Abstract

The mechanical stability, elasticity, inherent bioactivity, and self-assembly properties of elastin make it a highly attractive candidate for the fabrication of versatile biomaterials. The ability to engineer specific peptide sequences derived from elastin allows for precise control of these physicochemical and organizational characteristics, and further broadens the diversity of elastin-based applications. Elastin and elastin-like peptides can also be modified or blended with other natural or synthetic moieties, including peptides, proteins, polysaccharides and polymers, to augment existing capabilities or confer additional architectural and biofunctional features to compositionally pure materials. Elastin and elastin-based composites have been subjected to diverse fabrication processes, including heating, electrospinning, wet spinning, solvent casting, freeze-drying, and cross-linking, for the manufacture of particles, fibers, gels, tubes, sheets and films. The resulting materials can be tailored to possess specific strength, elasticity, morphology, topography, porosity, wettability, surface charge and bioactivity. This extraordinary tunability of elastin-based constructs enables their use in a range of biomedical and tissue engineering applications such as targeted drug delivery, cell encapsulation, vascular repair, nerve regeneration, wound healing, and dermal, cartilage, bone and dental replacement.

Keywords: Tropoelastin, elastin, elastin-like peptide, fabrication, tissue engineering, biomaterials

1. Introduction

1.1. Structural and biological properties of elastin

Elastin is a polymeric extracellular matrix protein consisting of cross-linked tropoelastin monomers organized around a fibrillin-rich microfibrillar structure [1]. In vivo, elastin forms part of the elastic fibers that provide elastic properties to tissues such as arteries, ligaments and lungs. These elastic fibers display incredible resilience and structural stability, with aortic isolates of elastin exhibiting a half-life of ~70 years [2].

The principal component of elastin is tropoelastin, which consists of mostly non-polar amino acids arranged in alternating hydrophobic and hydrophilic domains. Within the hydrophobic domains are repeating sequence motifs, which confer elasticity to the protein and contribute to cell signalling [3]. The hydrophilic domains consist mainly of lysine-rich stretches involved in cross-linking. This cross-linking process is facilitated in vivo by lysyl oxidase, which converts lysine residues to form allysine aldol, lysinonorleucine, desmosine and isodesmosine bonds with surrounding modified and unmodified lysine residues [4], conferring functionally important stability to the protein array.

Tropoelastin, as a biologically active molecule, has a number of cell-interactive sites [5, 6] that direct numerous signalling events through glycosaminoglycans (GAGs) [7], the elastin binding protein (EBP) [8], and integrins [9], Tropoelastin interactions with EBP primarily occur via the hydrophobic VGVAPG motif. In contrast, integrin contacts have been characterised at the tropoelastin C-terminus, which terminates with an RKRK recognition site for the integrin αvβ3 [5]. Additional interactions also transpire at an upstream tropoelastin site for integrin αvβ5 [6, 10]. Tropoelastin not only mediates cellular processes such as cytoskeletal organization, chemotaxis, proliferation, and differentiation, but also mediates the local tissue environment through the regulation of matrix proteases [11].

1.2. Organizational ability of elastin

Tropoelastin exhibits the ability to self-assemble into higher-order structures. Coacervation is a highly ordered process that aligns specific lysine residues between tropoelastin monomers through the entropic association of hydrophobic regions [12]. In an aqueous solution, the hydrophobic domains are surrounded by clathrate water, whose thermodynamic stability is altered internally by protein concentration, and externally by solution temperature, pH, and ionic strength [13]. A temperature increase at physiological salt concentration is most commonly used to decrease clathrate order and reveal the hydrophobic domains for tropoelastin association [14]. The alignment of lysines within the elastin assemblies is critical for cross-linking. In the absence of coacervation, tropoelastin monomers fail to cross-link, despite the appropriate oxidative modifications to lysine residues [15].

The importance of the tropoelastin self-assembly to functional elastic fiber formation is reflected in elastic fiber pathologies such as ductus arteriosus [16], congenital supravalvular aortic stenosis (SVAS) [17] and cutis laxa [18], all of which feature alterations to the tropoelastin primary structure that disrupt intermolecular coacervation and crosslinking, and result in impaired fiber assembly [19].

1.3 Use and derivation for applications

The structural stability, elastic resilience, and bioactivity of tropoelastin, combined with its capacity for self-assembly, make this protein a highly desirable candidate for the fabrication of biomaterials. In addition, its dominant presence in a number of native tissues, accompanied by inefficient replacement during injury, drives its use as biomimetic scaffolds. Such scaffolds would not only reflect the physical features of the extracellular matrix, but would also possess biological cues for target cell incorporation and signaling for extracellular matrix remodeling in tissue engineering applications. The ability to distill important structural, biological and self-assembly properties of tropoelastin within short, chemically synthesizable peptide derivatives has further broadened the development and applications of elastin-based materials. These elastin-like peptides (ELPs) are predominantly based on repetitive hydrophobic sequences in tropoelastin, most commonly the VPGXG motif, where X represents any amino acid except proline [20]. This review explores the primary fabrication methods, properties and applications of elastin-based constructs, and focuses on materials that are synthesized solely from tropoelastin or ELPs, or integrated with other proteins, peptides, polymers or compounds that confer additional structural and functional benefits for specific purposes.

2. Elastin-only constructs

This section addresses the fabrication techniques and biological applications of materials that are constructed predominantly from elastin, either in the form of the tropoelastin monomer, or hydrolyzed elastic fibers. The elastin can be pre-modified to facilitate immediate cross-link formation, or post-processed with the addition of cross-linking agents.

2.1 Elastin production

The ability of tropoelastin to self-assemble has driven investigations into utilizing coacervation to facilitate the fabrication of elastin-based materials such as hydrogels and electrospun scaffolds for tissue repair. However, obtaining pure tropoelastin/elastin in large quantities has historically been a major challenge. Elastin isolation can be achieved by a number of methods, resulting in a range of end products. Solubilization with hot alkali, guanidine, or more recently, oxalic acid (produces α-elastin) and potassium hydroxide (produces κ-elastin) treatment can be used to hydrolyze elastic fibers components harvested from animal tissues [21]. Tissues such as ligamentum nuchae or large arterial vessels are preferred, as their high elastin content improves yields and reduces contaminant proteins [22]. Solubilized elastin retains many physiochemical properties of tropoelastin, including the ability to self-assemble [7]. However, these methodologies do not give rise to intact tropoelastin monomers and often consist of heterogeneous products due to their harsh nature [23]. In addition, the reliance on animal tissues limits large-scale production and carries additional ethical and moral implications.

The introduction of recombinant technology to produce synthetic tropoelastin addresses these concerns, by providing scalable host overexpression systems to meet the demands of industrial applications. In the development of these systems, gene optimization is critically important. This was exemplified by poor yields in early implementations of an Escherichia coli overexpression system, due to rare bacterial codons populating up to 35% of the native human tropoelastin gene [24]. By engineering a synthetic gene highly-optimized for bacterial expression, significantly enhanced protein yields of multi-gram quantities are obtained for biomaterial fabrication [25].

2.2 Elastin-only fibrous scaffolds

2.2.1 Fabrication

Electrospinning is a robust process that allows for the construction of nano-to-micro diameter fibers from both synthetic polymers and natural proteins. As fiber size is decreased, the surface-to-volume ratio increases, offering more sites for cellular interaction [26]. When designed to match the mechanical and signaling properties of the native tissue environment, electrospun materials can improve and accelerate healing in a variety of clinical applications [27].

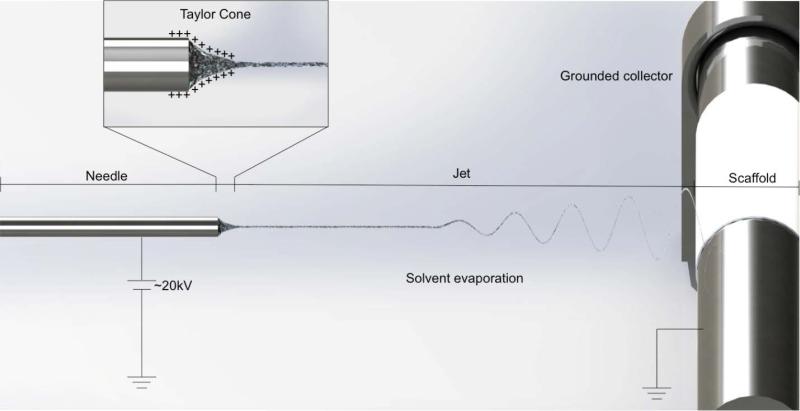

A typical electrospinning apparatus used to produce elastin-based scaffolds requires at least three components: a high voltage supply, a flow-controlled syringe needle, and a conductive collecting target that is typically grounded [28] (Figure 1). The collecting target geometry is most commonly manipulated to produce desired structures, such as sheets and tubes of varying dimensions. Parallel collectors have also successfully produced aligned parallel fibers that have important cellular and mechanical implications as subsequently discussed [29].

Figure 1.

Schematic diagram of a typical electrospinning setup used to produce fibrous elastin materials.

Tropoelastin solutions are prepared by dissolving in a volatile solvent such as 1,1,1,3,3,3-hexafluoro-2-propanol (HFP) and loaded into a syringe [30]. A high direct current voltage in the order of 20 kV is applied to the syringe needle to create an electric field that produces a polymer jet at a predetermined flow rate [31]. At the needle tip, an electric charge is conveyed to the contacting solution, inducing a mutual charge repulsion force in the opposite direction to the surface tension. This force reshapes the solution into a conical shape (Taylor cone) [32]. At the tip, there is sufficient charge repulsion to overcome the surface tension, and the solution is expelled as a jet towards the grounded target. As it travels towards the target, the solvent evaporates and the polymer fiber is deposited to form a nascent scaffold [33]. Elastin scaffolds may subsequently be treated with cross-linkers (commonly chemicals such as glutaraldehyde or hexamethylene diisocyanate (HMDI) to improve stability and insolubility [34]. Variations in cross-linking efficiency have been observed depending on the cross-linker used, however, this can easily be compensated for by adjusting the length of incubation periods. Upon cross-linking, elastin scaffolds are highly stable, maintaining structural integrity beyond 180 days under physiological conditions [35].

