Abstract

Milk proteins were hydrolyzed by papain and their effect on the rheological, textural and sensory properties of cookies were investigated. Water absorption (%) decreased significantly as the amount of milk protein concentrates and hydrolysates increased up to a level of 15 % in the wheat flour. Dough extensibility decreased with inrease in parental proteins and their hydrolysates in wheat flour, significantly. Similarly, the pasting properties also varied significantly in direct proportion to the quantity added in the wheat flour. The colour difference (ΔE) of cookies supplemented with milk protein concentrates and hydrolysates were significantly higher than cookies prepared from control. Physical and sensory characteristics of cookies at 5 % level of supplementation were found to be acceptable. Also the scores assigned by the judges for texture and colour were in good agreement with the measurements derived from the physical tests.

Keywords: Milk proteins, Hydrolysis, Functional properties, Textural properties, Nutritional properties

Introduction

Proteins are important constituents of the human diet, since they are a principal source of nitrogen and essential amino acids. Milk proteins have a high nutritional value compared to other proteins, because of their relatively high content of essential amino acids and better digestibility (Hambraeus 1992). Moreover, milk proteins may contribute to structural properties of products, such as emulsion, foam and gel properties. Milk proteins are used in many different food products, ranging from dairy products to beverages, dietary and medical products (Mulvihill 1992; Walstra et al. 1999). Caseins and whey proteins are the two main protein groups in milk. Typical for casein proteins is the clustering of amino acids in hydrophobic and hydrophilic domains, giving rise to the amphipathic character of the proteins (Mulvihill 1992; Swaisgood 1992). Whey proteins (or milk serum proteins) are defined as proteins in milk that remain soluble after acid or after rennet casein precipitation (Barth and Behnke 1997). The former whey protein source is known as acid whey, the latter is referred to as sweet- or rennet whey (Schmidt et al. 1984, Morr 1989). Rennet whey contains the rennet proteolysis product of K-casein, glycomacropeptide (GMP), which is obviously absent in acid whey (Barth and Behnke 1997; Walstra et al. 1999). Whey proteins are globular proteins that are soluble over a broad pH range (Mulvihill 1992). The most important proteins in whey are β-lactoglobulin and α-lactalbumin, representing 70 to 80 % of the protein content of whey (Morr 1989). Like caseins, different genetic variants of these proteins exist. The remaining of whey proteins mainly consists of immunoglobulins, proteose, peptones and bovine serum albumin (Schmidt et al., 1984; Barth and Behnke 1997).

Great interest has been shown in the role played by dietary proteins in clinical diets and their use in specific formulations. Enzymatic hydrolysis seems to be the most appropriate method for preparation of tailor made peptides, not because of their large scale commercial availability and moderate cost but also because of high quality of such products (Clemente et al. 1999), consumption of intact proteins, may however, cause allergic reactions in sensitive individuals (Asselin et al. 1988). As an alternative, extensively hydrolyzed proteins can be used in the diet, as nutritional value is preserved (Boza et al. 1994). Hydrolyzed proteins might also be beneficial for patients suffering from specific digestive disorders like cystic fibrosis or short bowel syndrome (Farrell et al. 1987), or can be used in high protein diets in case of malnutrition (Schmidl et al. 1994). Enzymatic hydrolysis of proteins does not only affect digestibility and allergenicity of proteins, but also induces modification of functional properties like solubility, viscosity, gelation, emulsifying and foaming properties of the proteins (Chobert et al. 1988).

The wheat based products are becoming increasingly popular and are normally consumed with adjuncts in households, industrial canteens, restaurants, etc. Commercial bread and biscuits contain around 7–8 % protein, which is low. Protein-calorie malnutrition (PCM) is a serious problem in people whose diets consist mainly of cereal or starchy food. The present trend in population growth indicates that protein gap may continue to increase in the future unless well-planned measures are taken to tackle the situation (Iqbal et al. 2006). Refined wheat flour forms the main raw material for bakery products and its protein quality can be improved by addition of supplements, which are high in lysine. Milk proteins are the best quality proteins available and have high Protein efficiency ratio (3.6) and possess almost all the essential amino acids. Recent findings suggest that benefits of milk proteins may extend beyond muscle anabolism (Ha and Zemel 2003). Apart from being nutritious, milk proteins are highly functional and exhibit properties like solubility, gelation, water binding, viscosity and emulsifying action. Most bakery products can easily be enriched and fortified at low cost with proteins, various vitamins and minerals to meet the specific needs of the target groups and vulnerable sections of the population, who are undernourished and malnourished.

There are several reports of the effect of whey and whey protein concentrate (WPC) on the properties of wheat-based products (Erdogdu-Arnoczky et al. 1996; Kadharmestan et al. 1998; Zadow 1981; Indrani et al. 2007). The performance of whey protein concentrate (WPC) in bread and cake baking has been studied by De Vilbiss et al. (1974). But studies on effect of milk protein hydrolysates on bakery products are in scanty. Hence, the present work was undertaken to study the effect of supplementation of milk protein concentrates and hydrolysates on the rheological characteristics of wheat flour and quality of cookies.

Materials and methods

Materials

Whey protein and casein protein concentrates, having a protein content of 80 and 88.03 % respectively, were obtained from Mahaan proteins, New Delhi. All the chemicals used in this study were of analytical grade, from E. Merck, India, Ltd, Mumbai. Papain having activity of 450 TU/mg was procured from Enzochem Company, Nasik, India. For manufacturing of cookies, the wheat variety used (HD-2888) was procured from Samastipur (IARI-RS) research station Bihar. Bakery ingredients such as hydrogenated vegetable fat and granulated cane sugar were procured locally.

