Abstract

Mayonnaise is an oil in water emulsion and egg components are its emulsifier. In this research application of soy milk to stabilize mayonnaise was studied. Egg was replaced with full fat soy flour-prepared soy milk at levels of 25, 50, 75, and 100 % and microstructure, stability, color, viscosity and sensory analysis were performed and results were compared with those of control samples containing yolk and whole egg as emulsifier. Results showed that yolk-prepared control (YC) had higher stability and viscosity values and the value of these two attributes decreased as more amounts of soy milk was used. In the case of viscosity there was no statistical difference between soy milk-prepared samples and egg-prepared control (EC) up to 75 % replacement. Color factors changed, which were affected by different proportions of soy milk. Sensory evaluation showed no statistical difference in acceptability of EC and samples with substitution levels up to 50 %. So it can be concluded that egg can be substituted with soy milk in mayonnaise.

Keywords: Mayonnaise, Emulsion, Soy milk, Full fat soy flour, Soy protein

Introduction

An oil in water emulsion is a system in which oil droplets are distributed in a water phase called aqueous phase. Emulsifier molecules possess surface activity because they are amphiphilic, meaning both polar and non-polar regions exist within their molecular structure. This structure helps the emulsifier to interact with both phases, forming a protective layer at interface in which dispersed phase droplets are prevented from coalescence.

Most food emulsifiers are amphiphilic molecules, such as lipid-based emulsifiers (small molecule surfactants and phospholipids) and biopolymers (proteins and polysaccharides). In addition, some types of solid particles are also surface active and can act as emulsifiers in foods like granules from egg or mustard (McClements 2009).

Mayonnaise is an oil in water emulsion and egg components are its emulsifier. Egg contributes to the emulsification, stabilization, flavor and color of mayonnaise. Egg possesses high nutritional value and is comprised of 75 % water, 12.5 % protein, 12 % fat, and a small proportion of carbohydrate (Maghsoudi 2004). Both egg yolk and egg white contain several components, each of which possesses emulsifying activity (Mine 1998; Drakos and Kiosseoglou 2006; Drakos and Kiosseoglou 2008). Although egg possesses excellent emulsifying ability, concerns about high blood cholesterol are developing. Realizing they can contribute to their health, people eat much more knowledgably. So there have been done several studies on removing egg in mayonnaise. Aluko and McIctosh (2005) have studied canola proteins in native and hydrolyzed forms in mayonnaise, wheat protein functionality in mayonnaise was studied by Ghoush et al. (2008); Goankar et al. (2010) have done a research on milk proteins emulsifying performance in mayonnaise and used both native and hydrolyzed milk proteins to stabilize mayonnaise.

Soy beans have been an integral part of the diet of people in the Far East for more than 5,000 years. However the history of soy protein products is relatively short. In early years soy protein products were mainly used to meet nutritional needs, but more recently they have been used primarily for their unique functionality. With steadily improving production technology and intensive training in applications, full fat soy flours are finding wide application as a food or food ingredient. Full fat soy flours are primarily produced in Europe and Asia for the baking industry and production of soy milks (Choon Rhee 2004).

Water extractable soybean proteins can be divided in whey proteins (10 %), and globulins (90 %). Soybean globulins consist of four fractions, 2S (15 %), 7S (34 %), 11S (41.9 %) and 15S (9.1 %) (Fukushima 1991).Several trypsin inhibitors and cytochrome c exist in the 2S fraction; other minor proteins may also be present. The 7 s fraction comprises at least four different proteins: hemaglutinin, lipoxygenase, β-amylase, and a component designated 7 s globulin. The 7 s globulin (β-Conglycinin) represents more than one-half of the total 7 s fraction (Wolf and Sly 1967). In the 11 s fraction, a single protein called 11 s globulin (Glycinin), accounts for most of this fraction. The remaining of the protein constitutes the 15 s fraction, which has not been isolated and characterized (Wolf 1970). Functional properties of soy proteins such as emulsification, gel formation, etc. have been widely investigated by several researchers (Ahmad et al. 2010; Arjun Kulthe et al. 2011; Fukushima 1991; Poongodi Vijayakumar and Boopathy 2012; Vasu Pallavi et al. 2011)

Although soy proteins emulsifying properties have been studied by different authors, there is no scientific research on investigating soy proteins emulsification when full soy flour is used. As a result, this study aimed at removing egg, partially or totally, and developing an egg- reduced product without any financial disadvantage for industry. Therefore, our objectives in this study were to investigate soy milk prepared with full soy flour emulsifying property and the characteristics of the mayonnaise when soy milk is employed to stabilize it.

