Abstract

Research Significance

Toxicological evidence suggests the potential for a wide range of health effects, which could result from exposure to carbon nanotubes (CNTs) and carbon nanofibers (CNFs). The National Institute for Occupational Safety and Health (NIOSH) has proposed a recommended exposure limit (REL) for CNTs/CNFs at the respirable size fraction. The current literature is lacking exposure information, with few studies reporting results for personal breathing zone (PBZ) samples in occupational settings. To address this gap, exposure assessments were conducted at six representative sites identified as CNT/CNF primary or secondary manufacturers.

Methods

Personal and area filter-based samples were collected for both the inhalable mass concentration and the respirable mass concentration of elemental carbon (EC) as well as CNT structure count analysis by transmission electron microscopy to assess exposures. When possible, full-shift PBZ samples were collected; area samples were collected on a task-based approach.

Results

The vast majority of samples collected in this study were below the proposed REL (7 μg m−3). Two of the three secondary manufacturers’ surveyed found concentrations above the proposed REL. None of the samples collected at primary manufacturers were found to be above the REL. Visual and microscopy-based evidence of CNTs/CNFs were found at all sites, with the highest CNT/CNF structure counts being found in samples collected at secondary manufacturing sites. The statistical correlations between the filter-based samples for the mass concentration of EC and CNT structure counts were examined. A general trend was found with a P-value of 0.01 and a corresponding Pearson correlation coefficient of 0.44.

Conclusions

CNT/CNF concentrations were above the proposed NIOSH REL for PBZ samples in two secondary manufacturing facilities that use these materials for commercial applications. These samples were collected during dry powder handling processes, such as mixing and weighing, using fairly large quantities of CNTs/CNFs.

Keywords: carbon nanofibers, carbon nanotubes, exposure assessment, nanomaterials, nanoparticles

INTRODUCTION

Carbon nanotubes (CNTs) and carbon nanofibers (CNFs) offer enormous potential for technological breakthroughs in many different industries. CNTs and CNFs are currently used in numerous industrial and biomedical applications, including high-performance intermediates, such as coatings and composites for aerospace, automobiles, and construction and in electronics, displays, batteries, and various healthcare applications. A recent survey of US manufacturers handling engineered carbonaceous nanomaterials indicated that the most common material produced or used by companies were CNTs (72%), and employees in manufacturing operations involving CNTs increased 44% from 2006 to 2008 (Schubauer-Berigan et al., 2011). Globally, in 2004, CNT and CNF productions were estimated at ~65 tons year−1 (Cientifica, 2005). By 2007, it was reported that the global capacity for the production of multi-walled carbon nanotubes (MWCNTs) was ~300 tons year−1 (WTEC, 2007). The rapid increase in the number of companies within the USA and globally shows that there is a dynamic market for CNTs and CNFs and therefore a growing incorporation of these materials into several intermediate and final products (Invernizzi, 2011). As this market expands from research and development to industrial high-volume production, the potential for worker exposure, especially those involved in the manual handling or transferring of these materials, will increase as well.

Recent animal toxicological evidence suggests the potential for a wide range of health effects which could result from exposure to CNTs and CNFs (Shvedova et al., 2005; Pacurari et al., 2008; Poland et al., 2008; Kisen et al., 2011). Relatively long rigid CNTs were reported to possess asbestos-like pathogenicity when injected into the abdominal cavity of mice (Poland et al., 2008), which has raised even greater concerns about the possible carcinogenicity of CNTs and CNFs. Other animal studies also have linked these materials to possible adverse health effects such as pulmonary inflammation, oxidative stress, onset of early interstitial fibrosis, and granulomas (Donaldson et al., 2006; Porter et al., 2010). Genotoxicity may also result from exposure: single-walled carbon nanotubes (SWCNTs) have been found to induce aneuploidy in human respiratory epithelial cells through interference with mitosis (Sargent et al., 2009). A range of toxicities may vary between the differing types of CNTs (MWCNT, double-walled CNTs [DWCNT], SWCNT, or CNFs) and the varying individual characteristics which include raw versus purified forms, varying types of functional groups, agglomerated states versus single fibers, and fiber length (Donaldson et al., 2006; Poland et al., 2008).

With a growing body of toxicological literature indicating a potential hazard from exposure to a variety of CNTs and CNFs, several occupational exposure limits (OELs) have been proposed by various stakeholders. An interim OEL for MWCNTs was proposed in a report by the Japanese New Energy and Industrial Technology Development Organization of 21 μg m−3 (Kobayashi et al., 2009). Another, more recent, OEL of 50 μg m−3 was derived for Bay-tubes® (Pauluhn, 2010). The National Institute for Occupational Safety and Health (NIOSH) has also proposed a respirable mass-based recommended exposure limit (REL) for CNTs and CNFs. The proposed REL is an 8-h time-weighted average of 7 μg m−3 of elemental carbon (EC), a marker for CNT and CNF exposure, using NIOSH Manual of Analytical Methods (NMAM) 5040 (NIOSH, 2006a; NIOSH, 2010).

Several recent studies indicate the potential for worker exposure to CNTs (Bello et al., 2008; Han et al., 2008; Bello et al., 2009; Tsai et al., 2009; Bello et al., 2010; Lee et al., 2010; Methner et al., 2010) and CNFs (Methner et al., 2007; Evans et al., 2010; Birch et al., 2011). However, a majority of these studies have focused on the collection of area samples (ASs) during (primary) production of CNTs/CNFs or have been conducted in more controlled laboratory settings. Very little personal exposure information is available for exposures among downstream, secondary manufacturers, or manufacturers above the research and development phase. Though some of these studies have included instruments used for industrial hygiene sampling (Evans et al., 2010; Birch et al., 2011), most have employed large aerosol instruments that provide aerosol size distributions and concentrations, such as an electrical low-pressure impactor and/or a scanning mobility particle sizer. The latter instruments can provide invaluable information on the nature and sources of the many types of aerosols encountered in the work-place, but they are more expensive, complex, and less mobile compared to the equipment used throughout this study.

The present study employed a combination of filter-based samples to assess exposures at primary (producers) and secondary (downstream user) manufacturers. All instruments used in these site visits were portable and are more widely used for routine industrial hygiene sampling. The primary objective of this study was the identification, characterization, and differentiation of exposure points by job task and full-shift personal breathing zone (PBZ) samples at various CNT primary manufacturers and CNT and CNF secondary manufacturing facilities within the USA. This manuscript reports the results for the filter-based samples analyzed for EC and by transmission electron microscopy (TEM), while the direct reading instrument results, which included a condensation particle counter, photometer, and a diffusion charger, will be discussed in detail in a forthcoming manuscript. The work is part of an ongoing NIOSH industry wide exposure assessment and future epidemiologic study on CNTs and CNFs (Dahm et al., 2011; Schubauer-Berigan et al., 2011).

METHODS

Plant and process descriptions

A total of six site visits were conducted between May and September of 2010 at primary and secondary manufacturers of CNTs or CNFs. These companies were recruited from a previous NIOSH survey on engineered carbonaceous nanomaterials (Dahm et al., 2011; Schubauer-Berigan et al., 2011). Of the six companies that agreed to participate, three were primary manufacturers of MWCNTs, DWCNTs, or SWCNTs (coded as Sites A–C). The remaining three sites were secondary manufacturers of MWCNTs or CNFs (coded as Sites D–F). Efforts were made to select facilities that represented a variety of Cantor CNF uses, types, quantities, and workforce sizes. Site visits generally lasted 2 days but were dependent on the duration and frequency of the processes sampled. Replicate samples of processes/tasks were collected when possible. Facility and process descriptions are discussed in detail below.

