min, the absorbance (As) of the sample solutions was read with the isooctane as blank. Anisidine values were calculated as follows:

| 8 |

Functional muffin fortified with fish oil emulsion

At first oven was preheated to 180 ° C. all dry ingredients flour, sugar, milk powder, egg powder, baking powder and salt were weighed as shown in Table 1 and mixed in a large bowl with a whisk. It was mixed thoroughly at least 10 times to ensure the baking powder and salt was disappeared. Oil (soybean and fish) was added to different mixtures as stated in Table 1 and mixed thoroughly. Lastly, water or emulsion was added to mixture as indicated in Table 1 and kneaded properly. Muffin pans were sprayed by soybean oil and filled with batter up to 2/3 of pan. Pans were placed in the oven and heated for 15–20 min until golden brown colours of muffins. It was cooled to room temperatures, then analysed for sensory quality. Fish oil fortified muffin was contained 3 g fish oil per 80 g of final product or muffin.

Table 1.

Muffin preparation formulations for 100 g batter weight

| Ingredients | Types of muffins | |||

|---|---|---|---|---|

| 510 | 301 | 709 | 805 | |

| Wheat flour (g) | 30.00 | 30.00 | 28.00 | 28.00 |

| Fish oil emulsion with CBRS (g) | 0.00 | 0.00 | 0.00 | 26.70 (2 g fish oil) |

| Fish oil emulsion with Hylon VII (g) | 0.00 | 0.00 | 26.70 (2 g fish oil) | 0.00 |

| Sugar (g) | 25.20 | 25.20 | 25.20 | 25.20 |

| Milk powder (g) | 7.00 | 7.00 | 7.00 | 7.00 |

| Dry egg powder (g) | 4.00 | 4.00 | 4.00 | 4.00 |

| Soybean oil (g) | 100 | 8.00 | 8.00 | 8.00 |

| Fish oil (g) | 0.00 | 2.00 | 0.00 | 0.00 |

| Water (g) | 22.70 | 22.70 | 0.00 | 0.00 |

| Baking powder (g) | 0.90 | 0.90 | 0.90 | 0.90 |

| Salt (g) | 0.30 | 0.30 | 0.30 | 0.30 |

| Total (g) | 100.10 | 100.10 | 100.10 | 100.10 |

510 = Control muffin, no fish oil; 301 = Muffin made with vegetable oil & fish oil used directly (80:20, vegetable oil: fish oil); 709 = Muffin made with vegetable oil & fish oil emulsion containing CBRS (80:20, vegetable oil: fish oil); 805 = Muffin made with vegetable oil & fish oil emulsion containing Hylon VII (80:20, vegetable oil: fish oil)

Sensory evaluation of functional muffins

Functional muffins were evaluated by a sensory panel trained in descriptive analysis of fishy off-flavours. Four characteristics such as appearance, texture, flavour and overall acceptability of each muffin were scored by the panel. Ten-point unstructured scale ranging from 1 (dislike extremely) to 10 (like extremely) was used to evaluate this sensory quality by 15 panellists. Each muffin was cut into four pieces and set out for the taste panel. Panel was instructed to take one from each muffin plate randomly numbered namely 510, 301, 709 and 805.

Statistical analysis

In Food Science, statistical procedures are important to plan, analyse and interpret of experimental work (Granato et al. 2014). All the experiments were conducted in triplicate and means ± standard deviations were reported. Analysis of variance was done by one way ANOVA procedures of MSTAT-C software (Statistical package developed by the Crop and Soil Sciences Department of Michigan State University, USA). Comparisons among the samples were done by Duncan’s Multiple Range Test (DMRT).

