Abstract

Gingernut type biscuits were prepared with varying fat content (10, 20, and 30 % w/w flour basis) and with sugar beet molasses replacing 0, 25, and 50 % w/w of the honey in the formulation. To evaluate the effects of these modifications, dough properties, and the physical, and sensory properties, and chemical composition of the biscuits were determined. Dough properties were significantly affected by the fat content; higher fat gave softer dough with reduced adhesiveness, cohesiveness and springiness. Biscuit height and diameter were also significantly affected only by the fat content. The tested biscuit variants showed no difference with respect to hardness and fracturability. During storage, hardness, fracturability and brittleness of the biscuits significantly increased but significant differences within the biscuits variants were observed after two months of storage in terms of fracturability which was least impaired in the biscuits with 30 % fat. Higher fat content also contributed to better flavour keeping during storage. Substitution of honey with molasses resulted in products with darker colour, less yellow and more red tone. Molasses also contributed to better nutritive value of biscuits by increasing significantly the content of proteins, potassium, calcium, magnesium and iron.

Keywords: Biscuits, Molasses, Fat, Texture, Colour, Minerals

Introduction

Although they have never been considered a staple food, biscuits remain an important part of today’s eating habits. Worldwide per capita biscuit consumption has shown a steady trend upward with annual consumption figures ranging from 2.5 to 5.5 kg in the south Asian and European countries to 7.5 kg in the USA. Their popularity is mainly due to long shelf life, convenient use and human preference to sweet taste (Manley 2000).

Biscuits are usually defined as low moisture products prepared from wheat flour and appreciable amounts of sugar and fat. The recipes for biscuits are numerous and based on various proportions of major ingredients: flour, sugar and fat. Manley (2000) distinguishes 10 different categories of biscuits depending on the level of enrichment with sugar and fat. Gingernut type biscuits contain honey and, according to Manley (2000), represent a sugar rich variant of short dough biscuits. This biscuit class is characterised by the content of around 30–80 % sugar and 15–50 % fat on flour basis. Gavrilović (2003) lists proportions of major ingredients in typical recipes for gingernut biscuits as follows: 35–50 % honey, 28–32 % sugar, 0–5 % fat on a flour weight basis. Gingernut biscuits themselves are diverse owing to large possibilities in varying the proportions of the main ingredients and inclusion of new ingredients.

Because of a high proportion of sugar and fat, biscuits are not generally perceived by nutritionists as entirely healthy, but their nutritional value can be improved by including various ingredients having nutritional benefits. Modifications of basic recipes and incorporation of new ingredients such as fibres, fat replacers, cereals other than wheat, etc. have led to novel biscuit formulations with improved functionality and nutritive value (Handa et al. 2012; Yadav et al. 2012; Chakraborty et al. 2011; Gajera et al. 2010).

Honey and cane molasses are used in the bakery and confectionery industry usually as minor ingredients. In fact, there is a variety of nutritive and bulk sweeteners at disposal to manufacturers of biscuits and cookies by which appropriate choice, desirable textural and colour properties of final product can be achieved (Varzakas and Özer 2012). In general, molasses is an interesting ingredient in biscuit production because it is a natural sweetener and, as such, an alternative to unpopular highly refined sugars and, in addition, it is highly nutritious (abundant in minerals and vitamins) (Hickenbottom 1996). It also contributes to products colour, aroma and shelf-life (Hickenbottom 1996). Labropoulos and Anestis (2012) mention that in bakery goods, common substitution ratio of cane molasses syrup by sucrose ranges from 1.0 to 1.3. However, sugar beet molasses is not common in human consumption mainly due to strong flavour, which is found unpalatable to most people (Varzakas and Özer 2012) especially when consumed alone. Still, some researches have shown that it is possible to incorporate sugar beet molasses in bakery products, including biscuits without impairing product palatability (Filipčev et al. 2010; Pribiš et al. 2008; Šimurina et al. 2006). Sugar beet molasses is composed of approximately 50 % saccharose, 1 % rafinose and less than 1 % invert sugar (Šušić and Sinobad 1989; Olbrich 1963). From the nutrition point of view, very important is the natural occurrence of nutritionally significant nutrients such as potassium, calcium, magnesium, iron and B group vitamins. Sugar beet molasses contains more potassium, sodium, iron and niacin whereas cane molasses is a richer source of calcium, thiamine, panthotenic acid (Olbrich 1963; Hickenbottom 1996). Šušić and Sinobad (1989) noted that sugar beet molasses is more nutritious than honey as it contains less assimilable sugars by 20 %, by up to 3000 % more proteins, more minerals by 4000 %, and a wider spectrum of B vitamins with higher content by 3800 %.

Our objective was to evaluate the effect of partial replacement of honey (up to 50 %) with sugar beet molasses in gingernut type biscuit formulations with varying fat content (10, 20, 30 % flour basis) in terms of dough properties and the biscuits physical properties, and chemical composition.

Materials and methods

Materials

Basic ingredients needed for the preparation of gingernut biscuits were all commercially available (wheat flour (ash content (0.51 % dry basis (d.b)), wholemeal rye flour (ash content 1.68 % d.b.), honey, sugar, vegetable fat, baking soda, lecithin, cinnamon). Sugar beet molasses was procured in a single lot during the 2010 campaign from the sugar factory “TE-TO” AD, Senta (Serbia).

Biscuit preparation

Gingernut type biscuits were made according to the procedure described by Filipčev et al. (2011). The basic biscuit formulation consisted of flour (wheat flour 90 g + rye flour 10 g), honey 40 g, sugar 20 g, vegetable fat 10 g, baking soda 2 g, cinnamon 2 g, lecithin 1 g, water 15 g. For the preparation of biscuits with different fat contents, fat contents were increased to 20 g i.e. 30 g whereas water contents were reduced to 12 g i.e. 10 g, respectively. Within each group of biscuits with the same fat content, honey was replaced by 25 % and 50 % with sugar beet molasses. The corresponding biscuit formulations contained therefore 30 g honey + 10 g molasses and 20 g honey + 20 g molasses, respectively. Other ingredients were kept constant.

Chemical composition

Standard procedures (AOAC 2000) were used to evaluate all samples in duplicate for moisture (method 926.5), ash (method 930.22), crude protein (method 950.36), fat (method 935.38), reducing sugar as invert before hydrolysis (method 975.14), total dietary fibre (method 958.29). Starch content was determined according to the ICC Standard (ICC Standard No. 123/1 1994). Minerals were determined by atomic absorption spectrophotometry (method 984.27) on a Varian Spectra AA 10 (Varian Techtron Pty Limited, Mulgvare Victoria, Australia, 1989).

