Abstract

Misti dahi, a popular ethnic delicacy of eastern India analogous to caramel coloured set style sweetened yoghurt, besides several therapeutic virtues, contains high fat and sugar. Alike people elsewhere in the world, people in India too are now becoming health conscious and are aware of the relation between diet and health. Hence, high fat and sugar contents are causes of concern for the successful marketing of misti dahi in India. With a view to enhance the health attributes of misti dahi and improve marketability, three commercial dietary fiber preparations (inulin, soy fiber and oat fiber) were incorporated and their effect on the product's quality in terms of physicochemical, sensory and textural quality was assessed. Standard method was followed for the preparation of fiber fortified misti dahi (FFMD). Among the three dietary fibers, inulin significantly decreased viscosity and instrumental firmness and increased lightness (L*), redness (a*), yellowness (b*), syneresis and work of shear values of FFMD. Oat fiber settled at the bottom and gave a poor appearance. Soy fiber did not affect the flavor of FFMD. Although overall acceptability scores of inulin and soy fiber containing FFMD were significantly lower than control, they were still above the minimum acceptable score. Based on the results obtained in the present study, it was concluded that acceptable quality FFMD could be prepared using inulin and soy fiber at 1.5 % level of fortification.

Keywords: Misti dahi, Inulin, Soy fiber, Oat fiber, Fortification, Back extrusion

Introduction

Traditional dairy products and sweets are an integral part of Indian heritage. About 9 % of the total milk produced in India is converted into fermented milk products (Singh 2007). In eastern India, the traditional fermented dairy product, dahi, has been elevated to a dessert by sweetening it. The sweetened variety of dahi is popularly known as misti dahi or misthi doi and is analogous to caramel coloured set style sweetened yoghurt. With the successful development of a technology for the industrial production of misti dahi (Ghosh and Rajorhia 1990), it is now being manufactured and marketed in different parts of the country (Rao and Solanki 2007). Despite its several useful virtues as a fermented dairy product, presence of fat (1–12 %) and cane sugar (6–25 %) (Ghosh and Rajorhia 1987; Sarkar et al. 1992, 1996), in misti dahi is a cause of concern for calorie and health conscious people.

With the growing awareness of the link between diet and health among consumers, the demand for dietary fiber fortified health-based traditional Indian dairy products, without compromising the taste and texture, is increasing (Pal 2008). Dietary fiber promotes beneficial physiological effects including laxation, and/or blood cholesterol attenuation, and/or blood glucose attenuation (AACC 2001). Soybean fibers have claimed to exhibit multiple physiological benefits, like the regulating effect on blood lipids, glucose metabolism and nutrients absorption (Erdman and Fordyce 1989). Inulin is known for reduced calorific value and provide dietary fiber effects. It is neither digested nor absorbed in the small intestine, but is fermented in the colon by beneficial bacteria (Franck 2006). Prebiotic effects of inulin have attracted many food scientists across the world as a suitable fiber source for fortification (Nair et al. 2010) and have been associated with enhancing the gastrointestinal system and immune system. In addition, it has been shown to increase the absorption of calcium and magnesium (Bosscher et al. 2006), influence the formation of blood glucose, and reduce the levels of cholesterol and serum lipids (Causey et al. 2000).

Milk and most milk products are devoid of dietary fiber. Worldwide, growing awareness of the physiological benefits of dietary fiber, among consumers, coupled with the ready availability of commercial dietary fiber preparations, led to the successful development of various dietary fiber fortified dairy products such as yoghurt (Fernandez-Garcia and McGregor 1997; Fernandez-Gracia et al. 1998; Staffolo et al. 2004; Garcia-Perez et al. 2005; Aportela-Palacios et al. 2005; Kip et al. 2006; Aryana and McGrew 2007; Aryana et al. 2007; Guggisberg et al. 2009), cheese (Buriti et al. 2007, 2008; Cardarelli et al. 2008), imitation cheese (Hennelly et al. 2006), ice cream (Singh et al. 2005; Akalin et al. 2008), probiotic ice-cream (Akalin and Erisir 2008), yog-ice cream (El-Nagar et al. 2002; Ahmadi et al. 2012), dairy dessert (Tarrega and Costell 2006), lactic beverage (de-Castro et al. 2009; Villegas and Costell 2007). In India, some traditional milk-based confections like gajar-pak (milk-carrot based), giya-ka-halwa (milk-bottle gourd based), doda-burfi (milk-wheat based), kaju-burfi (milk-cashew nut based); cereals-based milk desserts like kheer and dalia (Patel and Arora 2005) and milk-cereal based beverages like raabadi (Pal 2008; Modha and Pal 2011) contain significant quantities of dietary fiber. Further, attempts were made to fortify other commonly consumed Indian milk products such as dahi, lassi, kheer, paneer (Kantha and Kanawjia 2007), whey based lassi-like beverage (Nair and Thompkinson 2008) with different commercial dietary fiber preparations to confer on them the physiological benefits of dietary fiber.

Because of the pleasant caramel and sour taste cherished by all age groups and the availability of technology for the industrial manufacture, misti dahi is now being sold in various parts of the country by leading brand owners. However, in the present health foods regime, the growing awareness of the relation between diets containing high fat and high sugar and non-communicable diseases among the consumers may impede the successful marketing of misti dahi in other areas. Recently, work has been carried out to partially address this concern by developing reduced fat (Raju and Pal 2009) and artificially sweetened misti dahi (Raju and Pal 2011) for the benefit of health conscious people. Fortification of misti dahi with dietary fiber can provide the product with a spectrum of health benefits to the consumer. Earlier studies have reported that source of dietary fiber affects both the sensory and textural properties of cultured dairy products (Fernandez-Garcia and McGregor 1997; Staffolo et al. 2004). Hence, the present study was undertaken to study the effect of some commercially available dietary fiber preparations on the physico-chemical, sensory and textural properties of misti dahi.

Materials and methods

Raw materials and ingredients

Milk

Fresh raw buffalo whole milk and skimmed milk were procured from the Experimental Dairy of the National Dairy Research Institute (NDRI), Karnal (India).

Starter culture

The mixed culture NCDC-263 containing Streptococcus thermophilus and Lactobacillus bulgaricus obtained from the National Collection of Dairy Cultures, NDRI, Karnal was used as starter culture. The starter culture was maintained in autoclaved reconstituted skimmed milk (12 g/100 mL) by sub-culturing once in a fortnight for attaining high activity.

Dietary fibers

Dietary fibers used in the study viz. oat fiber (Vitacel® HF-600®), soy fiber (Fimbrim®) and inulin (Raftiline® ST) were supplied by M/sJ. Rettenmair and Sohne Gmbh (Germanay), M/s Solae Company (Gurgaon, India) and M/s Orafti Active Food Ingredients (Belgium), respectively.

