Abstract

Background

Coal plays a crucial role in the U.S. economy yet underground coal mining continues to be one of the most dangerous occupations in the country. In addition, there are large variations in both profitability and the incidence of occupational injuries across mines.

Objective

The objective of this study was to examine the association between profitability and the incidence rate of occupational injuries in U.S. underground coal mines between 1992 and 2008.

Data and method

We used mine-specific data on annual hours worked, geographic location, and the number of occupational injuries suffered annually from the employment and accident/injury databases of the Mine Safety and Health Administration, and mine-specific data on annual revenue from coal sales, mine age, workforce union status, and mining method from the U.S. Energy Information Administration. A total of 5669 mine-year observations (number of mines × number of years) were included in our analysis. We used a negative binomial random effects model that was appropriate for analyzing panel (combined time-series and cross-sectional) injury data that were non-negative and discrete. The dependent variable, occupational injury, was measured in three different and non-mutually exclusive ways: all reported fatal and nonfatal injuries, reported nonfatal injuries with lost workdays, and the ‘most serious’ (i.e. sum of fatal and serious nonfatal) injuries reported. The total number of hours worked in each mine and year examined was used as an exposure variable. Profitability, the main explanatory variable, was approximated by revenue per hour worked. Our model included mine age, workforce union status, mining method, and geographic location as additional control variables.

Results

After controlling for other variables, a 10% increase in real total revenue per hour worked was associated with 0.9%, 1.1%, and 1.6% decrease, respectively, in the incidence rates of all reported injuries, reported injuries with lost workdays, and the most serious injuries reported.

Conclusion

We found an inverse relationship between profitability and each of the three indicators of occupational injuries we used. These results might be partially due to factors that affect both profitability and safety, such as management or engineering practices, and partially due to lower investments in safety by less profitable mines, which could imply that some financially stressed mines might be so focused on survival that they forgo investing in safety.

Keywords: Underground mines, Profitability, Injury, Negative binomial, Panel data

1. Introduction

Coal plays a crucial role in the U.S. economy. In 2009, 1.1 billion tons of mined coal produced more than half of all the electricity used in the country and generated more than $4 billion in export revenue. During the same year, approximately 90,000 workers were employed in coal production, more than half of whom worked underground (United Mine Workers of America, n.d.; PBS, n.d.; Energy Information Administration (EIA), 2010).

Underground coal mining has been and remains one of the most dangerous occupations in the country (Zimmerman, 1981; Bennett and Passmore, 1984; Reardon, 1993; Toscano and Windau, 1993; Kowalski-Trakofler et al., 2005; Esterhuizen and Gürtunca, 2006). In recent years, the fatal occupational injury rate in underground coal mining has been six times higher than that in all private industry (CDC, 2001; Groves et al., 2007; Bureau of Labor Statistics (BLS), 2010). Studies have also shown that the costs associated with occupational fatal and nonfatal injuries in coal mines have been increasing (BLS, 2007; National Institute for Occupational Safety and Health (NIOSH), 2008; Margolis, 2010; Moore et al., 2010).

Several explanations for the high number of injuries occurring in some mines have been proposed in the literature, including geological factors such as low seam height (Boden, 1985; Fotta and Mallett, 1997), room-and-pillar mining method (Pfleider and Krug, 1973; Boden, 1985; Pappas et al., 2003), small mine size (The President’s Commission on Coal, 1980; National Research Council, 1982; Fotta and Mallett, 1997; Grayson, 2001), nonunionized workforce (National Research Council, 1982; Appleton and Baker, 1984; Morantz, 2011), less experienced and younger miners (Hull et al., 1996; Margolis, 2010), inadequate miner training (Dames and Moore, 1977; FlorJancic, 1981; Zimmerman, 1981), incomplete understanding of the return on safety investments (Brody et al., 1990), inadequate safety regulations (The President’s Commission on Coal, 1980; Mendeloff, 1980; FlorJancic, 1981; Neumann and Nelson, 1981), and no prior experience with disaster (Madsen, 2009). Some of these factors, such as geological conditions, mining method, and mine size, might reflect how “easy to mine” a particular mine might be. In addition, differences in the level of investment in occupational injury prevention might explain some of the variation in the incidence rate and severity of injuries among underground coal mines.

The link between the financial strength of mines and the incidence of occupational injuries has been explored through the correlation between productivity and safety in at least two major studies by the National Research Council (1982) and Grayson (2001). While these studies supported the industry belief that “a productive mine is a safe mine,” their findings were not very robust after controlling for other variables. One possible explanation may be that productivity, measured in tons of coal produced per hour, is an imperfect measure of a mine’s financial strength. For example, in 2009, the average price of underground coal was $32.32/ton in Utah, while it was $78.75/ton in Virginia (EIA, 2010). Therefore, a mine in Virginia that is less productive than a mine in Utah might actually be more profitable than the mine in Utah.

Financially strong mines can reduce the incidence of occupational injuries by investing more in worker safety. For example, they can more easily improve the overall mining system, hire experienced workers, and provide comprehensive safety training to their workers than mines that are struggling to survive. There is evidence that investments in safety can boost the profitability of mines by lowering several categories of employer costs, such as insurance and wage premiums, workers’ compensation benefit payments, and frequent production disruptions associated with injuries (Brody et al., 1990; Cutler and James, 1996; Yakovlev and Sobel, 2010; Moore et al., 2010). Similar results have also been reported in other industries such as nuclear power plants (Waddock and Graves, 1997).

If a mine is not financially strong, however, employers might not believe they can afford to invest in occupational injury prevention, especially if the injuries targeted by the investment have a relatively low expected probability of occurring in the absence of prevention (Hopkins, 1999). This means that less profitable mines might not shift scarce financial resources from producing coal to investing in occupational injury prevention because the short-term benefits might not seem to exceed the costs of prevention. As a result, less profitable mines might be less likely to invest as much in safety as more profitable mines would.

In this study, we examined whether the profitability of underground coal mines was associated with the incidence rate of occupational injuries. We hypothesized that, after controlling for mine age, workforce union status, mining method, and geographic region, the incidence rates of all reported injures, reported injuries with lost workdays, and the most serious injuries reported would be higher in less profitable mines.

