Abstract

Green tea powder (GTP) was incorporated in wheat flour at different levels (1, 2 and 4 %) and its effect on quality parameters of flour and cookies were studied. Thermal analysis showed that addition of GTP did not increase the onset temperature, end temperature and enthalpy of flour significantly. However, the increase in GTP content retarded the retro gradation of the gelatinized wheat flour gel and decreased the water absorption capacity, Oil absorption capacity, water solubility index, Foam capacity and foam stability significantly. The L* and b* values of cookies decreased from 53.63 to 33.23 and 29.02 to 24.39 respectively, while as, a* value showed an increase from 3.61 to 5.23 indirect proportion to quantity added. The addition of GTP to wheat flour increased the DPPH (2,2-diphenyl-1-picrylhydrazyl) percent inhibition and reducing power of cookies. Further, it also increases the acceptability for color, aroma and taste; however it loosened its structural integrity and decreased the fracture force.

Keywords: Green Tea, Wheat Flour, Functional properties, Reducing Power, DPPH, Cookies

Introduction

Cookies have been consumed for thousands of years and are still a tasty delight. Traditional cookies are made from common ingredients (wheat flour, water and salt), and although it is claimed to be rich in carbohydrate, it lacks other essential nutritional components, such as dietary fiber, vitamins and minerals, which are removed during wheat flour refinement (Choo and Aziz 2010). In the past few decades, the demand for wheat based products with added value has tremendously increased. Several workers have incorporated natural bioactive components into wheat flour to improve functional & nutraceutical properties of products prepared from it. For cookies and similar food types like pasta, bread and noodles, numerous natural additive sources, such as lupin and pigeon pea flours (Martinez-Villaluenga et al. 2010), common bean protein (Gallegos-Infante et al. 2010) milk protein concentrates and hydrolysates (Gani et al. 2014) and mango peel powder (Ajila et al. 2010) have been studied in order to improve the nutritional value and functional properties of the product.

Tea and tea products mainly contain tea polyphenols, which are natural antioxidants and have been demonstrated to show antioxidative, anti-carcinogenic and anti-microbial properties by many researchers (Rietveld and Wiseman 2003). These health benefits of teas, in particular that of green tea, are gaining increased attention in recent years. Green tea contains the most abundant tea polyphenols such as tea catechins, etc. They are nowadays utilized in a wide range of applications, such as food, beverage, cosmetics, toiletries, etc. (Wang et al. 2000). In order to incorporate green tea in different foods, it should be used as powder, because the powder is easier to enter into the structure of food (Zhao et al. 2009). Whereas, at present, the incorporation of green tea powder in different foods is very limited and not much work has been reported on the effects of green tea powder on wheat flour and cookie properties, the objective of this research was to evaluate the influence of green tea powder on wheat flour dough and to prepare cookies with nutraceutical value.

Materials

Sample collection and preparation

Green tea (Camellia sinensis), wheat flour, sugar, salt and oil were purchased from the local market of Srinagar, Jammu & Kashmir, India. The moisture, ash and protein content in the wheat flour were 14.02, 0.57 and 10.32 % respectively. The green tea was reduced to powder by a grinder and a particle size of 212 μm was achieved by sieving the powder in a scientific sieve no.72 (British Sieve Standards). Blends of wheat flour and green tea powder (GTP) in the ratios of 100/0, 100/1, 100/ 2 and 100/4 (w/w) were prepared and packed in polypropylene bags and stored at refrigerated temperature.

Methods

Pasting properties

Pasting properties of flours were determined using a rapid visco analyzer (RVA TECMASTER, Perten instruments, Australia). The test profile STD1 was used for the determination of pasting characteristics. 3.5 g of flour were dispersed in 25 g of water in the RVA canister, the process run for 13 min. & from the pasting curves were obtained the characteristic parameters of pasting temperature (Ptemp); peak viscosity (PV, maximum paste viscosity achieved in the heating stage of the profile); hot paste viscosity (HPV, minimum paste viscosity at 95 °C); breakdown viscosity (BD = PV-HPV) and Set back viscosity (SB = CPV-PV), using the RVA Starch Master Software Setup Tool (SMST).

Dough water absorption and stability test

The green tea powder (at levels of 0, 1, 2 and 4 g per 100 g flour) was first mixed well with wheat flour in the mixing bowl of the farinograph (Brabender, Farinograph-E, Germany version 4.20). The bowl was connected with a circulating water pump and a thermostat, which operated at 30 ± 0.2 °C, farinograph water absorption and dough stability time were thus determined.

Thermodynamic properties

The thermodynamic properties of the above mentioned blend samples were measured using 61 DSC-Pyris Diamond (Per-kine Elmer Corp, Norwalk, CT, USA). The calorimeter was calibrated with an indium standard. Blends (about 4 mg) were accurately weighted into aluminum DSC pans (accuracy = 0.1 mg) and deionised water was added by micropipette in order to achieve a water-sample ratio of 2:1. The sample pans were sealed and equilibrated at room temperature for 24 h before analysis and then heated at a determined temperature program (25–95 °C,10 °C/min), using an empty pan as reference. Thereafter, the gelatinized samples were stored at 4 °C for 3 days for the retro gradation studies. The stored samples were scanned under the same conditions and the degree of retro gradation was expressed as the retro gradation enthalpy.