Physical evaluation of biscuits

Weight, thickness, diameter and spread were evaluated in biscuits. Spread ratio was calculated as the ratio of diameter and thickness. Density was calculated as the ratio of weight and volume. Volume was derived by approximating the cylinder volume using the biscuit geometrical parameters.

Instrumental texture analyses

Dough texture

Dough texture was evaluated using Texture Profile Analysis (TPA) on a TA.XT2 Texture Analyzer (version TA.XTPlus, Stable Micro Systems Ltd., Surrey, UK) according to Gallagher et al. (2005). A 30-kg load cell was used in the measurements. Compression was applied with a cylinder probe (36 mm diameter) at test speed 1.0 mm/s and two compression cycles and 5 s recovery time. Measurements were made at 45 % compression. Dough was prepared in the form of discs (60 mm diameter, 10 mm thickness) as in the baking tests. Hardness, adhesiveness, cohesiveness and springiness were determined in five replications.

Biscuit texture

Compressive force was determined using a TA.XT2 Texture Analyzer with a 5 kg load capacity. The apparatus configuration and settings were: 2 mm cylinder probe, pre-test speed 1.0 mm/s, test speed 0.5 mm/s, post-test speed 10.0 mm, travel distance 20 mm, trigger force 5 g. Biscuit hardness was calculated as the area under the curve and fracturability was the linear distance. Each sample was punctured five times in an X pattern. Five biscuits of each type were analyzed.

Colour determinations

Colour determinations were conducted using a Chroma meter (CR-400/410, Konica, Minolta, Japan). Prior to use, the apparatus was calibrated using the Minolta white calibration standard (CM –A70). Colour was measured at two points on the biscuit surface. The average L* a*b* values were provided per biscuit. Chroma (C*) was calculated using the equation:  . A measurement set included 5 samples of each biscuit type.

. A measurement set included 5 samples of each biscuit type.

Sensory evaluation

The sensory evaluation of biscuits was carried out by a panel of six experienced and trained judges who graded each product on a 1-9 intensity scale for brittleness (crumbly-brittle), flavour intensity (weak-strong) and overall acceptability (dislike very much-like very much).

Storage studies

Besides the main experiment in which the characteristics of biscuits were determined after baking, an additional storage study was conducted. Over a 2-month period, biscuit texture and sensory properties were evaluated. After baking and cooling for one hour, biscuits were packed in sandwich bags and stored at room temperature over two months.

Statistical analysis of data

All statistical analyses were performed using Statistica 10 data analysis software system (StatSoft Inc., Tulsa, Oklahoma). Two-factor ANOVA was performed using fat content and molasses content as two factors. To indicate differences among means, the Tukey’s HSD test was used. Statistical significance was expressed as p ≤ 0.05 unless otherwise indicated.

Results and discussion

Effect of fat content and replacement of honey with molasses on the biscuit dough properties

Table 1 shows the effect of molasses and fat content on the biscuit dough properties as measured on the texture analyzer. Biscuit dough hardness significantly varied depending on fat content. Fat reduction increased dough hardness. Increased molasses content tended to increase dough consistency especially in the case of biscuits with lower fat content. Dough adhesiveness was significantly affected by the fat content; higher fat content decreased dough adhesiveness. Reduced fat content significantly increased dough cohesiveness, whereas molasses decreased it but within each biscuit type these variations were not significant. Dough springiness significantly increased with fat reduction. At lower fat contents, increasing molasses content tended to decrease springiness but not to a significant level. Similar effects of fat content on dough textural properties were shown in the work of Sudha et al. (2007).

Table 1.

Dough consistency of biscuits of different ingredient composition

| Biscuit formulation | Dough hardness (N) | Adhesiveness (N sec) | Cohesiveness | Springiness | |

|---|---|---|---|---|---|

| Fat content (%) | Molasses content (%) | ||||

| 30 | 0 | 66.6 ± 3.45a | 205.2 ± 28.70a | 0.14 ± 0.007a | 0.40 ± 0.043a |

| 30 | 10 | 63.5 ± 4.60a | 276.2 ± 35.03a,b | 0.14 ± 0.008a | 0.46 ± 0.057a,b |

| 30 | 20 | 66.3 ± 2.28a | 229.4 ± 37.65a | 0.13 ± 0.007a | 0.39 ± 0.026a |

| 20 | 0 | 90.8 ± 1.94b,c | 477.5 ± 23.71c | 0.19 ± 0.017b | 0.72 ± 0.121b,c |

| 20 | 10 | 91.1 ± 3.30b,c | 421.3 ± 27.84b,c | 0.18 ± 0.019b | 0.61 ± 0.072a,b,c |

| 20 | 20 | 95.7 ± 2.71c | 408.5 ± 54.57b,c | 0.16 ± 0.021a,b | 0.61 ± 0.133a,b,c |

| 10 | 0 | 80.9 ± 2.01b | 938.3 ± 62.37d | 0.27 ± 0.007c | 0.82 ± 0.086c |

| 10 | 10 | 92.0 ± 7.00c | 977.1 ± 94.68d | 0.27 ± 0.006c | 0.80 ± 0.075c |

| 10 | 20 | 97.8 ± 6.25c | 934.4 ± 96.05d | 0.25 ± 0.003c | 0.75 ± 0.143c |

Means±SD value from 5 replications (n = 5)

a,b,c,dMeans in a column followed by different superscripts are significantly different (p < 0.05)

As seen from the above results, the majority of changes in the dough texture parameters were due to variable fat content. In our case, the fat level was linearly correlated to dough texture parameters (dough hardness R2 = −0.75, adhesiveness R2 = −0.95, cohesiveness R2 = −0.95, springiness R2 = −0.87). The presence of fat in sufficient amounts disable the creation of cohesive and extensible gluten by surrounding and isolating the proteins and starch granules and thus disrupting the continuity of gluten network, which results in a softer and less elastic dough (Ghotra et al. 2002; Perego et al. 2007). This is desirable in biscuit making because of less dough shrinking during lamination and molding. It also contributes to the tenderness of the product. Increased fat levels produce lubricating affect lowering the amount of water required for a desired dough consistency. This limits starch swelling and gelatinization which leads to the formation of more soft and tender texture of baked product.