Site A

Site A was a CNT manufacturing facility, which is specialized in the production of MWCNTs and DWCNTs. A chemical vapor deposition (CVD) synthesis method was used as the production method along with a metal catalyst. At Site A, there was the potential for 8–10 employees to handle the dry powder CNTs on any given day. Two tasks were primarily sampled, which included the production of MWCNTs and subsequent harvesting of the MWCNTs. During a typical day, two batches of MWCNTs would be produced and harvested with a daily yield of <50 g. Smaller quantities of DWCNTs are also produced at the facility but much less frequently. The production process for MWCNTs was enclosed and exhausted out of the building. However, no engineering exposure control methods were in place during the MWCNT and DWCNT harvesting processes.

Site B

Site B was an SWCNT and nanostructured carbon manufacturer that used three reactors for nanostructured carbon and SWCNT production. SWCNTs were produced through a proprietary process, which used a metal-based catalyst. The company had a total of 16 employees but would have 8–10 employees handling or actively working with the materials at any one time. A typical day may include both nanostructured carbon production and SWCNT production in the three available reactors. However, during this site visit, only one SWCNT reactor was used. Replicate samples were completed on two separate days for the same process. The reactor was run once per day and yielded ~5 g of material. After the SWCNTs were produced, the material was harvested and weighed near a chemical fume hood. The entire production process was under a vacuum with the product being harvested within a custom-made baghouse operating under vacuum to limit worker exposure during harvesting. Once the reactor had cooled to a manageable temperature, the inside of the reactor was cleaned using a high-efficiency particulate air (HEPA) vacuum in combination with a wet wiping method.

Site C

Site C was a primary manufacturer and secondary manufacturer of MWCNTs as well as a secondary manufacturer of SWCNTs. The facility currently has the capacity to produce 50–100 g of MWCNTs a day using a catalytic CVD method. Site C employed six individuals with five of them routinely handling nanomaterials on a daily basis. The company was operating in a research and development stage on several projects including CNT composites, MWCNT functionalization, spray coating dispersed CNT solutions, as well as MWCNT production. Multiple days of sampling were conducted at Site C with Day 1 focused on the production of MWCNTs within a reactor under vacuum and the harvesting of two batches of MWCNTs in a custom-made glovebox. Day 2 focused on sampling during the sonication of a 1 l solution of MWCNTs housed within an unventilated enclosure. The second process sampled on Day 2 focused on the sieving of 5 g of MWCNTs in a chemical fume hood concurrent to the spray coating of copper plates with an MWCNT solution within a chemical fume hood as well.

Site D

Site D used commercially available CNTs for the development of semiconductor devices. Clean room space was where MWCNTs were handled in powder form as well as in an aqueous solution. There was the potential for ~20 employees to handle or come in contact with CNTs in solution, which is the typical form, or in its powder form, on any given day. Sampling at Site D focused on several tasks, which included waste collection and disposal, sonication, weighing of powder form CNTs, and an office worker. CNT waste products were collected from all laboratory areas, which included wetted towels and other contaminated wastes, by an individual employee and disposed of in a designated hazardous waste room. A single employee also oversaw the sonication of a 5 l CNT aqueous solution. The sonicator was housed within a HEPA ventilated chemical fume hood. Another employee performed the weighing of 100 g of CNTs in its dry powder form inside of a HEPA ventilated glovebox. An additional sample was collected on a general office worker who did not have access to the laboratory areas where the CNTs were handled.

Site E

Site E was a secondary manufacturer of MWCNTs that specialized in polymer materials. Raw and functionalized MWCNTs were mixed with different formulations of resins to create specialized CNT enabled plastics. Roughly, 6–10 employees have access to the laboratory space where CNTs were handled but only 2–4 employees handle materials or are in the laboratory space on a daily basis. Sampling at Site E focused on several tasks, which included the weighing and extrusion of 1 kg of MWCNTs mixed with a polyvinyl chloride-based resin, the weighing of 14.75 g of MWCNTs, and use of a batch mixer as well as the milling of CNT composite materials. A single employee performed the weighing and extrusion task. The weighing was performed within a chemical fume hood into a sealed hopper that could then be directly connected to the extruder limiting the exposure potential. The end product composite was roughly 7% MWCNTs by weight. Another employee weighed 14.75 g of MWCNTs in a chemical fume hood, which was then mixed with various resins. Local exhaust ventilation was used during the mixing task along with a custom built glovebox. The final milling operation was conducted using an automated drill press with local exhaust ventilation as well.

Site F

Site F was a secondary manufacturer of MWCNTs and CNFs. One of these work areas includes clean room space where most of the CNT/CNF work is performed. Site F specialized in improving the durability and functionality of industrial composites. This facility had a total of seven employees, four of whom routinely work with nanomaterials and was operating in a pilot plant stage but was preparing to significantly scale up production. Several tasks were sampled throughout the day, which included the weighing, mixing, and sonicating of several grams of MWCNTs and CNFs inside chemical fume hoods (hoods were not always in operation during handling of nanomaterials) and on an open table top inside of a clean room, as well as the transferring of ~1 kg of CNFs from two large weighing boats inside of a custom made unventilated glovebox. All these tasks were performed within a clean room with one employee predominately performing the mixing, weighing, and sonicating and two other employees performing the transferring of the CNFs.

Sampling strategy

The current literature is lacking personal exposure information for most types of nanomaterials. Birch et al. (2011) reported personal exposures to CNF, but most of the exposure measurements to date on nanomaterials have focused on ASs during short tasks and have had a more explorative character, so a direct interpretation to workers’ exposures for a given process is not straightforward (Brouwer et al., 2004, 2009; Woskie et al., 2010). In order to address these deficiencies, this study focused on exposure assessment, collecting full-shift, or as close to full-shift as possible, side-by-side PBZ samples for EC and TEM analysis, as well as task-specific side-by-side ASs for EC and TEM analysis.

All side-by-side PBZ samples for TEM and EC analysis were collected using open-faced 25-mm cassettes to sample the inhalable size fraction. These samples were attached to the lapel of the worker as close together as possible and were collected concurrently. Side-by-side area filter-based samples were placed on carts for enhanced mobility and arranged with all sampling inlets placed as close as possible to each other in order to sample the same air space. These ASs for TEM and EC analysis were collected using open-faced 25-mm cassettes for the inhalable size fraction along with 37-mm cassettes attached to a cyclone to sample the respirable size fraction for EC.

The aerosol particle size-selective characteristics of the open-faced 25-mm cassettes have not yet been fully evaluated. However, this sampler is expected to exhibit a similar sampling efficiency to that of the 37-mm open-faced cassette. Considering wind-tunnel data described by Bartley (1998), the 37-mm cassette and the IOM inhalable aerosol sampler have close sampling efficiencies for particles with aerodynamic diameters <20 μm, Liden and Surakka (2009) likewise reported equivalence. Therefore, samples collected with the 25-mm open-face cassette can be considered to approximate the inhalable size fraction.