Water solubility index (WSI)

The water solubility index of flour was determined according to AACC method 56-20 (AACC 2000) with slight modifications. 2 g (M0) flour sample was dispersed in 40 ml deionized water and vortexed (Vortex-Genie, Scientific Industries, Inc, Bohemia, New York, USA) for 1 min. The sample was centrifuged at 100 rpm for 15 min and the supernatant was decanted. The centrifuge tubes were then inverted for 5 min on a paper towel. The residue from the water absorption was then dried in a universal hot air oven (NSW-143 OSA-1) for 24 h at 50 °C and weighed (M1). WSI was calculated as follows:

Swelling power

The swelling power was determined according to the method described by Gani et al.. (2013) with modification for small samples. 1 g of the flour sample was mixed with 10 ml distilled water in a centrifuge tube and heated at 80 °C for 30 min in a stirring water bath. After heating, the suspension was centrifuged at 1000 rpm for 15 min. The supernatant was decanted and the weight of the paste was taken. The swelling power was calculated as:

Water and oil absorption capacity

Water and oil absorption capacities (WAC and OAC) were determined using the AACC method 56-20 (AACC 2000) with slight modifications. 2 g (dry weight basis) of sample was dispersed in 40 ml distilled water or refined canola vegetable oil, vortexed intermittently for 10 min and centrifuged at 1000 g (15 min, 20 °C). The aqueous supernatant or clear oil obtained after centrifuging was decanted and the test tubes were inverted and allowed to drain for 5 min on a paper towel. By weighing the residue, WAC and OAC were calculated and expressed as grams of water or oil absorbed per gram of sample, respectively.

Foam capacity and foam stability

The method described by Narayana and Narasinga Rao (1982) was used for the determination of foaming capacity (FC) and foam stability (FS). 2 g of flour were mixed with 50 ml of distilled water at 30 ± 2 °C in a 100 ml measuring cylinder. The suspension was shaken properly by whipping for 3 min in an electrical blender (Double-M, Germany) to form foam. The content in the blender was transferred into the measuring cylinder and the volume of the foam after 30 s was recorded. The FC was expressed as a percentage increase in volume:

The foam volume was recorded 1 hour after whipping to determine the Foam Stability (FS) as a percentage of the initial foam volume.

Baking properties

Blends of wheat flour containing 0, 1, 2 and 4 % green tea powder were mixed well into the mixing bowl of the Farinograph (Brabender, Farinograph-E, Germany version 4.20). A sugar cookie recipe and procedure described by McWatters et al.. (2003) was used for cookie preparation. The basic ingredients used were 300 g of flour blend, 180 g of hydrogenated vegetable shortening, 225 g of granulated cane sugar, 21 g of beaten whole egg, 3.75 g of salt, and 1.8 g of baking powder. The dry ingredients (flour, sugar, salt and baking powder) were thoroughly mixed in a bowl by hand for 3–5 min. Vegetable shortening (180 g) was added and mixed uniformly. Egg was then added and mixture kneaded in a Kenwood mixer (Model A 907D) for 3.5 min to get slightly firm dough. The dough was manually rolled on a pastry board into sheets of uniform thickness of 0.5 cm and cut into circular shapes using a circular cutter. The dough pieces were transferred into oil-greased pans and baked at 180 °C for 10 min. The cookies were allowed to cool at room temperature (28 ± 1 °C) for 2 h and then stored in polyethylene bags at room temperature for further analysis

Color of cookies

The color of cookies at different levels of green tea fortification was determined using Hunter color lab (Hunter Lab D25, Hunter associates Lab, Reston, USA). Calibration with black and white tiles was performed before color measurement. The Hunter color L*, a* and b* values were used to measure the color of the cookies.

Cookie texture

The fracture force test was conducted on the cookies using a TA-XT2 Texture Analyzer (Stable Micro Systems, UK). Fracture force was recorded as the force required for shattering the cookies with the help of a sharp-blade cutting probe, 6 cm long and 0.1 mm thick. The analyzer was set at a ‘return to start’ cycle with a speed of 1 mm/s and a distance of 3 mm. The average force was calculated for 4 cookies and reported as fracture force.

In addition, flour gels after RVA tests were stored at 4 °C for 24 h, and then their hardness was measured using the P/15 probe, as an indicator of retrogradation.

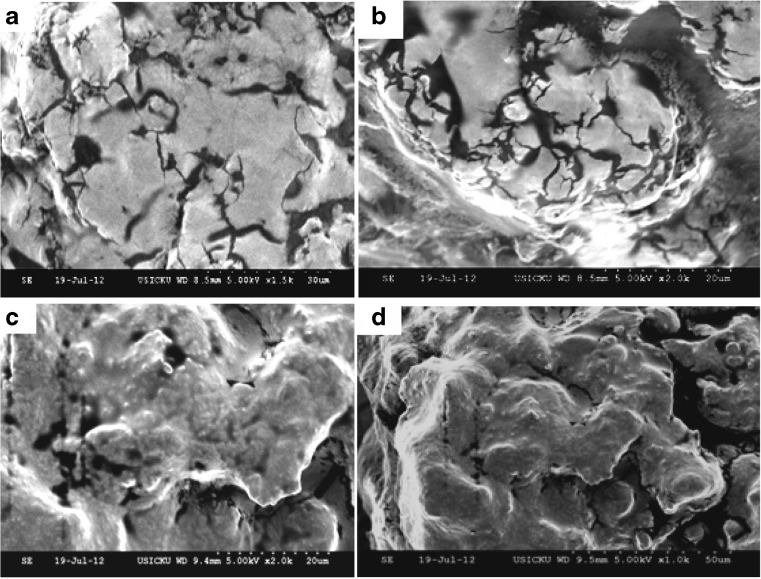

Microstructure

The cookie samples were fractured into sizes of about 1 × 1 × 0.5 cm using a knife and a hammer. The interior surface of the samples was exposed to gold sputtering. The preparations were then viewed and photographed with a Hitachi scanning electron microscope (model E-1030 Japan) at an accelerating voltage of 20 kV.

