Abstract

Millets have the potential to contribute to food security and nutrition, but still these are underutilized crops. The present study was undertaken with a view to analyse the physico-chemical, functional and nutritional composition of foxtail millet, barnyard millet and rice and to compare the sensory quality and nutritive value of food products from foxtail and barnyard millet with rice. Analysis of physico- chemical and functional characteristics revealed that the thousand kernel weight of foxtail millet, barnyard millet and rice was 2.5, 3.0 and 18.3 g, respectively and thousand kernel volume was 1.6, 13 2.0 and 7.1 ml, respectively. The water absorption capacity of foxtail millet, barnyard millet and rice was 1.90, 1.96 and 1.98 ml/g, respectively and water solubility index was 2.8, 1.2 and 1.0 %, respectively. Viscosity was measured for foxtail millet (1650.6 cps), barnyard millet (1581 cps) and rice (1668.3 cps). Analysis of nutritional composition showed that the moisture content of foxtail millet, barnyard millet and rice was 9.35, 11.93 and 11.91 %, respectively. The total ash, crude protein, crude fat, crude fibre and carbohydrate of foxtail millet were 3.10, 10.29, 3.06, 4.25 and 69.95 %, respectively, for barnyard millet were 4.27, 6.93, 2.02, 2.98 and 71.87 %, respectively and the corresponding values for rice were 0.59, 6.19, 0.53, 0.21 and 80.58 %, respectively. The energy value for foxtail millet, barnyard millet and rice was 349, 407 and 352 Kcal, respectively. The foxtail millet contained 30.10 mg/100 g calcium and 3.73 mg/100 g iron whereas barnyard millet contained 23.16 mg/100 g calcium and 6.91 mg/100 g iron. Values of 10 mg/100 g calcium and 0.10 mg/100 g iron were observed for rice. The formulated products viz. laddu, halwa and biryani from foxtail millet, barnyard millet and rice (control) were analysed for their sensory qualities. Among the products prepared, there was non significant difference with regard to the colour, flavor, texture, appearance and overall acceptability of foxtail and barnyard millet laddu and halwa when compared to control. Foxtail millet biryani was most acceptable compared to barnyard millet and control biryani. Nutritive value of formulated products was calculated and it was compared with the rice. The protein, fat and fibre content of the formulated products from foxtail and barnyard millet were higher than the rice products. Thus from the present study it was concluded that the foxtail millet and barnyard millet are superior in nutritive value to rice and have potential for use in traditional food products.

Keywords: Millets, Traditional food products, Nutritional quality

Introduction

The name millet is applied to numerous small seeded grasses which originated in Asia or Africa. They have in general wide adaptation and can fit into almost any situation. Millet is one of the most important drought-resistant crops and the 6th cereal crop in terms of world agriculture production. Also, millet has resistance to pests and diseases, short growing season, and productivity under drought conditions, compared to major cereals (Devi et al. 2011). Millets include five genera, Panicum, Setaria, Echinochloa, Pennisetum, and Paspalum. The most important cultivated species of millets are foxtail (Setaria italica), pearl or cattail millet (Pennisetum glaucum), proso (Panicum miliaceum), Japanese barnyard millet (Echinochola crusgalli), fingermillet (Eleusine coracana), browntop millet (Panicum ramosum), kodo or ditch millet (Paspalum scrobiculatum), and teff millet (Eragrostis tef). Various millets grown in India are finger millet (Eleusine coracana), foxtail millet (Setaria italica), kodo millet (Paspalum scrobiculatum), barnyard millet (Echinochloa frumentacea) and little millet (Panicum milliare) (Baker, 2003).

Nutritive value of these millets is quite comparable to wheat and rice. The non availability of refined and processed millets in ready- to- use form has limited their wider use and acceptability. Millets are therefore confined to traditional consumers and also to the people of lower economic strata. Millets are unique among the cereals because of their richness in calcium, dietary fibre, polyphenols and protein (Devi et al. 2011). The protein content is very close to that of wheat, but in addition they are also rich in B vitamins, especially niacin, B6 and folacin, calcium, iron, potassium, magnesium, and zinc. Foxtail millet (Setaria italica) is also known as Italian millet. In India cultivation of foxtail millet is mainly confined to lower Deccan plateau including high lands of Andhra Pradesh, Karnataka and Tamilnadu which accounts for 90 % in the country. It is mostly grown mixed with other crops like cotton, castor, pigeon- pea, bajra, groundnut and finger millet.

Barnyard millet (Echinochloa frumentacea) is short and fastest growing millet (Veena et al. 2005). Nutritionally too, barnyard millet is an important crop. It is a fair source of protein, which is highly digestible and is an excellent source of dietary fibre with good amounts of soluble and insoluble fractions (Veena et al. 2005). The carbohydrate content is low and slowly digestible, which makes the barnyard millet a nature’s gift for the modern mankind who is engaged in sedentary activities. Although barnyard millet like any other minor millet is nutritionally superior to other cereals, yet its utilization is limited. The major factor discouraging its cultivation and consumption with improvement in living standard or urbanization is the drudgery associated with its processing. However, there is a need to restore the lost interest in millets that deserves recognition for its nutritional qualities and potential health benefits.