Results and discussion

FTIR analysis of encapsutant materials

FT-IR spectra of three types of freeze dried encapsulant materials such as SPI, mixtures of CBRS & SPI and of Hylon VII & SPI were analysed as shown in Fig. 1. In all spectra, the region below 800 cm−1 demonstrated composite variational mode. The most important regions in proteins are the Amide I (C = O stretch) and Amide II (N-H and C-H stretch) are found around 1,630−1 and 1,530 cm−1 wave numbers respectively (Lodha and Netravali 2005). From 1,600 to 1,606 cm−1 wave numbers, Amide I band and from 1,488 to 1,500 cm−1 wave numbers, Amide II was observed in freeze dried SPI spectra. The insets graph from 500 to 1,750 and 2,750 to 3,750 cm−1 wave number range were made to zoom in the important regions to reflect the differences. A moderate peak was observed in SPI spectra in 2,913 to 2,925 cm−1 wave numbers. Widjanarko et al. (2011) also found a peak at 2,966 cm−1 wave number for CH and OH stretching in native SPI. Two spectra of the mixtures of CBRS & SPI and HylonVII & SPI are very similar to each other as shown in Fig. 1. One major peak was found at 987 to 1,039 cm−1 wave numbers in the mixture of CBRS & SPI spectra and from 989 to 1,024 cm−1 wave numbers in Hylon VII & SPI mixture considered for O-C stretch region. Fanga et al. (2002) reported that the most significant peak between 990−1 and 1,030 cm−1, represents the anhydrous glucose ring O-C stretch in native potato starch. Another prominent peak was observed at 3,332 to 3,417 cm−1 in the mixture of CBRS & SPI spectra and from 3,328 to 3,417 cm−1 in the mixture of Hylon VII & SPI spectra for O-H stretching regions.

Fig. 1.

FT-IR spectra of freeze dried SPI (S), mixture of CBRS & SPI (S-R) and mixture of Hylon VII & SPI (S-H)

Viscosity, droplet size and colour values of emulsions

Average particle size diameter (d32) of fish oil emulsions is illustrated in Table 2. The largest particle size was 7.25 μm observed in emulsions (7.5 % SPI +7.5 % fish oil) while 4.11 μm was the lowest in emulsions (3.75 % SPI +3.75 % Hylon VII +7.5 % fish oil). The bigger particle size was found in the emulsion made by the mixture of CBRS & SPI than that made with mixture of Hylon VII & SPI in both oil loads may be due to the hierarchy of the particle size used in the emulsions is SPI > CBS > Hylon VII.

Table 2.

Viscosity, particle size and colour values of fish oil emulsions (15 % total solid)

| Emulsion type |

Viscosity (cP) |

Particle size (d3,2) (μm) |

L* | a* | b* |

|---|---|---|---|---|---|

| E1 | 34.60 ± 2.75f | 6.24 ± 0.11 | 86.65 ± 0.2bc | +0.14 ± 0.04b | 12.98 ± 0.11a |

| E2 | 128.77 ± 5.80b | 5.74 ± 0.26 | 87.03 ± 0.08b | −1.13 ± 0.10c | 12.14 ± 0.30b |

| E3 | 96.14 ± 4.33d | 4.11 ± 0.21 | 87.68 ± 0.18a | −0.86 ± 0.12c | 9.21 ± 0.18d |

| E4 | 57.37 ± 4.25e | 7.25 ± 0.23 | 84.38 ± 0.24e | +0.60 ± 0.12a | 11.55 ± 0.19c |

| E5 | 146.48 ± 6.01a | 5.95 ± 0.27 | 84.85 ± 0.09d | −1.91 ± 0.14d | 8.96 ± 0.18d |

| E6 | 113.57 ± 5.65c | 4.91 ± 0.20 | 86.32 ± 0.20c | −1.64 ± 0.13d | 7.99 ± 0.19e |

Values are given as mean of triplicate determinations ± standard deviation

Means with different superscripts within a column indicate significant differences (P < 0.05)

E1 = 7.5 % SPI +7.5 % fish oil; E2 = 3.75 % SPI +3.75 % CBRS +7.5 % fish oil; E3 = 3.75 % SPI +3.75 % Hylon VII +7.5 % fish oil; E4 = 10 % SPI +5 % fish oil; E5 = 5 % SPI +5 % CBRS +5 % fish oil; E6 = 5 % SPI +5 % Hylon VII +5 % fish oil. 85 % water in all systems

The viscosity of fish oil emulsions ranged from 34.6 to 146.48 cP illustrated in Table 2. Viscosity increased with decreasing oil load in all types of emulsions.