2. Methods

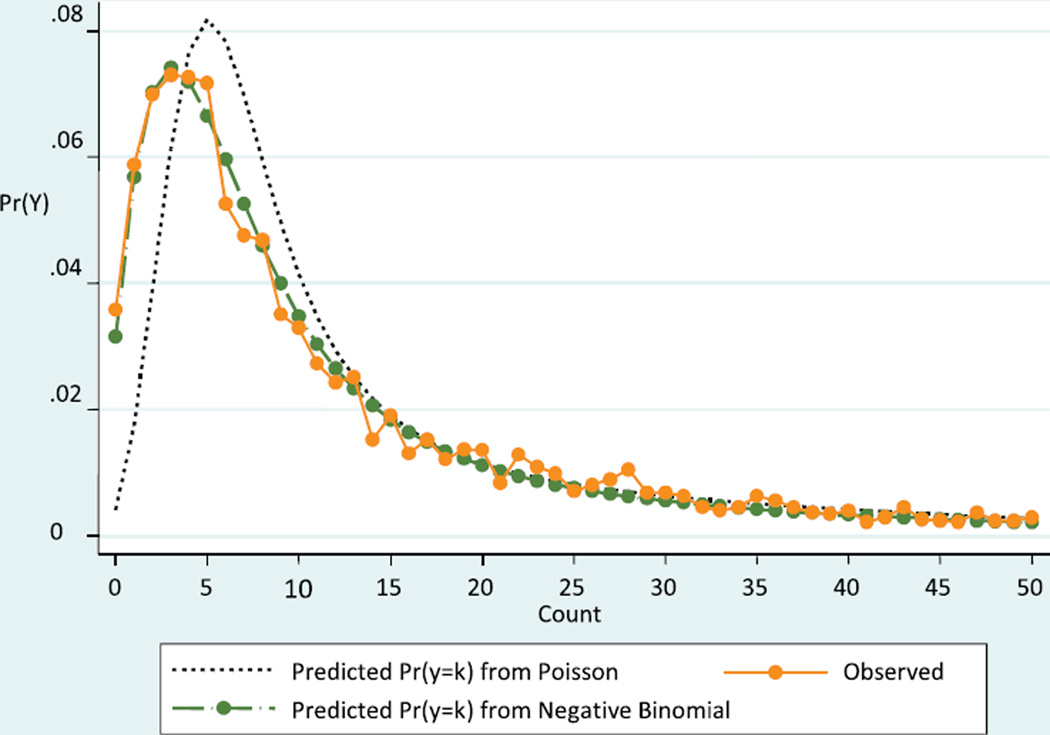

When using discrete and non-negative data, such as number of injuries, it is common to use count data models, such as Poisson or negative binomial. To determine which model to use, we examined the fitness of each distribution to our dependent variables. Fig. 1 presents the fitness of the Poisson and the negative binomial models using the number of all injures as an example. Details about the data used are provided in Section 3.

Fig. 1.

Comparison of the negative binomial and Poisson models: all reported injuries in the 5669 mine-year records used.

The Poisson model often does not fit actual data well due to its assumptions of equidispersion and independence of events. In our case, the Poisson model underestimates the predicted number of mine-year observations with no injury events. We used the negative binomial model because it fit all the dependent variable indicators we used better than the regular Poisson model.

While count data models treat injury variables as being independent across time, mine-specific variables, such as geological conditions and management practices, are more likely to be serially correlated. Therefore, we used a count data model for panels – that include cross-sectional and time-series data – with N number of mines and T number of years. In addition to controlling for observable individual mine heterogeneity, such as individual mine-specific characteristics that may include size, age, and mining method, analyzing panel data enables us to control for unobservable heterogeneity among individual mines (see for instance, Hsiao, 2003; Baltagi, 2009).

We assumed that each injury variable indicator (yit) takes a value of 0, 1, 2, 3, …, varies among mines i (i = 1, …, N) and over time t (t = 1, …, T), and has a negative binomial distribution that allows its variance to be greater than its mean. Following Hausman et al. (1984), the random effect overdispersion can be specified as:

| (1) |

where

| (2) |

and xit is a matrix of explanatory variables, β is a matrix of coefficients to be estimated, Γ is the gamma function, and δi is the dispersion parameter. The mean and variance of yit are given by:

| (3) |

and

| (4) |

Eqs. (3) and (4) indicate that the mean to the variance ratio is 1/(1 + δi), which can vary across mines but is constant through time. If δ is zero, Eq. (1) collapses to a Poisson model since E(yit) = var(yit) = λit. The maximum likelihood function can be formulated and the β coefficients can be estimated, based on Eq. (1) (see Hausman et al., 1984; Liang and Zeger, 1986; Cameron and Trivedi, 1998; Greene, 2007 for the maximum likelihood function).

The exponential function in Eq. (2) ensures that the number of injuries always takes a non-negative value. The way the equation is presented implicitly assumes that workers in each mine have an equal risk of injury or exposure to risk and also that the number of injuries suffered per year in each mine would depend on the number of workers employed and exposed during that year. For instance, keeping all other variables constant, the expected number of injuries in large mines where 500 or more workers are exposed to 1 million or more hours of mining activity per year (calculated by multiplying 500 workers by 2000 h worked by each worker per year) would be higher than the number of injuries in very small mines where 50 or less workers are exposed to 100,000 or less hours of mining activity per year. In order to control for potential differences in exposure across mines of different sizes, we considered incidence rates of injuries (rather than total number of injuries) by including an exposure variable in Eq. (2). Differences in exposure duration can be incorporated in Eq. (2) by multiplying both of its sides by ξit:

| (5) |

| (6) |

where ξit is the exposure duration at mine i at time t.

Eq. (6) shows that the effect of exposure duration can be included in the model in logarithmic form. This means that the regression coefficient of exposure duration would be constrained to a value of 1 which enables us to express injury incidence rates as a function of other explanatory variables.

3. Data and measurement of variables

Two primary data sources were used in this study. The first includes the employment and accident/injury databases of the Mine Safety and Health Administration (MSHA) for the period 1992 through 2008 (see www.msha.gov/stats/statinfo.htm). NIOSH has converted some of these data into SPSS and dBase IV file formats (see www.cdc.gov/niosh/mining/data/). The MSHA employment data file contains basic information for each coal mine such as type (e.g. surface or underground), total number of hours worked per year, total tons of coal produced per year, and geographic location. The MSHA accident/injury data file contains detailed information on injuries, such as the date and type of injury, and the characteristics of injured workers. For this study we constructed three different injury indicators: the number of all fatal and nonfatal injuries, the number of all nonfatal injuries with lost workdays, and the number of the “most serious” injuries that included fatal and serious nonfatal injuries.

The number of all injuries and the number of injuries with lost workdays were measured using the respective injury type (injtype) variable from the MSHA accident/injury file. The number of the ‘most serious’ injuries, according to our definition, was derived from the accident code (acccode) variable from the MSHA accident/injury file. We combined MSHA’s acccode = 1 (‘fatal’) and acccode = 2 (‘serious’) to create our ‘most serious’ injuries variable. According to MSHA, an injury is coded as ‘serious’ (acccode = 2) if it has reasonable potential to cause death – see www.msha.gov/forms/7000-1.pdf. Note that all injuries were ‘reported’ injuries, and the three injury indicators were not mutually exclusive.