Other ingredients

Medium heat classified mixed milk (buffalo and cow) skimmed milk powder (SMP) with about 3–4 whey protein nitrogen index (WPNI) (as per manufacturer’s report) was procured from M/s Modern Dairies Ltd., Karnal while cane sugar was obtained from the market. Caramel powder (P-III-190) (E 150 c) was supplied by M/s Alvin Chemicals (India) Pvt. Ltd. (Ahmednagar, India).

Preparation of fiber fortified misti dahi (FFMD)

Misti dahi was prepared from reduced fat buffalo milk as per the procedure described by Raju and Pal (2009). Fresh raw buffalo milk was divided into four batches of 2.5 kg each and was standardized to 3 % milk fat and 15 % solids-not-fat (SNF) using fresh raw skimmed buffalo milk and skimmed milk powder (SMP), respectively. All the batches were preheated to 60–65 °C. Cane sugar and caramel were added to each batch at a rate of 14 g/100 mL and 0.1 g/100 mL, respectively. In the present study, in the absence of legal standards for fiber fortified dairy products in India, the level of fiber incorporation in misti dahi was chosen slightly above the level (1.3 g/100 mL) as per earlier works carried out on similar products elsewhere in the world (Fernandez-Garcia and McGregor 1997; Fernandez-Gracia et al. 1998; Staffolo et al. 2004). Among the four batches, three were fortified with 1.5 g dietary fibers each of inulin (T2), soy fiber (T3) and oat fiber (T4) per 100 mL of mix and the one to which no fiber were added was treated as control (T1). Homogenization of all the batches was carried out (60 °C) in a two stage homogenizer (M/s Goma Engineers, Mumbai) with 6.89 MPa (1000 psi) and 3.44 MPa (500 psi) pressures at first and second stages, respectively. All the batches of misti dahi mixes were pasteurized at 90 °C for 10 min and then cooled to 45 °C. Then the starter culture was added at a rate of 2 g/100 mL to each batch and filled into pre-sterilized 100 mL standard cups (M/s Tarsons Products Pvt. Ltd., Kolkata). Incubation was carried out at 42 ± 1 °C for about 5–6 h till a final titratable acidity of 1 % expressed as lactic acid was reached. Once the desired acidity was obtained, without disturbing the set product, cups were transferred to refrigerated storage (6–8 °C). All the trials were carried out in triplicate.

Physico-chemical analysis

Titratable acidity

Titratable acidity in terms of per cent lactic acid was determined by adopting the method as described by AOAC for cheese (AOAC 1975). Two grams of sample was taken in a porcelain dish and mixed homogenously by adding 20 mL hot distilled water (65 °C). This was followed by addition of 10 mL of 0.1 mol equi/L sodium hydroxide and 1 mL of 0.5 g/100 mL phenolphthalein indicator. The mixture was titrated against 0.1 mol equi/L hydrochloric acid with continuous stirring till the pink color disappeared completely.

Water activity

Water activity of misti dahi was measured using water activity meter “Aqua Lab” (Model Series 3 TE) supplied by Decagon Devices, WA, USA. Prior to the measurement the samples were tempered to 25 °C.

Color

The surface color of set fiber fortified misti dahi was measured using a “Colorflex” colorimeter supplied by Hunterlab (Hunter Associates Laboratory, Inc., Reston, VA, USA) along with the software (version 4.10) and the results were expressed in terms of CIELAB system. Before the test, the instrument was calibrated with standard black and white tiles as specified by the manufacturer. The light source was dual beam xenon flash lamp. Data was received through the software in terms of L* (lightness), ranging from 0 (black) to 100 (white), a* (redness), ranging from +60 (red) to −60 (green) and b* (yellowness), ranging from +60 (yellow) to −60 (blue) values. For this, the pasteurized and cooled fiber fortified misti dahi mix was filled (75 mL) into a pre-sterilized glass beaker (10 cm height and 6 cm dia.) up to 3 cm and incubation was carried out along with the other cups. After about 16 h of storage at refrigerated temperature (6–8 °C), the cups were removed from the refrigerator and tempered at 25 °C for 2 h. Later the contents of the beakers were loosened from the sides with the help of a spatula and the contents were inverted and transferred into the sample container attached with the Colorflex instrument. During transfer care was taken to avoid breaking of the gel/curd. Readings were taken in triplicate for each sample.

Syneresis

Syneresis was determined following drainage method as described by Chawla and Balachandran (1994). In this case, after about 16 h of storage under refrigeration, the set FFMD cups were taken out and tempered to 25 °C. With the help of a spatula the contents of the cups were loosened from the sides and straight away emptied into a glass funnel (12.5 cm dia) with a Whatman No.1 filter paper (15.0 cm dia). The funnel was placed on a graduated glass cylinder (23 × 3.5 cm) of 100 mL capacity. The funnel with cylinder was kept in the room maintained at 25 °C. The quantity of whey collected after 2 h of drainage was considered as syneresis and expressed as per cent whey separated.

Viscosity

For measuring the viscosity, the FFMD samples were tempered to 20 °C and stirred gently 20 times in clockwise and anti-clockwise direction using a spatula and filled into a concentric rotational viscometer (Contraves Rheomat RM 108 ER) supplied by M/s Metler-Toledo, Switzlerland. Viscosity was measured using a 2–2 measuring system with a shear rate of 50 s-1 as per the procedure described in the supplier’s manual.

Texture measurement

Textural attributes such as firmness and stickiness were determined by back extrusion method using a texture analyzer, TA-XT2i (M/s Stable Micro Systems, UK) fitted with a 25 kg load cell and was calibrated with 5 kg standard dead weight prior to use. For determining the textural attributes, the pasteurized and cooled misti dahi mix was filled (~125 mL) up to 5 cm in a pre-sterilized glass beaker (10 cm height and 6 cm dia.) and incubation was carried out. The beakers were tempered at 25 °C for 2 h prior to analysis. The probe (A/BE 35) was penetrated up to 10 mm (20 % compression) into the set misti dahi at a cross head speed of 1.0 mm/s. The probe displaced the material by compression followed by back-extrusion, so that the fluid flowed upwards through the concentric annular space. From the resulting force-time curves, firmness i.e., the force for compression (N), stickiness i.e., the negative peak force (N) during withdrawal, work of shear (N.s) and work of adhesion (N.s) were calculated using the Texture Expert Exceed software (v 2.55) supplied by the manufacturer along with the instrument. All measurements were done in quadruplicate per each sample.