Enzymatic modification of milk proteins

Enzymatic hydrolysis was carried out using papain enzyme. This enzyme works under mild conditions of pH (6–8) and temperature (40–60 °C). WPC and casein were mixed with water in the ratio of 1:10 (w/v) to obtain slurry. The pH of one batch of slurry was adjusted to pH 6.2 with 1 N HCl (55 °C). It was allowed to stand for 1 h and then enzyme was added to the slurries in 1:60 ratio of enzyme to substrate. Hydrolysis experiments were carried out in a 1500 L reaction vessel maintained at 50 °C with the solution being agitated by an over-head stirrer. The hydrolysis process was adequately controlled by monitoring the degree of hydrolysis (DH) using the pH-stat technique (Adler-Nissen 1986). Aliquots (250 ml) were taken at 5, 10, 15 and 20 % DH. Enzyme was inactivated by placing in a boiling water bath for 10 min. The hydrolysates were centrifuged at 6000 rpm for 20 min and the supernatant collected, freeze dried and used for determination of functional properties.

Calculation of the degree of hydrolysis (DH)

The degree of hydrolysis DH (%) was calculated from the volume and the molarity of alkali used to maintain constant pH.

Where htot = total number of moles of peptide bonds present in I mole of proteins.

Wheat flour milling

The wheat grains were cleaned manually and stored at room temperature prior to milling. The grains were milled on a Chopin (Model, CD 1) and Promylogram (Model, M3 CE) Laboratory mills into flour of different extraction rates after tempering for 24 h. Wheat grains were tempered at 14.5 % moisture content before milling. Extra 0.5 % moisture was added, 30 min before milling to facilitate the separation process. The flour samples were stored at 20 °C before their analysis.

Chemical analysis of wheat flour

Moisture, protein and ash contents were determined by standard AACC methods (AACC 1983). The sodium dodiacyle sulphate (SDS) sedimentation volumes of flour samples were estimated according to the method of Axford, McDermott and Redman (1978). Five gram of flour (14 % moisture basis) was added to water (50 ml) in a cylinder, material was dispersed by rapid shaking for 15 s at 2 and 4 min immediately after the last shake, SDS-lactic acid reagent (50 ml) was added, and mixed by inverting the cylinder 4 times. The SDS-lactic acid reagent was prepared by dissolving SDS (20g) in distilled water (1 l) and then adding a stock diluted lactic acid solution (20 ml; 1 part lactic acid plus 8 part distilled water by volume). Inversion (4 times) was repeated at 2, 4 and 6 min before finally starting ones again from zero time. The contents of the cylinder were allowed to settle for 40 min before reading the sedimentation volume.

Supplementation of milk protein concentrates and hydrolysates into flour

Blends containing 0, 5, 10, and 15 % each of whey and casein protein concentrates and hydrolysates (with 15 % DH) replacing wheat flour were prepared.

Farinographic characteristics

Farinograph measures and records the resistance offered by the dough against mixing blades operating at a constant speed and temperature. Sample (50g on 14 % moisture basis) was taken in the mixing bowl. The mixing bowl and distilled water were kept at 30 °C for 60 min to maintain uniform temperature. Preliminary titration was carried out by running the machine for 1 min. Water was added to the sample from a burette equal to its expected water absorption capacity and allowed to mix. Quantity of water was added such that maximum consistency of the dough was attained at the centre of farinogram band [500 Brabender Unit (BU)]. For final titration, whole of the water was added within 25 s and sample run for 25 min. The information was recorded as water absorption and dough stability.

Pasting properties

The effect of the milk protein concentrates and hydrolysates on wheat flour pasting properties was determined with the use of a Starch Master (Newport Scientific Pvt. Ltd, Warrie-wood, Australia). Triplicate measurements using a 13 min controlled heating and cooling profile with constant shear were used. The sample (3.0g) was dispersed in water (25.0 ml) and stirred in an RVA container initially at 960 rpm for 10 s and finally at 160 rpm for the remaining test. The temperature profile was started from 50 °C for 1 min followed by ramping the temperature linearly to 95 °C in 3 min and 42 s, holding for 2 min and 30 s, cooling the system to 50 °C in 3 min and 48 s and ending the process in 13 min. Observations recorded were pasting point, peak viscosity (PV), final paste viscosity (FV), Hold viscosity, breakdown (BD) and set back (SB).

Dough extensibility

Dough extensibility was determined on TA-XT2 Texture Analyser (Stable Microsystems Ltd, Godalming, UK) according to the methods of Verbruggen et al. (2001). Small amount of oil was applied to both sides of the dough to avoid sample adhesion. Dough sample (15g) was clamped onto the grooved base of the form and cut into strips by pushing down the upper block of Kieffer Dough of the texture analyzer. The dough strips were placed onto the grooved region of the sample plate and holding down the spring loaded clamp lever, and the plate was inserted into the gluten extensibility rig. The handle was released slowly and the tensile test was performed. The pre test speed, test speed and post test speed of 2, 3.3 and 10.0 mm/s respectively were maintained. Distance of 75 mm and trigger force of 5g with a data acquisition rate of 200 bps was selected for the test.

Baking properties

Preparation of cookies

Blends containing 0, 5, 10, and 15 % each of whey and casein protein concentrate and their hydrolysates replacing wheat flour were prepared by gradual mixing in a rotary mixer. Cookies were prepared by the procedure described by McWatters et al. (2003) with following recipe:

| Ingredients | Quantity (grams) |

|---|---|

| Flour blend | 300 |

| Vegetable shortening | 180 |

| Sugar | 225 |

| Egg | 21 |

| Salt | 3.75 |

| Baking powder | 1.8 |

Cookie spread factor

The spread factor was measured according to the methods of AACC (1995).

Total color difference

The color of cookies at different levels of protein fortification was determined using Hunter Colorimeter fitted with an optical sensor (Hunter Associates Laboratory Inc. Restan VA, USA) on the basis of CIE L*, a*, b* colour system. Total colour difference (ΔE) was calculated as:

Where L* value is lightness, a* value is redness and b* value is yellowness.