As molasses contains approximately 50 % sucrose in dissolved form, its addition conveys sugar to biscuit dough. The presence of sugar delays starch gelatinization by increasing the gelatinization temperature. A similar effect of molasses-based ingredients was observed by Filipčev et al. (2009). However, in contrast to sugar (Mixolab User’s Manual 2005), molasses produces strong plasticizing effect on bread dough. In our case, increased molasses content within each biscuit category lowered dough springiness but not to a significant extent. Actually, none of the dough parameters were correlated to the molasses content, presumably due to the low applied dose.

Effect of fat content and replacement of honey with molasses on the chemical composition of biscuits

The chemical composition of biscuits is shown in Table 2. The contents of several components in biscuits were significantly affected by the amounts of fat and molasses in the formulations. The moisture, fibre and starch contents increased in those formulations containing less fat. The addition of molasses significantly increased the proteins, minerals and ash content but reduced the reducing sugar content in the biscuits. Within each biscuit subcategory, classified by the amount of fat included in the recipe, the increasing molasses content significantly increased the content of proteins, ash, potassium, iron, calcium and magnesium, whereas the sugar and copper contents were reduced. The starch and fibre contents tended to decrease significantly with the increasing fat and molasses levels.

Table 2.

Single and interactive effects of varying fat and molasses content on the chemical composition of gingersnaps

| Factor | Level | Moisture (g/100 g) | Ash (g/100 g d.m.) | Proteins (g/100 g d.m.) | Fat (g/100 g d.m.) | Starch (g/100 g d.m.) | Reducing sugars (g/100 g d.m.) | Fibers (g/100 g d.m.) | K (mg/100 g d.m.) | Ca (mg/100 g d.m.) | Mg (mg/100 g d.m.) | Fe (mg/100 g d.m.) | Mn (mg/100 g d.m.) | Zn (mg/100 g d.m.) | Cu (mg/100 g d.m.) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fate | 1e | 10.3 ± 0.26a** | 1.36 ± 0.26 | 8.24 ± 0.76 | 7.6 ± 0.15c** | 43.8 ± 1.09a** | 12.8 ± 0.85 | 4.3 ± 0.39a* | 410.2 ± 225.6 | 64.3 ± 28.41 | 22.3 ± 5.96 | 2.4 ± 0.38 | 0.55 ± 0.045 | 0.5 ± 0.020 | 0.10 ± 0.015 |

| 2 | 7.9 ± 0.24b** | 1.21 ± 0.30 | 7.65 ± 0.77 | 12.9 ± 0.20b** | 40.8 ± 1.09a,b** | 12.3 ± 1.07 | 3.6 ± 0.25a,b* | 399.9 ± 220.2 | 62.4 ± 24.72 | 22.3 ± 5.09 | 2.5 ± 0.46 | 0.50 ± 0.042 | 0.4 ± 0.030 | 0.09 ± 0.012 | |

| 3 | 6.7 ± 0.23c** | 1.13 ± 0.34 | 7.10 ± 0.63 | 17.5 ± 0.28a** | 38.8 ± 1.06b** | 10.2 ± 1.07 | 3.4 ± 0.21b* | 395.0 ± 217.5 | 61.6 ± 23.49 | 22.0 ± 5.03 | 2.2 ± 0.34 | 0.48 ± 0.045 | 0.4 ± 0.019 | 0.08 ± 0.015 | |

| Molasses | 0 | 8.2 ± 1.68 | 0.90 ± 0.16b** | 6.9b* ± 0.49 | 12.8 ± 4.36 | 41.3 ± 2.55 | 16.0 ± 1.14a** | 4.0 ± 0.52 | 147.0 ± 3.84c** | 31.5 ± 0.53a** | 16.0 ± 0.64c** | 1.9 ± 0.13b** | 0.51 ± 0.045 | 0.4 ± 0.030 | 0.10 ± 0.011a* |

| 1 | 8.1 ± 1.49 | 1.3 ± 0.18a,b** | 7.6 ± 0.46a,b* | 12.7 ± 4.33 | 41.2 ± 2.45 | 9.9 ± 1.00a* | 3.8 ± 0.52 | 400.8 ± 7.84b** | 69.2 ± 2.10b** | 22.4 ±0.58b** | 2.4 ± 0.43a** | 0.53 ± 0.047 | 0.4 ± 0.033 | 0.09 ± 0.007a,b* | |

| 2 | 8.5 ± 1.53 | 1.5 ± 0.12a** | 8.5 ± 0.61a* | 12.5 ± 4.13 | 40.9 ± 2.29 | 5.6 ± 1.03b** | 3.5 ± 0.33 | 657.4 ± 12.06a** | 87.7 ± 11.17c* | 28.3 ± 0.86a** | 2.8 ± 2.32a** | 0.49 ± 0.060 | 0.4 ± 0.036 | 0.08 ± 0.010b* | |

| Fat x Molasses | 10 | 10.4 ± 0.21a | 1.1 ± 0.12b,c,d | 7.5 ± 0.17e,d | 7.6 ± 0.15c | 44.2 ± 1.17a | 17.2 ± 0.91a** | 4.6 ± 0.21a* | 150.4 ± 3.32d** | 31.0 ± 0.24c** | 15.2 ± 0.28c** | 1.9 ± 0.03c | 0.54 ± 0.050a,b | 0.46 ± 0.021a | 0.11 ± 0.011a* |

| 11 | 10.0 ± 0.24a** | 1.5 ± 0.14a,b | 8.1 ± 0.21b,c | 7.6 ± 0.17c** | 44.0 ± 1.15a | 13.0 ± 0.91b | 4.5 ± 0.23a,b | 409.1 ± 5.21c | 71.4 ± 1.31b | 22.8 ± 0.53b | 2.4 ± 0.20b | 0.56 ± 0.040a* | 0.47 ± 0.022a** | 0.09 ± 0.008a,b | |

| 12 | 10.4 ± 0.22a | 1.5 ± 0.15a** | 9.2 ± 0.20a* | 7.7 ± 0.20c | 43.3 ± 1.14a** | 8.2 ± 0.57d | 3.9 ± 0.19b,c | 671.3 ± 6.03a** | 90.3 ± 21.86a* | 28.9 ± 0.81a | 2.9 ± 0.38a | 0.54 ± 0.060a,b | 0.45 ± 0.017a,b | 0.09 ± 0.007a,b,c | |

