Abstract

[Purpose] This study investigated the variations in muscle fatigue, time to fatigue, and maximum task duration at different levels of production standard time. [Methods] Twenty subjects performed repetitive tasks at three different levels of production standard time corresponding to “normal”, “hard” and “very hard”. Surface electromyography was used to measure the muscle activity. [Results] The results showed that muscle activity was significantly affected by the production standard time level. Muscle activity increased twice in percentage as the production standard time shifted from hard to very hard (6.9% vs. 12.9%). The muscle activity increased over time, indicating muscle fatigue. The muscle fatigue rate increased for the harder production standard time (Hard: 0.105; Very hard: 0.115), which indicated the associated higher risk of work-related musculoskeletal disorders. Muscle fatigue was also found to occur earlier for hard and very hard production standard times. [Conclusion] It is recommended that the maximum task duration should not exceed 5.6, 2.9, and 2.2 hours for normal, hard, and very hard production standard times, respectively, in order to maintain work performance and minimize the risk of work-related musculoskeletal disorders.

Key words: Muscle activity, Muscle fatigue, Task duration

INTRODUCTION

The term “musculoskeletal disorders” (MSDs) refers to conditions that affect muscles, nerves, tendons, and other soft tissues1). MSDs are common among the working population. Work-related musculoskeletal disorders (WMSDs) have become a major social concern, which affect a company’s bottom line2, 3). Problems related to WMSDs pose a significant threat to employees’ health and well-being across a wide range of industries and occupations4,5,6). Workers involved in static low loads or repetitive work frequently have complaints associated with WMSD7,8,9). In France, it is estimated that upper limb MSDs account for approximately two-thirds of the reported work-related disorders10). In Malaysia, the upper limb is the most commonly affected region in work-related injuries, with 22,978 cases constituting 39.5% of the total in the year 201011). Therefore, there is a critical need to prevent WMSDs among workers with the use of ergonomic interventions12) and by integrating ergonomic measures for upper extremities in the assembly line design13).

Most tasks in the manufacturing industry, particularly assembly tasks, are repetitive and performed manually14, 15). The tasks become more repetitive with harder production standard times and may predispose workers to a higher risk for WMSDs. The muscle fatigue rate may also vary according to the levels of the production standard time. Hence, the ability to assign maximum task duration according to the levels of the production standard time may reduce the risk of WMSDs. However, there is a lack of established references concerning variations in muscle fatigue, time to fatigue, and maximum task duration at different levels of production standard time. Therefore, this is a timely investigation of the variations in muscle fatigue at different levels of production standard time to predict the time to fatigue and maximum task duration, which are important factors in task design for minimizing the risk of WMSDs.

SUBJECTS AND METHODS

Twenty industrial workers (10 females and 10 males) were recruited to participate in this study. The subjects were between the ages of 22 and 45 years (30.9±7.711). None of the recruited participants had a history of any musculoskeletal injuries. The subjects gave their written consent prior to study initiation. The study was approved by the local Ethics Committee. Muscle activity was recorded using Noraxon Surface Electromyography (EMG) and Telemyo 2400 Gen2 Telemetric Real Time 8 Channel SEMG System (Noraxon, INC, USA) with disposable Ag/AgCl pregelled electrodes. The subjects’ skin was cleaned thoroughly and prepared before electrode placement. The surface electrodes were attached to the belly of the forearm muscles bilaterally. The subjects were then instructed to adopt a comfortable sitting posture, and the sitting height was adjusted individually so that the subjects’ knees were flexed to 90°. The working height was standardized by placing the table surface 5 cm below the position of the wrist, with the elbow flexed to 90°16).

The subjects were instructed to perform a maximum voluntary contraction (MVC) task as soon as the signals from all sensors were stable. The subjects performed the MVC task three times in the seated position; the duration of each task was approximately 10 seconds, with 30 seconds of rest provided in between contractions. The 30 seconds of rest served as recovery time after each task. A stable forearm support was arranged, and manual resistance was used. The MVC measurement procedure used in this study was based on Konrad’s guidelines17). MVC refers to the highest EMG amplitude obtained from the three recordings and is expressed as the percentage of MVC (%MVC). The MVC was used to normalize the surface EMG signals that were recorded during the series of experimental tasks.

