Abstract

Kodo millet-chickpea flour blend (70:30) was explored for development of directly expanded snack by twin-screw extrusion. Effect of process parameters like temperature (80–150 °C), screw speed (250–300 rpm) and feeder speed (15–30 rpm) on physical properties (expansion ratio, bulk density, hardness, crispiness) of extrudates were investigated and optimized using response surface methodology. Desirable crispy extrudates were obtained at higher screw speed 293 rpm, lower feeder speed 19 rpm, and medium to high temperature of 123 °C. Effect of extreme and intermediate process conditions on functional, proximate quality and colour of the extrudates were also evaluated.

Keywords: Twin screw extrusion, Millet, Response surface methodology, Process parameters, Nutritional quality, Direct expanded snack

Introduction

Millets are important ecological food security crops known for their nutritional quality and can be an immediate subsistence food for a nutrient-scarce community. Millets are known for drought resistance and need very little resources for their growth (Joshi et al. 2008). Although recognized as nutritious cereals, they are generally absent in commercial channels; rather they are little explored for the possibility of developing novel food products using new processing technologies. Kodo is one among the six other minor millets; kodo millet (Paspalum scrobiculatum) and barnyard millet together account for 10 % of total world millet production (Consultative Group on International Agricultural Research, 2011). Kodo millet is one of the major cereal grains grown and consumed along with other millet species in Africa (URL:http://www.sik.se/traditionalgrains/review/Oral%20presentation%20PDF%20files/Taylor.pdf). It is also grown in India and few other Asian countries and consumed traditionally after dehusking and cooking like rice. Nutrient composition of kodo is comparable to other major cereals having 65–72 % carbohydrate, 8–9 % protein, 1–2 % fat, 2–3 % minerals, and 9 % fiber. Starch content (79 %) favours extrusion process in developing directly expanded snack (Geervani and Eggum 1989). Also, gelatinization temperature of kodo is 77–90 °C (Shinoj et al. 2006) which is comparable to that of major cereals, which are generally used for extruded snack development. Rather kodo is more superior as their carbohydrate has certain uniqueness and millet diet releases sugar slowly. This was evident in a study where glyemic index (GI) was determined in 36 non-insulin-dependent diabetes mellitus (NIDDM) patients for commonly consumed foods in western India; GI of kodo alone and kodo in combination with whole green gram and bajra was significantly lower than that of Ragi (Mani et al. 1993). Dietary fiber protects against hyperglycemia, phytates protects against oxidative stress by chelating iron involved in Fenton’s reaction; phenolics, tannins act as antioxidants (Thompson 1993). But kodo millet protein is deficient in amino acids like lysine and tryptophan (Chung and Pomeranz 1985).

It is well known fact that pulses are consumed worldwide due to their high protein as well as high dietary fiber content. The chickpeas (Cicer arietinum) contain moderately high protein (17–22 %), low fat (6.48 %), high available carbohydrate (50 %) and crude fiber contents of 3.82 % (Saleh and Tarek 2006). Amino acid scores and digestibility values of chickpea protein isolates were superior to soybean protein isolate (Wang et al. 2009). Pulse starch also contributes to slow glucose release, inducing a low glycemic index (Winham et al. 2007), whereas dietary fiber is involved in gastrointestinal health (Marlett et al. 2002). Chickpea is also known to reduce cholesterol and blood glucose level (Singh and Singh 1992). Pasta containing chickpea flour as an ingredient recorded low glycemic index than the pasta containing wheat flour (Goni 2003). Thus blending of kodo and chickpea not only nutritionally balances the carbohydrate-protein requirement, but also serves as a good raw material for healthy alternative snack for today’s snack craving population with many health ailments like obesity which leads to diabetes, cardiovascular diseases etc.

Extrusion cooking is a versatile, cost effective process which is used to develop directly expanded snack apart from breakfast cereals, confectionery, pet food and texturized vegetable proteins. Generally maize (Zea mays) and rice (Oryza sativa) are widely used to formulate expanded products (Anton et al. 2009; Ding et al. 2006; Perez et al. 2006; Fletcher 1985). Kodo millet is a potential raw material, owing to its starch content; which is also cost effective (hardy crop demanding less resource), moreover, it is nutritionally superior compared to major cereals. The effect of extrusion variables on the properties of extrudates has been studied extensively (Yagci and Gogus 2008; Ainsworth et al. 2007; Ding et al. 2005; González et al. 2000; Gutoski and El-Dash 1999; Kokini et al. 1992; Mitchell and Areas 1992; Mason and Hoseney 1986). A good quality snack is the result of right combination of all the process parameters which needs to be studied and optimized. This neglected millet can be explored for value addition by extrusion cooking. Thus kodo millet-chickpea flour blend was extruded to investigate the effect of process parameters viz., screw speed, feeder speed and temperature on attributes like bulk density, expansion ratio, hardness, and crispiness. Extreme and intermediate process conditions were selected within the range studied to study the effect of selected process conditions on colour, proximate and functional properties of the extrudates.

Materials and methods

Sample preparation

Kodo millet (JK-155) was procured from an experimental farm of the College of Agriculture, Rewa, MP, India and chickpea was obtained from local market. Both the grains were cleaned, millet was dehusked, ground to pass through 30 μ sieve and analyzed for moisture, protein, fat, fiber, ash, carbohydrates and energy contents (AOAC 1984). Preliminary experiments were conducted with different proportions of kodo and chickpea flour and it was found that expansion ratio was high and hardness was less in the extrudates prepared from 70:30 kodo:chickpea blend compared to extrudates prepared from 60:40, 80:20 and kodo millet alone. Thus millet and chickpea flour were blended at 70:30 proportion (weight basis) and moisture content in the blend was maintained at 20 %(db) by adding a calculated amount of water after finding the initial moisture content of both the flours. Blending was done using a bakery mixer for 15 min to ensure homogeneity. The blend was kept in zip-lock plastic covers for conditioning for 24 h at 4 °C and then was allowed 3 h to equilibrate at room temperature before extrusion cooking.