| 20 | 7.8 ± 0.18b | 0.9 ± 0.10c,d | 6.8 ± 0.12f,g | 13.0 ± 0.18b | 40.6 ± 1.21a,b | 16.8 ± 0.94a | 3.8 ± 0.17b,c | 146.3 ± 3.22d | 31.3 ± 0.18c | 16.5 ± 0.30c | 1.9 ± 0.05c | 0.48 ± 0.040a,b | 0.41 ± 0.024a,b | 0.10 ± 0.009a,b | |

| 21 | 7.7 ± 0.15b | 1.2 ± 0.11a,b,c | 7.7 ± 0.20c–e | 12.9 ± 0.18b | 40.8 ± 1.25a,b | 11.8 ± 0.74b,c | 3.5 ± 0.18c | 398.7 ± 4.00c | 68.7 ± 1.21b | 22.2 ± 0.51b | 2.5 ± 0.08b | 0.54 ± 0.040a,b | 0.44 ± 0.026a,b | 0.09 ± 0.010a,b,c | |

| 22 | 8.1 ± 0.19b | 1.5 ± 0.11a | 8.5 ± 0.19b | 12.7 ± 0.16b | 40.9 ± 1.30a,b | 8.2 ± 0.53d | 3.4 ± 0.20c | 654.6 ± 5.82a,b | 87.3 ± 1.77b** | 28.2 ± 0.78a** | 3.0 ± 0.10a** | 0.49 ± 0.030a,b | 0.39 ± 0.017b | 0.08 ± 0.005b,c | |

| 30 | 6.5 ± 0.16c** | 0.8 ± 0.09d** | 6.4 ± 0.15g* | 17.7 ± 0.22a | 39.0 ± 1.23b | 14.0 ± 0.90b | 3.5 ± 0.20c* | 144.2 ± 2.92d | 32.1 ± 0.28c | 16.3 ± 0.27c | 1.8 ± 0.05c** | 0.51 ± 0.030a,b | 0.42 ± 0.013a,b | 0.10 ± 0.008a,b | |

| 31 | 6.7 ± 0.17c | 1.1 ± 0.11a-d | 7.1 ± 0.18e,f | 17.5 ± 0.24a | 38.9 ± 1.19b | 9.5 ± 0.69c,d | 3.5 ± 0.19c | 394.5 ± 5.32c | 67.5 ± 1.45b | 22.0 ± 0.50b | 2.4 ± 0.06b | 0.48 ± 0.030a,b | 0.41 ± 0.013a,b | 0.09 ± 0.007a,b,c | |

| 32 | 7.0 ± 0.18c | 1.5 ± 0.14a | 7.8 ± 0.17c,d | 17.2 ± 0.19a** | 38.6 ± 1.20b** | 7.1 ± 0.37d** | 3.2 ± 0.15c | 646.4 ± 5.37b | 85.4 ± 1.78b | 27.8 ± 0.90a | 2.5 ± 0.08b | 0.44 ± 0.050b* | 0.39 ± 0.020b** | 0.07 ± 0.005b* |

Means±SD value from 3 replications (n = 3)

*, **Means significantly different at 95 % and 99 % levels respectively within each group in a column

Unmarked values within each group are not significantly different

a,b,c,dMeans within each group followed by different superscripts are significantly different

eCodes: Fat, 1=10 % flour basis (f.b.), 2=20 % f.b., 3=30 % f.b.; Molasses, 0=without molasses, 1=10 % f.b., 2=20 % f.b.

Molasses is an ingredient rich in macro- and micro-minerals. Its addition is expected to raise the content of minerals and the elevated mineral content in formulations with molasses confirms this. The most prominent increase was observed for the macroelements; for upper supplementation levels the increases were 347 %, 178 %, and 77 % for K, Ca, and Mg, respectively. However, not all microelements were increased by the addition of molasses; a substantial increase was observed in the iron content (48 % increase) but the copper content was at the low side in the biscuits containing 20 % molasses. The manganese content was not significantly affected by the fat and molasses content in the recipe although the formulations lower in fat tended to have more manganese. Significant variation was found between two formulations: 10%F-10%M and 30%F-20%M. In the biscuits made with lower fat content, the proportion of wheat flour was higher, which probably contributed to increasing Mn contents trend. Remarkably high manganese levels in wheat grains harvested from major Serbian wheat growing regions have been reported by Škrbić and Filipčev (2007). Similarly, somewhat higher Zn content was measured in the biscuits made with 10 % fat although the single effect of fat was not found significant. Higher molasses content contributed to lower Zn contents in the biscuits, but the differences were not significant in comparison to the corresponding controls. The Cu contents were significantly affected by molasses levels; the biscuits made with higher molasses levels had lower Cu contents and there was significantly more Cu in the control biscuit with 10 % fat in comparison to those supplemented with 20 % molasses and 20 % or 30 % fat.

Effect of fat content and replacement of honey with molasses on the quality of biscuits

The results showed that the weight of biscuits 24 h after baking tended to be lower in biscuits with higher fat content, however, no significant major effect of fat content was observed here (Table 3). Pareyt et al. (2009) found a significant inverse linear relationship between biscuit weight and fat content in the recipe. The thickness of the biscuits significantly decreased with increasing fat content (R2 = −0.95) which is in line with the findings of Pareyt et al. (2009). Increasing the molasses content did not significantly affect thickness in any of the tested biscuit variants. The biscuit spread ratio ranged from 3.68 to 4.72 and it correlated linearly with fat content (R2 = 0.92), but significantly (p < 0.5) greater spread ratio was observed in the biscuits with 30 % fat content. A greater spread ratio of cookies with a higher fat content was also noted in the works of Sudha et al. (2007) and Pareyt et al. (2009). The addition of molasses at the tested doses did not affect this parameter. Similarly, the density of ginger snaps was significantly affected by the fat content (R2 = 0.86); those with 10 % fat had significantly lower density. Lower biscuit density is associated with higher crispiness and development of better over-all textural value (Mamat and Hill 2012).

Table 3.