We merged the MSHA employment and accident/injury files using the ‘mineid’ variable that is included in each file. Mine-years that were reported in the employment file but were not found in the accident/injury file were considered to include no injuries (see also Poplin et al., 2006). To construct a consistent data set, we only included information on underground coal mines which produced at least 20,000 tons of coal per year. Very small mines that produced less than 20,000 tons per year accounted for less than 1% of the total hours worked in our data set and were considered unrepresentative of the industry as a whole.

Our second primary data source was EIA, which collects information on coal prices and other mine-level data from the mining industry. Through an Information Access Agreement between EIA and NIOSH, we were provided with mine-specific annual data on total revenue, mine age, workforce union status, and mining method. We merged the EIA data with MSHA data using the ‘mineid’ variable that was included in both.

Our study required a measure of mine profitability as the main explanatory variable. Conventionally, profit is measured by the difference between total revenue and total costs. EIA data include the total revenue obtained from coal sales for each mine but do not include information on other factor prices, such as non-labor operating costs (e.g. for roof support and ventilation), capital investments, depreciation, and depletion, which would be necessary to compute the full cost of coal production. However, underground coal mining is relatively labor intensive, and labor typically accounts for one-third to one-half of total production costs (Bibb and Hargrove, 1992). Therefore, we approximated profitability in a surrogate variable calculated as total revenue per hour worked.1 We used the Consumer Price Index for all items (www.gpoaccess.gov/eop/2010/B62.xls) to convert current dollars to constant (1977 = 100) dollars and adjust the profitability variable for inflation.

In summary, in this study, we used merged mine-level annual data from MSHA and EIA to construct a data set that included: the three indicators of injury described above as dependent (or outcome) variables, hours worked per year as an exposure variable, total annual revenue per hour worked as the main explanatory variable, and mine age, workforce union status, mining method, and geographic location as control variables.

4. Results

4.1. Descriptive statistics

Table 1 provides summary descriptive statistics for all the variables used in the analyses. For the 17 years in the period 1992–2008, our panel data set included 1407 mines resulting in 5669 records, each representing one underground mine-year with complete information.

Table 1.

Descriptive statistics for variables in the 5669a mine-year records used.

| Variable | Value |

|---|---|

| Total number of all reported fatal and nonfatal injuries | 87,080 |

| Total number of reported nonfatal injuries with lost workdays | 58,791 |

| Total number of the most serious injuries reported, including fatalities | 3423 |

| Total number of hours worked | 1.45 billion |

| Average incidence of all reported injuries per 100 FTE | 12.81 |

| Average incidence of reported injuries with lost workdays per 100 FTE | 8.84 |

| Average incidence of the most serious injuries reported per 100 FTE | 0.67 |

| Average real revenue per hours worked (indicator of profitability) | $43 |

| Average mine age in years (tracked since 1983b) | 8.26 |

| Unionized (%) | 45.84 |

| Longwall mining method (%) | 15.86 |

| Regionc (%) | |

| North | 15.73 |

| Central | 65.71 |

| Midwest | 9.74 |

| West | 6.44 |

| South | 2.38 |

Data were unbalanced. Information was available for only 25 mines (2.5%) for the entire 17-year-long period from 1992 to 2008.

Publically available MSHA data.

Data were assigned to one of five regions: North (PA, OH, MD, and northern WV), Central (southern WV, VA, TN, and eastern KY), Southern (AL), Midwest (western KY, IL, and IN), and West (all mines west of the Mississippi).

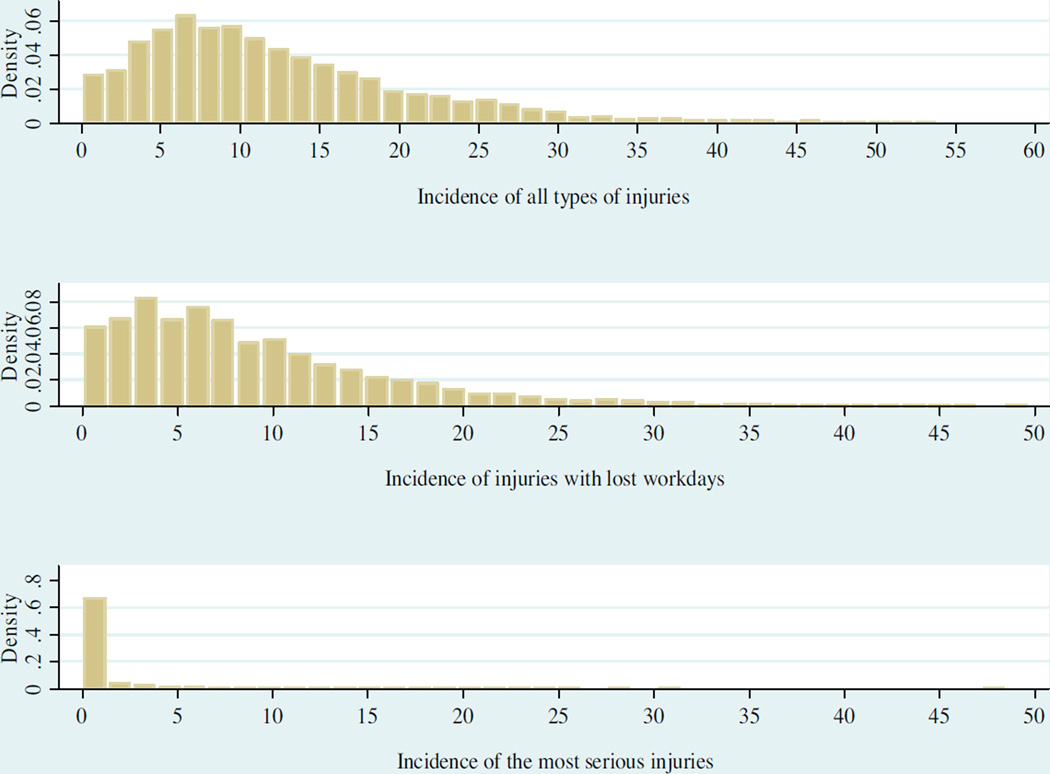

We used data on 87,080 (317 fatal and 86,763 nonfatal) injuries, 58,791 nonfatal injuries with lost workdays, 3423 ‘most serious’ injuries (including the 317 fatalities), and 1.45 billion h worked. Dividing the number of injuries by the total hours worked and assuming that 2000 h worked were equivalent to one full-time equivalent (FTE) worker, results in incidence rates of 12.81, 8.84, and 0.67 per 100 FTE workers, respectively, for each indicator of injury we used. Fig. 2 shows the histograms of the injury variables per 100 FTE workers. Throughout the rest of the paper, injury rates are expressed as number of injuries per 100 FTE workers.

