Abstract

Gluten-free bread production requires gluten-free flours or starches. Rice flour and maize starch are two of the most commonly used raw materials. Over recent years, gluten-free wheat starch is available on the market. The aim of this research was to optimize mixtures of rice flour, maize starch and wheat starch using an experimental mixture design. For this purpose, dough rheology and its fermentation behaviour were studied. Quality bread parameters such as specific volume, texture, cell structure, colour and acceptability were also analysed. Generally, starch incorporation reduced G* and increased the bread specific volume and cell density, but the breads obtained were paler than the rice flour breads. Comparing the starches, wheat starch breads had better overall acceptability and had a greater volume than maize-starch bread. The highest value for sensorial acceptability corresponded to the bread produced with a mixture of rice flour (59 g/100 g) and wheat starch (41 g/100 g).

Keywords: Rheology, Rice flour, Wheat starch, Maize starch, Gluten-free bread, Mixture design

Introduction

The market for gluten-free products is increasing. Due to better diagnostic methods, more people are identified as having coeliac disease, which is a disorder of the small intestine that causes chronic malabsorption (Laurin et al. 2002). The production of gluten-free bakery products continues to be a major challenge for bakers and cereal scientists in the twenty-first century.

Bread is a staple food in which gluten has an important function, as it forms a three-dimensional protein network during dough preparation; in gluten-free baking, this function has to be taken over by other additives, such as hydrocolloids. Most research into the development of gluten-free products has focussed on the substitution of wheat flours by mixtures of gluten-free flours, starches, hydrocolloids and proteins (Schober 2009).

Rice flour is one of the most suitable flours for baking gluten-free products due to its hypoallergenic properties, low sodium content, mild flavour and pale appearance (Torbica et al. 2012). The particle size of rice flour is also known to be important in gluten-free breadmaking. Among the different types of flour, those with a larger particle size produce breads with a higher specific volume and lower hardness (de la Hera et al. 2012).

Several studies have focused on the use of mixtures of starch and gluten-free flour for making breads suitable for coeliac patients. These mixtures can achieve better results than starch or flour alone. Taking this into account, Sánchez et al. (2002) applied response surface methodology (RSM) to optimize a bread formulation from maize starch, rice flour and cassava starch, with and without soy addition. Lopez et al. (2004) studied the use of rice flour supplemented with cassava and maize starch in the production of gluten-free breads. Sciarini et al. (2010) produced breads with mixtures of maize starch with rice and soy flour, and Onyango et al. (2011) used sorghum flour with the addition of different proportions of maize, cassava, potato and rice starch.

Historically there has been some controversy over the safety of gluten-free wheat starch-based products. In fact, the use of wheat starch was forbidden in some countries and allowed in others depending on the definition of the gluten-free diet (Thompson 2001). Nonetheless, Peräaho et al. (2003) showed that gluten-free wheat starch produce a similar histological and clinical recovery in patients with newly detected coeliac disease than a natural gluten-free diet do. The protein content of wheat starches that were used for food for normal consumption varied from 0.3 up to 5 % (Deutsch et al. 2008). Under the new European Union regulations (2009) only foods that contain less than 20 mg gluten/kg can be labelled as gluten-free. Recently, guaranteed gluten-free wheat starch has appeared on the market. This starch has not been sufficiently studied for the production of quality gluten-free bread. However its flavour is closer to that of conventional products made with wheat flour, and it may be an alternative to the starches currently used in these products. In addition, wheat starch has a bimodal size distribution due to the different molecular structures of the amylopectin chains (Jane 2009). The large granules have a disk shape and the small granules have a spherical shape. This bimodal distribution of wheat starch could influence gluten-free breadmaking processes since Zeng et al. (2014) observed changes in starch gelatinization when the proportion of granules of different shape varied. In order to better explain the results, dough rheology and its behaviour during the fermentation process were also assessed.

RSM is a statistical technique that has been successfully applied in the development and optimization of gluten-free breads (Gallagher et al. 2003). For this purpose, a mixture design to optimize a combination of rice flour, maize starch and wheat starch for the baking quality of gluten-free breads (specific volume, texture, colour, porosity, and acceptability) was made. Dough rheology and its behaviour during the fermentation process were also studied.

Materials and methods

Materials

The white rice flour employed in this study was japonica rice flour provided by Harinera Castellana (Medina del Campo, Spain). The flour contained 8,01 g/100 g of protein, 74,35 g/100 g of starch (with 22,13 g of amylose and 10,6 g damaged starch per 100 g of starch), and 12,5 g/100 g of humidity (data provided by the manufacturer). Flours were sifted 10 min in a Bühler MLI 300B sieve (Milan, Italy) with two screens, one of 106 microns and other of 180 microns. The flour fraction with particle size lower than 106 μm was removed as previous studies have shown that finer fractions gave poorer results in gluten-free breadmaking (de la Hera et al. 2013). Therefore, it was used flour with particle size of 106–180 μm. The maize starch, Merizet 100, was provided by Tate & Lyle (London, United Kingdom) and the gluten-free wheat starch with less than 20 mg/kg gluten content, according to the current European Union regulations (2009), provided by Roquette Laisa (Lestrem, France).