EC analysis

PBZ and ASs were collected on 25-mm-diameter quartz fiber filters (SKC Inc., Eighty Four, PA, USA). Additional area respirable cyclone samples were collected on a 37-mm-diameter quartz fiber filters (SKC Inc.). These samples were subsequently analyzed to determine the airborne mass concentration of EC. Samples were analyzed according to NMAM Method 5040 (NIOSH, 2006a), which is currently recommended by NIOSH to assess exposures to CNTs/CNFs (NIOSH, 2010). Open-faced PBZ and area sampling were performed to collect the inhalable mass concentration of EC using 25-mm diameter cassettes attached to a Leland Legacy pump™ (SKC Inc.) operating at ~7 l min−1. Respirable ASs were collected using 37-mm-diameter quartz fiber filters with a GK 2.69 BGI cyclone (BGI Inc., Waltham, MA, USA) (Kenny and Gussman, 1998). These samples were collected using an AirChek Sampler Model 224-PCXR8 pump (SKC Inc.) operating at a flow rate of 4.2 l min−1.

Twenty-five-millimeter quartz fiber filters were used preferentially over 37-mm quartz fiber filters for the EC analysis in order to decrease the limits of detection and quantitation (LOD and LOQ) for NMAM 5040. The LOD for any analytical procedure is the lowest analyte concentration at which detection is feasible, while the LOQ is the concentration at which quantitative results can be reported with a high degree of confidence. These limits for NMAM 5040 depend directly on the air volume collected and inversely with the filter deposit area (NIOSH, 2010). By decreasing the filter area and increasing the volume of air sampled through use of high flow commercially available personal sampling pumps, a lower LOD and LOQ were obtained.

TEM analysis

Additional PBZ and ASs were collected on 25-mm mixed cellulose ester filters (0.8-μm pore size; SKC Inc.). Leland Legacy pumps™ (SKC Inc.) operating at 5 l min−1 were used to collect the TEM samples, which were analyzed on a JEOL2100F TEM (JEOL USA, Inc., Peabody, MA, USA) using a modified NMAM 7402 asbestos by TEM (NIOSH, 2006b). Modifications to NMAM 7402 primarily consisted of eliminating all steps required for asbestos identification. These samples provided visual evidence (by TEM) of airborne CNTs as well as an indication of the structure of the particles collected, including general size, shape, and degree of agglomeration.

Three 3-mm copper TEM grids prepared from each collected sample were first examined at low magnification to determine the filter loading and preparation quality. Multiple grid openings from each TEM grid, 40 openings total, were then examined at high magnification and any particles containing CNTs/CNFs were counted as CNT/CNF ‘structures’, which ranged from single CNTs to large agglomerates. Along with the sampled air volume, the number of structures and grid openings counted were used to estimate the CNT/CNF air concentrations, reported as CNT structures per cubic centimeter. In order to estimate the air concentration, a reasonably homogeneous distribution across the filter was assumed. Similar structure counting methods have been used in previous studies (Han et al., 2008; Bello et al., 2008, 2009, 2010; Lee et al., 2010). Bulk CNT samples also were collected from the sites, when possible, and analyzed for a visual comparison with the collected air samples.

Background samples

Outdoor background measurements were collected on each day of sampling due to the potential for interference of anthropogenic sources of EC. Potential EC sources include diesel exhaust from vehicles, emissions from coal-fired power plants and fuel oil-fired power plants, as well as the seasonal burning of biomass (Magliano et al., 1999; Christoforou et al., 2000; Streets et al., 2001; Schauer, 2003). To account for these possible contributions, background samples were collected using a filter-based sample for the analysis of the mass concentration of EC. Locations for backgrounds samples were selected based on professional judgment and knowledge of the facility.

Quality control/statistical analysis

To ensure and evaluate the quality of the data, a variety of quality control procedures were instituted. These included sample flow rate calibrations, which occurred before and after each day of sampling. Proper chain-of-custody procedures, along with field and media blanks, were logged and samples were sent to the contract laboratory. Also, instrument calibrations and annual maintenance were performed on all sampling pumps. All EC filter-based samples were media blank corrected.

The statistical correlation between the side-by-side filter-based PBZ and ASs for the mass concentration of EC and CNT structure counts by TEM was examined using Proc CORR in SAS, version 9.1 (Cary, NC, USA). Statistical significance of the correlation was evaluated using a cut-point for P of 0.05. Analyses were run with and without including an outlying data point.

RESULTS

In total, 83 filter-based samples were collected for EC and TEM analysis within the six CNT primary manufacturers and secondary manufacturers operating at pilot scale or above. Inhalable mass concentration of EC and TEM CNT structure counts are presented in Table 1 (primary manufacturers, A–C) and Table 2 (secondary manufacturers, D–F) stratified by type of manufacturer, site, process, use of controls or personal protective equipment (PPE), and sample type. Any samples that were between the LOD and LOQ for NMAM 5040 are also noted in Tables 1 and 2. LODs for EC using the 25-mm filter-based samples at the six sites ranged from 0.2 to 0.5 μg EC per filter, while LOQs ranged from 0.71 to 1.7 μg EC per filter. Using the 37-mm filter-based samples, LODs for EC at the six sites ranged from 0.5 to 1 μg EC per filter, while LOQs ranged from 1.6 to 3.4 μg EC per filter.

Table 1.

EC (micrograms per cubicmeter) and TEM (CNT structures per cubic centimeter) results for primary manufacturers

| Site | Material, quantity handled | Sample characteristics

|

EC mass concentration samples

|

TEM samples

|

||||

|---|---|---|---|---|---|---|---|---|

| Process | Engineering controls present/PPE | Sample type (PBZ/AS/ASC) | Air volume sampled (l) | Mass concentration (μg m−3)a | Air volume sampled (l) | CNT structures cm−3 | ||

| A | MWCNT, DWCNT 40–50 g day−1, powder form | Outdoor background | N/A | PBZ (25) | — | — | — | — |

| AS (25) | 3428.1 | 0.33 | — | — | ||||

| ASC (37c) | — | — | — | — | ||||

| MWCNT production | Enclosed process ventilated to roof/nitrile gloves | PBZ | — | — | — | — | ||

| AS | 1312.9 | 0.49b | 954.5 | 0.034 | ||||

| ASC | 826.5 | 0.78b | — | — | ||||

| Harvesting MWCNTs | None/nitrile gloves, half-face respirator | PBZ | 199.6 | 2.28b | 234.9 | 0.090 | ||

| AS | 370.2 | 4.62 | 269.1 | 0.026 | ||||

| ASC | PF | PF | — | — | ||||

| Harvesting DWCNTs | None/nitrile gloves | PBZ | 21.7 | 5.25b | 25 | 0.123 | ||

| AS | 55.9 | ND | 40.6 | 0.047 | ||||

| ASC | 35 | ND | — | — | ||||

| Harvesting MWCNTs (second batch) | None/nuisance dust mask | PBZ | 69.4 | 2.74b | 80 | 0.399 | ||

| AS | 118.7 | 3.84b | 86.3 | 0.134 | ||||

| ASC | 74.8 | ND | — | — | ||||

| B | SWCNT 5–15 g day−1, powder form | Outdoor background | N/A | PBZ | — | — | — | — |

| AS | 1985 | 0.76 | — | — | ||||

| ASC | — | — | — | — | ||||

| SWCNT production, harvesting, and reactor clean out (PBZ-reactor clean out only) | Reactor under vacuum/nitrile gloves, R-95 filtering facepiece, and half-face respirator | PBZ | 103.7 | 3.28b | 75.4 | 0.013 | ||

| AS | 1150.3 | 1.13 | 826.7 | 0.012 | ||||

| ASC | 681.9 | ND | — | — | ||||

| Outdoor background (Day 2) | N/A | PBZ | — | — | — | — | ||

| AS | 1914.9 | 0.89 | — | — | ||||

| ASC | — | — | — | — | ||||

| SWCNT production, harvesting, and reactor clean out (Day 2) | Reactor under vacuum/nitrile gloves, R-95 filtering facepiece, and half-face respirator | PBZ | 1916.5 | 0.68 | 1392.2 | 0.003 | ||