The subjects were required to perform the experimental tasks after familiarizing themselves with the tasks for 30 minutes. They performed the tasks according to assigned production standard times over a one-hour period for each production standard time. Muscle activity was recorded using surface EMG. The tasks involved repetitive assembly actions, similar to the actual industrial assembly task. The subjects were given two types of components: plastic clips and plastic foam rings. These components were placed into a polybox and plastic container, respectively. The subjects were instructed to assemble the ring foam onto the plastic clip using a jig, which pushes the foam onto the clip. The subjects performed the tasks according to the production standard times assigned to them. The production standard times used in the experimental tasks were 100% normal standard time (normal, PSN), 126% normal standard time (hard, PSH) and 140% normal standard time (Very hard, PSVH). The normal standard time was determined to be 5 s from the Methods-Time-Measurement (MTM) analysis, and the task was categorized as a highly repetitive light task18).

EMG signals were recorded from four forearm muscles: the flexor carpi radialis (FCR) and extensor carpi radialis (ECR) on the right and left arms. Raw EMG signals were sampled during the test contraction with a sample frequency of 1,500 Hz and were band-pass filtered (20–400 Hz). Data were continuously recorded with the Telemyo 2400T G2 Telemetry EMG System. The EMG data were normalized with MVC to obtain the root-mean-square (RMS, %MVC). The RMS value corresponds to the square root of the average power of the raw EMG signal over a given period of time19). The normalized RMS (%MVC) was averaged for every 5 minutes. In this study, the mean value of the normalized RMS represents the muscle activity, while the rate of muscle fatigue is represented by the linear regression slope of the normalized RMS.

RESULTS

The mean value and standard deviation of the normalized RMS for all muscles are summarized in Table 1.

Table 1. Mean and standard deviation of normalized RMS.

| Production standard | FCRR | FCRL | ECRR | ECRL | ||||

|---|---|---|---|---|---|---|---|---|

| Mean | SD | Mean | SD | Mean | SD | Mean | SD | |

| PSN | 8.8* | 1.8 | 11.0* | 2.8 | 10.4* | 2.3 | 11.4* | 3.4 |

| PSH | 9.6* | 2.2 | 11.9* | 2.5 | 11.0* | 2.5 | 11.9* | 3.4 |

| PSVH | 9.9* | 2.4 | 12.4* | 2.9 | 11.9* | 3.1 | 12.7* | 3.5 |

*Production standard time has a significant effect on the mean RMS for all muscles, p<0.05.

Muscle activity increased with harder production times. PSVH had the highest RMS value for all muscles. The highest RMS value was obtained for ECR-left (ECRL) followed by FCR-left (FCRL), ECR-right (ECRR), and FCR-right (FCRR). Repeated measures ANOVA was conducted to investigate the effect of production standard time on muscle activity, and the results revealed that the production standard time has a significant effect on the mean RMS (muscle activity) for all muscles (Table 1).

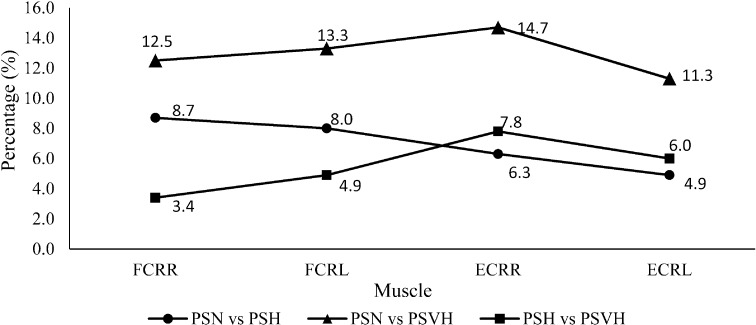

Figure 1 presents the percentage of increment in muscle activity at different levels of production standard times. The increment in muscle activity for a hard production standard time was in the 4.9–8.7% range. The provision of an assigned very hard production standard time showed that the muscle activity was higher than that for an assigned normal production standard time and hard production standard time, with an increment in the 11.3–14.7% and 3.4–7.8% ranges, respectively, depending on the type of muscles. On average, the muscle activity increased 6.9% for the hard production standard times and 12.9% for the very hard production standard times.

Fig. 1.

Percentage of increment in muscle activity for different levels of production standard time

The muscle fatigue rate was determined from the normalized RMS versus time, and the values are summarized in Table 2. It can be seen that the muscle fatigue rate is higher for harder production standard times.

