Abstract

In the present work, the bread-making performance of durum wheat flour under straight-dough and sourdough procedures were compared to those offered by soft wheat flour by means of selected physical properties (colour, texture, water dynamics, crumb grain characteristic, bulk volume) immediately after baking and during a 5-day shelf-life. The use of sourdough process better preserved both crumb grain characteristic and moisture content of the breads during shelf-life, independently of the wheat flour used. The flour seemed to significantly affect the water dynamics in sourdough breads, being the dehydration process of crust and under-crust faster in durum wheat breads. On the other hand, increasing trend of crumb firmness during the shelf-life was slower in durum wheat breads than in those obtained with soft wheat flour. Initial colour parameters of crust and crumb appeared to less change during shelf-life if durum wheat flour was used. Thus, the final quality of breads after baking and along the shelf-life was significantly affected by both the type of flours and the bread-making process. The results reported herein showed that technological performances of durum wheat flour, especially when combined with sourdough processes, could be successfully exploited for the production of innovative products in the bread-making industry.

Keywords: Bread, Durum wheat, Shelf-life, Physical analysis, Sourdough

Introduction

Bread is a world-wide staple food, which is consumed in large quantities, and in different forms depending on cultural habits. In the last ten years, its global consumption has been increased by about 30 % in Latin America and Africa, in particular; it has remained stable in the EU-countries with an average consumption of 50 kg of bread per person per year (The Federation of Bakers 2014).

Unfortunately, this product is perishable; its integrity begins to deteriorate immediately after baking due to the chemical and physical changes that occur during the well-known staling process (Gray and Bemiller 2003). In recent years, different baking technologies, e.g., frozen dough baking and new additives have been developed to better respond to market demands, and to drive the production of bread with an extended shelf life. In some cases, these technologies were a rediscovery and modernization of ancient, traditional Mediterranean procedures to improve flavour, texture, and to prolong the shelf-life of bread (Corsetti 2013). In particular, sourdough is now used as a form of leavening to avoid the use of additives (Chavan and Chavan 2011), becoming a fast-growing segment of the food market, but literature results about final quality improvement of the bread were often contrasting (Arendt et al. 2007). Sourdough bread is prepared with a mixture of flour and water that is then fermented by spontaneous lactic acid bacteria and yeasts originating from flour, dough ingredients and the environment. The metabolic activities of sourdough microbiota lead to the formation of different compounds involved in texture, flavour and taste characteristics of dough and bread (Chavan and Chavan 2011). The development and maintenance of the microbial species typical to sourdough are achieved using traditional discontinuous processes, which require subsequent refreshments of the primary dough (seed sour from a previous batch) to obtain the full sourdough after a single or multistage process (Pagani et al. 2006). The fermentation starts without the addition of baker’s yeast, thus extending the process for several hours (Corsetti 2013). Then, the refreshed sourdough is mixed along with the rest of the ingredients into the final dough (Corsetti 2013). This procedure is adopted in the most traditional bread productions, while dried/stabilized sourdoughs are nowadays used at the industrial level for obtaining a constant quality.

Durum wheat flour associated with sourdough fermentation has been rediscovered for bread-making in the Mediterranean area using ancient procedures, due to the recent introduction of new cultivars with stronger gluten properties. The end-products are traditional handmade breads, highly appreciated by consumers for the organoleptic quality. Some recent published studies address the characteristics of these breads and evaluate their shelf-life dynamics (Raffo et al. 2003; Chiavaro et al. 2008; Fadda et al. 2010). Other than the studies on specific traditional breads, the use of durum wheat flour in bread-making has rarely been debated in literature, and its addition to soft or other wheat flours can only been found in some dated studies. In these works, it was reported that the addition of 10–30 % of durum wheat flour to other weaker wheat flours improve the bread quality after baking (Boyacioğlu and D’Appolonia 1994a; Boggini et al. 1997). A longer shelf-life possibly associated with a higher water binding capacity of durum wheat flour was also documented (Boyacioğlu and D’Appolonia 1994b; Hareland and Puhr 1998). More recently, other aspects have been considered by scientists: the nutritional improvement of durum wheat flour with flours of other vegetable source in bread-making (Sabanis and Tzia 2009), the use of new durum wheat cultivars in bread-making (Mastromatteo et al. 2014), the influence of different packaging solutions on the shelf-life of industrial sliced durum wheat bread (Licciardello et al. 2014).

In this context of limited and dated literature, there is also a general lack of knowledge about the performances offered by durum wheat flour with different baking procedures as compared with those obtained from soft wheat flour. The aim of this work is to compare durum wheat and soft wheat flours in straight-dough and sourdough bread-making by analysing selected physical properties: colour, texture, water dynamics, crumb grain characteristic, and bulk volume. The four breads were analysed immediately after baking and during a 5-day shelf-life.

Materials and methods

Samples, bread-making and storage

Commercial baker’s durum wheat semolina containing 12.5 g/100 g proteins, whereof 10.5 g/100 g dry gluten, lipid < 1.0 g/100 g and 0.8 g/100 g ash, and commercial soft wheat flour with 11.0 g/100 g protein, whereof 10.0 g/100 g dry gluten, lipid < 1.0 g/100 g and 0.7 g/100 g ash were used (Molino Denti, Vicofertile, Parma, Italy). Compressed yeast for control breads was purchased on a local market (Lesaffre, Parma, Italy). The sourdough sample was collected from an Italian artisanal bakery (Parma, Italy) and it was immediately refrigerated (4 °C), delivered to the laboratory within 4 h and stored at 4 °C until used. The following bread types were studied: (1) soft wheat bread with compressed yeast (SWC), (2) soft wheat bread with sourdough (SWS), (3) durum wheat bread with compressed yeast (DWC), (4) durum wheat bread with sourdough (DWS).

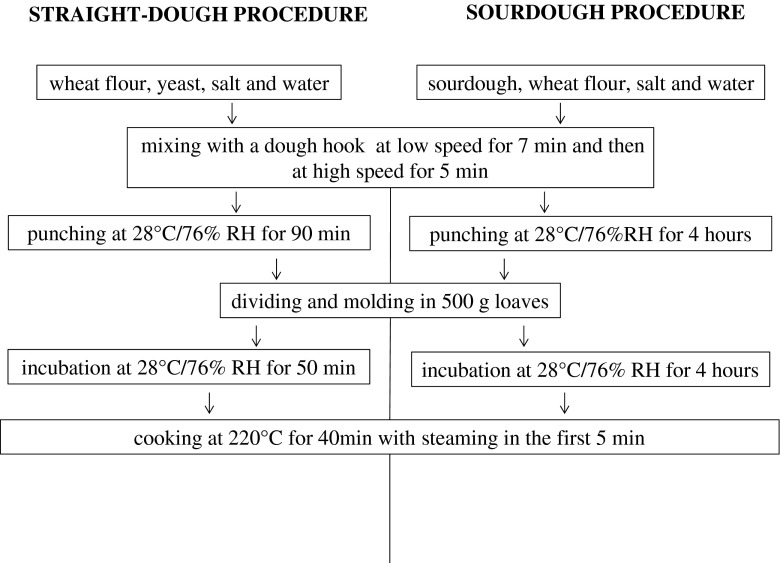

DWC and SWC breads were prepared by means of a straight-dough bread-making procedure, as shown in Fig. 1. The recipes, expressed in parts by weight, were soft wheat flour (100), yeast (3.0), salt (2.0) and water (60) and durum wheat flour (100), yeast (3.0), salt (2.0) and water (70) for SWC and DWC, respectively. DWS and SWS samples were prepared by means of a sourdough procedure, as reported in Fig. 1. The recipes were soft wheat flour (100), sourdough (30), water (60) and salt (2.0), for SWS breads and durum wheat flour (100), sourdough (30), water (70) and salt (2.0), for DWS breads.