Tristimulas values (L*, a* and b*) of each emulsion are also shown in Table 2. The highest L* value is 87.68 of the emulsion (3.75 % SPI +3.75 % Hylon VII +7.5 % fish oil) whereas; the lowest is 84.38 of that (10 % SPI +5 % fish oil). The L* value was decreased significantly (p < 0.05) in all emulsions with reducing oil load from 7.5 to 5 %. There is a good relation between particle size and L* value in the emulsions. L* value decreased with increasing particle sizes. It is known that the enlargement of particle size reduces its scattering efficiency that results a decrease of L value and an enrichment of colour. Emulsions made with SPI only had positive a* value (redness) where as that made with the mixture of starch and protein had negative a* value (greenness). The highest b* value (12.98) was found in the emulsions (7.5 % SPI +7.5 % fish oil) and lowest was in that (5 % SPI +5 % Hylon VII + 5 % fish oil). Because the colour of SPI is yellowish and colour of resistant starch is whitish. Like L*, b* value also decreased with decreasing oil load.

Flow properties

Table 3 illustrates the flow properties (BD, CI, HR and AR), MEE and free fat content of the microcapsules of three different encapsulant materials at 33 and 50 % oil loads. There were no significant differences (p < 0.05) in BD among fish oil microcapsules of different encapsulant materials but increased with decreasing oil load. CI and HR are two important factors to measure the flow property of powder. CI determines granular link strength and stability, where as HR determines inter granular friction (Rakhi et al. 2008).

Table 3.

Flow properties of encapsulated fish oil powder at 33.33 % and 50 % oil load

| Sample type | Bulk density (g/cm3) |

Hasner ratio | Compressibility Index (%) | Angle of repose (°) | MEE | Free fat (%) |

|---|---|---|---|---|---|---|

| S-50 | 0.18 ± 0.00b | 1.52 ± 0.03a | 34.23 ± 1.09 a | 40.88 ± 1.59a | 70.78 ± 0.84e | 14.64 ± 0.20a |

| SR-50 | 0.19 ± 0.01b | 1.44 ± 0.02b | 30.51 ± 0.74 b | 35.84 ± 0.53b | 75.96 ± 0.29c | 11.96 ± 0.10c |

| SH-50 | 0.19 ± 0.01b | 1.44 ± 0.01b | 30.57 ± 0.64 b | 35.29 ± 0.36b | 73.29 ± 0.79d | 13.43 ± 0.54b |

| S-33 | 0.23 ± 0.01ab | 1.55 ± 0.02a | 35.61 ± 0.69 a | 39.92 ± 1.83a | 75.40 ± 0.48c | 8.41 ± 0.26d |

| SR-33 | 0.25 ± 0.00a | 1.46 ± 0.02b | 31.29 ± 0.88 b | 36.04 ± 1.73b | 82.49 ± 0.42a | 5.84 ± 0.20f |

| SH-33 | 0.25 ± 0.01a | 1.45 ± 0.02b | 31.08 ± 0.87 b | 35.81 ± 1.20b | 79.04 ± 0.51b | 7.15 ± 0.18e |

Values are given as mean of triplicate determinations ± standard deviation

Means with different superscripts within a column indicate significant differences (P < 0.05)

S-50 = Microcapsule contains SPI in 50 % oil load; SR-50 = Microcapsule contains CBRS & SPI in 50 % oil load; SH-50 = Microcapsule contains Hylon VII & SPI in 50 % oil load; S-33 = Microcapsule contains SPI in 33 % oil load; SR-33 = Microcapsule contains CBRS & SPI in 33 % oil load; SH-33 = Microcapsule contains Hylon VII & SPI in 33 % oil load

Maximum HR (1.55) and CI (35.61) were found in the microcapsules made with SPI only. There was no significant difference (p < 0.05) between that made with Hylon VII & SPI and CBRS & SPI. The range of CI from 26 to 31 and that of HR from 1.35 to 1.45 is considered as ‘poor’ flow type materials. On the other hand, the range of CI from 32 to 37 and that of HR from 1.46 to 1.59 is considered as ‘very poor’ flow type powder (Rakhi et al. 2008). Kagami et al. (2003) reported that the CI was 40.1 and 37 in fish oil spray dried powder produced with maltodextrin & sodium caseinate and another made with highly branched cyclodextrin & sodium caseinate in 46 % oil load. The higher AR (35.39 to 40.88°) was shown in the powder made by SPI than that made by CBRS & SPI or Hylon VII & SPI in both oil loads. Angle of repose between 36 and 40 is a fair flow type powders (Rakhi et al. 2008).