Cookie texture

The fracture force test was conducted on the cookies using a TA-XT2 Texture Analyzer (Stable Micro Systems, UK). Fracture force was recorded, as force required for shattering the cookies with the help of a sharp-blade cutting probe, 6 cm long and 0.1 mm thick. The analyzer was set at a ‘return to start’ cycle with a speed of 1 mm/s and a penetration distance of 3 mm. The average force was calculated for 4 cookies and reported as fracture force.

Sensory evaluation

A panel of ten semi-trained panelists comprising staff and students evaluated sensory properties of cookies. In each session, samples were served on white saucers identified with three-digit code numbers to eliminate bias. Panelists were instructed to evaluate color at first and then taste each sample to evaluate flavour, texture and overall acceptability. A nine-point hedonic scale with 1 = dislike extremely, 5 = neither like nor dislike, 9 = like extremely was used. Samples that obtained 70 % of the scores in the ‘like (6–9 points)’ hedonic region for colour, flavour and texture, were considered acceptable. Water was provided to rinse the mouth between evaluations and covered expectoration cups if they did not wish to swallow the samples.

Statistical analysis

All other experiments were replicated three times and all measurements were carried out at least twice. Mean values, standard deviation, analysis of variance (ANOVA) were analyzed using a commercial statistical package SPSS 10.1 (USA). These data were then compared using Duncan’s multiple range tests at 5 % significance level.

Results and discussions

Proximate composition of whey and casein protein concentrates, and their hydrolysates

The protein, moisture and ash contents of whey and casein protein concentrates and their freeze-dried hydrolysates at four different DH levels were compared (Table 1). Significant difference in protein, moisture and ash contents was found in all hydrolysates produced at various DH levels. In general, protein content decreased after hydrolysis but no relationship between DH and protein content was observed. The differences in protein content of hydrolysates at different DH were due to the corresponding difference in non-protein nitrogen (NPN). The produced peptides can interact with unhydrolyzed protein (WPC or casein) via hydrophobic interactions resulting in an increase in the insoluble protein fraction (Sindayikengera and Xia 2005). In addition, some protein/peptides were lost during the centrifugation prior to freeze-drying with the apparent decrease in protein content of freeze-dried hydrolysates being also related to higher ash levels in the samples. In general, protein was lost and moisture increased with increasing hydrolysis. The differences in moisture could arise from varying efficiency of freeze-drying or storage conditions. Ash content of the hydrolysates increased with increasing DH with all hydrolysates having higher ash content than the unhydrolyzed protein (WPC or casein). Increase in ash content corresponded to the increase in consumption of alkali (NaOH) with DH and the adjustment of pH before enzymatic hydrolysis (Sindayikengera and Xia 2005).

Table 1.

Proximate composition of WPC, CPC and their hydrolysates

| Protein (%) | Moisture (%) | Ash (%) | ||||

|---|---|---|---|---|---|---|

| Sample | WPC | CPC | WPC | CPC | WPC | CPC |

| 0 % DH | 79.44d ± 1.10 | 88.14d ± 0.31 | 3.97a ± 0.06 | 4.78a ± 0.19 | 3.52a ± 0.50 | 5.10a ± 0.18 |

| 5 % DH | 60.36a* ± 1.90 | 84.95c* ± 0.08 | 6.51c* ± 0.01 | 5.30b* ± 0.10 | 9.24b* ± 0.28 | 8.68b* ± 0.17 |

| 10 % DH | 66.25c* ± 0.25 | 80.83b* ± 0.76 | 6.10b* ± 0.01 | 6.53d* ± 0.05 | 10.43c* ± 0.37 | 10.13c* ± 0.17 |

| 15 % DH | 64.66c* ± 0.35 | 76.21a* ± 0.20 | 6.22b* ± 0.02 | 6.30c* ± 0.07 | 12.0d* ± 0.35 | 11.90d* ± 0.17 |

| 20 % DH | 62.36b* ± 0.85 | 76.83a* ± 0.02 | 7.28d* ± 0.25 | 7.34e* ± 0.19 | 12.83e* ± 0.28 | 13.34e* ± 0.30 |

Means in the same column with different letters were significantly different at p < 0.05

*Denotes significant differences from control (P < 0.05)

Wheat flour quality

Protein content (11.0 %), ash content (0.48 %), SDS sedimentation value (30.19 %) and diastatic activity of 265 mg/10g flour was observed. Gluten content was found to be 21.29 and 8.78 % as wet and dry gluten respectively.

Farinographic characteristics

The farinographic parameters of wheat flour and blends of wheat flour with whey protein, casein and their hydrolysates were determined to evaluate changes in water absorption and dough stability (Table 2). Water absorption (%) decreased significantly (p ≤ 0.05) as the amount of milk protein concentrates and hydrolysates increased up to a level of 15 % in the wheat flour. However, more prominent decrease was observed in hydrolysates than concentrates which may be due to breakage of polypeptides into smaller fragments during enzymatic hydrolysis. The water absorption of wheat flour (control) was 58.4 %, however, it was in the range of 51.7–58.0 % for WPC, 49.8–58.1 % for WPH, 53.3–58.2 % for casein concentrate and 51.5–58.2 % for casein hydrolysate. The relative lower percentage of water absorption in wheat flour blend with protein concentrates and hydrolysates may be attributed to lower water binding ability of milk proteins than wheat flour. Indrani et al. (2007) reported water absorption decreased as the amount of whey protein concentrate in the wheat flour blend increased.

Table 2.