Free radical scavenging activity

The DPPH radical scavenging assay is regularly used for the relatively rapid evaluation of the antioxidant activity. DPPH is a stable free radical, even at room temperature, and shows strong absorbance at 515 nm. The DPPH radical accepts an electron or hydrogen radical to become a stable diamagnetic molecule with a different color. Thus, the degree of its discoloration from purple to yellow is attributed to the hydrogen donating ability of the added compound, which is indicative of its radical scavenging potential.

The antioxidant activity of cookies was determined according to the method of (Shah et al. 2015), with some modifications. 80 μL of the sample was mixed with 200 μL of 0.05 % DPPH in a total volume of 4 ml methanol and allowed to react in the dark for 30 min. The results were expressed as percent inhibition using the relation.

Reducing power

Reducing power on iron ion was measured according to the method of Baba et al. (2014) with some modifications. Extracts (40 μl) were mixed with 2.5 ml of phosphate buffer (0.2 M, pH 6.6) and 2.5 ml potassium ferricyanide [K3Fe(CN)6] (1 %) and the mixture was incubated at 50 °C for 30 min. Afterwards, 2.5 ml of trichloroacetic acid (10 %) were added to the mixture, which was then centrifuged at 1000 g for 10 min (eppendrof centrifuge 5810R). Finally, 2.5 ml of the upper layer solution was mixed with 2.5 ml of distilled water and 0.5 ml of FeCl3 (0.1 %), and the absorbance was measured at 700 nm using a spectrophotometer (Hitachi U-2900). Increased absorbance of the reaction mixture indicated increased reducing power.

Sensory evaluation

A panel of ten semi-trained panelists comprising staff and students evaluated sensory properties of cookies. In each session, samples were served on white saucers identified with three-digit code numbers to eliminate bias. Panelists were instructed to evaluate colour at first and then taste each sample to evaluate flavour, texture and overall acceptability. A nine-point hedonic scale with 1 = dislike extremely, 5 = neither like nor dislike, 9 = like extremely was used. Samples that obtained 70 % of the scores in the ‘like (6–9 points)’ hedonic region for colour, flavour and texture, were considered acceptable. Water was provided to rinse the mouth between evaluations and covered expectoration cups if they did not wish to swallow the samples.

Statistical analysis

Results were expressed as mean of triplicate analyses. A one-way analysis of variance and Duncan’s test were used to establish the significance of differences among the mean values at the 0.05 significance level. The statistical analyses were performed using SPSS software.

Results and discussion

Pasting properties

In the RVA test, a significant difference (P ≤ 0.05) was found when the GTP was added to the wheat flour (Table 1). Pasting properties are generally related to the swelling and rupture of starch granules. Set back value (final viscosity-hot paste viscosity) decreased significantly with the increase in GTP. The lower value of setback reflects lesser degree of retrogradation of a starch paste. (Varavinit et al. 2003). After RVA test, the gelatinized flour gels were stored at 4 °C for 24 h for the hardness measurement, during this period, the hardness of flour gels decreased significantly (P ≤ 0.05) as the GTP level increased, especially when the added dose was up to 2 and 4 g/100 g. These results suggest that adding GTP could significantly inhibit the retrogradation of the gelatinized wheat flour system. The decrease in retrogradation may be due to the presence of phenolic components. Zhu et al. (2009) has also reported that the phyto-chemical extracts of green tea (mainly phenolic compounds) considerably reduce the wheat starch gel hardness.

Table 1.

Effect of Green tea powder on pasting properties of wheat flour and hardness of gel

| Blend % | Peak (cp) | Trough (cp) | Breakdown(cp) | Final viscosity(cp) | Set back(cp) | hardness of gel (g) |

|---|---|---|---|---|---|---|

| 0 | 3380 ± 2.0d | 1526 ± 2.0d | 1854 ± 2.0d | 3260 ± 3.0d | 1734 ± 3.0d | 63.2 ± 1.1d |

| 1 | 2982 ± 5.0c | 1214 ± 5.0a | 1768 ± 5.0c | 2872 ± 4.0b | 1658 ± 4.0c | 58.2 ± 0.9c |

| 2 | 2651 ± 4.0b | 1574 ± 4.0c | 1077 ± 4.0ab | 2937 ± 2.0bc | 1363 ± 3.0b | 55.4 ± 0.3b |

| 4 | 2352 ± 3.0a | 1321 ± 3.0b | 1031 ± 3.0a | 2575 ± 4.0a | 1254 ± 3.0a | 54.3 ± 1.2a |

The values are mean ± S.D of three independent determinations

Means followed by different superscripts within a column are significantly (p ≤ 0.05) different