Fig. 2.

Histograms of incidence rates of all reported injuries, reported injuries with lost workdays, and the most serious injuries reported per 100 FTE workers in the 5669 mine-year records used.

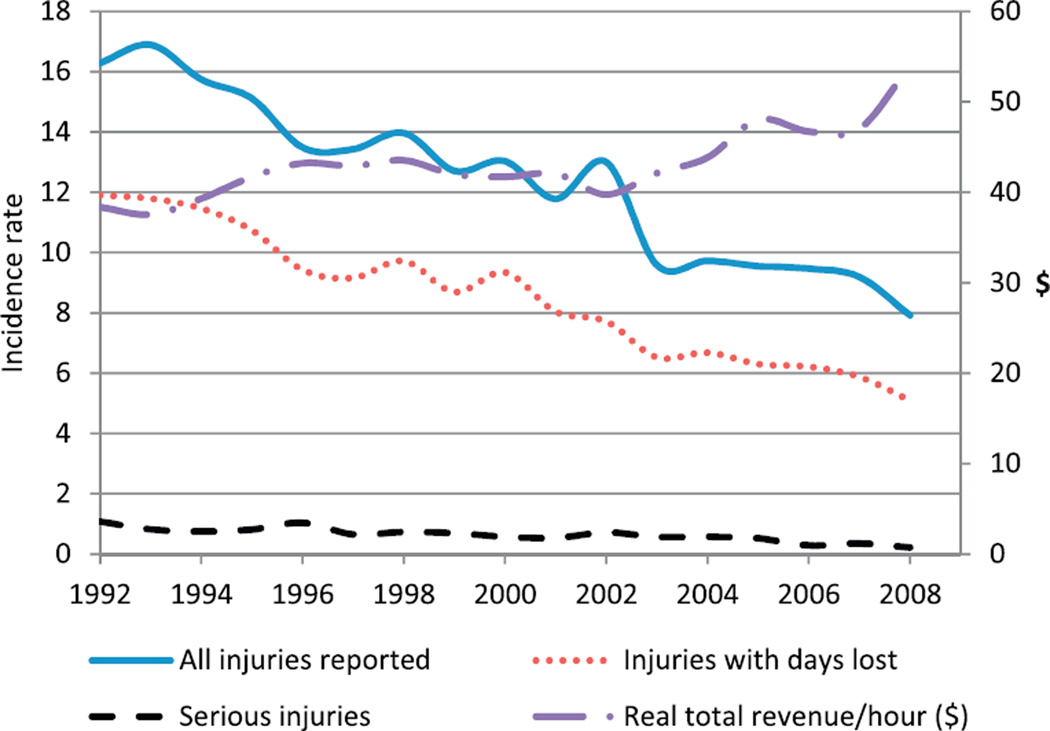

Fig. 3 presents the trend of these incidence rates and the real revenue per hour worked for the period 1992–2008. An overall downward trend can be observed in all three of our injury indicators; between 1992 and 2008, the incidence rates of all injuries, injuries with lost workdays, and the most serious injuries declined by 3.21%, 3.57%, and 4.96% annually, respectively. During the same time period, the average profitability of mines (real revenue per hour worked) grew by 2.55% annually. Nearly all of the increase in profitability occurred during the last 6 years of the time period studied.

Fig. 3.

Average trend of incidence rates of injuries and real total revenue per hour ($).

The average age of mines in our data set was 8.26 years. Interestingly, the share of unionized mines declined significantly from 1992, when 86% of the mines were unionized, to 2008, when only 13% were unionized. Longwall mines were represented in only 15.86% of the mine-years. Most of the mine-years in our data set were from smaller mines located in the Central region (65.71%), followed by the Northern region (15.73%).

5. Results of the negative binomial random effects model

Tables 2–4 present the results of the negative binomial random effects model for each dependent variable. Note again that the exposure variable was the number of hours worked in each mine during each year. The z-statistics tested the null hypothesis that the IRR = 1, i.e. that there was no relationship between the main explanatory or each control variable and the incidence rate of injuries. We also reported the 95% confidence intervals of the estimated IRR. The χ2 likelihood ratio test indicated that for all the injury indicators we examined, panel estimators were statistically significantly different from pooled (average) estimators (p < 0.001). The coefficients of ln_r and ln_s also indicated evidence of overdispersion. As is appropriate for negative binomial random effects models, we estimated McFadden’s (1974) pseudo R2 values using log likelihood values. Still, as indicated by Blomquist (1980), pseudo R2 values should be considered as rough goodness of fit indicators. The pseudo R2 values for all injuries, injuries with lost workdays, and the most serious injuries were 0.56, 0.68, and 0.21, respectively.

Table 2.

Incidence-rate ratios (IRR) and 95% confidence intervals (CI) for random effects negative binomial regression: all reported injuries in the 5669 mine-year records used.

| IRR | Std. err. | p > z | [95% CI] | ||

|---|---|---|---|---|---|

| Ln real revenue per hour worked | 0.911 | 0.012 | 0.000 | 0.887 | 0.935 |

| Mine age | 0.966 | 0.002 | 0.000 | 0.963 | 0.970 |

| Union status (union = 1) | 1.126 | 0.025 | 0.000 | 1.079 | 1.175 |

| Mining method (longwall = 1) | 0.865 | 0.031 | 0.000 | 0.806 | 0.929 |

| Region | |||||

| Central (reference) | |||||

| North | 1.062 | 0.047 | 0.172 | 0.974 | 1.157 |

| Midwest | 0.963 | 0.053 | 0.489 | 0.865 | 1.072 |

| West | 0.942 | 0.066 | 0.399 | 0.821 | 1.082 |

| South | 0.471 | 0.050 | 0.000 | 0.382 | 0.579 |

| Total hours worked | (Exposure) | ||||

| /ln_r | 1.851 | 0.061 | 1.732 | 1.970 | |

| /ln_s | 2.452 | 0.076 | 2.304 | 2.601 | |

| R | 6.368 | 0.386 | 5.655 | 7.172 | |

| S | 11.612 | 0.880 | 10.010 | 13.471 | |

| Number of observations | 5669 | ||||

| Number of groups | 1407 | ||||

| Obs. per group | |||||

| Min | 1 | ||||

| Max | 17 | ||||

| Average | 4 | ||||

| Wald χ2 (8) | 739.89 | ||||

| Log likelihood (prob > χ2) | −17,820 | ||||

| Pseudo R2 | 0.56 | ||||

Table 4.