Fig. 1.

Flow sheet of straight-dough and sourdough procedures used for bread-making

Before the bread-making process, sourdough was refreshed at least three times by mixing with flour (1:1; w:w) and water (1:0.4; w:w) at 22/24 °C with intervals of 4 h and incubated at 28 °C and then, the refreshed sourdough was added to the other ingredients. All the cooked samples were packed in sealed air-tight plastic bags sprayed with alcohol, stored at 25 °C in a temperature controlled chamber (ISCO 9000, Milan, Italy) in the dark, up to 5 days and analysed at 0, 1, 3 and 5 days after production. Three loaves were used for the characterization of breads at each storage time for a total of 12 loaves for each bread type. Two batches were analysed for each bread type.

Microbiological analysis and organic acids determination on dough

Ten grams of refreshed sourdough sample, ready for bread-making, were transferred into a sterile stomacher bag, 90 ml of Ringer solution (Oxoid, Milan,Italy) were added and mixed for 3 min in a Stomacher machine (Bag Mixer, Interscience, France). Further decimal dilutions were made in the same solution. Total lactobacilli were determined on MRS medium (Oxoid, Milan, Italy) modified by adding 1 % of maltose (Corsetti et al. 2001) and incubated for 48 h at 30 °C. Yeast were counted on Yeast Glucose Chloramphenicol, YGC, (Oxoid, Milan, Italy) incubated for 72 h at 28 °C. Each analysis was conducted in duplicate. The presence of microorganisms was confirmed by microscopic analysis (Olympus BX51, Milano, Italia). The amounts of lactobacilli (1.77 × 107 ± 1.6 × 106cfu/g) and yeast (5.53 × 106 ± 1.3 × 105 cfu/g) were in the range reported in literature (Corsetti 2013).

For organic acids analysis, 200 mg of bread dough at the beginning of the fermentation were dissolved in 1 ml of D2O and blended with magnetic stirring for 1 h at room temperature. To ensure a complete removal of the apolar component, 100 μl of CDCl3 were added. After centrifugation at 10000 rpm, 600 μl of supernatant were taken for the analysis according to Caligiani et al. (2007). Lactic and acetic acid resulted 5.14 ± 0.06 and 1.87 ± 0.07 g/kg higher compared to reported data for sourdough and equivalent to a fermentation quotient of 1.8 slightly lower compared to the optimum range 2.0–2.7 (Hammes and Gänzle 1998).

Bread analysis

Chemical analyses

Organic acid analysis was carried out on three bread slices for each sample at time 0 by means of the same method described in paragraph 2.2. pH was measured on each bread sample at time 0 according to Mo and Sung (2014) using a pH meter (Jenway 3510, Bibby Scientific, Staffordshire, UK). Triplicate analyses were carried out on each sample.

Crumb grain characteristic and specific bulk volume

Crumb grain was evaluated on three central slices (20 mm thickness) of each loaf at each storage time on 40 × 40 mm squares by means of a digital image analysis system, as reported previously (Chiavaro et al. 2008). The number of pores (expressed as percentage of the total number) was obtained according to four pre-selected dimensional classes based on their area: class-1: 0.01–0.099 mm2; class-2: 0.1–0.99 mm2; class.3: 1–4.99 mm2 class-4: >5 mm2. Crust thickness (mm) of all breads was measured by means of the size function of the image analysis software.

Specific bulk volume of breads was determined according to the AACC Approved Method 10–05.01 (AACC 2000) and expressed as the volume/weight ratio of cooked bread (cm3/g).

Physical analysis

The moisture content (g/100 g) of each bread loaf at crust, near crust layer and central crumb was evaluated following the standard method 44–15.02 (AACC 2000).

Colour was determined on ten pre-selected locations of the crust and crumb of each bread loaf by means of a Minolta Colorimeter (CM 2600d, Minolta Co., Osaka, Japan) equipped with a standard illuminant D65 and a 10° position of the standard observer. The instrument was calibrated before each analysis with white and black standard tiles. L* (lightness), a* (redness) and b* (yellowness) were quantified on each sample using the Spectramagic software (Ver. 3.6). The individual differences in L*,a*, and b* values of each bread at 1, 3 and 5 days were evaluated with respect to the colour of the samples at time 0 using ΔE calculation (CIE 1978).

Texture analysis was performed on crust and crumb using a TA.XT2 Texture Analyzer equipped with a 25 kg load cell (Stable Micro Systems, Godalming, UK) and Texture Expert for Windows software (version1.22) for data analysis on each loaf. Crust hardness was measured by means of a puncture test using a 3 mm diameter stainless steel probe and a test speed of 1 mm/s. Maximum peak force (N) was measured from the penetration curve and taken as crust hardness. Measurements were taken on five preselected points of the crust. Crumb evaluation was carried out on ten cube of 20 × 20 × 20 mm extracted from two central slices of the samples. A TPA test was performed with a 35 mm diameter cylindrical aluminium probe by means of a double compression with a speed of 1 mm/s up to the 50 % of the original sample height. The textural parameters considered were hardness (maximum peak force of the first compression cycle, N), cohesiveness (ratio of positive force area during the second compression to that during the first compression area, dimensionless), resilience (area during the withdrawal of the penetration, divided by the area of the first penetration, dimensionless), springiness (ratio of the time duration of force input during the second compression to that during the first compression, dimensionless) and chewiness (product of hardness × cohesiveness × springiness, N) (Bourne 1978).

Statistical analysis

SPSS (Version 20.0, SPSS Inc., Chicago, USA) statistical software was used to identify differences among the same type of bread during the shelf-life through one-way analysis of variance (ANOVA) and least significant difference (LSD) test at a 95 % confidence level (p < 0.05). Comparisons between breads made with the same flour and different procedure at the same time of storage were performed by means of a Student t-test at a 95 % confidence level (p < 0.05). The same statistical approach was used to compare breads made with different flours and the same procedure, when necessary.

Results and discussion

Chemical analyses on bread

Lactic acid contents were 1.63 ± 0.01 and 1.52 ± 0.01 g/100 g in DWS and SWS samples, respectively. These values were significantly higher compared to DWC and SWC (0.042 ± 0.003 and 0.044 ± 0.001 g/100 g, respectively). Acetic acid contents were almost three folds higher in samples prepared with sourdough procedure (1.25 ± 0.01 g/100 g and 1.22 ± 0.01 g/100 g for DWS and SWS, respectively) compared to breads with compressed yeast (0.045 ± 0.001 g/100 g and 0.044 ± 0.001 g/100 g for DWS and SWS, respectively). In general, these values were higher compared to values reported by Barber et al. (1992) probably due to the high sourdough addition percentage (15 %). The content of organic acids probably influenced the final pH values of breads, as expected. The samples with sourdough presented significantly lower values (3.90 ± 0.08 for DWS and 3.93 ± 0.06 for SWS), while breads with compressed yeast values showed pH values of 5.62 ± 0.09 for DWC and 5.65 ± 0.08 for SWC.