Dough water absorption and stability test

Effect of GTP on the dough mixing properties is shown in Table 2. The significant increase (P ≤ 0.05) was observed in stability time and water absorption of the dough with the increase of GTP. As previously reported, the larger water absorption values are likely caused by the huge number of hydroxyl groups existing in green tea components (Zhou et al. 2009), such as tea polyphenols (TPL) and tea polysaccharides (TPC). Stability values are usually indicators of flour strength and higher values represent stronger dough. Generally, addition of ingredients containing no gluten will weaken the gluten matrix and induce less stable dough, as reported by Petitot et al. (2010) for wheat incorporating split pea and faba bean flours, and Wood (2009) for the chickpea fortified wheat flour. Discrepancies in this study might mainly arise from the components of GTP. Green tea contains about 21–28 % proteins on dry-base, which are mainly glutelins (Shen et al. 2008). These glutelins may combine with the extra prolamines in wheat flour to form a network and fortify the dough structure. In addition, Zhou et al. (2009) has reported that TPC in green tea could strongly interact with the proteins in wheat flour, improving the mixing properties of dough. However, Wang et al. (2007) found that green tea extracts (GTEs) in a certain percentage could weaken the gluten matrix, resulting in some negative impacts on the bread quality. It can be attributed to the effect of the particle size of green tea and their interaction with wheat proteins, as similarly reported by Hao et al. (2008) for the influence of alfalfa powder granularity on the rheological properties of alfalfa wheat dough.

Table 2.

Effect of green tea powder on functional and farinographic characteristics of wheat flour.

| Blend | WAC | OAC | SP | WSI | FC | FS | WAC | DDT | Stability |

|---|---|---|---|---|---|---|---|---|---|

| (%) | (mL/100 g) | (ml/100 g) | (g/100 g) | (%) | (%) | (%) | (min) | (min) | |

| 0 | 0.87 ± 0.24d | 1.22 ± 0.09 a | 5.15 ± 0.08a | 9.74 ± 0. 10d | 75 ± 3.20 d | 61.71 ± 1.20 b | 60.0 ± 0.1a | 1.9 ± 0.01a | 4.8 ± 0.05a |

| 1 | 0.83 ± 0.40c | 1.322 ± 0.12b | 5.13 ± 0.11a | 8.92 ± 0.14c | 65 ± 4.30 c | 63.03 ± 1.90 c | 61.9 ± 0.1bc | 2.4 ± 0.03bc | 5.0 ± 0.09b |

| 2 | 0.74 ± 0.31b | 1.42 ± 0.15c | 5.11 ± 0.10a | 8.29 ± 0.20b | 26 ± 3.80 b | 0a | 63.7 ± 0.2c | 2.9 ± 0.02c | 5.3 ± 0.08c |

| 4 | 0.56 ± 0.21a | 1.46 ± 0.11d | 5.08 ± 0.09a | 7.58 ± 0.18a | 0a | 0a | 65.3 ± 0.1d | 3.4 ± 0.01d | 5.8 ± 0.05d |

The values are mean ± S.D of three independent determinations

Means followed by different superscripts within a column are significantly different (p ≤ 0.05) for each blend

FC (%) = Foam Capacity, FS (%) = Foam Stability, OAC (ml/g) = Oil Absorption Capacity, WAC = Water Absorption Capacity, WSI (%) = Water Solubility Index, SP = Swelling Power. WAC = Water Absorption Capacity%, DDT = Dough development time

Dough development time (DDT) is the time from water addition to the flour until the dough reaches the point of the greatest torque. During the mixing phase, water hydrates the flour components and the dough is developed. A significant increase (P ≤ 0.05) was found in DDT with the increase in green tea content from 0–4 g/100 g of wheat flour. The increase in DDT is due to the increase in water absorption of the dough (Zaidul et al. 2004)

Thermal analysis

The thermal analysis (Table 3) showed that as the GTP content increased, the onset temperature (To), end temperature (Te) and enthalpy (∆H) did not change significantly however upon reheating the flour samples a significant decrease in retro gradation ratios was seen with the increase in GTP content of flour blends. Wu et al. 2009 also reported the decreased retrogradation in rice starch gels after ten days of storage at 4 C with 10, 14 and 20 % of tea polyphenols. Zhou et al. 2009 indicated that polysaccharides of tea extracts could retard retro gradation of wheat starch along with reduction of loss of moisture content firmness and endothermic enthalpy of bread crumbs.

Table 3.

Effect of GTP on the thermo chemical properties of wheat flours

| Blend % | T 0 (°C) | Tp (°C) | DSC Te (°C) | ∆H1 (J/g) | ∆H2 (J/g) |

|---|---|---|---|---|---|

| 0 | 54.9 ± 1.23c | 61.9 ± 1.28c | 67.3 ± 1.70c | 4.31 ± 0.22a | 0.84 ± 0.05b |

| 1 | 54.8 ± 0.98 c | 61.6 ± 1.78bc | 66.8 ± 1.39b | 4.32 ± 0.43a | 0.69 ± 0.09a |

| 2 | 54.6 ± 1.43b | 61.3 ± 1.35ab | 66.5 ± 1.66b | 4.30 ± 0.98a | 0.18 ± 0.11c |

| 4 | 54.1 ± 1.56a | 60.8 ± 1.55a | 66.1 ± 1.02a | Nd | Nd |

T0, onset temperature; Te, end temperature; Tp, Pasting temperature; ∆H1 enthalpy of gelatinization; ∆H2 enthalpy of retrogradation & Nd not detected

Mean values followed by the same letter in the same column are significantly (P ≤ 0.05) different

Water solubility index and swelling power

The water solubility index decreased significantly (P ≤ 0.05) with the addition of GTP (0–4 g/100 g) to wheat flour, as shown in Table 2. This is an indication that blended flour was less soluble in water. The addition of GTP may have caused the soluble substances in the flour to mobilize, making their binding sites for water inaccessible. Medoua et al. (2005) also reported that the decrease in WSI could be due to the mobilization of soluble substances.