Table 2. Muscle fatigue rate.

| Production standard | Muscle fatigue rate | |||

|---|---|---|---|---|

| FCRR | FCRL | ECRR | ECRL | |

| PSN | 0.045 | 0.061 | 0.088 | 0.059 |

| PSH | 0.046 | 0.086 | 0.092 | 0.105 |

| PSVH | 0.050 | 0.088 | 0.103 | 0.115 |

Based on the prediction of time to fatigue at 15%MVC, it was found that muscle fatigue occurs earlier for hard and very hard production standard times compared to the normal production standard time. The time to fatigue at 15%MVC is predicted to be 5.6 hours. 2.9 hours, and 2.2 hours for continuous work at normal, hard, and very hard production standard times, respectively.

DISCUSSION

Muscle activity, expressed as the RMS value (%MVC), was observed to increase significantly with harder production standard times. The results of this study reveal that the average muscle activity increases by 6.9% and 12.9% for hard and very hard production standard times, respectively, whereby the values are determined relative to the normal production standard time. This indicates that the muscle activity is twice its initial value as the production standard time shifts from hard to very hard. This result is consistent with the findings of previous studies, which reported that an increase in work pace leads to an increase in muscle activity20, 21).

The maximum muscle activity occurred at the ECRL, with a value of 12.7%MVC at 140% of the normal standard time. The ECRL muscle exhibited the highest muscle activity, followed by the FCRL, ECRR, and FCRR. The results are also consistent with the findings of previous studies, which were focused on repetitive hand tasks, during which the forearm extensor muscle activity increases with respect to time20, 21).

It was found that the RMS value increases with respect to time for all muscles, which signifies the development of muscle fatigue. The highest indication of muscle fatigue was detected in the ECRL. The left-sided muscles were found to be more active compared to the right-sided muscles, which was possibly due to all subjects being right-handed. Moreover, the left-sided muscles are used to grip and hold the components while carrying out a task, and thus they have a greater number of active motor units22). The greater the motor unit recruitment and firing rate, the greater is the generated force23). The force generated shows a rapid decline when the muscles are stimulated continuously at a frequency close to the maximal force and leads to muscle fatigue24). Therefore, these findings explained the highest indication of muscle fatigue detected in the left extensor muscle.

Muscle activity was also found to increase over time for different production standard times. The result indicates muscle fatigue at different levels of production standard time. This result is in agreement with that of previous studies, which found that increment of muscle activity over time indicated a sign of muscle fatigue25). In addition, muscle fatigue rates were found to be higher as the production standard time became harder. The result showed that higher muscle activity corresponds to a higher muscle fatigue rate26). Manifestation of muscle fatigue was detected during the one-hour task duration, and the result was in agreement with previous studies, which reported muscle fatigue and reduction in worker performance due to WMSDs associated with tasks that were one hour27) or less28) in duration. Previous studies also found that muscle fatigue develops over time29), and the accumulation of muscle fatigue caused functional disability resulting in musculoskeletal disorders30). Therefore, long-term effects and longitudinal studies are required to further investigate WMSDs. However, the ability to control muscle fatigue, which is an indicator of WMSDs, will help to minimize the risk of developing WMSDs and maintain worker performance.

In general, it can be deduced that the muscle fatigue rate is higher for harder production standard times due to the shorter task time and higher frequency of movement. The muscle fatigue rate increases with a corresponding increase in muscle activity. An increase in muscle activity indicates the development of muscle fatigue. These results are in agreement with the results of previous studies in which an increase in muscle activity resulted in an increase in muscle fatigue and WMSD risks25, 30).

The maximum muscle activity is found to be below 15% of the MVC. Rohmert31) suggested that muscle fatigue occurs when the muscular activity exceeds 15%MVC. However, recent studies reported that muscle fatigue and fatigue-related changes occur at lower force levels32). To date, there is no consensus regarding the acceptable levels of muscle fatigue at the workplace, and fatigue risks are still debated33). The time to fatigue in this study was predicted at 15%MVC, and it was found that time to fatigue occurs earlier for harder production standard times compared to the normal production standard time. The time to fatigue at 15%MVC is predicted after 5.6, 2.9, and 2.2 hours for normal, hard, and very hard production standard times, respectively, assuming that the workers perform the repetitive tasks continuously.

