Abstract

The current investigation was conducted to study the effectiveness of chitosan coating in preserving the internal quality of table eggs stored under tropical room conditions of 32 ± 1 °C and 60–70 % r. h. Internal, physical and microbiological quality of eggs coated with chitosan was evaluated during 5-week storage at different temperature (22 ± 1 and 32 ± 1 °C). Chitin was extracted from shrimp processing raw byproducts and deacetylated to high quality chitosan. The prepared chitosan was analyzed for its characteristic properties. The chitosan with a viscosity of 2206 mPa.S was used to prepare the coating solution. The weight loss, Haugh unit, and yolk index values suggested that coating of eggs with shrimp α-chitosan increased the shelf life of eggs by almost 4-week at 22 ± 1 °C and 3-week at 32 ± 1 °C compared with controls (non chitosan coated and acetic acid coated) eggs. Three-time repeated coating was more effective in preserving the internal quality and preventing weight loss than with single-time coating of chitosan on egg. Therefore, three-time coating of eggs with 2206 mPa.S chitosan offer a protective barrier for preserving the internal quality of eggs stored at tropical room conditions and concomitantly prevent contamination with microorganisms.

Keywords: Egg, Egg quality, Chitosan, Chitosan coating, Haugh unit

Introduction

The chicken egg is one of the finest food, offering men an almost complete balance of essential nutrients with proteins, vitamins, minerals and fatty acids with great biological value (Cook and Briggs 1986). In addition to being one of the foods of the lowest cost, it increases the consumption of food of high nutritional value for the low-income population (Pasquoal et al. 2012). However, during storage of eggs several problems are encountered, including weight loss, interior quality deterioration, and microbial contamination (Bhale et al. 2003). Immediately after the egg is laid, the internal contents and structure begin to change. The movement of carbon dioxide and moisture through the shell governs quality changes in albumen and yolk, and weight loss of eggs (Stadelman 1986). It is a continual, irreversible process and even the most carefully controlled storage conditions can do no more than slowdown the rate of deterioration. Certain microorganisms that exist on the surface of the shell can penetrate into the interior of eggs and contaminate the internal content (Mayes and Takeballi 1983; Padron 1990; Messens et al. 2005; Inne et al. 2009). Eggshell quality is of primary importance to the egg industry worldwide. It is necessary to maintain good egg quality for economic viability of the worldwide egg industry (Roberts 2010). Thus, considerable attention has been given to the development of coating materials for preservation of eggs, including synthetic polymers, polysaccharides, proteins, oils, alone or a combination (Meyer and Spencer 1973; Obanu and Mpieri 1984; Herald et al. 1995; Lee et al. 1996; Bhale et al. 2003; No et al. 2005). Films and coatings can act as a barrier for moisture, gas, and aroma transfer (Wan et al. 2005). Chitosan coating is effective in preserving the internal quality of eggs without affecting consumer acceptance (Lee et al. 1996; Bhale et al. 2003; No et al. 2005; Kim et al. 2007).

Chitosan is a poly cationic natural copolymer consisting of β-(1 → 4)-2-acetamido-D-glucose (N-acetyl-D-glucosamine, GlcNAc) and β-(1 → 4)-2-amino-D-glucose (D-glucosamine, GlcN) units with the latter usually exceeding 70 % (Nidheesh and Suresh 2014). Chitosan is produced commercially from the marine crustaceans (shrimp and crab) chitin (poly-β-(1 → 4)-N-acetyl-D-glucosamine) by alkali N-deacetylation to a different degree (No et al. 2007; Suresh and Prabhu 2013). Chitosan possesses several unique chemical and biofunctional properties useful for various applications in many fields including food and biomedicine. In addition to biocompatible, biodegradable, non-antigenic and nontoxic, chitosan also possesses film forming property for use as edible coatings and strong antimicrobial activity against various food spoilage microorganisms and common foodborne pathogens (Jeon et al. 2002; Nidheesh and Suresh 2014). Studies reported showed that chitosan coating decreased weight loss and increased shelf-life of eggs by 2 to 3-week when compared to non-coated eggs (Lee et al. 1996; Bhale et al. 2003; No et al. 2005). However, all the previous works on chitosan-coated eggs have been done with eggs stored at ~25 °C (Lee et al. 1996; Bhale et al. 2003; No et al. 2005). Up to date, there is no information available in published literature on the shelf life and internal quality of chitosan-coated eggs stored at tropical temperature (32 ± 1 °C).

Egg production is an important and vital section of agriculture in India. India is 3rd largest egg producer in the world and exports eggs to various countries. However, Indian eggs are perceived as of lower quality and are quoted less value than the eggs from countries like USA and EU (Karthikeyan and Nedunchezhian 2014). In India, refrigeration is not compulsory, table eggs are maintained at room temperature at poultry farm and also in the domestic market. In addition, there is no specific law available to monitor the quality of eggs distributed in the domestic market. The increase in population of the country leads to more consumption of cheap protein rich diet like egg (Karthikeyan and Nedunchezhian 2014). Thus, there is a growing demand for quality eggs in the domestic market as well as for export. Storage temperature is one of the key factors affecting the quality of the egg (Jin et al. 2011). There is a need to improve processing, maintain its quality and preservation of table eggs in Indian system as well as other tropical nations. The main objective of this research was to evaluate the efficacy of chitosan coating in preserving the internal quality as well as the microbiological quality of table eggs during storage at tropical room conditions.

Materials and methods

Materials

Freshly laid, unwashed, feces-free, white-shell eggs (average weight 55 g) were procured from a poultry farm located in Mysore, India and immediately used for the experiment. All the reagents and chemicals used were of analytical grade.

Preparation of chitin and chitosan from shrimp processing raw byproducts

Pure α-chitin was prepared from marine shrimp processing raw byproducts according to Nidheesh and Suresh (2014). It was dried in a forced air drying oven at 50 ± 2 °C for 12 h. The chitin was deacetylated to chitosan using 50 % (w/v) NaOH solution at 100 °C for 24 h with a solid to solvent ratio of 1:10 (w:v). The resulting chitosan was washed to neutrality with potable tap water and finally repeatedly rinsed with demineralized water. The resulted chitosan was dried in a hot air oven at 50 ± 2 °C for 12 h and milled in a hammer mill to a particle size of <18 mesh.