Incidence-rate ratios (IRR) and 95% confidence intervals (CI) for random effects negative binomial regression: most serious injuries reported in the 5669 mine-year records used.

| IRR | Std. err. | p > z | [95% CI] | ||

|---|---|---|---|---|---|

| Ln real revenue per hour worked | 0.841 | 0.045 | 0.001 | 0.757 | 0.934 |

| Mine age | 0.947 | 0.007 | 0.000 | 0.933 | 0.962 |

| Union status (union = 1) | 0.960 | 0.077 | 0.608 | 0.820 | 1.123 |

| Mining method (longwall = 1) | 0.509 | 0.067 | 0.000 | 0.393 | 0.659 |

| Region | |||||

| Central (reference) | |||||

| North | 1.366 | 0.174 | 0.014 | 1.064 | 1.753 |

| Midwest | 0.682 | 0.098 | 0.008 | 0.515 | 0.904 |

| West | 1.500 | 0.297 | 0.041 | 1.017 | 2.212 |

| South | 0.655 | 0.145 | 0.055 | 0.425 | 1.009 |

| Total hours worked | (Exposure) | ||||

| /ln_r | 0.518 | 0.076 | 0.370 | 0.666 | |

| /ln_s | −0.004 | 0.109 | −0.218 | 0.211 | |

| R | 1.679 | 0.127 | 1.448 | 1.947 | |

| S | 0.996 | 0.109 | 0.804 | 1.235 | |

| Number of observations | 5669 | ||||

| Number of groups | 1407 | ||||

| Obs. per group | |||||

| Min | 1 | ||||

| Max | 17 | ||||

| Average | 4 | ||||

| Wald χ2 (8) | 191.64 | ||||

| Log likelihood (prob > χ2) | −4405 (0.000) | ||||

| Pseudo R2 | 0.21 | ||||

To facilitate interpretation, all estimates are presented as incidence rate ratios (IRR) rather than beta coefficients. IRR are the factors by which dependent variables (the three different injury indicators) should be multiplied for every unit increase in the explanatory variables and are defined as the exponential of the beta coefficients. An IRR of less than one indicates that an increase in the value of the explanatory variable resulted in a reduction in the incidence rate of injuries, while an IRR greater than one indicates that increasing the value of the explanatory variable increased the incidence rate of injuries.

The results presented in Table 2 indicated that a one unit increase in the log profitability was associated with a 9% decrease in the incidence rate of all injuries, while holding all the other (control) variables constant (p < 0.001, IRR = 0.91, 95% CI: 0.89, 0.94). The effect was even stronger for the other two injury indicators we used. As shown in Table 3, controlling for all other variables, a one unit increase in the log profitability was associated with an 11% decrease in the incidence rate of injuries with lost workdays (p < 0.001, IRR = 0.89, 95% CI: 0.86, 0.91). In the case of the most serious injuries (Table 4), the IRR of the log profitability was 0.84 (p = 0.001, 95% CI: 0.76, 0.93). This implies that a one unit increase in the log profitability was associated with a 16% decrease in the incidence rate of the most serious injuries, holding all else constant.

Table 3.

Incidence-rate ratios (IRR) and 95% confidence intervals (CI) for random effects negative binomial regression: reported injuries with lost workdays in the 5669 mine-year records used.

| IRR | Std. err. | p > z | [95% CI] | ||

|---|---|---|---|---|---|

| Ln real revenue per hour worked | 0.886 | 0.013 | 0.000 | 0.862 | 0.912 |

| Mine age | 0.962 | 0.002 | 0.000 | 0.958 | 0.966 |

| Union status (union = 1) | 1.170 | 0.028 | 0.000 | 1.117 | 1.226 |

| Mining method (longwall = 1) | 0.907 | 0.035 | 0.011 | 0.841 | 0.978 |

| Region | |||||

| Central (reference) | |||||

| North | 1.014 | 0.047 | 0.768 | 0.925 | 1.111 |

| Midwest | 0.953 | 0.055 | 0.402 | 0.851 | 1.067 |

| West | 0.897 | 0.068 | 0.148 | 0.774 | 1.040 |

| South | 0.709 | 0.083 | 0.003 | 0.564 | 0.891 |

| Total hours worked | (Exposure) | ||||

| /ln_r | 1.988 | 0.064 | 1.862 | 2.113 | |

| /ln_s | 2.265 | 0.079 | 2.110 | 2.420 | |

| R | 7.299 | 0.467 | 6.439 | 8.275 | |

| S | 9.632 | 0.761 | 8.250 | 11.245 | |

| Number of observations | 5669 | ||||

| Number of groups | 1407 | ||||

| Obs. per group | |||||

| Min | 1 | ||||

| Max | 17 | ||||

| Average | 4 | ||||

| Wald χ2 (8) | 743.99 | ||||

| Log likelihood (prob > χ2) | −15,989 (0.000) | ||||

| Pseudo R2 | 0.68 | ||||

Keeping all other variables included in the model constant, a 1 year increase in mine age was associated with a reduction in the incidence rates of all injuries, injuries with lost workdays, and the most serious injuries by factors of 0.97, 0.96, and 0.95, respectively (p < 0.001). Also as expected, mining method was strongly associated with the incidence of injury; the coefficient of the mining method variable indicated that, compared to room-and-pillar mines, longwall mines experienced a lower incidence rate of all injuries, injuries with lost workdays, and the most serious injuries by factors of 0.87, 0.91, and 0.51, respectively, keeping all other variables constant.

6. Discussion

The results of the negative binomial random effects model supported our hypothesis that profitability, our main explanatory variable, and the incidence rate of injuries were inversely related in U.S. underground coal mines. As shown in Tables 2–4, the coefficient of the profitability variable (logarithm of the real total revenue per hour worked) took the hypothesized negative sign (IRR < 1) and was statistically significant across all three injury indicators. A 10% increase in profitability (for example, from the mean of $43 to $47) would be associated with 0.9%, 0.11%, and 1.6% decrease, respectively, in the incidence rates of all injuries, injuries with lost workdays, and the most serious injuries.

