Abstract

PURPOSE

The aim of this study was to evaluate the effect of cyclic loading and screw retightening on reverse torque value (RTV) in external and internal type implants.

MATERIALS AND METHODS

Cement-retained abutments were connected with 30 Ncm torque to external and internal type implants. Experimental groups were classified according to implant connection type and retightening/loading protocol. In groups with no retightening, RTV was evaluated after cyclic loading for 100,000 cycles. In groups with retightening, RTV was measured after 3, 10, 100 cycles as well as every 20,000 cycles until 100,000 cycles of loading.

RESULTS

Every group showed decreased RTV after cyclic loading. Before and after cyclic loading, external type implants had significantly higher RTVs than internal type implants. In external type implants, retightening did not affect the decrease in RTV. In contrast, retightening 5 times and retightening after 10 cycles of dynamic loading was effective for maintaining RTV in internal type implants.

CONCLUSION

Retightening of screws is more effective in internal type implants than external type implants. Retightening of screws is recommended in the early stage of functional loading.

Keywords: Screw loosening, Reverse torque value, Retightening, Cyclic loading, Internal implant

INTRODUCTION

Screw clamping force via application of torque is an essential maintenance mechanism of implant prostheses.1 Unstable screw joints induce complications such as screw loosening under continuous cyclic loading. Screw loosening is the most common mechanical complication of implant therapy. The occurrence of screw loosening is reported to be 12.7% in single tooth restoration and 6.7% in partial fixed prostheses. 2,3 Jemt et al.4 observed that most of the screw loosening occurred within a year and the frequency of screw loosening was reduced over time.

Henry et al.5 and Khraisat et al.6 stated that screw loosening is more frequent in external type implants. This may be due to the unique connection systems of internal type implants. In internal type connections, the stability of the prosthesis is obtained from the clamping force of the screw joint and the frictional force created by contact between the conical mating parts of the implant-abutment assembly. Because of this connection, internal type implants have more favourable stress distribution, better stability, and superior resistance to lateral load.7 However, Tsuge and Hagiwara8 presented no significant difference between internal and external implant-abutment connections concerning their effect on the abutment screw loosening. Theoharidou et al.9 also reported that the frequency of screw loosening in single tooth restoration was 2.7% in external type implants and 2.4% in internal type implants; this difference was not statistically significant.

The frequency of screw loosening is reduced over time, but still occurs in spite of recent advances in the design and screw materials. Screw loosening produces discomfort for patients; therefore, methods to prevent screw loosening are needed. One method for preventing screw loosening that is easily applicable to clinical practice is retightening. Bickford10 suggested a 2-phase theory of screw loosening. In the first phase, gradual functional loading causes sliding of the screw thread and relief of screw extension induced by preload. The second phase occurs over a long period of time. Gradual reduction of preload below a critical point causes screw turning. Applying a greater preload on the screw in the first phase of screw loosening leads to increased resistance to screw loosening. Siamos et al.11 reported that in order to minimize the loss of preload, it is necessary to retighten the screw 10 minutes after the first screw tightening.

However, the retightening procedure may change the shape of the abutment screw and the inner screw thread of the implant; hence, stability during function may be affected.12 In addition, conflicting results on the effect of retightening have been reported. According to Tzenakis et al.,13 if the abutment screw is repeatedly retightened, a higher preload can be obtained because of surface wear that can lower the coefficient of friction. However, Weiss et al.14 reported that repeated tightening/removal procedures decreased the reverse torque value (RTV) of screws. Riccardi-Coppedê et al.15 reported that repeated tightening and removal of titanium screws caused the RTV to decrease gradually.

The effect of screw retightening remains controversial and on the timing and frequency of retightening are lacking. The aim of this study was to assess the effect of dynamic loading and screw retightening on RTV in external and internal connection type implants.

MATERIALS AND METHODS

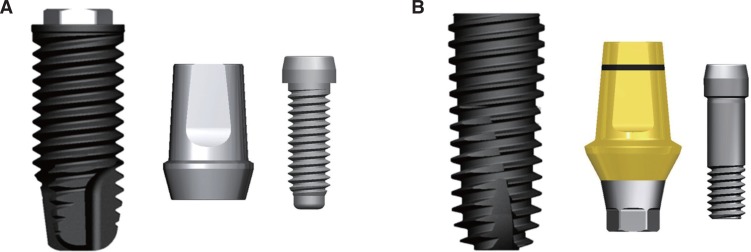

Twenty external type implants (diameter, 4 mm; length, 10 mm; Sola, Shinhung, Seoul, Korea) and 20 internal type implants (diameter, 4 mm; length, 10 mm; Luna, Shinhung, Seoul, Korea) were used (Fig. 1). Abutments for cementretained prostheses (diameter, 5 mm; gingival height, 5.5 mm; Esthetic abutment for external implant and Duo abutment for internal implant, Shinhung, Seoul, Korea) were connected to each implant (Fig. 1).