Sensory analysis

The cups of misti dahi subjected to different treatments were drawn from the refrigerator just before sensory evaluation. All the samples were evaluated for sensory attributes such as colour and appearance, body and texture, flavor and overall acceptability on a 9-point hedonic scale (9 for liking extremely and 1 for disliking extremely) by a panel of six semi-trained (discriminative and communicative) judges (5 male and 1 female with age ranged between 49–62 years) from the Faculty of Dairy Technology Division of NDRI, Karnal. As the nine-point hedonic scale occupies a unique place in terms of its general applicability to the measurement of product acceptance-preference (Stone and Sidel 2004) it was selected for the present study. The panelists have not been trained for the present study but they are dairy professionals having adequate knowledge about the sensory evaluation methods and the product attributes. Randomly one cup (100 mL) of each treatment was drawn from the refrigerator just before serving and was served to each panelist for judging. The colour and appearance scores were given by looking at the colour of the FFMD and presence or absence of whey separation on the surface of FFMD. Then a spoonful of FFMD was placed in the mouth and how it sticks to the tongue and sides of the mouth was noticed. The body and texture score was given based on the overall perception of sample’s firmness (force required to compress FFMD between the tongue and the palate), adhesiveness (amount of FFMD stuck to the tongue and palate after compression), thickness (consistency of FFMD after initial compression between tongue and the palate) and dissolvability (ease with which FFMD dissolved) in the mouth. After noticing the body and texture, the flavours and sensations perceived in the mouth were observed and recognized. Acidity, sweetness and caramel taste are one of the first sensations of misti dahi. Accordingly, the flavour scores of FFMD were given. Based on the overall perception of the samples, the overall acceptability scores of FFMD were given by the panelists. For any sensory attribute a minimum score of 6.5 (between like slightly and like moderately) was considered commercially acceptable.

Statistical analysis

The results obtained in the present study were subjected to analysis of variance (ANOVA) using MS-Excel software (v 2003) (Microsoft Corporation (I) Pvt. Ltd., Gurgaon, India). Data obtained from the triplicate trials were used for statistical analysis. Among the various available methods for finding out the significantly different treatment means, techniques such as least significant difference (LSD), also called as critical difference (CD) and the Duncan’s multiple range test (DMRT) are commonly applied. In the present study, LSD was calculated as per the method described by Rangaswamy (1995) and the significant differences were determined at 95 % level of confidence. Pearson’s correlation coefficients between sensory and instrumental parameters were calculated using SPSS v.16.0 for Windows software (SPSS South Asia (P) Limited, Bangalore, India).

Results and discussion

Sensory attributes

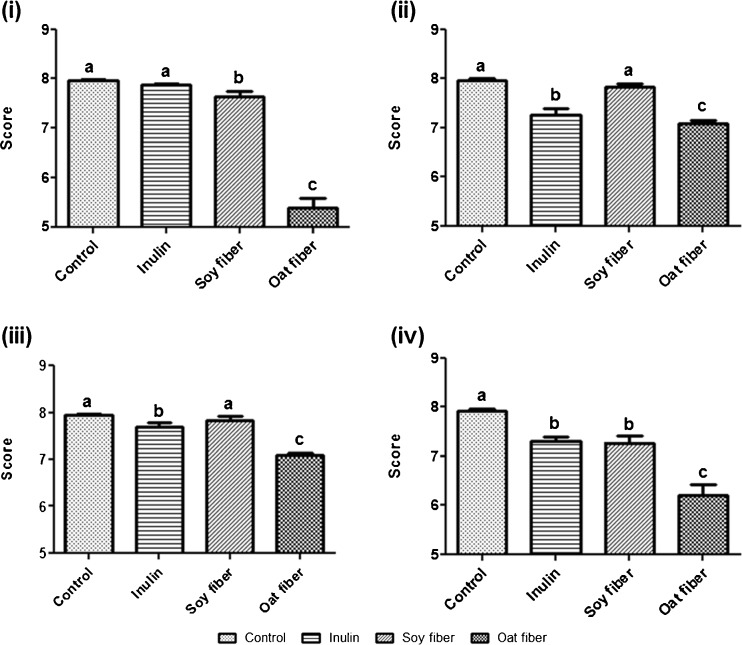

The effect of different dietary fibers on the sensory attributes of misti dahi is given in Fig. 1. It can be seen that highly significant differences were observed among all the sensory attributes of misti dahi (p < 0.01) (Table 1). The control misti dahi had higher colour and appearance score in comparison with misti dahi containing fibers. Among fiber containing samples, T4 (oat fiber) samples received significantly low score (5.39) from the panelists (p < 0.01) because of formation of a clear layer of settled oat fiber that was observed in all T4 cups. Fernandez-Garcia and McGregor (1997) reported that addition of sugar beet fiber and rice fiber significantly lowered the appearance scores of sweetened plain yoghurt. Contrary to present finding, Fernandez-Garcia and McGregor (1997) reported that yoghurt fortified with two oat fibers containing 88 % and 97 % insoluble dietary fiber, respectively at 1.32 g/100 mL level each were found to be commercially acceptable. Oat fiber used in the present study contained about 93 % insoluble fiber (as per manufacturer’s report) that got settled at the bottom of the cup with definite aggregates during incubation and resulted in an unacceptable appearance. This coupled with increased syneresis in T4 samples (Fig. 2) could be attributed for the lowest colour and appearance score of oat fiber containing misti dahi (T4). Although, inulin (T2) and soy fiber (T3) containing misti dahi recorded lower scores (7.88 and 7.64, respectively) compared to control (T1) (7.97), the mean scores were above 6.5 indicating acceptable quality.

Fig. 1.

Effect of dietary fibers on sensory attributes of misti dahi: (i) colour and appearance; (ii) body and texture; (iii) flavour; and (iv) overall acceptability. Each observation is a mean ± SD of three replicates (n = 3). abc mean values of treatments within a graph with different letters significantly differ (p < 0.05)

Table 1.

Analysis of variance for sensory, physico-chemical and textural properties of fiber fortified misti dahi

| Parameter | Mean sum of squares for dietary fibers as source of Variation | F-value | LSD(0.05) |

|---|---|---|---|

| Sensory attributes | |||

| Colour and appearance | 4.533 | 115.437** | 0.22 |

| Body and texture | 0.567 | 29.416** | 0.15 |

| Flavour | 0.432 | 31.077** | 0.13 |

| Overall acceptability | 1.524 | 25.938** | 0.27 |

| Physico-chemical properties | |||

| Acidity | 0.012 | 5.318* | 0.05 |

| Water activity | 0.000 | 20.250** | 0.0006 |

| Viscosity | 0.012 | 4.241** | 0.95 |

| Syneresis | 3.091 | 28.289** | 0.023 |

| Lightness (L*) | 2.274 | 28.785** | 0.31 |

| Redness (a*) | 0.099 | 6.248** | 0.14 |

| Yellowness (b*) | 0.083 | 1.380* | 0.27 |

| Textural attributes | |||

| Firmness | 0.837 | 27.006** | 0.195 |

| Stickiness | 0.005 | 0.658ns | 0.09 |

| Work of shear | 83.406 | 3.227ns | 5.64 |

| Work of adhesiveness | 0.023 | 0.214ns | 0.36 |

* P < 0.05, ** P < 0.01, ns non-significant, LSD (0.05) = Least Significant difference at 5 % level of significance