Free fat content and encapsulation efficiency (EE) of fish oil powder

Lowest percentage of free fat (5.84 %) was found in the microcapsules containing the mixture of CBRS & SPI in 33 % fish oil load and the highest (14.64 %) was in that containing SPI in 50 % oil load as shown in Table 3. Encapsulation efficiency among different type of microcapsules was ranged from 70.78 to 82.49 %. Higher EE was found in microcapsules containing the mixture of CBRS & SPI and lowest in that containing only SPI in both oil loads. Moreover, lower oil (33 %) load microcapsules had higher EE than that made with higher oil (50 %) load. Augustin et al. (2006) also revealed similar effects of the use of heated mixture of protein & carbohydrate to stabilize fish oil in encapsulated powders. Besides higher EE was shown in the microcapsules containing CBRS & SPI compared to those containing Hylon VII & SPI is generally due to the characteristics of the resistant starch component. Hylon VII contains RSII as it is native, lost its resistivity and crystalinity during heat treatments. On the other hand, CBRS was made by autoclaving treatment has higher amount of crystallinity, insolubility and RSIII that is stable in heat treatment (100 °C for 90 min) which allowed to make stable matrix to encapsulate the oils. The moisture content of all freeze-dried fish oil microcapsule was about 2 %.

Oxidative stability of encapsulated fish oil

Development of PV in the encapsulated fish oil microcapsules was increased with increasing storage time at both temperatures 4 °C and 20 °C, but the rate of increment was different at different temperatures as shown in Fig. 2. Highest amount of peroxide was produced in the microcapsules containing SPI in 50 % fish oil load and lowest in that made by CBRS & SPI in 33 % fish oil load in both storage temperature throughout the storage period. Up to 10 weeks PV was ≤5 meq/kg (permissible limit) in the encapsulated powder produced with CBRS & SPI in both oil loads at 4 °C storage temperature. From 10 to 12 weeks, PV increased drastically especially in the microcapsules made with SPI in 50 % oil load and reached to 32.2 5 meq/kg at 4 °C storage temperature. PV was not changed much up to 1 week in all type of powder stored at room temperature (20 °C) after that it was changed significantly in all type of microcapsules and reached up to 60 meq/kg in that containing SPI in 50 % oil load in 6 weeks.

Fig. 2.

Peroxide values of different encapsulated fish oil powder at 4 °C (A) and 20 °C (B) temperatures. The error bars represent the standard deviation of mean value of 3 replications. S-50 = Microcapsule contains SPI in 50 % oil load; SR-50 = Microcapsule contains CBRS & SPI in 50 % oil load; SH-50 = Microcapsule contains Hylon VII & SPI in 50 % oil load; S-33 = Microcapsule contains SPI in 33 % oil load; SR-33 = Microcapsule contains CBRS & SPI in 33 % oil load; SH-33 = Microcapsule contains Hylon VII & SPI in 33 % oil load

Like PV, the same trend was observed in the production of AV of freeze dried encapsulated fish oil powder in both storage temperatures as shown in Fig. 3. From 8 weeks, AV production rate changed significantly and the highest amount of AV was produced in the powder contained SPI in 50 % fish oil load and lowest was in that contained CBRS & SPI in 33 % oil load stored at 4 °C temperature. AV was ≤20 (permissible limit) up to 10 weeks in all samples stored at 4 °C and up to 3 weeks in that stored at room temperature (20 °C). Minimum level of PV and AV were produced in microcapsules containing 33 % fish oil than containing 50 % oil as shown in Figs. 2 & 3. A stronger interface might have been expected for less oil load, resulting in reduced porosity and thereby reduced oxygen diffusion and lower oxidation on extended storage. Heating of protein and carbohydrate in presence of water produce MRP has superior emulsifying and antioxidative properties for the stabilization of unsaturated oil powders compared with protein alone (Shepherd et al. 2000). Higher oxidative stability of microcapsules containing CBRS & SPI compared to those with Hylon VII & SPI is due to resistant starch. CBRS produced by autoclaving, having higher amount of crystallinity, insolubility and RSIII is stable in heat treatment (100 °C for 90 min). On the other hand, Hylon VII contains RSII as it is native, lost its resistivity and crystalinity during heat treatments which allowed higher access of oxygen to the oils and resulting in faster oxidation.