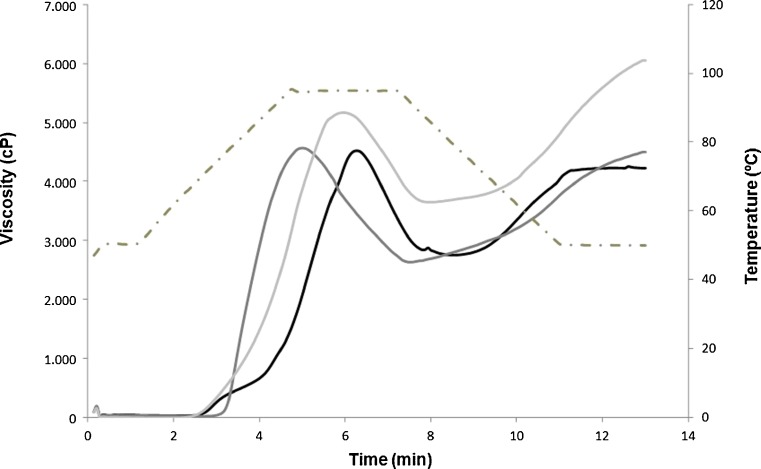

RVA curves from rice flour and maize and wheat starches are shown in Fig. 1.

Fig. 1.

Viscosity profiles of rice flour, maize starch and wheat starch determined by RVA. Rice flour (black line), maize starch (dark grey line), wheat starch (light grey line). Temperature (dot-dash line)

Saf-Instant yeast (Lesaffre, Lille, France), dry refined salt (Esco European Salt Company, Niedersachsen, Germany), white sugar (AB Azucarera Iberia, Valladolid, Spain), refined sunflower oil (Langosta, Ciudad Real, Spain) and hydroxypropyl methylcellulose (HPMC) K4M (Rettenmaier & Sohne, Rosenberg, Germany) were also used in the bread formulation.

Methods

Experimental design

To evaluate the effect of the independent variables (proportion of rice flour, maize starch and wheat starch) on the dependent variables, an experimental design of mixtures in which the ingredients under investigation added up to 100 % was established. Specifically, it was used a simplex centroid design in which the first trial groups were formulations of pure ingredients, the second group were mixtures of two ingredients at 50 % and the third group consisted of mixtures of 33.3 % of each ingredient. All the experiments were performed in duplicate. The response of each investigated parameter was analysed adjusting to cubic model (Eq. 1) with least square regression in order to identify significant (P < 0.05) effects of the variations in ingredient levels on the responses (Table 1).

| 1 |

Table 1.

Significant coefficients (95 % confidence interval) of independent variables of the adjusted cubic model for bread characteristics (dependent analytical variables)

| Variable | a | b | c | ab | ac | bc | abc | R2 (%) |

|---|---|---|---|---|---|---|---|---|

| Specific Volume (mL/g) | 7,75 | 4,72 | 7,20 | 92,34*** | ||||

| Firmness (N) | 0,63 | 0,55 | 1,91 | 1,47 | −1,35 | 96,22*** | ||

| Cohesiveness | 0,61 | 0,52 | 0,50 | −0,21 | 0,23 | 0,42 | 95,90*** | |

| Resilience | 0,42 | 0,26 | 0,32 | −0,17 | 0,31 | 95,94*** | ||

| Crust brightness | 81,39 | 68,91 | 84,46 | 19,65 | 94,40*** | |||

| Cell density (number of cells/cm2) | 53,56 | 46,67 | 63,78 | 34,67 | 23,56 | 4,89 | −6,33 | 69,86* |

| Appearance | 4,59 | 5,86 | 4,37 | 4,75 | 3,29 | −23,25 | 97,00*** | |

| Taste | 5,78 | 5,73 | 4,10 | 2,64 | 3,7 | −16,92 | 94,82*** | |

| Overall acceptability | 5,42 | 5,84 | 4,13 | 3,45 | 3,54 | −20,31 | 96,93*** |

Adjusted cubic model= a*Wheat starch + b*Rice flour + c*Corn starch + ab*Wheat starch*Rice flour + ac*Wheat starch*Corn starch + bc*Rice flour*Corn starch + abc*Wheat starch*Rice flour*Corn starch

Blanks correspond to non significant effects at level of significance of 5 %. *p < 0.05; **p < 0.01; ***p < 0.001; ns not significant

Significance of the lack-of-fit error term, R2 value and model significance were used to judge adequacy of model fit. For optimisation, a multiple response method was applied. The following responses were used: loaf specific volume (maximise), crust brightness (L*) (minimise), cell density (maximise); and loaf specific volume (maximise), crust L* (minimise), cell density (minimise).

Flour/Starch characterisation

The pasting properties of flours during the heating-cooling cycle was measured in duplicate with the Rapid Visco Analyser (RVA) (Newport Scientific, Warriewood, Australia) in accordance with AACC method 61.02.01 (AACC 2012).

Dough rheology

The rheological behaviour of doughs was studied using a Thermo Scientific Haake RheoStress 1 controlled strain rheometer (Thermo Fisher Scientific, Schwerte, Germany) and a Phoenix II P1-C25P water bath which controlled analysis temperature (set at 25 °C). The rheometer was equipped with parallel-plate geometry (60 mm diameter titanium serrated plate-PP60 Ti) with a 3-mm gap. After adjustment to the 3-mm gap, the excess dough was removed and Vaseline oil (Panreac, Panreac Química SA, Castellar del Vallés, Spain) was applied to cover the exposed sample surface. Dough samples for rheological test were prepared following the method explained in breadmaking section. In oscillatory tests, dough was rested for 300 s before measuring. Samples (without yeast) were analysed in duplicate. First, a strain sweep test was performed at 25 °C with a strain range of 0.1–100 Pa and a constant frequency of 1Hz to identify the linear viscoelastic region. On the basis of the results obtained, a strain value included into the linear viscoelastic region was used in a frequency sweep test at 25 °C with a frequency range of 100–0.1 Hz. Values of the complex modulus (G*[Pa]) were obtained for different frequency values (Hz) (Dobraszczyk and Morgenstern 2003).