Fig. 1. Implant/abutment assemblies: (A) External type, (B) Internal type.

Each implant and abutment assembly was held in a customized jig in all testing procedures. Using a digital torque controller (MGT 12, MARK-10 Co., New York, NY, USA), the recommended torque was applied to the abutments. After 10 minutes, the assemblies were retightened with 30 Ncm torque to compensate for embedment relaxation.11 After tightening the screws twice, an initial measurement of RTV was made.

The implant/abutment assemblies were divided into 4 groups (10 assemblies per group) in order to evaluate the effect of intermittent retightening: 1) Ext-N, external type implant with no retightening; 2) Ext-RT, external type implant with retightening; 3) Int-N, internal type implant with no retightening; 4) Int-RT, internal type implant with retightening.

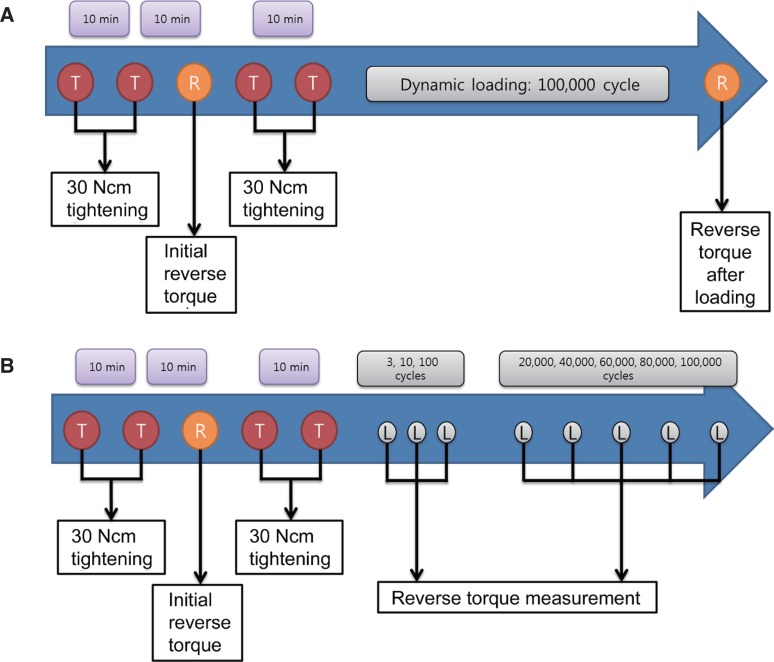

The implant/abutment assemblies were fitted to the mounting base of a universal testing machine (ElectroPlus E 3000, Instron, Washington DC, WA, USA) with the long axis of the implant fixed at 30 degrees relative to the vertical axis (Fig. 2). The implant/abutment assemblies were loaded with a cylindrical titanium cap. The testing device delivered sine curved cyclic loading between 20 and 250 N at 14 Hz for 100,000 cycles. In the groups with no retightening (Ext-N and Int-N), the RTV was measured after 100,000 cycles of loading, while RTV was measured after 3, 10, and 100 cycles as well as every 20,000 cycles in the retightening groups (Fig. 3).

Fig. 2. Cyclic loading test. (A) Mounting jig for implant, (B) Cylindrical titanium cap for abutment, (C) Loading axis.

Fig. 3. Experimental protocol for (A) Ext-N and Int-N group, (B) Ext-RT and Int-RT group.

For all statistical evaluations, SPSS version 20.0, SPSS Inc., Chicago, IL, USA) was used. One-way analysis of variance (ANOVA) was used for comparing RTV depending on the implant system and retightening. When the RTV was measured repeatedly after various loading cycles, a repeated measures ANOVA was applied for comparison. For all analyses, Tukey's test was used for post hoc comparisons, and the significance level was set at α=0.05.