Fig. 3.

Anisidine values of different encapsulated fish oil powder at 4 °C (a) and 20 °C temperature (b). S-50 = Microcapsule contains SPI in 50 % oil load; SR-50 = Microcapsule contains CBRS & SPI in 50 % oil load; SH-50 = Microcapsule contains Hylon VII & SPI in 50 % oil load; S-33 = Microcapsule contains SPI in 33 % oil load; SR-33 = Microcapsule contains CBRS & SPI in 33 % oil load; SH-33 = Microcapsule contains Hylon VII & SPI in 33 % oil load

Sensory evaluation of functional muffins

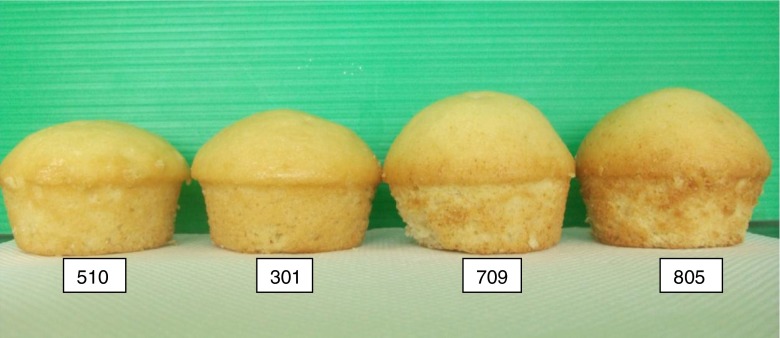

Table 4 & Fig. 4 represent different types of muffins made with emulsions containing fish oil and RS (CBRS or Hylon VII). There were no significant differences (p < 0.01) among the muffins in case of appearance. Maximum textural scores (9.1) was obtained by muffins (805) made with fish oil emulsions containing Hylon VII that was statistically similar (p < 0.01) with muffins (709) made with fish oil emulsions containing CBRS. Muffin made with RS had the highest sensory overall rating, best flavour and perceived best texture of any muffins. Control muffin (510) and that made with fish oil directly (301) had the highest and lowest flavour score respectively. On the other hand, muffin (709) made with emulsions containing CBRS exhibited less fishy odour in a greater extent than that containing Hylon VII (805) as muffin made with emulsions containing CBRS had better flavour score than that containing Hylon VII with statistical differences (p < 0.01). Control muffin (510) and that made by CBRS (709) had the highest (9.1) and second highest (8.3) overall acceptability respectively. All the results indicate that CBRS containing microcapsules and emulsions had higher stability than that made by Hylon VII as CBRS contains higher amount of crystallinity, insolubility and RSIII (mostly stable in heat treatment). Novel fish oil emulsion and microcapsules containing CBRS were developed that might be incorporated in bakery foods as better results were obtained from this emulsion fortified muffins.

Table 4.

Effect of emulsions containing fish oil and RS (CBRS or Hylon VII) on sensory quality of muffins

| Product code | appearance | texture | flavour | Overall acceptability |

|---|---|---|---|---|

| 510 | 8.80 ± 0.92 a | 7.40 ± 0.97 b | 9.00 ± 0.82 a | 9.10 ± 0.88 a |

| 301 | 9.00 ± 0.82 a | 7.20 ± 0.92 b | 5.80 ± 0.63 d | 6.10 ± 0.74 d |

| 709 | 9.40 ± 0.70 a | 9.10 ± 0.74 a | 7.10 ± 0.74 c | 7.50 ± 0.71 c |

| 805 | 9.40 ± 0.70 a | 8.60 ± 0.52 a | 8.30 ± 0.82 b | 8.30 ± 1.03 b |

Values are given as mean of triplicate determinations ± standard deviation

Means with different superscripts within a column indicate significant differences (P < 0.05)

510 = Control muffin, no fish oil; 301 = Muffin made with vegetable oil & fish oil used directly (80:20, vegetable oil: fish oil); 709 = Muffin made with vegetable oil & fish oil emulsion containing CBRS (80:20, vegetable oil: fish oil); 805 = Muffin made with vegetable oil & fish oil emulsion containing Hylon VII (80:20, vegetable oil: fish oil)

Fig. 4.