Single and interactive effects of varying fat and molasses content on the physical properties and texture of gingersnaps

| Factor | Level | Weight (g) | Height (mm) | Diameter (mm) | Spread ratio | Density (g/cm3) | Hardness (N) (1 day) | Fracturability (1 day) | Hardness (N) (30 days) | Fracturability (30 days) | Hardness (N) (60 days) | Fracturability (60 days) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fate | 1e | 29.4 ± 1.01 | 18.6 ± 0.75a** | 69.1 ± 0.48a** | 3.7 ± 0.15b** | 0.4 ± 0.03b** | 16.9 ± 1.80 | 463.5 ± 66.61 | 22.3 ± 2.64 | 634.3 ± 87.39 | 28.3 ± 3.26 | 1012.8 ± 173.27 |

| 2 | 29.6 ± 0.55 | 16.9 ± 0.29b* | 66.9 ± 0.57b** | 4.0 ± 0.06b** | 0.5 ± 0.02a** | 15.2 ± 2.30 | 425.6 ± 37.68 | 23.4 ± 3.09 | 659.6 ± 103.83 | 27.6 ± 2.96 | 980.3 ± 150.18 | |

| 3 | 28.1 ± 0.61 | 14.9 ± 0.35c** | 68.0 ± 0.70a,b** | 4.6 ± 0.14a** | 0.5 ± 0.02a** | 13.6 ± 1.62 | 394.3 ± 38.97 | 22.4 ± 3.30 | 640.1 ± 167.87 | 25.5 ± 3.82 | 734.3 ± 170.89 | |

| Molasses | 0 | 28.7 ± 1.09 | 16.6 ± 1.80 | 68.4 ± 0.91 | 4.2 ± 0.45 | 0.5 ± 0.05 | 14.8 ± 2.09 | 420.6 ± 44.41 | 21.4 ± 3.23 | 547.1 ± 87.72 | 26.1 ± 3.51 | 781.3 ± 175.84 |

| 1 | 29.1 ± 0.95 | 16.9 ± 1.68 | 68.1 ± 1.00 | 4.1 ± 0.39 | 0.5 ± 0.05 | 15.1 ± 2.72 | 407.0 ± 55.46 | 22.9 ± 2.28 | 640.2 ± 66.67 | 26.6 ± 3.42 | 866.9 ± 154.67 | |

| 2 | 29.2 ± 0.98 | 16.8 ± 1.54 | 67.5 ± 1.20 | 4.0 ± 0.32 | 0.5 ± 0.05 | 15.9 ± 1.94 | 455.8 ± 60.00 | 23.8 ± 3.01 | 746.8 ± 111.26 | 28.6 ± 3.30 | 1079.2 ± 161.86 | |

| Fat x Molasses | 10 | 29.3 ± 0.56 | 18.4 ± 0.97a,b* | 69.3 ± 0.69a** | 3.8 ± 0.21b | 0.4 ± 0.03c** | 16.0 ± 1.04 | 444.4 ± 45.23a,b | 23.5 ± 2.94 | 574.4 ± 73.23a,b | 28.6 ± 3.69 | 880.2 ± 84.55a,b,c** |

| 11 | 29.2 ± 0.76 | 18.8 ± 0.75a** | 69.0 ± 0.54a,b** | 3.7 ± 0.12b** | 0.4 ± 0.04c | 17.7 ± 1.88 | 435.3 ± 26.12a,b | 22.5 ± 2.99 | 657.6 ± 74.32a,b | 28.0 ± 3.84 | 980.2 ± 98.68a,b** | |

| 12 | 29.7 ± 0.88 | 18.6 ± 0.78a* | 69.0 ± 0.13a,b** | 3.7 ± 0.15b | 0.4 ± 0.02b,c | 17.1 ± 2.10 | 510.7 ± 34.71 a* | 21.1 ± 2.59 | 671.0 ± 98.91a,b | 28.2 ± 3.53 | 1178.1 ± 101.55a** | |

| 20 | 29.3 ± 0.64 | 17.1 ± 0.35b,c* | 67.4 ± 0.23b,c,d** | 4.0 ± 0.08b | 0.5 ± 0.01a,b,c | 15.1 ± 2.36 | 408.8 ± 26.00a,b | 20.8 ± 3.11 | 601.8 ± 70.20a,b | 26.4 ± 2.28 | 881.4 ± 121.93a,b,c** | |

| 21 | 29.8 ± 0.50 | 16.8 ± 0.25c* | 67.0 ± 0.42c,d* | 4.0 ± 0.08b | 0.5 ± 0.01a,b | 14.6 ± 2.29 | 422.3 ± 53.02a,b | 23.8 ± 2.39 | 622.9 ± 65.75a,b | 26.8 ± 2.39 | 922.2 ± 84.24a,b* | |

| 22 | 29.6 ± 0.59 | 16.8 ± 0.22c* | 66.3 ± 0.36c** | 4.0 ± 0.04b | 0.5 ± 0.02a | 16.1 ± 1.97 | 445.8 ± 33.77a,b | 25.5 ± 2.35 | 754.2 ± 115.89a,b | 29.5 ± 3.94 | 1137.2 ± 107.58a** | |

| 30 | 27.6 ± 0.57 | 14.5 ± 0.97d** | 68.3 ± 0.39a,b* | 4.7 ± 0.08a | 0.5 ± 0.01a** | 13.3 ± 2.23 | 408.5 ± 62.36a,b | 19.8 ± 3.56 | 465.0 ± 69.06b** | 23.3 ± 2.99 | 582.2 ± 111.63c** | |

| 31 | 28.2 ± 0.42 | 15.0 ± 0.75d* | 68.5 ± 0.51a,b* | 4.6 ± 0.04a | 0.5 ± 0.02a | 13.1 ± 2.11 | 363.5 ± 66.51b* | 22.3 ± 2.01 | 640.0 ± 83.85a,b | 25.0 ± 4.42 | 698.5 ± 111.63b,c** | |

| 32 | 28.4 ± 0.67 | 15.2 ± 0.78d* | 67.2 ± 0.41b,c* | 4.4 ± 0.05a** | 0.5 ± 0.02a | 14.4 ± 1.12 | 410.9 ± 65.98a,b | 24.9 ± 2.57 | 815.3 ± 102.70a** | 28.1 ± 3.70 | 922.2 ± 161.93a,b* |

Means±SD value from 5 replications (n = 5)

*, ** Means significantly different at 95 % and 99 % levels respectively within each group

Unmarked values within each group are not significantly different

a,b,c,dMeans within each group followed by different superscripts are significantly different

eCodes: Fat, 1=10 % flour basis (f.b.), 2=20 % f.b., 3=30 % f.b.; Molasses, 0=without molasses, 1=10 % f.b., 2=20 % f.b.