Materials and methods

Materials

Sunflower oil, egg, vinegar, salt, sugar, and mustard were provided from a local supermarket. Xanthan and guar gum were purchased from Sigma Aldrich Co., England and full soy flour was a gift from Toos Soya Co., Iran.

Protein measurement

To determine the exact protein content of provided flour, full fat soy flour was analyzed according to AOAC official method (Micro Kjeldahl). The assessed protein content was 39.28 % (w/v) rounded to 40 % for the experiments of the present study.

Emulsifier preparation

Soy milk was prepared according to Nikzade et al. (2011) method with modifications. Hot water (90-95 °C) was added into full fat soy flour with the weight ratio of 3:1(water: full fat soy flour). Then this mixture was stirred with stirrer (Digital Electric Stirrer) for 20 min at 680 rpm and soy milk was established with protein content of 10 %. Fresh eggs were broken manually and egg white and yolk were separated from each other to have pure egg yolk.

Emulsion preparation

Mayonnaise model emulsions were prepared as samples of high oil emulsions to investigate emulsifying ability of soy milk. Mayonnaise ingredients were oil 68 %, emulsifier 10 %, vinegar 7.9 %, xanthan 0.15 %, guar 0.15 %, water 10 %, sugar 3 %, salt 0.5 % and mustard 0.3 %. To prepare different mayonnaises; first, powder ingredients (salt, sugar, xanthan, guar, and mustard), water, and emulsifier were mixed with stirrer for 4 min at 800 rpm. Then 1/3 of vinegar was added and mixed for 2 min with the same speed. Then oil was added slowly in 8 min at 1,100 rpm into aqueous phase. The rest of the vinegar was poured (2/3 of vinegar) and mixed for 2 other minutes.Then this pre–emulsion was homogenized with the stirrer operating at 1,500 rpm for 7 min. Two different batches of each formula (each 500 g) were prepared. It should be mentioned that samples were made by different emulsifiers: 75 % egg + 25 % soy milk (25 %SM), 50 % egg + 50 % soy milk (50 % SM), 25 % egg + 75 %soy milk (75 % SM) and 100 % soy milk (100%SM). Also two samples were made as control experiments containing pure yolk (YC: yolk control) and whole egg (EC: egg control) as emulsifier.

Particle size measurement

Samples were diluted (1:100) using 0.1 % SDS solution and particle size (d3,2) of mayonnaise emulsions was determined employing particle sizer (Fritsch Particle sizer Analysette 22, Fritsch Co., Germany).

|

1 |

Where ni is the number of droplets showing diameter di.

Creaming and thermal creaming

To determine creaming value at room temperature, a fixed amount of each sample (8 ± 1 g) was transferred into cylindrical plastic containers and they were centrifuged at 5,000 rpm for 20 min. Then emulsion creaming at room temperature was determined by following equation:

|

2 |

Where %H is the percentage of creaming, H is the height of the cream separated from emulsion and H0 is the initial emulsion height in the container. Thermal creaming was determined by the same procedure but containers were incubated at 80˚c for 20 min before centrifugation. To measure mayonnaise creaming at low temperature, mayonnaises were placed in 2 °C for 3 months.

Optical microscope observation

Optical microscope observation was performed to compare emulsions, microstructure by using a light microscope (Olympus BX41) equipped with digital camera to prepare micrographs. One drop of each sample was transferred on a glassy flat without dilution and covered by a cover slip and micrographs were obtained.

Viscosity measurement

Viscosity measurement was performed by using viscometer (Visco 88, Bohlin Ltd., UK) at 23 °C. Apparent viscosity was measured at 50 s-1 shear rate.

Color measurement

Image processing was used to perform color measurement. Photographs (Jpeg format) in RGB color space system were taken by camera (Canon, power shot A520) connected with computer using Zoom Browser EX 5.0 software. Then photographs were converted into L٭, a٭, b٭ color space system using Image J1.40 g software (NIH Co. United States).

Sensory evaluation

Sensory evaluation was performed in formulation laboratory conducted on different samples to identify sensory characteristics of mayonnaises. Seven attributes, all of which were defined for 10 panelists to be familiar with them, were scored: non-textural attributes such as color and taste, and textural attributes such as thickness, spoonability, body and creaminess and also appearance and acceptability. The test was performed on 6 – point hedonic scale, 1 = the least, the lowest score, 6 = the most, the highest score for each attribute. Water was provided between samples to cleanse the palate and separate paper form was provided for each sample.

