Abstract

To further assess vibration exposure on haul trucks (HTs) and front-end wheel loaders (FELs), follow-up investigations were conducted at two US crushed stone operations. The purpose was to: 1) evaluate factors such as load/no-load conditions, speed, load capacity, vehicle age, and seat transmissibility relative to vibration exposure; 2) compare exposure levels with existing ISO/ANSI and EUGPG guidelines. Increasing HT speed increased recorded vibration at the chassis and seat as expected. Neither vehicle load nor vehicle speed increased transmissibility. Increasing HT size and age did show transmissibility decreasing. HT dominant-axis wRMS levels (most often the y-axis, lateral or side-to-side direction) were predominantly within the health guidance caution zone (HGCZ). However, several instances showed vibration dose value (VDV) above the exposure limit value (ELV) for the ISO/ANSI guidelines. VDV levels (all dominant x-axis or fore-aft) were within and above the HGCZ for the EUGPG and above the HGCZ for ISO/ANSI guidelines.

Keywords: haul truck drivers, loader operators, whole-body vibration exposures, WBV guidelines/standards, HGCZ, health guidance caution zone, heavy vehicle systems

1 Introduction

Exposures to WBV are evident in the industrial world, in particular for earth-moving equipment including off-road vehicles. WBV comprises mechanical vibration or shock transmitted to the body as a whole (Griffin, 1990). When WBV is transmitted to the human body at the natural frequency of the body as a whole or of its individual parts a condition known as resonance will result. During resonance, the body or a part of the body will vibrate at a magnitude higher than the applied excitation force. In response, muscles will contract in a voluntary or involuntary way and cause fatigue or a lowering of motor performance capacity (Chaffin and Andersson, 1984).

In light of postural elements, WBV is a contributing factor in the development of musculoskeletal disorders of the spine among workers exposed to a vibration environment (Kittusamy and Buchholz, 2004; Kittusamy, 2003, 2002; Bovenzi and Zadini, 1992; Johanning, 1991; Bongers et al., 1988, 1990; Seidel and Heide, 1986). Low-back pain (LBP) is a prominent and unfavourable health effect of WBV. A review by the National Institute for Occupational Safety and Health (NIOSH) reported a significant positive association between WBV exposure and LBP in 15 of 19 WBV studies reviewed by assigning its highest ranking descriptor of ‘strong evidence’ to the WBV-LBP relationship (NIOSH, 1997). A variety of field investigations have reported on WBV exposure for mining and quarry machinery (Smets et al., 2010; Mayton et al., 2008, 2009a; Eger et al., 2006; Kumar, 2004; Miller et al., 2000, 2004). Smets et al. (2010) reported on a review of Canadian accident statistics for the Ontario Mining Industry, which showed that 16% of the traumatic injuries were associated with HT operation. Moreover, Kumar in his study of WBV on HTs concluded that HT operator exposure to WBV posed a significant health risk and noted that the exposure limit recommended in ISO 2631 was exceeded for a majority of the exposure time (Kumar, 2004; ISO, 1997).

The introduction to the ISO 2631-1 standard, among other things, states that the standard

“... does not cover the potential effects of intense vibration on human performance and task capability since such guidance depends critically on ergonomic details related to the operator, the situation and the task design. Vibration is often complex, contains many frequencies, occurs in several directions and changes over time. The effects of vibration may be manifold. Exposure to WBV causes a complex distribution of oscillatory motions and forces within the body. There can be large variations between subjects with respect to biological effects. WBV may cause sensations (e.g., discomfort or annoyance), influence human performance capability or present a health and safety risk (e.g., pathological damage or physiological change). The presence of oscillatory force with little motion may cause similar effects.” (ISO, 1997)

2 Background

This paper discusses a continuation of the work conducted at two US eastern mid-Atlantic crushed stone operations with preliminary results reported previously (Mayton et al., 2008, 2009b). As a follow-up to this work, a more in-depth and systematic study was performed to further assess WBV exposure levels for drivers and operators of HTs and FELs relative to various factors that may influence them. The factors considered included vehicle, age, capacity, travelling with load and no-load, seat transmissibility, and vehicle speed. As part of a former NIOSH study that focused on implementing and evaluating ergonomic interventions in mining, a worker risk factor assessment was performed. Company management had received verbal and written responses from vehicle operators about back symptoms and vibration issues while performing their regular work cycles. Low-back discomfort was a frequently reported symptom at one quarry and vehicle vibration associated with bouncing and jarring was reported on a high percentage of cards. In some cases, employees indicated discomfort relative to the seating in vehicles. Quarry managers were thus interested in evaluating seating and operator exposure to WBV with the objective of learning how exposure levels compared to existing ISO/ANSI recommended standards.

3 Methods

NIOSH researchers conducted field studies and collected WBV exposure and global positioning system (GPS) data for a total of 10 vehicles and machines – three HTs and drivers and 2 FELs and operators operating at each of the two quarries (Table 1). The HTs were rear-dump, which differed by make/model, age, and capacity. The FELs were wheel-type and also differed by make/model, age, and capacity. Vibration measurements were recorded with an 8-channnel, digital data recorder (model PC208Ax, Sony Manufacturing Systems America, Lake Forest, CA). Other instrumentation (PCB Piezotronics, Inc. Depew, NY) included tri-axial accelerometers (models 356B18, 356B40), signal conditioning amplifiers (model 480E09), and in-line, 150-Hz low-pass filters (model 474M32). The floor- or frame-mounted accelerometer featured a frequency range of 0.3 Hz to 5 kHz and a charge sensitivity ranging from 949 mV/g to 1052 mV/g for the three orthogonal axes. The seat pad accelerometer featured a frequency range of 0.5–1 kHz and a charge sensitivity range of 97.4–105 mV/g for the three orthogonal axes. Vibration data were collected using accelerometers with pre-amplifiers and filters connected to a digital data recorder. The GPS unit, a Garmin Etrex C, was taped to the outside handrail of the HTs and FELs.

Table 1.

Description of heavy equipment operating at two aggregate stone quarries evaluated for driver/operator whole-body vibration exposure

|

Quarry – 1

| |||

|---|---|---|---|

| Haul truck (HT) | Year | Age (yrs) | Capacity (tons) |

| HT-1 | 2000 | 8 | 65 |

| HT-2 | 1999 | 9 | 65 |

| HT-3 | 2005 | 3 | 70 |

| Front-end loaders (FELs) | Year | Age (yrs) | Capacity (Cu. Yds) |

|---|---|---|---|

| FEL-1 | 2005 | 3 | 11.2 |

| FEL-2 | 2004 | 4 | 7 |

|

Quarry – 2

| |||

|---|---|---|---|

| Haul truck (HT) | Year | Age (yrs) | Capacity (tons) |

| HT-4 | 1992 | 16 | 50 |

| HT-5 | 1986 | 22 | 50 |

| HT-6 | 2007 | 1 | 70 |

| Front-end loaders (FELs) | Year | Age (yrs) | Capacity (Cu. Yds) |

|---|---|---|---|

| FEL-3 | 2006 | 2 | 8.3 |

| FEL-4 | 2002 | 6 | 8 |

Capacity is nominal rated value in short tons. Age is computed from vehicle year to date of latest data collection – 2008.