Extrusion cooking

The BTPL laboratory model co-rotating twin-screw extruder (EB-10 model) having L/D ratio of 14.4:1 and capacity of 25 kg/h was used with circular die having diameter of 2 mm. Calibration of the gravimetric feeder was done to determine the feed rate in terms of kg/h from rpm, average of three readings was taken. The extruder had three barrel zones. Temperatures of the first two zones were maintained at 60 and 80 °C, respectively, throughout the experiment while the temperature of the last zone was varied according to the experimental design. Once the steady state was attained (15 min) in the last zone, 100 g of blend was fed through the feeder. Only three blend combinations were extruded each time in order to avoid errors as the temperature of the barrel would go beyond the set temperature due to friction as a result of prolonged running of the extruder. Extrudates were cooled and stored in zip-lock covers in desiccators for further studies.

Experimental design and data analysis

A central composite rotatable design (CCRD) was employed for three independent variables viz., temperature (80–150 °C), screw speed (250–300 rpm), feeder speed (15–30 rpm) which corresponds to 5–8 kg/h. The levels were selected according to preliminary trials; lower range for temperature was selected to avoid excess nutritional loss. Table 1 shows the coded levels for process conditions as per Design Expert Version 7.0.0 (Statease, Minneapolis, USA). The same software was used for statistical analysis of experimental data. The basic principle of response surface methodology (RSM) is to relate product characteristics by using regression equations that describe interrelations between process variables and product responses (Colonna et al. 1984). RSM is a tool which is a collection of statistical and mathematical techniques useful for developing, improving, and optimizing processes in which several variables influence the response of interest and the objective is to optimize this response. The interaction effect of different variables (in combinations) can also be studied with this tool unlike the other tools where effect of only individual variable can be studied at a time. This tool not only analyzes the effect of independent variables, but also generates a mathematical model which describes the chemical or biochemical process (Myers and Montgomery 1995; Anjum et al. 1997). Thus RSM was applied in order to determine the effect of variables on the responses and further to locate the region of process conditions at which optimized physical characteristics can be obtained. Response surface plots were generated using the software as a function of two variables, while keeping the third variable constant at its intermediate value. Optimization was done to locate extrusion conditions where the extrudate would have a minimum bulk density and hardness and maximum expansion ratio and crispiness.

Table 1.

Coded levels for the independent variables

| Variables | Coded level | ||||

|---|---|---|---|---|---|

| −1 | −1.682 | 0 | +1.682 | +1 | |

| Screw speed (rpm) | 250 | 260 | 275 | 289 | 300 |

| Feeder speed (rpm) | 15 | 18 | 22.5 | 27 | 30 |

| Temperature (°C) | 80 | 94 | 115 | 136 | 150 |

Product characteristics

Expansion ratio, bulk density and textural (hardness and crispiness) properties of extrudates were measured after extrusion process.

Expansion ratio

Expansion ratio (ER) was measured as the cross-sectional diameter of the extrudates with a Vernier digital caliper and calculated as the ratio of extrudate diameter to the die diameter (Harper 1981). ER values were obtained from 5 random samples for each set of extrusion conditions.

-

2.

Bulk density

Bulk density (BD) was measured by measuring the actual dimensions of the extrudates and calculated as ratio of weight of product to its volume (Asare et al. 2004).

|

1 |

Where

- L

Length of extrudate (cm)

- d

Diameter of extrudate (cm)

- m

Mass of sample (g)

-

3.

Texture (hardness and crispiness)

Texture characteristics of extrudates were measured using a stable micro system TA-XT2 texture analyzer (Texture Technology corp., UK) fitted with a 25 mm cylinder probes. The studies were conducted at a pre test speed of 1.0 mm/s, test speed of 0.5 mm/s, post test speed of 10 mm/s, distance of 30 % strain, and load cell of 5 kg. Hardness value was considered as mean peak compression force and expressed in Newton (N). Crispiness was measured in terms of mean number of major peaks in texture analyzer graph obtained during product compression (Singh et al. 2009). Average values of five extrudates were considered.

Effect of extreme and intermediate process conditions on quality of extrudates

Extrudates obtained from extreme and intermediate conditions viz., lowest temperature (T) 80 °C, screw speeds (SS) 250 rpm, feeder speed (FS) 15 rpm; highest T 150 °C, SS 300 rpm, FS 30 rpm and intermediate conditions like T 275 °C, SS 115 rpm, FS 22.5 rpm were studied for proximate, functional and colour parameters. Measurements were done in replicates and means were compared by Duncan Multiple Range Test (DMRT) using SPSS version 17.

-

i)

Proximate quality of extudates from all the three selected process conditions were powdered and evaluated for proximate content like moisture, protein, ash, fat, fiber (AOAC 1984); carbohydrate by difference from 100 (Cardoso-Santiago, 2001) and energy (Osborne and Voogt 1978).

-

ii)

Functional properties viz., water absorption index (WAI) and water solubility index (WSI) were measured as per Eqs. 2 and 3 by Yagci and Gogus method (2008).

|

2 |

|

3 |

-

iii)

Colour was measured by portable colorimeter (Model: Spectro-guide 45/0 gloss, Make: BYK Gardner, Germany). Colorimeter was calibrated using white ceramic plate (L = 95.69, a = −0.83, b = 1.04). Coordinates ‘L’ represented the lightness of color (0 = black; 100 = white), −a/+a greenness or redness, and −b/+b blueness or yellowness. The extrudates were ground in a laboratory grinder and passed through a 60 mesh sieve prior to color analysis. For each sample, four measurements were taken and averaged. The total color change (ΔE) was calculated as per Eq. 4 (Altan et al. 2008).

|

4 |

Where the subscript ‘0’ indicates initial color values of the raw material.

Results and discussion

Product response viz., bulk density (g), expansion ratio, hardness (N), and crispiness obtained as a result of proposed experimental design were subjected to regression analysis in order to assess the effect of screw speed, feeder speed and temperature. A second-order polynomial regression model for the dependent variables was established to

|

5 |

fit the experimental data for each response. Xi,X2i,XiXj are linear, quadratic and interaction effect of the input variables which influence the response y, respectively, and β0, βi and βij are the regression coefficients to be determined. Regression models (Eq. 5) were developed from the experimental data. The coefficients of the model with their R2 are presented in Table 2.