| AS | 1869.2 | 1.02 | 1356.1 | 0.007 | ||||

| ASC | 1114.7 | 1.88 | — | — | ||||

| C | MWCNT 50–100 g day−1, powder, and aqueous forms | Outdoor background | N/A | PBZ | — | — | — | — |

| AS | 1700.4 | 0.76b | — | — | ||||

| ASC | — | — | — | — | ||||

| Production and harvesting of MWCNTs | Custom glovebox/lab coat, latex gloves, surgical mask, and safety glasses | PBZ | 1870.7 | 1.6 | 1324.5 | 0.012 | ||

| AS | 2533.4 | 0.47b | 1831.5 | ND | ||||

| ASC | 1358.9 | 0.96b | — | — | ||||

| Outdoor background (Day 2) | N/A | PBZ | — | — | — | — | ||

| AS | 1728 | ND | — | — | ||||

| ASC | — | — | — | — | ||||

| Sonication (Day 2) (PBZ-sonication, sieving, and spray coating) | None/lab coat, latex gloves, and half-face respirator | PBZ | 1147.5 | 1.13b | 790.7 | 0.010 | ||

| AS | 650.8 | ND | 466.9 | 0.002 | ||||

| ASC | 446.9 | ND | — | — | ||||

| Sieving and spray coating (Day 2) | Chemical fume hood/lab coat, latex gloves, and half-face respirator | PBZ | — | — | — | — | ||

| AS | 1132.1 | ND | 812.3 | 0.002 | ||||

| ASC | 782 | 0.7b | — | — | ||||

PF, pump fault; ND, non-detect. AS (25-mm cassette collected at a fixed position); PBZ (25-mm cassette fixed to lapel of worker); ASC, area sample cyclone (37-mm cassette w/cyclone collected at a fixed position).

All EC concentrations are media blank corrected.

Results are between the LOD and LOQ.

Table 2.

EC (micrograms per cubicmeter) and TEM (CNT structures per cubic centimeter) results for secondary manufacturers

| Site | Material, quantity handled | Sample characteristics

|

EC mass concentration samples

|

TEM samples

|

||||

|---|---|---|---|---|---|---|---|---|

| Process | Engineering controls present/PPE | Sample type (PBZ/AS/ASC) | Air volume sampled (l) | Mass concentration (μg m−3)a | Air volume sampled (l) | CNT structures cm−3 | ||

| D | MWCNT 100 g day−1, powder, and aqueous forms | Outdoor background | N/A | PBZ (25) | — | — | — | — |

| AS (25) | 923.8 | ND | — | — | ||||

| ASC (37c) | — | — | — | — | ||||

| General office worker outside of lab space | None/none | PBZ | 2375.5 | 0.8 | 1634.1 | 0.001 | ||

| AS | — | — | — | — | ||||

| ASC | — | — | — | — | ||||

| CNT waste collection and disposal | None/full protective suit with booties, nitrile gloves | PBZ | 1232.2 | 1.06b | 927.1 | 0.214 | ||

| AS | — | — | — | — | ||||

| ASC | — | — | — | — | ||||

| Weighing of 100 g of material | Ventilated glovebox/full protective suit with booties, nitrile gloves, and full-face respirator | PBZ | 146.7 | ND | 104.8 | ND | ||

| AS | 179.8 | ND | 129.2 | ND | ||||

| ASC | 107.3 | ND | — | — | ||||

| Sonication | Chemical fume hood/full protective suit with booties, gloves, acid smock, and face shield | PBZ | 845.2 | 0.83b | 601.1 | ND | ||

| AS | 1078.6 | ND | 783.3 | 0.003 | ||||

| ASC | 664.9 | ND | — | — | ||||

| E | MWCNT 14.75–1 kg, powder form | Extrusion, weighing, and batch mixer use | Chemical fume hood and glovebox/Safety glasses, half-face respirator, Tyvek suit/lab coat, nitrile gloves | PBZ | 783.9 | 3.19 | 562 | 0.067 |

| PBZ | 139.9 | 7.86b | 100.4 | 0.242 | ||||

| AS | 969.1 | 1.01b | 705.4 | 0.008 | ||||

| ASC | 582.8 | 1.89b | — | — | ||||

| Milling CNT composite | HEPA vacuum/safety glasses, half-face respirator, lab coat, and nitrile gloves | PBZ | 139.9 | ND | 100.4 | ND | ||

| AS | 151.2 | ND | 110.1 | ND | ||||

| ASC | 90.9 | ND | — | — | ||||

| F | MWCNT/CNF 2 g–1 kg, powder form | Transferring nanofibers | Clean room, custom glovebox/latex gloves, half-face respirator, and tyvek smock | PBZ | 265.1 | 4.15b | 190.9 | 1.613 |

| AS | 236.7 | ND | 172 | 0.295 | ||||

| ASC | 120.4 | ND | — | — | ||||

| Weighing, mixing, and Sonication of CNTs and CNFs | Clean room, chemical fume hoods/latex gloves, half-face respirator, and tyvek smock | PBZ | 1246.3 | 7.54 | 883.8 | 0.065 | ||

| AS | 939.7 | ND | 683.5 | 0.003 | ||||

| ASC | 580.5 | 2.76b | — | — | ||||

PF, pump fault; ND, non-detect. AS (25-mm cassette collected at a fixed position); PBZ (25-mm cassette fixed to lapel of worker); ASC, area sample cyclone (37-mm cassette w/cyclone collected at a fixed position).

All EC concentrations are media blank corrected.

Results are between the LOD and LOQ.

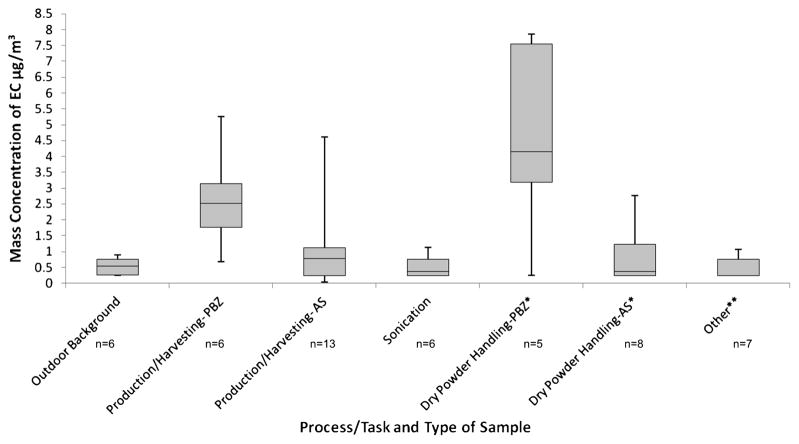

Similarities in processes/tasks were observed in both primary and secondary manufacturers of CNTs. Processes/tasks consistently observed at primary manufacturers included similar CNT production methods, harvesting of CNT products, and cleaning/housekeeping operations. Overall, the most common processes/tasks observed at secondary manufacturers included weighing, mixing, sonication, manual transfer of materials, cleaning operations, and spray coating processes. Figure 1 displays the filter-based mass concentrations of EC by common processes/tasks as well as the type of sample collected (AS versus PBZ sample). PBZ samples were generally higher than comparable ASs, and PBZ samples collected during dry powder handling task/processes were generally found to have the highest concentrations of EC compared to other processes/tasks.