Installation was done at the maintenance shop and vehicle parking area. Two tri-axial accelerometers were installed, one on the frame of the haul truck or loader next to the cab window (frame or chassis measurement) and one (encased in a disk-shaped, rigid, black pad) on the seat at the operator/seat interface (seat measurement). Frame accelerometers were ordinarily mounted on the floor of the operator's compartment near the base of the seat, but space and setup constraints within the truck cab necessitated mounting the frame accelerometers on small ledges on the cab walls that were rigid and structurally connected to the floor. A 12-volt deep-cycle marine battery allowed researchers to avoid interruptions in data collection that occurred in earlier field work caused by random vehicle bouncing and premature disconnect from the terminals in the recorder and recorder shutdown. Measures for the cyclical nature of load-haul-dump activities were considered to be representative of exposures for the shift. Quarry management estimated that driver/operator exposure was 9 h for a 10-hr shift. Given cab constraints and the setup of data collecting instrumentation, researchers decided not to ride along in the vehicles to observe truck operation.

Measurement periods for HTs ranged from 22.1 to 98.9 min with a mean of 68.3 and standard deviation of 18.9 min. Similarly, measurement periods for FELs ranged from 43.8 min to 99.2 min with a mean of 72.0 min and standard deviation of 23.5 min.

Truck routes began and ended in the pit and plant storage pile areas or the shop area (as was the done in earlier field work). Instrumentation were switched on just prior to the truck departing this area and returned to the same area at the end of the measurement period for uninstalling the instrumentation. Weather conditions during both studies were dry, warm and sunny to partly cloudy. The roadways were dusty and required constant watering for dust abatement. All of the trucks and their respective seats were considered to be in good working order.

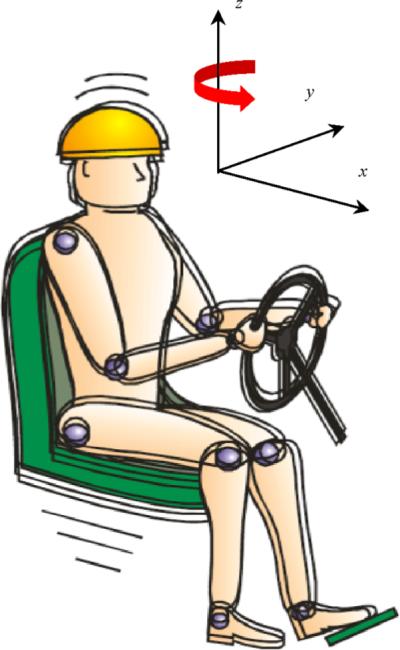

ISO 2631 and ANSI S3.18 (ISO, 1997; ANSI, 2002) were used to evaluate the WBV exposures for haulage truck drivers. For the x, y, and z directions (Figure 1), wRMS and VDV with overall totals of wRMS and VDV were used to evaluate driver/operator exposure. Considering an eight-hour exposure period, the European Union Good Practice Guide for WBV (EUGPG) recommends, for the worst-case axis, wRMS accelerations of 0.5 m/s2 as the action level and 1.15 m/s2 as the exposure limit. In using VDV to assess vibration, the EUGPG recommends 9.1 m/s1.75 as the action level and 21 m/s1.75 as the dose limit for an eight-hour exposure. The ISO/ANSI standards are slightly more conservative with recommended wRMS accelerations of 0.45 m/s2 as the action level and 0.90 m/s2 as the exposure limit and, for VDV, 8.2 m/s1.75 as the action level and 16 m/s1.75 Moreover, the EUGPG recommends measurement periods totalling a minimum of 20 min or longer, and if shorter periods are unavoidable, measurement periods should be at least 3 min long and repeated if possible, for a total time of more than 20 min.

Figure 1.

Vibration is measured along the orthogonal x, y and z axes or vectors (see online version for colours)

Source: Griffin et al. (2006). Graphic of seated driver downloaded from the Human Factors Research Unit website, Institute of Sound and Vibration, University of Southampton; http://resource.isvr.soton.ac.uk/HRV/VIBGUIDE/2008_11_08%20WBV_Good_practice_Guide%20v6.7h%20English.pdf. Orthogonal axes downloaded from Wikipedia http://en.wikipedia.org/wiki/File:Cartesian_coordinate_system_handedness.svg

Vibration transmitted through the seat was determined by the ratio – transmissibility (T) – of vibration level at the vehicle frame or chassis to the vibration level at the seat. A value greater than 1.0 (times 100%) would indicate a higher vibration level at the seat and that the seat is amplifying rather than attenuating the vehicle ride vibration. Griffin points out that comparing the accelerations on the seat with that at the seat base is the most direct method of obtaining accelerations. Impedance methods offer another means for measuring or predicting transmissibility. The seat effective amplitude transmissibility (SEAT) is given in two different ways by the following equations (Griffin, 1990):

| (1) |

| (2) |

In equation (1) GSS(f) and Gff(f) are the seat and floor acceleration power spectra and Wi (f) is the frequency weighting of the human response to vibration. In equation (2), VDV are the seat and floor or frame vibration dose values (VDVs). In this study, the authors used both wRMS, and VDV for the seat and frame of the truck cab to approximate and compare T values.

3.1 Analysis of whole-body vibration exposure

WBV data were analysed using GPS data and the Garmin Map Source software version 6.11.5. The GPS logs with time stamps and points were matched with the vibration time histories recorded with the Sony data recorder. Measures of wRMS and VDV were computed with Vibration, Acceleration and Statistical Analysis (VASA) developed by W. Utt and revised by R.E. Miller and I. May.1 One shortcoming with the VASA analysis was that the crest factors calculated by VASA used time domain data (peak/rms) to determine crest factor values instead of the frequency-weighted peak and weighted rms. These time domain values of crest factor were, in most cases, substantially lower than the designated value of 9.

Daily vibration exposures were computed from weighted RMS accelerations for the different haul trucks and drivers using equations (3) and (4). The activities of loading, roadway travel with full load and no load, and dumping were included in these exposure levels. Similarly, VDVs were obtained by using equations (3) and (4) to obtain A(8), 8-hr equivalent values the WBV exposures for six haul truck drivers, three drivers at each of two quarries.

For the x and y axes

| (3) |

And for the z axis

| (4) |

where Texp is the duration of vibration exposure daily and To is the reference duration of 8 h.

VDV exposures were computed from the measured samples as follows: For the x and y axes

| (5) |

And for the z axis

| (6) |

where Texp is the duration of vibration exposure daily and Tmeas is the measurement duration.