Even though the nutritional qualities of millet have been well recorded, its utilization for food is confined to the traditional consumers in tribal populations, mainly due to non-availability of consumer friendly, ready-to-use or ready-to-eat products as are found for rice and wheat. In recent years, millets have received attention, mainly because of their high fiber content and efforts are under way to provide it to consumers in convenient forms (Deshpande and Poshadri 2011). In many African and Asian areas, millets serve as a major food component and various traditional foods and beverages, such as bread (fermented or unfermented), porridges, and snack foods are made of millet, specifically among the non affluent segments in their respective societies (Chandrasekara et al. 2012).

Hence the study was carried out to study physico-chemical and functional properties of millet flour and compare the millets incorporated products with traditional food products for its sensory and nutritional quality characteristics.

Materials and methods

Source of raw material

Milled barnyard millet (Echinochloa frumentacea) and rice (Oryza sativa) were purchased from local Pantnagar market and foxtail millet (Setaria italica) was obtained from local market of Lohaghat.

Cleaning and milling of grains

For cleaning, grains of millet and rice were manually cleaned to remove stones, grit, chaff and other impurities. The seeds were then milled in milling machine (Atta master flour mill, Navdeep products, Bheempore- Daman (UT)). The flour made was sieved out manually through 40 mesh sieve and after there the prepared sample was packed in air tight containers and stored at room temperature until used.

Physico-chemical and functional characteristics

Physico-chemical and functional characteristics were analysed using the sample in triplicates.

Thousand kernel weight

Thousand kernel weight was determined using the method given by Williams et al. (1983). One thousand sound seeds were counted and weighed. Weight was calculated in grams.

Thousand kernel volume

Thousand kernel volume was determined using graduated cylinder by water displacement method given by Williams et al. (1983). One thousand sound seeds were counted, transferred to 50 ml measuring cylinder and 25 ml of distilled water was added to it. The cylinder was slightly shaken to ensure that no air bubble was trapped within and then the seed volume was recorded as total volume minus 25 ml.

Particle size distribution

For determining the particle size distribution, hundred gram of sample was sieved in a series of 25, 44, 60, 85 and 120 mesh standard sieves. The sieves were shaken for 15 min in a ro-top type electric sieve shaker. Weight of the samples retained over 25, 44, 60, 85 and 120 and through 120 mesh sieve was recorded. Particle size distribution was quantitated on percentage basis.

Water absorption capacity

Water absorption capacity of flour was estimated according to the method given by Smith and Circle (1974) for soyflour. Exactly 5 g of flour was mixed well with 30 ml. distilled water in a centrifuge tubeusing a glass rod. After 5 min the contents were centrifuged at 2000 rpm for 5 min. The supernatant was measured using a graduated cylinder. Volume of water absorbed equals to 30 minus supernatant. Water absorption capacity was recorded as follows.

Water solubility index

The water solubility index was determined using method of AOAC (1990). The supernatant liquid was decanted into a weighed evaporation dish, oven dried at 100 °C for 2 h and reweighed. The weight of dried solids recovered by evaporation of the supernatant was expressed as water solubility index.

Viscosity

Viscosity was determined by the viscometer (Anton Paar). Individual flours were prepared in 15 % (w/v) concentration. A paste was made by mixing 30 g of flour with 50 ml of distilled water in a 1 beaker. To the paste, 150 ml of boiling distilled water was added and mixed well with a glass stir rod. The flour slurry was heated in a boiling water bath, stirred every 5 min, and held at 95 °C for 10 min. Viscosity was measured with a viscometer (Digital Viscometer DV-1P. Anton Paar GmbH, Karntner Strasse 322, A-8054 Graz/ AUSTRIA- EUROPE) and spindle (L-4) at 100 rpm and 40 °C.

Proximate composition

The chemical analysis of prepared samples was done in triplicates. Moisture, crude protein, crude fat, total ash, and crude fiber contents were estimated according to AOAC, 1995. Calcium content was determined following AOAC (1984) method. Iron is determined colorimetrically by Wong’s method (1923) as given by Ranganna (1986)

Preparation of food products

Three products viz. laddu, halwa and biryani based on foxtail millet, barnyard millet and rice were prepared. Rice based food products were used as control. The particle size of flour for laddu and halwa was taken less than 355 m (mesh size) and more than 125 m.