Crumb grain characteristics and specific bulk volume

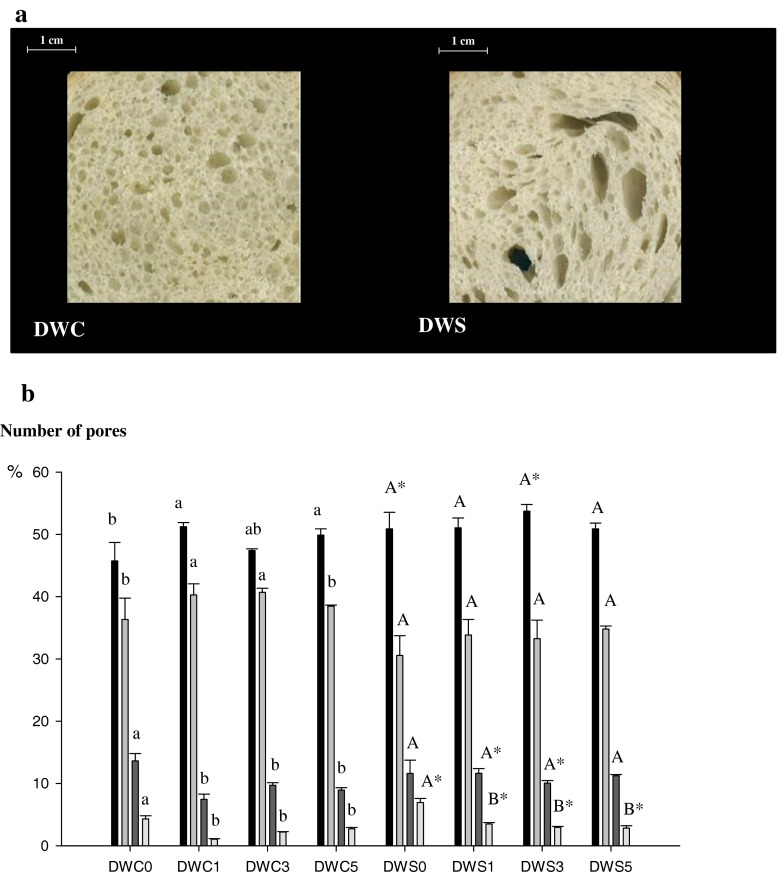

Characteristic images obtained on durum wheat breads at time 0 are reported in Fig. 2a. DWS bread showed an open and non-uniform crumb grain appearance with the presence of larger and more asymmetrical cavities in comparison with DWC loaf. Similar heterogeneous crumb grain characteristics were previously found for durum wheat sourdough artisanal bread in comparison with straight-dough durum wheat bread by Chiavaro et al. (2008). The presence of larger and more heterogeneous pores is likely the result of a more complex fermentation process that occurred under sourdough bread-making (Corsetti 2013). Crust thickness of DW breads presented a mean value of 2.6 mm and it was in some points detached in DWS loaves. The objective evaluation of pore number (Fig. 2b) confirmed the bread appearance. Crumb pores of DWS breads spanned over a larger dimensional range as a significantly higher number of crumb pores belonging to the class with highest dimension (>5 mm2) as well as those belonging to the lowest class (>0.1 mm2) was observed. The application of indirect bread-making procedure was previously associated to a crumb grain texture with a high number of bubbles and an irregular size distribution in the final product due to the long leavening times required (Pagani et al. 2006). This characteristic is not considered a defect for the Italian bread, in contrast with the common widespread statement that retains irregular cell distribution as undesirable (Pagani et al. 2006). The less uniform crumb grain distribution of DWS remained stable during storage in accordance with Chiavaro et al. (2008), who did not found significant changes of crumb grain classes, similarly determined, during storage of traditional Italian durum wheat sourdough bread. On the other hand, DWC exhibited a significant decrease of grains belonging to the largest classes after 24 h of storage with a slight increase of little pores (Fig. 2b). This was probably in relation to the crumb grain shrinkage, as a fixed area was used for the determination. A decrease of cell mean area and a reduction of pore dimensions were previously reported during 74 h storage time of sourdough soft wheat bread produced with a straight-dough procedure (Crowley et al. 2002). Bulk volume of DWS bread (3.07 ml/g) presented a significantly lower value than DWC (3.33 ml/g), probably due to the high level of sourdough addition (15 %) performed in this study according to the range commonly adopted in the Italian bakery tradition (5–20 % by weight to the final dough, Pagani et al. 2006). Contrasting results are present in literature about bread volume obtained with different wheat flours and/or procedures. Severini et al. (2002) observed a higher volume in a traditional durum wheat bread produced with the addition of Saccharomyces cerevisiae during a sourdough process. This fact was ascribed to the higher CO2 production upon alcoholic fermentation. On the other hand, bread produced with the straight-dough procedure was associated to lower volume than those produced with several refreshing steps in the so called sponge-dough procedure (Pagani et al. 2006), and this was also reported for both soft and durum wheat flour use in bread-making (Hareland and Puhr 1998). Otherwise, high level of sourdough was reported to significantly affect loaf volume by Torrieri et al. (2014) and Katina et al. (2009) due to the acidification. This was confirmed by the significantly lower pH values and organic acids content in DWS breads compared to DWC samples. Both bread types did not show any significant changes of bulk volume during storage.

Fig. 2.

Images of the central slice of loaf (panel a) and number of pores as percentage of the total number of pores for the selected dimensional classes at different storage times (panel b) for durum wheat breads. Error bars represent +/− 1 standard deviation, (n = 3, sample size = 3 for each bread type). Bars of histograms with the same lowercase and capital letters are not significantly different (p < 0.05). Bars with single (p < 0.05) or double (p < 0.01) asterisks differed significantly between the two types of bread at the same storage time. Abbreviations: DWCn durum wheat compressed yeast bread at each storage time, DWSn durum wheat sourdough bread at each storage time