Pictorial views of functional muffins, 510 = Control muffin, no fish oil; 301 = Muffin made with vegetable oil & fish oil directly (80:20, vegetable oil: fish oil); 709 = Muffin made with vegetable oil and fish oil emulsion containing CBRS & SPI (80:20, vegetable oil: fish oil); 805 = Muffin made with vegetable oil & fish oil emulsion containing Hylon VII & SPI (80:20, vegetable oil: fish oil)

Conclusion

Lowest droplet size (4.11–4.91 μm) was found in the emulsion made with the mixture of HylonVII & SPI followed by (5.74 to 5.95 μm) of that made with the mixture of CBRS & SPI. The highest encapsulation efficiency (82.49 %) was found in the microcapsule containing CBRS & SPI in 33 % fish oil load. Flowability of the microcapsules made with the mixture of protein and resistant starch was regarded as “poor flow” type and that made with only SPI was “very poor flow” type by analysing their BD, TD, CI, HR and AR. Oxidative analysis also proved that the microcapsules contained mixtures of CBRS & SPI in 33 % oil load was the most stable as it produced lowest amount of PV and AV throughout the storage period. Muffins made by fish oil emulsion containing CBRS or Hylon VII secured higher score than that made with fish oil or control muffin in case of appearance and texture. Less fishy odour was detected in the muffin made by emulsion containing CBRS than that containing Hylon VII with statistical differences (p < 0.05 %). Emulsions made with CBRS & SPI in both oil loads can be incorporated in other bakery foods like bread, cake to enhance its functionality, textural quality, sponginess and targeted delivery of functional components.

References

- Anal AK, Jaisanti S, Noomhorm A. Enhanced yield of phenolic extracts from banana peels (Musa acuminata Colla AAA) and cinnamon barks (Cinnamomum varum) and their antioxidative potentials in fish oil. J Food Sci Technol. 2012 doi: 10.1007/s13197-012-0793-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Augustin MA, Sanguansri L, Bode O. Maillard reaction products as encapsulants for fish oil powders. J Food Sci. 2006;71(2):E25–E32. doi: 10.1111/j.1365-2621.2006.tb08893.x. [DOI] [Google Scholar]

- Augustin MA, Abeywardena MY, Patten G, Head R, Lockett T, Luca A, De Sanguansri L. Effects of microencapsulation on the gastrointestinal transit and tissue distribution of a bioactive mixture of fish oil, tributyrin and resveratrol. J Funct Foods. 2011;3:25–37. doi: 10.1016/j.jff.2011.01.003. [DOI] [Google Scholar]

- Barrow CJ, Nolan C, Holub BJ. Bioequivalence of encapsulated and microencapsulated fish-oil supplementation. J Funct Foods. 2009;1(1):38–43. doi: 10.1016/j.jff.2008.09.006. [DOI] [Google Scholar]

- Boonyanuphap J, Wattanachaiyingcharoen D, Sakurai K. GIS-based land suitability assessment for Musa (ABB group) plantation. J Appl Hort. 2004;6(1):3–10. [Google Scholar]

- Chung C, Sanguansri L, Augustin MA. Resistant starch modification: effects on starch properties and functionality as co-encapsulant in sodium caseinate-based fish oil microcapsules. J Food Sci. 2010;75(9):636–642. doi: 10.1111/j.1750-3841.2010.01857.x. [DOI] [PubMed] [Google Scholar]

- Drusch S, Berg S, Scampicchio M, Serfert Y, Somoza V, Mannino S, Schwarz K. Role of glycated caseinate in stabilisation of microencapsulated lipophilic functional ingredients. Food Hydrocoll. 2009;23:942–948. doi: 10.1016/j.foodhyd.2008.07.004. [DOI] [Google Scholar]

- Fanga JM, Fowler PA, Tomkinson J, Hill CAS. The preparation and characterization of a series of chemically modified potato starch. Carbohydr Polym. 2002;47(3):245–252. doi: 10.1016/S0144-8617(01)00187-4. [DOI] [Google Scholar]

