Summary:

The advent of 3-dimensional (3D) printing technology has facilitated the creation of customized objects. The lack of regulation in developing countries renders conventional means of addressing various healthcare issues challenging. 3D printing may provide a venue for addressing many of these concerns in an inexpensive and easily accessible fashion. These may potentially include the production of basic medical supplies, vaccination beads, laboratory equipment, and prosthetic limbs. As this technology continues to improve and prices are reduced, 3D printing has the potential ability to promote initiatives across the entire developing world, resulting in improved surgical care and providing a higher quality of healthcare to its residents.

In science fiction, the ability to create a physical object expediently and rapidly is a commonly occurring theme. The advent of 3-dimensional (3D) printing technology has brought science fiction closer to reality by facilitating the creation of customized objects seemingly out of thin air. Indeed, we are getting closer to the matter compiler in Neal Stephenson’s “The Diamond Age” or the replicator in “Star Trek.”1

Despite many technological advancements over the course of human history, well over a billion people worldwide are living without food, water, shelter, or proper healthcare. Due to its enormity and complexity, this problem has remained unresolved. The lack of standard regulation in developing countries renders conventional means of addressing these issues very difficult.2 3D printing (or “additive manufacturing” as it is referred to by some authors3–5) may provide a venue for addressing many of these concerns in an inexpensive and easily accessible fashion. This review outlines the current uses of 3D printing in developing countries.

WHAT IS 3D PRINTING?

3D printing technology has been in existence for the last 3 decades. Only recently has it become readily available and inexpensive enough to be used by the general public.1,6 It is a means of generating physical models from digital designs.1,7 The software tools needed for producing printable items, as well as the materials used, and repositories for sharing and downloading designs have become easily obtainable.1,6 Michigan Technological University has already started the process of compiling an open library of 3D-printed components for optical devices. The most commonly used materials by 3D printers currently are polylactic acid and acrylonitrile butadiene styrene. In general, 3D printers function by constructing items from numerous thin layers of material. Depending on the type of printer used (Selective Laser Sintering [SLS], Fused Deposition Modeling [FDM], or Stereolithography), the choice of material and how the layers bond to one another vary.1

SLS is a method of 3D printing that uses powder-based materials. A laser is employed to draw the shape of the desired object in the powder and to bind the new layers of powder that are laid down. Shot peening is then done to strengthen the outermost layer. This mode of printing can be used to produce metal, wax, nylon, ceramic, or composite parts. SLS machines with postcuring processes result in very accurate models with smooth surfaces but are costly.1,8

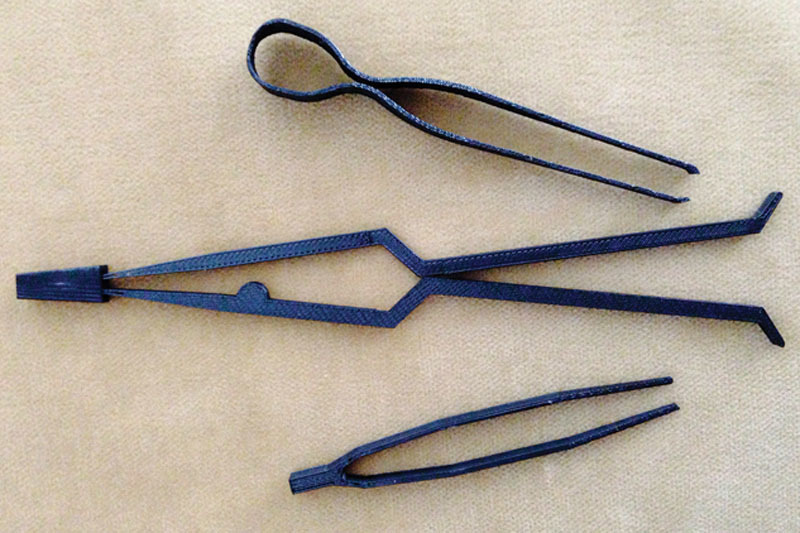

FDM operates in a similar fashion to an inkjet printer. It uses printer heads to deposit melted lines of plastic onto a platform in layers in a process called “layered manufacturing,” which is a rapid prototyping technique. The final model is created as the plastic cools and hardens. FDM is the economic choice, as it is inexpensive. Furthermore, depending on the complexity of the printer, it can use many types of plastic.1,8 Figures 1–4 show various medical supplies printed using FDM.

Fig. 1.