Statistical analysis

Analysis of variance and LSD test (P < 0.05) were used to establish significance of differences using MSTATC software.

Results and discussion

Microstructure, stability and viscosity

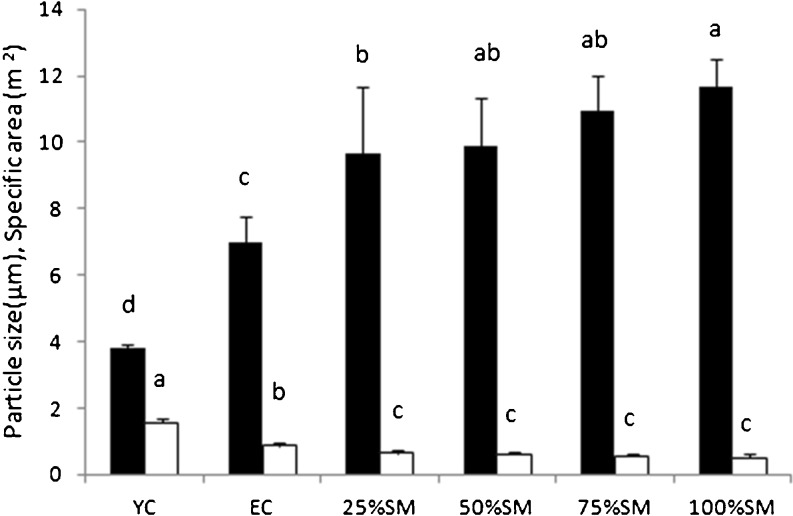

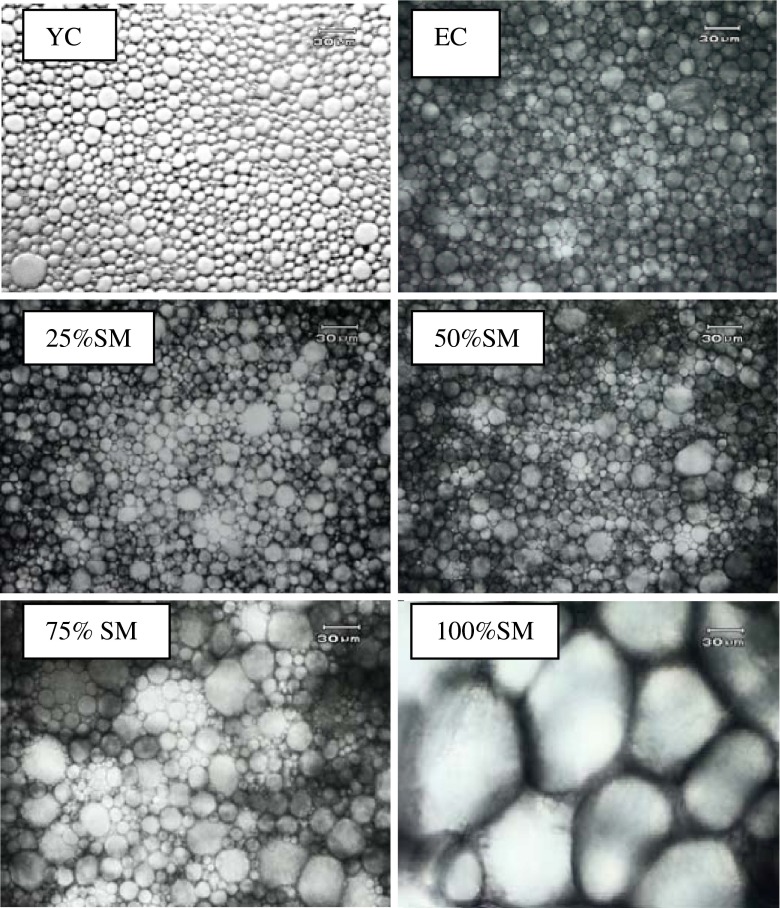

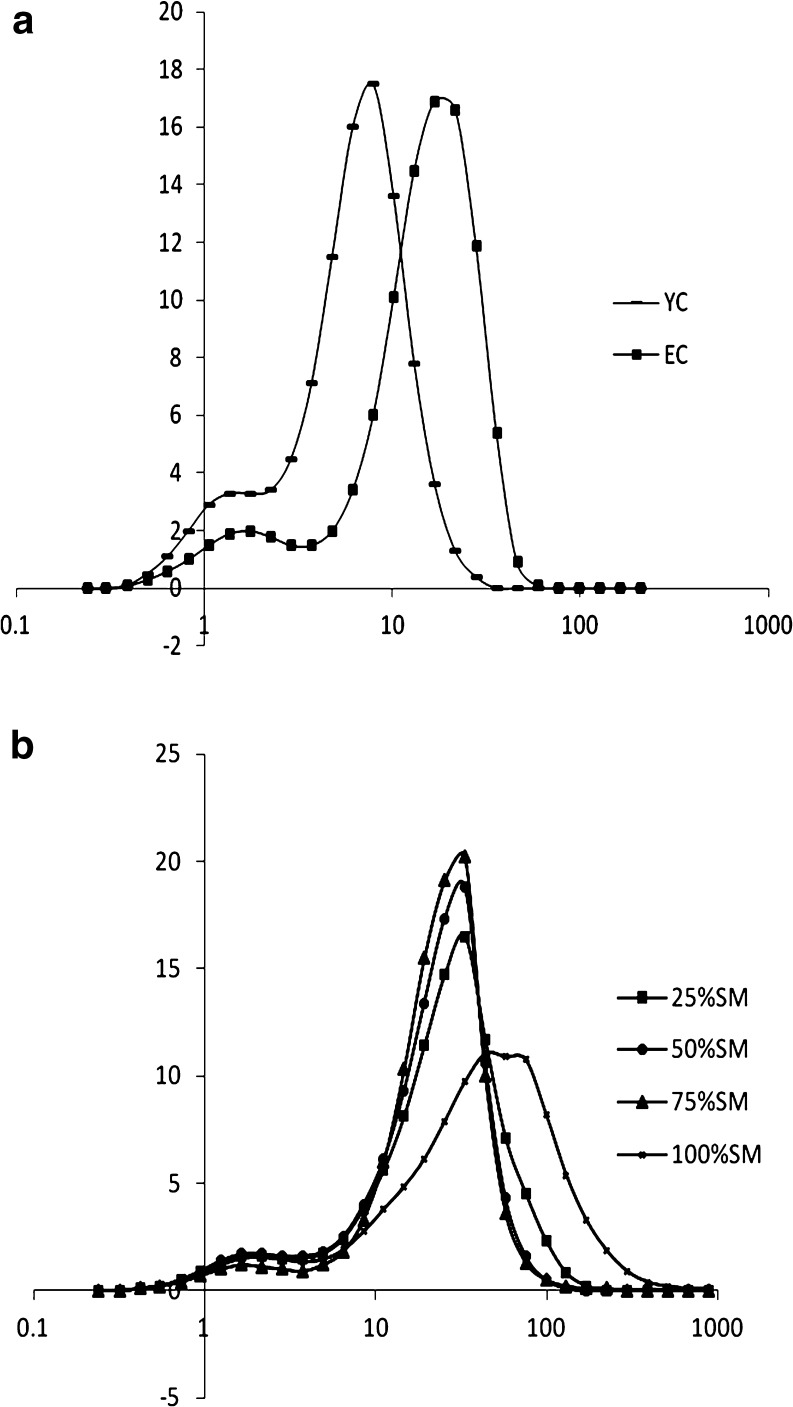

Mayonnaise is a typical oil in water emulsion stabilized with egg yolk. Figure 1 shows that the smallest and the highest particle size were found in YC and 100 % SM respectively referring to the lower capacity of soy proteins to emulsify compared to egg yolk components. In general, the use of small emulsifier molecules results in relatively small fat globules (Mangino 1994) and proteins are larger compared to emulsifier components in egg. Figure 2 demonstrates microstructure of the samples. YC, EC, 25 %SM, and 50 % SM samples had homogenous and pack microstructures and less homogenous structure was observed for 75 %SM. It can be understood from the observations, although 25 %SM and 50 %SM samples had less amounts of yolk, their microstructures did not have considerable difference with EC. DSD curves (shown in Fig. 3) reveal that samples in this study contain droplets with a range of different sizes, called poly disperse curves. According to the shape of the DSD curves, all samples exhibited mono modal or single peaked droplet size distribution except 100 %SM that showed bio modal or double peaked distribution. This result shows lower efficiency of emulsifier in this sample which produced more variety of sizes for oil droplets.

Fig. 1.

Particle size (d 3, 2) ■ and specific area □ for mayonnaises containing 68 % oil and different emulsifiers. Mean ± SD values are means of 3 replicates. Values followed by the same letter in each column are not significantly different at P < 0.05 by LSD test YC: yolk control, EC: egg control, SM: soy milk

Fig. 2.