Fig. 1.

EC exposures by process/task and type of sample. Box plot represents range (minimum to maximum), 25th percentile, median, and 75th percentile. Non-detect samples were graphed as half of the limit of detection. AS (also included ASC, area sample w/cyclone). Sonication included AS, ASC, and PBZ samples. *Tasks include weighing; extrusion, weighing, and batch mixer use; transferring CNFs; weighing and mixing of CNTs and CNFs. **Tasks include CNT waste collection; general office work; milling CNT composite; sieving; and spray coating; and included both AS and PBZ samples.

Primary manufacturers

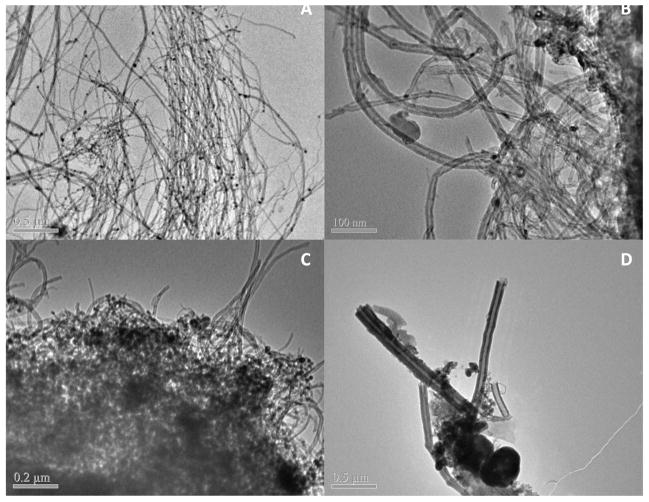

A total of 30 filter-based samples were collected for the mass concentration of EC along with 16 collected for analysis by TEM at the three primary manufacturers producing CNTs that participated in this study (Table 1). A total of seven PBZ samples were collected, and every sample found quantifiable levels of EC ranging from 0.68 to 5.25 μg m−3 with an average concentration of 2.42 μg m−3. The remaining 23 samples for EC were collected as ASs or background samples. The 10 ASs that found quantifiable levels of EC ranged from 0.47 to 4.62 μg m−3, while seven ASs were found to be non-detects (ND). One area cyclone sample from Site A suffered a pump fault early in sampling and was not included in any analysis. The five outdoor background samples ranged from ND to 0.89 μg m−3. The seven side-by-side PBZ samples collected for TEM analysis ranged from 0.003 to 0.399 CNT structures cm−3. The remaining nine ASs collected for TEM analysis, which could visually identify CNTs, ranged from ND to 0.134 CNT structures cm−3. Examples of PBZ TEM images are shown from Sites A and C (primary manufacturers) as well as Sites E and F (secondary manufacturers) in Fig. 2.

Fig. 2.

TEM images of collected PBZ samples. (A) Site A during the harvesting of MWCNTs. (B) Site C during the production and harvesting of MWCNTs. (C) Site E during extrusion, weighing, and batch mixer use with MWCNTs (EC concentration >7 μg m−3). (D) Site F during the weighing, mixing, and sonication of CNTs and CNFs (EC concentration >7 μg m−3).

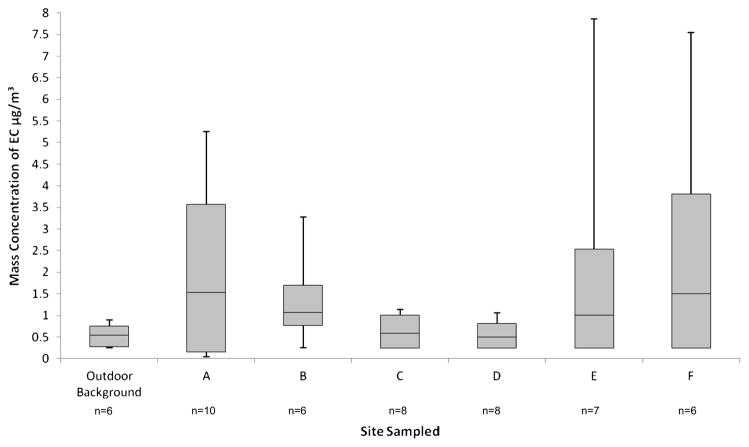

Secondary manufacturers

At the three participating secondary manufacturers, a total of 22 filter-based samples were collected for the mass concentration of EC, along with 15 samples collected for analysis by TEM. Figure 3 displays the range of EC results for both primary and secondary manufacturing sites. A total of nine filter-based samples were collected as PBZ samples, with two of the nine samples not detecting any amounts of EC. The seven PBZ samples that detected EC ranged from 0.8 to 7.86 μg m−3. One sample collected from Sites E (extrusion, weighing, and batch mixer tasks, 7.86 μg m−3) and F (weighing, mixing, and sonicating tasks, 7.54 μg m−3) each detected an EC exposure above the proposed NIOSH REL of 7 μg m−3, and visual evidence of CNTs was found as shown in Fig. 2C and D. The remaining 13 samples for EC were collected as ASs or background samples. The three ASs that found quantifiable levels of EC ranged from 1.01 to 2.76 μg m−3. The only outdoor background sample collected was a non-detectable sample. Background samples were not collected in the two other secondary manufacturers because CNT/CNF processes were conducted in clean rooms or clean room-like atmospheres without any external sources of anthropogenic EC contamination. The nine side-by-side PBZ samples collected for TEM analysis ranged from 0.001 to 1.613 CNT structures cm−3 with three samples showing no visual evidence of CNTs/CNFs. From the remaining six ASs collected for TEM analysis, four could visually identify CNTs and ranged from 0.003 to 0.295 CNT structures cm−3.

Fig. 3.

EC exposures for all tasks by site. Box plot represents range (minimum to maximum), 25th percentile, median, and 75th percentile. Non-detect samples were graphed as half of the limit of detection. Grouped samples by site included all sampled tasks as well as all types of samples—AS; ASC, area sample cyclone; and PBZ sample; primary manufacturing Sites A–C; and secondary manufacturing Sites D–F.

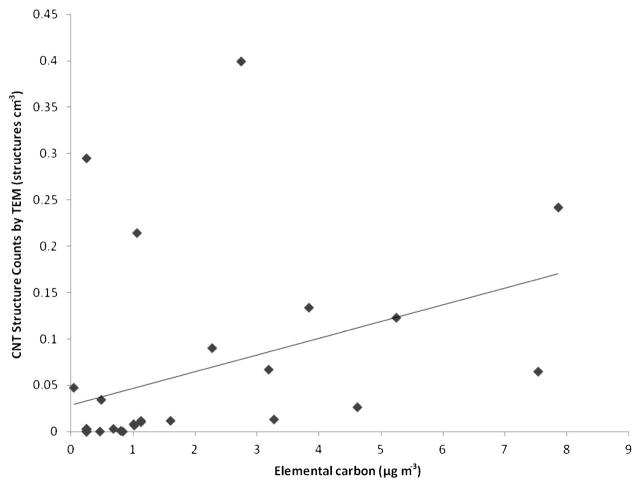

Throughout the set of samples collected at the six individual sites, there seems to be a general trend of the higher EC filter-based mass concentration samples corresponding to the higher CNT structure counts performed by TEM (Fig. 4). The statistical correlation between the side-by-side filter-based PBZ and ASs for the mass concentration of EC and CNT structure counts was therefore examined. An apparent outlier was found from a PBZ sample collected during the transferring of CNFs collected at Site F. When the single outlier was included in the analysis, the P-value was 0.07, with a Pearson correlation coefficient of 0.33. When the outlier was excluded, the relationship was found to be significant with a P-value of 0.01 and a corresponding Pearson correlation coefficient of 0.44.