The hardness and fracturability of gingersnaps were neither significantly affected by fat nor by molasses addition. The samples with higher fat content tended to be softer and less brittle (fracturable), whereas those with higher molasses content tended to be firmer and more fracturable but generally significant effects were not observed. Sudha et al. (2007) showed that biscuits containing less fat developed harder texture and increased breaking strength. Extreme reduction of hardness and increased fracturability in shortbread biscuits with fat addition was reported by Maache-Rezzoug et al. (1998). Hardness reduction of fat containing biscuits is because fat lubricates, coats and segregates the flour particles during mixing, interrupting the formation of cohesive gluten network which leads to the formation of less hard and more tender structure (Manley 2000). Mamat and Hill (2012) showed that the effect of fat on biscuit hardness is rather complex as it depends not only on its content but on fat type, too. The mechanisms for biscuit tenderization and hardening by fat and sugar, respectively, were explained earlier. The effect of molasses on biscuit geometry and texture was not significant in our case probably due to lower doses in comparison to sugar contents in short dough biscuits which reached almost 60 % (flour basis) in the study of Maache-Rezzoug et al. (1998) and may be as high as 70–80 % (flour basis) (Manley 2000).

Similar relations in biscuit hardness and fracturability within the tested gingersnaps were observed during two-month storage. During storage, the biscuits increased in hardness and fracturability. After two months, these changes were the lowest in the biscuits with 30 % fat, especially regarding fracturability. After one and two months of storage, in the group of biscuits made with 30 % fat, there was a significant difference in the fracturability between the variants without molasses and 20 % molasses.

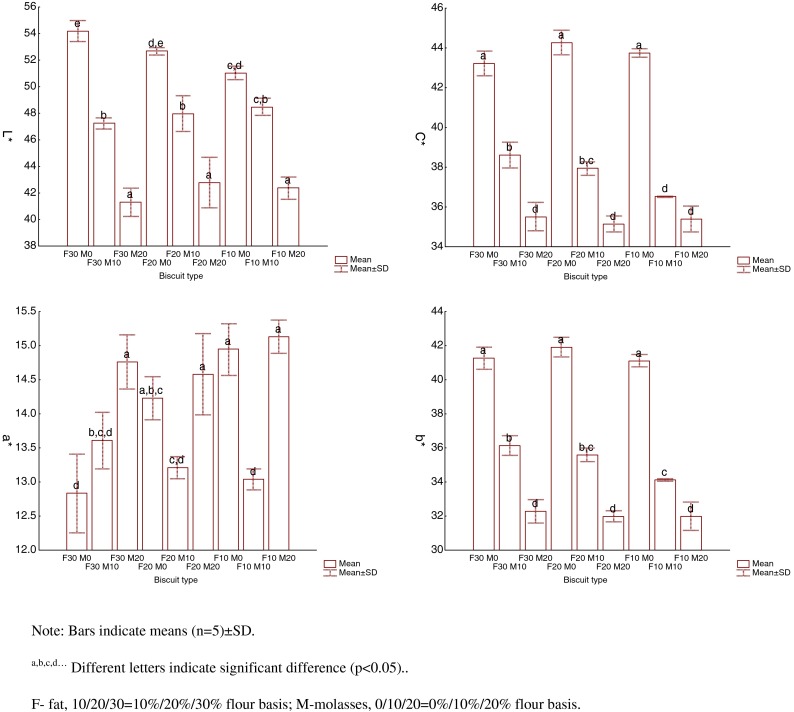

Effect of fat content and replacement of honey with molasses on the colour of biscuits

The effects of molasses addition and varying fat content on the colour of biscuits were shown in Fig. 1 As expected, molasses darkened the biscuits. Three distinct groups were formed regarding L* values depending on molasses supplementation levels; the lightest (higher L* values) were those without molasses and the darkest (the lowest L* values) were those with 20 % molasses. Molasses contains coloured substances formed by Maillard reaction and caramelization during sugar processing which contribute to dark colour (Šušić and Sinobad 1989).

Fig. 1.

Comparison of colour parameters of gingernut type biscuits by varying fat and molasses content. L* is lightness; C* is chroma; a* defines red-to-green; b* defines blue-to-yellow

Similarly, three distinct groups of biscuits could be observed depending on the intensity of the yellow tone (b* value); increasing molasses content contributed to the decrease in the yellow tone. The biscuits with 20 % molasses had increased redness in comparison to those with 10 % molasses. Within the control samples (without molasses), a reduction in the red tone was observed with increasing fat content. In biscuits with higher fat content, the relative proportion of other constituents (flour, sugar, honey) is lower and it seems that a “diluting effect” of increased fat proportion could be associated with a decrease in redness.

The chroma values (C*) were significantly lower in the samples with increasing molasses content. Similar observations were made by Ferriola and Stone (1998) when determining the colour of breakfast cereals made with molasses. Lower chroma values indicate less vivid tones which approach to greyer nuances.

There were very significant linear correlations between parameters of CIELAB coordinates, except a* values, and reducing sugar content and molasses content (Table 4). Higher reducing sugar content (characteristic for biscuits without molasses) contributed to the formation of lighter, more vivid surface biscuit colour with increased yellow tone probably due to formation of products of Maillard reactions during baking. However, melanoidines, already contained in molasses as products of the same reactions during the sugar refining process, in combination with low reducing sugar content contributed to darker, less intense biscuit colour with increased red tone.

Table 4.