RESULTS

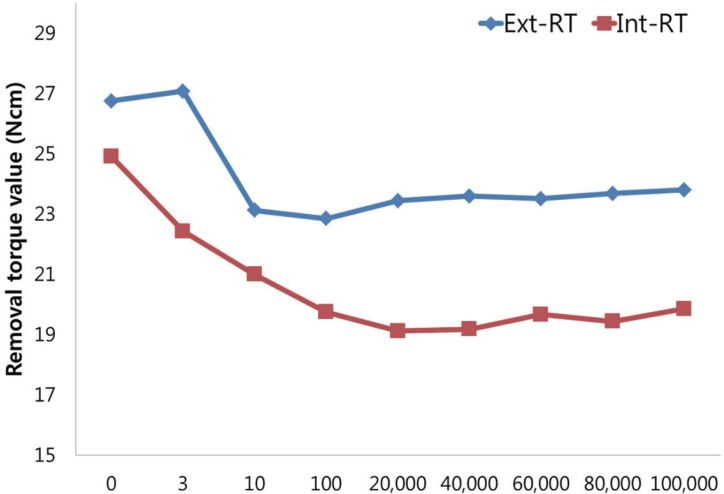

The initial RTVs were 27.8 ± 1.3 Ncm in external implants and 25.1 ± 1.9 Ncm in internal implants. Both implant systems showed decreased RTVs when compared with the tightening torque value of 30 Ncm. The initial RTV of external implants was significantly higher than that of internal implants (P<.05).

The RTVs of all implant/abutment assemblies were significantly reduced after cyclic loading (P<.05, Table 1, Table 2). The RTVs of the groups without retightening were 25.4 ± 1.2 Ncm in the Ext-N group and 15.8 ± 1.8 Ncm in the Int-N group. The Ext-N group showed a significantly higher RTV when compared with the Int-N group (P<.05). The RTVs of the groups with retightening were 23.8 ± 1.8 Ncm in the Ext-RT group and 19.9 ± 3.3 Ncm in the Int-RT group. The Ext-RN group showed a significantly higher RTV than the Int-RN group (P<.05).

Table 1. Mean reverse torque value and standard deviation of implant-abutment assemblies.

| Group | Torque (Ncm) | Initial RTV (Ncm) | Post-dynamic loading RTV (Ncm) |

|---|---|---|---|

| Ext-N | 30 | 27.3 ± 1.4a | 25.4 ± 1.2C |

| Ext-RT | 30 | 25.0 ± 2.3b | 23.8 ± 1.8C |

| Int-N | 30 | 25.1 ± 1.9b | 15.8 ± 1.8A |

| Int-RT | 30 | 24.9 ± 2.7b | 19.9 ± 3.3B |

※The same superscriptive letters indicate the values that are not significantly different (P>.05).

Table 2. Repeated measures ANOVA for differences in implant systems and retightening.

| Sum of squares | df | Mean square | F | Sig. | |

|---|---|---|---|---|---|

| Between subjects | 549.131 | 3 | 183.044 | 38.405 | .000 |

| Within subjects | 171.579 | 36 | 4.766 | ||

| Sum | 720.710 | 39 |

In external implants, retightening did not affect RTV (P>.05). On the other hand, retightened internal implant/abutment assemblies showed superior RTVs when compared to internal implants with no retightening (Table 1, Table 2).

Most of the decreases in RTV occurred after 10 cycles of loading. RTVs were maintained after 10 cycles without significant changes (Fig. 4).

Fig. 4. RTV changes according to dynamic loading and retightening cycles in external and internal type implants.

DISCUSSION

Screw loosening is the most frequently occurring mechanical complication of implant restorations.5,16 Abutment screw loosening has been reported in a large number of studies with an incidence ranging from 2% to 15% of abutments. 2,3,5,9 Screw loosening is caused by inadequate tightening torque, settling of implant components, inappropriate implant position, inadequate occlusal scheme or crown anatomy, poorly fitting frameworks, improper screw design/material, and heavy occlusal forces.17,18,19 To overcome screw loosening and joint instability, many technical solutions have been suggested. For example, new abutment screw designs and materials for maximizing preload,1,20 mechanical torque-applying instruments for optimizing tightening torque,21 precise implant components for antirotation, and internal conical connection implants with no micromotion or microgaps have been proposed.