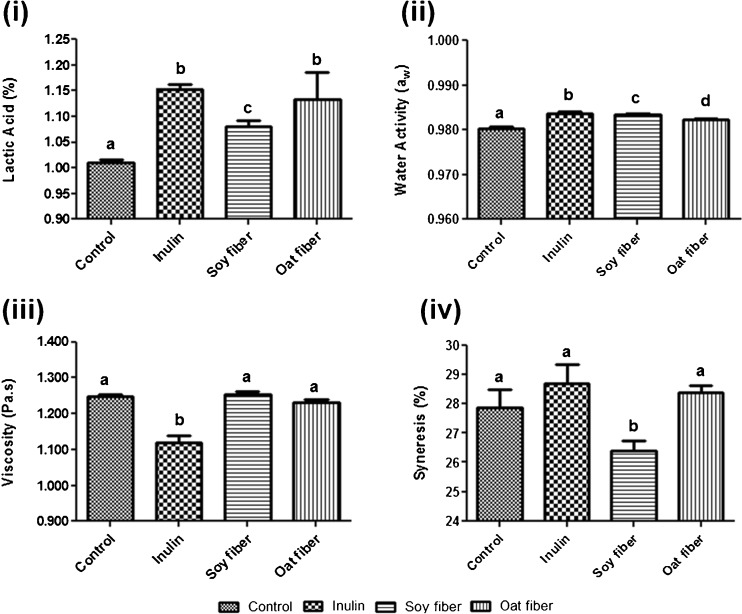

Fig. 2.

Effect of dietary fibers on the physico-chemical properties of mishi dahi: (i) acidity; (ii) water activity; (iii) viscosity; and (iv) syneresis. Each observation is a mean ± SD of three replicates (n = 3). abcd mean values of treatments within a graph with different letters significantly differ (p < 0.05)

Among the FFMD samples, inulin (T2) and oat fiber (T4) containing batches received significantly low body and texture scores (p< 0.01). However, soy fiber containing samples (T3) were comparable with control (T1) (p > 0.05) (Fig. 1). The reduced body and texture scores of fiber fortified misti dahi are in agreement with the results of fiber fortified yoghurt as reported by Fernandez-Garcia and McGregor (1997). The lower score for body and texture of FFMD could be attributed to interactions of the fiber with milk solids that led to weak gel formation. The instrumental firmness results of FFMD given in Textural attributes section confirm the same.

In general, fiber incorporation significantly decreased the flavour scores of misti dahi (Table 1). Inulin and oat fiber significantly (p < 0.01) lowered the flavour scores of misti dahi. However, the flavour score of soy fiber containing samples (T3) was not different from the control (p > 0.05). Fernandez-Gracia et al. (1998) reported that fiber addition significantly reduced the flavour scores of yoghurt. Contrary to our results, Fernandez-Garcia and McGregor (1997) reported that soy fiber with more amount of insoluble fiber reduced the flavour score of yoghurt while the flavour scores of oat fiber containing yoghurt were comparable to control.

Fiber fortification significantly reduced the overall acceptability of FFMD compared to control misti dahi (p < 0.01). Among all the batches, oat fiber containing misti dahi (T4) recorded least acceptability score (p < 0.01). Although the overall acceptability scores of T2 and T3 batches were less compared to control, the difference was not significant (p > 0.05). The reduced overall acceptability score (6.21) of T4 batch could also be attributed to poor appearance and increased syneresis (Fig. 2). In the present study, although fiber containing misti dahi recorded lower scores compared to control (T1), the mean scores of inulin (T2) and soy fiber (T3) containing FFMD were above 6.5 indicating that FFMD of acceptable quality could be manufactured using inulin and soy fiber.

Physico-chemical properties

The effect of incorporation of dietary fibers on the physico-chemical characteristics of misti dahi is given in Fig. 2 with their statistical analysis results in Table 1. It can be observed that fiber incorporation significantly (p < 0.01) affected most of the physico-chemical properties. The fiber incorporation led to increased acidity of misti dahi (p < 0.05). Inulin containing misti dahi (T2) recorded significantly higher (p < 0.05) acidity than the control (T1) and soy fiber (T3) containing samples. Inulin contains soluble fiber (Franck 2006) which might have been easily digested by the bacteria resulting in the formation of byproducts such as organic acids (Fernandez-Garcia and McGregor 1997; Fernandez-Gracia et al. 1998) including lactic acid leading to increased titratable acidity. Fernandez-Gracia et al. (1998) reported that oat fiber addition in sweetened yoghurt slightly increased the lactic acid content after 6 h of fermentation. Fernandez-Garcia and McGregor (1997) reported that fiber addition did not significantly affect lactic acid production by the starter cultures although, at the end of the fermentation and after 4 weeks of cold storage, a higher concentration of lactic acid in the fiber fortified yoghurts with similar pH values was observed. Similar observations were made by Aryana (2006) in fiber fortified probiotic fat-free plain set yoghurt. Our observation in the present study, the higher acidity of FFMD fortified with dietary fibers, is in the order of earlier reports.

Soy fiber (T3) significantly reduced the syneresis of misti dahi compared to control and other batches. Inulin (T2) and oat fiber (T4) addition resulted in slight increase in syneresis in FFMD (Fig. 2), which was insignificant (p > 0.05). Guven et al. (2005) reported that inulin significantly increased whey separation in set-type low-fat yoghurt. However, it was reported that upon storage for 3 days inulin resulted in decreased whey separation (p < 0.01). Garcia-Perez et al. (2005) reported that addition of orange fiber at 0.6 % and 0.8 % had a breakening effect in the gel structure of yoghurt which led to increase in syneresis. Further, when added at 1 % level, the syneresis decreased due to increased water holding of fiber that absorbed the whey released by the gel structure (Garcia-Perez et al. 2005). However, Aryana (2006) reported that the average syneresis values of most fiber fortified yogurts were comparable to the control. Decreased syneresis of T3 samples could be attributed to the water holding capacity of soy fiber. The slight increase in syneresis of inulin containing misti dahi could be due to disturbance in gel structure that led to whey separation.

Water activity significantly (p < 0.01) increased with fiber incorporation into misti dahi (Table 1). T2 samples recorded the highest water activity among all the batches. Water activity gives a better indication about water’s ability to function as a reactant and solvent (Bell 2007). In the present study, the gel structure of misti dahi was observed to be affected by fiber fortification as revealed by lower body and texture scores (Fig. 1) and increased syneresis (Fig. 2). Expulsion of water from the gel matrix of misti dahi due to the presence and interaction of fibers that led to increased syneresis could be attributed to increased water activity of FFMD samples.

