Abstract

PURPOSE

This study was to evaluate the marginal fit of two CAD-CAM anatomic contour zirconia crown systems compared to lithium disilicate glass-ceramic crowns.

MATERIALS AND METHODS

Shoulder and deep chamfer margin were formed on each acrylic resin tooth model of a maxillary first premolar. Two CAD-CAM systems (Prettau®Zirconia and ZENOSTAR®ZR translucent) and lithium disilicate glass ceramic (IPS e.max®press) crowns were made (n=16). Each crown was bonded to stone dies with resin cement (Rely X Unicem). Marginal gap and absolute marginal discrepancy of crowns were measured using a light microscope equipped with a digital camera (Leica DFC295) magnified by a factor of 100. Two-way analysis of variance (ANOVA) and post-hoc Tukey's HSD test were conducted to analyze the significance of crown marginal fit regarding the finish line configuration and the fabrication system.

RESULTS

The mean marginal gap of lithium disilicate glass ceramic crowns (IPS e.max®press) was significantly lower than that of the CAD-CAM anatomic contour zirconia crown system (Prettau®Zirconia) (P<.05). Both fabrication systems and finish line configurations significantly influenced the absolute marginal discrepancy (P<.05).

CONCLUSION

The lithium disilicate glass ceramic crown (IPS e.max®press) had significantly smaller marginal gap than the CAD-CAM anatomic contour zirconia crown system (Prettau®Zirconia). In terms of absolute marginal discrepancy, the CAD-CAM anatomic contour zirconia crown system (ZENOSTAR®ZR translucent) had under-extended margin, whereas the CAD-CAM anatomic contour zirconia crown system (Prettau®Zirconia) and lithium disilicate glass ceramic crowns (IPS e.max®press) had overextended margins.

Keywords: Anatomic contour zirconia crown, CAD-CAM, Lithium disilicate glass ceramic crown, Marginal gap, Absolute marginal discrepancy, Marginal fit

INTRODUCTION

Zirconia has excellent aesthetic quality, biocompatibility, and mechanical property. In addition, the price of zirconia is inexpensive compared to gold. Thus, zirconia is getting attention as a proper material for posterior teeth restoration to replace the existing ceramic.1,2,3 Commercialization of zirconia is closely linked to the development of CAD/CAM introduced to the dental industry 20 years ago.4,5,6 Recently, the introduction of new CAD/CAM milling technology and new zirconia made it possible to manufacture anatomic contour zirconia crown, enabling the forming of occlusal surface anatomically instead of in the form of porcelain veneer.7,8 Anatomic contour zirconia crowns have excellent fracture resistance property because it does not have superstructure. In addition, it has higher strength even when the volume of tooth preparation is small during the manufacture of a crown.9 However, long-term clinical success of dental restoration is influenced not only by mechanical property, aesthetic quality, and biocompatibility, but also by marginal fit. Large marginal gap causes failure of a crown by dissolving dental cement so quickly that plaques easily accumulate, leading to marginal leakage and secondary caries.10,11 Through in vitro and in vivo studies on marginal fit of dental restorations, marginal fit has been proven to be one of the major factors causing secondary caries and periodontal diseases.12,13,14,15,16 It has been proven by McLean in 1971 that clinically allowable marginal fit is within 120 µm range when fabricating a dental restoration.17 Martínez-Rus has reported that CAD/CAM ceramic crown has clinically allowable marginal fit within the range of 17 to 118 µm.18 Chamfer margins and shoulder margins were recommended to fabricate the precise anatomic contour crowns.19

Although computer-controlled technique is used in producing dental restoration in order to improve the accuracy during the manufacturing process, not enough studies have been conducted on the marginal fit of anatomic contour zirconia crowns fabricated using CAD/CAM system. Therefore, the objective of this study was to compare the marginal fit of anatomic contour zirconia crown to that of lithium disilicate glass ceramic crown regarding the finish line configuration and fabrication systems.

Null hypotheses for this experiment are as follows: (1) Finish line configuration has no influence on the marginal fit of anatomic contour crowns; (2) Fabrication systems do not affect the marginal fit of anatomic contour crown.