Swelling power results from the ability of starch to trap and retain water within its structure, prior to and during gelatinization (Whistler and Daniel 1985). The swelling power (SP) of the blended flour did not show any significant difference (P ≤ 0.05) with the increase of GTP content in the wheat flour system

Water absorption and oil absorption

The water absorption capacity (WAC) of wheat flour was found to decrease significantly (P ≤ 0.05) with increase in GTP (0–4 g/100 g), as shown in Table 2. The lower WAC may be due to the presence of lower amount of hydrophilic constituents in GTP .The same was reported by Akubor and Badifu (2001) in buck wheat. The oil absorption capacity (OAC) of the flour was found to increase significantly (P ≤ 0.05) with increase in the amount of GTP. The increase in OAC suggests the presence of lipophillic components in GTP. Cichelli and Pertesana (2004) also reported various lipophillic pigments in green tea, i.e, chlorophylls, pheophytins and carotenoids. Though these compounds were present in minute amount but can significantly affect OAC of flour. The oil absorption capacity (OAC) of flour is very important as it improves the mouth feel and retains the flavor.

Foaming capacity and foam stability

A significant difference was found in the foaming capacity and foam stability of each blend. The foaming capacity of the control was 75 % in 2 % (w/v) solution, after which foam capacity reduced progressively as the concentration of GTP in solution increased as shown in Table 2. The foaming capacity of 65 and 26 % was recorded in 1 and 2 % blends, respectively and in the 4 % blend the foaming capacity was found to be 0 %. The foam stability in the control was found to be 61.71 % while as, it was 63.03 % in 1 % blend and 0 % in 2 and 4 % blend each. The addition of GTP might have changed the configuration of protein molecules in wheat flour due to its highly ordered globular structure. As previously reported by Graham and Phillips (1976), foaming capacity is assumed to be dependent on the configuration of protein molecules. Flexible proteins have good foaming capacity but highly ordered globular molecule reduces foam ability.

Color measurement of cookies

Color measurements were performed to determine the influence of GTP on cookie formulation. Comparison of cookie color between the control and cookie with 1, 2 & 4 % levels of GTP is listed in Table 4. No significant difference (P ≤ 0.05) was found in the values of L* (brightness), a* (negative value indicates greenness and positive value indicates redness) and b* (negative value indicates blueness and positive value indicates yellowness), when GTP was increased from 1–2 g/100 g of wheat flour, however all the color values were significantly different from control. The increase in concentration of GTP up to 4 g/100 g reduced the L* and b* values significantly (P ≤ 0.05) but a* value increased. Almost similar results were found by Wang et al. (2007) in a comparative study of the effect of green tea extract on the quality of bread by instrumental analysis and sensory evaluation. These changes were obviously due to the color discrepancy of the GTP and wheat flour in nature. It is also well known that the flour color is often influenced by its polyphenolic content (Takata et al. 2007) and studies have revealed that green tea is characterized mainly by polyphenols. Therefore, the change in color of cookies is attributed to the addition of GTP to the wheat flour.

Table 4.

Characteristics of cookies prepared from the blended flours

| Parameters | 0 % | 1 % | 2 % | 4 % |

|---|---|---|---|---|

| DPPH(% inhibition) | 5.5 ± 2.0a | 23.54 ± 2.1b | 81.33 ± 3.4c | 90.72 ± 2.3d |

| Reducing power (% w.r.t control) | – | 27.36 ± 0.78a | 53.22 ± 0.98b | 59.64 ± 1.23c |

| Color: | ||||

| L* | 53.63 ± 0.82b | 52.37 ± 0.77b | 49.85 ± 2.7b | 33.23 ± 2.74a |

| a* | 3.71 ± 0.31a | 4.05 ± 0.42a | 4.15 ± 0.71a | 33.23 ± 2.74b |

| b* | 29.02 ± 0.59a | 28.67 ± 0.73a | 27.93 ± 0.93a | 33.23 ± 2.74b |

| Fracture force (kg) | 4.98 ± 0.22c | 4.53 ± 0.24b | 3.11 ± 0.15a | 3.10 ± 0.19a |

Means with different smalll letter within a row are significantly (P ≤ 0.05) different

The values are mean ± S.D of independent determinations

DPPH, 2,2-diphenyl-1-picrylhydrazyl

Texture analysis

Breaking strength of cookies was measured using a texture analyzer, revealing a significant decrease in the force required to break/snap the cookies from 4.98 to 3.10 kg as the level of GTP increased from 0 to 4 % (Table 4). Similar results in case of cookies from sorghum-wheat blends and oat-wheat blends were observed (Chavan and Kadam 1993). However, Hoseney and Rogers (1994) reported that hardness of the cookies is caused by the interaction of proteins and starch by hydrogen bonding. According to the previous studies, it was observed that higher content of dietary fiber in GTP might also have a role in the TPA parameters of Cookie products.

