Abstract

The aim of this study was to develop a gluten-free formulation of quinoa (Chenopodium quinoa Willd.)-based cookies using experimental design of mixture to optimize a ternary mixture of quinoa flour, quinoa flakes and corn starch for parameters of colour, specific volume and hardness. Nutritional and sensory aspects of the optimized formulation were also assessed. Corn starch had a positive effect on the lightness of the cookies, but increased amounts of quinoa flour and quinoa flakes in the mixture resulted in darker product. Quinoa flour showed a negative effect on the specific volume, producing less bulky cookies, and quinoa flour and quinoa flakes had a positive synergistic effect on the hardness of the cookies. According the results and considering the desirability profile for colour, hardness and specific volume in gluten-free cookies, the optimized formulation contains 30 % quinoa flour, 25 % quinoa flakes and 45 % corn starch. The quinoa-based cookie obtained was characterized as a product rich in dietary fibre, a good source of essential amino acids, linolenic acid and minerals, with good sensory acceptability. These findings reports for the first time the application of quinoa processed as flour and flakes in mixture with corn starch as an alternative ingredient for formulations of gluten-free cookies-type biscuits.

Keywords: Bakery products, Quinoa, Mixture design, Optimization

Introduction

The increasing consumer demand for foods that combine additional benefits in addition to common nutrients imposes on the food industry a need for advances in ingredients and formulations, particularly for the production of functional foods (Falguera et al. 2012). Quinoa (Chenopodium quinoa Willd) is a gluten-free pseudo-cereal that contains a high amount of fibre, high biological-value proteins, essential fatty acids (ω-3 and ω-6), vitamins, and minerals (Stikic et al. 2012; James 2009). Consumed in natura or processed as flakes and flour, quinoa can also be used in the bakery industry because the starch present in the seeds has properties similar to those found in wheat (Gómez-Caravaca et al. 2011). In addition to augmenting the nutritional value, the addition of quinoa flour has shown positive effects on the rheological and sensory characteristics of bakery products, such bread and cookies (Stikic et al. 2012; Harra et al. 2011; Lorenz et al. 1995).

Cookies-type biscuits have long shelf life and wide acceptance by consumers of all ages (Mareti et al. 2010; Fasolin et al. 2007), making these items attractive in the development of alternative products, such as gluten-free foods. In the design of new products, parameters such as colour, texture and volume which directly influence consumer acceptance, should be considered (Bassinello et al. 2011; Canett-Romero et al. 2004). Within this context, the experimental design of mixtures is a tool that allows modelling by simulating and optimizing certain properties of the ingredients in a formulation, thus decreasing the production time and cost (Mareti et al. 2010; Dutcosky et al. 2006).

Considering these aspects, the present study used a mixture experiment aimed to optimize a formulation of gluten-free quinoa-based cookies. The effects and interactions of the components of the ternary mixture composed of quinoa flour, quinoa flakes and corn starch and their effects on the colour, texture and specific volume of the prepared cookies were considered. In addition, the cookies obtained using the optimized formulation was characterized with regard to their nutritional and sensory aspects.

Material and methods

Quinoa ingredients

Quinoa flour (composition in g/100 g: carbohydrate 65.2; protein 16.92; lipids 5.73; fibre 9.65, ash 2.49) and quinoa flakes (composition in g/100 g: carbohydrate 69.25; protein 13.36; lipids 5.53; fibre 9.83, ash 2.17) were obtained from Quinoa Real Company (São Paulo, Brazil). Pasteurised egg powder and corn starch (composition in g/100 g: carbohydrate 91; protein 0.3; lipids 0.1; fibre 0.9) were obtained from S. Trajano Aromas & Ingredientes Company (Recife, Brazil) and Unilever® (São Paulo, Brazil), respectively. The other ingredients [sugar (União, São Paulo, Brazil), salt (Cisne®, Rio de Janeiro, Brazil), sodium bicarbonate (Kitano®, São Paulo, Brazil) and soy oil (Soya®, Santa Catarina, Brazil)] used for the preparation of the cookies were obtained from local supermarkets in the city of João Pessoa (Paraíba, Brazil).

Experimental design of mixtures

The formulations were prepared from the base formulation presented in Table 1. A full simplex lattice factorial was used for the experimental design of the mixtures, with internal points and global centroid and without restrictions for minimum and maximum levels, using the Statistica 7.0 software (Statsoft 2004) (Table 2). The quinoa flour, quinoa flakes and corn starch concentrations ranged in each assay from 0 to 100 % for the equivalent of 55.7 % of the formulation, whereas the remaining components remained constant (Mareti et al. 2010). The order of execution of the assays was randomized, and the dependent variables analysed in each test were the colour, hardness and specific volume of the cookies. For each dependent variable, a complete cubic model was generated according to Eq. 1 (Cornell 1981), which, after adjustment, was as follows:

| 1 |

Table 1.