Chemical and microbiological analysis

Moisture, fat, protein (Kjeldahl) and ash contents of shrimp byproducts, chitin and chitosan (AOAC 2000) and chitin content of shrimp byproducts (Nidheesh and Suresh 2014) were determined. The microbiological examination by standard plate count method and the heavy metal content by dry ash method using Atomic Absorption Spectrophotometer (AAS) (Shimadzu AA6701F, Japan) were analyzed (AOAC 2000).

The viscosity was measured using a 1 % (w/v) chitosan solution in 1 % (v/v) acetic acid with a viscometer (Rheology, International Viscometer) using spindle no.4 at 50 rpm at room temperature and values were reported in milli Pascal (mPa.S) unit. The degree of N-acetylation of chitin and chitosan were assessed by Fourier-transform infrared (FTIR) spectroscopy using NICOLET 5700 FTIR spectrometer (Thermo Electron Corporation, Madison, WI 53711) (Nidheesh and Suresh 2014).

Bio-preservation of egg using chitosan

Chitosan with viscosity of 2206.0 mPa.S was used for the preservation studies of eggs. Chitosan solution was freshly prepared before being applied to eggs shells. Each egg then coated by dipping in chitosan solution and allowed to dry under fan about 10 min. Eggs with one-time and three-time (three repeated coating after drying of each coating) chitosan coating were analyzed. Non-coated eggs and eggs coated with 1 % (v/v) acetic acid were used as the controls. Eggs were weighed individually and placed in plastic egg tray with the broader end upright and stored at 32 ± 1 and 22 ± 1 °C. A total of 300 eggs were used for the study (75 eggs per each group). Nine eggs from each group were randomly taken at 1-week intervals for analyzing various egg quality and microbiological parameters.

Microbiology of egg

External microbiology of egg

Three eggs were randomly selected from each group, and each egg was washed aseptically in 25 ml of sterile physiological saline (0.85 %, NaCl) and pooled the washing of each egg in the same group. The pooled washing was considered as 10−1 dilution. After the serial dilution aliquots were plated on pre-solidified agar plates for the enumeration of total aerobic bacteria, Escherichia coli and Salmonella were analyzed by standard methods (AOAC 2000).

Internal microbiology of egg

Eggs used for external microbiological analysis were used for the internal microbiological analysis. The washed eggs were wiped with alcohol and broken by a sterile knife, and the inner contents were aseptically transferred to sterile beaker. The inner contents of the eggs belonging to the same group were pooled together and were considered as a sample. The sample was homogenized using sterile glass beads. One ml of homogenized sample was added to 99 ml of sterile physiological saline and mixed well by shaking and considered as 10−1 dilution and a serial dilution was carried out. Plating and enumeration microbial count were performed as described above (external microbiology of egg).

Determination of weight loss

The weight of whole eggs was measured with a digital electronic balance (Kern PFB, Kern & Sohn Gmbh, Germany). The percentage weight loss of both control (non-coated and 1 % acetic acid-coated) and chitosan-coated eggs was calculated using the following equation (Eq. 1).

| 1 |

Determination of Haugh unit, albumen index and yolk index

The height of the albumen and yolk was measured using a tripod micrometer (AMES S-6428, IMM, Waltham, Mass., US) and width of the albumin and yolk was measured using a digital caliper. The yolk index was calculated as yolk height/yolk width. The albumin index was calculated as thick albumin height/thick albumen width. The Haugh unit (HU) was calculated using the following equation (Eq. 2) (Lee et al. 1996).

| 2 |

where, H is the thick albumin height (mm) and W is the whole egg weight (g).

Determination of shell thickness

Shell thickness of eggs was measured using a Baxlo Precision thickness gauge (Baxlo, Instrumentos De Media Y Precision, S. L).

Determination of depth of the air cell

The depth of the air cell was measured using a digital caliper after marking the air cell using an egg Candler. The depth of the air cell is the distance from its top to its bottom when the egg is held with the air cell up.

Determination of colour

Egg yolk color was also measured using a Minolta spectrophotometer (Model CM-508d, Minolta Camera Co. Ltd., Osaka, Japan) with 10° standard observer and D65 illuminant. Results were recorded as L*, a*, b*, and ∆E*ab values, where L* describes lightness, a* redness (−a* greenness), b* yellowness, ∆E*ab is the total color difference was used to indicate the magnitude of color differences when compared to the control. Color of egg yolk was also measured using DSM Yolk Colour Fan (Roche colour chart).

pH measurement

The albumen was separated from the yolk using yolk separator. The pH of the albumen and yolk was measured with a digital pH meter (Cyberscan, EuTech Instruments, Singapore) immediately after blending a pooled albumen and yolk sample obtained from 3 eggs.

Determination of shell strength

Mechanical shell strength (puncture strength) of egg was determined by using a Universal texture measuring system (LLOYED instruments, UK), equipped with a 1KN compression load cell and integrator. Each egg was mounted on a platform and punctured. The force (N) required puncturing the eggshell was recorded and expressed as the strength of the eggshell.

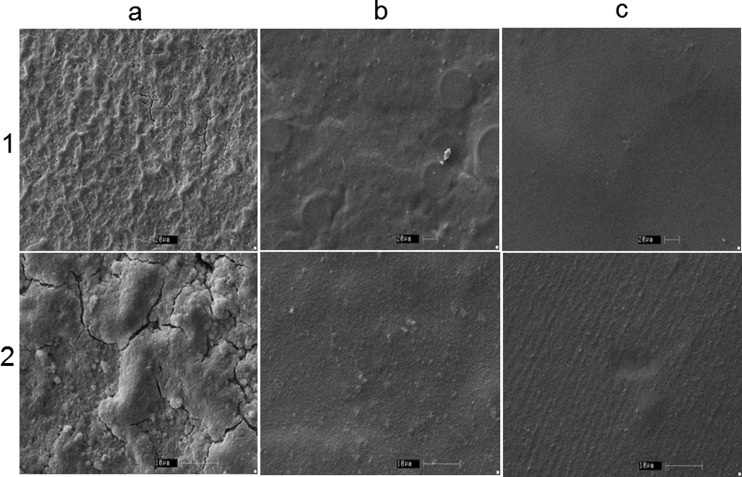

Scanning electron microscopy of shell

Shell surface of non-coated eggs (control) and eggs coated with chitosan dissolved in 1 % acetic acid was observed using a Scanning Electron Microscope (LEO 435 VP, LEO Electron Microscopy Ltd., Cambridge, UK) at 20 kV after gold covering (~100Å).