In the manufacturing industry, workers are usually given rest breaks after a certain task duration. Previous studies suggested that recovery from muscle fatigue can be achieved with appropriate rest breaks, such as a one-hour break34, 35). Shin and Kim36) suggested that an appropriate rest break can be used as an early intervention to prevent muscle fatigue at the workplace. Meanwhile, other studies have shown that setting a limit for the task duration is more useful than improving break allowance37). Based on these findings, we suggest that the maximum task duration for normal, hard, and very hard production standard times should be limited before time to fatigue. Hence, the maximum task duration should not exceed 5.6, 2.9, and 2.2 hours for normal, hard, and very hard production standard times, respectively. The maximum task duration for different levels of production standard time is an important factor in the work design for sustaining the desired work performance and for minimizing the risk of developing WMSDs.

Acknowledgments

This work was financially supported by the Ministry of Higher Education Malaysia under the High Impact Research Grant UM.C/HIR/MOHE/ENG/35 (D000035) and UM.C/HIR/MOHE/ENG/23 (D000023).

REFERENCES

- 1.NIOSH: Musculoskeletal Disorders and Workplace Factors : A critical review of epidemiologic evidence for WRMDs. NIOSH Publication, 1997, pp 97–141. [Google Scholar]

- 2.Hendrick HW: Determining the cost-benefits of ergonomics projects and factors that lead to their success. Appl Ergon, 2003, 34: 419–427. [DOI] [PubMed] [Google Scholar]

- 3.Neumann WP, Kihlberg S, Medbo P, et al. : A case study evaluating the ergonomic and productivity impacts of partial automation strategies in the electronics industry. Int J Prod Res, 2002, 40: 4059–4075. [Google Scholar]

- 4.Eatough EM, Way JD, Chang CH: Understanding the link between psychosocial work stressors and work-related musculoskeletal complaints. Appl Ergon, 2012, 43: 554–563. [DOI] [PubMed] [Google Scholar]

- 5.Onishi T, Kurimoto S, Suzuki M, et al. : Work-related musculoskeletal disorders in the upper extremity among the staff of a Japanese university hospital. Int Arch Occup Environ Health, 2014, 87: 547–555. [DOI] [PubMed] [Google Scholar]

- 6.Chung SH, Her JG, Ko T, et al. : Work-related Musculoskeletal disorders among Korean physical therapists. J Phys Ther Sci, 2012, 25: 55–59. [Google Scholar]

- 7.Punnett L, Wegman DH: Work-related musculoskeletal disorders: the epidemiologic evidence and the debate. J Electromyogr Kinesiol, 2004, 14: 13–23. [DOI] [PubMed] [Google Scholar]

- 8.Kim T, Roh H: Analysis of risk factors for work-related musculoskeletal disorders in radiological technologists. J Phys Ther Sci, 2014, 26: 1423–1428. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Cho TS, Jeon WJ, Lee JG, et al. : Factors affecting the musculoskeletal symptoms of Korean police officers. J Phys Ther Sci, 2014, 26: 925–930. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Aptel M, Aublet-Cuvelier A, Cnockaert JC: Work-related musculoskeletal disorders of the upper limb. Joint Bone Spine, 2002, 69: 546–555. [DOI] [PubMed] [Google Scholar]

- 11.SOCSO: Annual Report 2011: Social Security Organisation (SOCSO), 2011. [Google Scholar]

- 12.Martimo KP, Shiri R, Miranda H, et al. : Effectiveness of an ergonomic intervention on the productivity of workers with upper-extremity disorders—a randomized controlled trial. Scand J Work Environ Health, 2010, 36: 25–33. [DOI] [PubMed] [Google Scholar]

- 13.Xu Z, Ko J, Cochran DJ, et al. : Design of assembly lines with the concurrent consideration of productivity and upper extremity musculoskeletal disorders using linear models. Comput Ind Eng, 2012, 62: 431–441. [Google Scholar]

- 14.Sullivan LW, Gallwey TJ: Effects of gender and reach distance on risks of musculoskeletal injuries in an assembly task. Int J Ind Ergon, 2002, 29: 61–71. [Google Scholar]

- 15.van Tulder M, Malmivaara A, Koes B: Repetitive strain injury. Lancet, 2007, 369: 1815–1822. [DOI] [PubMed] [Google Scholar]

- 16.Bosch T, Mathiassen SE, Visser B, et al. : The effect of work pace on workload, motor variability and fatigue during simulated light assembly work. Ergonomics, 2011, 54: 154–168. [DOI] [PubMed] [Google Scholar]