Basic formulation of quinoa-based gluten-free cookies

| Ingredient | Quantity (%) |

|---|---|

| Baking powder (sodium bicarbonate) |

0.55 |

| Pasteurized powder egg | 2.65 |

| Corn oil | 13.25 |

| Salt | 0.90 |

| Water | 13.25 |

| Sugar | 13.70 |

| Mixture (QF + QF + CS)a | 55.70 |

a QF, quinoa flour; QFL, quinoa flakes; CS, Corn starch

Table 2.

Experimental design of a simplex-type lattice mixture for the formulation of cookies in actual proportions of the ingredients and pseudocomponents in the mixture and average values of the variables of colour, hardness and specific volume

| Proportion of ingredients in the mixture | Response | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Percentage of added ingredients in F | Amount of ingredients (g) | Y1 | Y2 | Y3 | Y4 | Y5 | |||||

| QF (x1) | QFL (x2) | CS (x3) | QF (x1) | QFL (x2) | CS (x3) | (N) | (cm3.g−1) | ||||

| 1 | 1 | 0 | 0 | 252.00 | - | - | 4.65 | 32.27 | 61.54 | 51.11 | 0.80 |

| 2 | 0 | 1 | 0 | - | 252.00 | - | 4.66 | 30.55 | 60.66 | 70.14 | 1.63 |

| 3 | 0 | 0 | 1 | - | - | 252.00 | −3.33 | 23.22 | 89.76 | 8.67 | 1.57 |

| 4 | 0.33 | 0.67 | 0 | 83.16 | 168.84 | - | 5.48 | 34.49 | 64.59 | 44.05 | 0.76 |

| 5 | 0.33 | 0 | 0.67 | 83.16 | - | 168.84 | 4.99 | 31.81 | 70.61 | 9.56 | 0.85 |

| 6 | 0 | 0.33 | 0.67 | - | 83.16 | 168.84 | 1.55 | 27.97 | 75.65 | 19.67 | 2.27 |

| 7 | 0.67 | 0.33 | 0 | 168.84 | 83.16 | - | 8.61 | 32.94 | 59.10 | 75.74 | 0.81 |

| 8 | 0.67 | 0 | 0.33 | 168.84 | - | 83.16 | 8.54 | 33.61 | 60.98 | 70.40 | 0.83 |

| 9 | 0 | 0.67 | 0.33 | - | 168.84 | 83.16 | 7.07 | 32.28 | 64.13 | 50.92 | 1.88 |

| 10 | 0.33 | 0.33 | 0.34 | 83.92 | 83.92 | 84.17 | 10.02 | 34.10 | 58.02 | 59.83 | 0.98 |

| 11 | 0.67 | 0.17 | 0.17 | 168.84 | 41.58 | 41.58 | 4.64 | 31.41 | 61.23 | 66.68 | 0.92 |

| 12 | 0.17 | 0.67 | 0.17 | 41.58 | 168.84 | 41.58 | 4.36 | 33.54 | 64.72 | 42.57 | 0.90 |

| 13 | 0.17 | 0.17 | 0.67 | 41.58 | 41.58 | 168.84 | 4.38 | 30.50 | 72.58 | 13.38 | 1.83 |

| 14 | 0.33 | 0.33 | 0.33 | 83.92 | 83.92 | 84.17 | 4.57 | 34.06 | 58.98 | 54.94 | 0.97 |

F, Formulations generated by the experimental design of mixtures; QF, quinoa flour; QFL, quinoa flakes; CS, Corn starch; Y1 colour a*, Y2 colour b*, Y3 colour L*, Y4 hardness, Y5 specific volume

Where:

y = the dependent variable or response; b = the equation coefficients; d = are the parameters of the model and x = the independent variables.

The maximization, minimization and desirability profile were also generated using Statistica 7.0 software (Statsoft 2004). The optimization process of the ternary mixture of the ingredients was designed from the desirability profile to produce a biscuit possessing features of colour, hardness and specific volume within an optimal region. The data of the analysis of the 14 formulations were analysed with the results for commercial gluten-free cookies VITAO®, stored at room time, formulated with rice flour in replacement of wheat flour, for the same parameters.

Preparation of cookies

For the production of the cookies, after individual weighing, solid and liquid ingredients were individually weighed and mixed manually until homogeneous dough was achieved. The dough was then divided in 15 g portions and shaped in 6 cm diameter cookies. The cookies were baked at 180 °C for 30 min, cooled to room temperature and subjected to laboratory analyses.

Cookie colour

The colour analyses were performed using a Minolta CR-300 (Japan) digital colorimeter. The parameters of L* (lightness), a* (red/green intensity) and b* (yellow/blue intensity) of the CIE-Lab system (Comission Internationale d’le Ecleraige) were determined using illuminant D65, a viewing angle of 8° and standard observer angle of 10°, with a specular included. The analyses were performed in triplicate (CIE 1978).