Statistical analysis

All the experiments were conducted at least in triplicate and average values ± standard deviation are reported. The results were statistically analyzed by using the Analysis of Variance (ANOVA) techniques, where the p value of ≤ 0.05 was regarded as significant. Statistica version 7.1 software system (Statistica 2005) was used for the data analysis.

Results and discussion

Characteristics of chitosan extracted

The yield of chitosan obtained from the chitin by alkali deacetylation was 81.5 % (w/w). In these conditions, the residual content (%, dwb) of ash (mineral) 1.7 ± 0.04 and protein zero with a moisture content of 5.2 ± 0.2 was in the chitosan. The viscosity of the prepared chitosan was 2206.0 mPa.S. The percentage of degree of deacetylation, calculated from the FTIR spectrum, was >93 %. From the AAS results, it was clear that the prepared chitosan did not contain sodium and heavy metal lead. Microbiological count (cfu/g) was found to be < 10 for total aerobic bacteria, < 5 yeast and mold count and zero for coliform. This result is in accord with specified qualities for food grade chitosan.

Effects of various coating of chitosan on shell thickness

Chitosan coating significantly (P ≤0.01) increased the thickness of eggshell. There was an average 10 μm increase in the eggshell thickness with one-time coating of eggs (340 ± 3 μm) as compared with control non-coated egg (330 ± 2 μm). Similarly, an average of 30 μm increase in the eggshell thickness was observed with three-time coating of chitosan (370 ± 3 μm) as compared with control non-coated egg. However, no changes (P ≤0.05) was observed in the thickness of the shell in both control (non-coated and 1 % acetic acid-coated) and chitosan coated (one and three-time coat) eggs during 5-weeks of storage at 32 ± 1 and 22 ± 1 °C (data not presented). Not much information is available regarding the thickness of the shell of chitosan coated and their effect on the shelf life of eggs stored at 32 ± 1 and 22 ± 1 °C. Most of the works on chitosan coated eggs were carried out at 25 °C (Lee et al. 1996; Bhale et al. 2003; No et al. 2005).

Shell thickness has a significant effect on moisture loss during storage and incubation. Shell quality affect consumer appeal, packaging, egg breakage, storage/shelf life, etc. Thin shelled eggs loose more moisture than do thick shelled eggs, causing deterioration on quality for table eggs (King’ori 2012). Eggshells can easily be damaged after the egg is laid, and cracking is one of the most common reasons for downgrading. It may be either due to an inadequate eggshell being laid or to poor handling which may occur during collection, grading or transportation. In addition, a strong, intact shell helps to keep the contents of the egg safe from microbial invasion (Roberts 2010).

Effects of coating of chitosan on weight loss

The weight loss of the control (non-coated and 1 % acetic acid-coated) and eggs coated with chitosan (one and three-time coating) during 5-week of storage at 32 ± 1 and 22 ± 1 °C is given in Table 1. Eggs stored at 22 ± 1 °C, lost weight significantly (P ≤0.05) with increasing storage periods, ranging from 5.75 ± 0.4 % to 9.29 ± 0.1 % after 5-week. Within the control groups, 1 % acetic acid-coated eggs showed more weight loss than non-coated eggs. This might be due to the degradation of CaCO3 of the eggshell and exposure of more pores. While, in eggs stored at 32 ± 1 °C, the weight loss gradually increased with increased storage periods ranging from 6.80 to13.07 % after 5-week for all eggs.

Table 1.

Effect of chitosan coating on percentage weight loss of eggs during 5-week of storage at 22 ± 1 and 32 ± 1 °C (n = 3)

| Storage period (Week) | Egg samples | |||

|---|---|---|---|---|

| NCE | ACE | ESC | ETC | |

| (a) Storage temperature 22 ± 1 °C | ||||

| 1 | 1.64 ± 0.3a | 1.31 ± 0.1a | 1.10 ± 0.1a | 0.88 ± 0.04a |

| 2 | 3.18 ± 0.4b | 3.21 ± 0.2b | 2.35 ± 0.2b | 1.93 ± 0.3b |

| 3 | 4.97 ± 0.8c | 5.07 ± 0.5c | 3.02 ± 0.1c | 3.26 ± 0.01c |

| 4 | 7.02 ± 0.6d | 6.57 ± 0.2d | 5.19 ± 0.5d | 4.42 ± 0.5d |

| 5 | 9.29 ± 0.1e | 9.05 ± 0.4e | 5.91 ± 0.4e | 5.75 ± 0.4e |

| (b) Storage temperature 32 ± 1 °C | ||||

| 1 | 2.96 ± 0.3a | 2.71 ± 0.1a | 1.93 ± 0.2a | 2.00 ± 0.1a |

| 2 | 6.77 ± 0.8b | 6.57 ± 0.2b | 5.62 ± 0.3b | 4.35 ± 0.5b |

| 3 | 10.08 ± 0.7c | 8.55 ± 0.2c | 6.97 ± 0.3c | 6.47 ± 0.2c |

| 4 | 13.53 ± 0.9d | 14.39 ± 0.9d | 9.29 ± 0.4d | 8.00 ± 0.7d |

| 5 | na | na | 11.02 ± 0.4e | 10.61 ± 0.2e |

Means ± standard deviations of three measurements

Means with different letters within a column indicate significant differences

NCE non-coated egg, ACE egg with acetic acid coat, ESC egg with one-time chitosan coat, ETC egg with three-time chitosan coat, na not analyzed

Weight loss of eggs during storage is caused by the evaporation of water and loss of carbon dioxide from the albumen through the shell (Obanu and Mpieri 1984; Stadelman 1986). The shell of chitosan-coated eggs showed no surface porosity (Fig. 1), which contributed to less weight loss during storage. This study shows that chitosan coating, specifically with three-time coating may offer a protective barrier against transfer of carbon dioxide and moisture through the eggshell even when stored at 32 ± 1 °C, thus minimizing weight loss and extending the shelf life of eggs (Lee et al. 1996).

Fig. 1.