Overall weighted total RMS acceleration or vector sum normalised to an 8-hr shift is obtained by equation (7), whereas VDVtot exposure is provided by equation (8).

| (7) |

| (8) |

Frequency-weighted RMS accelerations were then calculated using the appropriate weighting factors as described in ISO 2631-1 (x-axis = Wd; y-axis = Wd; z-axis = Wk) (ISO, 1997, ANSI, 2002). Scaling factors associated with the determination of health for seated exposure were also applied (x-axis, k = 1.4; y-axis, k = 1.4; z-axis, k = 1.0). The axis with the highest mean wRMS acceleration level was selected for comparison to the ISO-2631-1 HGCZ limits associated with 8 h of daily exposure. According to the standard, health effects are not well documented for vibration exposure levels below the HGCZ. Exposures falling within the HGCZ should be viewed with caution in regards to health risks, while health risks are likely if the exposure is above the HGCZ (ISO, 1997; ANSI, 2002).

The axis associated with the highest level of acceleration was used to determine likely health risks based on ISO 2631-1 HGCZ limits for 8 h of exposure (Table 2). According to ISO 2631-1, the frequency-weighted acceleration values corresponding to the lower and upper limits of the HGCZ (for 8 h of exposure) are 0.45 m/s2 and 0.90 m/s2 respectively (ISO, 1997; ANSI, 2002). According to the standard, “health effects are not well documented for vibration exposure levels below the HGCZ. Exposures falling within the HGCZ should be viewed with caution in regards to health risks, while health risks are likely if the exposure is above the HGCZ” (ISO, 1997; ANSI, 2002).

Table 2.

Whole-body vibration exposures evaluated by weighted, root-mean-square (wRMS) accelerations for axes x, y, and z and vector summations for haul truck drivers/operators at two stone quarries. Weighted acceleration levels for the total sample times were normalised to full-shift equivalent levels to compare with the ISO health guidance caution zone (HGCZ) action and limit boundary level conditions of ISO 2631-1 and the European Union Directive 2002/44/EC presented in the European Union good practices guide (EUGPG)

| Quarry | Haul truck driver/operator | Total sampling time (min) | A(8) wRMS X-axis | A(8) wRMS Y-axis | A(8) wRMS Z-axis | A(8) wRMS vector sum | ISO 2631-1 8-hr shift1 equivalent HGCZ dominant axis | EUGPG 8-hr shift1 equivalent HGCZ dominant axis |

|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 82.4 | 0.41 | 0.77 | 0.43 | 1.30 | Within HGCZ | Within HGCZ |

| 1 | 1 | 98.9 | 0.33 | 0.63 | 0.54 | 1.13 | Within HGCZ | Within HGCZ |

| 1 | 1 | 83.8 | 0.42 | 0.69 | 0.42 | 1.21 | Within HGCZ | Within HGCZ |

| 1 | 2 | 22.1 | 0.49 | 0.51 | 0.39 | 1.06 | Within HGCZ | Within HGCZ |

| 1 | 2 | 75.6 | 0.49 | 0.54 | 0.47 | 1.13 | Within HGCZ | Within HGCZ |

| 1 | 2 | 81.8 | 0.49 | 0.54 | 0.36 | 1.08 | Within HGCZ | Within HGCZ |

| 1 | 3 | 61.3 | 0.50 | 0.56 | 0.39 | 1.12 | Within HGCZ | Within HGCZ |

| 1 | 3 | 60.0 | 0.47 | 0.54 | 0.42 | 1.09 | Within HGCZ | Within HGCZ |

| 1 | 3 | 66.7 | 0.44 | 0.58 | 0.43 | 1.11 | Within HGCZ | Within HGCZ |

| 2 | 4 | 85.0 | 0.62 | 0.56 | 0.33 | 1.22 | Within HGCZ | Within HGCZ |

| 2 | 4 | 65.6 | 0.99 | 0.79 | 0.40 | 1.82 | Within HGCZ | Within HGCZ |

| 2 | 5 | 67.2 | 0.45 | 0.66 | 0.44 | 1.20 | Within HGCZ | Within HGCZ |

| 2 | 5 | 47.5 | 0.42 | 0.62 | 0.38 | 1.12 | Within HGCZ | Within HGCZ |

| 2 | 6 | 59.3 | 0.44 | 0.55 | 0.42 | 1.07 | Within HGCZ | Within HGCZ |

| Mean | 68.3 | 0.50 | 0.61 | 0.42 | 1.19 | Within HGCZ | Within HGCZ | |

| STD | 18.9 | 0.16 | 0.09 | 0.05 | 0.19 | |||

Full-shift applies to 9-hr daily exposure during a 10-hr shift for wRMS; International Standards Organization (ISO). The multiple entries for individual drivers indicate the operation of different makes and models of haul trucks or ages of the same model. Units of wRMS are presented as m/s2. The activities associated with the haul truck driver exposures were loading, roadway travel with full load and no load, and dumping.

4 Results and discussion

4.1 Overall assessment

4.1.1 Haul trucks

Table 2 shows haul truck driver WBV exposures in terms of wRMS accelerations for six haul trucks operating at two stone quarries. Acceleration levels were normalised or adjusted using equations (3) and (4) to obtain 8-hr equivalent levels, A(8), of WBV exposures for the three drivers haul truck at each of two quarries. The activities performed during vibration data collection included loading, roadway travel with full load and no load, and dumping.

For all three truck drivers at Quarry 1, the dominant axis (highest level) of vibration exposure was the lateral y-axis (lateral or side-to-side direction) primarily and the x-axis (fore-aft or front-to-back direction) secondarily. All levels, normalised for an 8-hr shift, were within the HGCZ for both ISO and EUGPG boundary conditions.

In Table 3, VDV values showed similar results to those of wRMS, where the dominant axis of exposure was again the y-axis, although secondarily the z-axis (vertical or up-and-down direction) was dominant. In six of 14 instances, the more conservative ISO ELV was exceeded.

Table 3.

Whole-body vibration exposures evaluated by vibration dose value (VDV) for axes x, y, and z and vector summations for haul truck drivers/operators at two stone quarries. VDV levels for the total sample times were normalised to full-shift equivalent levels to compare with the ISO health guidance caution zone (HGCZ) action and limit boundary level conditions of ISO 2631-1 and the European Union Directive 2002/44/EC presented in the European Union good practices guide (EUGPG)

| Quarry | Haul truck driver/operator | Total sampling time (min) | A(8) VDV X-axis | A(8) VDV Y-axis | A(8) VDV Z-axis | A(8) VDV total | ISO 2631-1 8-hr shift1 equivalent HGCZ dominant axis | EUGPG 8-hr shift1 equivalent HGCZ dominant axis |

|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 82.4 | 10.8 | 19.8 | 10.8 | 33.4 | Above HGCZ | Within HGCZ |