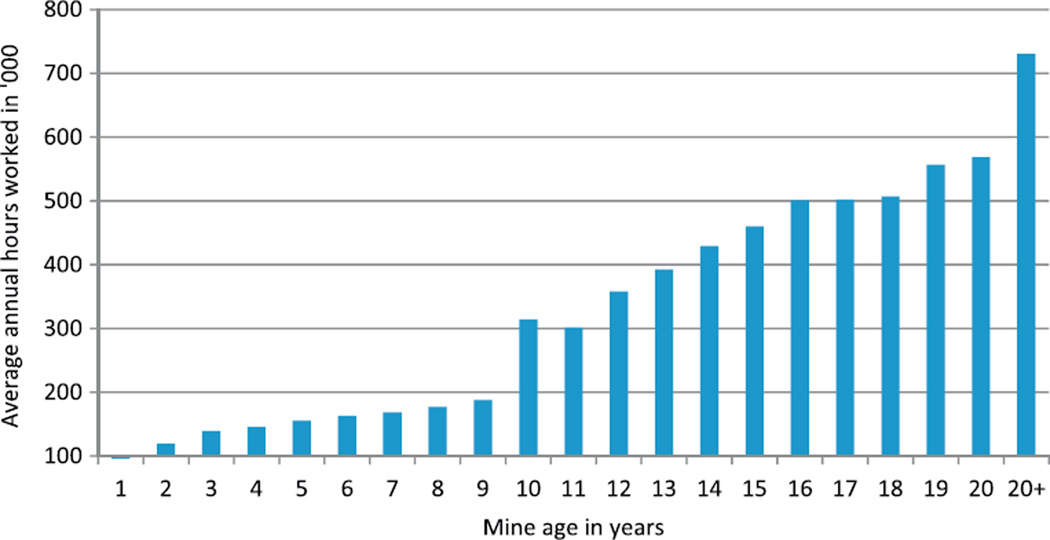

Several other covariates that might affect the incidence of injury in underground coal mines such as mine age (data are available since 1983), workforce union status, mining method (longwall vs. room-and-pillar), and geographic region, were included in the regression analysis as control variables. As was previously mentioned, these variables might at least partially capture the overall ease of mining in a particular mine. Mine size was not directly included in the analysis because its two traditional measures, hours worked and tons produced, were already included in the exposure and profitability variables. In addition, both mining method and mine age, both of which were used as control variables, are highly correlated with mine size. The longwall method is more capital intensive than room-and-pillar mining, and longwall mines tend to be the largest underground mines. For example, in 2009, 40 longwall mines produced as much coal as the other 500 room-and-pillar mines combined (EIA, 2010). Larger room-and-pillar mines that require substantial capital investments, such as those that require shafts or slopes to access the coal seam, also tend to be longer-lived than the small drift mines that are most typical of the Central coalfields (see Fig. 4). Because of the positive correlation of mining method and capital investment, we believe that the cost of capital also was captured by the control variables included in the model.

Fig. 4.

Relationship between mine age and size (annual hours worked) in the 5669 mine-year records used.

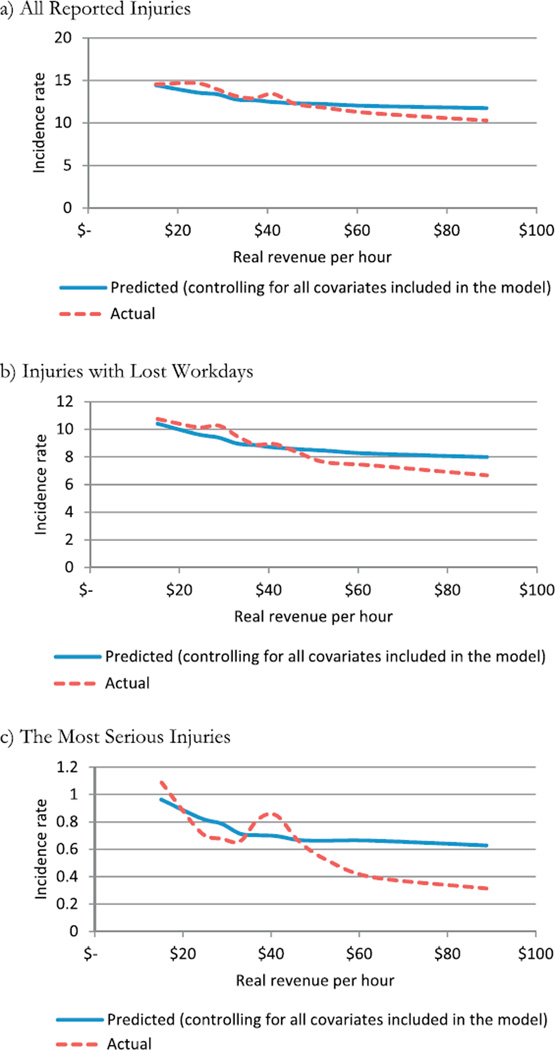

To provide a visual association between profitability and the incidence rates of injuries, we plotted the predicted incidence rates of injuries against the actual and predicted profitability values, fixing the random effects at zero. To facilitate the presentation, predicted values were plotted by profitability deciles of mines. Results are presented in Fig. 5; panels a, b, and c depict the association between profitability and the predicted and actual incidence rates of all injuries, injuries with lost workdays, and the most serious injuries, respectively, keeping all other variables constant.

Fig. 5.

Predicted impact of profitability on the incidence rate of (a) all reported injuries, (b) injuries with lost workdays, and (c) the most serious injuries.

The graphs indicate that the predicted incidence rate of all injuries in mines in the lowest profit deciles (where the average real revenue per hour worked was $15) was 14.3 compared to only 11.4 in mines in the highest profit deciles (where the average real revenue per hour worked was $89). This means that the predicted incidence rate of all injuries in mines in the least profitable deciles was 26% higher than in mines in the most profitable deciles. Similarly, mines in the least profitable deciles had a 34% higher incidence rate of injuries with lost workdays compared to mines in the most profitable deciles. The association between profitability and the incidence rates of the most serious injuries was consistent with our previous results and much stronger. The predicted incidence rate of the most serious injuries in mines in the least profitable deciles was 0.94 compared to only 0.60 in mines in the most profitable deciles. This implies that the average predicted incidence rate of the most serious injuries in the least profitable mines was 60% higher than the average predicted incidence rate of the most serious injuries in the most profitable mines.

We also analyzed several models in which we replaced profitability with productivity, defined as the logarithm of tons produced per hour. Results were consistent with but less robust than those from the profitability analysis for all three injury indicators. In the most extreme case, where the outcome variable was the most serious injuries, the p value for the profitability variable was 0.001, compared to only 0.233 for the productivity variable.

Most of the control variables we used to estimate the negative binomial random effects model took the expected sign and were statistically significant. For example, both mine age and longwall mining method were negatively and significantly associated with each of the three injury indicators we used. As previously mentioned, both a higher mine age and a longwall mining method are associated with larger, more capital intensive mines. Therefore, larger mines tend to have higher labor productivity (which reduces worker exposure to hazards) and to employ a higher percentage of their workforce in support operations rather than in more hazardous production operations at the coal face (National Research Council, 1982).

One important feature of the MSHA injury data used in our study is that they are self-reported by the mines. Past studies have found evidence that some mines may significantly under-report injuries, and in particular, that injury reporting practices may differ between union and non-union mines (Appleton and Baker, 1984; Hirsch et al., 1997; Azaroff et al., 2002; Morse et al., 2003; Morantz, 2011). In our study, the unionization variable was indeed positively associated with the incidence rates of all reported injuries and reported injuries with lost workdays. This finding is consistent with the respective finding by Morantz (2011) and could be in part due to a reporting effect, because unionized workers may be less fearful of repercussions if they report relatively minor injuries. However, we could find no empirical evidence that injury reporting behavior is systematically different between profitable and less profitable mines. If less profitable mines are indeed less likely to report injuries, our results could underestimate the impact of profitability on the rates of occupational injuries.