Effect of whey, casien protein concentrates and their hydrolysates on Farinograph dough characteristics of wheat flour (n = 3)

| Water absorption (%). | Dough stability time (min) | Force (Kg) | Distance (cm) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Protein% added | Whey protein | Casein Protein | Whey protein | Casein Protein | Whey protein | Casein Protein | Whey protein | Casein Protein | |

| Concentrate | 0 | 58.4c ± 0.10 | 58.4d ± 0.10 | 14.8c ± 0.20 | 14.8c ± 0.03 | 0.05c ± 0 | 0.05d ± 0 | 7.2d ± 0.1 | 7.2c ± 0.04 |

| 5 | 58.0c ± 0.05 | 58.2c* ± 0.10 | 14.5c ± 0.01 | 14.6c ± 0.01 | 0.04b* ± 0 | 0.03c* ± 0 | 5.6c* ± 0.06 | 5.4b* ± 0.09 | |

| 10 | 53.5b* ± 0.08 | 54.3b* ± 0.05 | 13.8b* ± 0.08 | 14.0b* ± 0.15 | 0.03a* ± 0 | 0.02b* ± 0 | 5.3b* ± 0.02 | 5.0b* ± 0.05 | |

| 15 | 51.7a* ± 0.24 | 53.3a* ± 0.01 | 13.3a* ± 0.02 | 13.6a* ± 0.01 | 0.02a* ± 0 | 0.01a* ± 0 | 4.0a* ± 0.05 | 4.1a* ± 0.07 | |

| Hydrolysate | 0 | 58.4c ± 0.01 | 58.4c ± 0.10 | 14.8c ± 0.20 | 14.8c ± 0.20 | 0.05c ± 0 | 0.05c ± 0 | 7.2d ± 0.07 | 7.2d ± 0.09 |

| 5 | 58.1c ± 0.60 | 58.5c ± 0.07 | 14.0c ± 0.02 | 14.5c ± 0.14 | 0.04b* ± 0 | 0.03b* ± 0 | 4.3c* ± 0.04 | 4.5c* ± 0.05 | |

| 10 | 50.3ab* ± 0.01 | 52.5b* ± 0.15 | 13.7b* ± 1.20 | 13.7b* ± 0.02 | 0.03a* ± 0 | 0.03a* ± 0 | 3.7b* ± 0.06 | 4.0b* ± 0.06 | |

| 15 | 49.8a* ± 0.11 | 51.5a* ± 0.07 | 13.1a* ± 0.32 | 13.3a* ± 0.04 | 0.02a* ± 0 | 0.03a* ± 0 | 3.3a* ± 0.05 | 3.7a*0.08 | |

Means for the same blend and variable with unlike superscripts indicate significant differences using Duncan’s multiple range test (P < 0.05)

*Denotes significant differences from control (P < 0.05)

Baking performance is associated with high resistance of dough to extension, which is measured with texture analyzer or extensograph. Dough extensibility (Force in Kg required to break the dough) decreased significantly (p ≤ 0.05) with increase in parental proteins and their hydrolysates in wheat flour (Table 2). This could be due to dilution of gluten content as well as interaction of milk protein with wheat protein fractions, which resulted in short dough. Hydrlysates showed a significant decrease in dough extensibil-ity as compared to protein concentrates. This may be due to stronger interaction of hydrolysate products with wheat proteins than concentrates. Zadow (1981) also reported that addition of WPC in the preparation of bread resulted in a weaker and less elastic dough. He further opined that the weakening of the wheat flour dough is due to interference of WPC sulphydryl groups in the normal sulphydryl/disulphide interchange reactions occurring during wheat flour dough development.

Pasting properties

The pasting point, peak viscosity, final viscosity, hold paste viscosity, breakdown viscosity and set back viscosity showed significant decrease (p ≤ 0.05), when compared with wheat flour at all levels of addition of whey and casein protein concentrates and hydrolysates in the wheat flour (Table 3). Variations in pasting properties were also observed among protein concentrates and their hydrolysates. The difference in pasting properties may be attributed to dilution of starch (determining factor for pasting properties) and gluten protein by the addition of milk proteins, starch protein interactions and protein-protein interactions. Greater decrease in hydrolysates than concentrates may be attributed to fragmentation of proteins during hydrolysis which resulted in loss of water entrapping capacity of proteins.

Table 3.

Effect of whey, casein protein concentrates and their hydrolysates on pasting properties wheat flour (n = 3)

| Protein Added (%) | Peak viscosity (*cP) | Final viscosity (*cP) | Paste point (*cP) | Hold viscosity (*cP) | Breakdown viscosity (*cP) | Setback viscosity (*cP) | |

|---|---|---|---|---|---|---|---|

| WPC | 0 | 2925d ± 7.7 | 3432l ± 3.5 | 334d ± 4.9 | 2094d ± 5.6 | 831d ± 2.1 | 1338d ± 8.4 |

| 5 | 2243c* ± 2.5 | 3048k* ± 2.0 | 263c* ± 7.6 | 1861c* ± 3.6 | 383c* ± 2.5 | 1187a* ± 7.0 | |

| 10 | 1832b* ± 1.5 | 2448j* ± 2.5 | 191b* ± 1.7 | 1563b* ± 2.5 | 271b* ± 3.0 | 1033c* ± 2.5 | |

| 15 | 1328a* ± 4.5 | 2020i* ± 0.57 | 184a* ± 3.6 | 1208a* ± 2.6 | 123a* ± 3.0 | 817b* ± 5.6 | |

| WPH | 0 | 2925h ± 7.07 | 3415d ± 3.5 | 334d ± 4.9 | 2094d ± 5.6 | 831d ± 2.1 | 1338d ± 8.4 |

| 2078g* ± 2.5 | 2570c* ± 2.08 | 243c* ± 2.5 | 1800c* ± 4.5 | 278c* ± 1.0 | 771c* ± 2.3 | ||

| 10 | 1513f* ± 2.0 | 2005b* ± 2.08 | 204b* ± 3.6 | 1276b* ± 2.0 | 234b* ± 3.6 | 725b* ± 4.7 | |

| 15 | 1047e* ± 2.0 | 1483a* ± 3.0 | 178a* ± 1.0 | 868a* ± 2.5 | 180a* ± 1.5 | 616a* ± 4.0 | |

| CPC | 0 | 2925d ± 7.7 | 3432l ± 3.5 | 334c ± 4.9 | 2094d ± 5.6 | 831d ± 2.1 | 1338d ± 8.4 |

| 5 | 2498c* ± 1.0 | 2462k* ± 2.0 | 75b* ± 1.0 | 1787c* ± 1.5 | 712a* ± 2.0 | 977a* ± 3.0 | |