Free radical scavenging activity

The scavenging of the stable DPPH is based on the measurement of the reducing ability of antioxidants towards DPPH (Prior et al. 2005). Table 4 shows that the percent inhibition of DPPH increases with the increase in amount of GTP in wheat flour. This is largely because, tea and tea products mainly contain polyphenols and compounds like myristic acid and palmitic acid, which are natural antioxidants and have been demonstrated to show antioxidative, anti-carcinogenic and anti-microbial properties (Ahmad et al. 2013; Rietveld and Wiseman 2003).

Reducing power

The reducing power increased significantly (P ≤ 0.05) with the increase in the green tea content in cookies (Table 4). The cookie extract showed a good reductive ability which is a reflection of its antioxidative potential The reducing properties are generally associated with the presence of reductones (Duh 1998), such as catechins, epigcatechins (EC), epigaloocatechins (EGC), epigallocatechingalate (EGCG) (a potent reducing agent), which have been shown to exert antioxidant action by breaking the free radical chain by donating a hydrogen atom (Gordon 1990). Reductones are also reported to react directly with peroxides (Shimada et al. 1992) and also with certain precursors of peroxides, thus preventing peroxide formation (Xing et al. 2005).

Microstructure

Typical electron micrographs of the cross-section of each cookie type are shown in Fig 1. Microscopic examination revealed a major difference between the cookie structure of 0–1 % blend and 2–4 % blends of GTP. As the level of GTP increased from 2–4 % in the cookies, the structure appeared to loose, consisting of gaps. The cookies with 4 % GTP had a more open structure than cookies with 2 % GTP. The difference in structure may be due to the presence of fiber and other components of green tea or differential response of tea powder in comparison to wheat flour towards baking process. The presence of green tea in cookie appears to disrupt the starch-gluten matrix. Gan et a1. (1992) also reported disruption in the starch-gluten matrix in case of bread due to the presences of fiber in bran. The deleterious effects of the addition of fiber on dough structure have been suggested to be due to the dilution of the gluten network, Pomeranz et al. (1977).

Fig. 1.

SEM of cookies with varying degrees of blends of green tea powder. a 0 % blend b 1 % blend c 2 % blend & d 4 % blend

Sensory analysis

The sensory analyses showed that addition of 4 % GTP to wheat flour scored significantly higher (P ≤ 0.05) values for color (7.0 ± 0.08), aroma (7.2 ± 0.01) and taste (7.4 ± 0.10) as compared to control (Table 5), however no significant difference was detected in 1 % and 2 % blended cookies for color, aroma and taste respectively. The score for appearance and texture decreased significantly (P ≤ 0.05) as the addition of GTP to wheat flour increased. The results of sensory analysis showed that scores assigned by the judges for texture and colour were in good agreement with the measurements derived from the physical test. The increase in color aroma and taste of cookies is likely due to presence of tea volatiles and polyphenols. The panelists suggested that GTP can be incorporated into Wheat flour at lower levels as higher levels may have negative effect on hardness and appearance of cookies.

Table 5.

Sensory characteristics of cookies prepared from blended flour

| GTP % added to wheat flour | Appearance | Color | Aroma | Taste | Texture | Overall accept-ability |

|---|---|---|---|---|---|---|

| 0 | 7.0d ± 0.01 | 6.2a ± 0.21 | 6.3a ± 0.14 | 6.6a ± 0.25 | 7.3d ± 0.02 | 6.7c ± 0.07 |

| 1 | 5.9c ± 0.05 | 6.6b ± 0.12 | 6.7b ± 0.11 | 7.0b ± 0.01 | 6.1c ± 0.03 | 6.4b ± 0.03 |

| 2 | 5.4b ± 0.02 | 6.7b ± 0.13 | 6.8b ± 0.11 | 7.1b ± 0.04 | 5.6b ± 0.03 | 6.3b ± 0.10 |

| 4 | 5.0a ± 0.02 | 7.0c ± 0.08 | 7.2c ± 0.01 | 7.4c ± 0.10 | 3.7a ± 0.08 | 6.0a ± 0.05 |

The values are mean ± S.D of independent determinations

Mean values followed by the same letter in the same column are significantly (P ≤ 0.05) different

Conclusion

Green tea powder was successfully added into cookies as a new type of natural additive. The addition of GTP resulted in a significant improvement of the stability, visco-elastic and functional properties of wheat dough. The color, aroma taste and antioxidant capacity of green tea cookies increased with the increase in GTP proportion in wheat flour. It was concluded that GTP can be substituted into wheat flour in lower proportions to prepare cookies with added nutraceutical values without compromising the technological aspects of the product.

Acknowledgments

Authors are thankful to the Department of Biotechnology, Government of India for financial support.

Contributor Information

Mudasir Ahmad, Email: mudasirahamad63@yahoo.in.

Waqas N. Baba, Email: waqasbaba7@gmail.com

Asir Gani, Email: asir.gani@gmail.com.

Adil Gani, Phone: +918715022903, Email: adil.gani@gmail.com.

Umar Shah, Email: umarzahoorshah@yahoo.com.