MATERIALS AND METHODS

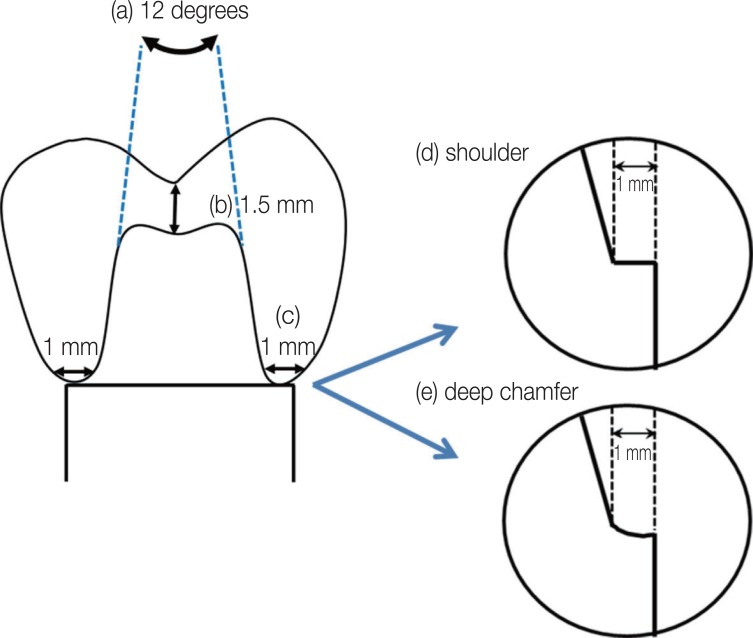

An acrylic resin model of maxillary first premolar (Columbia Dentiform Corp, Long Island City, NY, USA) was prepared. Tooth reduction was uniformly conducted with hand piece mounted in a milling machine (F4 basic, DentsplyDeguDent, Germany, Fig. 1). Total occlusal convergence angle was 12 degrees. An occlusal reduction of 1.5 mm at the center of the occlusal surface was executed. The definitive die had a 1 mm shoulder and deep chamfer margin on each mesiodistal and buccolingual marginal surface (Fig. 2). Four reference points were formed at the middle of the buccal, palatal, mesial, and distal root surface of tooth margin for later measurements. The width of each margin was managed by keeping it no wider than half of the diamond tip used for preparation. A flat-end diamond bur with 2.3 mm in diameter (Komet 6848.314.023; Gebr. Brasseler GmbH & Co KG) was used for the shoulder margin. A tapered diamond bur with 2.1 mm in diameter (Komet 6856.314.021; Gebr.Brasseler GmbH & Co KG) was used for the chamfer margin. The widths of the margins were measured with a 3-dimensional measuring microscope (Measuring microscope; Mitutoyo, Kawasaki, Japan) to determine whether planned dimensions (1 mm shoulder and chamfer) were achieved. Forty eight impressions of the resin tooth were obtained from the definitive die by using a light viscosity and putty vinyl polysiloxane (Exaflex and Exafine; GC Corporation, Tokyo, Japan). Forty eight impressions were poured with type IV die stone (suprastone, Kerr Corporation, Orange, CA, USA). Each stone die was carefully removed from the impression and examined for the presence of air bubbles or other defects.

Fig. 1. Photograpic view of the handpiece mounted milling machine.

Fig. 2. Proximal view of tooth preparation on the die and finish line configuration. (a) total occlusal convergence angle; (b) occlusal reduction; (c) margin width; (d) shoulder margin; (e) deep chamfer margin.

Two CAD/CAM system (Prettau®Zirconia; Zirkonzahn GmbH; Gais, Italy/ZENOSTAR®ZR translucent; Wieland Dental GmbH, Pforzheim, Germany) zirconia crowns and IPS e.max®press (IvoclarVivadent AG, Schaan, Liechtenstein) lithium disilicate glass ceramic crowns were divided into three groups according to fabrication methods (n=16). Each group was sub-categorized into two groups (shoulder margin, chamfer margin) based on the finish line configuration. Therefore, a total of 6 groups were used in this study (n=8, Table 1).