Optical microscope micrographs of mayonnaise samples, magnification is × 40, bar is 30 μm. YC: yolk control, EC: egg control, SM: soy milk

Fig. 3.

Droplet size distribution for different mayonnaise samples, a: control experiments and b: samples made of combination of egg and soy milk YC: yolk control, EC: egg control, SM: soy milk

Creaming data are shown in Fig. 4a. Creaming refers to phase separation due to upward rise of fat globules due to differences in density between the dispersed and the continuous phases (McClements 2009). For large globules, the extent of creaming will depend upon the duration of storage time of the product (Mangino 1994). Thermal creaming results of samples are shown in Fig. 4a, describing accelerated flocculation that results in more creaming caused by the high temperature samples were placed in. The most stable sample was YC and stability values decreased with increasing soy milk content. The major mechanism preventing droplet flocculation, in protein stabilized emulsions is electrostatic repulsion and it occurs between emulsion droplets with electrically charged surfaces, which may occur in emulsions due to the adsorption of ionic or ionizable components such as surfactants, phospholipids, proteins or polysaccharides (McClements 2009). The isoelectric points of soy protein subunits, glycinin and β-conglycinin are 4.64 and 4.90 respectively (Koshiyama 1983). Therefore, soy protein is positively charged in mayonnaise which results in electrostatic stability of emulsion.

Fig. 4.

a. Creaming □ and thermal creaming ■ values of different samples, b. Viscosity (pa.s) of mayonnaise samples. Mean ± SD values are means of 2-4 replicates. Values followed by the same letter in each column are not significantly different at P < 0.05 by LSD test. YC: yolk control, EC: egg control, SM: soy milk

After being stored in 2 °C for 3 months, 100 %SM showed the least stability value compared to those of the others and a layer of oil was clear after 10 days of storage but there was no marked oil separation in the case of other samples.

Viscosity values are presented in Fig. 4b. YC was more viscous than all the other samples, likely due to the higher emulsifier property of egg yolk which resulted in particles of smaller size, improve surface contact area and friction force between drops in the YC sample (as data are shown in Fig. 1). Not affecting viscosity up to 75 % replacement statistically, soy milk can be employed in mayonnaise formula.

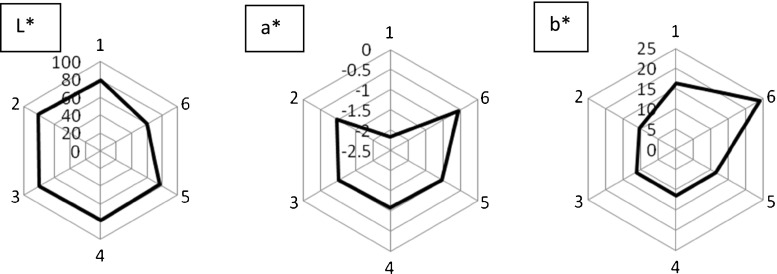

Color analysis results

As indicated in Table 1 and in Fig. 5, EC was the lightest sample with a higher L-value probably due to the greater proportion of added egg white. As more amounts of soy milk were used the value of L* decreased. Another factor affecting lightness of emulsions is particle size. According to Mc Clements and Demetriades, (1998) report the emulsions, color changes from a bright white color to an increasingly gray color as the droplet size increases and droplet sizes in this study confirm this report. This result was also reported by Worrasinchai et al. (2006) and Mun et al. (2009).Surely, this attribute affects mayonnaise appearance. In the case of a-value, 25 %, 50 %, and 75 %SM samples showed no significant difference with sample EC. In terms of b-value, 100 % substitution caused the highest value, probably due to the most amount of soy milk affecting the color. High b-value of YC was due to higher content of yolk which contains pigments. There was no significant difference in b-value of 25 %SM, 50 %SM and 75 % SM. In addition yellowness (b-value) of EC was lower than the others due to the proportion of egg white in this sample decreasing yellowness.

Table 1.