Factors of Pearson correlation matrix

| Fat dose | Molasses dose | Reducing sugars | L* | a* | b* | C* | |

|---|---|---|---|---|---|---|---|

| Fat dose | 1.00 | ||||||

| Molasses dose | 0.00 | 1.00 | |||||

| Reducing sugars | −0.30 | −0.92** | 1.00 | ||||

| L* | 0.03 | −0.96** | 0.90** | 1.00 | |||

| a* | −0.29 | 0.38 | −0.33 | −0.44* | 1.00 | ||

| b* | 0.09 | −0.97** | 0.90** | 0.93** | −0.21 | 1.00 | |

| C* | 0.06 | −0.95** | 0.89** | 0.90** | −0.13 | 1.00** | 1.00 |

*Correlation significant at 95 % level

**Correlation significant at 99 % level

Sensory evaluation

Data on the sensory properties are displayed in Table 5. Scores for brittleness, flavour and overall acceptability determined one day after baking showed that there were no significant differences among the biscuit variants although higher fat content contributed to crumblier and softer crumb, whereas molasses imparted a stronger flavour. Maache-Rezzoug et al. (1998) explained that crumbliness in higher fat biscuits is because fat coats flour particles, inhibits gluten development and make them more easily detachable. However, in our case, plasticizing effect of molasses partially counteracted this effect; therefore the biscuits did not show significant differences in brittleness. After two months of storage, biscuits with 10 % fat were rated significantly lower for flavour and overall acceptability. They also significantly increased in crumb brittleness. These can be attributed to lower fat content which negatively affected the crumb texture during storage. The best scored biscuits during storage were those with 30 % fat, especially regarding flavour and overall acceptability. Mitzel et al. (1996) suggested that fat is an aroma carrier in biscuits since lower fat content of gingersnap cookies resulted in significantly lower intensity of ginger scent.

Table 5.

Sensory attributes of gingersnaps

| Fat level (%) | Molasses level (%) | Brittleness | Flavour | Overall acceptability | ||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1 day | 30 days | 60 days | 1 day | 30 days | 60 days | 1 day | 30 days | 60 days | ||

| 10 | 0 | 3.0 ± 0.00a | 3.2 ± 0.69a | 4.8 ± 0.37b | 7.7 ± 0.45a | 6.2 ± 0.40a | 2.2 ± 0.70b | 8.8 ± 0.37a | 6.7 ± 0.47b | 3.8 ± 0.37c |

| 10 | 10 | 3.2 ± 0.37a | 3.7 ± 0.75a | 5.3 ± 0.45b | 8.2 ± 0.37a | 5.5 ± 0.51b | 2.0 ± 0.82c | 8.7 ± 0.45a | 6.5 ± 0.50b | 3.3 ± 0.47c |

| 10 | 20 | 3.3 ± 0.47a | 3.7 ± 0.48a | 5.8 ± 0.33b | 8.2 ± 0.69a | 4.7 ± 0.75b | 2.0 ± 0.58c | 8.2 ± 0.40a | 6.0 ± 0.82b | 3.2 ± 0.38c |

| 20 | 0 | 2.7 ± 0.45a | 2.8 ± 0.38a | 4.8 ± 0.36b | 8.2 ± 0.71a | 7.3 ± 0.75a | 4.3 ± 0.48b | 9.0 ± 0.00a | 7.2 ± 0.37b | 5.7 ± 0.75c |

| 20 | 10 | 3.0 ± 0.58a | 3.2 ± 0.37a | 5.0 ± 0.58b | 7.8 ± 0.36a | 7.3 ± 0.49a | 5.0 ± 0.58b | 9.0 ± 0.00a | 7.3 ± 0.47b | 5.5 ± 0.76c |

| 20 | 20 | 3.0 ± 0.54a | 3.3 ± 0.47a | 5.5 ± 0.50b | 8.5 ± 0.50a | 7.8 ± 0.36a | 5.2 ± 0.69b | 8.7 ± 0.45a | 7.0 ± 0.00b | 5.3 ± 0.47c |

| 30 | 0 | 2.0 ± 0.57a | 2.7 ± 0.47a | 4.00 ± 0.59b | 8.2 ± 0.37a | 7.5 ± 0.51a,b | 5.8 ± 0.38b | 9.0 ± 0.00a | 6.7 ± 0.47b | 5.7 ± 0.47b |

| 30 | 10 | 2.3 ± 0.46a | 3.0 ± 0.00a | 4.3 ± 0.47b | 8.5 ± 0.50a | 7.8 ± 0.38a,b | 6.3 ± 0.47b | 9.0 ± 0.00a | 6.5 ± 0.50b | 5.7 ± 0.75b |

| 30 | 20 | 2.5 ± 0.76a | 3.5 ± 0.74a | 4.7 ± 0.44b | 8.5 ± 0.52a | 7.8 ± 0.37a,b | 6.7 ± 0.50b | 8.8 ± 0.35a | 6.2 ± 0.37b | 5.5 ± 0.50b |

Means±SD value from 6 replications (n = 6)

a,b,cMeans in a row within each sensory attribute followed by different superscripts are significantly different (p < 0.05)

Conclusion

The results of the current study showed that only fat content had a significant effect on dough properties whereas the partial replacement of honey with sugar beet molasses did not affect dough properties within each biscuit category. Increasing fat content produced softer, less adhesive, less cohesive and less springy dough which is desirable in biscuit-making.

Similarly, biscuit geometry and physical attributes were significantly affected by fat content, whereas the applied molasses doses did not cause significant changes. Increasing fat content, increased biscuit spread ratio and density. Biscuit texture was neither affected by varying fat content nor addition of molasses. During storage, the hardness, fracturability and brittleness of biscuits significantly increased. After 2-month storage, these changes were less marked for biscuits containing 30 % fat. Moreover, higher fat content appeared to have an effect in maintaining flavour during storage. When molasses was incorporated into the biscuits, the products had darker colour with a less yellow and more red tone.

Results of chemical analyses revealed that more nutritious biscuits can be prepared by up to 50 % replacement of honey with sugar beet molasses, with significantly increased protein potassium, calcium, magnesium and iron content.

At the applied doses, sugar beet molasses can be used to partially replace honey in the gingernut biscuit formulation as it beneficially affects the nutritive composition and does not impair the textural, physical and sensory attributes of the biscuits.

Acknowledgement

The authors acknowledge the support of the Ministry of Education and Science, Republic of Serbia within the Project TR 31055 coordinated by Prof. Lj. Lević.

