Abstract

Biobased food packaging materials are gaining more attention owing to their intrinsic biodegradable nature and renewability. Selection of suitable biobased polymers for food packaging applications could be a tedious task with potential mistakes in choosing the best materials. In this paper, an expert system was developed using Exsys Corvid software to select suitable biobased polymer materials for packaging fruits, dry food and dairy products. If – Then rule based system was utilized to accomplish the material selection process whereas a score system was formulated to facilitate the ranking of selected materials. The expert system selected materials that satisfied all constraints and selection results were presented in suitability sequence depending on their scores. The expert system selected polylactic acid (PLA) as the most suitable material.

Keywords: Expert system, Material selection, Exsys Corvid software, Biobased polymers, Food packaging

Introduction

The numerous types of biobased polymers coupled with their closely similar properties, often complicates their selection process for any application. Possible risk of neglecting best biobased polymer materials for intended applications may occur, when inaccurate selection decisions are done. Consequently, the developed product may fail to satisfy its designed purpose and thus, unable to fulfil the demand of end users. It may also contribute to non-compliance with prevailing safety and environmental regulations. In view of these risks, systematic selection procedures are employed to address potential material selection problems.

Material selection is the process of picking the best materials for a specific design (Thakker et al. 2008). It is a significant step in developing new products or enhancing existing products (Maleque and Salit, 2013; Hambali et al. 2009). It contributes a crucial part in the development of products that are efficient, safe, quality and satisfactory to consumers. Material selection also helps to eradicate materials with potential environmental hazards from early stages of product development. Maleque and Salit (2013) recommended that one should know what product is to be developed or manufactured, what it does and how it does it. Providing appropriate answers to these questions at the initial stages of product development will enable effective product design and proper material selection. In order to resolve the issue of material selection for better product performance, many computerized material selection systems have been developed to select the most fitting materials for a certain application (Fairuz et al. 2012; Hambali et al. 2010).

Exsys Corvid software helps to develop user-friendly expert system for any material selection purpose. The software assists users in choosing suitable materials from among a definable group of materials. Expert systems are problem solving and decision making systems based on knowledge of their task and logical rules. The selection decisions are based on logical steps that represent expertise of domain experts (Maleque and Salit, 2013). Gonzalez and Dankel (1993) defined an expert system as “a computerized system that uses knowledge about some domain to arrive at a solution to a problem from that domain. This solution is essentially the same as that concluded by a person knowledgeable about the domain of the problem when confronted with the same problem”.

Previous studies on material selection using various expert systems were reported in literature. Sapuan and Abdalla (1998) conducted material selection for composite pedal box system using rule and frame based expert system. However, the system was incapable to automatically rank the materials after the first selection stage. Sapuan and Mujtaba (2010) developed a computational framework for material selection of natural fibre-reinforced polymer composite materials using neutral network. In their work, the initial stage of material selection process was carried out by neutral network whereas the ranking of selected materials was accomplished manually. Mun et al. (2009) also developed an expert system (PHPMY/ADMIN) for polymer material selection for automotive dash board. Their system could only select all the materials that fitted within the set range of properties. However, it was unable to suggest a single final candidate among the qualified materials.

Base on the above succinct drawbacks, Exsys Corvid expert system was developed in the current study for material selection. This software has the ability to select suitable materials and automatically rank them in a single step (Fairuz et al., 2012). Binti Ahmad and Yaacob (2002) used Exsys Corvid software in the decision making for diagnosis of a suspected transformer faults and the appropriate maintenance actions to be taken based on dissolved gas analysis techniques. Alibaba and Özdeniz (2004) employed Exsys Corvid to construct an expert system for the evaluation and selection of suitable building elements for construction. Kowalski et al. (2006) came up with an online academic advising website using Exsys Corvid software to provide decision making knowledge and customized recommendations to students through an interactive interface. Pavleković et al. (2007) developed an expert system for detecting a child’s gift in mathematics in the fourth grade of elementary school using Exsys Corvid software. Flior et al. (2010) studied the feasibility of using an Exsys Corvid based expert system to detect and respond to network threats and appropriately administrate a Linux-based iptables firewall in real-time. Fairuz et al. (2012) also developed an expert system using Exsys Corvid software for material selection of polymeric-based composites for fishing boat components. To the best of our knowledge, this work is the first to investigate biobased polymer material selection for food packaging using Exsys Corvid software. The primary objective of this investigation was to determine the most suitable biobased polymer packaging materials for fruits, dry food and dairy products to extend shelf-life, maintain nutritional and sensory quality, plus provide microbial safety.