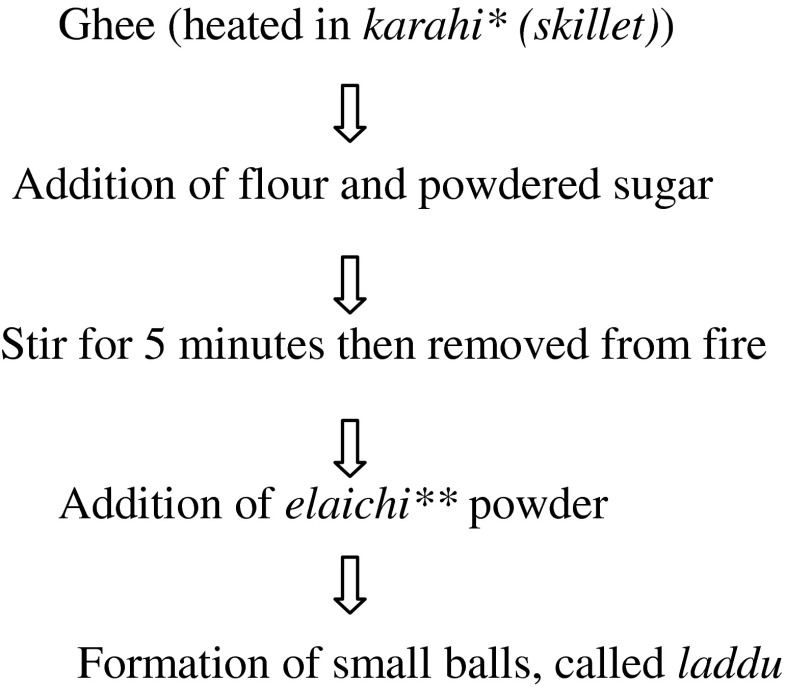

Laddu

Laddu is a sweetened food product, prepared by using wide variety of cereals, millets, legumes and oilseeds, sugar and shortening, that is shaped into a ball and is more popular in North India.

Method of preparation

Ingredients

Flour–100 g

Sugar powder–55 g

Ghee–50 g

Elaichi powder–½ tsp

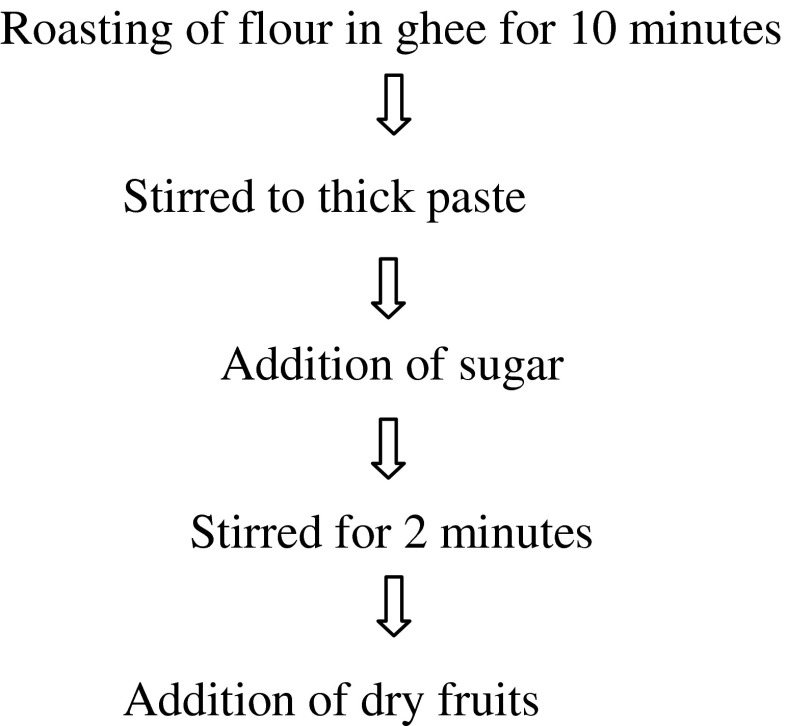

Halwa

Halwa is a dessert (sweet Indian dish) made from various kinds of fruits, vegetables, grains and lentils boiled with milk, almonds, sugar, butter and cardamom It is made in the Middle East, Central Asia and India.

Method of preparation

Ingredients

Flour - 30 g

Ghee/oil -15 g

Sugar -30 g

Water - 250 ml

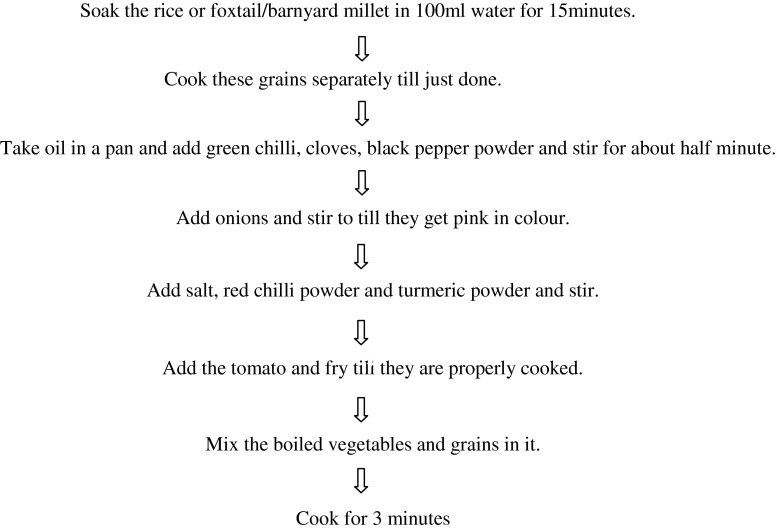

Vegetable biryani

Vegetable biryani is an Indian dish made with highly seasoned rice and vegetables flavored with saffron or turmeric.