Table 2.

Coefficients for the regression model for process parameter and product response

| Parameters | Product response | |||

|---|---|---|---|---|

| Bulk density | Expansion ratio | Hardness | Crispiness | |

| Intercept | 0.58 | 2.57 | 25.14 | 12.51 |

| X1-Screw speed | −0.05٭٭٭ | 0.07 | −2.47٭ | 0.61 |

| X2-Feeder speed | 0.02 | −0.03 | 3.10٭ | |

| −1.01٭ | ||||

| X3-Temperature | −0.20٭٭٭ | 0.74٭٭٭ | −10.22٭٭٭ | |

| 3.16٭٭٭ | ||||

| X1X2 | 1.25 × 10−3 | 0.09 | Nil | −0.37 |

| X1X3 | 0.01٭ | −0.19٭ | Nil | 0.38 |

| X2X3 | −0.02 | 0.09 | Nil | 0.38 |

| X21 | −0.05٭ | 0.16٭٭ | ||

| Nil | −0.25 | |||

| X22 | −0.11 | −0.06 | Nil | −0.25 |

| X23 | −9.24 × 10−3 | 0.32٭٭٭ | Nil | −0.25 |

| R2 | 0.95 | 0.98 | 0.91 | 0.93 |

X1- Screw speed, X2 - Feeder speed, X3 -Temperature

Significant at P < 0.05

Significant at P < 0.01

Significant at P < 0.001

Effect of extrusion process parameters on physical characteristics of extrudates

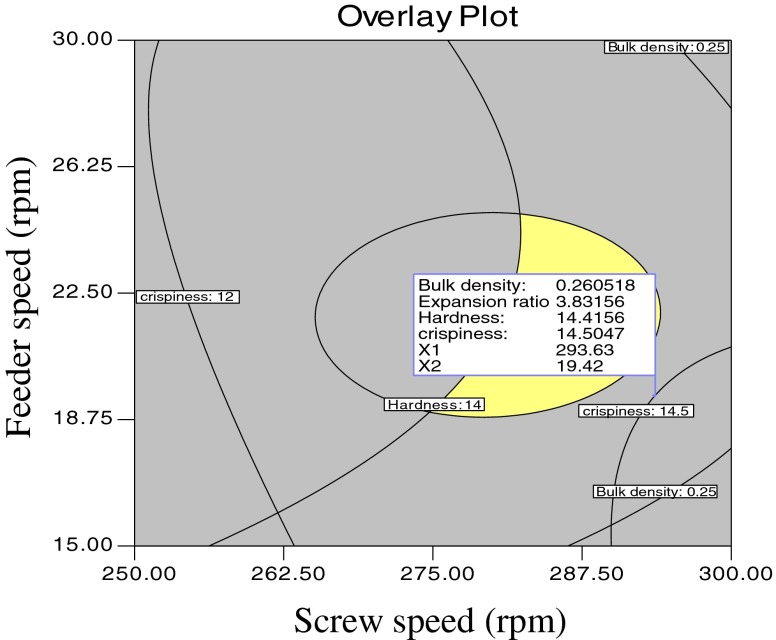

Effect of temperature, screw speed and feeder speed on physical characteristics of extrudates as shown by 3D contour graphs are discussed below. Only graphs which show significant effect are shown.

Bulk density (BD)

Bulk density values ranged from 0.19–0.88 g/cm3. The regression coefficients (Table 2) shows that screw speed (P < 0.05) had significant negative linear effect on BD. Response surface plot (Fig. 1a) shows that there is an inverse relationship between BD and screw speed. At screw speed of 250 rpm the value of BD is highest and then decreased as screw speed increased and 0.19 g/cm3 was recorded at 300 rpm. This is in agreement with the results of chickpea flour based snack (Meng et al. 2010). Higher screw speeds may decrease the melt viscosity of the blend, increasing the elasticity of the dough, resulting in a reduction of density of the extrudates (Ding et al. 2006). Temperature (P < 0.001) had highly significant negative linear effect, as the temperature increased, BD decreased (Fig. 1b) which is in accordance with the trend observed in rice based snack (Ding et al. 2005). The interaction effect of screw speed and temperature (P < 0.05) was observed. An increase in the barrel temperature and screw speed might increase the degree of superheating of water in the extruder thus enhancing bubble formation and also a decrease in melt viscosity (Fletcher et al. 1985; Lawton et al. 1985). Bulk density values decreased when the extrusion temperature and the screw speed increased due to starch gelatinization (Hagenimana et al. 2006; Case et al. 1992). As gelatinization increases, the volume of extruded products increases and bulk density decreases. Feeder speed did not have any significant effect.

-

2.

Expansion ratio (ER)

Fig. 1.

Effects of screw speed, temperature and/or feeder speed on bulk density, expansion ratio of extrudates

ER ranged from 2.2–4.8, temperature had a significant positive linear effect (Table 2) on ER (P < 0.001). As the temperature increased, (Fig. 1c) ER increased. It has been reported that the expansion ratio of extruded cereals depends on the degree of starch gelatinization (Case et al. 1992; Chinnaswamy and Hanna 1988). Kodo has starch content 79 % (Geervani and Eggum 1989), and a high gelatinization temperature of 82 °C, as the temperature in this study ranges from 80–150 °C, the ER is high. Moreover, chickpea also has a high (40–50 %) starch content (Huang et al. 2007), which may favour an extrusion process to produce extrudates with good ER. Temperature also had significant quadratic effect (P < 0.001), this was similar to results obtained in rice-green gram extrudates, (Bhattacharya 1997) where significant quadratic effect of barrel temperature in the range 75 to 185 °C on the ER was observed. Similar results were also reported in the extrudates of corn starch (Chinnaswamy and Hanna 1988) and in another study where rice and chickpea flour blend was extruded (Bhattacharya and Prakash 1994). Avin et al. (1992) observed similar effects of temperature for the expansion of red bean extrudates. Screw speed recorded significant quadratic effect on ER. Increase in shear leads to decrease in melt viscosity induced by high screw speed (Kokini et al. 1992). Similar trend was observed when the extrudates were prepared from brewers-spent-grain, maize, corn and chickpea flour blends (Ainsworth 2007). Overall and radial expansion increased with screw speed in the range 80–200 rpm (Ali et al. 1996), although in this study the screw speed range studied was 250–300 rpm similar trend for ER was observed. There was a significant negative interaction effect of screw speed and temperature (P < 0.05). According to response surface plots (Fig. 2a), increase in temperature led to a significant increase of ER at lower screw speed. These results are similar to those reported (Bhattacharya 1997) for rice-green gram blend. Feeder speed had no significant effect (Fig. 1d) on the product characteristics.