In the current study, the initial RTV was always smaller than the tightening torque (30 Ncm) in external and internal type implants. This result may have been caused by the loss of tightening torque. Tightening torque is partly consumed by frictional force. Haack et al.22 reported that most of the tightening torque is used to overcome the friction of the surface and only 10% of the tightening torque is used to generate preload. They suggested that 75 - 80% of tightening torque remained in titanium or gold screws.22 Kim et al.23 reported that the amount of remaining torque was affected by the screw material (77% remained in titanium alloy and 66% remained in gold alloy). For standardization of the results, the same titanium alloy was used for both internal and external abutment screws in the present study. The results showed that the remaining torque was 90.9% in external implants and 83.3% in internal implants. These relatively high remaining initial RTVs might have been caused by advanced milling technique and/or the screw design/material.

In the current experiments, initial RTVs and post-cyclic loading RTVs were higher in external implants than in internal implants. This is a result of the difference in connection type between the implants. In external implants, joint stability is obtained by the tension of the screw, while it is achieved mainly by friction between the abutment and the implant in internal type implants.24 Most of the tightening torque is used to produce preload in external implants,25 while in internal implants, tightening torque is distributed between friction with the abutment and preload on the screw. Therefore, less preload is generated in internal type implants. Moreover, internal implants are susceptible to the wedge effect, which arises when tightening torque and mechanical load are applied, leading to axial displacement of the abutment, so that the tensile force of the screw is lost and preload is decreased.23,24,25 According to Lee et al.24 and Kim et al.,25 axial displacement of the abutment is greater in internal implants, while RTV is greater in external implants. One other possible reason is the different screw design. Although screws from the same manufacturer were used for standardisation, the screws for external implants have longer threads than those of the screws used for internal implants (Fig. 1). The thread-engaging surface may affect the preload in screw-tightening procedures. To our knowledge, no internal/external implant system manufactured by the same manufacturer offers either similar or identical screw shapes owing to the different inner structures of internal/external implants. Although the 2 implant systems had different screw sizes and dimensions, the lengths of the engaging or the mating threads were similar in both.24 The upper part of the thread in the screw of the external implant was not in contact and just passed through the inner surface of the implant.

Comparison of the groups with and without retightening after cyclic loading revealed no significant differences in RTVs in external implants. However, in internal implants, retightening resulted in higher RTVs than those found in implants without retightening. These results can be explained by the difference in connection type between the implants and the number of times the implants were retightened. In internal type implants, less settling effect occurs during tightening and loosening procedures, because tightening torque generates less preload due to dissipation of force via friction between the abutment and the implant. Therefore, a greater number of retightening procedures allows more settling effect and making an adequate surface of the screw.

Cardoso et al.26 found that RTVs decreased as the number of insertion/removal cycles increased in external type implants. In contrast, Tzenakis et al.13 reported an increase of preload in internal type implants. These results coincide with those of the present study. Therefore, retightening of screws is strongly recommended for joint stability, especially in internal type implants.

The appropriate number of retightening procedures is not clear from the results of previous studies. Tzenakis et al.13 reported a gradual increase in gold screw preload from tightening for the first time to retightening 5 and 10 times in internal type implants. In the current study, retightening was performed 12 times until completion of cyclic loading. RTV did not decrease after retightening was conducted 5 times. It should be noted that retightening more than 5 times is not recommended for the maintenance of preload.

In the present study, RTVs in retightened implants remained constant after 20,000 cycles of loading. This phenomenon was observed in both external and internal type implants. According to Delben et al.,27 RTVs were maintained constantly by retightening after every 100,000 cycles of loading in external type implants. According to Binon and McHugh,28 the average daily number of mastication is about 2,700 and so 100,000 cycles corresponds to around one month. In the current study, the load cycle was decreased to 20,000 cycles (corresponding to one week) in order to infer the timing of retightening, because previous studies found no significant differences with 100,000 load cycles.

In the current experiments, RTVs decreased only 10 rounds of cyclic loading in external and internal type implants. In our previous study,24 axial displacement of abutments took place after only 10 cycles of loading. Thus, axial displacement of the abutment screw can affect joint stability, especially in internal implants. To increase preload and secure joint stability, it is recommended that retightening be performed after 10 loading cycles for both external and internal implants. Moreover, retightening after 1 week is also profitable for internal type implants.

CONCLUSION

This study evaluated RTV according to retightening and cyclic loading in external and internal type implants.