Cookies hardness

The determination of the cookie hardness was performed using a TA-XT2 plus texture analyzer, and the results were analysed using Stable Micro System TE 32 L S® Version 4.0 software. The Heavy Duty Platform (HDP) was placed horizontally in a position that enables the upper blade to be equidistant from the two lower supports. The sample was placed centrally over the supports and cut in half with a “probe” 3-Point Bending Rig (3 PB) 256 × 250 mm at a pre-test speed of 1 mm/s, test speed of 3 mm/s and post-test speed of 10 mm/s, with a trigger force of 50 g and 5.0 mm of distance. Five reading replicates were performed for each cookie formulation.

Cookie specific volume

The sample volume was determined by the displacement of millet seeds in a 1000 mL graduated test tube, and the dough weight was determined using an analytical balance (Feddern et al. 2011). The specific volume was expressed in cm3.g−1, and its determination in each assay was performed in triplicate.

Nutritive value of optimized cookie formulation

All analysis of characterization of the optimized cookie formulation, generated after the analysis of the desirability profile, were performed in triplicate on three different replications. The cookies were analysed for moisture (925.09), total fat (920.39A), crude protein (N × 5.83) (990.03), ash (930.30), dietary fibre (992.16), Aw (978.18) and pH analyses (947.05) according to AOAC (2006). Carbohydrates were quantified using the phenol-sulphuric method with 6 % of phenol (p/v); the absorbance at 490 nm was measured using glucose as a standard. The energy value was calculated using the Atwater formula (FAO/WHO/UNO 1985) with the conversion factors of 4 kcal.g−1 for carbohydrates and proteins and 9 kcal.g−1 for lipids; the results are expressed in kcal. g−1.

The minerals in the sample were quantified by the method of flame photometry for K; P, Ca, Mg, Cu, Fe, Mn, and Zn were determined by atomic absorption spectrophotometry using a Varian Spectr AA-200 model VARIAN spectrophotometer (AOAC 2006).

The fatty acid profile of cookies was determined, after saponification and esterification of total lipids according to Hartman and Lago (1973), by a Varian 430-GC gas chromatograph with a flame ionisation detector (FID) and a fused silica capillary column (Varian CP WAX 52 CB) with dimensions of 60 m × 0.25 mm × 0.25 mm thick film. Helium was used as carrier gas at a flow rate of 1 mL/min. The oven temperature was initially 100 °C and increased 2.5 °C/min to a final temperature of 240 °C for 20 min, with a total time of 76 min. The injector and detector temperatures were maintained at 250 and 260 °C, respectively. A 1.0 μL aliquot of the esterified extract was injected into a split/splitless type injector at 250 °C, and the chromatograms were recorded using Galaxie Chromatography Data System software. Fatty acids were identified by comparing the methyl ester retention times with standards from the Supelco ME19-Kit (Fatty Acid Methyl Esters C6-C24). The fatty acids results were quantified by area normalisation of the methyl esters and expressed as percent (%) area.

The amino acid profile was performed according to White et al. (1986). The samples were previously hydrolysed in redistilled 6 N hydrochloric acid, followed by pre-column derivation of free amino acids with phenylisothiocyanate (PITC). The separation of the derived phenylthiocarbamyl amino acids (PTC-AA) was performed by liquid chromatography (VARIAN, Waters 2690, California, USA). Detection was performed at wavelength of 254 nm at 35 °C and a flow rate of 1 mL/min.

To ensure that the final product was not (cross) contaminated during the manufacturing process with some source containing gluten, cookies were assayed with anti-omega gliadin antibody using EZ Gluten® test (ELISA Technologies, Inc., Florida, USA), a recognized method to detect levels of gluten as low as 10 ppm (Allred and Park 2012).

Sensory evaluation

Prior to the sensory analysis, the cookies were subjected to a microbiological analysis using methods recommended by the American Public Health Association (APHA 2001) to ensure their sanitary quality.

Eighty five untrained panelists evaluated the optimized quinoa cookies. These evaluators were recruited from students, employees and professors of the Federal University of Paraíba (João Pessoa, Brazil) and selected according to interest and cookies consumption habit. Age range was from 18 to 65 years, both sexes. Overall acceptance and purchase intent analyses were performed as described by Meilgaard et al. (1987). The panelists were instructed to evaluate the overall acceptance of each sample using a 9-point hedonic scale in which 1 corresponded to “entirely disliked”, 5 to “neither liked nor disliked” and 9 to “entirely liked”. The test of purchase intent was conducted simultaneously with the acceptance test using a 5-point structured scale that ranged from 1 (certainly would not buy) to 5 (certainly would buy). Analyses were performed in individual booths with controlled temperature and lighting, and the samples were served in separate disposable dishes in random order coded with three random digits, accompanied with water to cleanse the palate between samples.

Statistical analysis

The independent and dependent variables were adjusted to a third-order model equation and examined for quality of the adjustment. An analysis of variance was performed to determine the lack of fit, and the significance of the effects and interactions of the independent variables on each response, considering each formulation with the Fisher test, was also applied. The significance was evaluated by determining the degree of probability considering a significance level less than 5 %. The statistical analyses were performed using Statistica 7.0 software (Statsoft 2004). The physicochemical analyses were performed in triplicate, and the experimental data are presented as average values.