Selection process

Structure of expert system for material selection

Figure 1 illustrates the architecture of the developed expert system for biobased packaging material selection for food applications. Expert systems typically possess three main components which are knowledge base, inference engine and user interface. The relationship between these different components is shown in Fig. 1.

Fig. 1.

Architecture of Exsys Corvid expert system for biobased polymer material selection

The knowledge base of the expert system contains high level information coupled with expert-level heuristic rules for solving material selection problems in a particular domain. The domain knowledge and rules are inserted into the knowledge base by the knowledge engineer. The knowledge engineer acquires relevant domain information from online database, material handbooks and research publications. He/she also receives valuable data by holding verbal discussions with experienced design specification experts or other domain experts regarding the approaches and rules of thumb employed in solving material selection problems. Good communication with the domain experts enables the knowledge engineer to identify the factors that influences the selection of materials for a specific design. Consequently, this passed-on knowledge helps the knowledge engineer in formulating accurate rules of thumb to ensure suitable material selection for the known design specifications.

The inference engine provides the expert system with a systematic procedure for filtering through the knowledge base and electing the applicable rules in an orderly manner to reach recommended solutions (Farag, 2002). In other words, the inference engine is considered as a computerized reasoning system that assesses the facts stored in the knowledge base and applies relevant rules to those known facts, and then deduces new facts. The new facts are communicated back to the knowledge base. The primary role of the inference engine is to distinguish, select and match the rules in knowledge base to obtain optimum solutions.

The inference engine serves as the link between the knowledge base and the user interface. The user interface permits easy interaction between user and inference engine. The users can key in significant parameters for the problem. In return, the user interface provides recommendations.

Biobased polymer material data acquisition and storage

Firstly, biobased polymer materials were sieved out from material handbooks, online database and research articles. However, data are scarce compared to petroleum-derived polymers. Information on the most crucial properties of biopolymers which determines their suitability for application in the food packaging industry are widely scattered over many sources.

The most essential material properties with regard to food packaging were classified into four intrinsic properties which are mechanical, thermal, gas barrier and water vapour barrier properties (Weber 2000). Compostibility of the materials was also included for environmental safety consideration. The focus of the selection was on these five mentioned properties. The mechanical and thermal properties were recorded as quantitative data whereas gas and water vapour barrier properties and compostibility of materials were in qualitative data format such as Excellent, Very good, Good, Fair and Poor. Each qualitative datum was represented by a grade (i.e. Excellent = 5, Very good = 4, Good = 3, Fair = 2, Poor = 1).

The developed expert system (Exsys Corvid) has a database system feature called MetaBlock. Data of material properties were stored in MetaBlock. Each row and column in the MetaBlock represents a particular biobased polymer (i.e. PHB, PLA, maize starch, etc.) and material property (i.e. gas barrier, water vapour barrier, tensile strength etc.), respectively. Material data can be stored in MetaBlock (Fig. 2) directly using MetaBlock data editor window which allows data to be added, edited and deleted. The second alternative method of storing material data in MetaBlock is by importing data into MetaBlock from external material sources. In the present work, biobased polymer materials with relevant properties were entered in Microsoft Excel spread sheet and then transferred into the MetaBlock to create a database for food packaging material selection.

Fig. 2.

MetaBlock window

Knowledge based construction for biobased polymer materials selection

If – Then rule system

Domain experts are able to make complex material selection decisions by considering numerous relevant factors to reach solutions. Interestingly, the expert system captures this decision making logic of domain experts as rules that are processed by the inference engine. The If - Then rules simply imitate the critical thinking technique used by domain experts when solving material selection problems. Knowledge acquired from domain sources are converted into If – Then rules during the construction of the knowledge base. The If – Then rules of thumb are rules where there exist an If part that can be tested to be true or false based on the data in the knowledge base. When the If part is true, then the statement in the Then part is considered true and vice versa.

With the Exsys Corvid software the rules are formulated in the Logic Block system in the format of: IF < attribute 1 > THEN < solution A>, meaning, if attribute 1 is true, then solution A also must be true. Most material selection problems involve multi-attribute decision making. Therefore, the reasoning mechanism to determine which materials are suitable can be illustrated by the general format of If – Then rules shown in Fig. 3.