| 1 | 1 | 98.9 | 9.2 | 15.9 | 13.9 | 29.2 | Within HGCZ | Within HGCZ |

| 1 | 1 | 83.8 | 11.3 | 18.2 | 14.5 | 33.3 | Above HGCZ | Within HGCZ |

| 1 | 2 | 75.6 | 12.5 | 13.8 | 12.2 | 28.8 | Within HGCZ | Within HGCZ |

| 1 | 2 | 75.6 | 12.5 | 13.4 | 12.6 | 28.6 | Within HGCZ | Within HGCZ |

| 1 | 2 | 81.8 | 12.4 | 13.3 | 9.5 | 27.2 | Within HGCZ | Within HGCZ |

| 1 | 3 | 61.3 | 13.4 | 13.8 | 15.1 | 30.9 | Within HGCZ | Within HGCZ |

| 1 | 3 | 60.0 | 12.7 | 13.6 | 14.3 | 29.7 | Within HGCZ | Within HGCZ |

| 1 | 3 | 66.7 | 11.7 | 14.2 | 15.5 | 30.1 | Within HGCZ | Within HGCZ |

| 2 | 4 | 85.0 | 13.3 | 18.9 | 17.5 | 36.8 | Above HGCZ | Within HGCZ |

| 2 | 4 | 65.6 | 12.2 | 16.6 | 12.0 | 31.2 | Above HGCZ | Within HGCZ |

| 2 | 5 | 67.2 | 13.5 | 16.8 | 17.3 | 34.8 | Above HGCZ | Within HGCZ |

| 2 | 5 | 47.5 | 13.7 | 13.4 | 18.8 | 32.8 | Above HGCZ | Within HGCZ |

| 2 | 6 | 59.3 | 11.0 | 11.8 | 9.3 | 24.4 | Within HGCZ | Within HGCZ |

| Mean | 68.3 | 12.2 | 15.2 | 13.8 | 30.8 | Within HGCZ | Within HGCZ | |

| STD | 18.9 | 1.3 | 2.5 | 2.9 | 3.2 | |||

Full-shift applies to 9-hr daily exposure during a 10-hr shift for VDV; International Standards Organization (ISO). The multiple entries for individual drivers indicate the operation of different makes and models of haul trucks or ages of the same model. Units of VDV are presented as m/s1.75. The activities associated with the haul truck driver exposures were loading, roadway travel with full load and no load, and dumping.

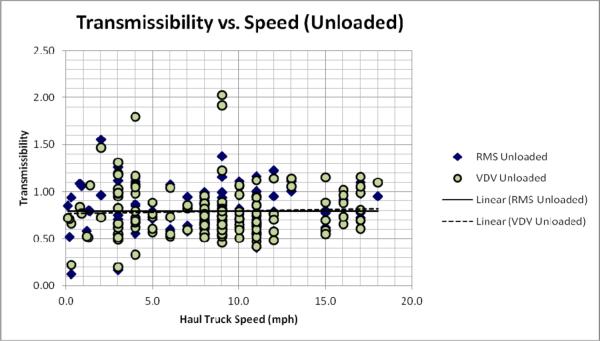

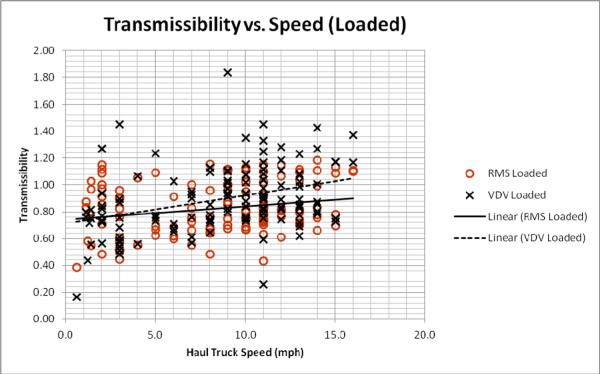

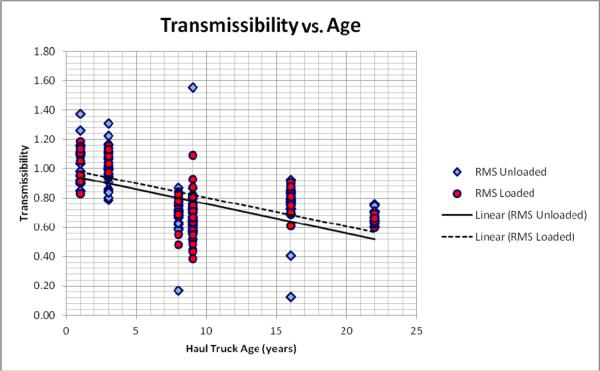

Figure 2 shows transmissibility (computed using wRMS and VDV) vs. speed for all haul truck drivers driving with no load. The general trend is flat and the trend lines for both transmissibility computational methods virtually coincide. The preponderance of transmissibility values fell below 1, which indicates the seat is attenuating rather than amplifying vibration. Similar results are seen in Figure 3 with a slight upward trend for both wRMS and VDV computed transmissibilities for all haul truck drivers driving with a load. Figures 4 and 5 show transmissibility vs. speed for all haul truck drivers, using the wRMS and VDV methods of computation, and driving with no-load and a load, respectively. The majority of values are again below 1 and the trends are downward with increasing age. The trend lines for wRMS and VDV are virtually superimposed on one another in Figure 4 as seen for the trend lines in Figure 2. Figure 5, as in Figure 3, shows slight separation in the trend lines for wRMS and VDV when HTs were travelling with a load.

Figure 2.

Transmissibility (output/input) vs. speed computed from weighted RMS and VDV for all haul truck drivers travelling with no load (see online version for colours)

Figure 3.

Transmissibility (output/input) vs. speed computed from weighted RMS and VDV for all haul truck drivers travelling with full load (see online version for colours)

Figure 4.

Transmissibility (output/input) vs. age computed from weighted RMS for all haul truck drivers travelling with no load and full load (see online version for colours)

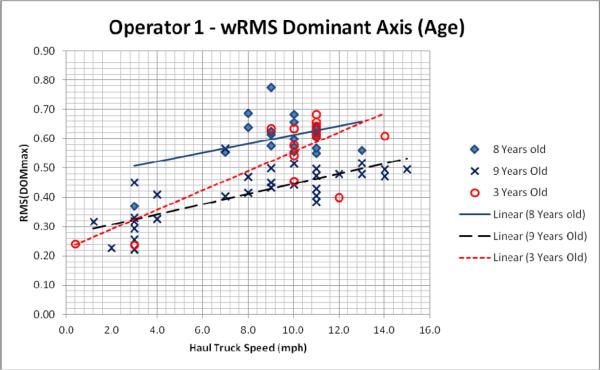

Figure 5.