Method of preparation

Ingredients

Rice or foxtail/barnyard millet- 70 g

Mixed vegetables- 80 g

Onion- 40 g

Tomato- 40 g

Refined oil- 2 tbsp

Green chilli- 2

Cloves - 4

Turmeric powder- ½ tps

Red chilli powder- ¼ tps

Sensory evaluation

The food products prepared were evaluated for sensory quality by score card method. The evaluation of food products was done by a semi trained panel of 10 members from department of Foods and Nutrition for various attributes viz. colour, texture, taste, flavor, appearance and overall acceptability (Lawless and Heymann, 2010). The panelists were asked to score the food products for their colour, flavor, texture, taste, appearance and overall acceptability.

Nutrient composition of food products

Food products viz. laddu, halwa and biryani based on foxtail millet, barnyard millet and rice (control) were prepared (Figs. 1, 2 and 3). Weight of all 3 cooked products was recorded. The nutritive value of formulated products was obtained by the calculation method (Gopalan et al. 2007). Nutrients were calculated per 100 g of cooked food product.

Fig. 1.

Flow diagram for the preparation of laddu. * A bowl shaped frying pan with two handles used in Indian cookery. ** Cardamom

Fig. 2.

Flow diagram for the preparation of halwa

Fig. 3.

Flow diagram for the preparation of biryani

Statistical analysis

Data on the chemical composition of foxtail millet, barnyard millet and rice and sensory of formulated products viz. laddu, halwa and biryani were subjected to statistical analysis using one way ANOVA to find out significant differences between control (rice) with foxtail millet and barnyard millet (Snedecor and Cochran, 1967).

Results and discussion

The results revealed that the thousand kernel weight of foxtail millet, barnyard millet and rice was observed to be 2.5, 3.0 and 18.3 g, respectively which are significantly different at 5 % level of significance in their value (Table 2). Hadimani and Malleshi (1993) reported thousand kernel weights of foxtail and barnyard millet as 2.6 and 3.0 g, respectively. The thousand kernel volume of foxtail millet, barnyard millet and rice was found to be 1.6, 2.0 and 7.1 ml, respectively (Table 2). All three samples were significantly different in thousand kernel volume at 5 % level of significance. Hadimani and Malleshi (1993) reported thousand kernel volume of foxtail and barnyard millet as 1.9 and 2.4 ml, respectively.

Table 2.

Functional characteristics of foxtail millet, barnyard millet and rice flour*

| Properties | Flour | |||

|---|---|---|---|---|

| Foxtail millet | Barnyard Millet | Rice | CD at 5 % | |

| Thousand kernel weight (g) | 2.5 ± 0.01 | 3.0 ± 0.05 | 18.3 ± 0.01 | 0.06 |

| Thousand kernel volume (ml) | 2.0 ± 0.05 | 1.6 ± 0.05 | 7.1 ± 0.05 | 0.11 |

| Water absorption capacity (ml/g) | 1.90 ± 0.02 | 1.96 ± 0.01 | 1.98 ± 0.01 | 0.02 |

| Water solubility index (%) | 2.80 ± 0.02 | 1.20 ± 0.01 | 1.00 ± 0.02 | 0.014 |

| Viscosity (cps) | 1650.6 ± 0.57 | 1581 ± 1.00 | 1668.3 ± 0.57 | 0.94 |

*Average of triplicate values reported

CD Critical difference

Table 1 shows the specific particle size distribution or percentage of foxtail millet, barnyard millet and rice flour on each sieve size. All flours were classified as fine, because 98 % of all particles passed through the no. 44 sieve. Rice flour produced a higher percentage of particles that passed through the 85 mesh size (88.25 %) and the greatest percentage of fine particles, less than 125 μm in diameter, as seen in the collection pan. Except the 44 mesh size, particle size distribution of foxtail millet, barnyard millet and rice showed the significant difference in all the mesh size viz. 60, 253 85, and 120.

Table 1.

Particle size distribution of foxtail millet, barnyard millet and rice flour

| Flour | Sieve No./Mesh Size (m) | |||||

|---|---|---|---|---|---|---|

| 25/600 | 44/355 | 60/250 | 85/180 | 120/125 | Collection pan | |

| Foxtail millet (%) | 0.0 | 1.88 ± 0.06 | 6.61 ± 0.35 | 13.43 ± 0.68 | 22.52 ± 1.30 | 56.41 ± 1.33 |

| Barnyard millet (%) | 0.0 | 1.68 ± 0.21 | 5.56 ± 0.72 | 12.59 ± 0.53 | 21.36 ± 10.76 | 58.80 ± 1.52 |

| Rice (%) | 0.0 | 1.27 ± 0.16 | 4.43 ± 0.48 | 11.76 ± 0.28 | 19.93 ± 1.25 | 62.22 ± 1.21 |