Many researchers reported that the apparent viscosity of yoghurts affected differently depending on the type of fiber source. In the present study, it was observed that inulin (T2) significantly decreased the viscosity of misti dahi (p < 0.01) while soy fiber and oat fiber did not affect the viscosity (p > 0.05) (Fig. 2). Staffalo et al. (2004) reported that the apparent viscosity of yoghurt decreased when inulin was incorporated at 1.3 %. Fernandez-Garcia and McGregor (1997) reported that fiber treatments increased the apparent viscosity of the yoghurt compared to control but the differences were insignificant. However, Aryana (2006) reported that the apparent viscosity of fiber fortified yoghurts were comparable to the control when six different fibers were separately added at 0.02 % level. Fernandez-Gracia et al. (1998) reported that fiber addition resulted in significant increase in apparent viscosity. Aportela-Palacios et al. (2005) reported that wheat bran addition led to significant increase in the apparent viscosity of yoghurt. The reduction in the viscosity of inulin fortified misti dahi (T2) could be due to interaction of inulin and milk proteins and thus formation of weak gel.

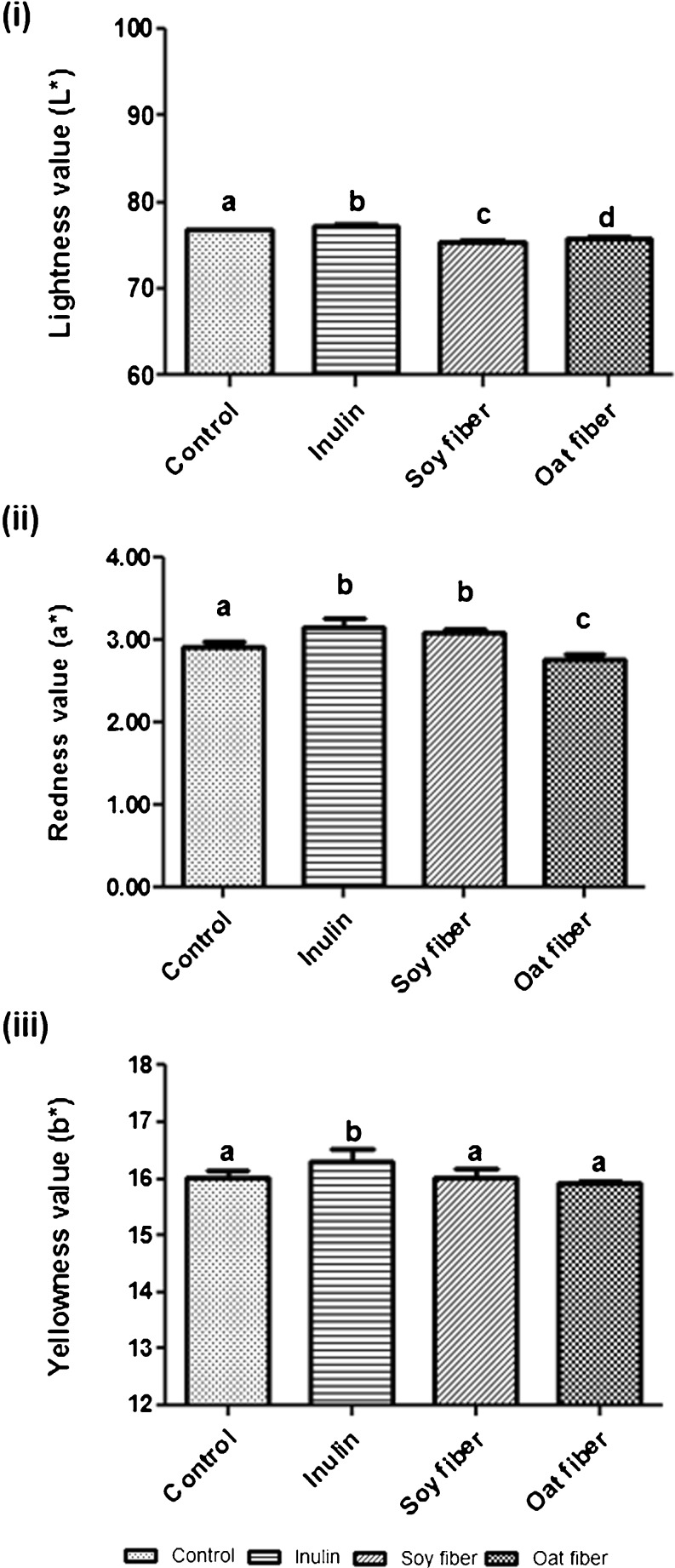

Fiber fortification led to significant changes in the instrumental colour of misti dahi (Table 2). It can be seen from Fig. 3 that lightness (L*) values of misti dahi were significantly decreased in T3 and T4 batches (p < 0.01) compared to control (T1). Mean L* value (77.24) of T2 samples was observed to be significantly higher (p < 0.01) compared to T1 samples (76.77). Soy fiber (75.35) and oat fiber (75.77) addition significantly reduced the L* value of misti dahi compared to control (p < 0.01). Staffalo et al. (2004) reported that among different fibers studied, only apple fiber addition imparted distinctive brownish colour and lower L* value to yoghurt. In a study on prebiotic fiber fortified yoghurt, Aryana (2006) reported that L* value of Hydrobind, an off-white to light grey coloured commercial dietary fiber, was significantly lower than the L* values of other studied fibers. The redness value of misti dahi increased significantly (p < 0.01) with soy fiber and inulin fortification while significantly reduced (p < 0.01) with oat fiber fortification. The yellowness of misti dahi increased significantly (p < 0.05) with inulin incorporation while decreased significantly with oat incorporation (p < 0.05).

Table 2.