2.2.2 Properties and applications

Electrospun elastin fibers exhibit a characteristic thin ribbon-like morphology, ranging from 0.9 – 5.5 μm for tropoelastin and 0.6-3.6 μm for α-elastin [36] (Table 1). Fiber width is strongly dependent on flow rate and concentration. Continuous fibers are produced in 20% (w/v) solutions [37]. When concentrations are lowered to 15% (w/v) and below, fibers become discontinuous and gain the appearance of bead-like structures throughout the scaffold. The characteristic ribbon morphology is maintained independent of fiber alignment, which can be altered from a wavy whip-like appearance to parallel fibers via adjustments to the collecting target. Post-processing of scaffolds with cross-linkers has a modest effect on fiber width due to hydration [38], but gross fiber morphology is maintained even after extended cross-linking.

Table 1.

Mechanical properties and applications of elastin-only electrospun materials.

| Scaffold materials | Cross-linker | Fiber diameter (μm) | Pore size (μm) | Tensile modulus (kPa) | Cells cultured | Potential application/s | Reference |

|---|---|---|---|---|---|---|---|

| Tropoelastin | GA | 1-7 | 7-12 | 140-220 | Fibroblasts | Dermal replacement; wound healing | [41] |

| Tropoelastin | HMDI | 1-3.5 | 111 | Vascular smooth muscle cells | Vascular biomaterial | [29] | |

| Tropoelastin | GA | - | - | - | Adipocyte derived stem cells | Stem cell delivery vehicle | [27] |

| Tropoelastin | DSS | - | - | 160-240 | Bone marrow derived endothelial cells | Vascular scaffold | [274] |

| Tropoelastin | DSS | - | - | 150 | Bone marrow derived endothelial cells | Vascular scaffold | [274] |

GA: glutaraldehyde; HMDI: Hexamethyene diisocyanate; DSS: disuccinimidyl suberate

Due to the intrinsic stability of tropoelastin, its secondary structure and biological activity are preserved after the electrospinning process [35]. In contrast, electrospun collagen becomes denatured and suffers from degradation [39]. Remarkably, even uncross-linked tropoelastin scaffolds show no evidence of degradation, and when re-dissolved retain their ability to coacervate and promote cell growth [35].

Electrospun tropoelastin scaffolds are highly elastic, with a Young's modulus of 265 kPa, comparable to that of natural elastin which ranges from 100-350 kPa [40]. By aligning the fibers within the scaffold, elasticity can be increased to deliver a Young's modulus of 111 kPa, while preserving ultimate stress (116 kPa) and strain characteristics (~1.5%) [29].

A broad range of cell types have demonstrated positive growth and spreading on electrospun tropoelastin scaffolds, such as dermal fibroblasts, and vascular endothelial and smooth muscle cells. Cell attachment occurs within 30 minutes post-seeding [41]. After 14 days, extracellular matrix remodeling by the adherent cells is apparent, with the deposition of matrix proteins such as collagen and fibronectin to mimic their native environment. The scaffolds support extended cell growth to at least 35 days post-seeding [41]. For cell types or applications where cellular orientation is important for function, elastin scaffolds have been demonstrated to direct cell growth in an organized manner parallel to aligned fibers, while maintaining native cell morphology [29].

Achieving cellular infiltration requires scaffolds with sufficiently large porosity. In dermal replacements, pore sizes of at least 11 um were required to achieve fibroblast penetration into the material [41]. In conditions that produced smaller average pore sizes (~7 um), cell proliferation was restricted to the surface of the scaffold. Scaffold porosity is typically modulated by increasing the solution flow rate. Scaffold structures produced at high flow rates (3-5 mL/h) support cell penetration [42]. Inversely, scaffolds benefit mechanically from lower flow rates (1 mL/h), displaying a higher tensile strength while maintaining a similar elastic modulus. Flow rates of 5 mL/h represent a critical point, where any further increase in flow rate, and consequent increases in average fiber diameter and scaffold porosity, substantially decreases material density and structurally limits its potential usefulness [38].

The biocompatibility of tropoelastin scaffolds engineered with high porosity has been assessed in subcutaneous murine models [41]. Six-week-old implants demonstrate multilayer encapsulation by fibroblast cells and moderate scaffold remodeling and degradation. The main contributors to scaffold degradation are infiltrating fibroblast cells that reconstruct the local environment by depositing native extracellular matrix proteins such as collagen fibers. Immunogenic factors including neutrophils and monocytes are not observed, which indicates that the scaffolds are well-tolerated by the host.

Tropoelastin scaffolds have also found use as a stem cell delivery vehicle, as they mechanically and biologically reflect a native ECM which is important in regulating stem cell differentiation. Scaffolds laden with adipose-derived stem cells are non-immunogenic, increase the rate of wound closure, and enhance wound healing in vivo [27].

Electrospun scaffolds also serve as a viable treatment alternative to allogenic and xenogenic skin grafts for the >6 million severe burns injuries occurring worldwide each year [43]. While acceptable for short-term use, foreign skin grafts have limited availability, are strongly rejected by the host immune system, and possess elevated infection risks [44]. Elastin-based scaffolds are therefore appealing as they mimic the dermal environment and avoid the cytotoxic leaching common in synthetic polymers such as poly(lactide-co-glycolide) and poly(ε-caprolactone) [45]. Additionally, they offer advantages over similar ECM-like scaffolds formed from collagen, which contract and lead to reduced patient mobility [46].

2.3 Elastin-only hydrogels

2.3.1 General fabrication

Hydrogels are a class of highly absorbent materials consisting of a cross-linked polymer structure. Elastin hydrogels are typically cast by cross-linking tropoelastin solutions under physiological conditions. In the initial stages of this process, tropoelastin monomers reversibly self-organize into spherical nanoparticles [13]. By altering the concentration of tropoelastin, the size of these nanoparticles can be modulated up to a maximum of ~200 nm. Upon the addition of cross-linkers, these spheres coalesce to form interconnected beaded networks with distinct concentration-defined morphologies. Hydrogels formed at high tropoelastin concentrations (30-40 mg/mL) have a porous structure, and possess fiber diameters resembling those of in vivo elastic fibers [47].

Hydrogel cross-linking can be achieved through numerous enzymatic, chemical and irradiation methods. The degree of cross-linking is influenced by the concentration of the cross-linking agent and the duration of incubation [48]. The most commonly used cross-linkers for elastin-based hydrogels are chemical reagents such as glutaraldehyde, bis(sulfosuccinimidyl) suberate (BS3), and HMDI [49]. Each exhibits varying cross-linking efficiencies that dictate the cross-linking density, and hence, the structural properties of the resulting material. Elastin hydrogels formed with glutaraldehyde exhibit lower mechanical strength compared to constructs produced with HMDI, as glutaraldehyde limits crosslinking to lysine residues which represent under 1% of the tropoelastin sequence [50]. HMDI-cross-linked hydrogels are more mechanically robust, due to increased cross-link formation involving additional cysteine and histidine residues.

The degree and nature of a hydrogel's porosity largely dictate its function and potential applications. Hydrogels designed with high porosity and interconnectivity to allow nutrient and oxygen exchange are attractive candidates for tissue regeneration applications. Strategies to engineer porosity into hydrogels include phase inversion, use of organic solvents, or foaming with dense gases [51]. Such methods introduce pores into the hydrogel structure by thermodynamically-driven phase separation, which divides the solution into polymer-rich and polymer-deficient phases. During processing, the polymer-deficient phase is removed, and the remaining polymer-rich phase solidifies. The manner and kinetics by which this occurs influences the final physical form of the hydrogel [52].

2.3.2 General properties and applications

Tropoelastin hydrogels are highly elastic, exhibiting a Young's Modulus of 220-280 kPa, compared with 300-600 kPa for hydrogels made from solubilized elastin [48]. Both α-elastin and tropoelastin hydrogels display a uniquely linear stress/strain relationship when extended, far exceeding all other known biologically-derived materials [53]. Stress/strain measurements to gauge elasticity reveal a linear relationship up to about 60% strain for α-elastin and 150% for tropoelastin [48]. Material stiffness is dictated largely by porosity, and as such, can be readily controlled. For example, α-elastin hydrogels destined for orthopedic applications have been produced with compressive moduli closely matched to the 5.4 kPa compressive modulus of intervertebral discs [54].

Comparisons between hydrogels synthesized from tropoelastin and solubilized elastin are complicated by the differential use of cross-linkers, casting conditions, and rehydration conditions (Table 2). At 4 °C, tropoelastin hydrogels absorb 63±5 g H2O / g protein. This absorptive ability is reduced to around half (33±4 g H2O / g protein) upon a temperature increase to 37 °C. The addition of ionic salts further reduces swelling, with physiological NaCl concentrations resulting in over 10-fold reduction at both temperatures [48].

Table 2.

Mechanical properties and applications of elastin-only hydrogels.

| Precursor materials | Cross-linker | Tensile / compressive modulus (kPa) | Swelling ratio (g PBS / g Protein) | Cells cultured | Potential application/s | Reference | |

|---|---|---|---|---|---|---|---|

| Tropoelastin/α-elastin | 0/100 | GA + high pressure CO2 | 11E; 2C | 7-18 | Fibroblasts | Dermal replacement | [50] |

| 25/75 | 14E; 5C | 7 | |||||

| 50/50 | 29E; 12C | 5-7 | |||||

| 100/0 | 47E; 6C | 6-8 | |||||

| Tropoelastin/α-elastin | 25/75 | GA | 8E; 2C | - | Fibroblasts | Dermal replacement | [50] |

| 50/50 | 12E; 6C | - | |||||

| 100/0 | 33E; 4C | - | |||||

| Tropoelastin | BS3 | 220-280E | 4-7 | Epithelial cells | Elastic tissue repair | [48] | |

| Tropoelastin | Lysyl oxidase | 8-12E | 5.4 | - | - | [275] | |

| Tropoelastin | MA | 2.8-14.8E | Human umbilical vein endothelial cells | - | [42] | ||

| α-elastin | EGDE | 4-120E | 10-25 | Vascular smooth muscle cells | - | [276] | |

| α-elastin | HMDI + high pressure CO2 | 4-9C | 6.8 | - | Soft tissue repair; spinal replacement | [54] | |

| α-elastin | HMDI | 11-19C | 4.8 | Fibroblasts | - | [54] | |

GA: glutaraldehyde; BS3: bis(sulfosuccinimidyl)suberate; MA: Methacrylic anhydride; EGDE: ethylene glycol diglycidyl ether; HMDI: Hexamethylene diisocyanate.