| CD at 5% | 0.0 | 0.50 | 0.27 | 0.51 | 0.15 | 0.66 |

Among all three types of flours, significant difference was found in water absorption capacity of rice flour with that of foxtail millet flour at 5 % level of significance. Rice exhibited higher water absorption capacity (1.98 ml/g) than barnyard (1.96 ml/g) and foxtail millet (1.90 ml/g) (Table 2). Non significant difference was found between water absorption capacity of barnyard millet and rice. Foxtail millet showed significantly higher value for water solubility index as compared to barnyard millet and rice (Table 2). There was non significant difference in water solubility index between barnyard millet (1.20 %) and rice flour (1.10 %). Table 2 illustrates the viscosity of single grain gruels (15% w/v). 261 Viscosity was more than 1,500 ± 0.57 cps for all gruels. Rice consistently recorded significantly higher viscosity (1668.3 ± 0.57 cps) rather than foxtail millet (1650.6 cps) and barnyard millet flour 263 (1581 ± 1.0 cps). This is attributed to the availability of more starch for gelatinization (Griffith and Perez Castell 1998). All the three samples were significantly different at 5 % level of significance in their viscosity values.

The moisture content of foxtail millet flour, barnyard millet flour and rice flour was 9.35, 11.93 and 11.91 % respectively. Foxtail millet showed significantly lower moisture content than rice and barnyard millet. Barnyard millet and rice have almost same moisture content. Non significant difference was found between moisture content of barnyard millet and rice flour. Total ash represents the total mineral content of foodstuff. From the results presented in Table 3, it can be observed that total ash content in the foxtail millet flour was 3.10 %. The value obtained is slightly lower than the value reported by Agarwal et al. (2005) which is 3.52 % and is very close to the result given by Verma and Raghuvanshi (2001) which is 3.0 %. Total ash content of barnyard millet was observed to be 4.27 % which is close to the result given by Hulse et al. (1980) who reported a value of 4.50 % for barnyard millet. Total ash content of rice flour was 0.59 % which is very close to the result given by Gopalan et al. (2007) and Rajyalakshmi and Geervani (1994) who have reported total ash content of rice as 0.60 %. Foxtail and barnyard millet have significantly higher total ash content at 5 % level of significance as compared to rice and therefore these are more mineral dense in comparison with rice. All the three samples viz. foxtail millet, barnyard millet and rice were significantly different (at 5 % level of significance) in total ash content.

Table 3.

Proximate composition of foxtail millet, barnyard millet and rice on dry weight basis

| Components | Foxtail millet | Barnyard millet | Rice | CD at 5 % |

|---|---|---|---|---|

| Moisture % | 9.35 ± 0.05 | 11.39 ± 0.05 | 11.91 ± 0.10 | 0.15 |

| Ash % | 3.10 ± 0.06 | 4.27 ± 0.02 | 0.59 ± 0.05 | 0.08 |

| Crude protein % | 10.29 ± 0.12 | 6.93 ± 0.13 | 6.19 ± 0.03 | 0.29 |

| Crude fat % | 3.06 ± 0.20 | 2.02 ± 0.06 | 0.53 ± 0.03 | 0.25 |

| Crude fibre % | 4.25 ± 0.15 | 2.98 ± 0.12 | 0.21 ± 0.17 | 0.11 |

| carbohydrate by difference % | 69.95 ± 0.14 | 71.87 ± 0.10 | 80.58 ± 0.17 | 0.29 |

| Energy (Kcal)/100 g | 349 ± 0.35 | 333 ± 1.5 | 352 ± 0.34 | 1.86 |

| Calcium (mg/100 g) | 30.10 ± 0.58 | 23.16 ± 1.50 | 10.00 ± 1.210 | 0.14 |

| Iron (mg/100 g) | 3.73 ± 0.05 | 6.91 ± 0.11 | 1.23 ± 0.05 | 0.10 |

*Average of triplicate values reported

CD Critical difference

Crude protein content of foxtail millet flour, barnyard millet flour and rice flour was 10.29, 6.93 and 6.19 % respectively, which was significantly different from each other. The crude fat content of foxtail millet, barnyard millet and rice flour was 3.06, 2.02, and 0.53 % respectively. It was found that foxtail millet has 2.54 % and barnyard millet has 1.5 % more fat content as compared to rice. Crude fat content was significantly different (at 5 % level of significance) among foxtail millet, barnyard millet and rice.

The crude fibre content of foxtail millet was found as 4.25 % which is in accordance with the value of 4.8 % reported by Arya (2008). The crude fibre content of barnyard millet flour was 2.98 % and of rice flour was 0.21 % which is similar to the value of 0.20 % given by Gopalan et al. (2007) and Rajyalakshmi and Geervani (1994). Thus, millet grains have good amount of fibre as compared to the rice. Significant difference was observed among crude fibre content of all the three grains (at 5 % level of significance). The carbohydrate content of foxtail millet flour was 69.95 %. The carbohydrate content of barnyard millet flour was 71.87 % and of rice flour was 80.58 %. The carbohydrate content of foxtail millet and barnyard millet has been observed to be significantly lower than the carbohydrate content of rice. The carbohydrate content was significantly different (at 5 % level of significance) in both millets and rice flour.