Pearson’s correlation coefficients between sensory attributes, physico-chemical and textural parameters

| CA | BT | FL | OA | Acd | aw | Visc | Syn | L* | a* | b* | Frm | Stk | WS | WA | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Colour and appearance (CA) | 1.000 | ||||||||||||||

| Body and texture (BT) | 0.680* | 1.000 | |||||||||||||

| Flavour (FL) | 0.915** | 0.780* | 1.000 | ||||||||||||

| Overall acceptability (OA) | 0.889* | 0.806* | 0.901* | 1.000 | |||||||||||

| Acidity (Acd) | −0.304 | −0.640* | −0.426 | −0.405 | 1.000 | ||||||||||

| Water activity (aw) | −0.033 | −0.490 | −0.164 | −0.391 | 0.585* | 1.000 | |||||||||

| Viscosity (Visc) | −0.204 | 0.537 | −0.001 | 0.003 | −0.631* | −0.537 | 1.000 | ||||||||

| Syneresis (Syn) | −0.212 | −0.507 | −0.341 | −0.152 | 0.311 | −0.189 | −0.500 | 1.000 | |||||||

| Lightness (L*) | 0.442 | −0.089 | 0.291 | 0.406 | −0.022 | −0.152 | −0.640* | 0.510 | 1.000 | ||||||

| Redness (a*) | 0.606* | 0.193 | 0.500 | 0.327 | 0.111 | 0.505 | −0.428 | −0.377 | 0.301 | 1.000 | |||||

| Yellowness (b*) | 0.353 | −0.190 | 0.220 | 0.123 | 0.296 | 0.467 | −0.599* | −0.197 | 0.399 | 0.592* | 1.000 | ||||

| Firmness (Frm) | 0.773** | 0.777** | 0.853** | 0.849** | −0.726** | −0.540 | 0.191 | −0.085 | 0.375 | 0.184 | −0.042 | 1.000 | |||

| Stickiness (Stk) | −0.316 | −0.174 | −0.476 | −0.251 | 0.495 | −0.046 | 0.012 | 0.269 | −0.149 | −0.316 | −0.296 | −0.513 | 1.000 | ||

| Work of Shear (WS) | 0.512 | 0.027 | 0.386 | 0.372 | −0.043 | 0.207 | −0.526 | 0.305 | 0.543 | 0.449 | 0.112 | 0.386 | −0.419 | 1.000 | |

| Work of Adhesion (WA) | 0.264 | 0.206 | 0.187 | 0.317 | 0.254 | −0.078 | −0.165 | −0.067 | 0.182 | 0.118 | 0.282 | −0.017 | 0.533 | −0.437 | 1.000 |

* Correlation is significant at 0.05 level (P < 0.05) ** Correlation is significant at 0.01 level (P < 0.01)

Fig. 3.

Effect of dietary fibers on colour (CIELAB) of mishi dahi: (i) lightness (L*); (ii) redness (a *); and (iii) yellowness (b *). Each observation is a mean ± SD of three replicates (n = 3). abcd mean values of treatments within a graph with different letters significantly differ (p < 0.05)

Textural attributes

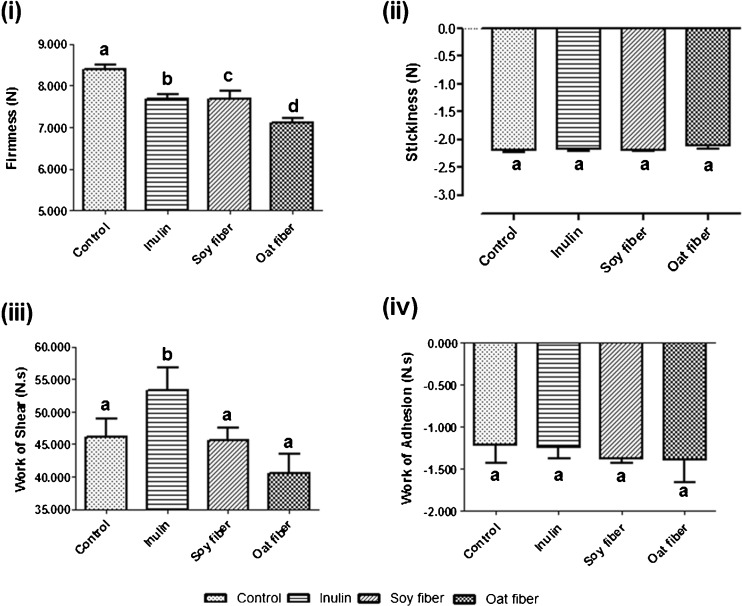

Texture of misti dahi as affected by incorporation of different dietary fibers is given in Fig. 4. Fiber fortification significantly reduced the firmness of misti dahi (p < 0.01) (Table 1) and among all the fibers, oat fiber containing misti dahi recorded the lowest firmness value. The decreased firmness values of misti dahi could be attributed to the disrupting effect of fiber on the gel.

Fig. 4.

Effect of dietary fibers on textural attributes of mishi dahi: (i) Firmness; (ii) Stickiness; (iii) Work of shear; and (iv) Work of adhesion. Each observation is a mean ± SD of three replicates (n = 3). abcd mean values of treatments within a graph with different letters significantly differ (p < 0.05)

Work of shear is the amount of force required to perform shearing process. It thus measures the resistance offered by the sample throughout the probe penetration, unlike the maximum force or peak force measured for firmness/hardness. Inulin significantly increased the work of shear than the control and other fiber containing samples (p < 0.05). However, no significant change in work of shear was observed between the soy fiber and oat fiber containing misti dahi (p > 0.05). In the present study, work of shear decreased with oat fiber and soy fiber addition but increased with inulin addition.

Stickiness is an important sensory attribute of semi-solid food materials, which is described as a feeling that can be perceived by tongue and palate (Adhikari et al. 2001). The degree to which the product becomes loose from different parts of the mouth determines the intensity of stickiness. The work of adhesion values increased by fortification with all the fibers. However, no significant differences were observed in the stickiness and work of adhesion values upon fiber fortification in misti dahi (p > 0.05). Garcia-Perez et al. (2006) reported that low doses of orange fiber viz. 0.6 % and 0.8 % reduced textural parameters whereas 1 % fiber addition improved textural properties.

Correlation between sensory and instrumental parameters

Pearson’s correlation coefficients between sensory and instrumental data are presented in Table 2. Overall acceptability of FFMD was highly and positively correlated with colour and appearance (r = + 0.889, p < 0.05), flavour (r = + 0.901, p < 0.05) and body and texture (r = + 0.806, p < 0.05). Body and texture was positively correlated with colour and appearance (r = + 0.680, p < 0.05). The correlation of flavour scores was highly positive with colour and appearance (r = + 0.915, p < 0.01) and body and texture (r = + 0.780, p < 0.05) scores. Syneresis negatively correlated with all the sensory attributes but the correlation was found to be non significant (p > 0.05). Redness (a*) was positively correlated with colour and appearance (r = + 0.606, p < 0.05). The correlation of firmness was highly positive with all the sensory attributes viz. colour and appearance (r = + 0.773, p < 0.01), flavor (r = + 0.853, p < 0.01), body and texture (r = + 0.777, p < 0.01, and overall acceptability (r = + 0.849, p < 0.01). Stickiness was negatively correlated with all the sensory attributes but the correlation was observed to be non-significant (p > 0.05).