Forceps printed by FDM. Material used: acrylonitrile butadiene styrene. Cost: 5 cents per gram.

Fig. 4.

Tongue depressor printed by FDM. Material used: acrylonitrile butadiene styrene. Cost: 5 cents per gram.

Fig. 2.

Scalpel handle printed by FDM. Material used: acrylonitrile butadiene styrene. Cost: 5 cents per gram.

Fig. 3.

Splints printed by FDM. Material used: acrylonitrile butadiene styrene. Cost: 5 cents per gram.

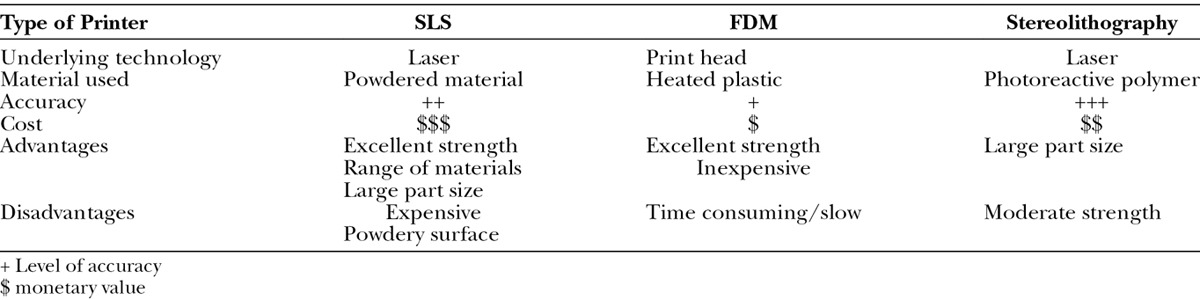

In stereolithography, the model is created using a photoreactive polymer as the base material. A light source is used to solidify a layer of polymer liquid. Once this has been done, the machine continues to add layers of the thin liquid polymer. Finally, when the entire model is solidified, the structure is lifted out and any excess liquid flows away. An optional stroboscopic postcuring process follows which uses ultraviolet light to ensure that the photoreaction has gone to completion, which will in turn enhance the mechanical properties of the model. Each of these 3 printing processes has its own advantages and disadvantages that may be taken into consideration when deciding on which mode of 3D printing to use (Table 1).8

Table 1.

Comparison of Different 3D Printing Processes

CURRENT APPLICATIONS OF 3D PRINTING IN MEDICINE

The potential applications of 3D printing in medicine are widespread.7 Rapid prototyping has been used in numerous medical applications over the last decades. These include research, education and training, and individual patient care.7 Its many potential advantages in plastic surgery have also been described previously.6,9–11

Medical Research

Models produced by rapid prototyping can be used to aid in gaining a better understanding of the physiological processes and complex pathologies associated with various conditions than can be achieved with traditional visualization tools.12–14 Furthermore, they can be used to simulate in vivo conditions providing insight into the aerodynamic features of airway disease or hemodynamic facets of cardiovascular ailments. Accurate models can be constructed using silicon or polyurethane to emulate the texture and physical properties of blood vessels.12,15,16 Numerous advancements have also been made in the realm of bioprinting where inkjet techniques have been implemented to construct functional body parts and organs with a high degree of accuracy and personalization.3,17–20 Furthermore, it has the ability to construct tissue scaffolds for cellular growth and production of vascular networks.18

Education and Training

The use of 3D printing technology permits the construction of 3D models that can aid in precise discernment of human anatomy. This in turn improves the learning experience of physicians-in-training and facilitates patients’ understanding of different human structures and tissues, which may sometimes be inadequate when viewed as a 2D or 3D image on a flat screen.7,14,21 With online repositories containing many anatomical designs, the printing of 3D models of bones, organs, and other biological features can be easily accessed. Furthermore, these models can be catered to specific patient characteristics allowing for the development of an accurate surgical plan and enhancing surgeon preparedness before performing a procedure.22,23 In this way, preoperative counseling and management of postoperative outcomes for patients are also improved.