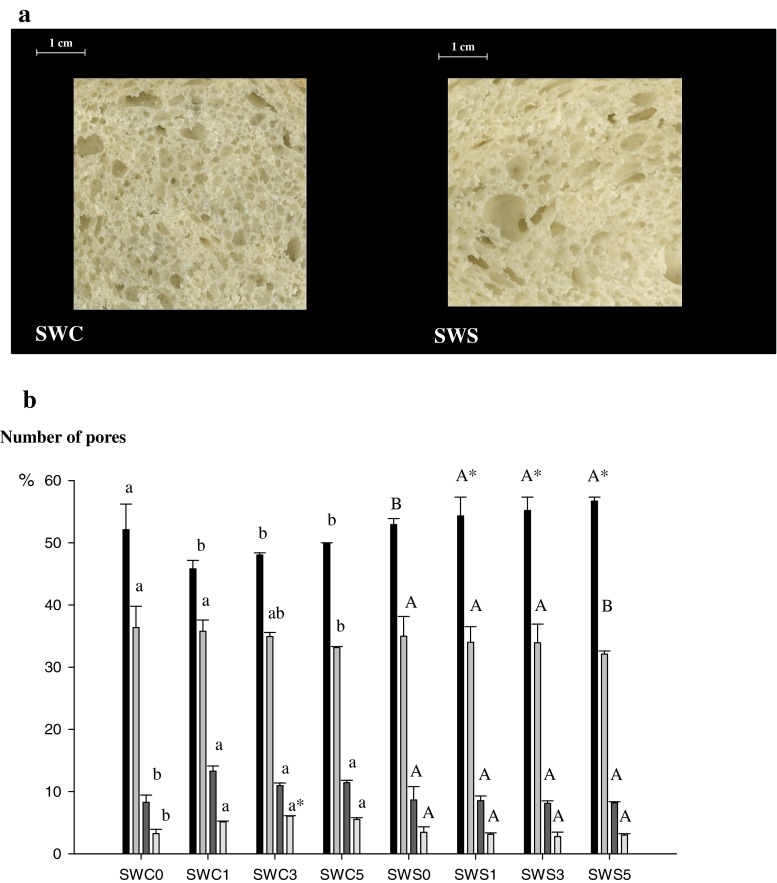

Soft wheat bread images at time 0 are shown in Fig. 3a. SWS presented a more heterogeneous crumb grain appearance in comparison with SWC, as for durum wheat bread. Crowley et al. (2002) found higher mean cell area values in 20 % sourdough soft wheat bread straight-dough produced compared to standard sample immediately after baking. Anyway, largest pore number of sourdough breads was not significantly higher than that found in breads obtained with a straight-dough procedure, as shown in Fig. 3b. Both SW breads appeared to be less stable than DW samples during storage. The addition of sourdough caused a significant increase in the number of pores of lowest dimension (0.01–0.099 mm2) starting from day 1, and a consequent decrease of those belonging to one of the intermediate classes (0.1–0.99 mm2) at day 5 (Fig. 3b), in agreement with Crowley et al. (2002). The opposite was found for SWC bread in which the largest pores (>1 mm2) significantly increased after 24 h of storage (Fig. 3b) and the smallest pores decreased, being also significantly lower than in SWS. This effect was previously associated to the moisture migration from crumb to crust during storage, which increased pore areas reducing their thickness (Gray and Bemiller 2003). Crumb moisture significantly decreased during the shelf-life of this type of bread, as below discussed. At time 0, bulk volume of SWS samples were significantly lower (3.04 ml/g) than SWC (3.47 ml/g), as found for DW samples. Both values did not significantly differ to those obtained for the correspondent DW breads, although they were both lower, as previously reported (Sabanis and Tzia 2009), revealing a higher impact of bread-making procedure on loaf volume than the use of different wheat flour. Otherwise, SWS bulk volume presented a significant decrease during storage (2.95 and 2.85 ml/g at day 3 and 5 respectively), probably due to the structure collapse and its shrinkage (keyhole effect) (Garimella Purna et al. 2011). This fact leads, as a consequence, to the observed decrease of the mean cell area, as previously reported (Crowley et al. 2002). Crust thickness of SW breads presented a mean value of 1.8 mm, being ticker than DW breads, as previously shown (Sabanis and Tzia 2009).

Fig. 3.

Images of the central slice of loaf at time 0 (panel a) and number of pores as percentage of the total number of pores for the selected dimensional classes at different storage times (panel b) for soft wheat breads. Error bars represent +/− 1 standard deviation, (n = 3, sample size = 3 for each bread type). Bars of histograms with the same lowercase and capital letters are not significantly different (p < 0.05). Bars with single (p < 0.05) or double (p < 0.01) asterisks differed significantly between the two types of bread at the same storage time. SWCn soft wheat compressed yeast bread at each storage time; SWSn, soft wheat sourdough bread at each storage time