In creep-recovery tests, the dough was rested for 600 s to allow relaxation before the measurement. Creep tests were performed by imposing a sudden step shear stress in the linear viscoelastic region for 60 s. In the recovery phase the stress was suddenly removed and the sample was allowed to rest for 180 s to recover the elastic (instantaneous and retarded) part of the deformation. Each test was performed in triplicate.

Dough development and gas production

Dough proofing behaviour was determined using a rheofermentometer (Chopin, Villeneuve-la-Garenne, France), obtaining information on dough development and gas production during fermentation. In contrast to the traditional method, the weight of dough was reduced to 200 g and the weights were removed from the piston due to the weakness of this kind of dough compared with those prepared with wheat flour. Analyses were run in duplicate.

Breadmaking

The following ingredients were used in breadmaking: water (90 g/100 g flour, starch or flour/starch mixture), Saf-Instant yeast (3 g/100 g), salt (1.8 g/100 g), oil (6 g/100 g), HPMC (2 g/100 g) and white sugar (5 g/100 g). In all tests, the water temperature was held between 20 °C and 22 °C. All the ingredients were mixed for 8 min in a Kitchen Aid 5KPM50 mixer (Kitchen Aid, Michigan, USA), after which 250 g of the bread dough were placed in aluminium pans of 2322 × 108 × 43.5 mm (ALU-Schale, Wiklarn, Germany). Fermentation was performed at 30 °C and 75 % RH for 90 min. After fermentation, doughs were baked in an electric modular oven for 40 min at 190 °C. The loaves were removed from the moulds after a 60-min cooling period and were weighed. They were then introduced into polyethylene plastic bags and stored at 20 °C until analysis. Measurements on the breads were performed 24 h after baking. All the elaborations were performed twice.

Bread characteristics

Bread volume was determined using a laser sensor with the Volscan Profiler (Stable Micro Systems, Godalming, UK). The volume measurements were performed on two loaves from each elaboration. The specific volume was calculated as the ratio of bread volume to its mass.

Crumb texture was measured with a TA-XT2 texture analyser (Stable Microsystems, Surrey, UK) fitted with the “Texture Expert” software. A 25-mm diameter cylindrical aluminium probe was used in a “Texture Profile Analysis” (TPA) double-compression test to penetrate up to 50 % of the sample depth at a test speed of 2 mm/s, with a 30 s delay between the two compressions. Firmness (N), cohesiveness and resilience were calculated from the TPA curve (Gomez et al. 2007). Texture analyses were performed on 30 mm thick slices. Analyses were performed on two slices from two loaves from each elaboration (each formulation). Each elaboration was performed in duplicate (2×2×2).

Bread colour was measured using a Minolta CN-508i spectrophotometer (Minolta, Co. LTD, Tokio, Japan) using the D65 illuminant with the 2° standard observer. Results are expressed in the CIE L*a*b* colour space. Crust colour was measured at two different points on two loaves from each type of elaboration (2×2).

Cell densities (number of cells/cm2) of the breads were assessed using digital image analysis in black and white with an HP Scanjet G3110 scanner (HP, Palo Alto, EEUU). The analysis was performed on 15 × 15 mm squares taken from the centre of a slice. Images were processed using “WCIF ImageJ” software. Cell densities were measured on two slices from different loaves from each elaboration.

Consumer testing

Hedonic sensory evaluation of breads was conducted with 63 volunteers who used to consume bread as part of their diet on a regular basis. Samples were analysed 1 day after baking. Samples were presented as half pieces for appearance and 2 cm slices for sensory evaluation on white plastic dishes coded with three-digit random numbers and served in random order. Participants were provided with water for rinsing between each sensory evaluation. The elaboration of breads was evaluated on the basis of acceptance of their appearance, taste and overall liking on a nine-point hedonic scale. The scale of values ranged from “like extremely” to “dislike extremely”, corresponding to the highest and lowest scores of “9” and “1” respectively.

Statistical analysis

The Statgraphics Centurion XVI software (StatPoint Technologies Inc, Warrenton, USA) was used both for the experimental design and to generate the corresponding response surfaces for evaluation of the independent variables.