-

3.

Hardness

Fig. 2.

Effects of screw speed, temperature and/or feeder speed on hardness and crispiness of extrudates

Regression analysis (Table 2) shows that screw speed (P < 0.05) had negative linear effect. As the screw speed increased hardness decreased (Fig. 2a), similar trend was also observed in the extrudates prepared from brewers-spent-grain, maize, corn and chickpea flour (Ainsworth 2007; Meng et al. 2010) whereas feeder speed (P < 0.05) had positive linear effect. Increase in feeder speed increases the hardness; this may be due to reduced starch conversion and compressed bubble growth which would result in a dense product thus increasing the hardness (Ding et al. 2005). Barrel temperature ((P < 0.001) had highly significant negative linear effect on hardness of the extrudates. Increase in temperature significantly decreased the hardness (Fig. 2b), which is in agreement with the results obtained in rice and green gram extrudates (Bhattacharya 1997). Higher temperature with high screw speed leads to expansion of extrudates as the superheated steam is released and disrupts the material due to shear.

-

4.

Crispiness

Screw speed (P < 0.05) and temperature (P < 0.001) had positive linear effect and feeder speed (P < 0.01) had negative linear effect on the crispiness of the extrudates (Table 2). Crispiness values ranged from 6–18. Decrease in feeder speed (Fig. 2c) increased the crispiness this maybe due to less compaction and better air cell formation. As the screw speed increases, crispiness increased and maximum was recorded at high temperature (Fig. 2d). Increase in screw speed might have caused good puffing of the starch-rich feed into hot melts which can be expanded as they emerge from the die, thus forming bubbles and expand within the melt to form continuous foam (Guy 2001). High temperature results in increased bubble radius simultaneously causing increase in matrix radius and decrease in shell wall thickness (Wang et al. 2005). This gives the extrudate a brittle structure needed for a good snack which is measured as the extrudate fractures when compression force is applied.

Correlation between the physical characteristics

The bulk density and expansion ratio describes the degree of puffing undergone by the melt as it exits the extruder. Bulk density is a better measure of volumetric expansion as there is an inverse relationship between sectional and longitudinal expansion (Dogan and Karwe 2003; Ilo et al. 1996). Increase in barrel temperature results in extrudates with low values for hardness, where reduced BD was observed in the present study similar to that observed by Altan et al. (2008) and Bhattacharya (1997). Increase in gelatinization increases the volume and decreases the bulk density (Mercier and Feillet 1975; Case et al. 1992). Increase in ER leads to lower BD and hardness, thus expansion ratio, bulk density and hardness are inter-related. ER depends on starch content of the feed material, protein addition affects the ER inversely and increases hardness (Areas 1992), which shows that addition of protein to starch-rich flours results in the usual ‘protein type’ extrudates that are harder and expands less. Crispiness is inversely proportional to bulk density and hardness; expansion ratio does not seem to depict the crispiness.

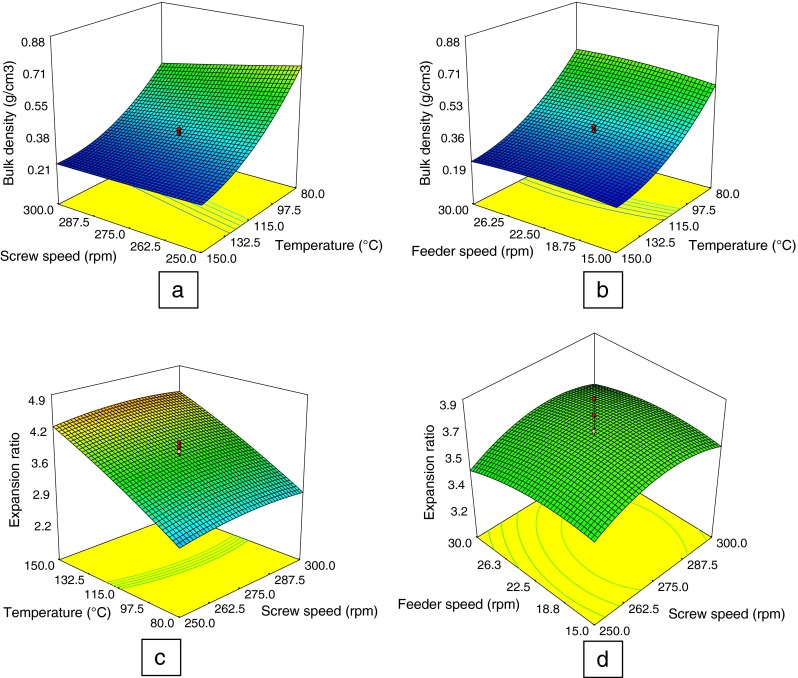

Optimization

Overlay plot (Fig. 3) obtained from Design Expert Version 7.0.0. shows extruder conditions at which best quality extrudates were obtained. According to graphical optimization, process parameters which yielded extrudates with desired qualities like less dense, highly expanded crispy snack are feeder speed 19 rpm which corresponds to 6 kg/h and temperature 123 °C and screw speed of 293 rpm was observed to give desirable quality extrudates having BD 0.26 g/cm3, ER 3.8, hardness 14.4 N and crispiness 15 positive peaks. Comparison of extrudates of low quality and those obtained from optimized process parameters revealed that optimized conditions resulted in more appealing extrudates with better expansion.