Initial RTV was always smaller than tightening torque and decreased after cyclic loading. Initial RTV and postcyclic loading RTV were higher in external implants than in internal implants. In external type implants, retightening did not produce a significant difference in RTV when compared with the non-retightening group after 100,000 rounds of cyclic loading. In internal type implants, the retightening group showed significantly increased RTVs when compared with the non-retightening group after cyclic loading. A decrease in RTV occurred after only 10 rounds of cyclic loading, which represents the early stage of cyclic loading. After 20,000 cycles of loading, RTVs were maintained constantly in both external and internal type implants.

Footnotes

The authors would like to acknowledge Shinhung MST Co., Ltd. (Korea) for providing the implant components.

References

- 1.Binon PP. Implants and components: entering the new millennium. Int J Oral Maxillofac Implants. 2000;15:76–94. [PubMed] [Google Scholar]

- 2.Jung RE, Zembic A, Pjetursson BE, Zwahlen M, Thoma DS. Systematic review of the survival rate and the incidence of biological, technical, and aesthetic complications of single crowns on implants reported in longitudinal studies with a mean follow-up of 5 years. Clin Oral Implants Res. 2012;23:2–21. doi: 10.1111/j.1600-0501.2012.02547.x. [DOI] [PubMed] [Google Scholar]

- 3.Pjetursson BE, Thoma D, Jung R, Zwahlen M, Zembic A. A systematic review of the survival and complication rates of implant-supported fixed dental prostheses (FDPs) after a mean observation period of at least 5 years. Clin Oral Implants Res. 2012;23:22–38. doi: 10.1111/j.1600-0501.2012.02546.x. [DOI] [PubMed] [Google Scholar]

- 4.Jemt T, Laney WR, Harris D, Henry PJ, Krogh PH, Jr, Polizzi G, Zarb GA, Herrmann I. Osseointegrated implants for single tooth replacement: a 1-year report from a multicenter prospective study. Int J Oral Maxillofac Implants. 1991;6:29–36. [PubMed] [Google Scholar]

- 5.Henry PJ, Laney WR, Jemt T, Harris D, Krogh PH, Polizzi G, Zarb GA, Herrmann I. Osseointegrated implants for single-tooth replacement: a prospective 5-year multicenter study. Int J Oral Maxillofac Implants. 1996;11:450–455. [PubMed] [Google Scholar]

- 6.Khraisat A, Abu-Hammad O, Dar-Odeh N, Al-Kayed AM. Abutment screw loosening and bending resistance of external hexagon implant system after lateral cyclic loading. Clin Implant Dent Relat Res. 2004;6:157–164. doi: 10.1111/j.1708-8208.2004.tb00216.x. [DOI] [PubMed] [Google Scholar]

- 7.Maeda Y, Satoh T, Sogo M. In vitro differences of stress concentrations for internal and external hex implant-abutment connections: a short communication. J Oral Rehabil. 2006;33:75–78. doi: 10.1111/j.1365-2842.2006.01545.x. [DOI] [PubMed] [Google Scholar]

- 8.Tsuge T, Hagiwara Y. Influence of lateral-oblique cyclic loading on abutment screw loosening of internal and external hexagon implants. Dent Mater J. 2009;28:373–381. doi: 10.4012/dmj.28.373. [DOI] [PubMed] [Google Scholar]

- 9.Theoharidou A, Petridis HP, Tzannas K, Garefis P. Abutment screw loosening in single-implant restorations: a systematic review. Int J Oral Maxillofac Implants. 2008;23:681–690. [PubMed] [Google Scholar]

- 10.Bickford JH. An introduction to the design and behavior of bolted joints. 3rd ed. New York: Marcel Dekker Inc; 1995. [Google Scholar]

- 11.Siamos G, Winkler S, Boberick KG. Relationship between implant preload and screw loosening on implant-supported prostheses. J Oral Implantol. 2002;28:67–73. doi: 10.1563/1548-1336(2002)028<0067:TRBIPA>2.3.CO;2. [DOI] [PubMed] [Google Scholar]

- 12.Guzaitis KL, Knoernschild KL, Viana MA. Effect of repeated screw joint closing and opening cycles on implant prosthetic screw reverse torque and implant and screw thread morphology. J Prosthet Dent. 2011;106:159–169. doi: 10.1016/S0022-3913(11)60115-7. [DOI] [PubMed] [Google Scholar]