References

- AOAC . Official methods of analysis of AOAC International. 17. Maryland: The Association; 2000. [Google Scholar]

- Chakraborty SK, Kumbhar BK, Chakraborty S, Yadav P. Influence of processing parameters on textural characteristics and overall acceptability of millet enriched biscuits using response surface methodology. J Food Sci Technol. 2011;48(2):167–174. doi: 10.1007/s13197-010-0164-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ferriola D, Stone M. Sweetener effects on flaked millet breakfast cereals. J Food Sci. 1998;63(4):726–729. doi: 10.1111/j.1365-2621.1998.tb15823.x. [DOI] [Google Scholar]

- Filipčev B, Šimurina O, Mišljenović N, Koprivica G, Pribiš V, Lević LJ. Effect of osmotically dehydrated apples and plums in sugar beet molasses on dough thermo-mechanical properties and bread quality parameters. J Process Energy Agric. 2009;13(2):174–175. [Google Scholar]

- Filipčev B, Lević LJ, Bodroža-Solarov M, Mišljenović N, Koprivica G. Quality characteristics and antioxidant properties of breads supplemented with sugar beet molasses-based ingredients. Int J Food Prop. 2010;13(5):1035–1053. doi: 10.1080/10942910902950526. [DOI] [Google Scholar]

- Filipčev B, Šimurina O, Bodroža-Solarov M, Vujaković M. Evaluation of physical, textural and microstructural properties of dough and honey biscuits enriched with buckwheat and rye. Chem Ind Chem Eng Q. 2011;17(3):291–298. doi: 10.2298/CICEQ110204014F. [DOI] [Google Scholar]

- Gajera HP, Kapopara MB, Patel VH. Application of peanut butter to improve fatty acid composition of biscuits. J Food Sci Technol. 2010;47(3):285–289. doi: 10.1007/s13197-010-0044-y. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Gallagher E, Kenny S, Arendt EK. Impact of dairy protein powders on biscuit quality. Eur Food Res Technol. 2005;221:237–243. doi: 10.1007/s00217-005-1140-5. [DOI] [Google Scholar]

- Gavrilović M. Tehnologija konditorskih proizvoda. 2. Novi Sad: University of Novi Sad; 2003. [Google Scholar]

- Ghotra BS, Dyal SD, Narine SS. Lipid shortenings: a review. Food Res Int. 2002;35:1015–1048. doi: 10.1016/S0963-9969(02)00163-1. [DOI] [Google Scholar]

- Handa C, Goomer S, Siddhu A. Physicochemical properties and sensory evaluation of fructoligosaccharide enriched cookies. J Food Sci Technol. 2012;49(2):192–199. doi: 10.1007/s13197-011-0277-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Hickenbottom J. Use of molasses in bakery products. Tech Bull. 1996;XVIII(6):1–6. [Google Scholar]

- ICC Standard No.123/1 (1994) Determination of Starch Content by Hydrochloric Acid Dissolution

- Labropoulos A, Anestis S (2012) Syrups. In: Varzakas T, Labropoulos A, Anestis S (eds) Sweeteners: nutritional aspects, applications and production technology. CRC Press, Taylor and Fransis Group, pp 150–151

- Maache-Rezzoug Z, Bouvier J-M, Allaf K, Patras C. Effect of principal ingredients on rheological behaviour of biscuit dough and on qualitx of biscuits. J Food Eng. 1998;35:23–42. doi: 10.1016/S0260-8774(98)00017-X. [DOI] [Google Scholar]

- Mamat H, Hill SE (2012) Effect of fat types on the structural and textural properties of dough and semi-sweet biscuit. J Food Sci Technol (Online First™ on 29 April 2012. doi:10.1007/s13197-012-0708-x) [DOI] [PMC free article] [PubMed]

- Manley D. Technology of biscuits, crackers and cookies. 3. Cambridge: CRC Press Woodhead Publishing Ltd; 2000. [Google Scholar]

- Mitzel TM, Sweeney CA, Gee DL. Semi-moist fruit puree as a fat replacement in gingersnap cookies. J Am Diet Assoc. 1996;96(9 Suppl. 1):A43. doi: 10.1016/S0002-8223(96)00462-2. [DOI] [Google Scholar]

- Mixolab User’s Manual (2005) Siége de Tripette & Renaud Chopin, Villeneuve-la-Garenne Cedex, France

- Olbrich H. The molasses. Kleinmachnow: Biotechnologie-Kempe GmbH; 1963. [Google Scholar]

- Pareyt B, Talhaoui F, Kerckhofs G, Brijs K, Goesaert H, Wevers M, Delcour J. The role of sugar and fat in sugar-snap cookies: structural and textural properties. J Food Eng. 2009;90:400–408. doi: 10.1016/j.jfoodeng.2008.07.010. [DOI] [Google Scholar]

- Perego P, Sordi A, Guastalli R, Converti A. Effects of changes in ingredient composition on the rheological properties of a biscuit industry dough. Int J Food Sci Technol. 2007;42(6):649–657. doi: 10.1111/j.1365-2621.2006.01330.x. [DOI] [Google Scholar]

- Pribiš V, Lević Lj, Filipčev B, Šimurina O (2008) Nutritive quality and sensory properties of fine yeast leavened bakery products with sugar beet molasses. J Process Energy Agric 12(3):158–161

- Šimurina O, Lević LJ, Pribiš V, Pajin B. Melasa šećerne repe kao dodatak u proizvodnji čajnog peciva. J Process Energy Agric. 2006;10(3–4):93–96. [Google Scholar]

- Škrbić B, Filipčev B. Element intakes through the consumption of different types of bread by Serbian population. Acta Aliment. 2007;36(2):217–229. doi: 10.1556/AAlim.36.2007.2.8. [DOI] [Google Scholar]

- Sudha ML, Srivstava AK, Vetrimani R, Leelavathi K. Fat replacement in soft dough biscuits: its implications on dough rheology and biscuit quality. J Food Eng. 2007;80(3):922–930. doi: 10.1016/j.jfoodeng.2006.08.006. [DOI] [Google Scholar]

- Šušić S, Sinobad V. Researches aimed at advancing the sugar industry of Yugoslavia—about chemical compositions of bee honey and sugar beet molasses and their biological values in human diet (Istraživanja u cilju unapređenja industrije šećera Jugoslavije—o hemijskim sastavima pčelinjeg meda i melase šećerene repe i o njihovim biološkim vrednostima za ljudsku ishranu) Hem Ind. 1989;43(Suppl. 1–2):10–21. [Google Scholar]

- Varzakas T, Özer B (2012) Application of sweeteners in food and drinks. In: Varzakas T, Labropoulos A, Anestis S (eds) Sweeteners: nutritional aspects, applications and production technology. CRC Press, Taylor and Fransis Group, pp 210–254

- Yadav RB, Yadav BS, Dhull N. Effect of incorporation of plantain and chickpea flours on the quality characteristics of biscuits. J Food Sci Technol. 2012;49(2):207–213. doi: 10.1007/s13197-011-0271-x. [DOI] [PMC free article] [PubMed] [Google Scholar]