Fig. 3.

Overlay plot for optimization of process conditions to obtain quality extrudates

Effect of process conditions on quality of extrudates

Effect of lowest (temperature (T) - 80 °C, screw speed (SS) - 250 rpm and feeder speed (FS) - 15 rpm); intermediate (T 115 °C, SS 275 rpm, FS 22.5 rpm) and highest (150 °C, SS 300 rpm, FS 30 rpm) process conditions were studied for the following qualities.

Effect of process conditions on proximate quality of extrudates

The proximate content (Table 3) of the extrudates shows that moisture and ash did not have any significant effect. Protein, fat, ash and energy content showed significant difference between the extrudates prepared at lowest and intermediate as well as lowest and highest process conditions, whereas there was no significant difference between intermediate and highest level of process conditions. Fat content recovered in lowest process conditions is higher compared to other two conditions this may be due to amylose-lipid formation leading to low extractability at higher temperatures beyond 165 °C (Cheftel 1986). Starch-lipid complex formation due to bonds that form between fat and starch fractions, which was not extractable with petroleum ether and thus fat loss percentage was found to be higher at higher temperature studied in rice starch extrusion conducted by De Pilli et al. (2011).

Table 3.

Effect of selected process conditions on proximate quality of extrudates

| Runs | Moisture | Protein | Fat | Ash | Fiber | Carbohydrate | Energy |

|---|---|---|---|---|---|---|---|

| (%) | (%) | (%) | (%) | (%) | (%) | (kcal) | |

| 1 | 10.4 ± 0.21a | 16.6 ± 0.14b | 0.44 ± 0.02b | 1.7 ± 0.21b | 1.8 ± 0.18c | 69.0. ± 0.27a | 346.5 ± 1.23a |

| 2 | 10.6 ± 0.72a | 11.6 ± 0.01a | 0.32 ± 0.10ab | 1.3 ± 0.02a | 0.47 ± 0.04b | 75.7 ± 1.05b | 351.9 ± 1.23b |

| 3 | 10.6 ± 0.25a | 11.4 ± 0.22a | 0.15 ± 0.19a | 1.1 ± 0.11a | 0.23 ± 0.08a | 76.4 ± 0.23c | 352.8 ± 1.92b |

Runs1, 2 and 3 corresponds to the following process conditions, Temperature (T) - 80 °C, Screw speed (SS) - 250 rpm, Feeder speed (FS) - 15 rpm; T - 115-°C, SS - 275 rpm, FS - 23 rpm; T - 150-°C, SS - 300 rpm, FS - 30 rpm, respectively. Values within the column with same letter are not significantly different (P < 0.05)

Values expressed as ± Standard deviation

Protein content shows decreasing trend as the severity of process conditions increases and there is a significant difference between the highest and lowest process conditions, same is true for fiber and carbohydrate contents as well, which showed significant difference between all the three process conditions. Although there is significant difference in the energy values between lowest and highest process conditions, intermediate and highest conditions did not show any difference. This shows that high temperature along with high screw speed increases the shear rate leading to break down of complex molecules to low molecular fractions leading to higher energy values (Guy 2001).

-

2.

Effect of process conditions on functional properties

The WAI is nothing but gelatinization index (Ding et al. 2005); it is the measure of water absorbed by starch after swelling in excess water due to dispersion occurred as a result of starch damage due to gelatinization and extrusion-induced fragmentation (Rayas-Duarte et al. 1998, Van den Einde et al. 2003). WAI ranged from 2.7 to 5.21 g/g. (Table 4). Values showed a significant effect (P < 0.05) between the highest and lowest extrusion conditions but did not show significant effect between intermediate and highest process conditions. WAI increases with increase in temperature, reaches maximum at temperatures of 180–200 °C and decreases probably due to increased dextrinization (Mercier and Feillet 1975; Owusu-Ansah et al. 1983). But the temperature range in this study did not record drop in WAI values due to high temperature, as the maximum temperature studied was 150 °C at which the phenomenon of gelatinization still persists. Increase in WAI was directly proportional to temperature and inversely proportional to screw speed (Yagci and Gogus 2008). On the other hand, Suksomboon and others (2011) in their study concluded that screw speed did not have significant effect on WAI of rice-soy extruded snack. But in this study WAI is directly proportional to screw speed and feeder speed within the range (250–300 rpm and 15–30 rpm, respectively) studied, there was significant difference between 250 and 300 rpm but not between 275 and 300 rpm. Higher temperature along with high screw speed may lead to very high shear which may enhance the starch degradation and hence lead to higher values of WAI beyond the temperature of 115 °C, screw speed 275 rpm and feeder speed 23 rpm.

Table 4.

Effect of selected process conditions on functional and colour quality of extrudates

| Runs | Process conditions | WAI | WSI | ΔE |

|---|---|---|---|---|

| T-°C, SS-rpm, FS-rpm | g/g | % | ||

| 1 | T-80, SS- 250, FS-15 | 2.7 ± 0.20a | 13.8 ± 0.16c | 15.0 ± 0.23a |

| 2 | T- 115, SS-275, FS- 23 | 5.0 ± 0.151b | 6.1 ± 0.16b | 23.9 ± 0.15b |

| 3 | T- 150, SS-300, FS- 30 | 5.2 ± 0.08b | 3.9 ± 0.12a | 26.2 ± 0.26c |

T Temperature, SS Screw speed, FS Feeder speed; WAI Water absorption index, WSI Water solubility index, ΔE Difference in colour

Values expressed as ± Standard deviation

The WSI of the extruded products is a measure of lower molecular weight components, which separate out easily from each other under severe processing conditions (Collona et al. 1989) it is the amount of soluble polysaccharide released from the starch component after extrusion (Ding et al. 2005). WSI values ranged between 3.8–13.75 %. All the process conditions are found to have significant effect (P < 0.05) on WSI. Values decreased with increase in severity of the process conditions. WSI decreased with increase in temperature and screw speed in case of rice grit snack (Yagci and Gogus 2008). Temperature was found to be inversely proportional to WSI in oat extrudates (Gutoski and El-Dash 1999) and in barley-tomato pomace extrudates Altan et al. 2008).