Results and discussion

Dough rheology

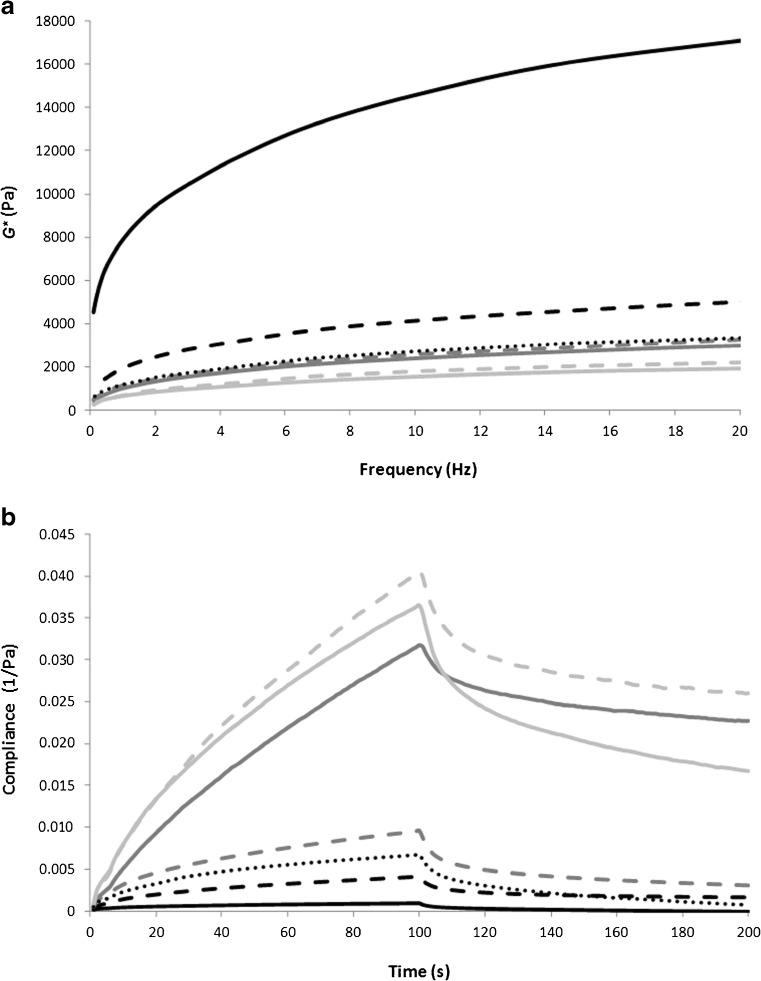

Figure 2a shows the G* frequency sweep corresponding to the different doughs. It can be seen that dough made with rice flour had a higher complex modulus than all other doughs, and maize starch dough had a higher complex modulus than wheat starch. Generally, the mixtures presented intermediate G* values that fell into the G* range corresponding to its individual components. The differences in dough rheology can be attributed to the internal structure of the starchy base (flour or starch), as the geometry of the particles may lead to different degrees of compactness, as reported by de la Hera et al. (2012, 2013). Furthermore, the milling technique and kernel properties in the manufacture of flours (rice flour in our case), unlike the manufacture of starches, increase damage to starch, which enhances water binding (Schober 2009). Additionally, the higher protein content of doughs made with rice flour could also favour greater water absorption by the dough. This could be a key aspect in increasing complex modulus of rice flour doughs.

Fig. 2.

Rheological behaviour of the different dough formulations: (a) G* values and (b) creep recovery curves. Rice flour (black line), maize starch (dark grey line), wheat starch (light grey line), rice flour-maize starch (discontinuous black line), rice flour-wheat starch (discontinuous dark grey line), maize starch-wheat starch (discontinuous light grey line), rice flour-maize starch-wheat starch (black dotted line)

The results of the creep recovery test are shown in Fig. 2b. Van Bockstaele et al. (2011) have studied wheat doughs and shown that the creep recovery test can be an excellent measurement of overall dough consistency, due to the interaction between water absorption, protein content and other flour constituents. The creep recovery curves of gluten-free doughs exhibited a typical viscoelastic behaviour combining both viscous fluid and elastic responses, as described by Lazaridou et al. (2007). The doughs produced from rice flour showed a very different behaviour in comparison with starch-based doughs. They had lower compliance values both in the creep and recovery phases, indicating higher dough strength (Edwards et al. 2003). Maize starch-wheat starch dough showed the highest values for creep and recovery compliance.

Flour doughs contain particles of larger size than doughs with starch granules and this leads to a more irregular structure (de la Hera et al. 2013). Additionally, the amount of damaged starch and the presence of proteins could favour greater water absorption by the dough, which would reduce the elastic component of maximum creep compliance (Lazaridou et al. 2007). The bimodal size distribution of wheat starch could promote greater continuity and density of the dough structure, as smaller granules would fit into the spaces between the larger granules, giving the dough a higher instant creep and recovery compliances. All formulations, except for the doughs made by starch-starch mixtures, which are more similar to the pure starch-based doughs, presented behaviour more similar to the rice-flour-based doughs, although with higher creep and recovery compliances.