Image process color values of mayonnaise samples stabilized with different proportions of soy milk

| Sample | L*a | a*b | b*c |

|---|---|---|---|

| YC d | 79.2 ±0.18c | -2.17 ± 0.04a | 16.4 ±0.14b |

| EC e | 80.8 ±0.14a | -0.97 ± 0.05b | 10.4 ±0.23d |

| 25 %SM f | 80.2 ±0.22b | -1.02 ± 0.16b | 11.2 ±0.17c |

| 50 %SM | 78.8 ±0.07d | -1.07 ± 0.06b | 11.3 ±1.02c |

| 75 %SM | 76.3 ±0.12e | -1.05 ± 0.19b | 11.3 ±1.01c |

| 100 %SM | 60.3 ±8.12f | -0.57 ± 0.90c | 23.9 ±3.60a |

Mean ± SD values are means of 4 replicates. Values followed by the same letter in each column are not significantly different at P < 0.05 by LSD test

a Lightness, b Redness, c Yellowness, d Yolk control, e Egg control, f Soy milk

Fig. 5.

Profiles of color characteristics of different samples: 1. YC (yolk control), 2. EC (egg control), 3. 25 %SM (soy milk), 4. 50 %SM, 5. 75 %SM, 6. 100 %SM. Values are means of 4 replicates

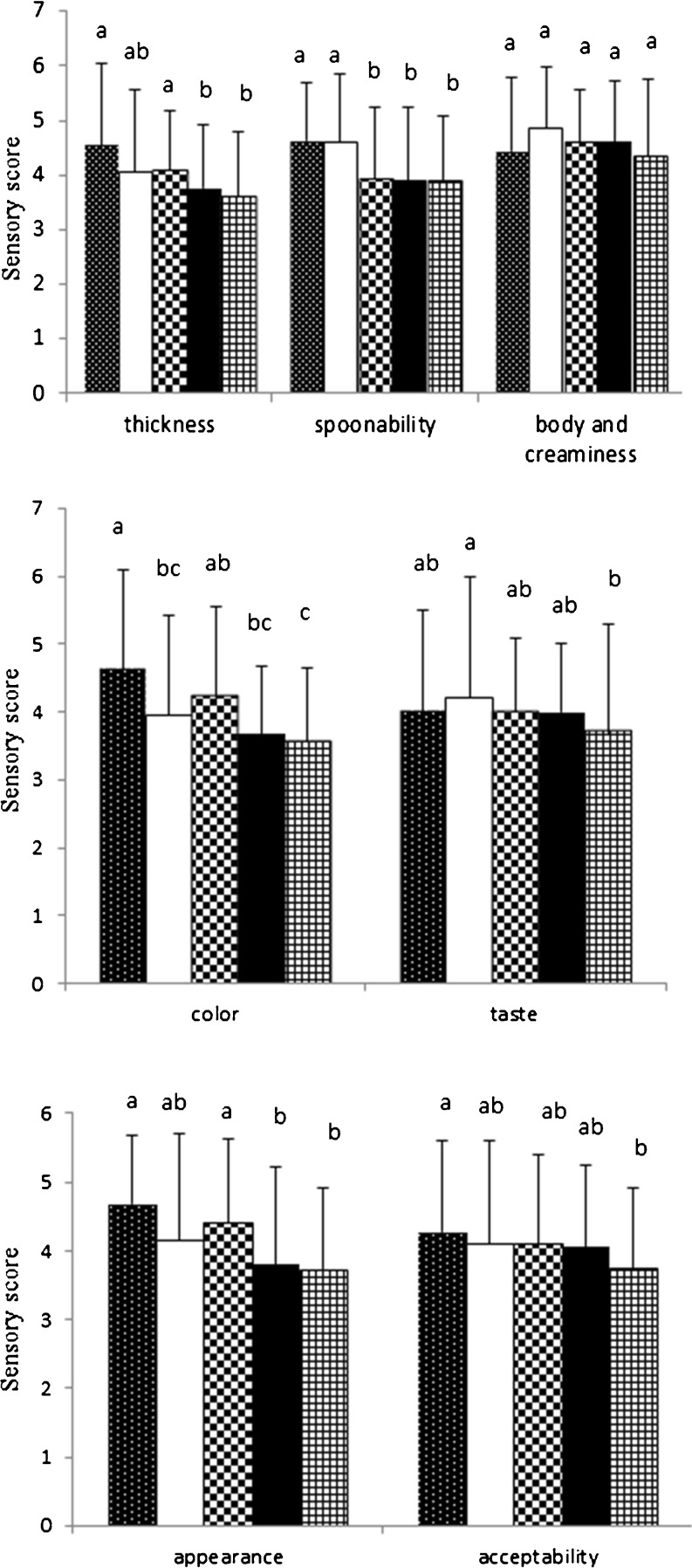

Sensory analysis results

As said before, 100 %SM showed the least stability value in comparison with the other samples and a layer of oil was clear after 10 days of storage, so its sensory data are not shown. Sensory attributes are categorized into two groups: textural and non- textural sensory attributes.