Results and discussion

Colour

The lightness (L* values) ranged from 58 to 90 in the 14 evaluated cookie formulations (Table 2). The determination coefficient (R2) of the model generated for this parameter was 0.94, showing adjustment to the experimental data (Table 3). The highest values for lightness were observed for the formulations that contained a higher amount of corn starch than quinoa flakes and quinoa flour in the mixture. A relationship between lightness and grain size of the flour used in the cookie formulation has already been described (Zucco et al. 2011). In the present study lightness of cookies decrease with increase of quinoa flour and quinoa flakes, which have larger grain size than corn starch. Moreover, the high protein content, sugars and phenolic compounds of formulations with higher proportions of quinoa flour and quinoa flakes, may have contributed to decrease the lightness values of the cookies, due to the Maillard reaction, with a consequent increase of melanoidin formation, resulting in a darkening of the product (Secchi et al. 2011; Zucco, et al. 2011; Bassinello et al. 2011; Singh and Mohamed 2007). In addition, oxidation of phenolic compounds present in quinoa flour and quinoa flakes with consequent formation of dark pigments may also have interfered (Adelakun et al. 2012; Takata et al. 2007).

Table 3.

Regression coefficients and mathematical equations models of response variables

| Parameter | Model equations | R2 | Adjusted R2 |

|---|---|---|---|

| Y1 | L* = 61.17*A +62.13*B +90.72*C – 50.38*A*C – 32.82*B*C | 0.94 | 0.92 |

| Y2 | H = 49.8*A +70.05*B +4.94*C + 60.34*A*C +213.93*A*B*(A-B) + 259.77*A*C*(A-C) | 0.94 | 0.90 |

| Y3 | Specific = 0.86*A +1.67*B +1.58*C – 2.47*A*B – 1.78*A*C +1.84*B*C + 2.96*A*B*(A-B) – 4.29*B*C*(B-C) | 0.96 | 0.90 |

Model: A, corresponds the ingredients in the mixture quinoa flour, B, quinoa flakes and C, corn starch; Y3 is the model equation for L * colour response, to the response Y4 and Y5 hardness for specific volume, (p ≤ 0.05)

The a* and b* values, corresponding to red/green and yellow/blue intensities, respectively, ranged among the cookie formulations, but these variations were not significant, indicating an absence of correlation between the a* and b* parameters and the corn starch, quinoa flakes and quinoa flour proportions in the mixture.

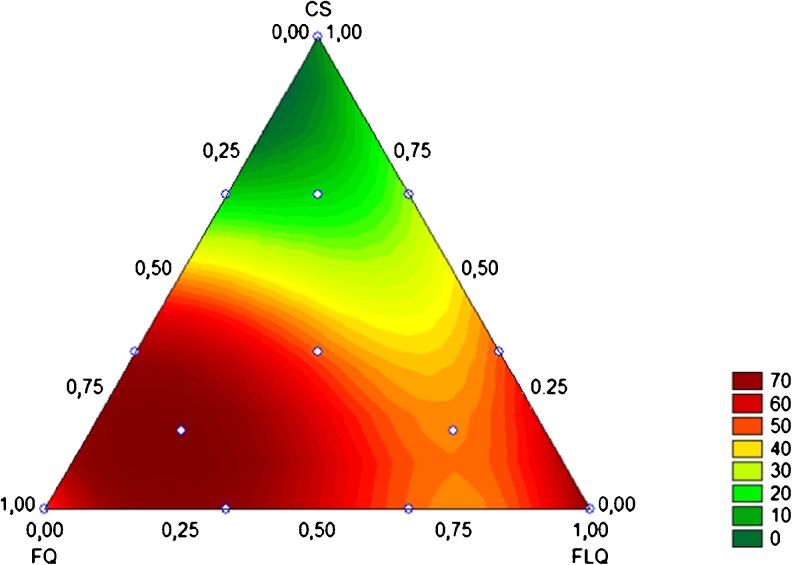

Hardness

Values between 8.7 and 75.7 N were found for the measurement of cookie hardness (Table 2), and the R2 of the model generated for the experimental data was 0.94 (Table 3). According contour curves generated from the model, quinoa flour and quinoa flakes concentrations presented positive effects on the hardness of the cookies, and the cookies prepared with higher amounts of corn starch showed the lowest hardness values (Fig. 1). Additionally, an increase in the hardness of the formulations was observed because the effect of the interaction between quinoa flour and quinoa flakes or quinoa flour and corn starch. However, when the amount of quinoa flour was lower or equal to quinoa flakes or corn starch in the mixture, the cookie hardness decreased. Previous studies reported that the inclusion of flour with an increased fibre content in cookies resulted in increased hardness (Brenaan and Samyue 2004; Sudha et al. 2007), although other studies related increased hardness in bakery products with high protein amounts in the formulation (McWatters et al. 2003; Pareyt et al. 2011). Considering the fibre and protein content present in quinoa flakes and quinoa flour composition, when compared to corn starch, both fibre and protein might have influenced the hardness of the quinoa cookies.