The overarching cellular response to tropoelastin hydrogels is attrractive. A wide range of cell types including fibroblasts, endothelial cells, epithelial cells, embryonic kidney and fibrosarcoma cells of both human and animals origin remain adherent and adopt proliferative states following seeding on these hydrogels [50]. Differential cell migratory responses are seen on the hydrogel surfaces, characterized by pervasive cell infiltration on the more porous top surface, and cell monolayer formation on the casting surface. Implantation of the hydrogels in the dorsum of guinea pigs to assess immunogenic response has demonstrated that tropoelastin hydrogels are innocuous and invoke only a mild foreign-body response comparable to collagen [48].

2.3.3 Hydrogels formed with high pressure carbon dioxide

While cross-linkers are necessary to achieve adequate mechanical integrity of elastin hydrogels, they also result in small pore sizes with insufficient interconnecting channels for nutrient exchange and cell infiltration. A popular strategy to overcome this issue is to incorporate high pressure (~60 bar) dense gases such as CO2 during the casting process. This facilitates coacervation through interactions with hydrophobic tropoelastin domains and accelerates cross-linking within the polymer-rich phase [55]. The changes in pressure and coacervation kinetics alter hydrogel porosity. At atmospheric pressure, thick-walled pores are produced with limited interconnectivity. When synthesized at high pressure, a more rigid material is achieved that contains pores with a 10-fold reduction in wall thickness. Additionally, cross-linking at high pressure results in the formation of micro-channels and a uniformly porous structure within the hydrogel. In contrast, gels fabricated at atmospheric conditions display non-uniform porosity underneath the solid surface layers. Due to this structural augmentation, the mechanical properties of the hydrogel are also altered, as exemplified by a 1.5-fold increase in elastic modulus [50].

When seeded with fibroblasts, elastin gels formed at high pressure enhance cellular infiltration throughout the material, primarily due to the presence of large channels. In contrast, hydrogels formed at atmospheric conditions are limited by their solid surfaces, which allow cells to form a confluent monolayer but tends to prevent them from extending into the material [56].

2.3.4 Hydrogels formed from tropoelastin and solubilized elastin

Hybrid gels formed from combining tropoelastin with α-elastin gain mechanical strength when a 50/50 ratio or higher of tropoelastin is used [42]. When characterized across a range of mechanical metrics, hybrid gels outperform single-constituent gels in key areas of compressive strength and energy loss. The compressive modulus of hybrid hydrogels is elevated over 6-fold compared to that of α-elastin gels [50]. Their ability to support cell growth, being largely dictated by porosity, is analogous to single-constituent gels. As in tropoelastin-only constructs, fibroblasts can be allowed to infiltrate hybrid gels by synthesizing them in high pressure CO2 order to enhance porosity [50].

2.3.5 Hydrogels formed from modified tropoelastin

The modification of tropoelastin residues is an emerging strategy to accelerate coacervation and allow for rapid, chemical-free cross-linking. Gel formation occurs within a short time frame (under a minute), which is multiple orders of magnitude faster than the typical requisite 24 hr incubation period. Cytotoxicity concerns are also addressed by removing the use of toxic cross-linkers and organic solvents from the process [57]. The manufactured elastin-based gels also benefit from enhanced stability and minimal leaching in vivo. Importantly, this fabrication process is cytocompatible, allowing for three-dimensional cellular encapsulation throughout the hydrogel structure.

The most explored methodology of tropoelastin modification is the reaction of tropoelastin lysine residues with methacrylic anhydride [58]. This process has a minimal effect on the protein as a whole, as illustrated by the maintenance of tropoelastin secondary structure in response to varying degrees of methacrylation. This process has been shown to increase tropoelastin hydrophobicity, thus enhancing the rate of coacervation. Gel properties are largely dictated by the degree of methacrylation [42]. Highly-methacrylated monomers increase the density of crosslinking, and consequently reduce the hydrogel pore size and swelling ratio. When compared to unmodified α-elastin hydrogels, the swelling ratio of methacrylated tropoelastin (MeTro) gels is reduced ~1.5 fold depending on casting conditions. The elastic benefit of constructing hydrogels from MeTro is consistently demonstrated, with a dramatically higher elastic modulus of up to 100-fold over similarly processed biological materials [59]. Additionally, MeTro gels experience low energy losses in response to deformation and show up to 400% extensibility, indicative of a high elastic resilience that is ~3 fold higher than that of native tropoelastin.

Cellular growth is actively promoted on the surface of MeTro gels, at far higher levels compared to hydrogels made from synthetic polymers such as polyethylene glycol (PEG), which suffer from poor cellular adhesion and growth [58]. The ability of MeTro gels to sustain an expansive array of cell types likely indicates that the cell-interactive regions of tropoelastin are presented in an active conformation on the material surface. The capacity of these fabricated gels to effectively conduct nutrient exchange throughout the gel structure has also been demonstrated. Cells embedded within the 3D hydrogel structure during casting remain viable for at least 7 days [58]. This technology represents a major breakthrough for elastin-based hydrogels and has potential applications as cell-laden constructs.

3. Composite elastin-based materials

Elastin can be synthesized in conjunction with other proteins or polymers to augment the structural and functional properties of a range of biomaterials.

3.1 Composite elastin-based fibrous scaffolds

As with pure-elastin materials, electrospinning of composite elastin-based constructs gives rise to a non-woven, nanofibrous, 3D structure with high specific surface area, high porosity, and high pore interconnectivity [33, 60, 61]. This technique allows for the fabrication of engineered scaffolds mimicking the structure and architecture of the native extracellular matrix [33, 60]. Electrospinning has been widely used for the fabrication of tubular and flat scaffolds with random or aligned fiber orientation for skin, bone, nerve, and particularly, vascular tissue applications (Table 3) [30, 60, 62-68].

Table 3.

Morphological and mechanical properties of composite elastin-containing fibrous scaffolds and their applications in tissue engineering.

| Scaffold materials |

Cross- linker |

Fiber diameter (μm) |

Pore size/ pore area/ porosity |

Young's modulus (MPa) |

Cells cultured |

Potential applications |

References |

|---|---|---|---|---|---|---|---|

| Collagen/Elastin | GA | 0.49 | 200 nm | - | Smooth muscle cells, fibroblasts | Vascular tissue engineering | [79] |

| Silk fibroin/Tropoelastin | GA | 1.9-3.25 | - | - | Human dermal fibroblasts | Tissue repair | [277] |

| Tropoelastin/Collagen | GA | 2.1-6.5 | 44-64.5 % | 0.14-0.84 | Human dermal fibroblasts | Dermal tissue engineering | [67] |

| Elastin/PDO | - | - | - | 4.89-.64 | Human dermal fibroblasts | Vascular graft | [76] |

| Collagen/Elastin/PLGA | GA | 0.72 | - | - | Bovine endothelial and smooth muscle cells | Vascular substitute (graft) | [68] |

| PLGA/Gelatin/α-elastin | - | 0.38 | - | 12-43 | Cardiac myoblasts, bone marrow stromal cells | Engineering of soft tissues | [74] |

| - | 0.317-1.196 | 0.57-4.74 μm2 | 0.085-0.77 | Endothelial cells, smooth muscle cells | Vascular tissue engineering | [66] | |

| Collagen/Elastin/(PLGA/PLLA/PCL/PLCL) | GA | 0.477-0.679 | - | 0.34-2.08 | Smooth muscle cells | Vascular graft | [65] |

| PGC/PCL/Elastin/Gelatin | EDC | 0.6-1.2 | - | 4.79-8.67 | Human umbilical vein endothelial cells | Vascular graft | [73] |

| Polyglyconate/Gelatin/Elastin | - | 0.2-0.4 | 82% | 20.4 | - | Vascular tissue engineering | [60] |

| Tropoelastin/PCL | GA | - | - | 0.025-0.3 | Human umbilical vein endothelial cells | Vascular graft | [30] |

| PCL/Elastin | - | 0.416-0.519 | 63.3-80.5 % | - | Embryonic chick dorsal root ganglia | Peripheral nerve regeneration | [63] |

| Collagen/Elastin/PEO | EDC/NHS | 0.22-0.6 | - | - | Smooth muscle cells | Blood vessel | [80] |

| Collagen/Elastin/PCL | GA | 0.47-1.61μm | 8.64-39.06μm2 | 20.35-23.7 | Human adipose-derived stem cells | Vascular tissue engineering | [26] |

| PCL/Elastin/Collagen | EDC/70% ethanol | 0.4-1.3 μm | 2.5-16 μm2 | 2.0-11.8 | - | Vascular graft | [64] |

Electrospun materials made entirely from natural polymers such as elastin or collagen have the advantage of being more biocompatible and less immunogenic, due to their inherent capacity for cell interactions [69]. However, they often lack the requisite mechanical properties for tissue replacement scaffolds [60]. For example, although collagen is a dominant component in many tissues, its use in biomaterial design is limited due to inadequate post-processing mechanical strength, compounded by rapid degradation and loss of structural integrity in vivo [70, 71]. On the other hand, electrospun constructs based on pure synthetic polymers such as poly (ε-caprolactone) (PCL), poly(lactic-co-glycolic acid) (PLGA), poly(lactic acid) (PLA) , poly (L-lactic acid) (PLLA), poly(L-lactide-co-ε-caprolactone) PLCL, and polydioxanone (PDO) exhibit superior mechanical properties and biodegradation kinetics [72]. However, although they can mimic the physical dimension and structure of the native ECM, they lack cell recognition sites necessary for biological signaling. Furthermore, the typically hydrophobic nature of these scaffolds adversely affects cell attachment and activity [70].

To overcome these problems, current strategies co-electrospin elastin with natural proteins or synthetic polymers [26, 63-66, 68, 73-77]. Fabrication of these hybrid materials is a simple and cost-effective process, which involves the physical blending of individual components at different ratios prior to electrospinning into nanofibrous materials with novel, complementary, and tunable mechanical properties [65, 66, 70, 74]. The composite tropoelastin solutions often display more favourable viscosity and electrospinning efficiency [67, 68]. The electrospun elastin-based hybrid scaffolds also better mimic the architecture and components of native tissue, and display improved strength, structural integrity, elasticity, and wettability [26, 63, 66, 68, 74, 76-78]. Moreover, they show increased bioactivity including cell attachment [30, 63, 66, 73, 74], proliferation [30, 68, 73, 74], maturation [63, 68], migration [67], and infiltration [64, 66, 67, 74, 76] compared to biologically inert synthetic scaffolds.