Scanning electron micrograph of eggshell. Non-chitosan coated shell (a); chitosan one-time coated eggshell (b); chitosan three-time coated eggshell (c). 1 = 20 μm magnification, 2 = 10 μm magnification

Effect of coating of chitosan on Haugh unit

The Haugh unit is an expression relating egg weight and height of the thick albumen, and used for measurement of the albumen (protein) quality. The higher the Haugh value, the better the albumen quality of the eggs (Stadelman 1986). Changes in the Haugh unit of control and chitosan-coated eggs during 5-week of storage at 32 ± 1 and 22 ± 1 °C is presented in Table 2. Generally, the Haugh unit decreased with increasing storage periods. The loss of albumen quality is mainly attributed to the original albumen quality and the movement of water from albumen to yolk (Muller 1959). During 5-week of storage, significant differences in the Haugh unit were not observed between non coated and 1 % acetic acid-coated eggs. Compared with the noncoated eggs, chitosan-coated eggs, irrespective of number coating, normally had higher Haugh units during 5-week of storage. These results support previous observations by Lee et al. (1996), Bhale et al. (2003) and No et al. (2005), they reported that chitosan coating was effective in preserving the albumen quality of eggs. Among chitosan-coated eggs, those with three-time coating showed higher Haugh units than did the one-time chitosan coated eggs after 5-week of storage at 32 ± 1 and 22 ± 1 °C.

Table 2.

Effect of chitosan coating on Haugh Unit eggs during 5-week of storage at 22 ± 1 and 32 ± 1 °C (n = 3)

| Storage period (Week) | Egg samples | |||

|---|---|---|---|---|

| NCE | ACE | ESC | ETC | |

| 0 | 85.1 ± 0.02a | 85.4 ± 0.01a | 85.6 ± 0.01a | 85.6 ± 0.02a |

| (a) Storage temperature 22 ± 1 °C | ||||

| 1 | 56.6 ± 0.01b | 58.4 ± 0.02b | 74.4 ± 0.01b | 77.7 ± 0.02b |

| 2 | 42.5 ± 0.03c | 47.3 ± 0.03c | 69.0 ± 0.01c | 72.4 ± 0.05c |

| 3 | 37.8 ± 0.01d | 33.9 ± 0.01d | 59.6 ± 0.02d | 60.9 ± 0.03d |

| 4 | 34.5 ± 0.01e | 28.2 ± 0.02e | 56.0 ± 0.02e | 59.2 ± 0.04d |

| 5 | 20.9 ± 0.002f | 21.6 ± 0.001f | 31.1 ± 0.004f | 44.6 ± 0.001e |

| (b) Storage temperature 32 ± 1 °C | ||||

| 1 | 36.7 ± 0.01b | 37.4 ± 0.04b | 55.5 ± 0.01b | 67.2 ± 0.02b |

| 2 | 29.2 ± 0.00c | 28.4 ± 0.02c | 43.8 ± 0.02c | 60.2 ± 0.01c |

| 3 | 23.0 ± 0.01d | 22.8 ± 0.03d | 40.7 ± 0.02d | 59.5 ± 0.01c |

| 4 | 21.0 ± 0.06e | 20.3 ± 0.04e | 35.0 ± 0.01e | 50.8 ± 0.01d |

| 5 | na | na | 20.0 ± 0.03f | 24.6 ± 0.04e |

Means ± standard deviations of three measurements

Means with different letters within a column indicate significant differences

NCE non-coated egg, ACE egg with acetic acid coat, ESC egg with one-time chitosan coat, ETC egg with three-time chitosan coat, na not analyzed

The Haugh unit of chitosan three-time coated eggs, after 5-week of storage was 44.6 ± 0.02 and 24.6 ± 0.03, respectively at 22 ± 1 and 32 ± 1 °C. However, the Haugh unit of chitosan one-time coated eggs after 5-week of storage was 30.1 and 20.0, respectively at 32 ± 1 and 22 ± 1 °C. This infers that chitosan three-time coating is more effective in preserving the albumen quality of eggs at 32 ± 1 °C than chitosan one-time coating. The data of the current study proved that, chitosan three-time coating could preserve the albumen quality of coated eggs for at least 3 more weeks compared with the non-coated and acetic acid coated eggs stored at tropical temperature (32 ± 1 °C).

Effect of coating of chitosan on air space of eggs

The size (height) of the air space is used as an approximate guide to the quality and age of an egg. As the egg ages, moisture and carbon dioxide continue to be lost through the pores. Air moves in and the air space increases in size at a rate which is determined by the temperature and the relative humidity of the surrounding air. The moisture loss from the egg will be quicker if the air is warm and dry. Table 3 shows changes in air space of control and chitosan coated eggs during 5-week of storage at 32 ± 1 and 22 ± 1 °C. In general, the air space increased with increasing storage periods. During 5-week of storage, significant differences in the air space were not observed between non-coated and acetic acid coated eggs. Compared with the non-coated eggs, chitosan-coated eggs, irrespective of number of coating, showed significantly lower air space during 5-week of storage at 32 ± 1 °C. Among chitosan-coated eggs, those with three-time coating generally showed air space lower than the ones with one-time coating of chitosan during 5-week of storage. In the present study, the air space of chitosan three-time coated eggs increased from 1.7 to 5.25 mm after 4th week of storage at 32 ± 1 °C. While, the air space of control eggs increased from 1.4 to 7.8 mm (non-coated eggs) and 1.8 to 8.4 mm (acetic acid coated eggs) after 4th week of storage at 32 ± 1 °C (Table 3). The air space of chitosan three-time coated eggs increased from 1.7 to 4.1 mm after 5th week of storage at 22 ± 1 °C. While, the air space of control eggs increased from 1.4 to 6.6 mm (non-coated eggs) and 1.8 to 6.2 mm (acetic acid coated eggs) after 5th week of storage at 22 ± 1 °C. This implies that chitosan three-time coating is more effective in preserving the internal quality of eggs stored at 32 ± 1 °C.

Table 3.