Conclusion

With a view to improve the health benefits of misti dahi, three commercially available dietary fiber preparations were incorporated and their effect on the quality of the product was determined. Among the three dietary fibers, inulin significantly decreased viscosity and instrumental firmness and increased lightness (L*), redness (a*), yellowness (b*), syneresis and work of shear values of FFMD. Oat fiber settled at the bottom and gave a poor appearance. Soy fiber did not affect the flavor of FFMD. Although overall acceptability scores of inulin and soy fiber containing FFMD were significantly lower than control, they were much above the minimum acceptable score. Based on the sensory analysis results obtained in the present study, it was concluded that acceptable quality FFMD could be prepared using inulin and soy fiber.

Acknowledgments

The first author is thankful to the Director, National Dairy Research Institute, Karnal for providing financial assistance in the form of Institutional Senior Research Fellowship for carrying out this work. The authors thankfully acknowledge M/s Alvin Caramel Colours (India) Pvt. Ltd., Ahmednagar, Maharashtra (India) for generously supplying caramel for the research study.

Contributor Information

P. Narender Raju, Phone: +91-184-2259597, FAX: +91-184-2250042, Email: pnr.ndri@gmail.com.

Dharam Pal, Email: dharampal_g@rediffmail.com.

References

- AACC The definition of dietary fiber. American Association of Cereal Chemists. Cereal Foods World. 2001;46(3):112–129. [Google Scholar]

- Adhikari B, Howes T, Bhandari BR, Truong V. Stickiness in foods: a review of mechanisms and test methods. Int J Food Prop. 2001;4:1–33. doi: 10.1081/JFP-100002186. [DOI] [Google Scholar]

- Ahmadi A, Milani E, Madadlou A, Mortazavi SA, Mokarram RR, Salarbashi D (2012) Synbiotic yogurt-ice cream produced via incorporation of microencapsulated lactobacillus acidophilus (la-5) and fructooligosaccharide. J Food Sci Technol. doi:10.1007/s13197-012-0679-y [DOI] [PMC free article] [PubMed]

- Akalin AS, Erisir D. Effects of inulin and oligofructose on the rheological characteristics and probiotic culture survival in low-fat probiotic ice cream. J Food Sci. 2008;73(4):M184–M188. doi: 10.1111/j.1750-3841.2008.00728.x. [DOI] [PubMed] [Google Scholar]

- Akalin AS, Karagozlu C, Unal G. Rheological properties of reduced-fat and low-fat ice cream containing whey protein isolate and inulin. Eur Food Res Technol. 2008;227:889–895. doi: 10.1007/s00217-007-0800-z. [DOI] [Google Scholar]

- AOAC . Official methods of analysis. Washington: Association of Official Analytical Chemists; 1975. [Google Scholar]

- Aportela-Palacios A, Sosa-Morales ME, Velez-Ruiz JF. Rheological and physicochemical behavior of fortified yogurt, with fiber and calcium. J Texture Stud. 2005;36:333–349. doi: 10.1111/j.1745-4603.2005.00020.x. [DOI] [Google Scholar]

- Aryana KJ. Probiotic, fiber fortified, fat free plain set yoghurt. Michwissenschaft. 2006;61(3):312–315. [Google Scholar]

- Aryana KJ, McGrew P. Quality attributes of yogurt with Lactobacillus casei and various prebiotics. LWT-Food Sci Technol. 2007;40(10):1808–1814. doi: 10.1016/j.lwt.2007.01.008. [DOI] [Google Scholar]

- Aryana KJ, Plauche S, Rao RM, McGrew P, Shah NP. Fat-free plain yoghurt manufactured with inulins of various chain lengths and Lactobacillus acidophilus. J Food Sci. 2007;72(3):M79–M84. doi: 10.1111/j.1750-3841.2007.00302.x. [DOI] [PubMed] [Google Scholar]

- Bell LN. Moisture effects on food’s chemical stability. In: Barbosa-Canovas GV, Fontana AJ, Schmidt SJ, Labuza TP, editors. Water activity in foods-fundamentals and applications. Iowa: Blackwell Publishing and IFT Press; 2007. pp. 173–198. [Google Scholar]

- Bosscher D, Van Loo J, Franck A. Inulin and oligofructose as functional ingredients to improve bone mineralization. Int Dairy J. 2006;16:1092–1097. doi: 10.1016/j.idairyj.2005.10.028. [DOI] [Google Scholar]

- Buriti FCA, Cardarelli HR, Filisetti TMCC, Saad SMI. Synbiotic potential of fresh cream cheese supplemented with inulin and Lactobacillus paracasei in co-culture with Streptococcus thermophilus. Food Chem. 2007;104(4):1605–1610. doi: 10.1016/j.foodchem.2007.03.001. [DOI] [Google Scholar]

- Buriti FCA, Cardarelli HR, Saad SMI. Influence of Lactobacillus paracasei and inulin on instrumental texture and sensory evaluation of fresh cream cheese. Braz J Pharm Sci. 2008;44(1):75–84. [Google Scholar]

- Cardarelli HR, Buriti FCA, Castro IA, Saad SMI. Inulin and oligofructose improve sensory quality and increase the probiotic viable count in potentially synbiotic petit-suisse cheese. LWT-Food Sci Technol. 2008;41(6):1037–1046. doi: 10.1016/j.lwt.2007.07.001. [DOI] [Google Scholar]

- Causey JL, Feirtag JM, Gallaher DD, Tungland BC, Salvin JL. Effects of dietary inulin on serum lipids, blood glucose and the gastrointestinal environment in hypercholesterolemic men. Nutr Res. 2000;20(2):191–201. doi: 10.1016/S0271-5317(99)00152-9. [DOI] [Google Scholar]

- Chawla AK, Balachandran R. Studies on yoghurt buffalo milk: effect of different solids not fat content on chemical, rheological and sensory characteristics. Indian J Dairy Sci. 1994;47:762–765. [Google Scholar]

- de-Castro FP, Cunha TM, Ogliari PJ, Teofilo RF, Ferreira MMC, Prudencio ES. Influence of different content of cheese whey and oligofructose on the properties of fermented lactic beverages: study using response surface methodology. LWT-Food Sci Technol. 2009;42:993–997. doi: 10.1016/j.lwt.2008.12.010. [DOI] [Google Scholar]

- El-Nagar G, Clowes G, Tudorica CM, Kuri V, Brennan CS. Rheological quality and stability of yog-ice cream with added inulin. Int J Dairy Technol. 2002;55(2):89–93. doi: 10.1046/j.1471-0307.2002.00042.x. [DOI] [Google Scholar]

- Erdman JW, Fordyce EJ. Soy products and the human nutrition. Am J Clin Nut. 1989;49:725–737. doi: 10.1093/ajcn/49.5.725. [DOI] [PubMed] [Google Scholar]

- Fernandez-Garcia E, McGregor JU. Fortification of sweetened plain yogurt with insoluble dietary fiber. Eur Food Res Technol. 1997;204:433–437. [Google Scholar]