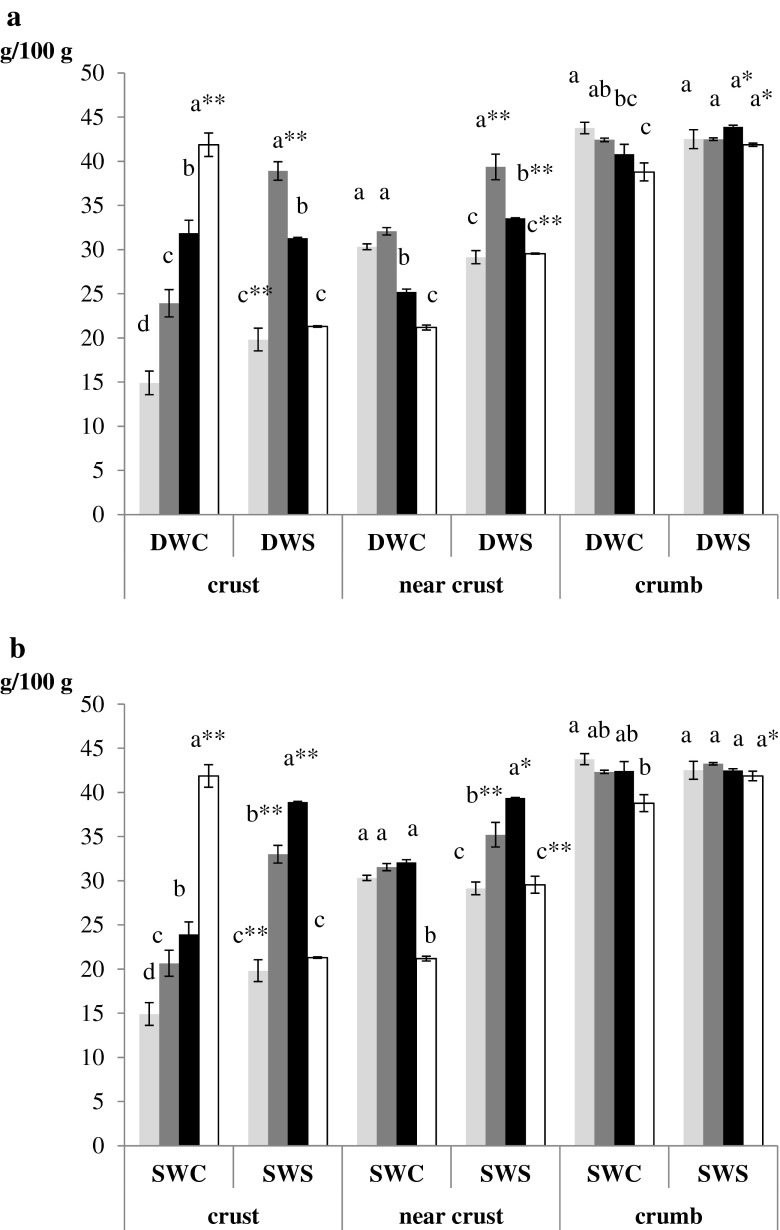

Moisture content

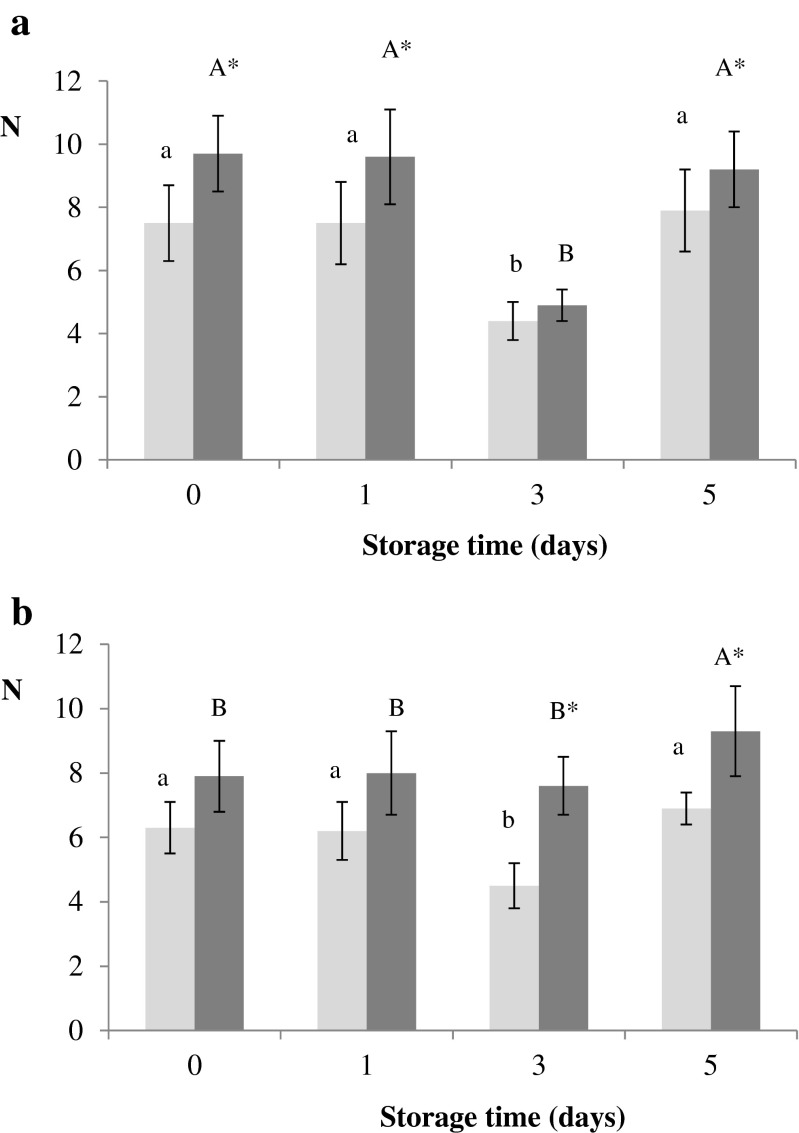

Moisture content of crust, near crust and crumb obtained in all analysed breads are reported in Fig. 4. Moisture content of DWC bread crust was significantly lower in comparison with DWS sample at time 0. During storage, it significantly increased due to the water migration within bread loaves, which is one of the macroscopic manifestations of bread staling if stored in sealed bags (Piazza and Masi 1995), reaching values significantly higher than those obtained for DWS bread at the end of storage. A different water dynamics was shown by DWS crust as moisture content significantly increased at day 1, to decrease until the end of shelf-life. It could be hypothesized that the water migration from crumb to crust occurred more slowly within DWS loaves, probably as a consequence of the different grain characteristic. These loaf characteristics have probably made the crust water “sucking” action from crumb slower compared to its evaporation from the crust into the headspace of the bags. A role may have also been played by the presence of some detachment between crumb and crust that have made null the sucking action of crust in DWS, as previously reported for durum wheat sourdough bread (Chiavaro et al. 2008). This detachment acts as a without crust storage, as previously found by Baik and Chinachoti (2002). Both DW breads did not show difference in moisture content at the under crust layer at time 0, but the storage trends reflected those obtained for crust. DWC breads presented significant moisture content decrease near crust from day 1 to the end of shelf-life in accordance to the crust content increase. On the other hand, DWS samples exhibited a significant increase at day 1 and then a decrease being moisture contents of this layer always significantly higher than those measured in DWC loaves. Finally, initial crumb moisture contents in DW breads were in accordance with previous studies (Raffo et al. 2003; Chiavaro et al. 2008) and did not differ between both DW breads. It also remained unchanged during shelf-life in bread produced with sourdough. On the contrary, a significant decrease was shown by DWC breads. Chiavaro et al. (2008) previously found a significant decrease of moisture content in a durum wheat bread produced with a straight dough baking procedure at the end of storage in accordance with the common behaviour exhibited by the crumb during shelf-life (Gray and Bemiller 2003). Sourdough probably played a positive effect against moisture redistribution inside the bread and hence caused a delay of crumb moisture content reduction over shelf-life. In addition, an effect of sourdough metabolites (e.g., organic acids, exopolysaccharides) on water interaction with the solids of the breads could not be excluded (Galle 2013).

Fig. 4.

Moisture content at crust, near crust and crumb for durum wheat flour bread (panel a) and soft wheat bread (panel b) at day 0 (light grey histogram), day 1 (dark grey histogram), day 3 (black histogram) and day 5 (white histogram). Error bars represent +/− 1 standard deviation, (n = 3, sample size = 3 for each bread type). Bars of histograms with the same lowercase and capital letters are not significantly different (p < 0.05) Bars with single (p < 0.05) or double (p < 0.01) asterisks differed significantly between the two types of bread at the same storage time

SWS breads showed higher crust moisture content than SWC, as shown by DW samples. During storage, SWC breads showed a quite similar water dynamics than DWC loaves with a consistent increase in crust up to the end of shelf-life and a concomitant decrease in both near crust and crumb at the end of storage. This is the typical crust moisture trend occurring during bread staling (Gray and Bemiller 2003). On the other hand, SWS breads exhibited crust and near crust moisture content increase up to day 3 and a significant decrease at the end of shelf-life, being values significantly higher than SWC, as for durum wheat breads. Water dynamics of the near crust appeared also to be different between DWS and SWS; the former reached the maximum moisture content in the crust and near crust regions before during storage, also dehydrating faster than soft wheat bread. This could be related to the different crumb grain characteristics of these two breads (see at Figs. 2a and 3a). Crumb moisture content did not significantly differ between the two soft wheat breads differently prepared up to 3 days of shelf-life, as it was found to significantly decrease at the end of storage only in SWC sample while it remained stable in SWS, as observed in durum wheat breads.

Physical analysis

Crust and crumb colour parameters for all samples are reported in Tables 1 and 2, respectively. The crust lightness (L*) of sourdough breads (DWS and SWS) resulted significantly lower (p < 0.01) than that obtained for breads made with compressed yeast (DWC and SWC) and this difference was maintained for the whole shelf-life. Chiavaro et al. (2008) found that the crust of a traditional sourdough durum wheat bread was darker than the sample obtained with a straight-dough baking procedure. Crowley and co-workers (2002) found a darker crust for sourdough soft wheat breads prepared with a straight-dough procedure. This was probably related to the first phases of Maillard reactions, which was more consistent under sourdough bread-making (Torrieri et al. 2014). DWS and SWS samples presented significantly lower b* values (higher opacity) also during shelf-life than DWC and SWC (except for DWC at time 5). Significant differences of a* values were observed only between the two SW breads being SWS crust more red than SWC also during storage, probably in relation with a more consistent formation of Maillard reaction products, too. During shelf-life, all samples exhibited high ∆E values (Table 1), showing a great change of crust colour, as consequence. This could be ascribed to the water migration from crumb to crust (Fig. 4a and b), which influenced the way the light was reflected and the colour appearance, as consequence. DWS samples presented significantly higher ∆E values compared to DWC ones with the exception of day 5, where no significant differences were observed between SWC and SWS (Table 1).

Table 1.

Crust colorimetric parameters for analysed breads

| Crust | L* | a* | b* | ΔE |

|---|---|---|---|---|

| DWC0 | 55.2 (4.1)x** | 14.5 (1.2)x | 33.6 (1.7)x** | – |

| DWC1 | 55.0 (3.0)x** | 14.3 (1.5)x | 33.1 (2.2)x** | 3.7 (0.4)z |

| DWC3 | 55.4 (3.2)x** | 13.3 (1.4)xy | 33.9 (1.6)x** | 6.3 (0.8)y |

| DWC5 | 45.2 (3.5)y** | 12.7 (1.1)y | 25.1 (3.0)y | 12.6 (1.3)x |

| DWS0 | 37.8 (1.8)Y | 13.5 (0.7)X | 17.1 (1.1)Y | – |

| DWS1 | 47.0 (4.6)X | 14.9 (1.2)X | 27.6 (5.2)X | 8.1 (1.3)X** |

| DWS3 | 44.8 (1.9)X | 13.7 (1.1)X | 25.5 (1.0)X | 9.2 (1.0)X** |

| DWS5 | 45.4 (3.4)X | 14.2 (1.3)X | 25.6 (2.2)X | 11.7 (1.4)X |

| SWC0 | 53.3 (3.8)b* | 13.8 (1.9)a | 33.2 (0.9)a* | – |

| SWC1 | 59.3 (3.5)a* | 11.3 (1.5)b | 31.9 (1.5)ab** | 8.4 (1.1)b |

| SWC3 | 57.2 (2.9)a* | 10.9 (1.4)b | 28.9 (1.3)b** | 9.0 (0.9)b |

| SWC5 | 57.1 (5.2)a* | 11.3 (1.4)b | 27.7 (2.0)b* | 11.8 (1.1)a |

| SWS0 | 50.5 (8.4)A | 15.8 (1.7)A* | 29.3 (3.1)A | – |

| SWS1 | 42.4 (2.6)B | 15.4 (1.2)A* | 23.8 (3.2)B | 8.9 (0.8)b |

| SWS3 | 40.7 (2.9)B | 13.1 (0.4)B** | 20.9 (2.0)B | 11.6 (1.1)a |

| SWS5 | 40.4 (3.9)B | 13.4 (1.3)B* | 21.4 (2.2)B | 12.5 (1.4)a |

n = 10, sample size =30 for each type of bread at each storage time, standard deviations are given in parenthesis. Means in columns followed by different lowercase and capital letters differed significantly for the same sample (p < 0.05). Means in row followed by single (p < 0.05) or double (p < 0.01) asterisks differed significantly between the two different bread-making procedures at the same storage time and for the same flour employed

Abbreviations DWCn durum wheat compressed yeast bread at each storage time, DWSn durum wheat sourdough bread at each storage time, SWCn soft wheat compressed yeast bread at each storage time, SWSn soft wheat sourdough bread at each storage time

Table 2.