Effect of chitosan coating on air space (mm) of eggs during 5-week of storage at 22 ± 1 and 32 ± 1 °C (n = 3)

| Storage period (Week) | Egg samples | |||

|---|---|---|---|---|

| NCE | ACE | ESC | ETC | |

| 0 | 1.83 ± 0.37a | 1.83 ± 1.25a | 1.93 ± 0.23a | 1.7 ± 0.75a |

| (a) Storage temperature 22 ± 1 °C | ||||

| 1 | 2.76 ± 0.33b | 2.30 ± 0.29b | 2.40 ± 0.44b | 2.10 ± 0.03b |

| 2 | 3.22 ± 0.52c | 3.55 ± 0.60c | 3.19 ± 0.37c | 3.06 ± 0.44c |

| 3 | 4.32 ± 0.30d | 4.37 ± 0.46d | 4.05 ± 0.75d | 3.52 ± 0.53d |

| 4 | 6.00 ± 0.61e | 5.27 ± 0.46e | 4.95 ± 0.50e | 4.50 ± 1.01e |

| 5 | 6.55 ± 0.11f | 6.15 ± 1.18f | 5.65 ± 0.26f | 5.12 ± 0.13f |

| (b) Storage temperature 32 ± 1 °C | ||||

| 1 | 3.32 ± 0.73b | 3.02 ± 0.11b | 3.13 ± 0.26b | 3.64 ± 0.50b |

| 2 | 4.50 ± 1.13c | 5.12 ± 0.45c | 3.65 ± 2.04c | 4.19 ± 3.39c |

| 3 | 6.68 ± 0.99d | 6.75 ± 1.30d | 4.40 ± 0.18d | 4.41 ± 0.53c |

| 4 | 7.80 ± 2.12e | 8.40 ± 1.34e | 4.85 ± 0.38e | 5.25 ± 0.56d |

| 5 | na | na | 7.96 ± 0.60g | 7.62 ± 0.42g |

Means ± standard deviations of three measurements

Means with different letters within a column indicate significant differences

NCE non-coated egg, ACE egg with acetic acid coat, ESC egg with one-time chitosan coat, ETC egg with three-time chitosan coat, na not analyzed

Effect of coating of chitosan on yolk index

A yolk index value is an indication of freshness of eggs and calculated as yolk height/yolk width (Stadelman 1986). A decrease in a yolk index value during storage indicates a progressive weakening of the vitelline membranes and liquefaction of the yolk caused mainly by diffusion of water from the albumen (Obanu and Mpieri 1984). Table 4 shows changes in yolk index of control and chitosan coated eggs during 5-week of storage at 32 ± 1 and 22 ± 1 °C. Overall, the yolk index decreased with increasing storage periods, as also observed for the Haugh unit (Table 2). Compared with the non-coated eggs, chitosan-coated eggs, irrespective of number of coating, showed significantly higher yolk index during 5-week of storage at 32 ± 1 °C. Among chitosan-coated eggs, those with three-time coating generally showed higher yolk index than the ones with one-time coating of chitosan during 5-week of storage. In the current study, the yolk index of chitosan three-time coated eggs decreased by 0.21 (from 0.39 to 0.18) after 4th week of storage at 32 ± 1 °C and 0.16 (from 0.39 to 0. 23) after 5th week of storage at 22 ± 1 °C (Table 4). Similar observations were reported by other researchers (Lee et al. 1996; Bhale et al. 2003; No et al. 2005)

Table 4.

Effect of chitosan coating on egg yolk index of eggs during 5-week of storage at 22 ± 1 and 32 ± 1 °C (n = 3)

| Storage period (Week) | Egg samples | |||

|---|---|---|---|---|

| NCE | ACE | ESC | ETC | |

| 0 | 0.40 ± 0.01a | 0.40 ± 0.01a | 0.40 ± 0.01a | 0.39 ± 0.01a |

| (a) Storage temperature 22 ± 1 °C | ||||

| 1 | 0.34 ± 0.01b | 0.36 ± 0.01b | 0.37 ± 0.01b | 0.38 ± 0.01a |

| 2 | 0.32 ± 0.03c | 0.32 ± 0.03c | 0.37 ± 0.01b | 0.36 ± 0.02b |

| 3 | 0.30 ± 0.01d | 0.28 ± 0.02d | 0.32 ± 0.02c | 0.34 ± 0.05c |

| 4 | 0.23 ± 0.02e | 0.26 ± 0.03e | 0.29 ± 0.02d | 0.31 ± 0.03d |

| 5 | 0.029 ± 0.002f | 0.029 ± 0.001f | 0.24 ± 0.004e | 0.23 ± 0.001e |

| (b) Storage temperature 32 ± 1 °C | ||||

| 1 | 0.20 ± 0.01a | 0.15 ± 0.10a | 0.27 ± 0.01a | 0.35 ± 0.02a |

| 2 | 0.14 ± 0.00b | 0.14 ± 0.01a | 0.18 ± 0.02b | 0.30 ± 0.01b |

| 3 | 0.10 ± 0.01c | 0.09 ± 0.02b | 0.17 ± 0.02b | 0.23 ± 0.01c |

| 4 | 0.07 ± 0.006d | 0.04 ± 0.02c | 0.14 ± 0.01c | 0.18 ± 0.01d |

| 5 | na | na | na | na |

Means ± standard deviations of three measurements

Means with different letters within a column indicate significant differences

NCE non-coated egg, ACE egg with acetic acid coat, ESC egg with one-time chitosan coat, ETC egg with three-time chitosan coat, na not analyzed

Effect of chitosan coating on albumin and yolk pH of eggs

Newly laid chicken eggs have an initial albumin pH of 7.6 to 8.5 and are saturated with CO2. During storage, the albumin pH gradually increases at a temperature dependent rate to a maximum value of about 9.7, accompanied by a loss of CO2 (Heath 1977; Kim et al. 2007; Banerjee et al. 2011). Li-Chan et al. (1995) reported that after 21 days of storage, the albumen had a pH close to 9.4, regardless of storage temperature between 3 and 35 °C. Increases in albumen pH are due to CO2 loss through the shell pores, and depend on dissolved CO2, bicarbonate ions, carbonate ions and protein equilibrium. Table 5 shows changes in albumin pH of control and chitosan-coated eggs during the 5-week storage at 32 ± 1 and 22 ± 1 °C. During 5-week of storage, significant differences in the albumen pH were not observed between non-coated (9.5–9.6) and acetic acid coated (9.4–9.5) eggs. Compared with the non-coated eggs, chitosan-coated eggs (irrespective of number of coating) showed significantly lower pH of albumin after 5-week of storage at 32 ± 1 °C. Among chitosan-coated eggs, three-time chitosan coating generally showed lower albumin pH than with one-time chitosan coating during 5-week of storage (Table 5). These results indicate that chitosan coating decreased CO2 release through the shell by acting as a gas barrier. This concludes that chitosan three-time coating is more effective in preventing the increase of albumen pH of eggs stored at 32 ± 1 °C. Heath (1977) observed that when CO2 loss was prevented by the oiling of the shell, the albumen pH of 8.3 did not change over a 7-day period of storage at 22 °C. In oiled eggs stored at 7 °C, albumen pH dropped from 8.3 to 8.1 in 7 days (Li-Chan et al. 1995).