The positive association of our unionization variable with the incidence rates of all injuries and injuries with lost workdays may also be due to the fact that in our the data set, most of the injuries in union mines occurred during the early years of the study period, when the overall injury rates in both union and non-union mines were higher. Despite this bias in the data, our analysis indicated that unionization was negatively associated with the incidence rate of the most serious injuries, though the relationship was not statistically significant at the 10% level.

In addition to estimating the random effects model, we estimated a fixed effects model and derived roughly similar results. We presented only the results of the random effects model for the following three reasons. First, the fixed effects model assumes that the covariance is zero between time variant variables and variables that do not change much over time, such as geographic region. This means that the coefficients of the variables that do not change much over time cannot be estimated. Second, the fixed effects model does not consider cases with no variation in the dependent variable over time, which results in the analysis including only mines that reported experiencing injuries. This problem is larger in the case of relatively rare injuries such as serious injuries (see also Madsen, 2009). Third, the dispersion of injuries might vary across mines because of unobserved mine-specific factors which would not be accounted for by the fixed effects model.

In addition to potential data and method limitations mentioned above, in our study we could not establish a causal relationship between profitability and the incidence of injuries because of the potential endogeneity of the profitability variable. A profitable mine might be more likely to invest in safety, but it may also be that both safety and profitability are correlated with other, less tangible, factors. These might include the quality of mine management, the suitability of the mining equipment to the particular conditions in the mine, or the caliber of the mine planning and engineering. Future research could include a more detailed examination of the characteristics of the least profitable mines with high incidence of occupational injuries, in order to better understand how to guide specific strategies for prevention. The industry could be involved in identifying ways to improve safety indicators at mines with weaker economic performance. Future research could also explore the relationship between safety and financial health at surface mines and non-coal underground mines.

In summary, our study provided empirical evidence of the association between profitability and occupational injury incidence rates in the U.S. underground coal mines. The study joins a growing body of research in a variety of industries (see for instance Lake (2002) and Joskow (2006) for the relationship between economic performance and safety indicators in nuclear power plants). Policy can be informed by the findings that the least profitable mines experience the highest incidence rates of all injuries, injuries with lost workdays, and the most serious injuries. Mine operators of financially stressed mines also need to be aware of the association between profitability and occupational injuries, which could imply that they cannot afford to forgo investing in worker safety while struggling to improve mine profitability.

Acknowledgments

We thank the U.S. Energy Information Administration (EIA) for allowing us to use non-publically available information through an Information Access Agreement between EIA and NIOSH. We would also like to thank Gregory Wagner (MSHA), Stephen Hudock, Susan Moore, Frank Hearl, and John Piacentino (all from NIOSH) for their helpful comments and suggestions on the earlier version of the paper.

Footnotes

Disclaimer: The findings and conclusions in this paper are those of the authors and do not necessarily represent the views of the National Institute for Occupational Safety and Health or the Mine Safety and Health Administration.

Data on mining wages are available from BLS but we chose to use hours worked rather than labor cost per ton mined because BLS data show that mining wages do not vary substantially around the country. For example, in 2002, wages in the lowest-wage state (KY) were 90% of the national average, while they were 113% of the national average in the highest-wage state (PA). BLS data can be accessed at http://data.bls.gov/cgibin/srgate.

References

- Appleton CW, Baker GJ. The effect of unionization on safety in bituminous deep mines. Journal of Labor Research. 1984;5(2):139–147. [Google Scholar]

- Azaroff SL, Levenstein C, Wegman HD. Occupational injury and illness surveillance: conceptual filters explain underreporting. American Journal of Public Health. 2002;92(9):1421–1429. doi: 10.2105/ajph.92.9.1421. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Baltagi BH. Econometric Analysis of Panel Data. Chichester, UK: John Wiley & Sons Ltd.; 2009. [Google Scholar]

- Bennett DJ, Passmore LD. Correlates of coal mine accidents and injuries: a literature review. Accident Analysis and Prevention. 1984;16(1):37–45. [Google Scholar]

- Bibb TC, Hargrove KM. SME Mining Engineering Handbook. Vol. 2. Littleton, CO: Society for Mining, Metallurgy, and Exploration; 1992. Coal Mining Method Selection; pp. 1854–1866. (Chapter 21.4). [Google Scholar]

- Blomquist SN. A note on the use of the coefficient of determination. Scandinavian Journal of Economics. 1980;82:409–412. [Google Scholar]

- Boden LI. Government regulation of occupational safety: underground coal mine accidents 1973–75. American Journal of Public Health. 1985;75(5):497–501. doi: 10.2105/ajph.75.5.497. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Brody B, Létourneau Y, Poirier A. An indirect cost theory of work accident prevention. Journal of Occupational Accidents. 1990;13:255–270. [Google Scholar]

- BLS. Coal Mining Injuries, Illnesses, and Fatalities Fact Sheet and Charts. 2007 www.bls.gov/iif/oshwc/osh/os/osar0006.pdf.

- BLS. Fact Sheet, Coal Mining, Injuries, Illnesses, and Fatalities in the Coal Mining Industry. 2010 www.bls.gov/iif/oshwc/osh/os/osar0012.htm.

- Cameron AC, Trivedi PK. Regression Analysis of Count Data. Cambridge: Cambridge University Press; 1998. [Google Scholar]

- CDC. MMWR Weekly: Fatal Occupational Injuries – United States, 1980–1997. 2001 www.cdc.gov/mmwr/preview/mmwrhtml/mm5016a4.htm. [PubMed]

- Cutler T, James P. Does safety pay? A critical account of the health and safety executive document: ‘The Costs of Accidents’. Work, Employment and Society. 1996;10(4):755–765. [Google Scholar]

- Dames and Moore. Safety Analysis of Shaft-sinking Operations. Park Ridge, IL: Dames and Moore; 1977. Jun, (NTIS No. PB 282289). [Google Scholar]

- EIA. Annual Coal Report for 2009. 2010 Report No.: DOE/EIA-0584 (2009), www.eia.doe.gov/cneaf/coal/page/acr/acr_sum.html.