-

3.

Effect of process condition on colour of extrudates

Colour change in extrusion cooking is a visual indicator to assess the process intensity concerning chemical changes or nutritional loss in food (Iwe et al. 2004). Colour difference ΔE of the extrudates from that of raw flour ranged from 15.06–26.18 and showed significant effect (P < 0.05) due to all the process conditions (Table 4). Several reasons are known to affect the colour change during extrusion cooking viz., maillard, caramelization, hydrolysis, and others, as well as a non-enzymatic reaction, such as the degradation of pigments (Camire et al. 1990). Nevertheless, changes in color can also be an indicator of the intensity of the process and may be related to chemical changes (Berset 1989). Higher values of ΔE were recorded at severe extrusion conditions this may be due to maillard reaction which is evident at higher temperature and screw speed since chickpea has higher protein and also high temperature combined with intermediate moisture leads to non-enzymatic browning. Maillard reaction happens noticeably around 154 °C, significant browning of food does not occur until all surface water is vaporized, so browning is not seen in lower and intermediate process conditions. Ilo and Berghofer (1999) who studied the kinetics of colour change concluded that change in colour mainly depends on product temperature. Shear may cause the destruction of same corotenoid pigments in extrusion cooking (Marty and Berset 1986). Increasing screw speed in extrusion cooking increase the shear stress in the active cooking zone, leading to higher product temperature and thus cause overheating of material. These conditions would favour browning reactions and thus the changes in the colour.

Conclusion

Product quality was affected by process parameters like screw speed, feed rpm and temperature. The temperature significantly affected all the product attributes. Screw speed affected BD, hardness and crispiness significantly, while feeder speed affected ER, hardness and crispiness. Kodo-chickpea flour blend gives desirable crispy extrudates at higher screw speed 280 rpm, lower feeder speed 20 rpm, and medium to high temperature 123 °C. Effect of intermediate and highest process conditions did not vary much on their effect on proximate content. Highest process conditions resulted in extrudates with higher energy values. WAI and WSI were inversely proportional. Highest process conditions resulted in darker extrudates. Thus kodo millet and chickpea blend can be further explored for bioactive components which may add therapeutic value to the snack.

Acknowledgment or Role of the funding Source

The first author is grateful to Indian Council of Agricultural Research (ICAR), New Delhi, India, for granting the financial assistance to complete this work, Dr. P.S. Rao for providing the extruder lab facility, Dr. S.K. Bag for lending a helping hand for statistical analysis of the data.

References

- Ainsworth P, Ibanoglu S, Plunkett A, Ibanoglu E, Stojceska V. Effect of brewers spent grain addition and screw speed on the selected physical and nutritional properties of an extruded snack. J Food Eng. 2007;81:702–709. doi: 10.1016/j.jfoodeng.2007.01.004. [DOI] [Google Scholar]

- Ali Y, Hanna MA, Chinnaswamy R. Expansion characteristics of Extruded Corn Grits. LWT - Food Sci and Technol. 1996;29(8):702–707. doi: 10.1006/fstl.1996.0109. [DOI] [Google Scholar]

- Altan A, McCarthy KL, Maskan M. Evaluation of snack foods from barley-tomato pomace blends by extrusion processing. J Food Eng. 2008;84(2):231–242. doi: 10.1016/j.jfoodeng.2007.05.014. [DOI] [Google Scholar]

- Anjum MF, Tasadduq I, Al-Sultan K. Response surface methodology: a neural network approach. Eur J Oper Res. 1997;101:65–73. doi: 10.1016/S0377-2217(96)00232-9. [DOI] [Google Scholar]

- Anton AA, Fulcher RG, Arntfield SD. Physical and nutritional impact of fortification of corn starch-based extruded snacks with common bean (Phaseolus vulgaris L.) flour: effects of bean addition and extrusion cooking. Food Chem. 2009;113:989–996. doi: 10.1016/j.foodchem.2008.08.050. [DOI] [Google Scholar]

- AOAC . Official methods of analysis. 14. Washington, DC: Association of Official Analytical Chemists; 1984. [PubMed] [Google Scholar]

- Areas JAG. Extrusion of food proteins. Crit Rev Food Sci Nutr. 1992;32:365–392. doi: 10.1080/10408399209527604. [DOI] [PubMed] [Google Scholar]

- Asare EK, Sefa-Dedeh S, Sakyi-Dawson E, Afoakwa EO. Application of response surface methodology for studying the product characteristics of extruded rice-cowpea-groundnut blend. Int J Food Sci Nutr. 2004;55:431–439. doi: 10.1080/09637480400003238. [DOI] [PubMed] [Google Scholar]

- Avin D, Kim CH, Maga JA. Effect of extrusion variables on the physical characteristics of red bean (Phaseolis vulgaris) flour extrudates. J Food Process Pres. 1992;16(5):327–335. doi: 10.1111/j.1745-4549.1992.tb00213.x. [DOI] [Google Scholar]

- Berset C. Color. In: Mercier C, Linko P, Harper JM, editors. Extrusion cooking. St. Paul: American Association of Cereal Chemists Inc; 1989. pp. 399–434. [Google Scholar]

- Bhattacharya S. Twin-screw extrusion of rice-green gram blend: extrusion and extrudate characteristics. J Food Eng. 1997;32:83–99. doi: 10.1016/S0260-8774(97)00004-6. [DOI] [Google Scholar]

- Bhattacharya S, Prakash M. Extrusion of blends of rice and chickpea flours: a response surface analysis. J Food Eng. 1994;21(3):315–330. doi: 10.1016/0260-8774(94)90076-0. [DOI] [Google Scholar]

- Camire ME, Camire A, Krumhar K. Chemical and nutritional changes in foods during extrusion. Crit Rev Food Sci Nutr. 1990;29:35–57. doi: 10.1080/10408399009527513. [DOI] [PubMed] [Google Scholar]

- Case YK, Hanna MA, Scwartz SJ. Effect of starch gelatinization on physical properties of extruded wheat and corn based products. Cereal Chem. 1992;69:401–404. [Google Scholar]