Table 5.

Effect of chitosan coating on albumen and yolk pH of eggs during 5-week of storage at 22 ± 1 and 32 ± 1 °C

| Storage period (Week) | Egg samples | |||||||

|---|---|---|---|---|---|---|---|---|

| NCE | ACE | ESC | ETC | |||||

| pH | ||||||||

| Albumen | Yolk | Albumen | Yolk | Albumen | Yolk | Albumen | Yolk | |

| 0 | 8.4 | 5.8 | 8.4 | 5.8 | 8.4 | 5.8 | 8.4 | 5.8 |

| (a) Storage temperature 22 ± 1 °C | ||||||||

| 1 | 9.0 | 6.0 | 9.2 | 6.0 | 8.9 | 6.1 | 8.9 | 6.1 |

| 2 | 9.5 | 6.3 | 9.6 | 6.2 | 9.2 | 6.1 | 9.2 | 6.2 |

| 3 | 9.5 | 6.4 | 9.6 | 6.4 | 9.3 | 6.3 | 9.1 | 6.3 |

| 4 | 9.5 | 6.2 | 9.4 | 6.1 | 9.1 | 6.6 | 8.9 | 6.1 |

| 5 | 9.5 | 6.9 | 9.4 | 6.6 | 8.8 | 6.2 | 8.9 | 6.3 |

| (b) Storage temperature 32 ± 1 °C | ||||||||

| 1 | 9.4 | 6.4 | 9.1 | 6.2 | 9.3 | 6.4 | 8.8 | 6.2 |

| 2 | 9.6 | 6.5 | 9.5 | 6.9 | 9.4 | 6.7 | 8.7 | 6.3 |

| 3 | 9.6 | 6.8 | 9.5 | 7.1 | 9.5 | 7.3 | 8.5 | 6.4 |

| 4 | 9.6 | 7.0 | 9.5 | 6.9 | 9.0 | 7.1 | 8.5 | 6.3 |

| 5 | na | na | na | na | na | na | na | na |

NCE non-coated egg, ACE egg with acetic acid coat, ESC egg with one-time chitosan coat, ETC egg with three-time chitosan coat, na not analyzed

In newly laid eggs, the yolk pH is in general close to 6.0; however, during storage it gradually increases to reach 6.4 to 6.9. Table 5 shows changes in yolk pH of control and chitosan-coated eggs during the 5-week storage at 32 ± 1 and 22 ± 1 °C. During 5 week of storage, significant differences in the yolk pH were not observed between non-coated and acetic acid coated eggs. Compared with the non-coated eggs, chitosan-coated eggs, irrespective of number of coating, showed significantly lower yolk pH during 5-week of storage at 32 ± 1 °C. Among chitosan-coated eggs, those with three-time coating showed significantly lower yolk pH than the ones with one-time coating of chitosan during 5-week of storage (Table 5). The decrease in internal egg quality once the egg is laid is due to the loss of water and CO2. In consequence, the egg pH is altered, resulting in watery albumen due to the loss of the thick albumen protein structure. Increases in yolk pH were observed with increasing storage time (Samli et al. 2005).

Effect of chitosan coating on egg yolk color

Egg yolk color is chiefly dependent upon the content of yolk carotenoids which can be degraded by oxidative processes, varying the yolk pigmentation during storage (Caner 2005; Caner and Cansiz 2008). Changes in yolk color of control and chitosan-coated eggs during a 5-week storage at 32 ± 1 and 22 ± 1 °C were observed (data not shown). A 5-week storage resulted in an overall decrease in L* (except for three-time chitosan coating) and a* values, and an increase in b* and H° values of control and chitosan-coated eggs, compared with the 0 day samples. However, no significant (P ≤0.05) color differences were observed amongst control and chitosan-coated eggs during a 5-week storage at 32 ± 1 and 22 ± 1 °C.

Effect of chitosan coating on shell strength

Eggshell must be strong enough to minimize breakage during handling and storage. During 5-week of storage, significant differences in the shell strength were not observed between non-coated and acetic acid coated eggs. Shell strength of non-coated (from 34.98 N to 26.74 N) and acetic acid coated (from 36.03 N to 24.59 N) eggs were decreased after 5-week storage at 32 ± 1 °C. Compared with the non-coated eggs, chitosan-coated eggs, irrespective of number of coating, showed significantly high shell strength during 5-week of storage at 32 ± 1 °C. Results showed that chitosan coating enhances the shell strength and minimizes the breakage during storage (Table 6). Similar observation was reported (Caner 2005; Caner and Cansiz 2008). Wong et al. (1996) stated that improved shell strength will result in reduced breakage during handling and storage. The results of the current investigation shows that chitosan coating improves the shell breaking strength and this may offer to minimize the breakage during storage at higher temperature.

Table 6.

Effect of chitosan coating on egg shell strength during 5-week of storage at 22 ± 1 and 32 ± 1 °C (n = 3)

| Egg sample | Storage temperature (°C) | Maximum load (N) | |||||

|---|---|---|---|---|---|---|---|

| Storage period (week) | |||||||

| 0 | 1 | 2 | 3 | 4 | 5 | ||

| 22 ± 1 | |||||||

| ESC | 37.05b | 41.24b | 40.38a | 43.99b | 40.67b | 41.27b | |

| ETC | 36.92b | 38.49c | 40.66a | 43.07b | 40.76b | 39.25b | |

| ACE | 36.03b | 37.2c | 34.78b | 34.27c | 32.44c | 30.42c | |

| NCE | 34.98c | 37.3c | 35.07b | 34.28c | 31.59c | 27.46d | |

| 32 ± 1 | |||||||

| ESC | 37.05b | 38.95b | 40.56b | 40.56b | 39.73b | 35.23b | |

| ETC | 36.92b | 44.23c | 43.65c | 43.65c | 33.83c | 32.83c | |

| ACE | 36.03b | 35.24d | 36.43d | 36.43d | 24.59d | 21.25d | |

| NCE | 34.98c | 34.11d | 38.68b | 34.58e | 26.74e | 24.86e | |

Means with different letters within a column indicate significant differences

NCE non-coated egg, ACE egg with acetic acid coat, ESC egg with one-time chitosan coat, ETC egg with three-time chitosan coat

Grade of chitosan-coated eggs during storage

Eggs can be classified into 4 grades based on the Haugh unit, AA (above 72), A (71 to 60), B (59 to 31) and C (below 30) grades (Lee et al. 1996; Bhale et al. 2003). Changes in the classified egg grade during a 5-week storage at 32 ± 1 and 22 ± 1 °C is presented in Table 7. The classified grade decreased with increasing storage periods, from AA to B after 1 week for the control eggs at 32 ± 1 °C storage. Three-time chitosan-coated eggs changed from AA to C after 4-weeks at 32 ± 1 °C and AA to B grades after 5-week at 22 ± 1 °C. These data reveal that three-time chitosan coating is more effective in preserving the egg quality than one-time coating for storage of egg at 32 ± 1 °C. Based on the Haugh unit, Herald et al. (1995) reported that the uncoated and spray-dried wheat gluten-coated eggs changed from grade A to grade B after 1- and 2-week storage at room temperature, respectively. Bhale et al. (2003) reported that 1 and 2 % chitosan-coated eggs, respectively, changed from AA to C and AA to B grades after 5-week, irrespective of the molecular weight of chitosan used for coating.