The energy content of foxtail millet flour, barnyard millet flour and rice flour was observed to be 349, 333 and 352 Kcal/ 100 g respectively. Significant difference was observed in energy content of these three grains (at 5 % level of significance). Thus, these millet grains has low calorie with higher content of nutrients like minerals, protein, fat, fibre etc. as compared to rice.

The calcium content of foxtail millet flour was observed to be 30.10 mg per 100 g and of barnyard millet, it was 23.16 mg/100 g (Table 3). Gopalan et al. (2007) reported the calcium content of barnyard millet as 20 mg/100 g. The calcium content of rice was found to be 9.96 mg/100 g. Yadav et al. (2007) reported the calcium content of milled rice as 10.0 mg /100 g. Foxtail millet, barnyard millet and rice were significantly different in their calcium content (at 5 % level of significance). Foxtail millet and barnyard millet grains have approximately three and two times more calcium content than the calcium content of rice, respectively. Thus, it can be said that these millet grains contain higher calcium as compared to rice.

The iron content of foxtail millet flour was 3.73 mg/ 100 g, which is 0.93 mg higher than the value (2.80 mg) reported by Gopalan et al. (2007). The iron content of barnyard millet was found to be 6.91 mg /100 g which is close to the value of 7.31 mg/ 100 g reported by Mittal et al. (2004). The iron content of rice was 1.23 mg/100 g. Thus the result of present study is within the reported range. Yadav et al. (2007) reported the iron content of rice as 1.0 mg per 100 g. Comparing the value of iron i.e. 3.73 mg/100 g for foxtail millet and 6.91 mg/100 g rice, it was found that foxtail millet has 2.5 mg and barnyard millet has 5.68 mg/100 g more iron content as compared to rice. Iron content was significantly different among foxtail millet, barnyard millet and rice (at 5 % level of significance) (Table 4).

Table 4.

Sensory quality characteristics of laddu

| Food base | Attributes | |||||

|---|---|---|---|---|---|---|

| Colour | Flavor | Texture | Taste | Appearance | Overall acceptability | |

| Foxtail millet | 8.5 | 6.8 | 7.0 | 7.6 | 8.2 | 7.7 |

| Barnyard millet | 8.5 | 7.9 | 8.2 | 7.8 | 8.5 | 8.4 |

| Rice (control) | 8.1 | 7.7 | 7.2 | 7.2 | 8.3 | 7.6 |

| SEM ± | 0.257 | 0.325 | 0.305 | 0.282 | 0.323 | 0.349 |

| CD at 5% | 0.74 | 0.94 | 0.88 | 0.82 | 0.93 | 1.01 |

*Average of fifteen values reported

S.Em Standard error of mean

CD Critical difference

Food products namely, halwa, laddu and biryani were prepared by the method given in Figs. 1, 2 and 3. Sensory quality evaluation of foxtail millet, barnyard millet and rice (control) food products viz. laddu, halwa and biryani was done using score card method. Regarding ladoo, shows a non significant difference in colour, flavor, texture, appearance and overall acceptability among laddus on foxtail millet, barnyard millet and rice (control). As per the evaluation proforma, all the sensory evaluation parameters of three types of laddus were observed to be good. For halwa all the sensory quality characteristics of control halwa viz., colour, flavour, texture, taste, appearance and overall acceptability were rated as good (Table 5). Non significant difference in colour, texture, taste, appearance and overall acceptability of halwa based on foxtail millet, barnyard millet and rice (control) were observed.

Table 5.

Sensory quality characteristics of halwa

| Food base | Attributes | |||||

|---|---|---|---|---|---|---|

| Colour | Flavor | Texture | Taste | Appearance | Overall acceptability | |

| Foxtail millet | 8.9 | 7.3 | 8.5 | 7.8 | 8.3 | 8.0 |

| Barnyard millet | 8.3 | 7.8 | 8.0 | 7.7 | 8.4 | 8.1 |

| Rice (control) | 8.0 | 8.3 | 8.8 | 8.6 | 7.9 | 8.7 |

| SEM ± | 0.337 | 0.270 | 0.365 | 0.375 | 0.281 | 0.327 |

| CD at 5% | 0.95 | 0.78 | 1.06 | 1.09 | 0.816 | 9.50 |

*Average of fifteen values reported

S.Em Standard error of mean

CD Critical difference

The data obtained on the sensory evaluation of the biryani revealed that the colour, flavour, taste and overall acceptability of biryani based on foxtail millet were rated very good against barnyard millet and control which were rated good. Biryani of all three different grains showed significant difference in colour and flavour. Barnyard millet and foxtail millet biryani showed significant difference (at 5 % level of significance) in all the sensory evaluation parameters (Table 6).

Table 6.