Fig. 3.

General format of If – Then rules

For the chaining process, if attribute 1 and attribute 2 and attribute 3 are true, then solution A will be true. Similar rules are constructed for each of the heuristics in the decision making process to obtain the logic for the expert system. The rules can be chained either forward or backward direction. However, the present work was forward chaining because it commenced from the event of new data input. Therefore, this chaining process is also known as event driven or data driven.

Scoring system

The developed expert system was designed to select suitable biobased polymer materials for food packaging applications as well as arrange the qualified candidates in order of excellence. Hence, a scoring system was formulated to enable the system arrange suitable selected materials depending on their scores. Each attribute is represented by a score in the logic rules which are finally accumulated to provide an overall score for each material. The closer the attribute values to the maximum attribute specification, the higher the score assigned to the material. Figure 4 shows a sample format of individual If – Then rules together with the scoring system that are described in the Logic Block to make-up the overall decision.

Fig. 4.

Sample of If – Then rules, scoring and reporting systems used in this work

The score for each attribute is calculated as illustrated in Equations (1) - (3). The final score is the accumulated score of all the given attributes as in Equation 4.

| 1 |

| 2 |

| 3 |

| 4 |

Reporting system of selection results

The variable ‘Report’ was used in the Logic Block as a command to display the results of the material selection. The ‘ADDSORTED’ feature which was attached to ‘Report’ as shown in Fig. 4 enables the system to sort each selected material base on its score value. Therefore, these selected materials are sorted from the highest to the lowest scores. This indicates that the material with the highest score is the most eligible candidate for the desired design specification.

Case study: Biobased polymer material selection for Food packaging applications

Food packaging materials

The purpose of food packaging is to efficiently guarantee safety and preserve the quality of food products from production through handling and storage, and finally to consumer uses (Weber 2000). The absence of packaging or deficiency in packaging leads to rapid deterioration of food quality and safety, instigating enormous commercial losses of valuable foodstuffs. Petroleum-derived plastic polymers, metals, glass, paper and board, or their combination are commonly used for food packaging (Weber et al. 2002). However, petroleum-based polymers such as polyethylene and polystyrene are dominantly utilized in the food packaging industry (Cha and Chinnan 2004). Though man-made polymers derived from petroleum are still the overriding food packaging material, they are considered as the principal source of solid waste generation due to their non-biodegradable nature (Rhim and Ng 2007). Out of ~ 200 million tons of petroleum-derived plastics produced globally, packaging proves to be the largest single market for plastics, amounting to over 12 million tons per year (Zhang et al. 2002; Rhim and Ng 2007). Therefore, it is considered necessary for packaging materials to biodegrade in an acceptable time period after use to eliminate environmental waste disposal problems. In this regard, biobased packaging materials are not only environmental waste problem free, but also possess commendable properties to maintain food quality and prolong food shelf-life. Biobased packaging films may also serve as carrier of some active substances such as antimicrobial, antioxidant etc. (Rhim and Ng 2007).

Biobased food packaging materials

Keywords such as “biopolymers” “biobased-plastics” “biodegradable” “compostable” “renewable” “sustainable” environmentally-friendly” “eco-friendly” and “green” are now a common sight in packaging-related literatures. This observation sends an imperative signal regarding the drastic awareness and concern about environmental issues which are triggered by non-biodegradable plastic waste problem together with fast exhaustion of global petroleum reserves. Peoples growing concerns in relation to the negative environmental impacts of petroleum-derived plastics especially for packaging brought biobased food packaging materials into spotlight. Biobased packaging deals with packaging that contains raw materials from renewable sources (i.e. agricultural and marine sources). Weber et al. (2002) reported that “Biobased food packaging materials are materials derived from renewable sources and they can be used for food applications”. Figure 5 shows the three main categories of biobased polymers

Fig. 5.