Co-electrospun tropoelastin-based blends have been developed as vascular grafts. Composite solutions were loaded in a syringe pump and electrospun onto a rotating mandrel under a high voltage power supply to produce a cylindrical structure [64-67, 74, 76]. Tubular electrospun scaffolds have been manufactured from elastin mixed with collagen [67, 79, 80], elastin with PDO [76], elastin with gelatin and PLGA [37, 66, 74], elastin with collagen and PLGA [65, 68] or other synthetic polymers like PLLA, PLCL [65] and PCL [64, 65, 81].

An ideal biomimetic vascular graft should not only resemble the composition and structure of native vessels, but should also possess sufficient mechanical integrity to withstand the high pressure, pulsatile environment of the blood stream [79]. To address this need, multilayered vascular grafts have been developed. One such construct is a cell-laden, tri-layer vascular graft composed of collagen type I and tropoelastin [79]. It is characterized by an electrospun, cross-linked outer tube with 20:80 tropoelastin:collagen ratio, and an inner tube with 70:30 tropoelastin:collagen. Fibroblasts are seeded on the external surface, smooth muscle cells between the tube layers, and smooth muscle cells and endothelial cells within the innermost lumen. Another bilayer vascular conduit consists of sequentially electrospun tropoelastin and PCL. First, tropoelastin solution is delivered on the mandrill to generate the inner luminal layer, then a hybrid solution of tropoelastin:PCL (80:20) is deposited atop and cross-linked with glutaraldehyde vapor [30]. In other studies, tri-layer grafts have been constructed, in which the intima comprises only elastin and PCL, the media comprised elastin, collagen and PCL, and the adventitia comprised only collagen and PCL. These scaffolds are cross-linked with either 1-ethyl-3-(3-dimethylaminopropyl)-carbodiimide (EDC) and 70% ethanol or genipin [64, 77]. Other multi-layered constructs have likewise been formed by sequential electrospinning of elastin, gelatin and polyglyconate blends [60], or elastin, gelatin, poliglecaprone (PGC) and PCL [73]. This process enables the tuning of each layer to fit various structural and compositional requirements. Electrospun elastin-based composite vascular conduits have increased elasticity and burst strength to reduce the compliance mismatch between the graft and the native vasculature [64, 68, 73]. The elastin component, on the other hand, improves biocompatibility and decreases the risk of thrombosis [30, 65, 66].

Aside from vascular repair, electrospun elastin-based composite scaffolds can serve other tissue engineering applications. Combinations of elastin with PCL have been reported for peripheral nerve regeneration. Neural cells attach and elongate in the direction of aligned nanofibers within the material [63]. Blended collagen and elastin mats have been studied as potential dermal substitutes for wound healing [67]. An elastin, gelatin and PLGA composite scaffold has been investigated for replacement of soft tissues such as heart, lung and blood vessels [37].

3.2 Composite elastin-based hydrogels

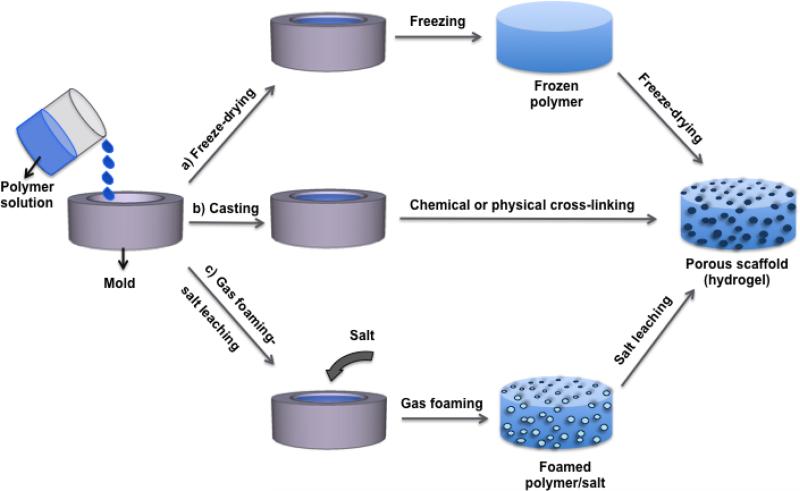

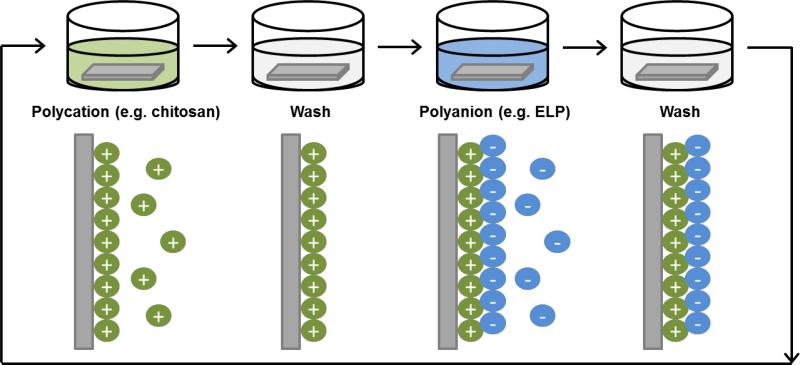

To fabricate elastin-based porous scaffolds (hydrogels) with desirable properties for tissue engineering, various methods including gas foaming and freeze-drying have been employed (Figure 2) [82-87].

Figure 2.

Schematic diagram showing various paths to fabricate elastin-based hydrogels. The single/blended polymer solution is poured into a mold, and a) freeze-dried, b) chemically or physically cross-linked to form a hydrogel. C) The polymer solution was mixed with salt and poured in a mold to cast. The disc was placed in in a high pressure vessel for gas foaming by dense gas, then placed in water to leach out the salt, so forming a porous scaffold.

Gas foaming utilizes a foaming agent added to a viscous polymer solution to generate inert gas inside the solution. The expansion of dispersed gas within the solution, followed by sudden gas release, results in porous structures [88-90]. This has been demonstrated by the fabrication of a highly porous hydrogel composed of elastin and PCL. PCL and NaCl particles were mixed by melt mixing and gas–foamed using carbon dioxide at 65 bar and 70 °C. The PCL scaffolds were then impregnated with an elastin solution containing glutaraldehyde, at atmospheric pressure, in vacuum, or at high pressure CO2 [88, 89, 91].

Freeze-drying is another technique for the fabrication of highly porous elastin-based composite scaffolds [82-87]. Freezing a dispersion or solution results in the formation of ice crystals, which are subsequently removed by freeze-drying to leave pores inside the material. Pore size is inversely related to the freezing rate [82]. To illustrate, a tropoelastin-collagen solution frozen at -80°C and freeze-dried produces porous disc-shaped [86] or tubular scaffolds [87]. Likewise, an elastin-glycosaminoglycan-collagen composite hydrogel has been manufactured by gelation at 37°C, followed by lyophilization and cross-linking with 1-ethyl-3-(3 dimethylaminopropyl)carbodiimide/N-hydroxysuccinimide (EDC/NHS) [85]. Similarly, silk-elastin hydrogels have been made by freeze-drying genipin-cross-linked samples, and further stabilizing them via methanol immersion [84]. Tubular porous scaffolds are constructed by dipping a mandrill in protein solution and freeze-drying. Repeated solution coating and freeze-dry cycles allow build-up into multi-layered constructs, such as that produced with an outer collagen film and an inner tropoelastin-collagen sheet [87].

As previously discussed, elastin-based hybrid materials have excellent ECM-mimetic properties [83, 87, 89, 91]. Structurally, composite hydrogels allow greater tailoring of mechanical properties for diverse applications (Table 4) [83, 84, 86, 89, 91]. The elastin component confers elasticity to the composite scaffolds [83], and hence decreases the energy loss and hysteresis of the constructs [89, 91]. This permits the scaffolds to withstand high burst pressures [87] and extreme deformation under compressive load [85, 86]. Moreover, the addition of elastin induces large pore formation [84, 86], which enhances cell growth and infiltration within the scaffolds [84-86, 91]. Elastin also imparts hydrophilicity to composite scaffolds, and thus improves their wettability and water uptake [83, 84, 89, 91].

Table 4.

Physical and mechanical properties and applications of composite elastin-containing hydrogels fabricated by freeze-drying, casting, or gas foaming.

| Scaffold materials | Cross- linker |

Pore size/ porosity |

Mechanical properties |

Cells cultured | Potential applications |

References |

|---|---|---|---|---|---|---|

| Collagen/Elastin/Glycosaminoglycans | EDC/NHS | - | 4.16 kPa C | Human adipose-derived stem cells | Nucleus pulposus regeneration | [85] |

| 20-100 μm | 0.54 - 0.76 MPa E | Fibroblasts | Tissue engineering/slow-release vehicle for growth factor release | [83] | ||

| Collagen/Elastin | EDC/NHS | 130 μm | 0.25 - 5.3 MPa E | Smooth muscle cells | Small-diameter blood vessels | [86] |

| 300 μm | 1.12 MPa E | - | Vascular graft | [87] | ||

| Silk fibroin/Elastin | Genipin | 78-88 % | - | Human dermal fibroblasts | Wound dressing | [84] |

| PCL/α-elastin | GA | 540 μm/91% | 1.30 MPa C | Chondrocytes | Cartilage repair | [89, 91] |

EDC/NHS: 1-ethyl-3-(3 dimethylaminopropyl)carbodiimide/N-hydroxysuccinimide; GA: glutaraldehyde

Porous elastin-based composite hydrogels have been utilized in various applications. Tropoelastin and collagen composites have been developed for small-diameter blood vessels [86]. Collagen-elastin-GAG constructs haven been investigated for nucleus pulposus regeneration [85], or as mimetic scaffolds for skin and cartilage [83]. Silk-tropoelastin scaffolds have also been eyed as wound dressings and drug release vehicles [84], and elastin-PCL composites as cartilage replacement [89, 91].

3.3 Composite elastin-based cast materials

Casting is another method used for the construction of elastin-based composite materials [75, 92-96]. In this process, a solution is poured into a mold or on a substrate and allowed to solidify, such as by air drying. This technique has been employed to cast a porous membrane composed of alginate, elastin and PEG on a glass petri dish, followed by crosslinking using CaCl2/carbodiimide [75]. Elastic patches have also been prepared in a similar manner using a combination of elastin, hyaluronan and silk. The components were mixed with the BS3 cross-linker and immediately casted into polydimethylsiloxane (PDMS) molds at 37°C to facilitate elastin-driven coacervation and cross-linking [92]. Silk-elastin films have similarly been prepared by casting the blended solution on a PDMS substrate, and physically cross-linking the resulting material with water vapour under vacuum at 60°C, or with thermal treatment such as autoclaving [93-96].