Sensory quality characteristics of biryani

| Food base | Attributes | |||||

|---|---|---|---|---|---|---|

| Colour | Flavor | Texture | Taste | Appearance | Overall acceptability | |

| Foxtail millet | 9.0 | 9.1 | 8.9 | 9.1 | 8.9 | 9.0 |

| Barnyard millet | 7.6 | 7.6 | 7.7 | 7.4 | 7.0 | 7.3 |

| Rice (control) | 8.3 | 8.2 | 7.7 | 8.6 | 8.3 | 8.3 |

| SEM ± | 0.197 | 0.181 | 0.202 | 0.270 | 0.265 | 0.212 |

| CD at 5% | 0.57 | 0.52 | 0.58 | 0.78 | 0.76 | 0.61 |

*Average of fifteen values reported

S.Em Standard error of mean

CD Critical difference

The nutritive value of formulated products was obtained by the calculation method. Nutrients were calculated per 100 g of cooked food product. The data on nutrient composition of laddu on cooked weight basis has been presented in Table 7. Foxtail and barnyard millet laddu had comparatively high protein content, 5.00 and 3.41 %, respectively compared to rice (control) laddu (3.04 %). Foxtail and barnyard millet based laddu had lower carbohydrate content. Foxtail millet, barnyard millet and control laddu have fat content of 25.63, 25.01 and 24.64 %, respectively and energy 503, 495 and 508 kcal/100 g, respectively. Crude fibre content of millet based laddu was also higher than control based laddu. Dietary fibre content of foxtail millet laddu, barnyard millet laddu and rice laddu was 10.2, 4.6 and 1.25 % respectively. Calcium content of foxtail millet laddu was higher (17.6 mg/100 g) followed by barnyard millet laddu (14.6 mg/100 g) and rice laddu (8.1 mg/100 g). Iron content of foxtail millet laddu, barnyard millet laddu and rice laddu was 1.82, 3.40 343 and 0.60 mg/100 g respectively.

Table 7.

Nutrient composition of laddu

| Food base | Foxtail millet | Barnyard millet | Rice |

|---|---|---|---|

| Protein (%) | 5.00 | 3.41 | 3.04 |

| Fat (%) | 25.63 | 25.01 | 24.64 |

| Fibre (%) | 2.25 | 1.45 | 0.10 |

| Carbohydrate (%) | 62.90 | 64.00 | 68.40 |

| Dietary fibre (%) | 10.2 | 4.6 | 1.25 |

| Energy kcal/100 g | 503 | 495 | 68.40 |

| Calcium(mg/100 g) | 17.6 | 14.6 | 8.1 |

| Iron(mg/100 g) | 1.82 | 3.40 | 0.60 |

Table 8 shows nutrient composition per 100 g of halwa. It was found that the protein content of foxtail and barnyard millet based halwa was higher that is 1.89 and 1.26 %, respectively than the rice (0.99 %). Control halwa had relatively high carbohydrate content. Carbohydrate in foxtail and barnyard millet halwa was observed to be 30.70 and 30.61 %, respectively. Fat content of foxtail millet, barnyard millet and control halwa was 9.60, 9.29 and 8.92 %, respectively. Dietary fibre of millet based halwa was higher than control halwa, which is 3.9, 1.6 and 0.44 % for foxtail millet halwa, barnyard millet halwa and rice halwa, respectively. Calcium content was also higher in millet based halwa than rice halwa. Iron content of foxtail millet, barnyard millet and rice halwa was 0.73, 1.27 and 0.22 mg/100 respectively.

Table 8.

Nutrient composition of halwa

| Food base | Foxtail millet | Barnyard millet | Rice |

|---|---|---|---|

| Protein (%) | 1.89 | 1.26 | 0.99 |

| Fat (%) | 9.60 | 9.29 | 8.92 |

| Fibre (%) | 0.78 | 0.53 | 0.03 |

| Carbohydrate (%) | 30.70 | 30.61 | 32.00 |

| Dietary Fibre (%) | 3.9 | 1.6 | 0.44 |

| Energy kcal/100 g | 216 | 211 | 212 |

| Calcium | 5.6 | 4.2 | 1.8 |

| Iron | 0.73 | 1.27 | 0.22 |

In the current study it was found that the foxtail millet, barnyard millet and rice biryani had protein content of 4.00, 3.12 and 2.90 % and fat content of 7.06, 6.75 and 6.31 %, respectively. Control biryani had relatively low fibre content that is 0.79 % as compare to foxtail millet (1.67 %) and barnyard millet (1.52 %). Carbohydrate in foxtail and barnyard millet biryani was observed to be 21.08 and 21.63 % whereas control recorded 23.09 % of charbohydrate (Table 9). Dietary fibre of foxtail millet biryani was higher (4.72 %) than barnyard millet biryani and rice biryani (2.13 and 0.21 %, respectively). Calcium content of foxtail millet, barnyard millet and rice biryani was 18.75, 16.9 and 12.46 mg/100 respectively. Iron content was 0.84, 1.5 and 0.07 mg/100 respectively for foxtail millet, barnyard millet and rice biryani.

Table 9.