Table 1. Experimental groups depending on the fabrication system and finish line configuration used in this study.

| Fabrication system | Composition | Finish line configuration |

|---|---|---|

| IPS e.max®press (IvoclarVivadent AG,Schaan, Liechtenstein) |

Lithium disilicate glass-ceramic | Deep chamfer (n=8) |

| Shoulder (n=8) | ||

| Prettau®Zirconia (Zirkonzahn GmbH; Gais, Italy) |

Presintered yttrium stabilized zirconium dioxide | Deep chamfer (n=8) |

| Shoulder (n=8) | ||

| ZENOSTAR®ZR translucent (Wieland Dental GmbH, Pforzheim, Germany) |

Deep chamfer (n=8) | |

| Shoulder (n=8) |

All crowns were fabricated with anatomical shape according to the directions of manufacturing companies for each fabrication system (Fig. 3). The 5-TEC CAD/CAM system (Zirkonzahn GmbH; Gais, Italy) was used to fabricate the Prettau®Zirconia crowns. The dies were scanned sequentially with a SCANNER S600 ARTI (Zirkonzahn GmbH; Gais, Italy). ZirkonzahnArchiv software (Zirkonzahn GmbH; Gais, Italy) was used to design anatomic contour zirconia crowns. The simulated die spacer was programmed at 30 µm, starting at 1 mm ahead from the margin. The Prettau® Zirconia blocks were milled with M5 milling machine (Zirkonzahn GmbH; Gais, Italy). All specimens were fired in a furnace (Zirkonofen600; Zirkonzahn GmbH; Gais, Italy) at 1600℃. The ZENO TEC®System (Zenotec; Wieland Dental GmbH, Pforzheim, Germany) was used to fabricate the ZENOSTAR®ZR translucent crowns. The dies were scanned sequentially with 3shape D250 (Wieland Dental GmbH, Pforzheim, Germany). Anatomic contour zirconia crowns were designed with design software (Dental Designer; Wieland Dental GmbH, Pforzheim, Germany). This information was transmitted to a milling machine (Zenotec T1; Wieland Dental GmbH, Pforzheim, Germany). The crowns were produced by milling the ZENOSTAR® ZR translucent block and firing (Zenotec Fire; Wieland Dental GmbH, Pforzheim, Germany) at 1450℃. The IPS e.max®Press lithium disilicate glass ceramic crowns were fabricated using the lost wax technique. Two coats of die spacer were applied to the stone dies20 1 mm above the cervical end of the preparation to ensure good marginal fit. The crowns were fabricated by pressure injection of ceramic ingots in the Programat®EP5000 furnace (IvoclarVivadent AG, Schaan, Liechtenstein) following the manufacturer's recommendations.

Fig. 3. Photograpic view of the three types of crown restoration: (A) Prettau®Zirconia; (B) ZENOSTAR®ZR translucent; (C) IPS e.max®press lithium disilicate glass ceramic.

Forty eight crowns were luted with resin cement (Rely X Unicem, 3M ESPE, Seefeld, Germany) on the stone dies, respectively. Finger pressure was then applied for ten minutes as in clinical situation. All crowns that were completely bonded to stone dies were embedded with acrylic resin (Caulk, Dentsply, Milford, DE, USA) for observation. Cured resin blocks were cut in the middle of buccopalatal and mesiodistal directions using linear precision saw (Isomet 5000; Buehler Ltd., Lake Bluff, IL, USA) referring to four reference points. Each reference point of every sample was measured three times using a light microscope equipped with a digital camera (Leica DFC295; Leica Microsystems Ltd., Heerbrugg, Switzerland) and magnified by a factor of 100.

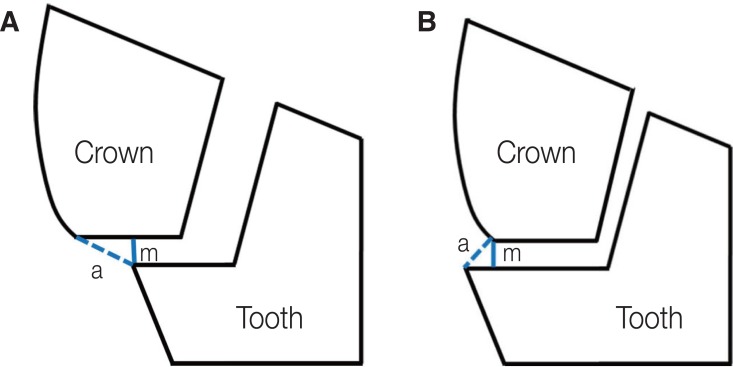

The criterion proposed by Holmes et al.21 was used to measure the marginal fit. The marginal gap and the absolute marginal discrepancy were measured. The perpendicular measurement from internal surface of the crown to the edge of the tooth finish line was defined as marginal gap. The distance from the edge of the crown to the edge of the tooth finish line was defined as absolute marginal discrepancy (Fig. 4).