- 13.Tzenakis GK, Nagy WW, Fournelle RA, Dhuru VB. The effect of repeated torque and salivary contamination on the preload of slotted gold implant prosthetic screws. J Prosthet Dent. 2002;88:183–191. doi: 10.1067/mpr.2002.127604. [DOI] [PubMed] [Google Scholar]

- 14.Weiss EI, Kozak D, Gross MD. Effect of repeated closures on opening torque values in seven abutment-implant systems. J Prosthet Dent. 2000;84:194–199. doi: 10.1067/mpr.2000.108069. [DOI] [PubMed] [Google Scholar]

- 15.Ricciardi Coppedê A, de Mattos Mda G, Rodrigues RC, Ribeiro RF. Effect of repeated torque/mechanical loading cycles on two different abutment types in implants with internal tapered connections: an in vitro study. Clin Oral Implants Res. 2009;20:624–632. doi: 10.1111/j.1600-0501.2008.01690.x. [DOI] [PubMed] [Google Scholar]

- 16.Andersson B, Odman P, Lindvall AM, Lithner B. Single-tooth restorations supported by osseointegrated implants: results and experiences from a prospective study after 2 to 3 years. Int J Oral Maxillofac Implants. 1995;10:702–711. [PubMed] [Google Scholar]

- 17.Artzi Z, Dreiangel A. A screw lock for single-tooth implant superstructures. J Am Dent Assoc. 1999;130:677–682. doi: 10.14219/jada.archive.1999.0277. [DOI] [PubMed] [Google Scholar]

- 18.Schwarz MS. Mechanical complications of dental implants. Clin Oral Implants Res. 2000;11:156–158. doi: 10.1034/j.1600-0501.2000.011s1156.x. [DOI] [PubMed] [Google Scholar]

- 19.Cavazos E, Bell FA. Preventing loosening of implant abutment screws. J Prosthet Dent. 1996;75:566–569. doi: 10.1016/s0022-3913(96)90464-3. [DOI] [PubMed] [Google Scholar]

- 20.Park JK, Choi JU, Jeon YC, Choi KS, Jeong CM. Effects of abutment screw coating on implant preload. J Prosthodont. 2010;19:458–464. doi: 10.1111/j.1532-849X.2010.00595.x. [DOI] [PubMed] [Google Scholar]

- 21.McGlumphy EA, Mendel DA, Holloway JA. Implant screw mechanics. Dent Clin North Am. 1998;42:71–89. [PubMed] [Google Scholar]

- 22.Haack JE, Sakaguchi RL, Sun T, Coffey JP. Elongation and preload stress in dental implant abutment screws. Int J Oral Maxillofac Implants. 1995;10:529–536. [PubMed] [Google Scholar]

- 23.Kim JM, Han JS, Lee SH, Yang JH, Lee JB, Kim YS. A study of screw loosening after dynamic continous fatigue test of several abutment screw. J Korean Acad Prosthodont. 2003;41:519–531. [Google Scholar]

- 24.Lee JH, Kim DG, Park CJ, Cho LR. Axial displacements in external and internal implant-abutment connection. Clin Oral Implants Res. 2014;25:e83–e89. doi: 10.1111/clr.12062. [DOI] [PubMed] [Google Scholar]

- 25.Kim KS, Lim YJ, Kim MJ, Kwon HB, Yang JH, Lee JB, Yim SH. Variation in the total lengths of abutment/implant assemblies generated with a function of applied tightening torque in external and internal implant-abutment connection. Clin Oral Implants Res. 2011;22:834–839. doi: 10.1111/j.1600-0501.2010.02063.x. [DOI] [PubMed] [Google Scholar]

- 26.Cardoso M, Torres MF, Lourenço EJ, de Moraes Telles D, Rodrigues RC, Ribeiro RF. Torque removal evaluation of prosthetic screws after tightening and loosening cycles: an in vitro study. Clin Oral Implants Res. 2012;23:475–480. doi: 10.1111/j.1600-0501.2011.02165.x. [DOI] [PubMed] [Google Scholar]

- 27.Delben JA, Gomes EA, Barão VA, Assunção WG. Evaluation of the effect of retightening and mechanical cycling on preload maintenance of retention screws. Int J Oral Maxillofac Implants. 2011;26:251–256. [PubMed] [Google Scholar]

- 28.Binon PP, McHugh MJ. The effect of eliminating implant/abutment rotational misfit on screw joint stability. Int J Prosthodont. 1996;9:511–519. [PubMed] [Google Scholar]