These tropoelastin-silk composite films have tuneable surface charge [94] and roughness [93, 95] based on the ratio of individual components, which greatly impact material functionality. By modulating surface charge, the growth of charge-sensitive cell/tissue networks such as neural cells can be defined [94]. Scaffolds can be tailored with low surface roughness and high stiffness to promote the proliferation and myogenic differentiation of C2C12 myoblasts [93, 96].

4. Elastin-like peptide (ELP) constructs

ELPs are artificial biopolymers which contain elastin-based repeat motifs, commonly the pentapeptide sequence Val-Pro-Gly-Xaa-Gly (VPGXG), where the guest residue Xaa can be any naturally occurring amino acid except for proline [97]. Other elastin-based motifs used in the design of ELPs are the nonapeptide LGAGGAGVL [98] and pentapeptides KGGVG [99], GVGVP [100], VGGVG [101]. Another well-characterized ELP consists of repeats of the VPVXG motif derived from bovine tropoelastin. More recently, in an attempt to enhance the properties of the polypeptide, human elastin-like polypeptides (HELPs) have been synthesized based on the VAPGVG motif, the most highly-recurring sequence in the human tropoelastin homolog [102].

4.1 Synthesis of ELPs

Genetically encoded synthesis of ELPs in an heterologous host, most commonly bacteria or eukaryotic cells, allows precise control over the sequence, molecular weight, and hence stereochemistry of the polypeptides [103, 104]. These variables are often difficult to control in chemical polymerization processes [105]. ELPs are readily produced from biological expression systems at relatively high yields, and conveniently purified via inverse temperature cycling without the need for chromatography [106]

Historically, ELP synthesis involved the generation of a library of oligomeric genes by concatemerization, or random unidirectional ligation of a monomer gene [107]. However, this method does not allow control over the number or order of repeat units, resulting in heterogeneous oligomer populations of different lengths [107, 108].

An alternative approach, termed overlap extension polymerase chain reaction (OEPCR) [109], uses short DNA oligonucleotides that simultaneously serve as primer and template to yield various repetitive DNA chain lengths. To overcome the low specificity of this method, a modified technique was applied, termed overlap extension rolling circle amplification. This approach combines rolling circle amplification with OEPCR [110]. It involves a single PCR-type reaction that utilizes circular single-stranded DNA to produce linear repeats of the gene, followed by thermally-cycled overlap extension to generate high-fidelity and high-yield repetitive gene libraries. The synthesis of such extensive gene libraries has enabled the investigation of previously unidentified ELP polymers.

Another method of ELP synthesis is recursive directional ligation (RDL), which utilizes stepwise oligomerization of a DNA monomer encoding a short ELP oligomer of 5-10 pentapeptides. The monomer DNA contains restriction endonuclease recognition sequences for isolation of the DNA insert from the parent vector [103]. The number of repetitive sequences is increased until a specified target is reached. This process enables the production of large block copolymers with customized sequence, mass and orientation [111]. However, only particular sequences are compatible with this method of synthesis, as the endonuclease restriction sites overlap with the coding region. Additionally, cloning efficiency is limited by incomplete vector digestion or self-ligation events [112, 113].

To address the limitations of the RDL technology, a significantly improved cloning methodology called recursive directional ligation by plasmid reconstruction was utilized [113]. This method ligates two segments of a parent plasmid, each containing a copy of the desired oligomer, to reconstitute a functional plasmid. The ligation step utilizes type II restriction endonucleases, which are compatible with any oligonucleotide sequence. Furthermore, cloning efficiency is improved as a functional plasmid is produced only after successful ligation.

Most ELP applications require large quantities of the polypeptide at high purity and at competitive economic cost, which can be addressed by recombinant expression systems such as E. coli [114]. Yields of up to 400mg/L culture have been obtained from E. coli expression systems, for either free ELPs or chimeric constructs [115]. However, obtaining such yields requires the optimization of many factors, such as the addition of exogenous proline and alanine, amino acids that are disproportionately abundant in ELPs [115, 116]. Endotoxins are difficult to remove from the final ELP product [117], so an alternative recombinant expression system based on Pichia pastoris as a host organism has been explored. Expressed ELPs are secreted by yeast cells and can be purified directly from the culture medium [118]. Yeast-based expression systems also have the ability to be incorporated into industrial-scale fermentation processes. However, product yields obtained from yeast systems, at approximately 255 mg/L culture, are often lower than those from bacterial systems [118, 119]. Plant-based systems are increasingly being recognized as an efficient and inexpensive means of ELP production [120], but this is not yet optimized for maximum yield and purification efficiency [121]. Column chromatography is a standard method for the purification of expressed ELPs but lower cost alternatives have been explored [122]. A common strategy, inverse transition cycling (ITC) exploits the reversible inverse temperature transition property of ELPs. This technique typically involves several rounds of sequential steps which include heating, centrifugation, cooling, and solubilization [106, 123]. As increasing the temperature allow the aggregation of ELPs, forming a coacervate, centrifugation will then allow the pellet to be separated from the supernatant that may contain soluble contaminants and other compounds. Resolubilization in a cooler environment, then repeating the sequence of heating and centrifugation allow further purification [124]. Conveniently, this property is retained even after the ELP is grafted to other polypeptide or protein components, allowing the purification of a diverse range of ELP fusion proteins [106, 122].

4.2 Tunable properties of ELPs

The genetic engineering of ELPs allows precise control over their composition, sequence, and molecular weight, which, in turn, determine the physicochemical properties of resulting constructs [103]. ELPs are widely used in bioapplications due to their responsiveness to stimuli, monodispersity, biocompatibility, and established biodegradation profile [125].

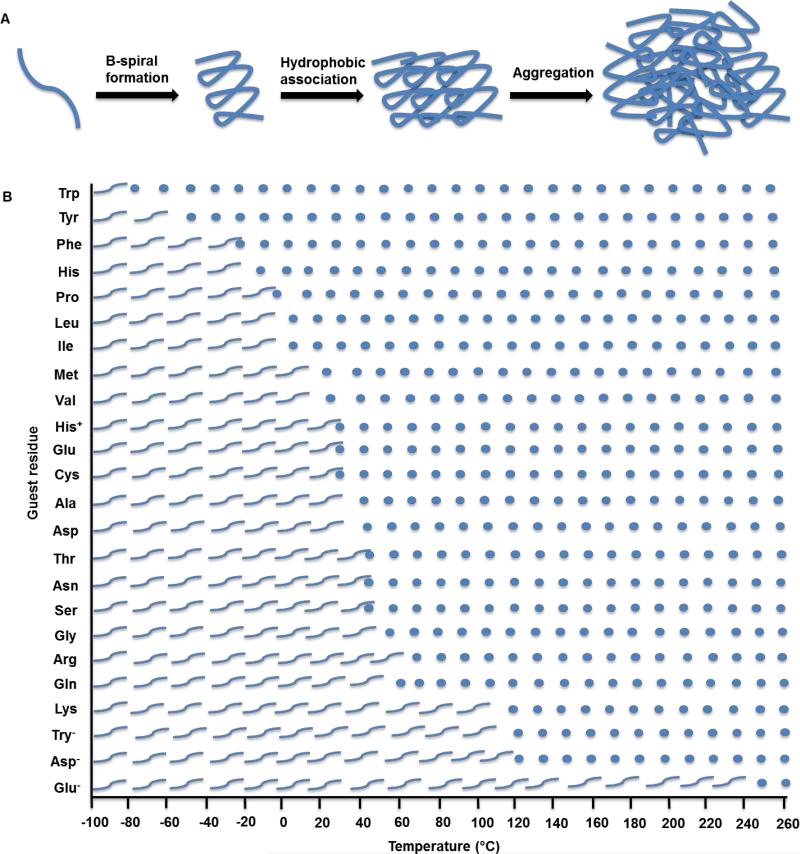

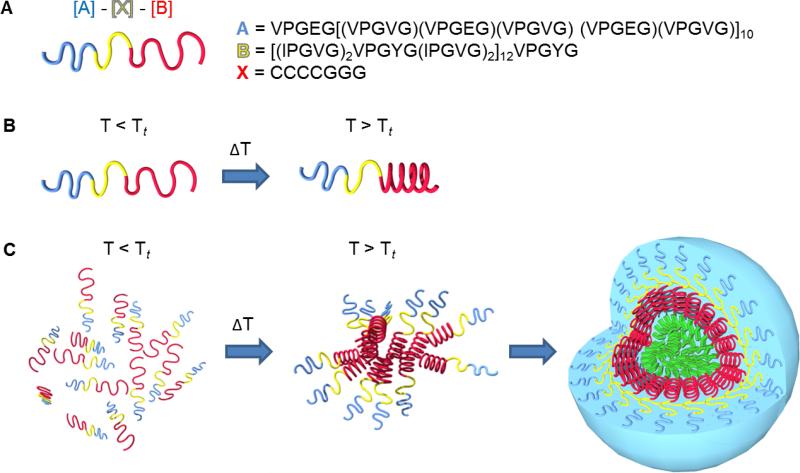

ELPs are thermally responsive and undergo a reversible inverse temperature phase transition [126]. An increase in temperature above a characteristic transition temperature (Tt,) induces the hydrophobic self-association of ELP molecules to form a highly viscous coacervate [127]. Below the Tt, the polymer chains are hydrated by clathrate water and the ELPs remain soluble in aqueous solution [128]. However, above the Tt,, the clathrate water structures become disorganized [129], allowing hydrophobic assembly of polymer chains into ordered and dynamic β-spirals [126]. The β-spirals then assemble to form filaments or other 3D structures as determined by the ELP sequence (Figure 3A) [130].

Figure 3.

A) The mechanism of ELP transition from a soluble state to a coacervated state at the transition temperature. ELP monomers form β-spirals which are stabilized by hydrophobic interactions. The polypeptide chains then associate into larger aggregates. B) Effect of the guest residue X on the coacervation temperature of [VPGXG]n ELPs. Wavy lines represent ELPs in soluble form below their inverse transition temperatures, while circles represent coacervated ELPs.