- Esterhuizen GS, Gürtunca RG. Coal mine safety achievements in the USA and the contribution of NIOSH research; South African Institute of Mining and Metallurgy Conference, Mining Achievements, Records and Benchmarks; 2006. Sep 13–15, [Google Scholar]

- FlorJancic RJ. Cost/Benefit Analysis of Deep Mine Federal Safety Legislation and Enforcement. Pittsburgh, PA: Consolidation Coal Company; 1981. [Google Scholar]

- Fotta BA, Mallett LG. NIOSH Information Circular Report 9447. Pittsburgh, PA: NIOSH; 1997. Effects of Mining Height on Injury Rates in U.S. Underground Nonlongwall Bituminous Coal Mines. [Google Scholar]

- Grayson RL. Safety vs. productivity and other factors in US underground coal mines. Mining Engineering. 2001;53(8):40–44. [Google Scholar]

- Greene W. Fixed and Random Effects Models for Count Data. Leonard N. Stern School of Business. 2007 Paper No. ISSN 1547-3651. http://ssrn.com/abstract=990012. [Google Scholar]

- Groves WA, Kecojevic VJ, Komljenovic D. Analysis of fatalities and injuries involving mining equipment. Journal of Safety Research. 2007;38(4):461–470. doi: 10.1016/j.jsr.2007.03.011. [DOI] [PubMed] [Google Scholar]

- Hausman JA, Hall BH, Griliches Z. Econometric models for count data with an application to the patents – R&D relationship. Econometrica. 1984;52:909–938. [Google Scholar]

- Hirsch TB, MacPherson AD, Dumond JM. Workers’ compensation recipiency in union and nonunion workplaces. Industrial and Labor Relations Review. 1997;50(2):213–236. [Google Scholar]

- Hopkins A. For whom does safety pay? The case of major accidents. Safety Science. 1999;32:143–153. [Google Scholar]

- Hsiao C. Analysis of Panel Data. Cambridge: Cambridge University Press; 2003. [Google Scholar]

- Hull PB, Leigh J, Driscoll RT, Mandryk J. Factors associated with occupational injury severity in the New South Wales underground coal mining industry. Safety Science. 1996;21:191–204. [Google Scholar]

- Joskow PL. The Future of Nuclear Power in the United States: Economic and Regulatory Challenges. Massachusetts Institute of Technology, Center for Energy and Environmental Policy Research Working Paper. MIT Center for Energy and Environmental Policy Research. 2006 http://hdl.handle.net/1721.1/45065. [Google Scholar]

- Kowalski-Trakofler KM, Steiner LJ, Schwerha D. Safety considerations for the aging workforce. Safety Science. 2005;43:779–793. [Google Scholar]

- Lake JA. The fourth generation of nuclear power. Progress in Nuclear Energy. 2002;40(3–4):301–307. [Google Scholar]

- Liang KY, Zeger SL. Longitudinal data analysis using generalized linear models. Biometrika. 1986;73:13–22. [Google Scholar]

- Madsen PM. These lives will not be lost in vain: organizational learning from disaster in U.S. coal mining. Organization Science. 2009;20(5):861–875. [Google Scholar]

- Margolis AK. Underground coal mining industry: a look at how age and experience relate to days lost from work following an injury. Safety Science. 2010;48:417–421. [Google Scholar]

- McFadden D. The measurement of urban travel demand. Journal of Public Economics. 1974;3(4):303–328. [Google Scholar]

- Mendeloff J. Regulating Safety: An Economic and Political Analysis of Occupational Safety and Health Policy. Cambridge, MA: M.I.T. Press; 1980. [Google Scholar]

- Moore SM, Pollard J, Mark C, Bhatt SK. An analysis of the potential of roof screening to reduce workers compensation costs. Mining Engineering. 2010 Dec;:49–54. [Google Scholar]

- Morantz AD. Coal Mine Safety: Do Unions Make a Difference? Stanford Law and Economics Olin Working Paper No. 413. 2011 http://ssrn.com/abstract=1846700. [Google Scholar]

- Morse T, Punnett L, Warren N, Dillon C, Warren A. The relationship of unions to prevalence and claim filing for work-related upper-extremity musculoskeletal disorders. American Journal of Industrial Medicine. 2003;44(1):83–93. doi: 10.1002/ajim.10234. [DOI] [PubMed] [Google Scholar]

- National Research Council. Toward Safer Underground Coal Mines. Washington, DC: National Academy Press; 1982. [Google Scholar]

- NIOSH. Washington, DC: 2008. Coal Operator Mining Facts – 2006. NIOSH Publication No. 2008-159, www.cdc.gov/niosh/mining/pubs/pdfs/2008-159.pdf. [Google Scholar]

- Neumann GR, Nelson JP. Graduate School of Business, University of Chicago and Department of Economics. Chicago, IL: The Pennsylvania State University; 1981. Safety Regulation and Firm Size: Effects of the Coal Mine Health and Safety Act of 1969. [Google Scholar]

- Pappas DM, Mark C, Dolinar DR, Bhatt SK. Profile of ground fall accidents in underground coal mines. Mining Engineering. 2003 Sep;:65–71. [Google Scholar]

- PBS. Coal’s Role in the U.S. Economy. n.d. www.pbs.org/nbr/blog/2010/04/coals_role_in_the_us_economy.html. [Google Scholar]

- Pfleider EP, Krug AD. The Development of Health and Safety Indices for the Evaluation of Underground Coal Mining Systems. Minneapolis, MN: University of Minnesota, Department of Civil and Mineral Engineering; 1973. Nov, (NTIS No. PB 235 126). [Google Scholar]

- Poplin SG, Miller BH, Ranger-Moore J, Bofinger MC, Kurzius-Spencer M, Harris BR, Burgess LJ. International evaluation of injury rates in coal mining: a comparison of risk and compliance based regulatory approaches. Safety Science. 2006;46(8):1196–1204. [Google Scholar]

- Reardon J. Injuries and illnesses among bituminous and lignite coal miners. Monthly Labor Review. 1993;116:49–55. [Google Scholar]

- The President’s Commission on Coal. Recommendations and Summary Findings. Washington, DC: U.S. Government Printing Office; 1980. [Google Scholar]

- Toscano G, Windau J. Fatal work injuries: results from the 1992 national census. Monthly Labor Review. 1993;116:3–8. [Google Scholar]

- United Mine Workers of America. n.d. http://www.umwa.org/. [Google Scholar]

- Waddock S, Graves S. The corporate social performance-financial performance link. Strategic Management Journal (1986–1998) 1997;18(4):303–320. [Google Scholar]

- Yakovlev P, Sobel SR. Occupational safety and profit maximization: friends or foes? Journal of Socio-Economics. 2010;39(3):429–435. [Google Scholar]

- Zimmerman WF. Safety Evaluation Methodology for Advanced Coal Extraction Systems. Pasadena, CA: California Institute of Technology, Jet Propulsion Laboratory; 1981. (NTIS No. WE/ET/l2548-6). [Google Scholar]