Fig. 4.

Correlation of EC versus TEM filter-based area and PBZ samples. Non-detect samples were graphed as half of the limit of detection. All side-by-side PBZ samples and ASs were used. Included only PBZ and AS samples.

DISCUSSION

This study provides detailed information about the occupational exposures to CNTs and CNFs among a population of workers not previously studied. This exposure study investigated six facilities (~14% of the total number of US CNT/CNF manufacturers; Schubauer-Berigan et al., 2011) involved in the production of CNTs/CNFs or the downstream use of the materials in manufacturing. For the most part, the facilities visited were startup companies that were operating in the pilot scale with the intention of scaling up production very rapidly. Overall, most of the exposures measured at these facilities were below the proposed NIOSH REL for CNTs and CNFs. However, it is important to note that the PBZ samples collected during these site visits were collected as the inhalable mass concentration of EC, while the proposed NIOSH REL is based on the respirable mass concentration of EC. To date, the authors are aware of only one study (Birch et al., 2011) that has used the mass concentration of EC as a marker for exposure to CNTs/CNFs, as suggested by the proposed NIOSH REL (NIOSH, 2010).

The sites visited in this exposure study each had roughly 5–20 employees that may come in contact with CNTs/CNFs on a daily basis. Generally, these facilities did not have the resources to have a health and safety department dedicated solely to issues such as worker training, exposure monitoring, and engineering controls. However, every company visited did have at least one employee who worked part-time on these issues and did express awareness of the importance of controlling exposures to CNTs/CNFs through the use of a combination of engineering, administrative, and PPE exposure controls.

PPE varied depending on the potential for exposure but generally consisted of several different forms of respiratory protection, which included half-face elastomeric respirators, filtering face piece respirators, nuisance dust masks, or surgical masks. Protection from dermal exposures consisted of gloves, safety glasses, lab coats, full-body protective suits, as well as protective smocks. Several facilities visited wore PPE that was not adequate to control exposures to airborne CNTs/CNFs such as surgical masks or nuisance dust masks. Also, more than one facility wore half-face elastomeric respirators; however, they were not equipped with the appropriate type of particulate filter (any 95 or 100 series N, R, or P filter) to properly control exposures (NIOSH, 2010). Almost all facilities visited did implement some sort of engineering controls during use of raw or powder form CNTs or CNFs. The most common types of engineering controls observed in use during times of potential exposures at both primary and secondary manufacturers generally included chemical fume hoods, enclosed production processes, custom-made gloveboxes, and HEPA filtered vacuums. However, it was observed at several facilities that it was common to shut down chemical fume hoods during the handling of CNTs/CNFs to reduce the amount of product loss from air disturbance.

EC analysis

Overall, the two highest exposures, which were over the proposed NIOSH REL of 7 μg m−3, occurred only at secondary manufacturing facilities during dry powder handling processes/tasks that included mixing and weighing operations (7.54 and 7.86 μg m−3, Sites E and F, respectively) within fume hoods that were not always in operation or being utilized properly during material handling procedures. Both of these samples were PBZ samples, as seen in Fig. 1. Other significant processes that led to exposures at secondary manufacturers, which were under the currently proposed NIOSH REL, included the transferring of CNFs (4.15 μg m−3, Site F) as well as the extrusion and weighing of CNTs (3.19 μg m−3, Site E). The greatest amounts of CNTs/CNFs were handled for some of the longest durations at the secondary manufacturing facilities Sites E and F, which contributed to the overall exposures seen in Fig. 3.

All filter-based samples analyzed for EC collected at primary manufacturers were below the proposed NIOSH REL. Significant processes that contributed to exposures in these facilities were mainly the harvesting of the raw CNTs. Engineering controls in place during the harvesting operations ranged from no forms of controls to baghouse collection systems and custom made gloveboxes. The highest exposures were generally found in the harvesting operations that had no type of engineering controls in place at Site A. Figure 1 shows that the two overall highest exposures by processes occurred during the production and harvesting of CNTs as well as during any operations involving dry powder handling. Both of these samples were collected as PBZ samples, which emphasizes the need for continued personal sampling as opposed to stationary area sampling.

Outdoor background samples were collected due to the potential for interference from anthropogenic sources of EC. EC in atmospheric particulate matter originates from a broad range of sources in many urban locations and can vary significantly based upon the day and season. Outdoor background samples were collected at all facilities that had fairly open heating, ventilation, and air conditioning systems, which used outdoor air exclusively as make up air (Sites A, B, and C. Site D was collected for an office worker outside of the clean room area). At these types of facilities, outdoor background samples were collected as far away from roads and other potential sources of EC as possible. The two facilities (Sites E and F) that showed the highest levels of exposure were collected in clean rooms or laboratory spaces that had close to100% of the makeup air filtered before entering the room. Outdoor background samples were not collected at these facilities due to lack of anthropogenic sources of EC contamination inside of the clean rooms or clean room like atmospheres.

The EC LOD for NMAM 5040 was reduced through the use of 25-mm filters and by increasing the volume of air sampled (i.e. increasing the flow rate), as recommended in the method (NIOSH, 2006a; NIOSH, 2010). As discussed elsewhere and shown throughout these site visits, a lower LOQ can be readily obtained (NIOSH, 2010).

TEM analysis

There is currently no widely accepted method to analyze CNTs/CNFs for microscopic analysis. Several previous studies have used similar counting methods, as discussed in this paper, to assess exposures in manufacturing and laboratory settings (Han et al., 2008; Bello et al., 2008, 2009, 2010; Lee et al., 2010). In this study, samples were collected for TEM analysis by a modified NMAM 7402 to determine CNT/CNF structure concentrations for all area and PBZ samples. The highest CNT/CNF structure counts from the primary manufacturers came from the harvesting operations at Site A, which did not have any engineering controls in place. The two highest structure counts at secondary manufactures were seen at Site F during the manual transferring of CNFs (1.613 and 0.295 CNT structures cm−3). The next highest exposures occurred at Site E during weighing and mixing (0.242 CNT structures cm−3) followed by the CNT waste collection task at Site D (0.214 CNT structures cm−3). For the most part, the highest exposures seen by TEM occurred at the secondary manufacturing sites. Although there is no current accepted OEL for CNTs/CNFs, other OELs have been set for asbestos fibers, which include the Occupational Safety and Health Administration permissible exposure limit and NIOSH REL, both set at 0.1 fiber cm−3.

In general, there seemed to be agreement between the PBZ and ASs collected for the mass concentration of EC and the side-by-side samples collected for analysis by TEM, as indicated by the Pearson correlation coefficient of 0.44. This finding was intriguing since many factors such as the uneven deposition on the filter media for CNT structure counts, the degree of agglomeration of the particles, and the variability in EC background levels can significantly impact the CNT structure count and mass concentration of EC determined and consequently may obscure any potential correlation that exists between these two metrics.

This agreement between the elevated levels of EC and structure counts seen by samples analyzed by TEM should be further investigated, to determine a true relationship under more controlled settings. Currently, the American Society for Testing and Materials (ASTM) has a draft method for determining the airborne CNT concentration in ambient and indoor atmospheres (ASTM Work Item WK28561, 2011). However, much more work needs to be conducted on the utility of TEM sizing and ‘structure’ counting methods in toxicological studies to determine whether an eventual health based OEL, based on size-specific structure counts, can be realized.