Individual Patient Care

Surgical Planning

Rapid prototyping has shown marked enhancements in the diagnosis and treatment of different diseases spanning numerous medical disciplines. Owing to its ability to provide a better understanding of complex underlying conditions and appreciation of the pathological structures, 3D models may permit meticulous preoperative planning. Having the knowledge of a patient’s individual anatomy before performing a procedure may enable surgeons to simulate the necessary surgical steps in advance and potentially reduce the incidence of complications and improve outcomes.7,14,22,24–28 This may also result in cost-saving through decreased operative time.6,29

Customized Devices

What has excited most about this technology is the prospect of developing customized devices. This includes the ability to produce implants (eg, breast and facial), designed in the office setting and generated to complement patients’ individual anatomical needs.7 Similarly, it can be used to create precontoured plates and help to plan for potential bone graft harvest geometry before facial fracture fixation, which has been successfully implemented previously.9,30 In addition to being used for bony reconstruction, 3D printing can also help in soft-tissue reconstruction as demonstrated in patients with anotia requiring auricular reconstruction.3,31 Perhaps further into the future, it will be used to make individualized extremity prostheses.7

THE STATE OF SURGERY IN DEVELOPING COUNTRIES

Before attempting to describe the potential applications of 3D printing in the developing world, it is vital that the challenges at hand be properly understood. There is no universally agreed-upon criterion for what constitutes a developing country. However, general reference points such as Gross Domestic Product per capita are often used.32 The International Statistical Institute employs the World Bank classification which defines a developing country by its Gross National Income per capita per year. Countries with a Gross National Income of $11,905 or less are deemed developing.33

The volume of surgery performed worldwide is large, and this volume ranges between 187.2 million and 281.2 million cases annually, exceeding the yearly volume of childbirth.34 73.6% of these surgical procedures are performed in developed countries (which account for 30.2% of the world’s population), whereas only 3–5% of all operations undertaken are done in the poorest 34.8%. Although fewer than a third of the world’s people with an annual per-person health expenditure of $400 or more undergo three quarters of surgical procedures, those residing in nations with a per-head expenditure of $100 or less may be subject to a lack of timely and appropriate delivery of basic surgical services for various reasons. There is a large disparity in access to healthcare between poor and rich countries.34 Although surgery has been viewed for a long time as a high-cost treatment, it is now recognized as a public-health intervention aimed at preventing disability and death.35 Furthermore, there is a growing body of evidence that supports the notion of surgical services being comparable from a cost-effective perspective to primary care interventions.35–38 The obstacles preventing delivery of healthcare in developing countries include inadequate physical resources and poor infrastructure. In addition, a majority of patients reside in the rural setting and therefore lack access to adequate surgical services found only at tertiary medical centers in urban areas. Another major concern is the lack of trained physicians and other healthcare workers who choose to emigrate from their home countries in search of a better life. This in turn creates a void at the primary health facilities, where care is administered by nonspecialists or even nonmedical personnel, many of whom do not have proper training.39

In an attempt to address the current healthcare situation in the world’s poorest countries, the World Health Organization established the Clinical Procedures Unit in its Department of Essential Health Technologies, which initiated the Emergency and Essential Surgical Care Project (EESC).39–41 The goal of the EESC is the delivery of essential surgical and anesthetic services to everyone in low-income and middle-income countries.39 It outlines the World Health Organization’s minimum standards and technologies for essential surgical care. To date, EESC workshops have been held in 24 countries. These workshops are organized in collaboration with the Ministries of Health and both local and international partners.40 This training program calls to attention simple and cost-effective means for managing surgically treatable disorders at primary healthcare facilities. Furthermore, it promotes a basic level of infrastructure and technology to ensure safe performance of procedures and encourages not only raising the number of trained healthcare providers but also enhancing their skills. The development of strategies to promote delivery of essential surgical services in middle- and low-income countries based on ethical, practical, scientifically sound, and socially acceptable methods and technology may help to reduce the burden of disability and death in these regions.39

USES OF 3D PRINTING IN DEVELOPING COUNTRIES

Over the course of the year, numerous reports have emerged on how 3D printing technology will change the manufacturing industry. However, the question remains as to the capability of this technology to become economically and environmentally sustainable and if it holds much promise. The potential uses of 3D printing in developing countries are starting to surface. (See Video, Supplemental Digital Content 1, which demonstrates a three dimensional printed template for titanium plate adaptation being created in Egypt. The process took more than 4 hours and the video has been sped up to display the entire process. This video is available in the “Related Videos” section of the Full-Text article on PRSGlobalOpen.com or available at http://links.lww.com/PRSGO/A112.)

Video.

Supplemental Digital Content 1, which demonstrates a three dimensional printed template for titanium plate adaptation being created in Egypt. The process took more than 4 hours and the video has been sped up to display the entire process. This video is available in the “Related Videos” section of the Full-Text article on PRSGlobalOpen.com or available a. http://links.lww.com/PRSGO/A112.