The phase transition temperature of ELPs is affected by the sequence, molecular mass, and concentration of the polypeptide, as well as the ionic strength and pH of the solution [131], allowing fine-tuning of the assembly process. The choice of guest residue within the ELP repeat motif influences the Tt (Figure 3B). An apolar guest residue increases the overall hydrophobicity of the polypeptide and therefore lowers its Tt. Conversely, a polar guest residue increases Tt. The correlation between Tt and ELP polarity has been demonstrated by the different phase transition behaviour of a V8X2 ELP with different guest residues. Increasing the ELP hydrophobicity by replacing Val with Ile, Leu, Phe, Tyr or Trp decreases Tt. In contrast, decreasing hydrophobicity by replacing Val with Gln, Asn, Ser, Thr, Gly or Ala increases Tt [132]. Proline is not substituted as a guest residue because it disrupts the conformation of the molecule, which hinders the native folding and coacervation process [97]. The presence of lysine residues in ELPs confers an amphiphilic characteristic [133] that allows the formation of stable micelle-like structures [134].

Studies have shown that increasing the molecular weight without substantially changing overall hydropathy significantly lowers Tt [135]. In addition, guest residues that contain groups susceptible to ionization allow the regulation of Tt via changes in solution pH [129]. The mechanical properties of ELPs can also be altered by replacing the glycine in the third position of the VPGXG repeat with alanine and an additional methyl group. The property of the ELP becomes plastic-like [136]. However, the first glycine cannot be replaced by any other amino acid apart from alanine, as it impedes β-turn formation during assembly [137].

The biocompatibility of ELPs can be improved with the incorporation of sequence motifs for cell interactions [138, 139]. ELPs designed to include an RGD based integrin ligand have been shown to restrict non-specific adsorption of proteins. Accordingly, polymer surfaces functionalized with such ELPs demonstrate a higher level of cell attachment and spreading, stronger cell binding affinity, and increased proliferation compared to random short peptides [140] This tunable functionality has encouraged the use of ELPs in substrate modification strategies for enhanced cellular responses [138].

4.3 ELP hydrogels

4.3.1 Fabrication

The tunable properties of ELPs are highly advantageous for the fabrication of diverse materials such as hydrogels, films and fibers [141]. ELP hydrogels, in particular, have drawn a lot of attention in the past decade due to their applications in drug delivery and tissue engineering [142].

ELP hydrogels can be constructed from the physical polymerization of monomers in the absence of covalent bonds between the polypeptide moieties. This method is illustrated by the hydrophobic aggregation of ELP triblock copolymers designed with a central hydrophilic region and capped with hydrophobic residues at both ends [143]. The hydrophobic domains aggregate at temperatures above the ELP Tt, creating a hydrogel that is stabilized by physical cross-links. Another method of physical polymerization involves ultrasonication of the ELP monomers to produce a hydrogel by physical chain entanglement [144]. This technique is beneficial for the encapsulation and preservation of bioactive molecules within the hydrogel structure. For example, drug-laden ELP hydrogels have been formed by the sonication of a [VGVPG]120 solution below the Tt, followed by addition of drug molecules and gelation above Tt [144]. Physical cross-linking has several advantages over chemical cross-linking approaches, including the simplicity of processing and the minimization of potential chemical toxicity. However, although the mechanical properties of physically cross-linked polymers can be tuned through the choice of solvent and the ELP sequence, they generally exhibit a lower strength matrix which may not be suitable for tissue engineering purposes [145].

The strength and cohesion of ELP hydrogels can be greatly increased by chemical cross-linking to generate covalent bonds between ELP moieties to build a macroscopic networked matrix. Chemical cross-linking of ELPs is typically achieved via reactive residues such as lysine, glutamine or cysteine. ELP materials can be cross-linked by γ-irradiation [146, 147], transglutaminase enzymes [148], UV light [149], or chemical cross-linking agents such as the amine-reactive compounds BS3, disuccinimidyl suberate (DSS), β-[tris(hydroxymethyl)phosphino]-propionic acid (THPP) or tris-succinimidyl aminotriacetate (TSAT) [150-153]. Separate teams led by McMillan [108, 154] and Trabbic-Carlson [153] have generated ELP hydrogels using the amine-reactive reagents BS3 and TSAT, respectively. ELP blocks utilised for the construction of these hydrogels are often lysine-rich, such as the sequence [(VPGVG)4(VPGKG)] [108, 154] or [(VPGKG)(VPGVG)n] 153, in order to facilitate cross-linking. The ELP solutions are blended with these chemical cross-linkers and allowed to set into a hydrogel.

4.3.2 Properties

ELP hydrogels exhibit thermal responsiveness, which can be controlled by altering the constituent ELP. The use of an ELP component with charged residues enables the temperature transition properties of the resulting hydrogel to be modulated by pH and salt content. To illustrate, a standard VPGXG template with Ile as the guest residue produced a pH-insensitive material with a Tt of 34 °C [108, 152]. In contrast, the Tt of a material with a Lys guest residue shifted from 28°C in 0.1 M NaOH to 75°C in unbuffered water. The magnitude of this shift is suggestive of self-buffering by the lysine residues. Additionally, the lysine-substituted ELP construct did not coacervate below 100°C in a Tris-buffered solution, indicating inhibition of the aggregation process by the charged residues. The addition of salt (150 mM NaCl) to buffered or unbuffered solutions produced a uniform Tt of 50°C, presumably due to the screening of electrostatic repulsion between charged lysines [155]. Following the same principle, the hydrogel Tt drops from 75°C to 35°C after cross-linking due to the conversion of amine groups to uncharged amides.

The correlation between ELP hydrogel fabrication temperature and temperature of transition impacts greatly on the structural properties of the material. Cross-linked hydrogels exhibit opalescence indicative of microsyneresis, which is a microscopic phase separation of the hydrophobic and hydrophilic moieties of the material [156]. To investigate the structural rearrangements that accompany this phase transition, ELP hydrogels cross-linked above and below the Tt were snap-frozen in liquid ethane. Electron microscopy studies revealed that gels formed below the Tt exhibit an interconnected network of dendritic leaflets, while those formed at high temperatures consist of beaded, worm-like filaments. These filaments aggregate into bundles resembling the structure of the native elastic fiber, consistent with the morphology reported for elastin-mimetic materials [157]. This structure is proposed to be the result of inherent elastin-based molecular self-organization which forms the basis of elastic function [108, 152].

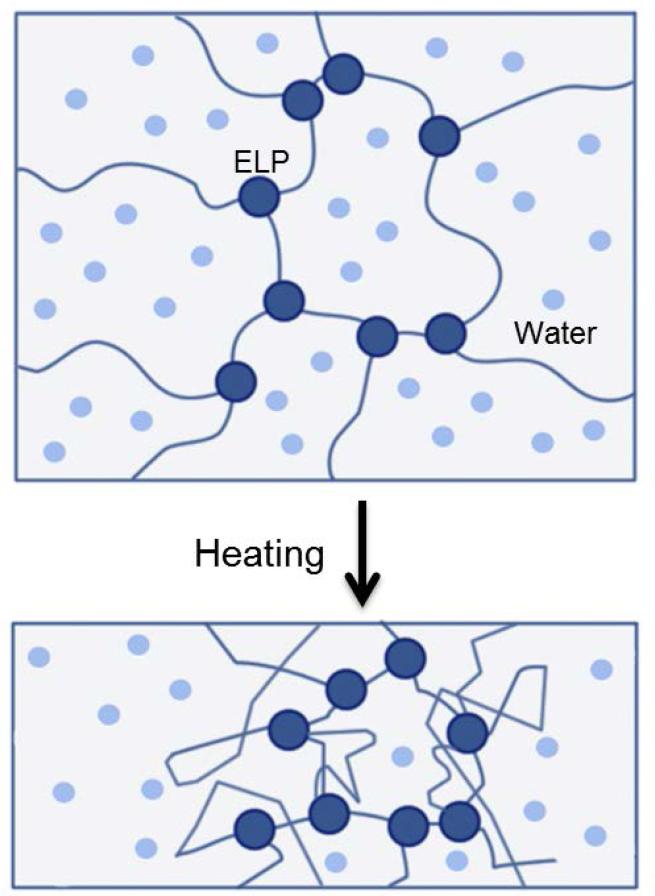

ELP hydrogels also display variable temperature-dependent stiffness, ranging from 0.24-3.7 kPa at 7°C to 1.6-15 kPa at 37°C, depending on the primary structure of the ELP component [158]. At low temperatures, the gels are almost perfectly elastic with very little measurable phase shift. At higher temperatures, the gels lose water, which increases viscous loss. Loss angles vary from ~1 at 7°C to 5-15 at 37°C, with the greatest losses evident in gels with low ELP concentration, and in which the ELP component is of low molecular mass and has low lysine content (Figure 4). When strained at low temperatures (e.g. 7°C), the functional crosslinks of the hydrogel bear the entire load. However, at higher temperatures where the ELP gels display a contracted structure, strain forces are transmitted not only through the cross-links but also through the closely-interacting ELP chains [153].

Figure 4.

Schematic diagram of water loss arising from the contraction of ELP hydrogels upon a temperature increase. At 7 °C, the ELP component within the hydrogel is fully extended, with water molecules scattered around the ELP segments. Once the temperature is raised to 37°C, the gels contract, allowing the escape of water molecules.

Functionally, the extent of hydration displayed by ELP hydrogels can also be tailored according to the temperature response of the materials. In contrast to the rapid aggregation of ELP solutions at Tt, cross-linked ELP hydrogels exhibit gradual changes in swelling behavior. ELP hydrogels can contract up to 90% of their volume, as the temperature is increased over a 50 °C range [153, 159], which likely reflects changes in the molecular morphology of the material with temperature.

Chemically cross-linked ELP hydrogels have shear and elastic moduli similar to that of native elastin and other connective tissues (Table 5). These features can be regulated by altering the type of cross-linker, as well as the concentration and molecular weight of the ELP monomer. Mechanical properties of ELP hydrogels can also be enhanced by reducing the propensity of ELP solutions for phase separation. One approach is the design of ELP tri-block co-polymer polypeptides, composed of a central hydrophilic block with a Tt above 37 °C flanked by hydrophobic end-blocks with a Tt below 37 °C. Gelation is promoted by the reduction in phase separation due to the bridging of the central blocks [111, 160].

Table 5.