Limitations

One of the goals of this study was to conduct full-shift sampling on employees handling CNTs/CNFs. Since a majority of the companies visited were still operating in a pilot/experimental scale, most employees were not handling CNTs/CNFs for a full shift. Several samples were collected over a relatively short sample time due to the short duration of the processes/tasks.

A level of caution should be exercised when interpreting results from samples analyzed for the mass concentration of EC using NMAM 5040 as discussed in the NIOSH current intelligence bulletin on CNT/CNF (NIOSH, 2010). The method does not exclude the potential interference of other natural or anthropogenic sources of airborne EC. This could lead to a potential overestimation of exposure. However, by collecting outdoor background samples for the mass concentration of EC, a greater level of certainty regarding exposure to CNTs/CNFs can be obtained.

Comparisons to the NIOSH REL for the inhalable mass concentration of EC collected during these site visits may be difficult since the proposed NIOSH REL is based on a respirable 8-h time-weighted average. However, EC ASs were collected in the same side-by-side fashion as the PBZ samples, with the exception that one sample was collected as the inhalable mass concentration of EC, while the other was collected in the respirable size fraction of EC. Six of the eight side-by-side area respirable size fraction samples, where detectable EC concentrations were measured for one or both size fractions, had similar or a slightly greater measurable EC concentration compared to the same inhalable mass concentration samples. This, along with visual evidence from the side-by-side TEM samples, indicated that in most cases, during this study, the aerosols sampled were most likely within the respirable size fraction.

A majority of the samples collected at these sites that were analyzed for EC by NMAM 5040 were found to be between the LOD and LOQ. Because the uncertainty in exact exposure concentrations between the LOD and LOQ is higher than for samples above the LOQ, there may be a positive or negative bias in these results that may limit the usefulness and generalizability of the data.

CONCLUSIONS

Most exposures to CNTs/CNFs in this study of six primary and secondary manufacturers of CNTs/CNFs were detectable but were below the currently proposed NIOSH REL of 7 μg m−3. Only 2 of the 52 samples collected for the mass concentration of EC were above the proposed REL. Both of these samples were collected at secondary manufacturers during mixing and weighing processes using fairly large quantities of CNTs/CNFs. At primary manufacturers, the harvesting of raw CNTs, after production, consistently had the highest exposures but were all under the proposed REL. However, if a lower REL is adopted, many more of the samples could be above it.

Filter-based PBZ samples were consistently higher than concurrent ASs, showing the importance of collecting personal samples, as reported recently for CNFs (Birch et al., 2011). It is still unknown what exposure metric may have the most health relevance for humans. However, at this time, a mass metric based on EC may be the most reliable and realistically feasible metric to determine exposure to CNTs/CNFs, until a thorough microscopy method is developed and validated.

The highest levels of exposure occurred during processes that did not use engineering controls to limit exposures or during processes where significant amounts of CNTs/CNFs were used for longer durations. Since a vast majority of the samples collected while engineering controls were in use were well below the NIOSH REL, this suggests that conventional engineering controls and source enclosures may work well to reduce exposures to CNTs/CNFs (Han et al., 2008; Old and Methner, 2008; Evans et al., 2010; Lee et al., 2010).

Nearly all the facilities sampled during this study were small startup companies that were operating in the pilot scale with the intention of scaling up production very rapidly. As the demand increases for the greater production of CNTs and CNFs as well as the need for nano-enabled products, the potential for exposure will inevitably increase. The companies visited during this study have already begun expanding their operations to increase production and uses of CNTs/CNFs. It is very likely that exposures will increase concurrently with the widespread increase of these nanomaterials being handled.

Acknowledgments

FUNDING

NIOSH Nanotechnology Research Center supplemental funding.

The authors would like to thank Brian Curwin, Catherine Beaucham, Greg Kinnes for their assistance in collecting field data; Donnie Booher, Karl Feldmann, and Kevin L. Dunn for their technical assistance. The authors would also like to thank Catherine Beaucham, Ralph Zumwalde, and Cherie Estill for their helpful insight.

Footnotes

Disclaimer: The findings and conclusions in this report are those of the author(s) and do not necessarily represent the views of the NIOSH. Mention of any company name or product does not constitute endorsement by NIOSH.

References

- ASTM Work Item WK28561. New test method for airborne carbon nanotube concentration in ambient and indoor atmospheres as determined by transmission electron microscopy direct transfer (TEM) West Conshohocken, PA: ASTM international; 2011. [Accessed 8 November 2011]. Available at http://www.astm.org. [Google Scholar]

- Bartley DL. Inhalable aerosol samplers. Appl Occup Environ Hyg. 1998;13:274–8. [Google Scholar]

- Bello D, Hart JA, Ahn K, et al. Particle exposure levels during CVD growth and subsequent handling of vertically-aligned carbon nanotube films. Carbon. 2008;46:974–81. [Google Scholar]

- Bello D, Wardle BL, Yamamoto N, et al. Exposure to nanoscale particles and fibers during machining of hybrid advanced composites containing carbon nanotubes. J Nanopart Res. 2009;11:231–49. [Google Scholar]

- Bello D, Wardle B, Zhang J, et al. Characterization of exposures to nanoscale particles and fibers during drilling of hybrid advanced composites containing carbon nanotubes. Int J Occup Environ Health. 2010;16:434–50. doi: 10.1179/107735210799159996. [DOI] [PubMed] [Google Scholar]

- Birch ME, Ku BK, Evans DE, et al. Exposure and emissions monitoring during carbon nanofiber production–part I: elemental carbon and iron-soot aerosols. Ann Occup Hyg. 2011;55:1016–36. doi: 10.1093/annhyg/mer073. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Brouwer DH, Gijsbers JH, Lurvink MW. Personal exposure to ultrafine particles in the workplace: exploring sampling techniques and strategies. Ann Occup Hyg. 2004;48:439–53. doi: 10.1093/annhyg/meh040. [DOI] [PubMed] [Google Scholar]

- Brouwer DH, van Duuren-Stuurman B, Berges M, et al. From workplace air measurement results toward estimates of exposure? Development of a strategy to assess exposure to manufactured nano-objects. J Nanopart Res. 2009;11:1867–81. [Google Scholar]

- Christoforou CS, Salmon LG, Hannigan MP, et al. Trends in fine particle concentration and chemical composition in Southern California. J Air Waste Manage Assoc. 2000;50:43–53. doi: 10.1080/10473289.2000.10463985. [DOI] [PubMed] [Google Scholar]

- Cientifica. Market research report: carbon nanotubes global production. [Accessed 12 May 2011];On-line report. 2005 Apr; Available at http://www.mindbranch.com/listing/product/R386-42.html.