Nonmedical Uses

Construction of Homes

There are over 1 billion people living in slums, sleeping and eating under unsanitary conditions, and with little protection from extremes of weather.2 In underdeveloped countries, traditional construction methods are expensive; they take time and are inefficient as a result of poor regulation. Recently, 3D printing has been touted as means to build entire homes in a process termed “contour crafting.” The Department of Engineering at the University of Southern California is at the forefront of testing this technology. They support the notion that everything including floors, walls, plumbing, and electricity can be completed in as quickly as 20 hours. The potential to develop strong and safe housing through “contour crafting” may vastly improve the quality of life for so numerous people.2

Food

At least 1 million malnourished children die each year. An additional 34 million children suffer from severe acute malnutrition.42 A major step toward attempting ending world hunger is the ability to manufacture cheap, nutritious food. In 2013, the National Aeronautics and Space Administration awarded an engineering firm based in Texas a 6-month grant worth $125,000 to create the world’s first 3D food printer.43 It was announced at the 2014 Consumer Electronics Symposium in Las Vegas that 2 food-creating 3D printers will be released later in the year. Both models have the ability to print using chocolate or sugar infused with vanilla, mint, sour apple, cherry, and watermelon flavors. This technology has the potential to be life-saving for the many malnourished children in the developing world.44

Water and Sanitation

Over 3.4 million people each year die from water- and sanitation-related issues; 99% of these deaths occur in the developing world. To put things into perspective, an American taking a 5-minute shower uses more water than the average person living in a slum, in a developing country, would use in an entire day. Lack of clean water and proper sanitation kills children at a rate equal to a jumbo jet crashing every 4 hours.45 Engineers from the University of Washington are partnering with the charity “Water for Humans” to use 3D printing techniques for constructing toilets and rainwater collectors. Furthermore, they plan to teach local entrepreneurs in developing countries how to use, build, and maintain these 3D printers. Once this technology is established for toilets and water collectors, they hope to introduce additional products. The first trial will take place in Oaxaca, Mexico.46

Boats

In an attempt to conserve rare species of trees such as teak, which is used to build small boats in West Africa, there are efforts underway to manufacture 3D-printed vessels from waste plastic alternatively.46

Disaster Relief

It has been proposed that 3D printers shipped to a disaster zone can be used to produce medical supplies to help the injured. Indeed, more advanced 3D printers can be configured to operate on solar power and used in areas where power lines have been cut.47

Shoes

An idea out of Kenya’s University of Nairobi has advocated for the production of 3D-printed shoes to help solve Kenya’s jigger problem. Jiggers are tiny parasites resembling fleas that are embedded in the hands and feet of animals and humans alike. They can elicit severe inflammatory reactions causing autoamputation and may even promote secondary infection such as tetanus. Shoes would be produced from reused plastic and also be recyclable once they are worn out.48

Medical Uses

For many of the nonprofit medical clinics and academic centers in the developing world surviving on governmental support and/or private donations, the many advanced applications of 3D printing in medicine are just not feasible. Even the most basic supplies can sometimes be costly and the wait for simple items to be shipped from a distant city or even from overseas can take too much time. Despite this, numerous different uses of this technology have recently surfaced.

Basic Medical Supplies

The development of a 3D-printed finger splint was recently recognized by the United States Army and Air Force who awarded its inventor, Ian McHale, a senior at Steinert High School, for his idea. The goal is not only to inexpensively make (costing about 2 cents apiece) splints but also to circumvent the need for developing countries to ship large supplies of splints from overseas. For small clinics located away from major cities, 3D printing will surely be practical when supplies run low. This is especially important in farming communities where patients from the nearby fields who come in with work-related injuries could be outfitted with custom splints that are printed as needed. This splint prototype serves as a stepping stone toward rectifying the problem of sparse availability of medical supplies seen in developing nations.49 Already in Haiti, a 3D printing laboratory has been established that produces umbilical clamps for a local hospital.