Table 7.

Grade of eggs based on Haugh Unit during 5-week of storage at 22 ± 1 and 32 ± 1 °C (n = 3)

| Storage period (Week) | Egg samples | |||

|---|---|---|---|---|

| NCE | ACE | ESC | ETC | |

| 0 | AA | AA | AA | AA |

| (a) Storage temperature 22 ± 1 °C | ||||

| 1 | B | B | AA | AA |

| 2 | B | B | A | AA |

| 3 | B | B | A | A |

| 4 | B | C | B | A |

| 5 | C | C | B | B |

| (b) Storage temperature 32 ± 1 °C | ||||

| 1 | B | B | B | A |

| 2 | C | C | B | A |

| 3 | C | C | B | B |

| 4 | C | C | B | B |

| 5 | na | na | C | C |

Grade = Haugh Unit: AA = >72; A = 71–60; B = 59–31; C = < 30

NCE non-coated egg, ACE egg with acetic acid coat, ESC egg with one-time chitosan coat, ETC egg with three-time chitosan coat, na not analyzed

Effect of chitosan coating on microbiology

Total aerobic plate count is a quality indicator of the raw material before processing (ICMSF 1986). At day 0, total aerobic plate count of noncoated eggs (control) was <10 cfu/ml. After 5-weeks of storage, total aerobic plate count of noncoated eggs was increased to ~ 20 cfu/ml. Total aerobic plate count was not detected in all coated eggs before and after 5-weeks of storage. The internal microbial count remained zero for coated as well as uncoated eggs before and after 5-weeks of storage at 32 ± 1 and 21 ± 1 °C. No Salmonella and E. coli colonies were detected in all control and coated eggs before and after 5-weeks of storage. Similarly, no yeast and mold colonies were detected in all coated eggs before and after 5-weeks of storage. Egg products should meet the specification of less than 2.5 × 104 cfu/g for aerobic plate count and negative presence of Salmonella (Ricke et al. 2001). ICMSF (1986) establishes a presence between 5.0 × 104 and 1.0 × 106 cfu/g for aerobic plate count and zero for Salmonella as limits for egg products. Thus, our present results indicate that chitosan coating improves the microbiological quality eggs throughout the 5-weeks of storage at 32 ± 1 and 21 ± 1 °C. Coated eggs keep internal quality due to the reduction of the breakage of eggshell and egg microbial contamination (Wong et al. 1996).

Conclusions

This study clearly demonstrates that chitosan coating is effective in preserving the interior quality of eggs stored at room temperature (32 ± 1 °C) in tropical climates. Not much differences in weight loss, Haugh unit, and the albumin index were observed among two chitosan treatments (one and three-time coating) after 5-week of storage at 22 ± 1 °C. However, three-time chitosan coating is beneficial in reducing weight loss and obtaining higher Haugh unit and albumen (higher albumen index) quality during a 5-week storage period at 32 ± 1 °C. Three-time chitosan coating increased the shelf life of eggs by more than 3-week at 32 ± 1 °C compared with that of non-coated eggs. Extension of egg shelf life by 3-week at 32 ± 1 °C is highly significant in view of the open domestic market in India as well as other tropical nations, where refrigeration is not enforced. Further investigations are required to scale-up trials under the large production capacity, typical of commercial conditions. Investigations are also required for automatization of the process.

Acknowledgments

NT thank the University Grants Commission (UGC), New Delhi, India and GKP thank the Department of Science and Technology (DST), New Delhi, India for the award of Research Fellowship. Authors thank Director, CSIR-CFTRI, Mysore for his encouragement and permission to publish this work.

Competing interests

The authors declare that they have no conflict of interest

References

- AOAC . Official methods of analysis of AOAC International. 17. Gaithersburg: AOAC International; 2000. [Google Scholar]

- Banerjee P, Keener KM, Lukito VD. Influence of carbon dioxide on the activity of chicken egg white lysozyme. Poult Sci. 2011;90(4):889–895. doi: 10.3382/ps.2010-00854. [DOI] [PubMed] [Google Scholar]

- Bhale S, No HK, Prinyawiwatkul W, Farr AJ, Nadarajah K, Meyers SP. Chitosan coating improves shelf life of eggs. J Food Sci. 2003;68(7):2378–2383. doi: 10.1111/j.1365-2621.2003.tb05776.x. [DOI] [Google Scholar]

- Caner C. The effect of edible eggshell coatings on egg quality and consumer perception. J Sci Food Agric. 2005;85:1897–1902. doi: 10.1002/jsfa.2185. [DOI] [Google Scholar]

- Caner C, Cansiz O. Chitosan coating minimises eggshell breakage and improves egg quality. J Sci Food Agric. 2008;88:56–61. doi: 10.1002/jsfa.2962. [DOI] [Google Scholar]

- Cook F, Briggs GM. The nutritive value of eggs. In: Stadelman WJ, Cotterill OJ, editors. Egg science and technology. 3. Westport: AVI Publishing; 1986. pp. 141–163. [Google Scholar]

- Heath JL. Chemical and related osmotic changes in egg albumen during storage. Poult Sci. 1977;56:822–828. doi: 10.3382/ps.0560822. [DOI] [Google Scholar]

- Herald TJ, Gnanasambandam R, McGuire BH, Hachmeister KA. Degradable wheat gluten films: preparation, properties and applications. J Food Sci. 1995;60(1147–50):1156. [Google Scholar]