| 10 | 2133b* ± 3.5 | 2361j* ± 3.0 | 48a* ± 1.0 | 1466b* ± 1.0 | 667c* ± 2.6 | 895c* ± 1.5 | |

| 15 | 1773a* ± 3.0 | 2025i* ± 5.0 | 75b* ± 2.5 | 1335a* ± 2.5 | 438b* ± 5.0 | 690b* ± 1.0 | |

| CPH | 0 | 2925h ± 7.07 | 3432d ± 3.5 | 334c ± 4.9 | 2094d ± 5.6 | 831d ± 2.1 | 1338d ± 8.4 |

| 5 | 2345g* ± 4.5 | 2674c* ± 3.0 | 87b* ± 2.0 | 1847c* ± 7.6 | 498c* ± 1.5 | 827b* ± 2.5 | |

| 10 | 1854f* ± 2.0 | 2143b* ± 3.0 | 86b* ± 2.0 | 1497b* ± 1.5 | 357a* ± 1.5 | 646c* ± 5.0 | |

| 15 | 985e* ± 3.0 | 1360a* ± 5.0 | 69a* ± 1.0 | 763a* ± 2.6 | 222b* ± 5.1 | 597a* ± 4.0 |

WPC, Whey protein concentrate; WPH, Whey protein hydrolysates; CPC, Casein protein concentrate; CPH, Casein protein hydrolysate

Means for the same blend and variable with unlike superscripts indicate significant differences using Duncan’s multiple range test (P < 0.05)

*Denotes significant differences from control (P < 0.05)

Indrani et al. (2007) also reported decrease in peak viscosity values with increased level of WPC in the wheat flour WPC blend. Lorenz et al. (1979) reported that with the increase in percentage of faba bean protein concentrate, viscosity at each of the reference points decreased in faba protein-wheat flour blends. Gomez et al. (2008) and Lorenz et al. (1979) observed lower peak viscosity, holding strength, breakdown, final viscosity and total setback in flours blended with chickpea flour and faba bean protein concentrate than the wheat flour respectively. This is likely due to their lower carbohydrate content and also their different protein content could affect the viscometric parameters (Morris et al. 1997).

Milk protein supplementation induced lower viscosity during cooling than wheat flour. The increase in viscosity is related to the ability of the amylose chains to reassociate and form a gel and it is referred to as setback. Low setback values obtained with milk protein supplementation could be expected to result in softer crumbs (Gomez et al. 2008).

Baking properties

Effect of milk protein concentrates and hydrolysates on physical attributes of cookies

The top colour difference (ΔE) of cookies supplemented with milk protein concentrates and hydrolysates were significantly (p ≤ 0.05) higher than cookies prepared from control (Table 4). However, the colour difference (ΔE) varied with increasing levels of concentrates and hydrolysates. This was attributed to higher degree of non-enzymatic browning due to increase in protein content and consequent interaction with the sugars. Hydrolysates showed more prominent effect on colour difference than concentrates which may be due to exposure of reactive sites on hydrolysis. The increase in colour difference (ΔE) is reported in cookies supplemented with faba bean protein concentrates at different levels by Lorenz et al. (1979).

Table 4.

Effect of whey, casein protein concentrates and their hydrolysates on the physical attributes of cookies, (n = 4)

| Cookie spread (W/T) | Top color difference (ΔE) | Texture (Fructure Force in KG) | |||||

|---|---|---|---|---|---|---|---|

| Protein (%) added | Whey protein | Casein Protein | Whey protein | Casein Protein | Whey protein | Casein Protein | |

| Concentrate | 0 | 7.83a ± 0.03 | 7.83a ± 0.03 | 26.3e ± 0.13 | 26 .3e ± 0.13 | 3.6a ± 0.43 | 3.6a ± 0.43 |

| 5 | 7.71a ± 0.25 | 7.80a ± 0.49 | 27.3f* ± 0.10 | 27.3f* ± 0.04 | 4.3b* ± 0.07 | 4.1a ± 0.10 | |

| 10 | 7.76a ± 0.03 | 7.73a ± 0.03 | 29.2g* ± 0.03 | 29.4g* ± 0.42 | 5.5c* ± 0.05 | 5.3b* ± 0.23 | |

| 15 | 7.63a ± 0.03 | 7.62a ± 0.03 | 31.4h* ± 0.10 | 31.2h* ± 0.07 | 6.5d* ± 0.13 | 6.3c* ± 0.30 | |

| Hydrolysate | 0 | 7.83a ± 0.03 | 7.83a ± 0.03 | 26.3e ± 0.13 | 26.3e ± 0.13 | 3.6a* ± 0.43 | 3.6a ± 0.43 |

| 5 | 7.78a ± 0.33 | 7.81a ± 0.25 | 30.1f* ± 0.05 | 30.1f* ± 0.10 | 5.2b* ± 0.20 | 5.3b* ± 0.11 | |

| 10 | 7.77a ± 0.02 | 7.77a ± 0.04 | 31.3g* ± 0.04 | 31.2g* ± 0.05 | 6.8c* ± 0.04 | 6.6c* ± 0.18 | |

| 15 | 7.70a ± 0.02 | 7.69a ± 0.02 | 33.5h* ± 0.05 | 33.2h* ± 0.03 | 7.6d* ± 0.10 | 7.5d* ± 0.22 | |

Means for the same blend and variable with unlike superscripts indicate significant differences using Duncan’s multiple range test (P < 0.05)

*Denotes significant differences from control (P < 0.05)

The cookie spread factor did not vary significantly (p ≤ 0.05) with increasing levels of milk protein concentrates and hydrolysates (Table 4). Similar findings have been reported for cookies fortified with faba bean protein concentrate up to 10 % but beyond this level reduced values for spread factor were observed (Lorenz et al. 1979). Claughton and Pearce (1989) reported a reduction in spread factor of cookies by increasing the enrichment levels with sunflower protein isolates. McWatters (1978) and Singh et al. (1993) also reported a decrease in spread factor with increased protein in the cookies.