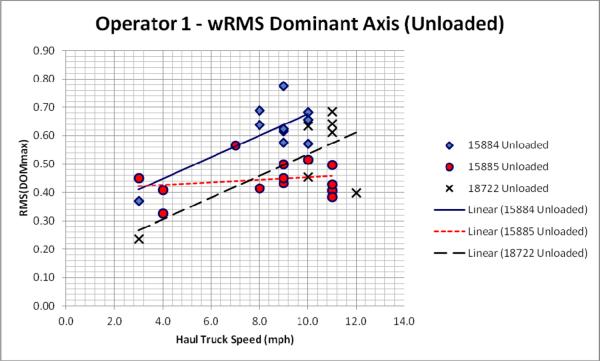

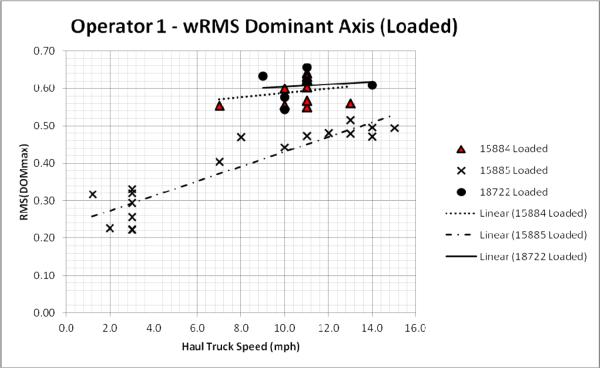

Weighted RMS accelerations, dominant axis, for haul truck driver 1 from quarry 1 vs. vehicle speed for roadway travel, with and without a load, and different vehicle age (see online version for colours)

Using Driver 1, Quarry 1, Figures 5–7 show examples of how wRMS varied for the dominant axis vs. speed when driving vehicles of different makes, models, and ages during the loaded/no-load conditions. In Figure 5, the trend lines are upward and the newest of the three vehicles, shows the steepest trend. The flatter trend is shown for the oldest vehicle, which may be indicative of stiffer vehicle suspensions and related components for the newer vehicle. The steeper trends, indicative of higher exposure levels, appear for the unloaded condition for the trucks 8, 3, and 9 years of age respectively.

In Figure 6, the wRMS accelerations of the dominant axis are compared against vehicle speed for the no-load condition, whereas Figure 7 shows the same for the HT travelling with a load. As expected, the exposures for the no-load condition trend higher than those for the loaded condition.

Figure 6.

Weighted RMS accelerations, dominant axis, for haul truck driver 1 from quarry 1 vs. vehicle speed for no-load conditions and different haul truck makes/models (see online version for colours)

Figure 7.

Weighted RMS accelerations, dominant axis, for haul truck driver 1 from quarry 1 vs. vehicle speed for full-load conditions and different haul truck makes/models (see online version for colours)

Roughly half of the dominant axis exposures were either in z-axis or the y-axis. The percentage breakdown of haul truck wRMS for dominant axis with and without a load was 47% z-axis, 46% y-axis, and 7% x-axis. Of the 275 HT selected incidents (not normalised to an equivalent 8-hr shift), 129 were within the HGCZ and 146 of 275 were below the HGCZ. Of those within the HGCZ, 56% of the 129 incidents were the vertical or z-axis, whereas 44% were the lateral y-axis.

4.1.2 Front-end loaders

Tables 4 and 5 show FEL operator exposures in terms of wRMS accelerations and VDV. The loader operator exposure included roadway travel, pushing/moving material, and loading HTs. The majority of wRMS levels in Table 4 normalised to 8-hr shift equivalent are shown to be within the HGCZ for both ISO/ANSI and EUGPG criteria. Again, the dominant axis levels are for the lateral x- and y-axes vs. the vertical z-axis. In contrast to wRMS levels, VDVs in Table 5 show that all recorded levels (normalised to the 8-hr equivalent) are dominant along the x-axis and are above the HGCZ for the ISO/ANSI criteria and within and above the criteria for the EUGPG. This is not entirely surprising, since VDV not only is more reflective of jarring/jolting, but is also cumulative across the shift.

Table 4.

Whole-body vibration exposures evaluated by weighted, root-mean-square (wRMS) accelerations for axes x, y, and z and vector summations for front-end loader operators at two stone quarries. Weighted acceleration levels for the total sample times were normalised to full-shift equivalent levels to compare with the ISO health guidance caution zone (HGCZ) action and limit boundary level conditions of ISO 2631-1 and the European Union Directive 2002/44/EC presented in the European Union good practices guide (EUGPG)

| Quarry | Front-end loader operator | Total sampling time (min) | A(8) wRMS X-axis | A(8) wRMS Y-axis | A(8) wRMS Z-axis | A(8) wRMS vector sum | ISO 2631-1 8-hr shift1 equivalent HGCZ dominant axis | EUGPG 8-hr shift1 equivalent HGCZ dominant axis |

|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 64.7 | 0.50 | 0.55 | 0.53 | 1.17 | Within HGCZ | Within HGCZ |

| 1 | 2 | 99.2 | 1.04 | 0.93 | 0.49 | 2.01 | Above HGCZ | Within HGCZ |

| 2 | 3 | 80.1 | 0.88 | 0.75 | 0.40 | 1.67 | Within HGCZ | Within HGCZ |

| 2 | 4 | 43.8 | 0.42 | 0.48 | 0.35 | 0.96 | Within HGCZ | Below HGCZ |

| Mean | 72.0 | 0.71 | 0.68 | 0.44 | 1.45 | Within HGCZ | Within HGCZ | |

| STD | 23.5 | 0.29 | 0.20 | 0.08 | 0.47 | |||

Full-shift applies to 9-hr daily exposure during a 10-hr shift for wRMS; International Standards Organization (ISO). Units of wRMS are presented as m/s2. The activities associated with the front-end loader operator exposures were pushing /moving material, loading haul truck, and roadway travel.

Table 5.

Whole-body vibration exposures evaluated by vibration dose values (VDVs) levels for axes x, y, and z and vector summations for front-end loader operators at two stone quarries. VDVs were normalised to full-shift equivalent levels to compare with the ISO health guidance caution zone (HGCZ) action and limit boundary level conditions of ISO 2631-1 and the European Union Directive 2002/44/EC presented in the European Union good practices guide (EUGPG)

| Quarry | Front-end loader operator | Total sampling time (min) | VDV X-axis | VDV Y-axis | VDV Z-axis | VDV total | ISO 2631-1 8-hr shift1 equivalent HGCZ dominant axis | EUGPG 8-hr shift1 equivalent HGCZ dominant axis |

|---|---|---|---|---|---|---|---|---|

| 1 | 1 | 64.7 | 18.8 | 13.0 | 14.1 | 35.0 | Above HGCZ | Within HGCZ |

| 1 | 2 | 99.2 | 21.5 | 18.3 | 9.6 | 40.6 | Above HGCZ | Above HGCZ |

| 2 | 3 | 80.1 | 23.2 | 22.2 | 12.4 | 46.7 | Above HGCZ | Above HGCZ |

| 2 | 4 | 43.8 | 19.9 | 18.9 | 10.2 | 39.7 | Above HGCZ | Within HGCZ |

| Mean | 72.0 | 20.8 | 18.1 | 11.6 | 40.5 | Above HGCZ | Within HGCZ | |

| STD | 23.5 | 1.9 | 3.8 | 2.1 | 4.8 | |||

Full-shift applies to 9-hr daily exposure during a 10-hr shift for wRMS; International Standards Organization (ISO). Units of VDV are presented as m/s1.75. The activities associated with the front-end loader operator exposures were pushing /moving material, loading haul truck, and roadway travel.