Fig. 1.

Contour curves relating the hardness (N) of the cookies produced from a ternary mixture of corn starch (CS), quinoa flour (FQ) and quinoa flakes (FLQ)

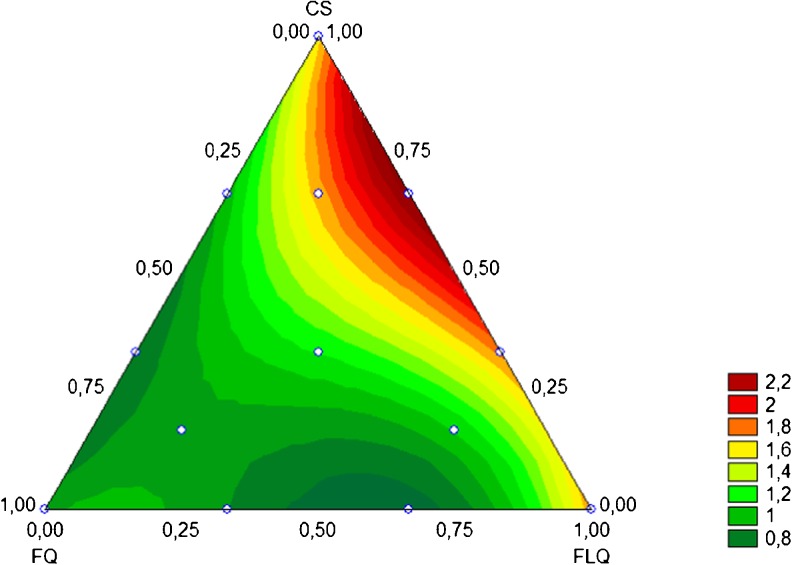

Volume

For the cookie volume, the model also showed a good adjustment with the experimental data, with an R2 of 0.96 (Table 3) and values ranging from 0.76 to 2.27 cm3.g−1 (Table 2). Quinoa flakes and corn starch had the greatest positive effect on the volume of the assessed cookies. As can be observed in contour curves, in formulations with higher amounts of quinoa flour in relation to quinoa flakes and corn starch, the volume of the cookies was lower, showing a negative interaction between quinoa flour and quinoa flakes or quinoa flour and corn starch (Fig. 2). In contrast, the interaction between quinoa flakes and corn starch had positive effects when the amount of quinoa flakes was smaller than corn starch (F6 and F13), with the volume being greatest. The effect was the opposite (Fig. 2) for the cookies prepared with quinoa flakes in amounts larger than corn starch (F4, F7, F12). The expansion of cookies is primarily a physical process controlled by the ability of the ingredients to retain water (Kissel et al. 1975), thus an increase in the ingredients possessing this property, for example, quinoa flakes, causes a competition for the free water present in the cookies, limiting the expansion rate. In addition, a correlation between an increase in the protein content and a decrease in the expansion rate of cookies has been reported (Zucco et al. 2011; Gupta et al. 2010), which would explain the decrease of volume in the cookies with higher amount of quinoa flour and quinoa flakes compared to those of corn starch.

Fig. 2.

Contour curves relating the specific volume (cm3.g−1) of the cookies produced from a ternary mixture of corn starch (CS), quinoa flour (FQ) and quinoa flakes (FLQ)

Desirability profile

In the analysis performed with the commercial gluten-free cookies, values of L* = 53.66, hardness = 56.99 and volume = 1.49 were found. After superposition of the contour curves generated in the analysis of the 14 cookie formulations developed in this study, the desirability profile generated by Statistica 7.0 showed that the optimal response was generated by the formulation containing 30 % quinoa flour, 25 % quinoa flakes, and 45 % corn starch. The formulation indicated (optimized cookie) values of L* = 71.26, hardness = 53.17 and specific volume = 1.2, validating the optimization of the mixture composed of quinoa flour, corn starch and quinoa flakes designed by the analysis of the experimental data.

Nutritive value of optimized cookie formulation

Each 100 g of optimized quinoa cookies presented 7.09 g of protein and a caloric value of 56.13 kcal. The optimized cookie was characterized as fibre-rich product due to its high content of dietary fibre, which was 11 g/100 g. Considering the recommended fibre intake (25 to 30 g of fibre per day) by FAO/WHO for adults to assist in the prevention of diet-related chronic diseases, the consumption of four quinoa cookies (as prepared) would supply approximately 22 % of the minimum daily recommended intake of fibre. The Aw and moisture values for the cookies were 0.37 and 3.33 g 100 g−1, respectively, indicating a product with good storage stability. The moisture values in the optimized quinoa cookies were below those reported in other studies involving cookies enriched with barley (Gupta et al. 2010), unripe banana flour (Agama-Acevedo et al. 2012) and black bean and rice flour (Bassinello et al. 2011). Low moisture is a positive parameter related to crispness, an important desirable attribute in cookies (Canett-Romero et al. 2004) as those formulated in the present study. From the identification of the minerals present in the quinoa cookies (Table 4), the consumption of 100 g of cookies supplies the daily requirement of Zn, Mn and Fe at 21.88, 18.25 and 40 %, respectively (Padovani et al. 2006). These minerals have important roles in the maintenance of health, cell growth and proliferation, metabolism, development and immunological functions (Sandstead et al. 2008; Legrand et al. 2006).