Categories of biobased polymers

To satisfy the demand of customers for safe and high quality food while shrinking waste disposal problems, biobased polymers are being explored as better alternative to conventional food packaging plastics. Biobased polymers such as polysaccharides, proteins, lipids, PLA and PHA have gained significant attention for the development of environmentally-friendly food packaging materials to surrogate their non-biodegradable polymer counterparts (Guilbert et al. 1996; Gennadios et al. 1997; Krochta and De Mulder-Johnston, 1997; Cuq et al. 1998; Rhim and Ng 2007). They have secured increasing focus owing to their numerous inherent advantages such as renewability, sustainability, biocompatibility, biodegradability, compostibility, processability and less energy dependence during processing (Grenha et al. 2010; Rasal et al. 2010; ValderramaSolano and Rojas de Gante 2014). Recent technological innovations and the inbuilt properties of biobased plastics films fuelled their accelerating usage as suitable food packaging materials (Cha and Chinnan 2004).

Exsys Corvid expert system for biobased food packaging material selection

Food packaging materials are designed to physically protect and generate acceptable physicochemical conditions for food products that are intended to attain satisfactory shelf-life. Hence, selecting suitable packaging materials bestowed with proper gas and water vapour barriers and mechanical properties would help to preserve food quality during storage and handling as well as prevent their premature deterioration. The packaging requirements of food products are complicated due to their dynamic nature with limited shelf-life (Weber, 2000). Thus, stringent food packaging requirements should be met to guarantee food quality and safety. In this light, potential biobased packaging materials must undergo vigorous selection processes in order to satisfy specific food packaging needs. However, most food packagers found it quite challenging to figure out the best biobased materials for specific food products, since these biobased materials possess diverse properties. Therefore, an expert system was developed to ease the task of food packagers and other users in selecting the most fitting biobased packaging materials for different food products. In the expert system, rules were set for the inference engine to facilitate material selection for three types of food products (i.e. fruits, dry food and dairy products). Each product has a specific packaging requirement.

The If – Then rules shown in the Logic Block window of Fig. 6 were implemented to conduct the biobased material selection process for each packaging design. Each material underwent constraint testing to determine which material successfully fulfilled all the design requirements specified in the logic rules and the ones that failed the constraints. The materials that satisfied all constraints were selected as the suitable candidates for that particular food packaging application. On the other hand, if any material violates the constraints, the system automatically disqualifies that material. For example, the minimum tensile strength for fruit packaging materials is set at 5 MPa while the maximum is 60 MPa. Therefore, any material less than 5 MPa will be automatically disqualified (negative score value). For materials within the desired range of 5 – 60 MPa, Eq. (1) is use to determine the score for the material’s tensile strength (score between 0 and 1). Similar procedure is implemented for tensile modulus, glass transition and melting point temperature.

Fig. 6.

Rules described in the Logic Block

In the case of compostibility, gas and water vapor barrier properties, the requirements are actually qualitative but represented in grading format such as excellent = 5, very good = 4, good = 3, fair = 2 and poor = 1. For example, the minimum compostability requirement for food packaging materials must be 3 (good) to prevent waste disposal problems. Therefore, any material which has fair or poor compostability will be automatically disqualified. The same steps are followed for gas and water vapor barrier properties.

Presentation of selection results

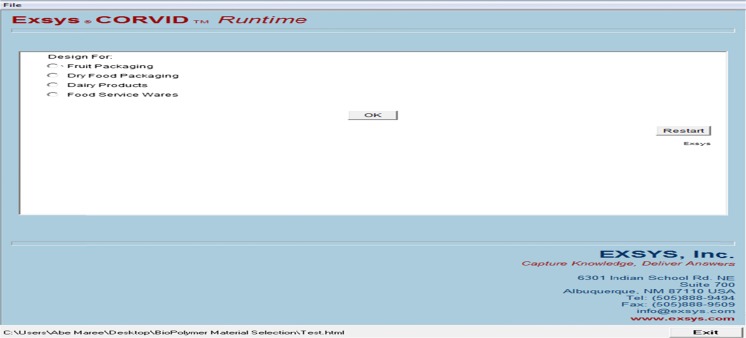

Figure 7 shows a user interface window that is displayed for the users to choose which type of food packaging they are considering for the selected biobased material. Upon clicking the desired type of food packaging, the selected biobased materials are displayed in sequence with the most suitable biobased polymer material on top. The selected materials were displayed together with their properties.

Fig. 7.

Food Packaging options displayed on user interface

The results of the biobased polymer material selection for fruit, dry product, dairy product packaging and food service wares are presented in Fig. 8. PolyLactic acid (PLA) was selected as the most suitable biobased polymer material for all four food packaging applications with different scores as shown in Table 1. This implies that PLA fulfilled all the design requirements for each application and satisfied the constraints of the rules. Thus, it was selected as the best candidate with the highest score for each design packaging application.