Fig. 4. Schematic diagram of crown and tooth with the following measurement part: A, over-extended margin; and B, under-extended margin. (m): marginal gap; (a): absolute marginal discrepancy.

IBM SPSS Statistics 20 (IBM SPSS Inc., Chicago, IL, USA) was used for statistical analysis. Two-way analysis of variance (ANOVA) and post-hoc Tukey's HSD test were conducted to analyze significance of crown marginal fit regarding the finish line configuration and the fabrication system.

RESULTS

The mean marginal gap of shoulder and deep chamfer finish line configurations was 118.8 ± 78.2 µm and 109.0 ± 83.3 µm in the Prettau®Zirconiagroup, 91.5 ± 43.7 µm and 84.7 ± 41.5 µm in the ZENOSTAR®ZR translucent group, 41.2 ± 31.0 µm and 40.5 ± 42.9 µm in the IPS e.max®press group, respectively (Table 2). The two-way ANOVA showed that the fabrication system significantly influenced the marginal gap (P<.05). There was no significant difference in marginal gap depending on the finish line configuration, and in the interaction between the fabrication system and the finish line configuration (P>.05)(Table 3). According to Tukey honestly significant difference (HSD) test results, the marginal gap of IPS e.max®press was significantly smaller than Prettau®Zirconia (P<.05). The mean absolute marginal discrepancy of shoulder and deep chamfer finish line configurations was 73.9 ± 32.9 µm and 37.8 ± 37.1 µm in the Prettau®Zirconia group, -14.3 ± 61.2 µm and -51.3 ± 66.9 µm in the ZENOSTAR®ZR translucent group, 29.4 ± 19.1 µm and 22.5 ± 20.5 µm in the IPS e max press group, respectively (Table 4). ZENOSTAR®ZR translucent had under-extended margin, whereas Prettau®Zirconia and IPS e.max®press had over-extended margin. The two-way ANOVA analysis results showed that both the fabrication system and the finish line configuration significantly influenced the absolute marginal discrepancy (P<.05). There was no significant interaction between the 2 variables (P>.05)(Table 5). Tukey honestly significant difference (HSD) test indicated a significant difference between IPS e.max®press and ZENOSTAR®ZR translucent, and also between Prettau® Zirconia and ZENOSTAR®ZR translucent (P<.05).

Table 2. The mean and standard deviations of marginal gap depending on fabrication system in each finish line configuration (unit: µm).

| Fabrication system | Shoulder | Deep Chamfer | ||

|---|---|---|---|---|

| Mean | SD | Mean | SD | |

| Prettau®Zirconia | 118.8a | 78.2 | 109.0 | 83.3 |

| ZENOSTAR®ZR translucent | 91.5a,b | 43.7 | 84.7 | 41.5 |

| IPS e.max®press | 41.2b | 31.0 | 40.5 | 42.9 |

Different superscripted lowercase letters in column indicate significant differences (P<.05).

Table 3. Two-way ANOVA results for effect of fabrication system, finish line configuration, and their interactions on mean marginal gap.

| Source | Sum of squares | Degree of freedom | Mean squares | F-statistics | P vlaue |

|---|---|---|---|---|---|

| Corrected Model | 44492.075a | 5 | 8898.415 | 2.742 | .031 |

| Intercept | 314466.469 | 1 | 314466.469 | 96.902 | .000 |

| Fabrication system | 43922.085 | 2 | 21961.043 | 6.767 | .003 |

| Finish line configuration | 396.175 | 1 | 396.175 | .122 | .729 |

| Finish line configuration×Fabrication system | 173.814 | 2 | 86.907 | .027 | .974 |

| Error | 136298.839 | 42 | 3245.210 | ||

| Total | 495257.383 | 48 | |||

| Corrected Total | 180790.914 | 47 |

a. R Squared = .246 (Adjusted R Squared = .156).

Table 4. The mean and standard deviations of absolute marginal discrepancy depending on fabrication system in each finish line configuration (unit: µm).

| Fabrication system | Shoulder | Deep chamfer | ||

|---|---|---|---|---|

| Mean | SD | Mean | SD | |

| Prettau®Zirconia | 73.9a | 32.9 | 37.8a | 37.1 |

| ZENOSTAR®ZR translucent | -14.3b | 61.2 | -51.3b | 66.9 |

| IPS e.max®press | 29.4c | 19.1 | 22.5a | 20.5 |

Different superscripted lowercase letters in column indicate significant differences (P<.05).