Table 4.

Nutritional value, pH and Aw of optimized gluten-free quinoa-based cookie

| Analysis | Mean valuea |

|---|---|

| Proteins (g 100 g −1) | 7.09 ± 0.19 |

| Carbohydrates (g 100 g −1) | 63.11 ± 4.28 |

| Lipids (g 100 g −1) | 18.69 ± 0.22 |

| Ash (g 100 g −1) | 2.24 ± 0.02 |

| Moisture | 3.33 ± 0.06 |

| Fibre (g 100 g −1) | 11 ± 0.01 |

| pH | 6.4 ± 0.04 |

| Aw | 0.37 ± 0.19 |

| Ca (mg g −1) | 1.7 ± 0.11 |

| Mg (mg g −1) | 0.8 ± 0.03 |

| K (mg g −1) | 7.3 ± 0.19 |

| P (mg g −1) | 2.0 ± 0.14 |

| Cu (mg g −1) | 2.60 ± 0.09 |

| Zn (mg g −1) | 1.75 ± 0.05 |

| Mn (mg g −1) | 0.72 ± 0.01 |

| Fe (mg g −1) | 1.5 ± 0.18 |

aData are mean values of triplicate measurements from three different replications ± standard deviations

Of the total fatty acids identified in the quinoa cookies, 60.53 % were of polyunsaturated fatty acids, 23.41 % were monounsaturated fatty acids, and 17.45 % were saturated fatty acids. The average content of desirable total fatty acids calculated for the quinoa cookies corresponded to 87 % of its lipid content (Table 5).

Table 5.

Fatty acid profile of optimized gluten-free quinoa-based cookie

| Fatty acid | Name | Percentb |

|---|---|---|

| C14:0 | Myristic acid | 0.09 ± 0.01 |

| C16:0 | Palmitic acid | 11.54 ± 0.21 |

| C17:0 | Margaric acid | 0.04 ± 0.01 |

| C 18:0 | Stearic acid | 3.48 ± 0.06 |

| C 20:0 | Eicosanoic acid | 2.29 ± 0.03 |

| C16:1 | Palmitoleic acid | 0.23 ± 0.04 |

| C18:1 | Oleic acid | 22.92 ± 2.11 |

| C20:1 | Eicosanoic acid | 0.24 ± 0.07 |

| C18:2 | Linoleic acid | 53.86 ± 3.01 |

| C18:3 (ω − 3) | α-Linoleic acid | 6.39 ± 0.71 |

| CLA-C18:2 | Conjugated linoleic acid | 0.12 ± 0.02 |

| C20:4 (ω − 6) | Arachidonic acid | 0.09 ± 0.01 |

| AGDa | 87.43 ± 0.98 |

aDesirable fatty acids, as represented by the sum of the proportions of C 18:0 + MUFA + PUFA

bData are mean values of triplicate measurements from three different replications ± standard deviations

In the amino acid profile analysis of the optimized quinoa cookies, twelve different amino acids were identified, including the essential amino acids valine, methionine, isoleucine, threonine and phenylalanine (Table 6). Gluten was no detected in final product, indicating no cross-contamination during processing of the product.

Table 6.

Amino acid profile of optimized gluten-free quinoa-based cookie

| Amino acida | Quinoa cookieb |

|---|---|

| Aspartic acid | 8.87 ± 0.03 |

| Glutamic acid | 13.61 ± 1.13 |

| Serine | 5.06 ± 0.87 |

| Glycine | 4.67 ± 0541 |

| Histidine | 9.35 ± 1.43 |

| Threonine | 9.03 ± 1.21 |

| Arginine | 0.79 ± 0.07 |

| Tyrosine | 3.31 ± 0.32 |

| Valine | 4.85 ± 0.54 |

| Methionine | 1.72 ± 0.01 |

| Isoleucine | 6.85 ± 0.36 |

| Phenylalanine | 1.83 ± 0.08 |

aAmounts in % for each gram of protein

bData are mean values of triplicate measurements from three different replications ± standard deviations

Sensory analysis

The average score obtained for overall acceptance of optimized quinoa-based cookie was 6.8, which corresponds to “liked”. When asked to report on the intent to purchase the product, the panellists revealed that “possibly would buy” the cookies (score 4.0). The scores of overall acceptance observed in the present study were similar to those reported for cookies formulated with banana flour in replacement of wheat flour (Fasolin et al. 2007) and higher than score (“neither like, neither dislike”) related for cookies made with rice and black bean extruded flours (Bassinello et al. 2011).