- Goula AM, Adamopoulos KG. Spray drying of tomato pulp: effect of feed concentration. Dry Technol. 2004;22:2309–2330. doi: 10.1081/DRT-200040007. [DOI] [Google Scholar]

- Granato D, Calado VMA, Jarvis B. Observations on the use of statistical methods in food science and technology. Food Res Int. 2014;55:137–149. doi: 10.1016/j.foodres.2013.10.024. [DOI] [Google Scholar]

- Huang H, Hao S, Li L, Yang X, Cen J, Lin W, Wei Y. Influence of emulsion composition and spray-drying conditions on microencapsulation of tilapia oil. J Food Sci Technol. 2012 doi: 10.1007/s13197-012-0711-2. [DOI] [PMC free article] [PubMed] [Google Scholar]

- IUPAC . Standard methods for the analysis of oils, fats and derivatives. 7. Oxford: Blackwell Scientific Publications; 1987. [Google Scholar]

- Kagami Y, Sugimura S, Fujishima N, Matsuda K, Kometani T, Matsumura Y. Oxidative stability, structure, and physical characteristics of microcapsules formed by spray drying of fish oil with protein and dextrin wall materials. J Food Sci. 2003;68:2248–2255. doi: 10.1111/j.1365-2621.2003.tb05755.x. [DOI] [Google Scholar]

- Klaypradit W, Huang YW. Fish oil encapsulation with chitosan using ultrasonic atomizer. LWT Food Sci Technol. 2008;41:1133–1139. doi: 10.1016/j.lwt.2007.06.014. [DOI] [Google Scholar]

- Kolanowski W, Swiderski F, Berger S. Possibility of fish oil application for food products enrichment with o-3 PUFA. Intl J Food Sci Nutr. 1999;50:39–49. doi: 10.1080/096374899101409. [DOI] [PubMed] [Google Scholar]

- Lodha P, Netravali AN. Thermal and mechanical properties of environment-friendly ‘green’ plastics from stearic acid modified-soy protein isolate. Ind Crop Prod. 2005;21(1):49–64. doi: 10.1016/j.indcrop.2003.12.006. [DOI] [Google Scholar]

- Madene A, Jacquot M, Scher J, Desorby S. Flavour encapsulation and controlled release-a review. Int J Food Sci Technol. 2006;41:1–21. doi: 10.1111/j.1365-2621.2005.00980.x. [DOI] [Google Scholar]

- Nasrin TAA, Anal AK. Resistant starch III from culled banana and its functional properties in fish oil emulsion. Food Hydrocoll. 2013;35:403–409. doi: 10.1016/j.foodhyd.2013.06.019. [DOI] [Google Scholar]

- Pisecky J (1997) Handbook of milk powder manufacture. Copenhagen, Denmark: Niro A/S (pp. 206)

- Rakhi BS, Mobin AT, Mansoor AK. Comparative evaluation of flow for pharmaceutical powders and granules. AAPS Pharm Sci Tech. 2008;9(1):250–258. doi: 10.1208/s12249-008-9046-8. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Shepherd R, Robertson A, Ofman D. Dairy glycoconjugate emulsifiers: casein-maltodextrins. Food Hydrocoll. 2000;14:281–286. doi: 10.1016/S0268-005X(99)00067-3. [DOI] [Google Scholar]

- Sheu TY, Rosenberg M. Microstructure of microcapsules consisting of whey proteins and carbohydrates. J Food Sci. 1998;63(3):491–494. doi: 10.1111/j.1365-2621.1998.tb15770.x. [DOI] [Google Scholar]

- Widjanarko BS, Nugroho A, Estiasih T. Functional interaction components of protein isolates and glucomannan in food bars by FTIR and SEM studies. Afr J Food Sci. 2011;5(1):12–21. [Google Scholar]

- Zhang P, Whistler RL, BeMiller JN, Hamaker BR. Banana starch: production, physicochemical properties, and digestibility—a review. Carbohydr Polym. 2005;59:443–458. doi: 10.1016/j.carbpol.2004.10.014. [DOI] [Google Scholar]