"-" indicate the under-extended margin.

Table 5. Two-way ANOVA results for effect of fabrication system, finish line configuration, and their interactions on mean absolute marginal discrepancy.

| Source | Sum of squares | Degree of freedom | Mean squares | F-statistics | P vlaue |

|---|---|---|---|---|---|

| Corrected Model | 75951.430a | 5 | 15190.286 | 7.955 | .000 |

| Intercept | 12776.765 | 1 | 12776.766 | 6.691 | .013 |

| Fabrication system × Finish line configuration | 2350.913 | 2 | 1175.456 | .616 | .545 |

| Fabrication system | 65075.848 | 2 | 32537.924 | 17.040 | .000 |

| Finish line configuration | 8524.668 | 1 | 8524.668 | 4.464 | .041 |

| Error | 80197.311 | 42 | 1909.459 | ||

| Total | 168925.508 | 48 | |||

| Corrected Total | 156148.742 | 47 |

a. R Squared = .486 (Adjusted R Squared = .425)

DISCUSSION

This study examined the marginal fit of two CAD/CAM anatomic contour zirconia crowns (Prettau®Zirconia of ZikozahnandZENOSTAR®ZR translucent of Wieland Dental) and lithium disilicate glass ceramic crowns (IPS e.max®press of IvoclarVivadent) which are widely used clinically. The null hypothesis that the fabrication system has no influence on marginal fit of anatomic contour crowns was rejected, whereas the other null hypothesis that the finish line configuration has no influence on marginal fit of anatomic contour crown was accepted.

Acrylic resin tooth was used in this study to simulate clinical situation. Tooth preparation was conducted uniformly using surveyor milling machine. Each crown was sectioned at the same position with four reference points. To simulate the cementation of the clinical situation, finger pressure was applied to each of the crowns for ten minutes. In general, sectioning embedded specimens22,23,24,25 and direct visualization26,27 are the two methods used to measure marginal fit. Direct visualization has an advantage that it is measurable without destroying specimens, making it applicable under clinical situation. However, it is hard to obtain precise measurements by direct visualization.24 The sectioning method was used in this study in order to measure marginal fit precisely.

Our results revealed that the maximum marginal gap was 118.8 ± 78.2 µm when shoulder margin was formed on crowns using Prettau®Zirconia. The amount of marginal gap was in the clinically acceptable range according to Martínez-Rus.18 The marginal fit of restoration manufactured by CAD/CAM system was increased compared to the IPS e.max®press system. Procedures added on computers caused some errors, although handwork errors were reduced by the CAD/CAM system.28 The large marginal gap compared to other studies are due to shrinkage error that could increase before and after sintering due to the larger material volume of anatomic zirconia crowns than zirconia copings. The differences in marginal fit between each system result from zirconia blocks with various shrinkage rates depending on manufacturing company, scanning process, size of milling bur used, and the number of milling axis.

This study has some limitations. Finger pressure used clinically to lute crowns on stone dies was not standardized. Therefore, the use of a loading device is needed to apply uniform load on all crowns. In addition, stone dies instead of teeth were used to evaluate marginal fit of anatomic contour crown. Although stone dies or resin dies have been allowed to be used for evaluating marginal fit,24,29 the use of human tooth would be ideal to simulate clinical procedure.

The results of this study suggest that IPS e.max®press is better than Prettau®Zirconia regarding the marginal gap when fabricating an anatomic contour crown. Further study and clinical applications should be performed to compensate for the shrinkage of zirconia that might happen during the fabricating procedure. The development of CAD/CAM technology is needed to produce more accurate milling process.

CONCLUSION

Within the limitations of this study, we have the following conclusions: 1) IPS e.max®press had significantly smaller marginal gap than Prettau®Zirconia; 2) Finish line configuration did not show significant influence on the marginal gap; 3) In terms of absolute marginal discrepancy, ZENOSTAR®ZR translucent had under-extended margins, whereas Prettau® Zirconia and IPS e.max®press had over-extended margins; 4) The measured marginal gaps of the two CAD/CAM anatomic contour zirconia crown and lithium disilicate glass ceramic crown were within the range of clinical acceptance.