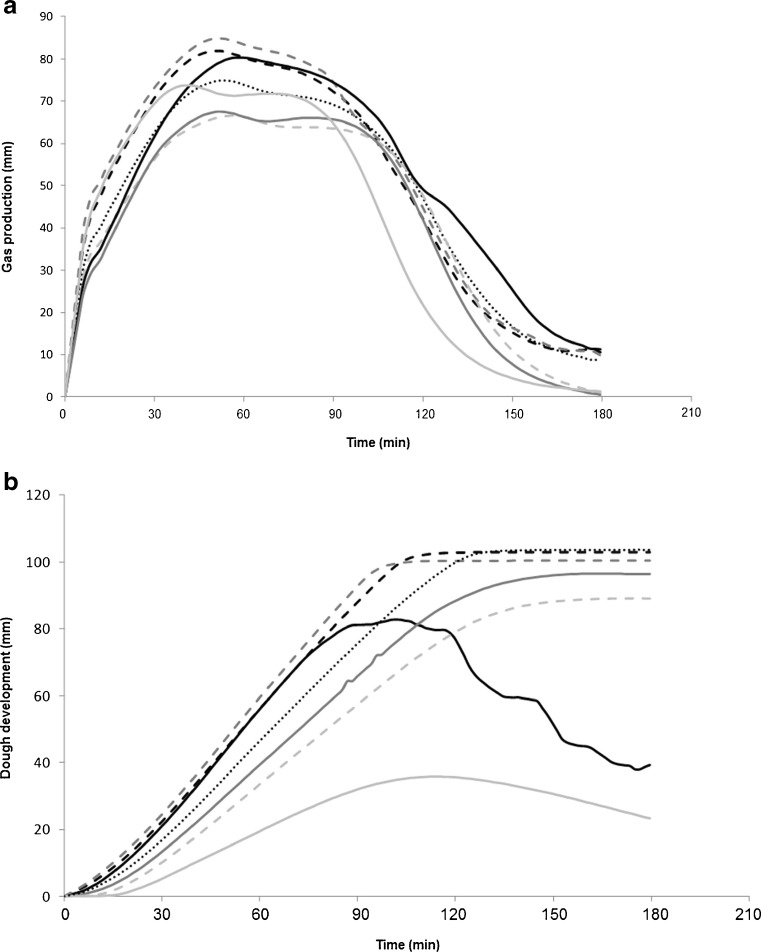

Dough development and gas production

Figure 3 shows the curves corresponding to gas production during fermentation. Yeast first fermented the sucrose that had been added to the dough, followed by the maltose produced by the action of amylases on damaged starched granules. In all cases the curves show an abrupt decrease in gas production between 90 and 120 min, which indicates that all the sugars that can be fermented had been consumed by the yeast. Doughs containing rice flour showed greater gas production, particularly in the intermediate and final phases of fermentation; this could be related to greater starch damage (Schober 2009) increasing the amount of maltose available. The decrease in fermentation at 90–120 min would not have affected the fermentation process of the breads produced in this study as the fermentation time (90 min) was shorter than the time needed for consumption of all the sugar. Gas production in the initial phases of fermentation (until 30 min) was greatest with wheat-starch doughs than pure corn-starch and rice flour doughs, but it suffered a sharper decline before the others. Up to 60 min, the greatest gas production was in samples containing rice flour.

Fig. 3.

Proofing behaviour of dough formulation determined by a rheofermentometer: (a) gas production and (b) dough development. Rice flour (black line), maize starch (dark grey line), wheat starch (light grey line), rice flour-maize starch (discontinuous black line), rice flour-wheat starch (discontinuous dark grey line), maize starch-wheat starch (discontinuous light grey line), rice flour-maize starch-wheat starch (black dotted line)

Regarding dough development (Fig. 3b), it may be observed that doughs made solely, by rice-flour had a greater initial development, but the dough structure became disassembled during the intermediate stage of fermentation, implying reduced gas retention, and dough height fell at 2 h after the initiation of fermentation. Including starch in rice-flour mixtures can resolve this problem and favour constant and greater dough development constant. Expansion in dough development could be related with the compliance results as samples with lower compliance values (rice flour doughs) had higher dough development.

Maize starch gave rise to good dough development, although slightly later than with rice flour. This could result in a lower bread volume if shorter fermentation times are used. However, wheat starch showed a very poor development that was not in accordance with the amount of gas produced. This analysis should be invalidated because the dough overflowed when the piston was assembled, and the recording of dough development was therefore innacurate; this may have been due to a lower G* of wheat-starch doughs.

The differences between the different combinations of flour and starches at dough development and gas retention during fermentation could be related to the internal dough structure. Starch-based doughs are formed of smaller particles that are usually regular and round. However rice-flour doughs present a more irregular structure, containing some flour particles that are larger than starch granules, (de la Hera et al. 2013), while the rice starch granules themselves are smaller than maize or wheat starch granules.

The continuous phase composed of water, HPMC and other smaller components is able to join flour and starch particles forming a layer responsible for retaining the gas produced (de la Hera et al. 2013). Variations in this internal structure have a marked influence on dough development. It could be attributed to the observed variations of complex modulus. Previous studies of gluten-free breads have demonstrated a relationship between dough consistency and dough development during fermentation (de la Hera et al. 2012).

Bread properties

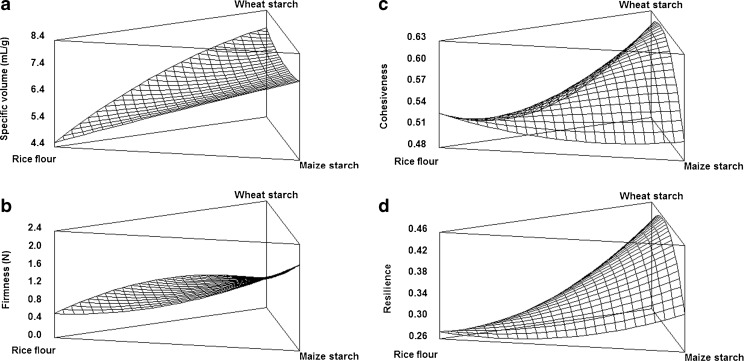

Figure 4a shows the changes in specific volume of breads prepared according to the experimental design. It can be seen that breads made with starches had a higher specific volume than rice flour breads. These results paralleled dough development, as doughs with starch showed a greater development (apart from wheat-starch dough which, as already mentioned, should not be taken into account). It was also observed that dough with a lower complex modulus produced bread with a greater specific volume; this correlation has been already reported in other studies (Matos and Rosell 2013) and has been attributed to the fact that a high consistency can restrict dough expansion during the proofing stage. Regarding the creep recovery test, lower Jcmax values were associated with lower specific volumes, indicating that less dough strength leads to greater development. Higher Jsteady values, which are associated with greater dough elasticity (Moreira et al. 2012), also were in accordance with a greater bread specific volume. Our results coincide with those of other studies that have investigated the use of mixtures of starches and gluten-free flours and have found that the inclusion of starches generally increased bread volume (Lopez et al. 2004; Mariotti et al. 2013; Onyango et al. 2011). The difference in the specific volume of breads made with wheat starch and maize starch, and the differences in dough structure and G*, may be due to variations in pasting behaviour. As can be seen from the RVA curves (Fig. 1), pure maize starch had an earlier pasting than pure wheat starch. Therefore expansion during baking could be lower with pure maize than pure wheat starch, as pasting signals the end of expansion.

Fig. 4.