Having a medical 3D printer following a major disaster such as hurricane or tsunami will permit the production of crutches, splints, and whatever else is needed on the ground, instead of having to ship everything. Moreover, if a condition is not life threatening, triage teams can print out casts or splints to take care of people with broken bones by simply inputting the required data into a system. Supplies would be available on a case-by-case basis without being wasteful.47

Vaccination and Medication

The concept of VaxBeads, which are 3D-printed beads that represent different vaccines, was named the winner of Michigan Technological University’s Printers for Peace Contest. The idea is for patients to wear these beads as a bracelet to serve as a visual medical chart. Each VaxBead string is personalized to the patient and is printed out with their initials, date of birth, and an identifying number. To take this idea a step further, it has been suggested that these “beads” also be representative of patient medications including dosages. Often, due to inaccurate record keeping or incomplete clinical files, patients in poorer countries may not be attentive to the exact name and dosage of the pills that they are taking. This finding can be especially dangerous when considering the many issues that antidiabetic or antihypertensive medications can cause.50

Laboratory Equipment

3D printing has also been suggested for use in remote and underfunded medical clinics for the production of laboratory equipment.51 Indeed, if a 3D printer, itself, can assembled de novo from 3D-printed parts, there are many uses that we are just discovering.

Prosthetic Limbs

In April 2012, Time magazine reported on a company called “Not Impossible,” a research firm that specializes in undertaking difficult healthcare challenges using low-cost, open-source methods. “Not Impossible” has started to manufacture low-cost high-tech prosthetic limbs with controllable fingers using 3D printing in war-torn Sudan. Dr. Tom Catena, an American surgeon, who has long been involved in providing healthcare to patients in the developing world, has joined forces with the co-founder and CEO of “Not Impossible,” Mick Ebeling, to set up a laboratory at a local hospital that utilizes consumer-grade 3D printers, which create low-cost prosthetic limbs, designed to be simple and affordable enough for anyone who needs one. A prosthetic arm produced at this laboratory takes 6 hours to make and costs $100. Although refined versions of the original design may improve on its functionality, these limbs have already likely restored a significant measure of independence to amputees. This effort represents a huge step forward in providing high-quality healthcare for those in poorer nations suffering from debilitating ailments.52–54 Moreover, 3D printing is not just limited to helping individuals living in war zones but may also prove useful in those suffering from gangrene or severe diabetes necessitating amputation.51

COST CONSIDERATIONS FOR 3D PRINTING

With advancing technology and falling prices in recent years, domestic 3D printers are now available in the United States for less than $1000. Although plastic has primarily been used for printed objects or “printouts,” attempts are being made to make metal and edible materials more affordable. The Filabot, developed by Tyler McNaney, looks to solve 2 of the biggest issues with 3D printing: to eliminate the cost of currently used plastic filaments ($40 per 1-kg spool) and to rid any waste produced. The device accomplishes this goal by melting existing plastic waste into the filament, thereby recycling and producing more filaments.53 In addition, 3D printing could markedly reduce carbon emission from factories by reducing shipping costs. Additive manufacturing by nature also produces much less waste.53 This technology is already proving helpful in numerous developing countries, and as commercially available 3D printers fall below the $500 mark, 3D printers will become more common.47 By 2019, the worldwide market for 3D printing is expected to double to more than $6 billion.53

CONCLUSIONS

3D printing offers the possibility of manufacturing precisely designed objects inexpensively and readily. These may potentially include the production of basic medical supplies, vaccination beads, laboratory equipment, and prosthetic limbs. It has the ability to promote initiatives across the entire developing world, increasing living standards and providing a higher quality of healthcare to its residents. There are still numerous untapped applications for 3D printing in medicine that have yet to surface, but if harnessed correctly may positively affect millions of lives.

Footnotes

Disclosure: The authors have no financial interest to declare in relation to the content of this article. The Article Processing Charge was paid for by PRS GO at the discretion of the Editor-in-Chief.

REFERENCES

- 1.Hoy MB. 3D printing: making things at the library. Med Ref Serv Q. 2013;32:94–99. doi: 10.1080/02763869.2013.749139. [DOI] [PubMed] [Google Scholar]

- 2.Kitchen S. 3D printing and the 3rd world: “Contour Crafting” may offer a solution to the world’s housing crisis. 2014. Available at: https://medium.com/thre3d-printing/f4b527b3e799. Accessed April 25, 2014.