- Cheftel JC. Nutritional effects of extrusion cooking. Food Chem. 1986;20:263–283. doi: 10.1016/0308-8146(86)90096-8. [DOI] [Google Scholar]

- Chinnaswamy R, Hanna MA. Relationship between amylose content and extrusion-expansion properties of corn starches. Cereal Chem. 1988;65:138–143. [Google Scholar]

- Chung OK, Pomeranz Y. Amino acids in cereals protein fractions. In: Finley TJW, Hopkins DT, editors. Digestibility and amino acid availability in cereals and oilseeds. St. Paul: American Association of Cereal Chemists; 1985. pp. 65–107. [Google Scholar]

- Colonna P, Doublier JL, Melcion JP, Monredon FD, Mercier C. Extrusion cooking and drum drying of wheat starch. I. Physical and macro-molecular modifications. Cereal Chem. 1984;61:538–543. [Google Scholar]

- Colonna P, Tayeb J, Mercier C. Extrusion cooking of starchy products. In: Mercier C, Linko P, Harper JM, editors. Extrusion Cooking. St. Paul: American Association of Cereal Chemists; 1989. pp. 321–342. [Google Scholar]

- Consultative Group on International Agricultural Research (CGIAR), Research & Impact: Areas of Research: Millet URL: http://www.gramene.org/species/setaria/foxtailmillet_maps_and_stats.html Accessed 7/02/2011.

- De Pilli TA. Derossia RA, Taljab K, Jouppilac C, Severinia (2011) Study of starch-lipid complexes in model system and real food produced using extrusion-cooking technology, Innovative Food Science and Emerging Technologies, doi:10.1016/j.ifset.2011.07.011

- Ding Q, Ainsworth P, Tucker G, Marson H. The effect of extrusion conditions on the physicochemical properties and sensory characteristics of rice-based expanded snacks. J Food Eng. 2005;66:283–289. doi: 10.1016/j.jfoodeng.2004.03.019. [DOI] [Google Scholar]

- Ding Q, Ainsworth P, Plunkett A, Tucker G, Marson H. The effect of extrusion conditions on the functional and physical properties of wheat-based expanded snacks. J Food Eng. 2006;72(2):142–148. doi: 10.1016/j.jfoodeng.2005.01.013. [DOI] [Google Scholar]

- Dogan H, Karwe MV. Physicochemical properties of quinoa extrudates. Food Sci Tech Inter. 2003;9(2):101–114. doi: 10.1177/1082013203009002006. [DOI] [Google Scholar]

- Fletcher SI, Richmond P, Smith AC. An experimental study of twin-screw extrusion cooking of maize grits. J Food Eng. 1985;4:291–312. doi: 10.1016/0260-8774(85)90009-3. [DOI] [Google Scholar]

- Geervani P, Eggum BO. Nutrient composition and protein quality of minor millets. Pl Foods Hum Nutr. 1989;39:201–208. doi: 10.1007/BF01091900. [DOI] [PubMed] [Google Scholar]

- Goni I, Valentin-Gamazo C. Chickpea flour ingredient slows glycemic response to pasta in healthy volunteers. Food Chem. 2003;81:511–515. doi: 10.1016/S0308-8146(02)00480-6. [DOI] [Google Scholar]

- Gonzalez RJ, Torres RL, Anon MC. Comparison of rice and corn cooking characteristics before and after extrusion. Polish J Food Nutr Sci. 2000;9(5):29–34. [Google Scholar]

- Gutoski LC, El-Dash AA. Effect of extrusion process variables on physical and chemical properties of extruded oat products. Pl Foods Hum Nutr. 1999;54:315–325. doi: 10.1023/A:1008101209353. [DOI] [PubMed] [Google Scholar]

- Guy R. Extrusion cooking technologies and applications. 1. Cambridge: Woodhead publishing Ltd; 2001. [Google Scholar]

- Hagenimana A, Xiaolin D, Fang T. Evaluation of rice flour modified by extrusion cooking. J Cereal Sci. 2006;43:38–46. doi: 10.1016/j.jcs.2005.09.003. [DOI] [Google Scholar]

- Harper JM. Extrusion of Foods. Boca Raton: CRC Press, Inc.; 1981. [Google Scholar]

- Huang J, Schols HA, Van Soest JJG, Jin Z, Sulmann E, Voragen AGJ. Physicochemical properties and amylopectin chain profiles of cowpea, chickpea and yellow pea starches. Food Chem. 2007;101(4):1338–1345. doi: 10.1016/j.foodchem.2006.03.039. [DOI] [Google Scholar]

- Ilo S, Berghofer E. Kinetics of colour changes during extrusion cooking of maize grits. J Food Eng. 1999;39:73–80. doi: 10.1016/S0260-8774(98)00148-4. [DOI] [Google Scholar]

- Ilo U, Tomschik E, Berghofer MN. The effect of extrusion operating conditions on the apparent viscosity and the properties of extrudates in twin-screw extrusion cooking of maize grits. LWT. 1996;29(7):593–598. doi: 10.1006/fstl.1996.0092. [DOI] [Google Scholar]

- Iwe MO, Iwe DJ, Van Zuilichem W, Stolp W, Ngoddy PO. Effect of extrusion cooking of soy-sweet potato mixtures on available lysine content and browning index of extrudates. J Food Eng. 2004;62:143–150. doi: 10.1016/S0260-8774(03)00212-7. [DOI] [Google Scholar]

- Joshi A, Rawat K, Bhawana K. Millet as “Religious offering” for nutritional, ecological, and economical security. Comp Rev Food Sci Food Saf. 2008;7:369–372. [Google Scholar]

- Kokini JL, Chang CN, Lai LS. The role of rheological properties on extrudate expansion. In: Kokini JL, Ho CT, Karwe MV, editors. Food extrusion science and technology. New York: Marcel Dekker; 1992. pp. 631–652. [Google Scholar]

- Lawton AB, Davis KC, Behnke KC. High-temperature, short-time extrusion of wheat gluten and bran-like fraction. Cereal Chem. 1985;62:267–269. [Google Scholar]