Effect of rice flour, maize starch and wheat starch content on specific volume (a), Firmness (b), Cohesiveness (c) and Resilience (d) of the breads

When the maize starch content was increased, the bread firmness also increased (Fig. 4b), but the differences between breads with rice flour or wheat starch were minimal. These results may seem surprising, since other studies have shown an inverse relationship between bread specific volume and firmness (Gallagher et al. 2003; Sabanis et al. 2009). However, these data may be related to the changes in internal bread and cell structure. Breads made with starch presented a more compact structure, with a larger number of cells and smaller mean cell area. Gueven and Hicsasmaz (2013) stated that the relationship between the texture and the cell structure of porous foods depends not only on the percentage of pores, but also on their distribution and shape. Breads made with wheat starch presented greater cohesiveness (Fig. 4c) and resilience (Fig. 4d) than rice-flour and maize-starch breads. The variations in these parameters may be related to the internal structure of the breads. One of the main problems with gluten-free breads is their lack of cohesiveness and resilience (Matos and Rosell 2012). Thus, these aspects can be improved by the incorporation of wheat starch.

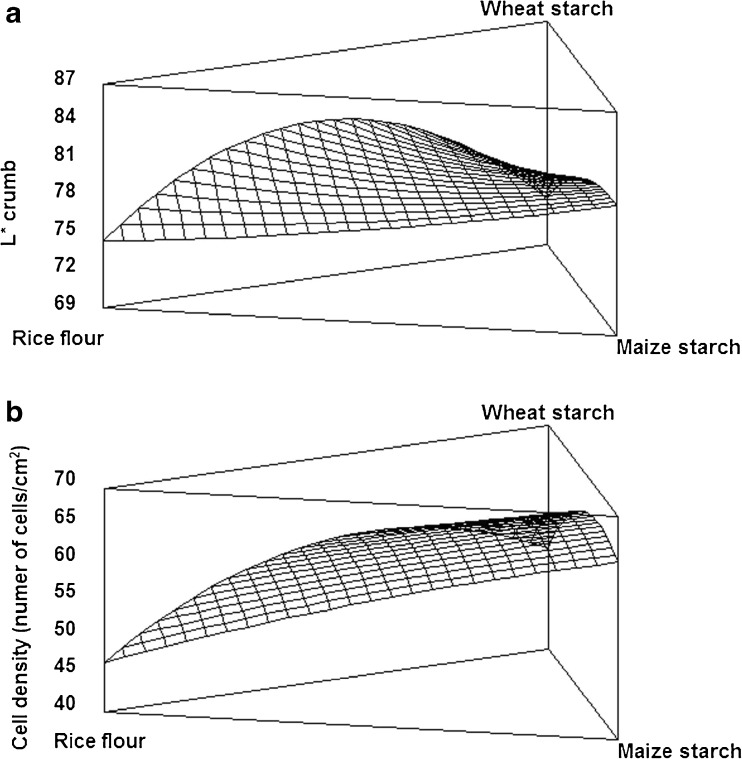

Crust brightness (Fig. 5a) was affected by the type of mixture, and was lower in the case of breads with rice flour. However, there were no differences between the breads made with different starches. Our results agree with those reported by Miñarro et al. (2010) who observed that rice-flour breads had lower brightness values and that they were therefore less white than breads made with starches. These differences may be due to the higher protein content of doughs made with rice flour than doughs made with starches and therefore to a greater colour development through Maillard reactions. The excessively pale crust colour in gluten-free breads in comparison with standard wheat breads is a problem (Gallagher et al. 2002), but the inclusion of rice flours can minimize this defect. Figure 5b (cell density) displayed a lower cell density in breads made with rice flour whereas breads made with wheat or rice starch appeared with higher cell density. These trends coincide with the findings reported by Lopez et al. (2004), who studied mixtures of rice flours with maize and cassava starches. In wheat bread, which is commonly used as a model for gluten-free breads, the cell structure is preferred to be more closed for pan breads, but more open for other breads such as baguettes. The proportion of rice flour should therefore be varied according to the type of bread. As previously stated, this different crumb structure can affect the final bread texture (Mariotti et al. 2013), and the differences observed may be related to dough structure, how the air bubbles were integrated during the mixing stage, and how these bubbles grow during the fermentation and baking stages.

Fig. 5.

Effect of rice flour, maize starch and wheat starch content on crumb L* (a) and cell density (b) of the breads