- 3.Lindsay RW, Herberg M, Liacouras P. The use of three-dimensional digital technology and additive manufacturing to create templates for soft-tissue reconstruction. Plast Reconstr Surg. 2012;130:629e–631e. doi: 10.1097/PRS.0b013e318262f509. [DOI] [PubMed] [Google Scholar]

- 4.Rogers CM, Morris GE, Gould TW, et al. A novel technique for the production of electrospun scaffolds with tailored three-dimensional micro-patterns employing additive manufacturing. Biofabrication. 2014;6:035003. doi: 10.1088/1758-5082/6/3/035003. [DOI] [PubMed] [Google Scholar]

- 5.Dimas LS, Buehler MJ. Modeling and additive manufacturing of bio-inspired composites with tunable fracture mechanical properties. Soft Matter. 2014;10:4436–4442. doi: 10.1039/c3sm52890a. [DOI] [PubMed] [Google Scholar]

- 6.Gerstle TL, Ibrahim AM, Kim PS, et al. A plastic surgery application in evolution: three-dimensional printing. Plast Reconstr Surg. 2014;133:446–451. doi: 10.1097/01.prs.0000436844.92623.d3. [DOI] [PubMed] [Google Scholar]

- 7.Rengier F, Mehndiratta A, von Tengg-Kobligk H, et al. 3D printing based on imaging data: review of medical applications. Int J Comput Assist Radiol Surg. 2010;5:335–341. doi: 10.1007/s11548-010-0476-x. [DOI] [PubMed] [Google Scholar]

- 8.Schmidt C, Hung C. 3-D printing; seeing the world in a new dimension.. Twelfth Annual Freshman Conference. Session A5 Mechanical Engineering.2012. [Google Scholar]

- 9.D’Urso PS, Earwaker WJ, Barker TM, et al. Custom cranioplasty using stereolithography and acrylic. Br J Plast Surg. 2000;53:200–204. doi: 10.1054/bjps.1999.3268. [DOI] [PubMed] [Google Scholar]

- 10.Faber J, Berto PM, Quaresma M. Rapid prototyping as a tool for diagnosis and treatment planning for maxillary canine impaction. Am J Orthod Dentofacial Orthop. 2006;129:583–589. doi: 10.1016/j.ajodo.2005.12.015. [DOI] [PubMed] [Google Scholar]

- 11.Müller A, Krishnan KG, Uhl E, et al. The application of rapid prototyping techniques in cranial reconstruction and preoperative planning in neurosurgery. J Craniofac Surg. 2003;14:899–914. doi: 10.1097/00001665-200311000-00014. [DOI] [PubMed] [Google Scholar]

- 12.Canstein C, Cachot P, Faust A, et al. 3D MR flow analysis in realistic rapid-prototyping model systems of the thoracic aorta: comparison with in vivo data and computational fluid dynamics in identical vessel geometries. Magn Reson Med. 2008;59:535–546. doi: 10.1002/mrm.21331. [DOI] [PubMed] [Google Scholar]

- 13.Tek P, Chiganos TC, Mohammed JS, et al. Rapid prototyping for neuroscience and neural engineering. J Neurosci Methods. 2008;172:263–269. doi: 10.1016/j.jneumeth.2008.03.011. [DOI] [PubMed] [Google Scholar]

- 14.Kim MS, Hansgen AR, Wink O, et al. Rapid prototyping: a new tool in understanding and treating structural heart disease. Circulation. 2008;117:2388–2394. doi: 10.1161/CIRCULATIONAHA.107.740977. [DOI] [PubMed] [Google Scholar]

- 15.Sulaiman A, Boussel L, Taconnet F, et al. In vitro non-rigid life-size model of aortic arch aneurysm for endovascular prosthesis assessment. Eur J Cardiothorac Surg. 2008;33:53–57. doi: 10.1016/j.ejcts.2007.10.016. [DOI] [PubMed] [Google Scholar]

- 16.Pekkan K, Dasi LP, de Zélicourt D, et al. Hemodynamic performance of stage-2 univentricular reconstruction: Glenn vs. hemi-Fontan templates. Ann Biomed Eng. 2009;37:50–63. doi: 10.1007/s10439-008-9591-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Mannoor MS, Jiang Z, James T, et al. 3D printed bionic ears. Nano Lett. 2013;13:2634–2639. doi: 10.1021/nl4007744. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 18.Miller JS, Stevens KR, Yang MT, et al. Rapid casting of patterned vascular networks for perfusable engineered three-dimensional tissues. Nat Mater. 2012;11:768–774. doi: 10.1038/nmat3357. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Mironov V, Boland T, Trusk T, et al. Organ printing: computer-aided jet-based 3D tissue engineering. Trends Biotechnol. 2003;21:157–161. doi: 10.1016/S0167-7799(03)00033-7. [DOI] [PubMed] [Google Scholar]