Crumb colorimetric parameters for analysed breads

| Crumb | L* | b* |

|---|---|---|

| DWC0 | 79.7 (3.6)x* | 15.1 (1.8)x* |

| DWC1 | 76.6 (3.2)x* | 15.1 (1.1)x* |

| DWC3 | 78.2 (3.6)x* | 15.0 (0.9)x* |

| DWC5 | 68.0 (5.5)y* | 15.2 (1.2)x* |

| DWS0 | 65.7 (5.0)X | 13.5 (0.9)X |

| DWS1 | 67.6 (3.7)X | 12.8 (0.7)X |

| DWS3 | 67.3 (3.5)X | 12.7 (1.5)X |

| DWS5 | 61.3 (9.2)Y | 12.6 (1.0)X |

| SWC0 | 68.8 (1.7) a | 12.9 (1.2)a |

| SWC1 | 67.8 (1.2)a | 12.2 (1.3)a |

| SWC3 | 65.9 (1.5)b | 11.4 (1.9)a |

| SWC5 | 66.1 (1.5)b | 12.3 (1.4)a* |

| SWS0 | 72.7 (2.6)A* | 12.3 (1.0)A |

| SWS1 | 71.6 (2.2)A* | 11.5 (1.7)A |

| SWS3 | 73.3 (2.0)A* | 10.8 (0.9)AB |

| SWS5 | 66.1 (3.2)B | 9.8 (0.8)B |

n = 10, sample size =30 for each type of bread at each storage time, standard deviations are given in parenthesis. Means in columns followed by different lowercase and capital letters differed significantly for the same sample (p < 0.05). Means in row followed by single (p < 0.05) or double (p < 0.01) asterisks differed significantly between the two different bread-making procedures at the same storage time and for the same flour employed

Abbreviations DWCn durum wheat compressed yeast bread at each storage time, DWSn durum wheat sourdough bread at each storage time, SWCn soft wheat compressed yeast bread at each storage time, SWSn soft wheat sourdough bread at each storage time

Crumb colour of bread made with durum and soft wheat flours exhibited an opposite behaviour. DWC crumb was paler than DWS, as shown for the crust, probably due to the effect of sourdough. This difference remained also during storage. Surprisingly, SWC breads showed darker crumb than SWS and this trend was maintained up to 3 days of shelf-life. This may be related to the finer crumb grain structure of SWS bread during storage resulting in a lighter colour, as previously stated (Popov-Raljić et al. 2009). This statement was confirmed by DWS sample, which presented lower L* values than the other breads, as previously found in a sourdough durum wheat bread (Fadda et al. 2010) and a relatively high number of pores of great dimensions (Figs. 2a and 3a). The presence of great holes probably caused a different light reflection and crumb appeared darker from the instrumental measurement. Crumb of DW samples was more yellow (higher b*) (p < 0.05) and this difference remained also during storage, due to the higher amounts of xanthophylls in durum wheat flour, as previously reported (Sabanis and Tzia 2009) and to the starch gelatinization, which made the surface smoother and the tint more brilliant (Pasqualone et al. 2004). Yellowness (b*) remained stable in all samples during shelf-life, except for SWS, which showed a slight decrease at day 5, probably in relation with an increased opacity, which could occur during bread staling (Arendt et al. 2007). A* and ∆E (data not shown) did not show any differences among breads and during storage.

Crust hardness results were summarized in Fig. 5. Both durum wheat breads showed harder crust than soft wheat samples made with the same baking procedure, although not significantly (p > 0.05). In addition, DWS crust was slightly harder than DWC at time 0 and this difference was maintained during storage, in accordance with Chiavaro et al. (2008), who found harder crust in sourdough durum wheat artisanal bread compared to samples straight-dough produced. Crust showed also a slight decrease of hardness at day 3 of shelf-life in both DW bread followed by a further increase at the end of shelf-life. A similar trend wash shown by a traditional durum wheat bread by Chiavaro et al. (2008). Crust texture is generally expected to soften during bread staling, in conjunction with water uptake from the crumb (Gray and Bemiller 2003). Otherwise, changes of crust texture and moisture content were previously found to be not correlated during shelf-life perhaps in relation with a different rate of firmness increase and moisture uptake (Chin et al. 2011). Our results confirmed these previous findings as crust hardness of the two DW breads exhibited the same behaviour, although quite different water dynamics were shown by these samples (Fig. 4). Crust of SWS became significantly harder than SWC only at the end of storage, while SWC showed a similar trend to both DW samples with a significant decrease at day 3 and a further increase at the end of storage.

Fig. 5.

Crust hardness of durum (panel a, DWC light grey and DWS dark grey histograms) and soft wheat (panel b, SWC light grey and SWS dark grey histograms) breads at different time of storage. Error bars represent +/− 1 standard deviation, (n = 3, sample size = 5 for each bread type). Bars of histograms with the same lowercase and capital letters are not significantly different (p < 0.05). Bars with single (p < 0.05) asterisk differed significantly between the two types of bread at the same storage time

Crumb texture profile analysis results are shown in Table 3. Both bread-making procedures and type of flours influenced the initial firmness of crumb. Durum wheat flours showed higher firmness values in comparison with loaves made with soft wheat flour, as previously found by Boyacioğlu and D’Appolonia (1994b) and Sabanis and Tzia (2009), under common straight-dough procedure. In addition, both the straight-dough breads showed lower initial firmness than sourdough samples. Thus, the following initial crumb firmness scale was observed: DWS>SWS>DWC>SWC. Chiavaro et al. (2008) reported that durum wheat flour breads obtained by sourdough showed higher crumb hardness than those made with a straight-dough method. Armero and Collar (1998) reported that the sourdough process led to harder white wheat flour breads compared to those obtained by straight-dough procedure due to the lower specific loaf volume of the former samples. In addition, high concentration of acetic acid, produced by heterofermentative LAB, could be responsible for a shorter and harder gluten as well as excessive acidity and hydrolysis of gluten proteins could result in softer, less elastic dough, reducing the loaf volume and increasing bread firmness (Gocmen et al. 2007). The organic acid content was found to be significantly higher in DWS and SWS breads compared to DWC and SWC. Thus, the acidifying effect of LAB on both flour gluten and dough elasticity could explain the higher firmness of sourdough samples (Table 3).

Table 3.