Fig. 8.

Selected biobased materials for different food packaging applications with their scores attached

Table 1.

List of selected biobased materials for each packaging application and their scores

| Fruit packaging | Dry food packaging | Dairy products | Food service wares | |

|---|---|---|---|---|

| 1st choice | PLA Score = 4.5395 |

PLA Score = 4.0395 |

PLA Score = 3.7564 |

PLA Score = 3.7564 |

| 2nd choice | PLA/*TPSB5 (95:5) Score = 3.0175 |

PLA/CS (80:20) Score = 2.7524 |

PLA/CS (80:20) Score = 2.4090 |

PLA/CS (80:20) Score = 2.4090 |

| 3rd choice | PLA/*CS (80:20) Score = 2.7524 |

PLA/TPSB5 (95:5) Score = 2.5175 |

PLA/TPSB5 (95:5) Score = 2.2072 |

PLA/TPSB5 (95:5) Score = 2.2072 |

| 4th choice | – | – | – | PLA/CS (50:50) Score = 1.6923 |

*TPSB : Thermoplastic starch (cassava) bagasse

*CS: Corn starch

Conclusions

Exsys Corvid expert system developed in this work is an example of a knowledge-based system that simulates the thinking logic of field experts for proper decision making. The IF – THEN rules were used for the system to select suitable biobased food packaging materials. The outstanding advantage of using this expert system is its ability to choose and rank the selected materials according to their proximity to the design specifications.

The direct focus of this paper was to develop an expert system for the selection of suitable biobased polymer materials for food packaging applications. Interestingly, polylactic acid (PLA) was selected as the most suitable biobased polymer material for all four food packaging applications. Based on the results obtained, we are hopeful that such expert system can ease the task of material selection for both domain experts and non-experts. Furthermore, the work can be extended to cover other industrial applications regarding materials selection tasks.

Acknowledgments

The authors wish to acknowledge the support of A.M. Fairuz (Ph.D student, UPM) and also the assistance of Dr. Nukman Yusoff of Universiti Malaya. This research was funded by Ministry of Education Malaysia through Exploratory Research Grant Scheme (ERGS), project number ERGS/1–2013/5527190.

References

- Alibaba HZ, Özdeniz MB. A building elements selection system for architects. Build Environ. 2004;39(3):307–316. doi: 10.1016/j.buildenv.2003.09.010. [DOI] [Google Scholar]

- Binti Ahmad M, bin Yaacob Z (2002) Dissolved gas analysis using expert system. In Research and Development, 2002. SCOReD 2002. Student Conference on (pp. 313–316). IEEE.

- Cha DS, Chinnan MS. Biopolymer-Based Antimicrobial Packaging: A Review. Crit Rev Food Sci Nutr. 2004;44(4):223–237. doi: 10.1080/10408690490464276. [DOI] [PubMed] [Google Scholar]

- Cuq B, Gontard N, Guilbert S (1998) Proteins as agricultural polymers for packaging production. Cereal Chemistry 75 (1): 1–9.

- Fairuz AM, Sapuan S M, Zainudin ES. A prototype expert system for material selection of polymeric-based composites for small fishing boat components. J Food Agric Environ, accepted for publication. 2012;10(3&4):1543–1549. [Google Scholar]

- Farag MM (2002) Quantitative methods of materials selection. In: Kutz M (Ed.). Handbook of materials selection. J. Wiley, pp. 1–24.

- Flior E, Anaya T, Moody C, Beheshti M, Han J, Kowalski K (2010) A knowledge-based system implementation of intrusion detection rules. In Information Technology: New Generations (ITNG), 2010 Seventh International Conference on (pp. 738–742). IEEE.