Mechanical properties of ELP-based polymer networks compared to natural polymers and native tissues.

| Polymer | Cross-linker | Monomer MW (kDa) | Concentration (mg/ml) | Tensile modulus (kPa) | Dynamic shear modulus (kPa) | Reference |

|---|---|---|---|---|---|---|

| ELP | None (coacervate) | 36 | 324 | - | 0.08 | [194] |

| ELP | tTG | 47.1 | 100 | - | 0.26 | [148] |

| ELP | DSS | 37.1 | N/A | 350-970 | 120-320 | [150] |

| ELP fusion polypeptide | BS3 | 37.1 | 200-400 | 80-700 | 22-60 | [150] |

| ELP | TSAT | 42.7, 47.1 | 180 | - | 8-10 | [153] |

| ELP | THPP | 31, 28.3 | 200 | - | 5.8-45.8 | [151] |

| ELP fusion polypeptide | HMDI | 14-59 | 100 | 400-930 | - | [207] |

| ELP | γ-irradiation | 15-50 | 500 | - | 10-200 | [146] |

| ELP | Genipin | 10 | 10 | 1800 | - | [278] |

| ELP | PQQ | 10 | 10 | 400 | - | [279] |

| Nucleus pulposus | Enzymatic / in vivo | - | - | - | 11 | [280] |

| Articular cartilage | Enzymatic / in vivo | - | - | - | 440 | [281] |

| Ligament elastin | Enzymatic / in vivo | - | - | 1100 | - | [282] |

| Aortic elastin | Enzymatic / in vivo | - | - | 810 | - | [283] |

ELP, elastin-like polypeptide; tTG, tissue transglutaminase; DSS; BS3, bis(sulfosuccinimidyl) suberate; TSAT, tris-succinimidyl aminotriacetate; THPP, β-[tris(hydroxymethyl)phosphine]-propionic acid; HDMI, hexamethylene diisocynate; PQQ, pyrroloquinoline quinone.

4.4 Applications of ELP constructs

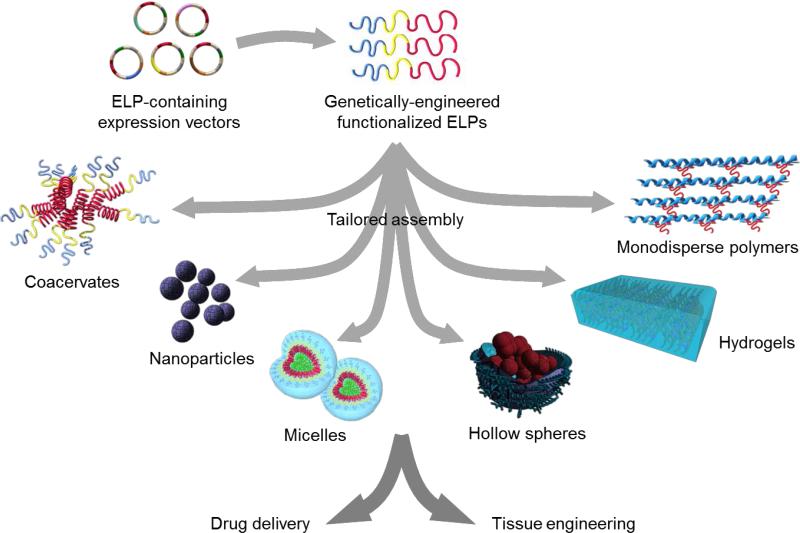

Regular elastin extracted from animal tissues are heterogeneous in mass, sequence and structural topology [161]. Materials derived from these products can therefore form structures that exhibit inconsistent and heterogeneous properties. Such products may also contain animal pathogens, immunogenic protein sequences, or harsh chemical residues [162]. While recombinant human tropoelastin addresses many of the problems associated with animal-sourced elastins, it is relatively technically difficult and expensive to mass produce. Moreover, the size, structural complexity and inherent flexibility of tropoelastin makes it immensely difficult to accurately determine the chemical and physical processes that occur in materials fabricated from tropoelastin. Therefore, it can be challenging to apply rational engineering principles to design novel materials [12, 162]. On the other hand, the relative ease of rationally designing ELP materials has resulted in a vast array of applications in biomedicine, such as drug delivery systems and tissue engineering technologies [153] (Figure 6).

Figure 6.

Production of ELPs by genetic engineering allows for precise sequence control and rational design of tunable properties. Fabrication techniques permit the modulation of temperature, pH, ionic strength, solvent, and cross-linking agent, and enable the incorporation of other functional molecules to produce a range of ELP-based materials such as coacervates, nanoparticles, micelles, hollow spheres and hydrogels. These materials have diverse applications in drug delivery and tissue engineering.

4.4.1 Local drug delivery

Injected small molecule drugs rapidly disperse throughout the body and are quickly cleared by kidney filtration, providing minimal therapeutic value [163]. As a result, many drugs that have shown great promise in vitro fail to translate into useful therapies in vivo. To increase drug accumulation in the target tissue and reduce drug density in surrounding tissues, current drug delivery strategies work toward increasing circulation time, decreasing incidental metabolization, and targeting tissue-specific cell receptors or specific intracellular locales [164]. Such targeted drug delivery systems must have a high capacity for drug loading, show sustained, controllable drug release, exhibit efficient tissue infiltration, and be resistant to reticuloendothelial degradation [165].

ELP constructs meet these criteria and are used as injectable drug depots [166, 167]. Chemically, these constructs possess low viscosity during administration, and can polymerize within minutes of injection. ELP solutions have been shown to be capable of intramuscular in situ gelation, and the resulting hydrogel material exhibits long term retention [166, 167]. In addition, ELP materials are non-cytotoxic and produce no toxic degradation products [168]. As an elastin mimetic, the ELP component is inherently biocompatible and biodegradable, and can be tuned to surpass the mechanical properties of naturally-derived polymers. Importantly, the inverse temperature transition of ELPs enables the entrapment of drug molecules within coacervate assemblies.

The ELP coacervates are able to maintain structural integrity when injected into parts of the body with low fluid flow, such as the intra-articular spaces of the synovial joints [169, 170]. Low concentrations of the bound drug are then released over a relatively long period as the ELP carriers slowly dissipate, allowing increased drug accumulation in target tissues [171]. To illustrate, the injection of an ELP-based anti-cytokine drug depot into rat spinal perineural tissue showed potential in the treatment of long-term sciatic pain [172]. The enzymatic degradation of ELP assemblies for drug release can be preferentially targeted to regions with increased elastase activity, which often correlate with pathological conditions such as pulmonary emphysema, cystic fibrosis, bacterial infections, inflammation, chronic wounds and atherosclerosis [173]. In support, a stable ELP hydrogel demonstrated enhanced drug release when exposed to elastolytic activity from Pseudomonas aeruginosa and from activated human polymorphonuclear leukocytes [174].

The cross-linking of ELPs increases the range of its drug depot applications. As an example, ELP cross-linking has been shown to dramatically increase the viscosity of ELP-drug preparations. THPP-treated ELPs have a frequency independent dynamic viscosity of ~0.37 Pa s at 0.1 Hz in contrast to the ~0.08 Pa s of uncross-linked ELPs [175]. This compares to the ~1 Pa s dynamic viscosity of synovial fluid and indicates the suitability of the material for syringe and needle injection at room temperature. Drug release by cross-linked ELP constructs depends on the cross-linked structure as well as the properties of the drug molecule. An ELP hydrogel saturated with either cefazolin or vancomycin exhibited variable drug release dynamics under simulated physiological conditions [175]. The higher molecular weight cefazolin drug was released consistently with no initial burst release, and reached the minimum inhibitory concentration for over 4 days. In contrast, the smaller vancomycin molecules behaved very differently, with an initial burst release and a release time constant of up to 120 days by the denser hydrogels.

4.4.2 Systemic drug delivery

ELP micro- and nanoparticles have also been developed for circumstances in which local drug delivery by site injection or implantation is not feasible. Such particles comprise simple ELP polymers or di-block and tri-block copolymers, and can either enclose or be conjugated with drug molecules. ELP polymers of the form (VPAVG)220 have been shown to self-assemble in physiological conditions into roughly spherical particles of ~250 nm diameter [176]. These particles can encapsulate medically relevant quantities of bone morphogenic growth factors that have been pre-mixed with the ELP solution. In vitro testing showed an initial ~15% burst release of the drug load, followed by a steady, sustained release over several days. The released growth factors retained osteoinductive activity as evidenced by osteoblast-like morphological changes in myoblast test cells, accompanied by a substantial increase in alkaline phosphatase production and calcium mineralization. Drug-laden ELP nanostructures can also be manufactured using an electrospray technique. ELPs mixed with a hydrophobic chemotherapeutic agent doxorubicin in water are electrosprayed to produce mainly spherical nanoparticles that encapsulate the drug [177].

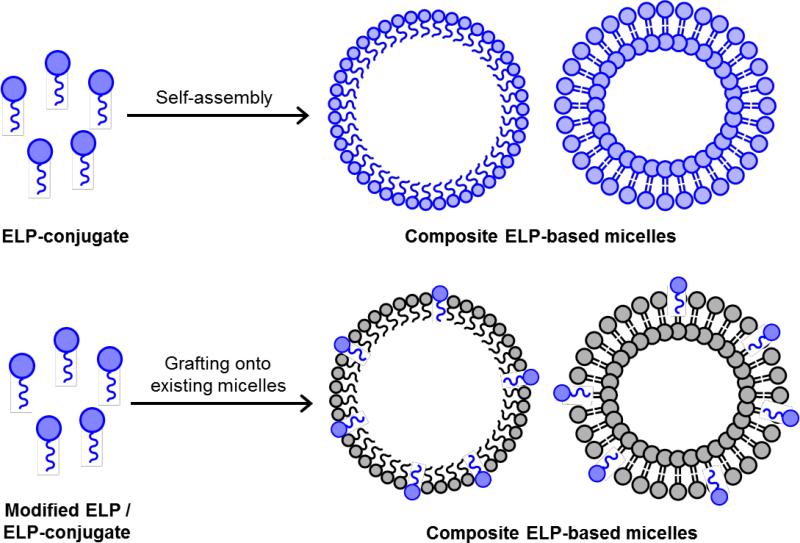

However, a limitation of these simple ELP nanoparticles is the burst release of drugs upon initial solubilization of the dried particles [177]. To overcome this problem, more stable structures have been sought. Di-block ELP copolymers of the form (GVGVP)60(GXGVP)64 (where X is Val:Gly:Ala in 1:7:8 ratio) [178], and tri-block ELP copolymers with hydrophobic end-blocks and a hydrophilic core, can all form stable micelles above a transition temperature, as the hydrophobic regions collapse to the center of the structure and the hydrophilic components remain solvent-exposed. The micellar dimensions are tunable from 90-120 nm in a temperature-dependent manner [160, 179]. ELP micelles are more stable than simple coacervates, and can be used to carry hydrophobic drugs through the circulatory system. Incorporation of tyrosine residues in the guest location of ELPs has been shown to increase the hydrophobicity of the micelle interior, enhancing their hydrophobic drug-carrying capability. The presence of cysteine residues at the core-shell interface increases micelle stability via disulfide bridge formation (Figure 5) [179]. Upon uptake into the intracellular environment, significantly increased levels of glutathione break the disulfide bonds [180], destabilizing the micelles for targeted drug delivery [181].