- 20.Visconti RP, Kasyanov V, Gentile C, et al. Towards organ printing: engineering an intra-organ branched vascular tree. Expert Opin Biol Ther. 2010;10:409–420. doi: 10.1517/14712590903563352. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Suzuki M, Ogawa Y, Kawano A, et al. Rapid prototyping of temporal bone for surgical training and medical education. Acta Otolaryngol. 2004;124:400–402. doi: 10.1080/00016480410016478. [DOI] [PubMed] [Google Scholar]

- 22.Armillotta A, Bonhoeffer P, Dubini G, et al. Use of rapid prototyping models in the planning of percutaneous pulmonary valved stent implantation. Proc Inst Mech Eng H. 2007;221:407–416. doi: 10.1243/09544119JEIM83. [DOI] [PubMed] [Google Scholar]

- 23.Kalejs M, von Segesser LK. Rapid prototyping of compliant human aortic roots for assessment of valved stents. Interact Cardiovasc Thorac Surg. 2009;8:182–186. doi: 10.1510/icvts.2008.194134. [DOI] [PubMed] [Google Scholar]

- 24.Giesel FL, Hart AR, Hahn HK, et al. 3D reconstructions of the cerebral ventricles and volume quantification in children with brain malformations. Acad Radiol. 2009;16:610–617. doi: 10.1016/j.acra.2008.11.010. [DOI] [PubMed] [Google Scholar]

- 25.Guarino J, Tennyson S, McCain G, et al. Rapid prototyping technology for surgeries of the pediatric spine and pelvis: benefits analysis. J Pediatr Orthop. 2007;27:955–960. doi: 10.1097/bpo.0b013e3181594ced. [DOI] [PubMed] [Google Scholar]

- 26.Hurson C, Tansey A, O’Donnchadha B, et al. Rapid prototyping in the assessment, classification and preoperative planning of acetabular fractures. Injury. 2007;38:1158–1162. doi: 10.1016/j.injury.2007.05.020. [DOI] [PubMed] [Google Scholar]

- 27.Paiva WS, Amorim R, Bezerra DA, et al. Application of the stereolithography technique in complex spine surgery. Arq Neuropsiquiatr. 2007;65:443–445. doi: 10.1590/s0004-282x2007000300015. [DOI] [PubMed] [Google Scholar]

- 28.Wurm G, Tomancok B, Pogady P, et al. Cerebrovascular stereolithographic biomodeling for aneurysm surgery. Technical note. J Neurosurg. 2004;100:139–145. doi: 10.3171/jns.2004.100.1.0139. [DOI] [PubMed] [Google Scholar]

- 29.D’Urso PS, Barker TM, Earwaker WJ, et al. Stereolithographic biomodelling in cranio-maxillofacial surgery: a prospective trial. J Craniomaxillofac Surg. 1999;27:30–37. doi: 10.1016/s1010-5182(99)80007-9. [DOI] [PubMed] [Google Scholar]

- 30.Singare S, Liu Y, Li D, et al. Individually prefabricated prosthesis for maxilla reconstruction. J Prosthodont. 2008;17:135–140. doi: 10.1111/j.1532-849X.2007.00266.x. [DOI] [PubMed] [Google Scholar]

- 31.Subburaj K, Nair C, Rajesh S, et al. Rapid development of auricular prosthesis using CAD and rapid prototyping technologies. Int J Oral Maxillofac Surg. 2007;36:938–943. doi: 10.1016/j.ijom.2007.07.013. [DOI] [PubMed] [Google Scholar]

- 32.Wikipedia. Developing country. 2014. Available at: http://en.wikipedia.org/wiki/Developing_country#Definition. Accessed April 28, 2014.

- 33.The International Statistical Institute. Developing countries. 2014. Available at: http://www.isi-web.org/component/content/article/5-root/root/81-developing. Accessed April 28, 2014.

- 34.Weiser TG, Regenbogen SE, Thompson KD, et al. An estimation of the global volume of surgery: a modelling strategy based on available data. Lancet. 2008;372:139–144. doi: 10.1016/S0140-6736(08)60878-8. [DOI] [PubMed] [Google Scholar]

- 35.Debas HT, Gosselin RA, McCord C, et al. Disease Control Priorities in Developing Countries. 2nd ed. New York, N.Y.: Oxford University Press; 2006. [Google Scholar]

- 36.Gosselin RA, Thind A, Bellardinelli A. Cost/DALY averted in a small hospital in Sierra Leone: what is the relative contribution of different services? World J Surg. 2006;30:505–511. doi: 10.1007/s00268-005-0609-5. [DOI] [PubMed] [Google Scholar]