S. M. Wani, Email: wanisajad84@gmail.com

F. A. Masoodi, Email: Masoodi_fa@yahoo.co.in

References

- AACC . Approved Methods of the American Association of Cereal Chemist. 10. St. Paul: American Association of Cereal Chemist Inc; 2000. [Google Scholar]

- Ahmad M, Gani A, Baba WN, Gani A, Wani SM, et al. Effect of extraction time, on physiologically important Constituents of green tea (Camellia sinensis), using GC/MS. J Food Process Technol. 2013;4:1–5. doi: 10.4172/2157-7110.1000276. [DOI] [Google Scholar]

- Ajila CM, Aalami M, Leelavathi K, Prasada Rao UJS. Mango peel powder: a potential source of antioxidant and dietary fiber in macaroni preparations. Innov Food Sci Emerg Technol. 2010;11:219–224. doi: 10.1016/j.ifset.2009.10.004. [DOI] [Google Scholar]

- Akubor PI, Badifu GIO. Chemical composition, functional properties and baking potential of African bread fruit kernel and wheat flour blends. Int J Food Sci Technol. 2001;39:223–229. doi: 10.1046/j.0950-5423.2003.00768.x. [DOI] [Google Scholar]

- Baba, W.N. Rashid I, Shah A, Ahmad M, Gani A, Masoodi FA Wani I A, Wani SM. (2014) Effect of microwave roasting on antioxidant and anticancerous activities of barley flour. J Saudi Soc Agr Sci. doi:10.1016/j.jssas.2014.06.003

- Chavan JK, Kadam SS. Nutritional enrichment of bakery products by supplementation with non-wheat flours. CRC Crit Rev Food Sci Nutr. 1993;33:189–226. doi: 10.1080/10408399309527620. [DOI] [PubMed] [Google Scholar]

- Choo CL, Aziz NAA. Effects of banana flour and β-glucan on the nutritional and sensory evaluation of noodles. Food Chem. 2010;119:34–40. doi: 10.1016/j.foodchem.2009.05.004. [DOI] [Google Scholar]

- Cichelli A, Pertesana GP. High-performance liquid chromatographic analysis of chlorophylls, pheophytins and carotenoids in virgin olive oils: chemometric approach to variety classification. J Chromatogr A. 2004;1046:141–146. [PubMed] [Google Scholar]

- Duh PD. Antioxidant activity of Burdock (Arctium lappa Linne): its scavenging effect on free-radical and active oxygen. J Am Oil Chem Soc. 1998;75:455–461. doi: 10.1007/s11746-998-0248-8. [DOI] [Google Scholar]

- Gallegos-Infante A, Rocha-Guzman NE, Gonzalez-Laredo RF, Ochoa-Martínez LA, Corzo N, Bello-Perez LA, et al. Quality of spaghetti pasta containing Mexican common bean flour (Phaseolus vulgaris L.) Food Chem. 2010;119:1544–1549. doi: 10.1016/j.foodchem.2009.09.040. [DOI] [Google Scholar]

- Gan Z, Calliard T, Ellis PR, Angold RE, Vaughan JC. Effect of the outer bran layers on the loaf volume of wheat bread. J Cereal Sci. 1992;15:151–163. doi: 10.1016/S0733-5210(09)80066-0. [DOI] [Google Scholar]

- Gani A, Wani SM, Masoodi FA, Salim R. Characterization of rice starches extracted from Indian cultivars. Food Sci Technol Int. 2013;19(2):143–152. doi: 10.1177/1082013212442189. [DOI] [PubMed] [Google Scholar]

- Gani A, Broadway AA, Ahmad M, Ashwar BA, Wani AA, Wani SM, Masoodi FA, Khatkar S. Effect of whey and casein protein hydrolysates on rheological, textural and sensory properties of cookies. J Food Sci Technol. 2014 doi: 10.1007/s13197-014-1649-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gordon MH. The mechanism of antioxidant action in vitro. In: Hudson BJF, editor. Food antioxidants. London: Elsevier Science; 1990. pp. 1–18. [Google Scholar]

- Graham DE, Philips MC. In: The conformation of proteins at the air-water interface and their role in stabilizing foam. Akers RJ, editor. New York: Academic Press; 1976. pp. 237–255. [Google Scholar]

- Hao CC, Wang LJ, Li D, Özkan N, Wang DC, Chen XD, et al. Influence of alfalfa powder concentration and granularity on rheological properties of alfalfae wheat dough. J Food Eng. 2008;89:137–141. doi: 10.1016/j.jfoodeng.2008.04.011. [DOI] [Google Scholar]

- Hoseney RC, Rogers DE (1994) Mechanism of sugar functionality in cookies. The science of cookie and cracker production. Am Assoc Cereal Chemists 203–225

- Martinez-Villaluenga C, Torres A, Frias J, Vidal-Valverde C. Semolina supplementation with processed lupin and pigeon pea flours improve protein quality of pasta. LWT Food Sci Technol. 2010;43:617–622. doi: 10.1016/j.lwt.2009.11.001. [DOI] [Google Scholar]

- McWatters KH, Ouedraogo JB, Resurreccion AVA, Hung YC, Phillips RD. Physical and Sensory characteristics of sugar cookies containing mixtures of wheat, Fonio (Digitaria exilis), and cowpea (Vigna unguiculata) flours. Int J Food Sci Technol. 2003;38:403–410. doi: 10.1046/j.1365-2621.2003.00716.x. [DOI] [Google Scholar]

- Medoua GN, Mbome IL, Agbor-Egbe T, Mbofung CMF. Physicochemical changes occurring during post-harvest hardening of trifoliate yam (Dioscorea dumetorum) tubers. Food Chem. 2005;90:597–601. doi: 10.1016/j.foodchem.2004.04.018. [DOI] [Google Scholar]

- Narayana K, Narasinga Rao MS. Functional properties of raw and heat processed winged bean flour. J Food Sci. 1982;47:1534–1538. doi: 10.1111/j.1365-2621.1982.tb04976.x. [DOI] [Google Scholar]