Footnotes

This research was supported by the Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT & Future Planning (2013R1A1A1010115).

References

- 1.Filser F, Kocher P, Weibel F, Lüthy H, Schärer P, Gauckler LJ. Reliability and strength of all-ceramic dental restorations fabricated by direct ceramic machining (DCM) Int J Comput Dent. 2001;4:89–106. [PubMed] [Google Scholar]

- 2.Conrad HJ, Seong WJ, Pesun IJ. Current ceramic materials and systems with clinical recommendations: a systematic review. J Prosthet Dent. 2007;98:389–404. doi: 10.1016/S0022-3913(07)60124-3. [DOI] [PubMed] [Google Scholar]

- 3.Christel P, Meunier A, Heller M, Torre JP, Peille CN. Mechanical properties and short-term in-vivo evaluation of yttrium-oxide-partially-stabilized zirconia. J Biomed Mater Res. 1989;23:45–61. doi: 10.1002/jbm.820230105. [DOI] [PubMed] [Google Scholar]

- 4.Kugel G, Perry RD, Aboushala A. Restoring anterior maxillary dentition using alumina- and zirconia-based CAD/CAM restorations. Compend Contin Educ Dent. 2003;24:569–572. 574, 576. [PubMed] [Google Scholar]

- 5.Rekow D. Computer-aided design and manufacturing in dentistry: a review of the state of the art. J Prosthet Dent. 1987;58:512–516. doi: 10.1016/0022-3913(87)90285-x. [DOI] [PubMed] [Google Scholar]

- 6.Yin L, Song XF, Song YL, Huang T, Li J. An overview of in vitro abrasive finishing & CAD/CAM of bioceramics in restorative dentistry. Int J Mach Tool Manuf. 2006;46:1013–1026. [Google Scholar]

- 7.Baig MR, Tan KB, Nicholls JI. Evaluation of the marginal fit of a zirconia ceramic computer-aided machined (CAM) crown system. J Prosthet Dent. 2010;104:216–227. doi: 10.1016/S0022-3913(10)60128-X. [DOI] [PubMed] [Google Scholar]

- 8.Preis V, Behr M, Kolbeck C, Hahnel S, Handel G, Rosentritt M. Wear performance of substructure ceramics and veneering porcelains. Dent Mater. 2011;27:796–804. doi: 10.1016/j.dental.2011.04.001. [DOI] [PubMed] [Google Scholar]

- 9.Jung YS, Lee JW, Choi YJ, Ahn JS, Shin SW, Huh JB. A study on the in-vitro wear of the natural tooth structure by opposing zirconia or dental porcelain. J Adv Prosthodont. 2010;2:111–115. doi: 10.4047/jap.2010.2.3.111. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 10.Felton DA, Kanoy BE, Bayne SC, Wirthman GP. Effect of in vivo crown margin discrepancies on periodontal health. J Prosthet Dent. 1991;65:357–364. doi: 10.1016/0022-3913(91)90225-l. [DOI] [PubMed] [Google Scholar]

- 11.Knoernschild KL, Campbell SD. Periodontal tissue responses after insertion of artificial crowns and fixed partial dentures. J Prosthet Dent. 2000;84:492–498. doi: 10.1067/mpr.2000.110262. [DOI] [PubMed] [Google Scholar]

- 12.Kokubo Y, Ohkubo C, Tsumita M, Miyashita A, Vult von Steyern P, Fukushima S. Clinical marginal and internal gaps of Procera AllCeram crowns. J Oral Rehabil. 2005;32:526–530. doi: 10.1111/j.1365-2842.2005.01458.x. [DOI] [PubMed] [Google Scholar]

- 13.Boening KW, Wolf BH, Schmidt AE, Kästner K, Walter MH. Clinical fit of Procera AllCeram crowns. J Prosthet Dent. 2000;84:419–424. doi: 10.1067/mpr.2000.109125. [DOI] [PubMed] [Google Scholar]

- 14.May KB, Russell MM, Razzoog ME, Lang BR. Precision of fit: the Procera AllCeram crown. J Prosthet Dent. 1998;80:394–404. doi: 10.1016/s0022-3913(98)70002-2. [DOI] [PubMed] [Google Scholar]