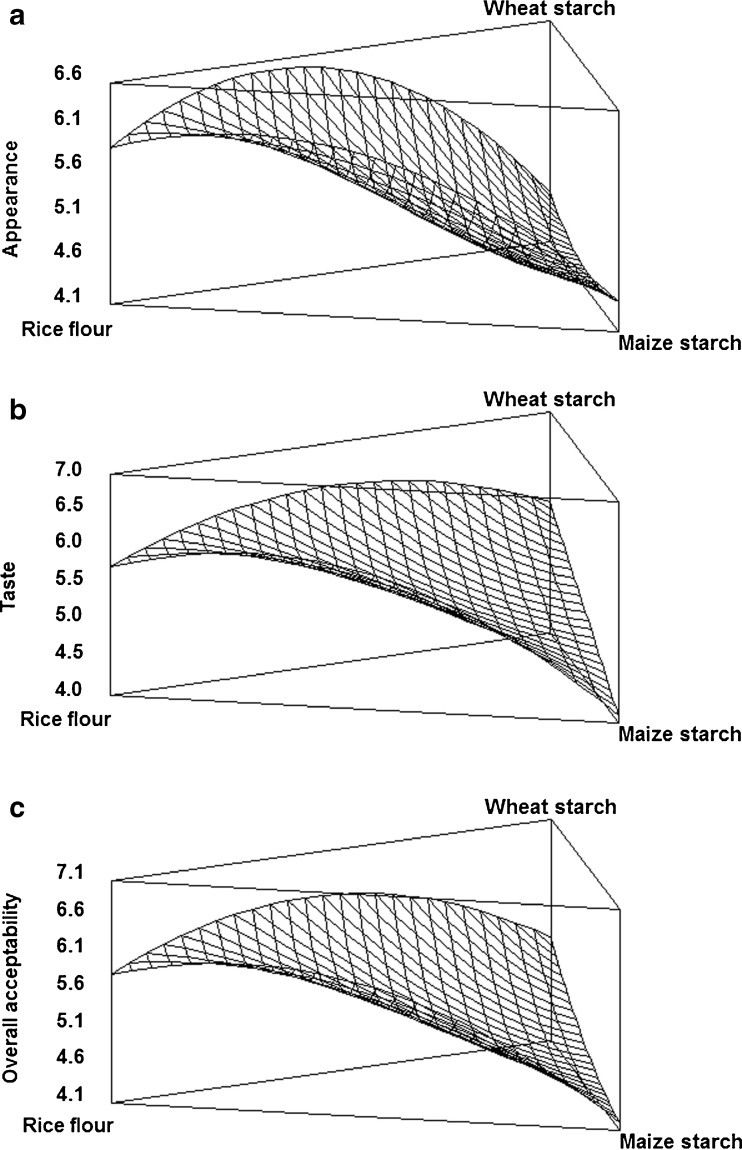

Sensorial evaluation

Figure 6 shows the response surfaces for appearance (a), taste (b) and overall acceptability (c). The lowest scores for appearance were given to the starch breads, which were much paler than the other breads. Bread with rice-flour and wheat-starch achieved the highest score. Regarding taste, rice-flour breads and wheat-starch breads were rated similarly, whereas maize-starch bread was considered to have the poorest taste. This can probably be explained by the fact that the taste of wheat starch was much more similar to conventional bread. With regard to the overall acceptability, the bread with the lowest score was again the maize-starch bread and the highest score was for the bread with wheat starch and rice flour. Our results confirmed those reported by Lopez et al. (2004), which indicated that rice-flour bread is generally better rated with regard to appearance, taste and overall acceptability than maize-starch bread. Matos and Rosell (2012) studied the characteristics of gluten-free breads from different commercial doughs. Most of them were made from maize starch, except for one, containing a mixture of maize starch and rice flour. In the present study, the mixture formulation also exhibited the highest score for the three parameters measured.

Fig. 6.

Effect of rice flour, maize starch and wheat starch content on appearance (a), taste (b) and overall acceptability (c) of the breads

Optimization

The highest value for sensorial acceptability was 6.50, corresponding to the bread produced with a mixture of rice flour (59 g/100 g) and wheat starch (41 g/100 g). Specific volume is one of the most commonly used parameters to evaluate bread quality and, when it was maximized the value obtained was wheat starch 100 g/100 g.

When only the instrumental values were took into account, using the results of the multiple response method, the optimal bread to achieve maximum specific volume and minimum crust luminosity contained 47 g/100 g rice flour and 53 g/100 g wheat starch when maximizing cell density; these proportions are relatively close to the optimal values obtained when maximizing for overall acceptability. However, when cell density was minimized, the optimal bread contained 98 g/100 g rice flour and 2 g/100 g wheat starch.

These data show that bread specific volume cannot be considered individually as a quality indicator for gluten-free bread, as consumers also value other parameters, such as crust brightness and cell density. The addition of rice flour to this kind of product has the advantage of a better taste and less crust brightness. At the same time, it has the drawback of a lower specific volume and cell density, which can be improved by the addition of wheat starch to the mixtures, since in all cases it gave better results than maize starch for the manufacture of an optimal bread.

Conclusion

It was confirmed that the mixture design is an effective tool to optimize gluten-free flour and starch mixtures for making breads suitable for coeliac patients. It has also been shown that there is a relationship between dough rheology and bread specific volume. In addition, the incorporation of wheat starch into gluten free bread formulations was found to improve the specific volume and increased the cell density of breads made with rice flour resulting in higher scores for the taste and acceptability than those of maize starch breads. Wheat starch is therefore a very interesting alternative for the development of both industrial and traditional gluten-free breads.

Acknowledgments

This study was supported by a grant from the Spanish Ministry of Science and Innovation (Grant: AGL2011-23802).

References

- AACC (2012) American Association of Cereal Chemist, 11th Edition. St Paul

- Commission Regulation (EC) No. 41/2009. Article 3: Composition and labelling of foodstuffs for people intolerant to gluten

- de la Hera E, Talegón M, Caballero P, Gomez M. Influence of maize flour particle size on gluten-free breadmaking. J Sci Food Agric. 2012;15:924–932. doi: 10.1002/jsfa.5826. [DOI] [PubMed] [Google Scholar]

- de la Hera E, Martínez M, Gómez M. Influence of flour particle size on quality of gluten-free rice bread. LWT-Food Sci Technol. 2013;54:199–206. doi: 10.1016/j.lwt.2013.04.019. [DOI] [Google Scholar]

- Deutsch H, Poms R, Heeres H, Van der Kamp J-W. Labeling and regulatory issues. In: Arendt EK, Dal Bello F, editors. Gluten-free cereal products and beverages. Burlington: Elsevier; 2008. pp. 29–46. [Google Scholar]

- Dobraszczyk BJ, Morgenstern MP. Rheology and the breadmaking process. J Cereal Sci. 2003;38:229–245. doi: 10.1016/S0733-5210(03)00059-6. [DOI] [Google Scholar]

- Edwards NM, Mulvaney SJ, Scanlon MG, Dexter JE. Role of gluten and its components in determining durum semolina dough viscoelastic properties. Cereal Chem. 2003;80:755–763. doi: 10.1094/CCHEM.2003.80.6.755. [DOI] [Google Scholar]

- Gallagher E, Polenghi O, Gormley TR. Improving the quality of gluten free breads. Farm Food. 2002;12:8–13. [Google Scholar]

- Gallagher E, Gormley TR, Arendt EK. Crust and crumb characteristics of gluten-free breads. J Food Eng. 2003;56:153–161. doi: 10.1016/S0260-8774(02)00244-3. [DOI] [Google Scholar]