- 17.Konrad P: The ABC of EMG. A practical introduction to kinesiological electromyography. Noraxon Inc. USA, 2005. [Google Scholar]

- 18.Silverstein BA, Fine LJ, Armstrong TJ: Hand wrist cumulative trauma disorders in industry. Br J Ind Med, 1986, 43: 779–784. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.De Luca G: Fundamental concepts in EMG signal acquisition. Delsys Inc., 2003. [Google Scholar]

- 20.Escorpizo RS, Moore AE: Quantifying precision and speed effects on muscle loading and rest in an occupational hand transfer task. Int J Ind Ergon, 2007, 37: 13–20. [Google Scholar]

- 21.Gooyers CE, Stevenson JM: The impact of an increase in work rate on task demands for a simulated industrial hand tool assembly task. Int J Ind Ergon, 2012, 42: 80–89. [Google Scholar]

- 22.Gnitecki JE, Kler GP, Moussavi Z: EMG signs of fatigue in anterior deltoid and posterior deltoid muscles: Questioning the role of RMS during fatigue. Canadian Medical and Biological Society (CMBES), 2002, pp 4–7. [Google Scholar]

- 23.Merletti R, Parker PJ: Electromyography: Physiology, engineering, and non-invasive applications. Wiley-IEEE Press, 2004. [Google Scholar]

- 24.Allen DG, Lamb GD, Westerblad H: Skeletal muscle fatigue: cellular mechanisms. Physiol Rev, 2008, 88: 287–332. [DOI] [PubMed] [Google Scholar]

- 25.Basmaijan J, DeLuca CJ: Muscles Alive: Their functions revealed by electromyography, 5th ed. Baltimore: Williams and Wilkins, 1985. [Google Scholar]

- 26.Abdullah AZ, Khan MA, Sharmin T, et al. : Muscle fatigue analysis in young adults at different MVC levels using EMG metrics. SoutheastCon, 2007, pp 390–394. [Google Scholar]

- 27.Sundelin G, Hagberg M: Electromyographic signs of shoulder muscle fatigue in repetitive arm work paced by the Methods-Time Measurement system. Scand J Work Environ Health, 1992, 18: 262–268. [DOI] [PubMed] [Google Scholar]

- 28.Finneran A, O’Sullivan L: Effects of grip type and wrist posture on forearm EMG activity, endurance time and movement accuracy. Int J Ind Ergon, 2013, 43: 91–99. [Google Scholar]

- 29.Putz-Anderson V: Cumulative trauma disorders: A manual for musculoskeletal diseases of the upper limbs. Taylor & Francis, 1988. [Google Scholar]

- 30.Ma L, Chablat D, Zhang W: Dynamic muscle fatigue evaluation in virtual working environment. Ergonomics, 2009, 39: 211–220. [Google Scholar]

- 31.Rohmert W: Problems in determining rest allowances Part 1: use of modern methods to evaluate stress and strain in static muscular work. Appl Ergon, 1973, 4: 91–95. [DOI] [PubMed] [Google Scholar]

- 32.Straker L, Mathiassen SE: Increased physical work loads in modern work—a necessity for better health and performance? Ergonomics, 2009, 52: 1215–1225. [DOI] [PubMed] [Google Scholar]

- 33.Rangan S, Van Dongen HP: Quantifying fatigue risk in model-based fatigue risk management. Aviat Space Environ Med, 2013, 84: 155–157. [DOI] [PubMed] [Google Scholar]

- 34.Kimura M, Sato H, Ochi M, et al. : Electromyogram and perceived fatigue changes in the trapezius muscle during typewriting and recovery. Eur J Appl Physiol, 2007, 100: 89–96. [DOI] [PubMed] [Google Scholar]

- 35.Barado RD, Mahon K: The effects of exercise and rest breaks on musculoskeletal discomfort during computer tasks: an evidence-based. J Phys Ther Sci, 2007, 19: 151–163. [Google Scholar]

- 36.Shin H, Kim J: Measurement of trunk muscle fatigue during dynamic lifting and lowering as recovery times changes. Int J Ind Ergon, 2007, 37: 545–551. [Google Scholar]

- 37.Mathiassen SE, Winkel J: Physiological comparison of three interventions in light assembly work: reduced work pace, increased break allowance and shortened working days. Int Arch Occup Environ Health, 1996, 68: 94–108. [DOI] [PubMed] [Google Scholar]