- 15.Weaver JD, Johnson GH, Bales DJ. Marginal adaptation of castable ceramic crowns. J Prosthet Dent. 1991;66:747–753. doi: 10.1016/0022-3913(91)90408-o. [DOI] [PubMed] [Google Scholar]

- 16.Behr M, Proff P, Kolbeck C, Langrieger S, Kunze J, Handel G, Rosentritt M. The bond strength of the resin-to-zirconia interface using different bonding concepts. J Mech Behav Biomed Mater. 2011;4:2–8. doi: 10.1016/j.jmbbm.2010.08.002. [DOI] [PubMed] [Google Scholar]

- 17.McLean JW, von Fraunhofer JA. The estimation of cement film thickness by an in vivo technique. Br Dent J. 1971;131:107–111. doi: 10.1038/sj.bdj.4802708. [DOI] [PubMed] [Google Scholar]

- 18.Martínez-Rus F, Suárez MJ, Rivera B, Pradíes G. Evaluation of the absolute marginal discrepancy of zirconia-based ceramic copings. J Prosthet Dent. 2011;105:108–114. doi: 10.1016/S0022-3913(11)60009-7. [DOI] [PubMed] [Google Scholar]

- 19.Pera P, Gilodi S, Bassi F, Carossa S. In vitro marginal adaptation of alumina porcelain ceramic crowns. J Prosthet Dent. 1994;72:585–590. doi: 10.1016/0022-3913(94)90289-5. [DOI] [PubMed] [Google Scholar]

- 20.Cho SH, Chang WG, Lim BS, Lee YK. Effect of die spacer thickness on shear bond strength of porcelain laminate veneers. J Prosthet Dent. 2006;95:201–208. doi: 10.1016/j.prosdent.2005.12.011. [DOI] [PubMed] [Google Scholar]

- 21.Holmes JR, Bayne SC, Holland GA, Sulik WD. Considerations in measurement of marginal fit. J Prosthet Dent. 1989;62:405–408. doi: 10.1016/0022-3913(89)90170-4. [DOI] [PubMed] [Google Scholar]

- 22.Blackman R, Baez R, Barghi N. Marginal accuracy and geometry of cast titanium copings. J Prosthet Dent. 1992;67:435–440. doi: 10.1016/0022-3913(92)90068-l. [DOI] [PubMed] [Google Scholar]

- 23.Oruç S, Tulunoglu Y. Fit of titanium and a base metal alloy metal-ceramic crown. J Prosthet Dent. 2000;83:314–318. doi: 10.1016/s0022-3913(00)70134-x. [DOI] [PubMed] [Google Scholar]

- 24.Gavelis JR, Morency JD, Riley ED, Sozio RB. The effect of various finish line preparations on the marginal seal and occlusal seat of full crown preparations. J Prosthet Dent. 1981;45:138–145. doi: 10.1016/0022-3913(81)90330-9. [DOI] [PubMed] [Google Scholar]

- 25.Han HS, Yang HS, Lim HP, Park YJ. Marginal accuracy and internal fit of machine-milled and cast titanium crowns. J Prosthet Dent. 2011;106:191–197. doi: 10.1016/S0022-3913(11)60120-0. [DOI] [PubMed] [Google Scholar]

- 26.Witkowski S, Komine F, Gerds T. Marginal accuracy of titanium copings fabricated by casting and CAD/CAM techniques. J Prosthet Dent. 2006;96:47–52. doi: 10.1016/j.prosdent.2006.05.013. [DOI] [PubMed] [Google Scholar]

- 27.Tan PL, Gratton DG, Diaz-Arnold AM, Holmes DC. An in vitro comparison of vertical marginal gaps of CAD/CAM titanium and conventional cast restorations. J Prosthodont. 2008;17:378–383. doi: 10.1111/j.1532-849X.2008.00302.x. [DOI] [PubMed] [Google Scholar]

- 28.Bornemann G, Lemelson S, Luthardt R. Innovative method for the analysis of the internal 3D fitting accuracy of Cerec-3 crowns. Int J Comput Dent. 2002;5:177–182. [PubMed] [Google Scholar]

- 29.Quante K, Ludwig K, Kern M. Marginal and internal fit of metal-ceramic crowns fabricated with a new laser melting technology. Dent Mater. 2008;24:1311–1315. doi: 10.1016/j.dental.2008.02.011. [DOI] [PubMed] [Google Scholar]