Crumb texture profile analysis parameters for analysed breads

| Hardness (N) | Cohesiveness | Resilience | Chewiness (N) | |

|---|---|---|---|---|

| DWC0 | 1.6 (0.4) y | 0.74 (0.04) x | 0.39 (0.01) x | 1.1 (0.3) z |

| DWC1 | 2.1 (0.4) y | 0.72 (0.04) x | 0.33 (0.03) y | 1.6 (0.3) y |

| DWC3 | 3.5 (0.7) x | 0.68 (0.04) x | 0.33 (0.03) y | 2.0 (0.3) x |

| DWC5 | 3.3 (0.5) x | 0.70 (0.04) x | 0.34 (0.03) y | 1.4 (0.2) y |

| DWS0 | 2.9 (0.8) Y* | 0.70 (0.05) X | 0.37 (0.03) X | 1.8 (0.3) Y* |

| DWS1 | 2.9 (0.4) Y* | 0.70 (0.03) X | 0.38 (0.03) X* | 1.8 (0.2) Y |

| DWS3 | 4.8 (0.9) X* | 0.64 (0.05) XY | 0.33 (0.03) Y | 2.8 (0.4) X* |

| DWS5 | 5.2 (0.9) X* | 0.60 (0.05) Y | 0.31 (0.03) Y | 2.8 (0.4) X* |

| SWC0 | 1.1.(0.2) c | 0.79 (0.02) a | 0.43 (0.04) a | 0.8 (0.2) c |

| SWC1 | 2.5 (0.4) b | 0.69 (0.04) b | 0.35 (0.02) b | 1.5 (0.2) b |

| SWC3 | 2.9 (0.6) b | 0.57 (0.02) c | 0.27 (0.03) c | 1.5 (0.2) b |

| SWC5 | 4.1 (0.8) a | 0.48 (0.08) d | 0.21 (0.04) d | 1.8 (0.2) a |

| SWS0 | 2.1 (0.6) D* | 0.79 (0.05) A | 0.45 (0.04) A | 1.6 (0.3) D* |

| SWS1 | 4.3 (0.6) C* | 0.65 (0.04) B | 0.32 (0.03) B | 2.5 (0.2) C* |

| SWS3 | 6.4 (1.0) B** | 0.57 (0.04) B | 0.26 (0.03) C | 3.3 (0.4) B* |

| SWS5 | 8.7 (1.1) A** | 0.49 (0.06) C | 0.21 (0.01) D | 3.8 (0.6) A* |

n = 3, sample size =10 (texture profile analysis) for each type of bread at each storage time, standard deviations are given in parenthesis. Means in columns followed by different lowercase and capital letters differed significantly for the same sample (p < 0.05). Means in row followed by single (p < 0.05) or double (p < 0.01) asterisks differed significantly between the two different bread-making procedures at the same storage time and for the same flour employed

Abbreviations DWCn durum wheat compressed yeast bread at each storage time, DWSn durum wheat sourdough bread at each storage time, SWCn soft wheat compressed yeast bread at each storage time, SWSn soft wheat sourdough bread at each storage time

All samples showed a significant crumb firmness increase during shelf-life, as expected, both in relation with bread-making procedure and flour type, too. In particular, DWS and SWS breads exhibited significantly higher hardness in comparison with DWC and SWC at every day of storage and this was probably related to the lowest volume of these loaves, as previously found (Maleki et al. 1980). This was in agreement with Barber et al. (1992), who found a direct correlation between the increase in crumb firmness during shelf life and the lactic acid content. Otherwise, the increase of firmness was more marked for soft wheat breads than those prepared with durum (Δ/day of 0.34, 0.45, 0.60 and 1.32 for DWC, DWS, SWC and SWS, respectively). Crowley et al. (2002) found that crumb firmness of 40 % sourdough soft wheat bread straight-dough produced became significantly higher than standard sample after 2 days of storage. Hareland and Puhr (1998) stated that the molecular interaction between starch-gluten complex and water were probably weaker in soft wheat flour bread compared to durum wheat flour samples due to the lower protein content of the flour. This less bound water may enhance the rate of starch complex recrystallization causing higher rate of crumb firmness. Sabanis and Tzia (2009) related the lower firmness increase during short-term storage (2 days) of durum wheat breads in comparison with those made with soft wheat to less water loss from the crumb, because of the thicker crust of DW bread, as found in our study. In the present study, the dynamics of firmness increase were quite different among analysed samples and they were not strictly related to the change of crumb moisture content in all breads (Fig. 4), as previously found by other authors (Raffo et al. 2003). Cohesiveness decreased in all samples during storage, as expected and in relation with the hardening of the crumb. Anyway, the decrement was less marked in both DW samples in relation with the reduced increase of crumb hardness (Table 3). Initial resilience, which indicates how well crumb fights to regain its original position, was higher in both soft wheat breads due to the lower firmness but it significantly decreased in all breads after 24 h of storage except for DWS, which showed a late consistent decrement. The decrease during shelf-life was more consistent for both soft wheat breads (>50 %). Springiness did not show significant differences during shelf-life among samples (data not shown). All samples required longer time for mastication during shelf-life (increased chewiness) showing similar hardness trends (Table 3), being SWS the chewiest sample.

Conclusions

In conclusion, both the type of flours and the bread-making process influenced the final quality of breads after baking and during the shelf-life. The use of sourdough process better preserved both crumb grain characteristic and moisture content of the breads during shelf-life and this occurred independently of the wheat flour used. On the other hand, water dynamics in crust and under-crust of sourdough breads were not those traditionally described during staling. In particular, sourdough durum wheat breads appeared to dehydrate faster than those obtained with soft wheat flour. Initial colour of crust and crumb appeared to be more stable if durum wheat flour was used. Finally, crumb firmness increase proceeded more slowly in durum wheat breads during shelf-life, although crumb of DWS breads was the hardest after baking.

The findings of this study may offer new perspective in the growing industrial sector of durum wheat bakery products, where the maintenance of the initial characteristics is an important goal to achieve during the shelf-life.

Footnotes

Straight-dough and sourdough bread-making results of durum and soft wheat flours were compared

Sourdough preserved bread crumb grain characteristic and moisture content during shelf-life

The flour type seemed to significantly affect the water dynamics in sourdough breads

Crumb firmness slowly increased in durum wheat breads during shelf-life

Initial crust and crumb colour of durum wheat flour bread less changed during shelf-life

References

- AACC, American Association of Cereal Chemists, Approved methods of the AACC. 10. St. Paul: Am Assoc Cereal Chem; 2000. [Google Scholar]

- Arendt EK, Ryan LA, Dal Bello F. Impact of sourdough on the texture of bread. Food Microbiol. 2007;24:165–174. doi: 10.1016/j.fm.2006.07.011. [DOI] [PubMed] [Google Scholar]

- Armero E, Collar C. Crumb firming kinetics of wheat breads with anti-staling additives. J Cereal Sci. 1998;28:165–174. doi: 10.1006/jcrs.1998.0190. [DOI] [Google Scholar]

- Baik MY, Chinachoti P. Effects of glycerol and moisture redistribution on mechanical properties of white bread. Cereal Chem. 2002;79:376–382. doi: 10.1094/CCHEM.2002.79.3.376. [DOI] [Google Scholar]

- Barber B, Ortolá C, Barber S, Fernández F. Storage of packaged white bread. Z Lebensm Unters Forsch. 1992;194:442–449. doi: 10.1007/BF01197726. [DOI] [Google Scholar]

- Boggini C, Pagani MA, Lucisano M. Bread-making quality of common and durum wheat flour blends. Tec Molit. 1997;7:781–791. [Google Scholar]

- Bourne MC. Texture profile analysis. Food Technol. 1978;32:62–66. [Google Scholar]

- Boyacioğlu MH, D’Appolonia BL. Characterization and utilization of durum wheat for bread-making. I. Comparison of chemical, rheological, and baking properties between bread wheat flours and durum wheat flours. Cereal Chem. 1994;71:21–27. [Google Scholar]

- Boyacioğlu MH, D’Appolonia BL. Characterization and utilization of durum wheat for bread-making. III. Staling properties of bread baked from bread wheat flours and durum wheat flours. Cereal Chem. 1994;71:34–41. [Google Scholar]