- Gomez M, Ronda F, Caballero P, Blanco C, Rosell CM. Functionality of different hydrocolloids on the quality and shelf-life of yellow layer cakes. Food Hydrocoll. 2007;21:167–173. doi: 10.1016/j.foodhyd.2006.03.012. [DOI] [Google Scholar]

- Gueven A, Hicsasmaz Z. Pore structure in food. New York: Springer; 2013. [Google Scholar]

- Jane J. Structural features of starch granules II. In: BeMiller J, Whistler R, editors. Starch: chemistry and technology. New York: Academic; 2009. pp. 193–236. [Google Scholar]

- Laurin P, Wolving M, Falth-Magnusson K. Even small amounts of gluten cause relapse in children with celiac disease. J Pediatr Gastroenterol Nutr. 2002;34:26–30. doi: 10.1097/00005176-200201000-00007. [DOI] [PubMed] [Google Scholar]

- Lazaridou A, Duta D, Papageorgiou M, Belc N, Biliaderis CG. Effets of hydrocolloids on dough rheology and bread quality parameters in gluten free formulations. J Food Eng. 2007;79:1033–1047. doi: 10.1016/j.jfoodeng.2006.03.032. [DOI] [Google Scholar]

- Lopez ACB, Pereira AJG, Junqueira RG. Flour mixture of rice flour, corn and cassava starch in the production of gluten-free white bread. Braz Arch Biol Technol. 2004;47:63–70. doi: 10.1590/S1516-89132004000100009. [DOI] [Google Scholar]

- Mariotti M, Pagani MA, Lucisano M. The role of buckwheat and HPMC on the breadmaking properties of some commercial gluten-free bread mixtures. Food Hydrocoll. 2013;30:393–400. doi: 10.1016/j.foodhyd.2012.07.005. [DOI] [Google Scholar]

- Matos ME, Rosell CM. Relationship between instrumental parameters and sensory characteristics in gluten free bread. Eur Food Res Technol. 2012;235:107–117. doi: 10.1007/s00217-012-1736-5. [DOI] [Google Scholar]

- Matos ME, Rosell CM. Quality indicators of rice-based gluten-free bread-like products: relationships between dough rheology and quality characteristics. Eur Food Res Technol. 2013;6:2331–2341. [Google Scholar]

- Miñarro B, Normahomed I, Guamis B, Capellas M. Influence of unicellular protein on gluten-free bread characteristics. Eur Food Res Technol. 2010;231:171–179. doi: 10.1007/s00217-010-1269-8. [DOI] [Google Scholar]

- Moreira R, Chenlo F, Torres MD. Rheology of gluten-free doughs from blends of chestnut and rice flours. Food Bioprocess Technol. 2012;6:1476–1485. doi: 10.1007/s11947-012-0927-1. [DOI] [Google Scholar]

- Onyango C, Mutungi C, Unbehend G, Lindhauer MG. Modification of gluten-free sorghum batter and bread using maize, potato, cassava or rice starch. LWT-Food Sci Technol. 2011;44:681–686. doi: 10.1016/j.lwt.2010.09.006. [DOI] [Google Scholar]

- Peräaho M, Kaukinen K, Paasikivi K, Sievänen H, Lohiniemi S, Mäki M, Collin P. Wheat-starch-based gluten-free products in the treatment of newly detected coeliac disease: prospective and randomized study. Aliment Pharmacol Ther. 2003;17:587–594. doi: 10.1046/j.1365-2036.2003.01425.x. [DOI] [PubMed] [Google Scholar]

- Sabanis D, Lebesi D, Tzia C. Effect of dietary fibre enrichment on selected properties of gluten-free bread. LWT-Food Sci Technol. 2009;42:1380–1389. doi: 10.1016/j.lwt.2009.03.010. [DOI] [Google Scholar]

- Sánchez HD, Osella CA, De La Torre MA. Optimization of gluten-free bread prepared from cornstarch, rice flour, and cassava starch. J Food Sci. 2002;67:416–419. doi: 10.1111/j.1365-2621.2002.tb11420.x. [DOI] [Google Scholar]

- Schober TJ. Manufacture of gluten-free specialty breads and confectionery products. In: Gallagher E, editor. Gluten-free food science and technology. Dublin: Wiley-Blackwell; 2009. pp. 130–180. [Google Scholar]

- Sciarini LS, Ribotta PD, León AE, Pérez GT. Influence of gluten-free flours and their mixtures on batter properties and bread quality. Food Bioprocess Technol. 2010;3:577–585. doi: 10.1007/s11947-008-0098-2. [DOI] [Google Scholar]

- Thompson T. Wheat starch, gliadin, and the gluten-free diet. J Am Diet Assoc. 2001;101:1456–1459. doi: 10.1016/S0002-8223(01)00351-0. [DOI] [PubMed] [Google Scholar]

- Torbica A, Hadnađev M, Dapčević Hadnađev T. Rice and buckwheat flour characterisation and its relation to cookie quality. Food Res Int. 2012;48:277–283. doi: 10.1016/j.foodres.2012.05.001. [DOI] [Google Scholar]

- Van Bockstaele F, De Leyn I, Eeckhout M, Dewettinck K. Non-linear creep-recovery measurements as a tool for evaluating the viscoelastic properties of wheat flour dough. J Food Eng. 2011;107:50–59. doi: 10.1016/j.jfoodeng.2011.06.001. [DOI] [Google Scholar]

- Zeng J, Gao H, Li G. Functional properties of wheat starch with different particle size distribution. J Sci Food Agric. 2014;94:57–62. doi: 10.1002/jsfa.6186. [DOI] [PubMed] [Google Scholar]