- 37.McCord C, Chowdhury Q. A cost effective small hospital in Bangladesh: what it can mean for emergency obstetric care. Int J Gynaecol Obstet. 2003;81:83–92. doi: 10.1016/s0020-7292(03)00072-9. [DOI] [PubMed] [Google Scholar]

- 38.Javitt JC. The cost-effectiveness of restoring sight. Arch Ophthalmol. 1993;111:1615. doi: 10.1001/archopht.1993.01090120037015. [DOI] [PubMed] [Google Scholar]

- 39.Spiegel DA, Gosselin RA. Surgical services in low-income and middle-income countries. Lancet. 2007;370:1013–1015. doi: 10.1016/S0140-6736(07)61457-3. [DOI] [PubMed] [Google Scholar]

- 40.Cherian MN, Noel L, Buyanjargal Y, et al. Essential emergency surgical, procedures in resource-limited facilities: a WHO workshop in Mongolia. World Hosp Health Serv. 2004;40:24–29. [PubMed] [Google Scholar]

- 41.Bickler SW, Spiegel DA. Global surgery–defining a research agenda. Lancet. 2008;372:90–92. doi: 10.1016/S0140-6736(08)60924-1. [DOI] [PubMed] [Google Scholar]

- 42.Action Against Hunger. ACF-USA nutrition. 2013. Available at: http://www.actionagainsthunger.org/impact/nutrition. Accessed April 28, 2014.

- 43.Pfeiffer E. NASA awards grant for 3-D food printer; could it end world hunger? Yahoo! News. 2013. Available at: http://news.yahoo.com/blogs/the-sideshow/nasa-awards-grant-3d-food-printer-could-end-194050661.html. Accessed April 28, 2014.

- 44.Kelion L. CES 2014: 3D food printers create sweets and chocolates. BBC News. 2014. Available at: http://www.bbc.com/news/technology-25647918. Accessed April 28, 2014.

- 45.Millions lack safe water. 2014. Available at: http://water.org/water-crisis/water-facts/water/. Accessed April 28, 2014.

- 46.3D printing: a third-world dimension. The Economist. 2012. Available at: http://www.economist.com/news/science-and-technology/21565577-new-manufacturing-technique-could-help-poor-countries-well-rich-ones. Accessed April 28, 2014.

- 47.Koebler J. Is 3D printing the future of disaster relief? Vice. 2013. Available at: http://motherboard.vice.com/blog/is-3d-printing-the-future-of-disaster-relief. Accessed April 30, 2014.

- 48.3D printed shoes in Kenya, to alleviate jigger sufferers. 3D Printing Buzz. 2012. Available at: http://textually.org/3DPrinting/2012/12/031454.htm. Accessed April 30, 2014.

- 49.Molitch-Hou M. High school senior 3D prints finger splint. 3D Printing Industry. 2013. Available at: http://3dprintingindustry.com/2013/06/07/high-school-senior-3d-prints-finger-splint/. Accessed April 30, 2014.

- 50.Molitch-Hou M. “3D Printers for Peace” contest - the results are in. 3D Printing Industry. 2013. Available at: http://3dprintingindustry.com/2013/09/06/3d-printers-for-peace-contest-the-results-are-in/. Accessed April 30, 2014.

- 51.Molitch-Hou M. How a medical clinic in the bolivian rainforest might use 3D printing. 3D Printing Industry. 2014. Available at: http://3dprintingindustry.com/2014/02/18/medical-clinic-bolivian-rainforest-might-use-3d-printing/. Accessed April 30, 2014.

- 52.McCracken H. How a Time article led to the invention of a $100 3D-printed artificial limb. Time. 2014. Available at: http://techland.time.com/2014/01/07/how-a-time-article-led-to-the-invention-of-a-100-3d-printed-artificial-limb/#ixzz2plDB48q8. Accessed April 28, 2014.

- 53.Nowak P. The promise and peril of 3D printing. UTNE. 2013. Available at: http://www.utne.com/science-technology/promise-and-peril-3d-printing-zm0z13ndzlin.aspx#axzz2zuRJOD1Q. Accessed April 28, 2014.

- 54.Chivers T. Printing new lives: how 3D printing could change the developing world. The Telegraph. 2014. Available at: http://blogs.telegraph.co.uk/news/tomchiversscience/100253441/printing-new-lives-how-3d-printing-could-change- the-developing-world/. Accessed April 28, 2014.