- Gennadios A, Hanna MA, Kurth LB. Application of edible coatings on meats, poultry and seafoods: a review. LWT-Food Science and Technology. 1997;30(4):337–350. doi: 10.1006/fstl.1996.0202. [DOI] [Google Scholar]

- Gonzalez AJ, Dankel DD. The engineering of knowledge-based systems: theory and practice. Prentice Hall: Englewood Cliffs; 1993. p. 12. [Google Scholar]

- Grenha A, Gomes ME, Rodrigues M, Santo VE, Mano JF, Neves NM, Reis RL. Development of new chitosan/carrageenan nanoparticles for drug delivery applications. Journal of Biomedical Materials Research Part. 2010;A92(4):1265–1272. doi: 10.1002/jbm.a.32466. [DOI] [PubMed] [Google Scholar]

- Guilbert S, Gontard N, Gorris LG. Prolongation of the shelf-life of perishable food products using biodegradable films and coatings. LWT-Food Science and Technology. 1996;29(1):10–17. doi: 10.1006/fstl.1996.0002. [DOI] [Google Scholar]

- Hambali A, Sapuan SM, Ismail N, Nukman Y (2009) Application of analytical hierarchy process in the design concept selection of automotive composite bumper beam during the conceptual design stage. Scientific Research and Essays 4(4):198–211

- Hambali A, Sapuan SM, Ismail N, Nukman Y (2010) Material selection of polymeric composite automotive bumper beam using analytical hierarchy process. J Cent South Univ T 17(2):244–256

- Kowalski K, Goetz J, Alam M (2006) Intelligent On-line Advising with Expert System Shell. In World Conference on E-Learning in Corporate, Government, Healthcare, and Higher Education (Vol. 2006, No. 1, pp. 687–694).

- Krochta JM, De Mulder-Johnston C. Edible and biodegradable polymer films: challenges and opportunities. Food Technol. 1997;51(2):61–74. [Google Scholar]

- Maleque MA, Salit MS. Materials Selection and Design. Singapore: Springer; 2013. Knowledge Based System in Materials Selection; pp. 99–116. [Google Scholar]

- Mun NK, Fairuz AM, Hambali A, Sapuan S M (2009) The Development of polymer materials selection system using PHPMY/ADMIN. Proceedings of the 9th National Symposium on Polymeric Materials, Putrajaya, Malaysia, 14 – 16 December 2009.

- Pavleković M, Zekić-Sušac M, Đurđević I (2007) Expert system for detecting a child’s gift in mathematics. Osijek, April 13, 2007, 98.

- Rasal RM, Janorkar AV, Hirt DE. Poly (lactic acid) modifications. Progress in polymer science. 2010;35(3):338–356. doi: 10.1016/j.progpolymsci.2009.12.003. [DOI] [Google Scholar]

- Rhim JW, Ng PKW. Natural Biopolymer-Based Nanocomposite Films for Packaging Applications. Critical Reviews in Food Science and Nutrition. 2007;47:411–433. doi: 10.1080/10408390600846366. [DOI] [PubMed] [Google Scholar]

- Sapuan SM, Mujtaba IM (2010) Development of computational framework for material selection of natural fiber-reinforced polymer composite materials using neutral network. In: Sapuan SM, MujtabaI M (Eds.). Composite Materials Technology: Neural Network Applications, CRC Press.

- Sapuan SM, Abdalla HS. A prototype knowledge-based system for the material selection of polymeric-based composites for automotive components. Composites Part A. 1998;29(7):731–742. doi: 10.1016/S1359-835X(98)00049-9. [DOI] [Google Scholar]

- Thakker A, Jarvis J, Buggy M, Sahed A. A novel approach to materials selection strategy case study: Wave energy extraction impulse turbine blade. Materials & Design. 2008;29(10):1973–1980. doi: 10.1016/j.matdes.2008.04.022. [DOI] [Google Scholar]

- ValderramaSolano AC, Rojas de Gante C. Development of biodegradable films based on blue corn flour with potential applications in food packaging.Effects of plasticizers on mechanical, thermal, and microstructural properties of flour films. Journal of Cereal Science. 2014;xxx:1–7. [Google Scholar]

- Weber CJ (2000) Biobased packaging materials for the food industry: status and perspectives, a European concerted action. The Royal Veterinary and Agricultural University. (http://www.biodeg.net/fichiers/Book%20on%20biopolymers%20(Eng).pdf)

- Weber CJ, Haugaard V, Festersen R, Bertelsen G. Production and applications of biobased packaging materials for the food industry. Food Additives & Contaminants. 2002;19:172–177. doi: 10.1080/02652030110087483. [DOI] [PubMed] [Google Scholar]

- Zhang L, Ruan D, Gao S. Dissolution and regeneration of cellulose in NaOH/thiourea aqueous solution. J Polym Sci B Polym Phys. 2002;40(14):1521–1529. doi: 10.1002/polb.10215. [DOI] [Google Scholar]