- Mani UV, Prabhu BM, Damle SS, Mani I. Glyceamic index of some commonly consumed foods in western India. Asia Pac J Clin Nutr. 1993;2:111–114. [PubMed] [Google Scholar]

- Marlett AJ, McBurney MI, Slavin JL. Position of the American Dietetic Association: health implications of dietary fiber. J Am Dietetic Assoc. 2002;102(7):993–1000. doi: 10.1016/S0002-8223(02)90228-2. [DOI] [PubMed] [Google Scholar]

- Marty CC, Berset C. Degradation of trans-ß-carotene during heating in sealed glass tubes and extrusion cooking. J Food Sci. 1986;51:698–702. doi: 10.1111/j.1365-2621.1986.tb13915.x. [DOI] [Google Scholar]

- Mason WR, Hoseney RC. Factors affecting the viscosity of extrusion cooked wheat starch. Cereal Chem. 1986;63(5):436–441. [Google Scholar]

- Meng X, Threinen D, Hansen M, Driedger D. Effects of extrusion conditions on system parameters and physical properties of a chickpea flour-based snack. Food Res Int. 2010;43(2):650–658. doi: 10.1016/j.foodres.2009.07.016. [DOI] [Google Scholar]

- Mercier C, Feillet P. Modification of carbohydrate components by extrusion-cooking of cereal products. Cereal Chem. 1975;52(3):283–297. [Google Scholar]

- Mitchell JR, Areas JA. Structural changes in biopolymers during extrusion. In: Kokini JL, Ho CT, Karwe MV, editors. Food extrusion science and technology. New York: Marcel Dekker; 1992. pp. 345–360. [Google Scholar]

- Myers RH, Montgomery DC. Response surface methodology: Process and product optimization using designed experiments. New York: Wiley; 1995. [Google Scholar]

- Osborne DR, Voogt P. Calculation of calorific value. In: The analysis of foods. London: Academic; 1978. pp. 107–110, 239. [Google Scholar]

- Owusu-Ansah J, Van de Voort FR, Stanley DW. Physicochemical changes in cornstarch as a function of extrusion variables. Cereal Chem. 1983;60(4):319–324. [Google Scholar]

- Perez-Navarrete C, González R, Chel-Guerrero L, Betancur-Ancona D. Effect of extrusion on nutritional quality of maize and Lima bean flour blends. J Sci Food Agric. 2006;86:2477–2484. doi: 10.1002/jsfa.2661. [DOI] [Google Scholar]

- Rayas-Duarte P, Majewska K, Doetkott C. Effect of extrusion process parameters on the quality of buckwheat flour mixes. Cereal Chem. 1998;75:338–345. doi: 10.1094/CCHEM.1998.75.3.338. [DOI] [Google Scholar]

- Saleh AA, Tarek AE. Nutritional composition of chickpea (Cicer arietinum L.) as affected by microwave cooking and other traditional cooking methods. J Food Comp Anal. 2006;19:806–812. doi: 10.1016/j.jfca.2006.03.015. [DOI] [Google Scholar]

- Santiago CRA, Areas JAG. Nutritional evaluation of snack obtained by chickpea and bovine-lung. Food Chem. 2001;74:35–40. doi: 10.1016/S0308-8146(00)00335-6. [DOI] [Google Scholar]

- Shinoj J, Vishwanathan R, Sajeev Moorthy SN. Gelatinisation and rheological characteristics of minor millets flours. Biosystems Eng. 2006;95(1):51–59. doi: 10.1016/j.biosystemseng.2006.05.012. [DOI] [Google Scholar]

- Singh U, Singh B. Tropical grain legumes as important human foods. Econ Bot. 1992;46(3):310–321. doi: 10.1007/BF02866630. [DOI] [Google Scholar]

- Singh J, Kaur L, McCarthy OJ, Moughan PJ, Singh H. Development and characterization of extruded snacks from New Zealand Taewa (Maori potato) flours. Food Res Int. 2009;42:666–667. doi: 10.1016/j.foodres.2009.02.012. [DOI] [Google Scholar]

- Suksomboon A, Limroongreungrat K, Sangnark A, Thititumjariya K, Noomhorm A. Effect of extrusion conditions on the physicochemical properties of a snack made from purple rice (Hom Nil) and soybean flour blend. Int J Food Sci Tech. 2011;46:201–208. doi: 10.1111/j.1365-2621.2010.02471.x. [DOI] [Google Scholar]

- Thompson LU. Potential health benefits and problems associated with antinutrients in foods. Food Res Inter. 1993;26:131–149. doi: 10.1016/0963-9969(93)90069-U. [DOI] [Google Scholar]

- Van den Elinde RM, Van der Goot AJ, Boom RM. Understanding molecular weight reduction of starch during heating-shearing process. J Food Sci. 2003;68:2396–2404. doi: 10.1111/j.1365-2621.2003.tb07036.x. [DOI] [Google Scholar]

- Wang L, Ganjyal GM, Jones DD, Weller CL, Hanna MA. Modeling of bubble growth dynamics and nonisothermal expansion in starch-based foams during extrusion. Adv Polym Techn. 2005;24(1):29–45. doi: 10.1002/adv.20030. [DOI] [Google Scholar]

- Wang X, Gao W, Zhang, J, Zhang H, Li, J, He, X, Ma H (2009) Subunit, amino acid composition and in vitro digestibility of protein isolates from Chinese kabuli and desi chickpea (Cicer arietinum L.) cultivars. Food Res Inter, (In Press).

- Winham DM, Hutchins AM, Melde CL. Pinto bean, navy bean, and black-eyed pea consumption do not significantly lower the glycemic response to a high glycemic index treatment in normoglycemic adults. Nutr Res. 2007;27(9):535–541. doi: 10.1016/j.nutres.2007.07.002. [DOI] [Google Scholar]

- Yagci S, Gogus F. Response surface methodology for evaluation of physical and functional properties of extruded snack foods developed from food-by-products. J Food Eng. 2008;86:122–132. doi: 10.1016/j.jfoodeng.2007.09.018. [DOI] [Google Scholar]