- Caligiani A, Acquotti D, Palla G, Bocchi V. Identification and quantification of the main organic components of vinegars by high resolution 1H NMR spectroscopy. Anal Chim Acta. 2007;585:110–119. doi: 10.1016/j.aca.2006.12.016. [DOI] [PubMed] [Google Scholar]

- Chavan RS, Chavan SR. Sourdough technology—A traditional way for wholesome foods: a review. Compr Rev Food Sci F. 2011;10:170–183. [Google Scholar]

- Chiavaro E, Vittadini E, Musci M, Bianchi F, Curti E. Shelf-life stability of artisanally and industrially produced durum wheat sourdough bread “Altamura” bread. LWT-Food Sci Technol. 2008;41:58–70. doi: 10.1016/j.lwt.2007.01.018. [DOI] [Google Scholar]

- Chin NL, Abdullah R, Yusof YA. Glazing effects on bread crust and crumb staling during storage. J Texture Stud. 2011;42:459–467. doi: 10.1111/j.1745-4603.2011.00307.x. [DOI] [Google Scholar]

- CIE (Commission Internationale de l’eclairage) (1978) Recommendations on uniform colourspaces-colour equations, psychometric colour terms. Supplement No. 2 to CIE Publ. No. 15 (E-1.3.L) 1971/9TC-1-3, CIE, Paris

- Corsetti A. Technology of sourdough fermentation and sourdough applications. In: Gobbetti M, Gänzle M, editors. Handbook on sourdough biotechnology. New York: Springer; 2013. pp. 85–103. [Google Scholar]

- Corsetti A, Lavermicocca P, Morea M, Baruzzi F, Tosti N, Gobbetti M. Phenotypic and molecular identification and clustering of lactic acid bacteria and yeasts from wheat (species Triticum durum and Triticum aestivum) sourdoughs of Southern Italy. Int J Food Microbiol. 2001;64:95–104. doi: 10.1016/S0168-1605(00)00447-5. [DOI] [PubMed] [Google Scholar]

- Crowley P, Schober TJ, Clarke CI, Arendt EK. The effect of storage time on textural and crumb grain characteristics of sourdough wheat bread. Eur Food Res Technol. 2002;214:489–496. doi: 10.1007/s00217-002-0500-7. [DOI] [Google Scholar]

- Fadda C, Santos EM, Piga A, Collar C. Innovative traditional Italian durum wheat breads: influence of yeast and gluten on performance of sourdough Moddizzosu breads. Cereal Chem. 2010;87:204–213. doi: 10.1094/CCHEM-87-3-0204. [DOI] [Google Scholar]

- Galle S. Sourdough: a tool to improve bread structure. In: Gobbetti M, Gänzle M, editors. Handbook on sourdough biotechnology. New York: Springer; 2013. pp. 217–228. [Google Scholar]

- Garimella Purna SK, Miller RA, Seib PA, Graybosch RA, Shi YC. Volume, texture, and molecular mechanism behind the collapse of bread made with different levels of hard waxy wheat flours. J Cereal Sci. 2011;54:37–43. doi: 10.1016/j.jcs.2011.02.008. [DOI] [Google Scholar]

- Gocmen D, Gurbuz O, Kumral AY, Dagdelen AF, Sahin I. The effects of wheat sourdough on glutenin patterns, dough rheology and bread properties. Eur Food Res Technol. 2007;225:821–830. doi: 10.1007/s00217-006-0487-6. [DOI] [Google Scholar]

- Gray JA, Bemiller JN. Bread staling: molecular basis and control. Compr Rev Food Sci F. 2003;2:1–21. doi: 10.1111/j.1541-4337.2003.tb00011.x. [DOI] [PubMed] [Google Scholar]

- Hammes WP, Gänzle MG. Sourdough breads and related products. In: Woods BJB, editor. Microbiology of fermented foods. 2. London: Blackie Academic/Professional; 1998. pp. 199–216. [Google Scholar]

- Hareland GA, Puhr DP. Baking performance of durum and soft wheat flour in a sponge-dough bread-making procedure. Cereal Chem. 1998;75:830–835. doi: 10.1094/CCHEM.1998.75.6.830. [DOI] [Google Scholar]

- Katina K, Maina NH, Juvonen R, Flander L, Johansson L, Virkki L, Tenkanen M, Laitila A. In situ production and analysis of Weissella confusa dextran in wheat sourdough. Food Microbiol. 2009;26:734–743. doi: 10.1016/j.fm.2009.07.008. [DOI] [PubMed] [Google Scholar]

- Licciardello F, Cipri L, Muratore G. Influence of packaging on the quality maintenance of industrial bread by comparative shelf-life testing. Food Pack Shelf-Life. 2014;1:19–24. doi: 10.1016/j.fpsl.2013.10.001. [DOI] [Google Scholar]

- Maleki M, Hoseney RC, Mattern JP. Effects of loaf volume, moisture content, and protein quality on the softness and staling rate of bread. Cereal Chem. 1980;57:138–140. [Google Scholar]

- Mastromatteo M, Danza A, Lecce L, Spinelli S, Lampignano V, Laverse J, Contò F, Del Nobile MA. Effect of durum wheat varieties on bread quality. Int J Food Sci Technol. 2014;49:72–81. doi: 10.1111/ijfs.12276. [DOI] [Google Scholar]

- Mo EK, Sung CK. Production of white pan bread leavened by Pichia anomala SKM-T. Food Sci Biotechnol. 2014;23:431–437. doi: 10.1007/s10068-014-0059-7. [DOI] [Google Scholar]

- Pagani MA, Lucisano M, Mariotti M. Italian bakery. In: Hui YH, editor. Bakery product, science and technology. Oxford: Blackwell Publishing; 2006. pp. 523–560. [Google Scholar]

- Pasqualone A, Caponio F, Simeone R. Quality evaluation of re-milled durum wheat semolinas used for bread-making in Southern Italy. Eur Food Res Technol. 2004;219:630–634. doi: 10.1007/s00217-004-1023-1. [DOI] [Google Scholar]

- Piazza L, Masi P. Moisture redistribution throughout the bread loaf during staling and its effect on mechanical properties. Cereal Chem. 1995;72:320–325. [Google Scholar]

- Popov-Raljić JV, Mastilović JS, Laličić-Petronijević JG, Popov VS. Investigations of bread production with postponed staling applying instrumental measurements of bread crumb color. Sensors. 2009;9:8613–8623. doi: 10.3390/s91108613. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Raffo A, Pasqualone A, Sinesio F, Paoletti F, Quaglia G, Simeone R. Influence of durum wheat cultivar on the sensory profile and staling rate of Altamura bread. Eur Food Res Technol. 2003;218:49–55. doi: 10.1007/s00217-003-0793-1. [DOI] [Google Scholar]

- Sabanis D, Tzia C. Effect of rice, corn and soy flour addition on characteristics of bread produced from different wheat cultivars. Food Bioprocess Technol. 2009;2:68–79. doi: 10.1007/s11947-007-0037-7. [DOI] [Google Scholar]

- Severini C, De Pilli T, Cannito G, Baiano A, Peri G. Use of different kinds of leaven to produce durum wheat bread. Tec Molit. 2002;53:560–574. [Google Scholar]

- The Federation of Bakers (2014) http://www.bakersfederation.org.uk/. Accessed 8 Feb 2015

- Torrieri E, Pepe O, Ventorino V, Masi P, Cavella S. Effect of sourdough at different concentrations on quality and shelf-life of bread. LWT-Food Sci Technol. 2014;56:508–516. doi: 10.1016/j.lwt.2013.12.005. [DOI] [Google Scholar]