Conclusions

Based on the optimization of the ternary mixture of quinoa flour, quinoa flakes and corn starch using experimental mixtures for the analysis of the parameters of hardness, colour and specific volume, the gluten-free quinoa-based cookies were found to be a good source of fibre, amino acids, essential fatty acids and minerals. The optimized quinoa-based cookies showed a good sensory acceptability and satisfactory purchase intention, revealing their potential for consumption by the general population and as an interesting option for individuals with celiac disease. These findings suggest the potential of quinoa (processed as flour and flakes) for application in mixture with corn starch as an alternative ingredient for gluten-free bakery products, particularly in cookies-type biscuits.

Acknowledgments

Thanks to National Council of Technological and Scientific Development-Brazil (CNPq), for financial support in the form of scholarship for B.I.L.

References

- Adelakun OE, Kudanga T, Parker A, et al. Laccase-catalyzed dimerization of ferulic acid amplifies antioxidant activity. J Mol Catal B: Enzym. 2012;7:29–35. doi: 10.1016/j.molcatb.2011.08.010. [DOI] [Google Scholar]

- Agama-Acevedo E, Islas-Hernández JJ, Pacheco-Vargas G, Osorio-Díaz P, Bello-Pérez LA. Starch digestibility and glycemic index of cookies partially substituted with unripe banana flour. LWT Food Sci Technol. 2012;46:177–182. doi: 10.1016/j.lwt.2011.10.010. [DOI] [Google Scholar]

- Allred LK, Park ES. EZ gluten for the qualitative detection of gluten in foods, beverages, and environmental surfaces. J AOAC Int. 2012;95:1106–1117. doi: 10.5740/jaoacint.11-396. [DOI] [PubMed] [Google Scholar]

- AOAC (2006) Official methods of analysis of the association of official analytical chemist (18th ed.). Washington. DC USA

- APHA . Compendium of methods for the microbiological examination of foods. 4. Washington: American Public Health Association; 2001. [Google Scholar]

- Bassinello PZ, Freitas DGC, Ascheri JL, et al. Characterization of cookies formulated with rice and black bean extruded flours. Proc Food Sci. 2011;1:1645–1652. doi: 10.1016/j.profoo.2011.09.243. [DOI] [Google Scholar]

- Brenaan CS, Samyue E. Evaluation of starch degradation and textural characteristics of dietary fiber enriched biscuits. Int J Food Prop. 2004;7:647–657. doi: 10.1081/JFP-200033070. [DOI] [Google Scholar]

- Canett-Romero R, Ledesma-Osuna AL, Robles-Sanchéz RM, Morales-Castro R, León-Martínez L, León-Galvez R. Characterization of cookies made with deseeded grape pomace. Arch Latin Nutr. 2004;54:93–99. [PubMed] [Google Scholar]

- Commission International De L’Eclairage (CIE) (1978) “Recommendations on uniform color spaces, color difference equations, psychometric color terms”. Supplement no. 2 to CIE Publication no. 15, Colorimetry, Bureau Central de la CIE, Paris

- Cornell JA. Experiments with mixtures: designs, models, and the analysis of mixture data. New York: Wiley; 1981. [Google Scholar]

- Dutcosky SD, Grossmann VME, Silva RSSF, Welsch AK. Combined sensory optimization of a prebiotic cereal product using multicomponent mixture experiments. Food Chem. 2006;98:630–638. doi: 10.1016/j.foodchem.2005.06.029. [DOI] [Google Scholar]

- Falguera V, Aliguer N, Falguera M. An integrated approach to current trends in food consumption: moving toward functional and organic products? Food Control. 2012;26:274–281. doi: 10.1016/j.foodcont.2012.01.051. [DOI] [Google Scholar]

- FAO/WHO (1985) Energy and protein requirements: report of a joint FAO/WHO/UNU expert consultation. WHO Tech. Rep. 724. Geneva [PubMed]

- Fasolin LH, Almeida GC, Castanho PS, Netto-Oliveira ER. Cookies produced with banana meal: chemical, physical and sensorial evaluation. Food Sci Technol. 2007;27:524–529. [Google Scholar]

- Feddern V, Durante VVO, Miranda MZ, Mellado MLMS. Physical and sensory evaluation of wheat and rice bran cookies. Braz J Food Technol. 2011;14:267–274. doi: 10.4260/BJFT2011140400032. [DOI] [Google Scholar]

- Gómez-Caravaca AM, Segura-Carretero A, Fern A, Caboni MF. Simultaneous determination of phenolic compounds and saponins in quinoa (Chenopodium quinoa Willd) by a liquid chromatography-diode array detection-electrospray ionization-time-of-flight mass spectrometry methodology. J Agric Food Chem. 2011;59:10815–10825. doi: 10.1021/jf202224j. [DOI] [PubMed] [Google Scholar]

- Gupta M, Singh A, Abu-Ghannam N. Food and bioproducts processing effect of barley flour and freeze – thaw cycles on textural. Food Bio Proc. 2010;89:520–527. doi: 10.1016/j.fbp.2010.07.005. [DOI] [Google Scholar]