Nutrient composition of biryani

| Food base | Foxtail Millet | Barnyard Millet | Rice |

|---|---|---|---|

| Protein (%) | 4.00 | 3.12 | 2.90 |

| Fat (%) | 7.06 | 6.75 | 6.31 |

| Fibre (%) | 1.67 | 1.52 | 0.79 |

| Carbohydrate (%) | 21.08 | 21.63 | 23.09 |

| Dietary Fibre (%) | 4.72 | 2.13 | 0.21 |

| Energy kcal/100 g | 163.86 | 159.75 | 160.75 |

| Calcium | 18.75 | 16.9 | 12.46 |

| Iron | 0.84 | 1.5 | 0.07 |

Conclusion

In the present study it was found that the millet based food products were acceptable as rice (control) food products. Foxtail millet biryani was more acceptable and was rated highest score for colour, appearance, texture, taste, appearance and overall acceptability as compared to rice biryani. All the millet food products had higher content of protein, fat and fibre as compared to rice (control) products. It was also found that millet based products viz., laddu, halwa and biryani was not only acceptable as rice products but also having good nutritional value regarding dietary fibre and major minerals like calcium and iron. This makes these products nutritionally more superior than rice products.

References

- Agarwal P, Singh G, Srivastava S. Effect of incorporating foxtail millet (Setaria italica) on the cooking characteristics of noodles. Beverage Food World. 2005;31(12):18–19. [Google Scholar]

- AOAC . Official methods of analysis of the association of official analytical chemist. 15. Arlington: The Association; 1990. [Google Scholar]

- AOAC . Official methods of analysis of the association of official analytical chemist. Washigton, DC: Association of official Analytical Chemists; 1995. [Google Scholar]

- Arya C. Formulation, nutritional evaluation and Glycemic response of millet flour incorporated breads. Pantnagar: P.hd. thesis. G. B. Pant Univ. of Agri. & Technol; 2008. [Google Scholar]

- Baker, R. D. 2003. Millet production. Guide A-114. New Maxico state University, Extension Agronomists, College of Agriculture and Home economics. At: http//www.google.com.

- Chandrasekara A, Naczk M, Shahidi F. Effect of processing on the antioxidant activity of millet grains. Food Chem. 2012;133:1–9. doi: 10.1016/j.foodchem.2011.09.043. [DOI] [Google Scholar]

- Deshpande HW, Poshadri A. Physical and sensory characteristics of extruded snacks prepared from foxtail millet based composite flour. Int Food Res J. 2011;18(730):735. [Google Scholar]

- Devi PB, Vijayabharathi R, Sathyabama S, Malleshi NG, Priyadarisini VB. Health benefits of finger millet (Eleusine coracana L.) polyphenols and dietary fiber: a review. J Food Sci Technol. 2011 doi: 10.1007/s13197-011-0584-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gopalan C, Ramasastri BV, Balasubramanian SC (2007) Nutritive value of Indian foods, Hyderabad, NIN, ICMR

- Griffith LD, Perez Castell ME. Effect on roasting and malting on physico-chemical properties of selected cereals and legumes. Cereal Chem. 1998;75(6):780–784. doi: 10.1094/CCHEM.1998.75.6.780. [DOI] [Google Scholar]

- Hadimani NA, Malleshi NG. Studies on milling, physico-chemical, nutrient composition and dietary fibre content of millets. J Food Sci Technol. 1993;30(1):17–20. [Google Scholar]

- Hulse JH, Laing EM, Pearson OE. Sorghum and the millets: their composition and nutritive value. London: Academic; 1980. p. 521. [Google Scholar]

- Lawless HT, Heymann H (2010) Sensory evaluation of food: principle and practices: food science text series. Food Sci Nutr 2nd ed, 2010. XXIII, 596 p. Ed

- Mittal M, Srivastava S, Singh G. Nutritive value of native and malted barnyard millet (Echinochloa frumentacea) Beverage Food World. 2004;31(12):50–52. [Google Scholar]

- Rajyalakshmi P, Geervani P. Nutritive value of the foods cultivated and consumed by the tribals of South India. Plant Foods Hum Nutr. 1994;46:53–61. doi: 10.1007/BF01088461. [DOI] [PubMed] [Google Scholar]

- Ranganna S. Handbook of analysis and quality control for fruit and vegetable products. 2. New Delhi: McGRaw Hill Publishing Co. Ltd. xvit; 1986. p. 122. [Google Scholar]

- Smith AR, Circle SJ (1974) Soyabean. Chemistry and technology. Wesport. Connecticut. Vol. 455–456.

- Snedecor GW, Cochran WG. Statistical methods. 6. Calcutta: Oxford IBH Publishing Corporation; 1967. [Google Scholar]

- Veena B, Chimmad BV, Naik RK, Shantakumar G. Physico-chemical and nutritional studies in barnyard millet. Karnataka J Agril Sci. 2005;18(1):101–105. [Google Scholar]

- Verma T, Raghuvanshi RS. Uncommon plant foods of India. All India co- ordinate reacher project in Home Science (Foods and Nutrition) New Delhi: ICAR; 2001. [Google Scholar]

- Williams PC, Nakoul H, Singh KB. Relationship between cooking time and some physical characteristics in chickpea. J Sci Food Agric. 1983;34:492–496. doi: 10.1002/jsfa.2740340510. [DOI] [Google Scholar]

- Wong J Biol Chem. 1923;55:421. [Google Scholar]

- Yadav RB, Khatkar BS, Yadav BS. Morphological, physicochemical and cooking properties of some Indian rice (Oryza sativa L.) cultivars. J Agric Technol. 2007;3(2):201–210. [Google Scholar]