4.2 Statistical assessment

Vibration data for both HTs and FELs were analysed using robust multivariate regression techniques (SPSS, Inc.) to determine the influence of various independent variables on vibration exposure. Independent variables included vehicle load condition (loaded vs. unloaded), vehicle speed (mph), vehicle capacity (short tons), and vehicle age (yrs). Dependent variables included wRMS vibration in the z axis (chassis) and in x, y, and z axes at the seat, along with total RMS vibration at the seat and RMS transmissibility. In addition, VDV vibration dependent measures included all three axes (x, y, and z) at the chassis and at the seat, as well as total VDV vibration measured at the seat and VDV computed transmissibility. The type I error rate for all analyses was set at 0.05.

4.2.1 Haul trucks

Results for the regression analyses of wRMS and VDV vibration measures are presented in Tables 6 and 7, respectively. Examination of wRMS vibration effects due to the loading condition of the HT indicated generally lower vibration responses when the HT was loaded as opposed to unloaded, as shown in Table 6. This was true for vibration measured at the seat in the x (p < 0.001) and y (p < 0.001) directions, as well as for total wRMS vibration measured at the seat (p < 0.001). Increased speed was found to lead to increased wRMS vibration for all measured axes at both the chassis and the seat (p < 0.001); however, speed did not affect wRMS transmissibility (p > 0.05).

Table 6.

Results of regression results for wRMS vibration and transmissibility for haul trucks

| wRMS Z-axis (chassis) | wRMS X-axis (seat) | wRMS Y-axis (seat) | wRMS Z-axis (seat) | wRMS vector sum (seat) | WRMS transmissibility | |

|---|---|---|---|---|---|---|

| Constant | –0.0882*** | 0.4391** | 0.7555*** | 0.8725 | 1.5198*** | 3.1663*** |

| Loaded vs. unloaded | –0.0202 | –0.0551*** | –0.0682*** | 0.0226 | –0.0958*** | 0.0366 |

| Speed (mph) | 0.0245*** | 0.0086*** | 0.0138*** | 0.0229*** | 0.0311*** | 0.0013 |

| Capacity (short tons) | –0.0052 | –0.0015 | –0.0056 | –0.0081** | –0.0108* | –0.0300*** |

| Vehicle age (years) | 0.0147*** | –0.0045 | –0.0057 | –0.0141*** | –0.0166* | –0.0564*** |

| Adjusted R2 | 0.48 | 0.33 | 0.31 | 0.53 | 0.44 | 0.43 |

p < 0.05

p < 0.01

p < 0.001).

Table 7.

Results of regression results for VDV vibration and transmissibility for haul trucks

| VDV X-axis (chassis) | VDV Y-axis (chassis) | VDV Z-axis (chassis) | VDV X-axis (seat) | VDV Y-axis (seat) | VDV Z-axis (seat) | VDV total (seat) | VDV transmissibility | |

|---|---|---|---|---|---|---|---|---|

| Constant | 1.3900 | 1.467 | 1.0626 | 2.2361 | 4.1378** | 5.6875** | 8.6892*** | 2.4269*** |

| Loaded vs. unloaded | –0.3081*** | –0.2291*** | –0.2764** | –0.3203*** | –0.4038*** | 0.1978 | –0.5063*** | 0.1029*** |

| Speed (mph) | 0.0380*** | 0.0578*** | 0.1588*** | 0.0686*** | 0.0986*** | 0.1631*** | 0.2287*** | 0.0086* |

| Capacity (short tons) | –0.0043 | –0.0046 | 0.0049 | –0.0098 | –0.0354* | –0.0605* | –0.0732* | –0.0211** |

| Vehicle age (years) | 0.0124 | 0.0073 | 0.0667* | –0.0159 | –0.0301 | –0.0817* | –0.0868* | –0.0431** |

| Adjusted R2 | 0.25 | 0.27 | 0.48 | 0.36 | 0.38 | 0.40 | 0.45 | 0.22 |

p < 0.05

p < 0.01

p < 0.001.

Vehicle characteristics of load capacity and age also influenced wRMS vibration measures. Specifically, higher load capacities were found to reduce wRMS vibration at the seat in the z axis (p < 0.001) as well as total wRMS vibration at the seat (p < 0.001), and was also associated with decreased wRMS transmissibility (p < 0.001). Increased vehicle age was associated with higher wRMS accelerations at the chassis in the z direction (p < 0.001), but was associated with lower accelerations at the seat in the z axis (p < 0.001) and total wRMS vibration (p < 0.001), and a decrease in transmissibility (p < 0.001).

Analysis of VDV vibration data in HTs produced similar results to wRMS accelerations (see Table 7). Loaded HTs were found to significantly reduce VDV acceleration at the chassis in x (p < 0.001), y (p < 0.001), and z (p < 0.001) directions and for x (p < 0.001), y (p < 0.001), and VDV total vibration at the seat (p < 0.001). Load condition did not affect VDV vibration transmissibility (p > 0.05). Increasing vehicle speed increased VDV vibration in all three axes at the chassis (p < 0.001) and all three axes at the seat (p < 0.001). However, vehicle speed did not affect VDV transmissibility.

HT load capacity significantly affected VDV vibration measures at the seat and affected VDV transmissibility as well. Specifically, increased load capacity was associated with decreased VDV vibration at the seat in the y (p < 0.05) and z (p < 0.05) directions as well as total VDV vibration at the seat (p < 0.05). VDV transmissibility was also decreased as haul truck capacity increased (p < 0.05). Vehicle age was associated with increased VDV vibration in the z axis at the chassis (p < 0.01), and with decreased vibration in the z axis (p < 0.01) and for total seat vibration (p < 0.05) as well as decreased VDV transmissibility (p < 0.001).

4.2.2 Front-end loaders

In contrast to HTs, where vibration was affected by all of the independent variables tested, FEL vibration was associated with only one of the independent variables tested – vehicle age. As Table 8 shows, wRMS vibration was found to increase with vehicle age in the z axis at the chassis ((p < 0.05), at the x (p < 0.001), y (p < 0.01), and z (p < 0.001) axes at the seat, and for total wRMS vibration measured at the seat (p < 0.001). Results of VDV vibration also indicated that vehicle age was the only influential variable, with increasing vehicle age being associated with decreased VDV vibration in the x (p < 0.05) and y (p < 0.01) axes at the chassis (Table 9).

Table 8.

Results of regression results for wRMS vibration and transmissibility for front-end loaders

| wRMS Z-axis (chassis) | wRMS X-axis (seat) | wRMS Y-axis (seat) | wRMS Z-axis (seat) | wRMS vector sum (seat) | WRMS transmissibility | |

|---|---|---|---|---|---|---|

| Constant | 0.1969 | –0.2931 | –0.0687 | 0.1233 | –0.3060 | 0.0631 |

| Loaded vs. unloaded | –0.0029 | 0.1088 | 0.0502 | –0.0230 | 0.1377 | –0.0803 |

| Speed (mph) | –0.0014 | 0.0140 | 0.0087 | –0.0038 | 0.0201 | –0.0077 |

| Vehicle age (years) | 0.0451* | 0.0944*** | 0.0696** | 0.0480*** | 0.1701*** | 0.0102 |

| Vehicle capacity (tons) | 0.0071 | 0.0391 | 0.0252 | 0.0080 | 0.0640 | 0.0306 |

| Adjusted R2 | 0.18 | 0.40 | 0.24 | 0.44 | 0.40 | 0.00 |

p < 0.05

p < 0.01

p < 0.001.