- Harra NM, Lemm T, Smith C. Quinoa flour is an acceptable replacement for all purpose flour in a peanut butter cookie. J Am Diet Assoc. 2011;111:SA45. doi: 10.1016/j.jada.2011.06.157. [DOI] [PubMed] [Google Scholar]

- Hartman L, Lago RCA. Rapid preparation of fatty acids methyl esters. Lab Pract. 1973;22:475–476. [PubMed] [Google Scholar]

- James LEA. Quinoa: composition, chemistry, nutritional, and functional properties. Adv Food Nut Res. 2009;58:1–31. doi: 10.1016/S1043-4526(09)58001-1. [DOI] [PubMed] [Google Scholar]

- Kissel LT, Prentice N, Yamazaki WT. Protein enrichment of cookie flours with wheat gluten and soy flour derivatives. Cereal Chem. 1975;52:638–649. [Google Scholar]

- Legrand D, Elass E, Carpentier M, Mazurier J. Interactions of lactoferrin with cells involved in immune function. Biochem Cell Biol. 2006;84:282–290. doi: 10.1139/o06-045. [DOI] [PubMed] [Google Scholar]

- Lorenz K, Coulter L, Johnson D. Functional and sensory characteristics of quinoa in foods. Dev Food Sci. 1995;37:1031–1041. doi: 10.1016/S0167-4501(06)80216-5. [DOI] [Google Scholar]

- Mareti MC, Grossmann MVE, Benassi MT. Physical and sensorial characteristics of cookies containing deffated soy flour and oat bran. Food Sci Technol. 2010;4:878–883. [Google Scholar]

- McWatters KH, Ouedraogo JB, Resurreccion VA, et al. Physical and sensory characteristics of sugar cookies containing a mixture of fonio (Digitaria exilis) and cowpea (Vigina unguiculata) flours. Int J Food Sci Technol. 2003;38:403–410. doi: 10.1046/j.1365-2621.2003.00716.x. [DOI] [Google Scholar]

- Meilgaard M, Civille GV, Carr BT (1987) Sensory evaluation techniques. Florida: CRC Press, 2, 158p

- Padovani RM, Amaya-Farfan J, Colugnat FAB, Domene SMA. Dietary reference intakes: application of tables in nutritional studies. Rev Nutr. 2006;19:741–760. doi: 10.1590/S1415-52732006000600010. [DOI] [Google Scholar]

- Pareyt B, Goovaerts M, Broekaert WF, Delcour JA. Arabinoxylan oligosaccharides (AXOS) as a potential sucrose replacer in sugar-snap cookies. LWT Food Sci Technol. 2011;44:725–728. doi: 10.1016/j.lwt.2010.11.008. [DOI] [Google Scholar]

- Sandstead HH, Prasad AS, Penland JG, et al. Zinc deficiency in Mexican American children: influence of zinc and other micronutrients on T cells, cytokines, and antiinflammatory plasma proteins. Am J Clin Nut. 2008;88:1067–1073. doi: 10.1093/ajcn/88.4.1067. [DOI] [PubMed] [Google Scholar]

- Secchi N, Stara G, Anedda R, et al. Effectiveness of sweet ovine whey powder in increasing the shelf life of Amaretti cookies. LWT Food Sci Technol. 2011;44:1073–1078. doi: 10.1016/j.lwt.2010.09.018. [DOI] [Google Scholar]

- Singh M, Mohamed A. Influence of gluten-soy protein blends on the quality of reduced carbohydrates cookies. Food Sci Technol. 2007;40:353–360. [Google Scholar]

- Statsoft. Inc (2004) STATISTICA (data analysis software system) Version 7.0. www.statsoft.com

- Stikic R, Glamoclija D, Demin M, et al. Agronomical and nutritional evaluation of quinoa seeds (Chenopodium quinoa Willd.) as an ingredient in bread formulations. J Cer Sci. 2012;55:132–138. doi: 10.1016/j.jcs.2011.10.010. [DOI] [Google Scholar]

- Sudha ML, Vetrimani R, Leelavathi K. Influence of fibre from different cereals on the rheological characteristics of wheat flour dough and on biscuit quality. Food Chem. 2007;100:1365–1370. doi: 10.1016/j.foodchem.2005.12.013. [DOI] [Google Scholar]

- Takata K, Yanaka M, Fujita Y, Ishikawa N. Evaluation of the grain and flour quality in near-isogenic wheat lines with waxy and double-null Wx proteins. Breed Sci. 2007;57:79–83. doi: 10.1270/jsbbs.57.79. [DOI] [Google Scholar]

- White JA, Hart RJ, Fry JC. An evaluation of the waters Pico-Tag system for the amino-acid analysis of food materials. J Autom Chem. 1986;8:170–177. doi: 10.1155/S1463924686000330. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Zucco F, Borsuk Y, Arntfield SD. Physical and nutritional evaluation of wheat cookies supplemented with pulse flours of different particle sizes. LWT Food Sci Technol. 2011;44:2070–2076. doi: 10.1016/j.lwt.2011.06.007. [DOI] [Google Scholar]