The hardness of cookies measured as fracture force is presented in Table 4. The fracture force of control was 3.6 (Kg) and protein blended wheat flour samples were in the range of 4.3 to 6.5 (kg), 5.2 to 7.6 (kg), 4.1 to 6.3 (kg) and 5.3 to 7.5 (kg) for whey protein concentrates, whey protein hydrolysates, casein concentrates and casein hydrolysates respectively. The fracture force of cookies blended with protein concentrates and hydrolysates increased significantly (p ≤ 0.05) with increased levels of protein concentrates and hydrolysates up to 15 %. A higher increase in fracture force was observed in case of hydrolysates than concentrates and may be attributed to increased number of hydrophilic sites generated during hydrolysis which are available to compete for the limited free water in dough. Increase in fracture force was also observed by (McWatters et al. 2003), who attributed the harder texture of the cookies to the increased protein content and its interaction during dough development and baking. Maache-Rezzoug et al. (1998) observed that higher the percentage of protein in dough, the lower the dough hydration, acked consistency and was crumbly. Composite flours form aggregates with increased number of hydrophilic sites available to compete for the limited free water in cookie dough (Kissell and Yamazaki 1975). Increasing the water content proportional to their water absorption could ease the competition and result in sufficient mixing of the dough.

Effect of milk protein concentrates and hydrolysates on sensory attributes of Cookies

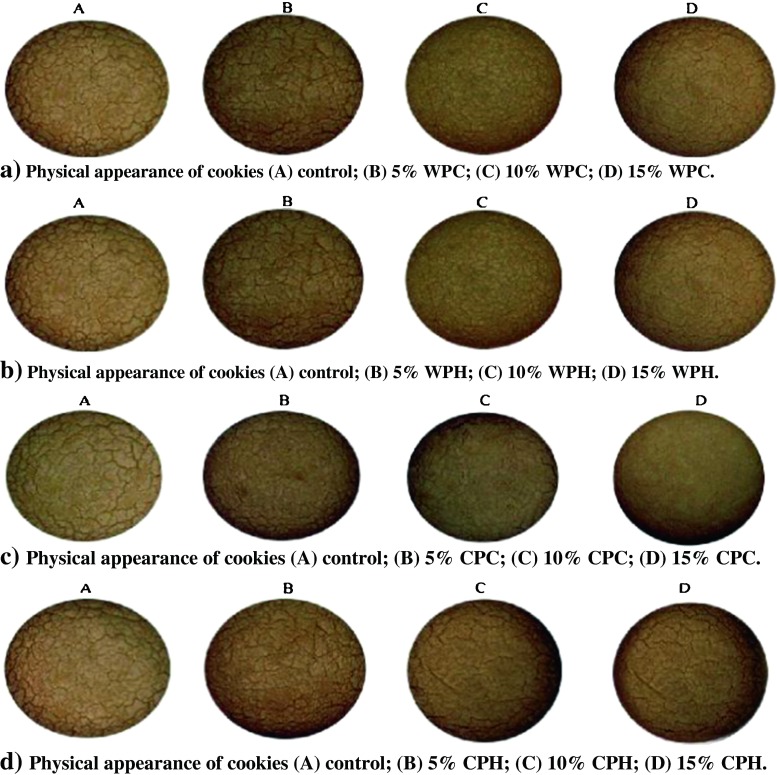

Sensory scores of cookies showed significant decrease in all the parameters when compared with control (Table 5). The results of sensory analysis showed that scores assigned by the judges for texture and colour were in good agreement with the measurements derived from the physical test. The panelists, to a crumbly texture, off flavor and darkening, attributed the low overall acceptability of the cookies from blends containing more than 5 % milk protein concentrates and hydrolysates. Colour darkening of cookies as is evident from Fig. 1 (a,b,c,d) is attributed to sugar caramelization and the Maillard reactions between sugars and amino acids. Panelists described the cookies containing more than 5 % milk protein concentrates and hydrolysates as having bitter aftertaste which was more prominent in hydrolysates than concentrates. It may be due to production of bitter peptides upon enzymatic hydrolysis. In the current study, the incorporation level upto 5 % gave desirable results. Sensory attributes of cookies supplemented with faba bean protein isolates revealed that fortification up to 10 % was satisfactory (Lorenz et al. 1979).

Table 5.

Sensory characteristics of cookies supplemented with whey protein and casein concentrates and their hydrolysates

| Protein (%) added | Appearance | Color | Aroma | Taste | Texture | Overall accept-ability | |

|---|---|---|---|---|---|---|---|

| WPC | 0 | 7.0d ± 0.01 | 7.3d ± 0.01 | 7.3d ± 0.14 | 7.6d ± 0.25 | 7.3d ± 0.02 | 7.3d ± 0.07 |

| 5 | 6.0c* ± 0.05 | 6.3c* ± 0.02 | 6.0c* ± 0.11 | 6.6c* ± 0.01 | 6.3c* ± 0.03 | 6.3c * ± 0.03 | |

| 10 | 5.3b* ± 0.02 | 5.3b* ± 0.43 | 5.0b* ± 0.11 | 5.3b* ± 0.04 | 5.6b* ± 0.03 | 5.3b* ± 0.10 | |

| 15 | 4.3a* ± 0.02 | 4.0a* ± 0.08 | 4.6a* ± 0.01 | 4.4a* ± 0.10 | 4.0a* ± 0.08 | 4.3a* ± 0.05 | |

| WPH | 0 | 7.0d ± 0.01 | 7.3d ± 0.01 | 7.3d ± 0.14 | 7.6c ± 0.25 | 7.3d ± 0.02 | 7.3d ± 0.07 |

| 5 | 6.0c* ± 0.03 | 6.6c* ± 0.02 | 6.6c* ± 0.02 | 6.1b* ± 0.13 | 6.3c* ± 0.05 | 6.3c* ± 0.03 | |