Table 9.

Results of regression results for VDV vibration and transmissibility for front-end loaders

|

VDV X-axis (chassis) |

VDV Y-axis (chassis) |

VDV Z-axis (chassis) |

VDV X-axis (seat) |

VDV Y-axis (seat) |

VDV Z-axis (seat) |

VDV total (seat) |

VDV transmissibility |

|

|---|---|---|---|---|---|---|---|---|

| Constant | 9.5152 | 10.7710 | 2.1358 | –2.7241 | –1.3505 | 2.4271 | –2.3440 | 0.9063 |

| Loaded vs. unloaded | 0.1154 | –0.2426 | 0.5380 | 1.1694 | 0.7225 | –0.3124 | 1.4953 | –0.1170 |

| Speed (mph) | –0.0596 | –0.0881 | –0.1508 | –0.0027 | –0.0343 | –0.0788 | –0.0676 | 0.0212 |

| Vehicle age (years) | –1.4978* | –1.4929** | –0.7325 | 0.2853 | 0.1591 | –0.1319 | 0.3077 | 0.0118 |

| Vehicle capacity (short tons) | 0.3418 | 0.1509 | 0.8660 | 0.6537 | 0.5550 | 0.2846 | 1.2077 | –0.0212 |

| Adjusted R2 | 0.10 | 0.19 | 0.15 | 0.15 | 0.06 | 0.00 | 0.08 | 0.00 |

p < 0.05

p < 0.01

***p < 0.001.

HT vibration was influenced by a variety of factors, including load condition, vehicle speed, vehicle load capacity, and vehicle age. When the HT was loaded, measured vibration was significantly lower (at the chassis and at the seat) compared to the unloaded condition. As noted in NIOSH underground mine shuttle car studies, the additional weight from the load allowed for more damping from the tyres (Mayton et al., 2009a). Increasing vehicle speed for the HTs increased the level of vibration at both the chassis and the seat. Seat transmissibility was not affected by vehicle load or vehicle speed, which indicates that the seat was not amplifying the vibration. Characteristics of the truck (size and age) did affect transmissibility. Increasing size and age showed a decrease in transmissibility, z-axis vibration, and total vibration at the seat. In contrast with haul trucks, the independent variables impacted FELs very little except for vehicle age. Also the size differences between the various models of FELs were not significant, which may explain why there was little effect. Higher vehicle age for FELs showed an increase in wRMS vibration levels at the chassis and the seat, whereas VDV levels showed a decrease (x-axis and y-axis at the chassis only).

5 Conclusions

This study compared exposure levels on HTs and FELs with existing ISO/ANSI and EUGPG guidelines and evaluated the influence of factors such as load/no-load conditions, speed, load capacity, vehicle age, and seat transmissibility on vibration exposures. Predictably, recorded vibration at the chassis and seat increased with increasing HT speed. Increases in transmissibility were not evident with increasing vehicle load or vehicle speed. Conversely, decreases in transmissibility were evident with increases in HT size and age. The wRMS exposure levels for HTs, compared to the ISO/ANSI standards and the EUGPG, were, in all but one instance, within the HGCZ for the dominant axis of exposure and, in 43% of the cases for VDV, above the ELV for the ISO/ANSI guidelines. The y-axis (lateral or side-to-side direction) was most often the dominant axis. Roughly half of the dominant axis exposures were either in z-axis (vertical or up-and-down direction) or the y-axis. Of the 275 HT separate incidents (not normalised to an equivalent 8-hr shift), 129 were within the HGCZ and 146 of 275 were below the HGCZ. Of those within the HGCZ, 56% of the 129 incidents were the vertical or z-axis, whereas 44% were the lateral y-axis. For FELs, the wRMS levels dominant x-axis (fore-aft or front-to-back direction) and were predominantly within the ISO/ANSI and EUGPG EAVs. In contrast, VDV levels all in the dominant x-axis, were within and above the HGCZ for the EUGPG and above the HGCZ for ISO/ANSI guidelines. The higher VDV levels in the fore-aft direction are not surprising and are indicative of the quick and sudden start/stop bucket filling-/-emptying activities associated with FELs during loading operations. Future work should continue ongoing data collection efforts to monitor vibration exposure data on HTs and FELs and solicit feedback from the respective drivers/operators over a longer period of time.

6 Limitations

Operating conditions and the mining processes shortened sampling time in some instances. There was also an obvious change in the working environment (pit and bench location changes for loading operations), and truck driving routes over the 12-month period were a limiting factor in drawing conclusions and comparing to earlier field work. Moreover, the accuracy of the GPS information was limited somewhat by fewer visible satellites at a relatively high vertical angle, which degraded to some extent the accuracy of the horizontal coordinates. The nature of the current data made examination of interactions rather problematic, such as interactions between two continuous independent variables (i.e., speed and vehicle age). While such analyses can be done, such interactions can be confounding and are extremely difficult to interpret.

Acknowledgements

The authors thank Caitlin Moore, Jeremy Goodman, Amber Jobes, David Palamides and Justin Patts for their contributions in processing the data.

Nomenclature

- EAV

Exposure action value

- ELV

Exposure limit value

- EUGPG

European Union good practices guide on whole-body vibration

- FELs

Front-end wheel loaders

- GPS

Global positioning system

- HTs

Haul trucks

- HGCZ

Health guidance caution zone

- h

Hour

- ISO

International Standards Organization

- ANSI

American National Standard Institute

- LBP

Low-back pain

- m/s2

Metres per second squared

- m/s1.75

Metres per second to the power 1.75

- mph

Miles per hour

- min

Minutes

- wRMS

Frequency-weighted root-mean-square acceleration

- VDV

Vibration dose value

- WBV

Whole-body vibration

- yrs

Years

Biography

Alan G. Mayton serves as Mining Engineer at the Office of Mine Safety and Health Research, National Institute for Occupational Safety and Health, Pittsburgh, PA. He earned the BS from West Virginia University in 1978 and has performed federally funded mining research since 1979. His research interests include, among others, human body vibration control, vehicle dynamics, and ergonomic design of mine vehicle seats and operator compartments. His memberships include the American Society of Mechanical Engineers, International Society of Mine Safety Professionals, and Human Factors and Ergonomics Society. He is a registered Professional Engineer in Pennsylvania and Certified Mine Safety Professional.

Christopher C. Jobes is Research Engineer for the National Institute for Occupational Safety and Health in Pittsburgh, PA and adjunct Professor of Mechanical Engineering at Geneva College in Beaver Falls, Pennsylvania. He earned his PhD from West Virginia University in 1987 and Professional Engineer certification from Pennsylvania in 1989. With the US Bureau of Mines he worked on control and navigation of a computer-assisted mining machine from 1987 through 1997. His work has also included mine equipment safety and jarring/jolting abatement for mining machinery with a current focus on investigating interventions to enhance continuous miner operator safety through the development of proximity detection technology.