- Petitot M, Boyer L, Minier C, Micard V. Fortification of pasta with split pea and faba bean flours: pasta processing and quality evaluation. Food Res Int. 2010;43:634–641. doi: 10.1016/j.foodres.2009.07.020. [DOI] [Google Scholar]

- Pomeranz Y, Shogren M, Finney KF, Bechtel DB. Fiber in breadmaking - effects on functional properties. Cereal Chem. 1977;5:25–41. [Google Scholar]

- Prior RL, Wu X, Schaich K. Standardized methods for the determination of antioxidant capacity and phenolics in foods and dietary supplements. J Agr Food Chem. 2005;53:4290–4302. doi: 10.1021/jf0502698. [DOI] [PubMed] [Google Scholar]

- Rietveld A, Wiseman S. Antioxidant effects of tea: evidence from human clinical trials. J Nutr. 2003;133:3285–3292. doi: 10.1093/jn/133.10.3285S. [DOI] [PubMed] [Google Scholar]

- Shah A, Ahmad M, Ashwar BA, Gani A, Masoodi FA, et al. Effect of γ-irradiation on structure and nutraceutical potential of β-d-glucan from barley (Hordeum vulgare) Int J Biol Macromol. 2015;72:1168–1175. doi: 10.1016/j.ijbiomac.2014.08.056. [DOI] [PubMed] [Google Scholar]

- Shen LQ, Wang XY, Wang ZY, Wu YF, Chen JS. Studies on tea protein extraction using alkaline and enzyme methods. Food Chem. 2008;107:929–938. doi: 10.1016/j.foodchem.2007.08.047. [DOI] [Google Scholar]

- Shimada K, Fujikawa K, Yahara K, Nakamura T. Antioxidative properties of xanthan on the autoxidation of soybean oil in cyclodextrin emulsion. J Agric Food Chem. 1992;40:945–948. doi: 10.1021/jf00018a005. [DOI] [Google Scholar]

- Takata K, Yanaka M, Fujita Y, Ishikawa N. Evaluation of the grain and flour quality in near-isogenic wheat lines with waxy and double-null Waxy proteins. Breed Sci. 2007;57:79–83. doi: 10.1270/jsbbs.57.79. [DOI] [Google Scholar]

- Varavinit S, Shobsngob S, Warunee V. Effect of amylose content on gelatinization, and pasting properties of different cultivars of Thai rice. Starch/ Stäke. 2003;55:410–415. doi: 10.1002/star.200300185. [DOI] [Google Scholar]

- Wang H, Provan GJ, Helliwell K. The flavonoids: their functions, ultilisation and analysis. Trends Food Sci Technol. 2000;11:152–160. doi: 10.1016/S0924-2244(00)00061-3. [DOI] [Google Scholar]

- Wang R, Zhou WB, Isabelle M. Comparison study of the effect of green tea extract (GTE) on the quality of bread by instrumental analysis and sensory evaluation. Food Res Int. 2007;40:470–479. doi: 10.1016/j.foodres.2006.07.007. [DOI] [Google Scholar]

- Whistler RL, Daniel JR. Carbohydrates. In: Fennema OR, editor. Food Chemistry. 2. New York: Marcel Dekker Inc; 1985. pp. 69–125. [Google Scholar]

- Wood JA. Texture, processing and organoleptic properties of chick pea fortified spaghetti with insights to the underlying mechanisms of traditional durum pasta quality. J Cereal Sci. 2009;49:128–133. doi: 10.1016/j.jcs.2008.07.016. [DOI] [Google Scholar]

- Wu Y, Chen ZX, Li XX, Li M. Effect of tea polyphenols on the retrogradation of rice starch. Food Res Int. 2009;42:221–225. doi: 10.1016/j.foodres.2008.11.001. [DOI] [Google Scholar]

- Xing R, Liu S, Guo Z, Yu H, Wang P, Li C, et al. Relevance of molecular weight of chitosan and its derivatives and their antioxidant activities in vitro. Bioorg Med Chem. 2005;13:1573–1577. doi: 10.1016/j.bmc.2004.12.022. [DOI] [PubMed] [Google Scholar]

- Zaidul ISM, Karim AA, Manan DMA, Ariffin A, Norulaini NAN, Omar AKM. A farinograph study on the viscoelastic properties of sago/wheat flour dough. J Sci Food Agric. 2004;84:616–622. doi: 10.1002/jsfa.1713. [DOI] [Google Scholar]

- Zhao XY, Ao Q, Yang LW, Yang YF, Sun JC, Gai GS. Application of superfine pulverization technology in biomaterial industry. J Taiwan Chem Eng. 2009;40:337–343. doi: 10.1016/j.jtice.2008.10.001. [DOI] [Google Scholar]

- Zhou YB, Wang DF, Wan XC, Zhang L, Du XF, Hu WS. Effect of tea polysaccharide addition on the properties of bread made from two flours. J Food Process Preserv. 2009;33:798–813. doi: 10.1111/j.1745-4549.2008.00312.x. [DOI] [Google Scholar]

- Zhu F, Cai YZ, Sun M, Corke H. Effect of photochemical extracts on the pasting, thermal, and gelling properties of wheat starch. Food Chem. 2009;112:919–923. doi: 10.1016/j.foodchem.2008.06.079. [DOI] [Google Scholar]