Textural sensory attributes

Sensory analysis results are shown in Fig. 6. Thickness represents viscosity of the sample. 75 %SM score of thickness was lower than those of the others as it is clear in Fig. 4b showing viscosity data. Spoonability was defined for panel members as the height of the sample in the spoon and it is related to the thickness of the sample too. All soy milk-prepared samples did not have statistical difference. Indeed panelists did not find the differences between samples due to the high thickness of the samples. In the case of body and creaminess, score of YC and 75 %SM were lower, may be due to the viscous and thicker texture of YC, made its stirring with spoon a bit difficult because it was not as creamy as the other samples and obtained the lowest score but the differences for this attribute were not significant. All of the samples except 100 %SM exhibited no fluidity as it was observed when their containers were turned upside down.

Fig. 6.

Scores of sensory attributes, YC (yolk control)  , EC (egg control)

, EC (egg control)  , 25 %SM (soy milk)

, 25 %SM (soy milk)  , 50 %SM

, 50 %SM  , and 75 % SM

, and 75 % SM  . Each value is the average of 10 observations. Values followed by the same letter in each column are not significantly different at P < 0.05 by LSD test

. Each value is the average of 10 observations. Values followed by the same letter in each column are not significantly different at P < 0.05 by LSD test

Non- textural sensory attributes

Color score of sample YC was the highest one due to the highest amount of yolk. Using 75 % soy milk affected mayonnaise color significantly but using lower proportions of soy milk caused no statistical difference between soy milk-prepared samples and EC and even EC score of color was lower than that of 25 %SM. In the case of taste, EC established the highest score. It may be due to the taste of the egg yolk in combination with egg white affecting the taste of the sample. Using soy milk up to 50 % did not influence mayonnaise taste considerably and all samples except 75 %SM were not significantly different with EC.

Total appearance is inclusive of color + texture. The first sensory impression of the quality of a food emulsion is its overall appearance (e.g., its color, opacity, gloss and homogeneity) (McClements and Demetriades 1998). Substitution at 25 % did not cause significant difference with YC and EC and even the score was higher than EC. The appearance score of sample with 75 % substitution was lower likely because of its color. In support to information reported by McClements (2009), the data of the present study clearly indicate that: the droplet size distribution of an emulsion-based food product has a major impact on its physico-chemical and sensory properties, e.g., shelf life, appearance, flavor, and texture.

Total acceptability is influenced by all attributes. YC obtained the highest score affected by its color and thickness. EC, 25 % and 50 %SM samples did not show any significant difference in acceptability and as it was expected, the least significant score was related to 75 %SM. According to total acceptability scores, it can be concluded that using soy milk up to 50 % of egg as emulsifier is accepted.

Conclusion

Based on the results of this study, substitution of egg with soy milk in mayonnaise did not affect mayonnaise viscosity up to 75 % replacement and stability up to 50 % substitution. In the case of sensory evaluation, 50 % of egg can be substituted by soy milk because results showed no statistical difference in acceptability compared with those of control sample containing whole egg as emulsifier. It may be concluded that although in a lot of researches soy protein concentrates and subunits were used to stabilize emulsions, soy flour showed high efficiency and regarding high nutritional value it is recommended to be used in mayonnaise at high levels in comparison with the other plant proteins.

References

- Ahmad S, Rizawi JA, Srivastava PK. Effect of soy protein isolate incorporation on quality characteristics and shelf-life of buffalo meat emulsion sausage. J Food Sci Technol. 2010;47:290–294. doi: 10.1007/s13197-010-0045-x. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Aluko RE, McIctosh T. Limited enzymatic proteolysis increases the level of incorporation of canola proteins into mayonnaise. Innov Food Sci Emerg Technol. 2005;6:195–202. doi: 10.1016/j.ifset.2004.11.003. [DOI] [Google Scholar]

- Arjun Kulthe A, Deorao Pawar V, Mohanlal Kotecha P, Dhyanu Chavan U, Vishwanath Bansode V (2011) Development of high protein and low calorie cookies. J Food Sci Technol. doi:10.1007/s13197-011-0465-2 [DOI] [PMC free article] [PubMed]

- Choon Rhee KH. Functionality of soy proteins. In: Hettiarachy NS, Zieglar GR, editors. Protein functionality in food systems. New York: M Dekker; 2004. pp. 311–324. [Google Scholar]