From 1984–2011, Sean Gallagher performed research to reduce the risk of musculoskeletal disorders in the mining industry, initially with the US Bureau of Mines and then the National Institute for Occupational Safety and Health. A major interest has been to quantify the physical demands associated with work in restricted work spaces. He has published over 40 journal papers, several book chapters, and numerous governmental publications detailing this research. He received his PhD in Industrial and Systems Engineering at the Ohio State University in 2003.

Footnotes

Vibration, Acceleration, and Statistical Analysis (VASA), 2006. Software Version 1.03 – Original DOS code by W.K. Utt, Revised by R.E. Miller and I. May. NIOSH – Spokane Research Laboratory, Spokane, WA.

Contributor Information

Alan G. Mayton, Office of Mine Safety and Health Research, National Institute for Occupational Safety and Health, Centers for Disease Control, P.O. Box 18070, 626, Cochrans Mill Road, Pittsburgh, PA 15236, USA.

Christopher C. Jobes, Office of Mine Safety and Health Research, National Institute for Occupational Safety and Health, Centers for Disease Control, P.O. Box 18070, 626, Cochrans Mill Road, Pittsburgh, PA 15236, USA

Sean Gallagher, Department of Industrial and Systems Engineering, Auburn University, 3304 Shelby Center, AL 36849-5346, USA szg0036@auburn.edu.

References

- American National Standards Institute (ANSI) ANSI S3. Vol. 18. American National Standards Institute; New York: 2002. ANSI: Guide for the Evaluation of Human Exposure to Whole-Body Vibration. 2002. [Google Scholar]

- Bongers PM, Boshuizen HC, Hulshof CTJ, Koemeester AP. Back disorders in crane operators exposed to whole-body vibration. International Archives of Occupational and Environmental Health. 1988;60(2):129–137. doi: 10.1007/BF00381494. [DOI] [PubMed] [Google Scholar]

- Bongers PM, Hulshof CTJ, Dijkstra L, Boshuizen HC, Groenhout HJ, Valken E. Back pain and exposure to whole-body vibration in helicopter pilots. Ergonomics. 1990;33(8):1007–1026. doi: 10.1080/00140139008925309. [DOI] [PubMed] [Google Scholar]

- Bovenzi M, Zadini A. Self-reported low back symptoms in urban bus drivers exposed to whole-body vibration. Spine. 1992;17(9):1048–1059. doi: 10.1097/00007632-199209000-00007. [DOI] [PubMed] [Google Scholar]

- Chaffin D, Andersson G. Occupational Biomechanics. John Wiley & Sons; New York: 1984. [Google Scholar]

- Eger T, Salmoni A, Cann A, Jack R. Whole-body vibration exposure experienced by mining equipment operators. Occupational Ergonomics. 2006;6(3–4):121–127. [Google Scholar]

- Griffin MJ. Handbook of Human Vibration. Elsevier Ltd; London: 1990. [Google Scholar]

- Griffin MJ, Howarth HVC, Pitts PM, Fischer S, Kaulbars U, Donati PM, Bereton PF. Guide To Good Practice on Whole-Body Vibration. Non-Binding Guide to Good Practice with a View to Implementation of Directive 2002/44/EC on the Minimum Health and Safety Requirements Regarding the Exposure of Workers to the Risks Arising from Physical Agents (vibrations) European Commission; Luxembourg: 2006. p. 65. (EU Good Practice Guide WBV, 6.7g), http://www.humanvibration.com/humanvibration/EU/VIBGUIDE.html. [Google Scholar]

- International Organization for Standardization (ISO) ISO 2631-1:1997, Mechanical shock and vibration: Evaluation of human exposure to whole-body vibration, Part 1, Geneva. 1997 [Google Scholar]

- Johanning E. Back disorders and health problems among subway train operators exposed to whole-body vibration. Scandinavian Journal of Work Environment and Health. 1991;17(6):414–419. doi: 10.5271/sjweh.1681. [DOI] [PubMed] [Google Scholar]

- Kittusamy N. Ergonomic risk factors: a study of heavy earthmoving machinery operators. Professional Safety – Journal of the American Society of Safety Engineers. 2002 Oct;:38–45. [Google Scholar]

- Kittusamy NK. Self-reported musculoskeletal symptoms among operators of heavy construction equipment. Proceedings of the XVth Triennial Congress of the International Ergonomics Association; Seoul, South Korea. 24–29 August; 2003. www.iea.org. [Google Scholar]

- Kittusamy NK, Buchholz B. Whole-body vibration and postural stress among operators of construction equipment: a literature review. Journal of Safety Research. 2004;35:255–261. doi: 10.1016/j.jsr.2004.03.014. [DOI] [PubMed] [Google Scholar]

- Kumar S. Vibration in operating heavy haul trucks in overburden mining. Appl. Ergon. 2004;35:509–520. doi: 10.1016/j.apergo.2004.06.009. [DOI] [PubMed] [Google Scholar]

- Mayton AG, Jobes CC, Miller RE. Comparison of whole-body vibration exposures on older and newer haulage trucks at an aggregate stone quarry operation. Proceedings of the 2008 ASME Design Engineering Technical Conference & Computers and Information in Engineering Conference; New York City, NY. 2008. p. 7. [Google Scholar]

- Mayton AG, Jobes CC, Ambrose DH, Kittusamy NK. Whole-body vibration exposure comparison of seat designs for low- and mid-seam shuttle cars in underground coal mines. Transactions of the Society for Mining, Metallurgy, and Exploration. 2009a;326:132–142. [Google Scholar]

- Mayton AG, Jobes CC, Miller RE. Assessment of whole-body vibration exposure on haulage trucks and front-end loaders at U.S. aggregate stone operations. Proceedings of the 2nd American Conference on Human Vibration; Chicago, IL. 2009b. pp. 26–27. [Google Scholar]

- Miller RE, Boman P, Walden J, Rhoades S, Gibbs R. Acceleration and GPS data monitor truck-haulage jolts. Mining Engineering. 2000;52(8):20–22. [Google Scholar]

- Miller RE, Lowe NT, Thompson R. A GPS Based System for Minimizing Jolts to Heavy Equipment Operators. NIOSH Office of Mine Safety and Health Research; 2004. [September 10, 2010]. http://www.cdc.gov/niosh/mining/pubs/pdfs/agbsf.pdf. [Google Scholar]

- National Institute for Occupational Safety and Health (NIOSH) Musculoskeletal Disorders and Workplace Factors. 1997 DHHS (NIOSH) Publication No. 97–141. [Google Scholar]

- Cincinnati OH, Seidel H, Heide R. Long-term effects of whole-body vibration: a critical survey of the literature. International Archives of Occupational and Environmental Health. 1986;58:1–26. doi: 10.1007/BF00378536. [DOI] [PubMed] [Google Scholar]

- Smets MPH, Eger TR, Grenier SG. Whole-body vibration experience by haulage truck operators in surface mining operations: comparison of various analysis methods utilized in the prediction of health risks. Applied Ergonomics. 2010 Oct;41(6):763–770. doi: 10.1016/j.apergo.2010.01.002. [DOI] [PubMed] [Google Scholar]