| 10 | 5.0b* ± 0.01 | 5.6b* ± 0.01 | 5.3b* ± 0.02 | 5.6b* ± 0.02 | 5.3b* ± 0.56 | 5.4b* ± 0.11 | |

| 15 | 4.0a* ± 0.02 | 4.6a* ± 0.06 | 4.0a* ± 0.07 | 4.3a* ± 0.44 | 4.0a* ± 0.07 | 4.2a* ± 0.07 | |

| 0 | 7.0d ± 0.01 | 7.3d ± 0.01 | 7.3d ± 0.14 | 7.6c ± 0.25 | 7.3d ± 0.02 | 7.3d ± 0.07 | |

| CPC | 5 | 6.4c* ± 0.32 | 6.3c* ± 0.04 | 6.1c* ± 0.10 | 6.6b* ± 0.03 | 6.4c* ± 0.14 | 6.3c* ± 0.01 |

| 10 | 5.3b* ± 0.01 | 5.2b* ± 0.26 | 5.3b* ± 0.43 | 5.3a* ± 0.06 | 5.6b* ± 0.09 | 5.3b* ± 0.12 | |

| 15 | 4.2a* ± 0.11 | 4.0a* ± 0.07 | 4.6a* ± 0.03 | 4.5a* ± 0.78 | 4.1a* ± 0.11 | 4.3a* ± 0.16 | |

| CPH | 0 | 7.0d ± 0.01 | 7.3d ± 0.01 | 7.3d ± 0.14 | 7.6d ± 0.25 | 7.3d ± 0.02 | 7.3d ± 0.07 |

| 5 | 6.2c* ± 0.32 | 6.6c* ± 0.03 | 6.5c* ± 0.12 | 6.1c* ± 0.05 | 6.1c* ± 0.20 | 6.3c* ± 0.04 | |

| 10 | 5.0b* ± 0.01 | 5.6b* ± 0.01 | 5.3b* ± 0.03 | 5.5b* ± 0.05 | 5.4b* ± 0.3 | 5.3b* ± 0.07 | |

| 15 | 4.0a* ± 0.02 | 4.5a* ± 0.07 | 4.3a* ± 0.45 | 4.3a* ± 0.44 | 4.6a* ± 0.30 | 4.4a* ± 0.21 |

WPC, Whey protein concentrate; WPH, Whey protein hydrolysates; CPC, Casein protein concentrate; CPH, Casein protein hydrolysate

Means for the same blend and variable with unlike superscripts indicate significant differences using Duncan’s multiple range test (P < 0.05)

*Denotes significant differences from control (P < 0.05)

Fig. 1.

Physical appearance of cookies. a Physical appearance of cookies (a) control; (b) 5 % WPC; (c) 10 % WPC; (d) 15 % WPC. b Physical appearance of cookies (a) control; (b) 5 % WPH; (c) 10 % WPH; (d) 15 % WPH. c Physical appearance of cookies (a) control; (b) 5 % CPC; (c) 10 % CPC; (d) 15 % CPC. d Physical appearance of cookies (a) control; (b) 5 % CPH; (c) 10 % CPH; (d) 15 % CPH

Conclusion

The results of this study have shown that highly nutritious cookies can be prepared by supplementing wheat flour with milk protein concentrates and hydrolysates at 5–15 % levels. The incorporation of WPC, casein and their hydrolysates up to the level of 5 % showed dough properties comparable to control. It was also found that 5 % level incorporation of milk proteins and their hydrolysates have no drastic effect on physical and sensory attributes of cookies. It was concluded that milk protein concentrates and hydrolysates can be used for supplementation of bakery products to minimize the problem of malnutrition, predominant in underdeveloped and developing countries.

Contributor Information

Adil Gani, Phone: +918715022903, Email: adil.gani@gmail.com.

A. A. Broadway, Email: broad.way@gmail.com

Mudasir Ahmad, Email: mudasirahmad63@yahoo.in.

Bilal Ahmad Ashwar, Email: Ashwar20@gmail.com.

Ali Abas Wani, Email: wani.abas@gmail.com.

Sajad Mohd Wani, Email: wanisajad84@gmail.com.

F. A. Masoodi, Email: masoodi_fa@yahoo.co.in

References

- AACC . Approved methods of analysis. 8. MN: American Association of Cereal Chemists. St. Paul; 1983. [Google Scholar]

- AACC . Approved methods American Association of Cereal Chemists. 9. MN: St. American Association of Cereal Chemists. St. Paul; 1995. [Google Scholar]

- Adler-Nissen J. Enzymic hydrolysis of food proteins. New York: Elsevier Applied Science Publishers; 1986. [Google Scholar]

- Asselin J, Amiot J, Gauthier F, Mourad W, Hebert J. Immunogenicity and allergenicity of whey protein hydrolysates. J Food Sci. 1988;53:1208–1211. doi: 10.1111/j.1365-2621.1988.tb13563.x. [DOI] [Google Scholar]

- Barth CA, Behnke U. Nutritional significance of whey and whey components. Nahrung. 1997;41:2–12. doi: 10.1002/food.19970410103. [DOI] [PubMed] [Google Scholar]

- Boza JJ, Jimenez J, Martinez O, Suarez MD, Gil A. Nutritional value and antigenicity of two milk protein hydrolysates in rats and guinea pigs. J Nutr. 1994;124:1978–1986. doi: 10.1093/jn/124.10.1978. [DOI] [PubMed] [Google Scholar]

- Chobert JM, Sitohy MZ, Whitaker JR. Solubility and emulsifying properties of caseins modified enzymatically by Staphylococcus aureus V8 protease. J Agric Food Chem. 1988;36:220–224. doi: 10.1021/jf00079a055. [DOI] [Google Scholar]

- Claughton SM, Pearce RJ. Protein enrichment of sugar snap cookies with sunflower protein isolate. J Food Sci. 1989;54:354. doi: 10.1111/j.1365-2621.1989.tb03079.x. [DOI] [Google Scholar]