- Drakos A, Kiosseoglou V. Stability of acidic egg white protein emulsions containing xanthan gum. J Agric Food Chem. 2006;54:10164–10169. doi: 10.1021/jf061306d. [DOI] [PubMed] [Google Scholar]

- Drakos A, Kiosseoglou V. Depletion flocculation effects in egg-based model salad dressing emulsions. Food Hydrocoll. 2008;22:218–224. doi: 10.1016/j.foodhyd.2006.11.003. [DOI] [Google Scholar]

- Fukushima D. Recent progress of soybean protein foods: chemistry, technology, and nutrition. Food Rev Int. 1991;7:323–351. doi: 10.1080/87559129109540915. [DOI] [Google Scholar]

- Ghoush MA, Samhouri M, Al-Holy M, Herald T. Formulation and fuzzy modeling of emulsion stability and viscosity of gum-protein emulsifier in a model mayonnaise system. J Food Eng. 2008;84:348–357. doi: 10.1016/j.jfoodeng.2007.05.025. [DOI] [Google Scholar]

- Goankar G, Koka R, Chen K, Campbell B. Emulsifying functionality of enzyme– modified milk proteins in o/w and mayonnaise-like emulsions. Afr J Food Sci. 2010;4:16–25. [Google Scholar]

- Koshiyama I. Storage proteins of soybean. In: Gottschalk W, Müller HP, editors. Seed proteins biochemistry, genetics, nutritive value. The Hague: Martinus Nijhoff/Dr W. Junk; 1983. pp. 427–450. [Google Scholar]

- Maghsoudi SH. The technology of sauces producing. Tehran: Marzedanesh; 2004. pp. 3–118. [Google Scholar]

- Mangino ME. Protein interactions in emulsions: protein-lipid interactions. In: Hettiarachchy NS, Ziegler GR, editors. Protein functionality in food systems. New York: M Dekker; 1994. pp. 147–180. [Google Scholar]

- McClements DJ (2009) Biopolymers in food emulsions. In: Kasapis S, Norton IT, Ubbink JB (ed) Modern Biopolymer Science, Springer. pp 129–166

- McClements DJ, Demetriades K. An integrated approach to the Development of reduced-fat food emulsions. Crit Rev Food Sci Nutr. 1998;38:511–536. doi: 10.1080/10408699891274291. [DOI] [PubMed] [Google Scholar]

- Mine Y. Emulsifying characterization of hen's egg yolk proteins in oil-in-water emulsions. Food Hydrocoll. 1998;12:409–415. doi: 10.1016/S0268-005X(98)00054-X. [DOI] [Google Scholar]

- Mun S, Kim YL, Kang CG, Park KH. Development of reduced-fat mayonnaise using 4αGTASE modified rice starch and xanthan gum. Int J Biol Macromol. 2009;44:400–407. doi: 10.1016/j.ijbiomac.2009.02.008. [DOI] [PubMed] [Google Scholar]

- Nikzade V, Mazaheri Tehrani M, Saadatmand-Tarzjan M. Optimization of low-cholesterol low-fat mayonnaise formulation: effect of using soy milk and some stabilizer by a mixture design approach. Food Hydrocoll. 2011;28:344–352. doi: 10.1016/j.foodhyd.2011.12.023. [DOI] [Google Scholar]

- Poongodi Vijayakumar T, Boopathy P (2012) Optimization of ingredients for noodle preparation using response surface methodology. J Food Sci Technol. doi:10.1007/s13197-012-0641-z [DOI] [PMC free article] [PubMed]

- Vasu Pallavi B, Chetana R, Yella Reddy S (2011) Processing, physico-chemical, sensory and nutritional evaluation of protein, mineral and vitamin enriched peanut chikki - an Indian traditional sweet. J Food Sci Technol. doi:10.1007/s13197-011-0467-0 [DOI] [PMC free article] [PubMed]

- Wolf WJ. Soybean proteins: their functional, chemical and physical properties. J Agric Food Chem. 1970;18:969–976. doi: 10.1021/jf60172a025. [DOI] [Google Scholar]

- Wolf WJ, Sly DA. Cryoprecipitation of Soybean 11S Protein. Cereal Chem. 1967;44:653–668. [Google Scholar]

- Worrasinchai S, Suphantharika M, Pinjai S, Jamnong P. β- Glucan prepared from spent brewer҆s yeast as a fat replacer in mayonnaise. Food Hydrocoll. 2006;20:68–78. doi: 10.1016/j.foodhyd.2005.03.005. [DOI] [Google Scholar]