- Dahm M, Yencken M, Schubauer-Berigan M. Exposure control strategies in the carbonaceous nanomaterial industry. J Occup Environ Med. 2011;53:S68–73. doi: 10.1097/JOM.0b013e31821b1d3b. [DOI] [PubMed] [Google Scholar]

- Donaldson K, Aitken R, Tran L, et al. Carbon nanotubes: a review of their properties in relation to pulmonary toxicology and workplace safety. Toxicol Sci. 2006;92:5–22. doi: 10.1093/toxsci/kfj130. [DOI] [PubMed] [Google Scholar]

- Evans DE, Ku BK, Birch ME, et al. Aerosol monitoring during carbon nanofiber production: mobile direct-reading sampling. Ann Occup Hyg. 2010;54:514–31. doi: 10.1093/annhyg/meq015. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Han JH, Lee EJ, Lee JH, et al. Monitoring multiwalled carbon nanotube exposure in carbon nano-tube research facility. Inhal Toxicol. 2008;20:741–9. doi: 10.1080/08958370801942238. [DOI] [PubMed] [Google Scholar]

- Invernizzi N. Nanotechnology between the lab and the shop floor: what are the effects on labor? J Nanopart Res. 2011;13:2249–68. [Google Scholar]

- Kenny LC, Gussman RA. Characterization and modelling of a family of cyclone aerosol preseparators. J Aerosol Sci. 1998;28:677–88. [Google Scholar]

- Kisen ER, Murray AR, Sargent L, et al. Genotoxicity of carbon nanofibers: are they potentially more or less dangerous than carbon nanotubes or asbestos? Toxicol Appl Pharmacol. 2011;252:1–10. doi: 10.1016/j.taap.2011.02.001. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Kobayashi N, Kishimoto A, Ogura I, et al. Risk assessment of manufactured nanomaterials: carbon nanotubes (CNTs) In: Nakanishi J, editor. Interim report issued on October 16, 2009. Executive summary. [Google Scholar]

- Lee JH, Lee SB, Bae GN, et al. Exposure assessment of carbon nanotube manufacturing workplaces. Inhal Toxicol. 2010;22:369–81. doi: 10.3109/08958370903367359. [DOI] [PubMed] [Google Scholar]

- Liden G, Surakka J. A headset-mounted mini sampler for measuring exposure to welding aerosol in the breathing zone. Ann Occup Hyg. 2009;53:99–116. doi: 10.1093/annhyg/mep001. [DOI] [PubMed] [Google Scholar]

- Magliano KL, Hughes VM, Chinkin LR, et al. Spatial and temporal variations in PM10 and PM2.5 source contributions and comparison to emissions during the 1995 integrated monitoring study. Atmos Environ. 1999;33:4757–73. [Google Scholar]

- Methner MM, Birch ME, Evans DE, et al., editors. Case study: identification and characterization of potential sources of worker exposure to carbon nanofibers during polymer composite laboratory operations. J Occup Environ Hyg. 2007;4:125–30. doi: 10.1080/15459620701683871. [DOI] [PubMed] [Google Scholar]

- Methner MM, Hodson L, Dames A, et al. Nanoparticle emission assessment technique (NEAT) for the identification and measurement of potential inhalation exposure to engineered nanomaterials—part B: results from 12 field studies. J Occup Environ Hyg. 2010;7:163–76. doi: 10.1080/15459620903508066. [DOI] [PubMed] [Google Scholar]

- NIOSH. Draft current intelligence bulletin occupational exposure to carbon nanotubes and nanofibers. Cincinnati, OH: US Department of Health and Human Services, Centers for Disease Control, National Institute for Occupational safety and Health; 2010. [Accessed 21 June 2011]. DHHS (NIOSH), NIOSH Docket Number: NIOSH 161-A; Available at http://www.cdc.gov/niosh/docket/review/docket161A/ [Google Scholar]

- NIOSH Manual of Analytical Methods. Method 5040 diesel particulate matter (as elemental carbon) In: Schlecht PC, O’Connor PF, editors. NIOSH method of analytical methods. 4. 1. Cincinnati, OH: Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health; 2006a. DHHS (NIOSH) Publication 94–113. [Google Scholar]

- NIOSH Manual of Analytical Methods. Method 7402 asbestos by TEM (modified for carbon nanotubes) In: Schlecht PC, O’Connor PF, editors. NIOSH method of analytical methods. 4. 1. Cincinnati, OH: Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health; 2006b. DHHS (NIOSH) Publication 94–113. [Google Scholar]

- Old L, Methner MM. Effectiveness of local exhaust ventilation (LEV) in controlling engineered nanomaterial emissions during reactor cleanout operations. J Occup Environ Hyg. 2008;5:63–9. doi: 10.1080/15459620802059393. [DOI] [PubMed] [Google Scholar]

- Pacurari M, Yin XJ, Zhao J, et al. Raw single-wall carbon nanotubes induce oxidative stress and activate MAPKs, AP-1, NF-κB, and Akt in normal and malignant human mesothelial cells. Environ Health Perspect. 2008;116:1211–7. doi: 10.1289/ehp.10924. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pauluhn J. Multi-walled carbon nanotubes (Bay-tubes®): approach for derivation of occupational exposure limit. Regul Toxicol Pharmacol. 2010;57:78–89. doi: 10.1016/j.yrtph.2009.12.012. [DOI] [PubMed] [Google Scholar]

- Poland CA, Duffin R, Kinloch I, et al. Carbon nanotubes introduced into the abdominal cavity of mice show asbestos-like pathogenicity in a pilot study. Nat Nanotechnol. 2008;3:423–8. doi: 10.1038/nnano.2008.111. [DOI] [PubMed] [Google Scholar]

- Porter DW, Hubbs AF, Mercer RR, et al. Mouse pulmonary dose- and time course-responses induced by exposure to multi-walled carbon nanotubes. Toxicology. 2010;269:136–47. doi: 10.1016/j.tox.2009.10.017. [DOI] [PubMed] [Google Scholar]

- Sargent LM, Shvedova AA, Hubbs AF, et al. Induction of aneuploidy by single-walled carbon nanotubes. Environ Mol Mutagen. 2009;50:708–17. doi: 10.1002/em.20529. [DOI] [PubMed] [Google Scholar]

- Schauer J. Evaluation of elemental carbon as a marker for diesel particulate matter. J Expo Anal Environ Epidemiol. 2003;13:443–53. doi: 10.1038/sj.jea.7500298. [DOI] [PubMed] [Google Scholar]

- Schubauer-Berigan M, Dahm M, Yencken M. Engineered carbonaceous nanomaterials manufacturers in the United States: workforce size, characteristics and feasibility of epidemiologic studies. J Occup Environ Med. 2011;53:S62–7. doi: 10.1097/JOM.0b013e31821b1e2c. [DOI] [PubMed] [Google Scholar]

- Shvedova AA, Kisin ER, Mercer R, et al. Unusual inflammatory and fibrogenic pulmonaryresponses to single-walled carbon nanotubes in mice. Am J Physiol Lung Cell Mol Physiol. 2005;289:698–708. doi: 10.1152/ajplung.00084.2005. [DOI] [PubMed] [Google Scholar]

- Streets DG, Gupta S, Waldhoff ST, et al. Black carbon emissions in China. Atmos Environ. 2001;35:4281–96. [Google Scholar]

- Tsai SJ, Hofmann M, Hallock M, et al. Characterization and evaluation of nanoparticle release during the synthesis of single-walled and multiwalled carbon nanotubes by chemical vapor deposition. Environ Sci Technol. 2009;43:6017–23. doi: 10.1021/es900486y. [DOI] [PubMed] [Google Scholar]

- Woskie SR, Bello D, Virji MA, et al. Understanding workplace processes and factors that Influence exposure to engineered nanomaterial. Int J Occup Environ Health. 2010;16:365–77. doi: 10.1179/107735210799159950. [DOI] [PubMed] [Google Scholar]

- World Technology Evaluation Center, Inc. (WTEC) [Accessed 12 May 2011];WTEC panel report on international assessment of research and development of CNT manufacturing and applications. 2007 [Online]. Available at http://www.wtec.org/cnm/CNM_final_report.pdf.