- Clemente A, Vioque J, Sanchez-Vioque R, Pedroche J, Bautista J, Millan F. Protein quality of chickpea (Cicer arietinum L.) protein hydrolysates. J Food Chem. 1999;67:269–274. doi: 10.1016/S0308-8146(99)00130-2. [DOI] [Google Scholar]

- De Vilbiss ED, Holsigner VH, Posati LD, Pallansch MJ. Properties of whey protein concentrate foams. Food Technol. 1974;28:40–48. [Google Scholar]

- Erdogdu-Arnoczky N, Czuchzjowska Z, Pomeranz Y. Functionality of whey and casein in bread making by fixed and optimized procedures. Cereal Chem. 1996;73:309–316. [Google Scholar]

- Farrell PM, Mischler EH, Sondel SA, Palta M. Predigested formula for infants with cystic fibrosis. J Am Diet Assoc. 1987;87:321–328. [PubMed] [Google Scholar]

- Gomez M, Oliete B, Rosell CM, Pando V, Fernandez E. Studies on cake quality made of wheat-chickpea flour blends. LWT Food Sci Technol. 2008;41:1701–1709. doi: 10.1016/j.lwt.2007.11.024. [DOI] [Google Scholar]

- Ha E, Zemel MB. Functional properties of whey, whey components, and essential amino acids: mechanisms underlying health benefits for active people. J Nut Biochem. 2003;14:251–258. doi: 10.1016/S0955-2863(03)00030-5. [DOI] [PubMed] [Google Scholar]

- Hambraeus L (1992). Nutritional aspects of milk proteins. In Advanced Dairy Chemistry- Vol. 1: Proteins; Fox, P.F, Ed.; Elsevier Science Publishers 457-490

- Indrani D, Prabhasankar P, Rajiv J, Venkateswara RG. Influence of whey protein concentrate on the rheological characteristics of dough, microstructure and quality of unleavened flat bread (parotta) Food Res Int. 2007;40:1254–1260. doi: 10.1016/j.foodres.2007.08.005. [DOI] [Google Scholar]

- Iqbal A, Khalil IA, Ateeq N, Khan MS. Nutritional quality of important food legumes. Food Chem. 2006;97:331–335. doi: 10.1016/j.foodchem.2005.05.011. [DOI] [Google Scholar]

- Kadharmestan C, Baik BK, Czuchajowska Z. Whey protein concentrated with high heat or hydrostatic pressure in wheat-based products. Cereal Chem. 1998;75:762–766. doi: 10.1094/CCHEM.1998.75.5.762. [DOI] [Google Scholar]

- Kissell LT, Yamazaki WT. Protein enrichment of cookie flours with wheat gluten and soy flour derivatives. Cereal Chem. 1975;52:638–649. [Google Scholar]

- Lorenz K, Dilsaver W, Wolt N (1979). Faba bean flour and protein concentrate in baked goods and in pasta products. Bakers Digest June 39-49

- Maache-Rezzoug Z, Bouvier JM, Allaf K, Patras C. Effect of principal ingredients on rheological behaviour of biscuit dough and on quality of biscuits. J Food Eng. 1998;35:23–42. doi: 10.1016/S0260-8774(98)00017-X. [DOI] [Google Scholar]

- McWatters KH. Cookie baking properties of defatted peanut, soybean, and field pea flours. Cereal Chem. 1978;55:853–863. [Google Scholar]

- McWatters KH, Ouedraogo JB, Resurrection AVA, Hung YC, Philips RD. Physical and sensory characteristics of sugar cookies containing mixtures of wheat, fonnio (Digitaria exilis) and cowpea (Vigna unguiculata) flours. Int J Food Sci Technol. 2003;38:403–410. doi: 10.1046/j.1365-2621.2003.00716.x. [DOI] [Google Scholar]

- Morr CV (1989). Whey proteins: manufacture. In Developments in Dairy Chemistry-4; Fox

- Morris C, King GE, Rubenthaler GL. Contribution of wheat flour fractions to peak hot paste viscosity. Cereal Chem. 1997;74:147–153. doi: 10.1094/CCHEM.1997.74.2.147. [DOI] [Google Scholar]

- Mulvihill D.M. (1992). Production, functional properties and utilization of milk protein products. In Advanced Dairy Chemistry- Vol 1: Proteins; Fox P.F, Ed.; Elsevier Science Publishers 369- 404

- Schmidl MK, Taylor SL, Nordlee JA. Use of hydrolysate based products in special medical diets. Food Technol. 1994;48:77–80. [Google Scholar]

- Sindayikengera S, Xia W. Nutritional evaluation of caseins and whey proteins and their hydrolysates from Protamex. J Zhejiang Univ. 2005;7:90–98. doi: 10.1631/jzus.2006.B0090. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Singh B, Bajaj M, Sharma S, Sidhu JS. Studies on the development of high-protein biscuits from composite flours. Plant Food Hum Nutr. 1993;43:181–189. doi: 10.1007/BF01087922. [DOI] [PubMed] [Google Scholar]

- Swaisgood HE. Chemistry of the caseins. In: Fox PF, editor. In Advanced Dairy Chemistry- Vol 1: Proteins. London: Applied Science publishers; 1992. pp. 63–110. [Google Scholar]

- Verbruggen IM, Veraverbeke WS, Delcour JA. Significance of LMW-GS and HMW-GS for dough extensibility: Addition versus Incorporation protocols. J Cereal Sci. 2001;33:253–260. doi: 10.1006/jcrs.2000.0353. [DOI] [Google Scholar]

- Walstra P, Geurts TJ, Noomen A, Jellema A, Van Boekel MAJS. Dairy technology: Principles of milk properties and processes. New York: Marcel Dekker; 1999. [Google Scholar]

- Zadow JG. Measurement of the effect of whey protein concentrates on fermenting doughs by the Instron Tester. Aust J Dairy Technol. 1981;36:56–59. [Google Scholar]