Figure 5.

Formation of ELP micellar structures. A) Schematic diagram a cysteine-enhanced amphiphilic ELP diblock showing the hydrophilic (A, blue), hydrophobic (B, red), and cysteine-enriched inter-block (X, yellow) regions. Example amino acid sequences for each block are indicated. B) Structural change in ELPs during self-assembly, characterized by the folding of the hydrophobic block into a β-spiral above the Tt. C) Below the Tt , the unfolded ELPs are soluble. Above the Tt, ELPs aggregate and form micelles if the critical ELP concentration is reached. The micelles are stabilized by disulfide bridges between cysteine residues (yellow). Micelles can trap hydrophobic drug molecules (green) within the apolar core.

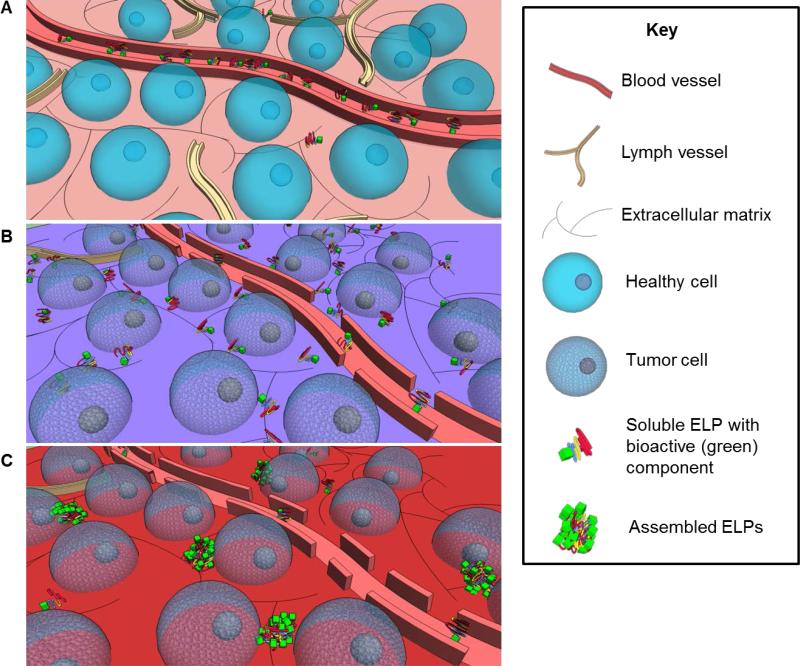

4.4.3 Tumor drug delivery

ELP drug delivery systems are particularly useful in cancer therapy (Figure 7). Tumors are characterized by leaky blood vessels and a scarcity of lymphatic vessels. Large molecule drug carriers such as ELPs infiltrate the tumor interstitium more easily than healthy tissue, and linger due to poor lymphatic drainage. ELPs have been found to preferentially accumulate in tumor tissue [182] due to this enhanced permeability and retention effect [183]. However, tumor vasculature is unevenly distributed. This impedes ELP-drug diffusion into poorly-vascularized regions. Furthermore, the lack of lymphatic vessels prevents lymphatic convection-based drug transport within the tumor [184]. The local heating of solid tumors to 42 °C via focused microwaves, ultrasound or infrared illumination [185, 186] has been shown to increase tumor vascular permeability and improve the local accumulation of large molecules [187], such as ELPs designed to have a transition temperature between the physiological and hyperthermic tumor temperatures [188].

Figure 7.

Targeted assembly of drug-carrying ELPs in tumor tissues. A) Blood vessels in healthy tissues retain soluble, large-molecule ELPs, while those that leak into the extracellular matrix are quickly drained by lymph vessels. B) Tumor tissues tend to be characterized by leaky blood vessels and scarce lymphatic drainage. Consequently, a high concentration of soluble ELPs build up in the tumor environment. C) Localized hyperthermia of tumor tissues by focused ultrasound, microwave or infrared radiation increases the leakiness of blood vessels and accumulation of ELPs above a critical concentration. The hyperthermic tumor environment induces ELP coacervation to preferentially present the bioactive moieties on the microspherule surface.

Cellular penetration of the ELP drug carriers can be improved by engineering the ELPs to preferentially present peptide signal motifs such as RGD, NGR and penetratin in the micellar corona following self-assembly at the induced hyperthermic temperature [189]. These signal motifs are known cell receptor ligands, and consequently lead to increased cellular uptake of the decorated ELPs at 42 °C, compared to undecorated ELPs or to decorated ELPs at 37 °C. ELP constructs designed for increased cellular uptake and functionalized with a c-Myc oncogenic protein inhibitory sequence [190] have been reported to dramatically reduce the proliferation of human breast cancer cells over ten days after a single 1 hr treatment [191]. This strategy of incorporating signal sequences to ELPs has since been expanded to other cell penetrating peptides and therapeutic peptides for cancer therapy (Figure 7) [186].

4.4.4 Cartilage tissue engineering

Tissue repair and regeneration relies on physical and biochemical cues between cells and the ECM. Cells respond to matrix signals for growth, proliferation and differentiation, and, in turn, secrete substances which remodel the ECM [192]. An ideal artificial ECM mimics and supports this dual feedback loop [193]. The customizable design and properties of ELPs described previously make them highly suitable for engineering ECM-mimetic scaffolds. ELP scaffolds formed by thermal-responsive coacervation [166], physical cross-linking [143], or chemical cross-linking of ELP solutions [151] have been developed for tissue repair.

Coacervated ELP materials with entrapped chondrocytes have been used to repair the non-regenerating articular cartilage. Despite the propensity of chondrocytes to de-differentiate when cultured outside of the native cartilage ECM, the ELP-encapsulated chondrocytes retain their characteristic rounded morphology and phenotype over 10 days, as shown by the accumulation of sulfated glycosaminoglycans and type II collagen [170]. Furthermore, the cells released from the coacervate matrix and cultured on a porous membrane are shown to be histologically and biochemically similar to native cartilage [194]. Following intra-articular injection [169], the ELP construct can induce chondrogenic differentiation of human adipose-derived adult stem cells even in the absence of chondrocyte growth factors [195].

Since cartilage is a load-bearing tissue, the ability to restore its mechanical function is highly paramount. Although coacervated ELP gels provide a suitable environment for chondrocyte growth and cartilage formation, they possess shear moduli that are four orders of magnitude below that of native articular cartilage [170, 196], which limit their value in the regeneration of load-bearing tissues. To increase their stability and mechanical strength, ELP gels have been modified with additional glutamine and lysine residues to allow cross-linking by tissue transglutaminase [148], an enzyme that has roles in cell growth and ECM organization [197]. The resulting cross-linked material exhibited a shear modulus two orders of magnitude greater than the ELP coacervate without loss of bioactivity [148, 170].

To overcome the slow kinetics of transglutaminase cross-linking, ELP materials containing periodic lysines within the ELP component can be rapidly (<5 min) polymerized by THPP in physiological conditions with water as the only by-product [151, 198, 199]. Crosslinked ELPs that are injected into a goat osteochondral defect, support cell infiltration and ECM production [199].

The large number of variables involved in optimizing ELP constructs has led to the development of a neural network analysis system, in order to recognize patterns in the competing mechanical and biological outcomes of ELP materials designed specifically for cartilage repair. This approach may provide a useful set of tools for the design of ELP biomaterials for cartilage tissue engineering [200].

4.4.5 Vascular tissue engineering

Small-diameter vascular grafts often fail due to stenosis and thrombosis triggered by the proliferation of myofibroblasts. Graft failure has also been attributed to a mechanical mismatch with the native vessel and inadequate endothelial cell growth [150, 201]. To address these issues, ELP materials can be tuned to match native tissue, and incorporated with biomimetically-spaced cell-signaling peptides for vascular applications. To illustrate, an ELP nonapeptide augmented at a 1:20 ratio with a GRGDSP fibronectin-derived cell binding sequence exhibited greatly increased aortic endothelial cell attachment and proliferation [202] compared to the ELP alone [203]. An ELP implant material with a single GRGDSP sequence per polypeptide also promoted angiogenesis and the formation of an ECM with normal distribution of collagen and elastin [204]. Similarly, a glutaraldehyde-cross-linked ELP construct containing a fibronectin-derived cell-adhesive sequence displayed a high affinity for endothelial cells [205]. Mechanically, ELP constructs integrated with signal sequences have tensile characteristics similar to native elastin [150, 206, 207].

4.4.6 Ocular tissue engineering

ELP scaffolds have also been designed to resemble the ECM of the ocular surface. The ELP component is based on the VPGIG repeat incorporated with VPGKG cross-link sequences, the fibronectin CS5 cell-binding sequence, and the VGVAPG protease target sequence. This functionalized material promotes the adhesion and growth of human conjunctival epithelial cells, while maintaining their differentiated phenotype as evidenced by the expression of characteristic protein markers [208].

4.4.7 Bone tissue engineering

ELP polymers that rapidly solidify at body temperature have been investigated as potential candidates for bone repair and replacement. Bone scaffolds require load-bearing capabilities and must interface with inorganic crystalline materials, primarily hydroxyapatite. In addition, they must support bone tissue mineralization. ELP materials can be engineered to incorporate signaling motifs that activate bone cell growth and guide hydroxyapatite deposition. For example, ELPs designed to include the 15-residue calcium phosphate binding domain (SNA15) from the salivary protein statherin facilitated the formation of well-structured HA deposits. Both the scaffold nanostructure and the density of SNA15 domains are thought to be essential for calcium phosphate accumulation [209].