- Fernandez-Gracia E, McGregor JU, Traylor S. The addition of oat fiber and natural alternative sweeteners in the manufacture of plain yogurt. J Dairy Sci. 1998;81:655–663. doi: 10.3168/jds.S0022-0302(98)75620-6. [DOI] [PubMed] [Google Scholar]

- Franck A. Inulin. In: Stephen AM, Phillips GO, Williams PA, editors. Food polysaccharides and their applications. Boca Raton: CRC Press-Taylor and Francis Press; 2006. pp. 335–351. [Google Scholar]

- Garcia-Perez FJ, Lario Y, Fernandez-Lopez J, Sayas E, Perez-Alvarez JA, Sendra E. Effect of orange fiber addition on yoghurt color during fermentation and cold storage. Colour Res Appl. 2005;30(6):457–463. doi: 10.1002/col.20158. [DOI] [Google Scholar]

- Garcia-Perez FJ, Sendra E, Lario Y, Fernandez-Lopez J, Sayas-Barbera E, Perez-Alvarez JA. Rheology of orange fiber enriched yoghurt. Milchwissenschaft. 2006;61(1):55–59. [Google Scholar]

- Ghosh J, Rajorhia GS. Chemical, microbiological and sensory properties of misti dahi sold in Calcutta. Asian J Dairy Res. 1987;6:11–16. [Google Scholar]

- Ghosh J, Rajorhia GS. Technology for production of misti dahi – a traditional fermented milk product. Indian J Dairy Sci. 1990;43(2):239–246. [Google Scholar]

- Guggisberg D, Cuthbert-Steven J, Piccinali P, Butikofer U, Eberhard P. Rheological, microstructural and sensory characterization of low-fat and whole milk set yoghurt as influenced by inulin addition. Int Dairy J. 2009;19(2):107–115. doi: 10.1016/j.idairyj.2008.07.009. [DOI] [Google Scholar]

- Guven M, Yasar K, Karaca OB, Hayaloglu AA. The effect of inulin as a fat replacer on the quality of set-type low-fat yogurt manufacture. Int J Dairy Technol. 2005;58(3):180–184. doi: 10.1111/j.1471-0307.2005.00210.x. [DOI] [Google Scholar]

- Hennelly PJ, Dunne PG, O'Sullivan M, O’Riordan ED. Textural, rheological and microstructural properties of imitation cheese containing inulin. J Food Eng. 2006;75:388–395. doi: 10.1016/j.jfoodeng.2005.04.023. [DOI] [Google Scholar]

- Kantha KL, Kanawjia SK. Response surface analysis of sensory attributes and yield of low fat paneer enriched with soy fiber. Indian J Dairy Sci. 2007;60(4):230–238. [Google Scholar]

- Kip P, Meyer D, Jellema RH. Inulins improve sensoric and textural properties of low-fat yoghurts. Int Dairy J. 2006;16:1098–1103. doi: 10.1016/j.idairyj.2005.10.011. [DOI] [Google Scholar]

- Modha H, Pal D. Optimization of Rabadi-like fermented milk beverage using pearl millet. J Food Sci Technol. 2011;48(2):190–196. doi: 10.1007/s13197-010-0146-6. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Nair K, Thompkinson DK. Optimization of ingredients for the formulation of a direct acidified whey based lassi-like beverage. Int J Dairy Technol. 2008;61(2):199–205. doi: 10.1111/j.1471-0307.2008.00387.x. [DOI] [Google Scholar]

- Nair K, Kharb S, Thompkinson DK. Inulin dietary fiber with functional and health attributes – a review. Food Rev Int. 2010;26:189–203. doi: 10.1080/87559121003590664. [DOI] [Google Scholar]

- Pal D. New innovations in the processing of traditional Indian dairy products. Indian Dairyman. 2008;60(3):127–131. [Google Scholar]

- Patel AA, Arora SK (2005) Fiber fortification of dairy products. Proceedings of the National Seminar on Value Added Dairy Products held at National Dairy Research Institute, Karnal from 21–22 December, 2005. pp: 139–144

- Raju PN, Pal D. The physico-chemical, sensory and textural properties of misti dahi prepared from reduced fat buffalo milk. Food Bioproc Technol. 2009;2:101–108. doi: 10.1007/s11947-008-0137-z. [DOI] [Google Scholar]

- Raju PN, Pal D. Effect of bulking agents on the quality of artificially sweetened misti dahi prepared from reduced fat buffalo milk. LWT-Food Sci Technol. 2011;44(9):1835–1843. doi: 10.1016/j.lwt.2011.03.010. [DOI] [Google Scholar]

- Rangaswamy R. A textbook of agricultural statistics. New Delhi: New Age International (P) Ltd; 1995. [Google Scholar]

- Rao KN, Solanki DC (2007) Fermented dairy products-lab to industry: Research creativity and experiences. In: Souvenir of the 3rd International Conference on Fermented Foods Health Status and Social Well-being, December 2007, Anand (India). pp 70–73

- Sarkar SP, Dave JM, Sannabhadti SS. Characterization of isolates of lactic acid bacteria from market sample of misti dahi. Indian J Dairy Sci. 1992;45(1):33–36. [Google Scholar]

- Sarkar S, Kuila RK, Misra AK. Organoleptical, microbiological and chemical quality of misti dahi sold in different districts of West Bengal. Indian J Dairy Sci. 1996;59:54–61. [Google Scholar]

- Singh R. Characteristics and technology of traditional Indian cultured dairy products. Bull Int Dairy Fed. 2007;415:11–20. [Google Scholar]

- Singh PK, Mann RS, Jha A (2005) Development of low fat fiber enriched ice cream – scope of entrepreneurship. Souvenir of the National Workshop on Entrepreneurship Development in Dairy and Food Industry held at National Dairy Research Institute, Karnal on 23rd December, 2005. pp: 84–88

- Staffolo MD, Bertola N, Martino M, Bevilacqua A. Influence of dietary fiber addition on sensory and rheological properties of yogurt. Int Dairy J. 2004;14:263–268. doi: 10.1016/j.idairyj.2003.08.004. [DOI] [Google Scholar]

- Stone H, Sidel JL. Sensory evaluation practices. Amsterdam: Elsevier Academic Press; 2004. p. 87. [Google Scholar]

- Tarrega A, Costell E. Effect of inulin addition on rheological and sensory properties of fat-free starch-based dairy desserts. Int Dairy J. 2006;16:1104–1112. doi: 10.1016/j.idairyj.2005.09.002. [DOI] [Google Scholar]

- Villegas B, Costell E. Flow behaviour of inulin-milk beverages. Influence of inulin average chain length and of milk fat content. Int Dairy J. 2007;17(7):776–781. doi: 10.1016/j.idairyj.2006.09.007. [DOI] [Google Scholar]