- ICMSF (International Commission on Microbiological Specifications for Foods) Microorganisms in foods 2: sampling for microbiological analysis: principles and specific applications. 2. Toronto: University of Toronto Press; 1986. [Google Scholar]

- Inne G, Richard D, Frank P, Freddy H, Richard G, Tom JH, Filip VI. Mechanisms of egg contamination by Salmonella Enteritidis. FEMS Microbiol Rev. 2009;33:718–738. doi: 10.1111/j.1574-6976.2008.00161.x. [DOI] [PubMed] [Google Scholar]

- Jeon YI, Kamil JYVA, Shahidi F. Chitosan as an edible invisible film for quality preservation of herring and Atlantic cod. J Agric Food Chem. 2002;50:5167–5178. doi: 10.1021/jf011693l. [DOI] [PubMed] [Google Scholar]

- Jin YH, Lee KT, Lee WI, Han YK. Effects of storage temperature and time on the quality of eggs from laying hens at peak production. Asian-Aust J Anim Sci. 2011;24(2):279–284. doi: 10.5713/ajas.2011.10210. [DOI] [Google Scholar]

- Karthikeyan R, Nedunchezhian VR. An analysis of price trends and its behavioral patterns of the Indian poultry market with reference to egg. Afr J Agric Res. 2014;9(1):8–13. doi: 10.5897/AJAR2013.7743. [DOI] [Google Scholar]

- Kim SH, No HK, Prinyawiwatkul W. Effect of molecular weight, type of chitosan, and chitosan solution pH on the shelf-life and quality of coated eggs. J Food Sci. 2007;72:S44–S48. doi: 10.1111/j.1750-3841.2006.00233.x. [DOI] [PubMed] [Google Scholar]

- King’ori AM. Egg quality deffects: types, causes and occurrence: a review. Anim Prod Adv. 2012;2(8):350–357. [Google Scholar]

- Lee SH, No HK, Jeong YH. Effect of chitosan coating on quality of egg during storage. J Korean Soc Food Nutr. 1996;25:288–293. [Google Scholar]

- Li-Chan EC, Powrie WD, Nakai S. The chemistry of eggs and egg products. In: Stadelman WD, Cotteril OJ, editors. Egg science and technology. New York: Food Products Press; 1995. pp. 105–176. [Google Scholar]

- Mayes FJ, Takeballi MA. Microbial contamination of the hen’s egg: a review. J Food Prot. 1983;46:1092–1098. doi: 10.4315/0362-028X-46.12.1092. [DOI] [PubMed] [Google Scholar]

- Messens W, Grijspeerdt K, Herman L. Eggshell penetration by Salmonella: a review. World Poult Sci J. 2005;61:71–85. doi: 10.1079/WPS200443. [DOI] [PubMed] [Google Scholar]

- Meyer R, Spencer JV. The effect of various coatings on shell strength and egg quality. Poult Sci. 1973;52:703–711. doi: 10.3382/ps.0520703. [DOI] [Google Scholar]

- Muller WJ. Factors affecting the quality loss in egg albumin during storage. Poult Sci. 1959;38:843–846. doi: 10.3382/ps.0380843. [DOI] [Google Scholar]

- Nidheesh T, Suresh PV (2014) Optimization of conditions for isolation of high quality chitin from shrimp processing raw byproducts using response surface methodology and its characterization. J Food Sci Technol. doi:10.1007/s13197-014-1446-z [DOI] [PMC free article] [PubMed]

- No HK, Prinyawiwatkul W, Meyers SP. Comparison of shelf life of eggs coated with chitosans prepared under various deproteinization and demineralization times. J Food Sci. 2005;70(6):S377–S382. doi: 10.1111/j.1365-2621.2005.tb11459.x. [DOI] [Google Scholar]

- No HK, Meyers SP, Prinyawiwatkul W, Xu Z. Applications of chitosan for improvement of quality and shelf life of foods: a review. J Food Sci. 2007;72(5):R87–R100. doi: 10.1111/j.1750-3841.2007.00383.x. [DOI] [PubMed] [Google Scholar]

- Obanu ZA, Mpieri AA. Efficiency of dietary vegetable oils in preserving the quality of shell eggs under ambient tropical conditions. J Sci Food Agric. 1984;35:1311–1317. doi: 10.1002/jsfa.2740351207. [DOI] [Google Scholar]

- Padron MN. Salmonella typhimurium penetration through the eggshells of hatching eggs. Avian Dis. 1990;34:463–465. doi: 10.2307/1591437. [DOI] [PubMed] [Google Scholar]

- Pasquoal CM, Evilda RL, Juliana PM, Wanessa NKO, Joaquim EN. Egg quality of laying hens in different conditions of storage, ages and housing densities. Rev Bras Zootec. 2012;41(9):2064–2069. doi: 10.1590/S1516-35982012000900014. [DOI] [Google Scholar]

- Ricke SC, Birkholddf SG, Gast RK. Eggs and egg products. In: Downes FP, Ito K, editors. Compendium of methods for the microbiological examination of foods. 4. Washington: American Public Health Association; 2001. pp. 473–481. [Google Scholar]

- Roberts JR. Factors affecting eggshell and internal egg quality. 18th Annual ASAIM SE Asian feed technology and nutrition workshop. Cambodia: Le Meridien Siem Reap; 2010. [Google Scholar]

- Samli HE, Agna A, Senkoylu N. Effects of storage time and temperature on egg quality in old laying hens. J Appl Poult Res. 2005;14:548–553. doi: 10.1093/japr/14.3.548. [DOI] [Google Scholar]

- Stadelman WJ (1986) Quality identification of shell eggs. Egg science and technology, 37–61

- Statistica . STATISTICA (data analysis software system), version 7.1. Tulsa: Statsoft Inc; 2005. [Google Scholar]

- Suresh PV, Prabhu GN (2013) Seafood. In: Chandrasekaran M (ed) Valorization of food processing by-products. Taylor & Francis, New York, pp 685–736

- Wan VCH, Kim MS, Lee SY. Water vapour permeability and mechanical properties of soy protein isolate edible films composed of different plasticizer combinations. J Food Sci. 2005;70:E387–E391. doi: 10.1111/j.1365-2621.2005.tb11443.x. [DOI] [Google Scholar]

- Wong YC, Herald TJ, Hachmeister KA. Evaluation of mechanical and barrier properties of protein coatings on shell eggs. Poult Sci. 1996;75:417–422. doi: 10.3382/ps.0750417. [DOI] [Google Scholar]