Abstract

The aim of this study was to find out the optimal moisture adding rate of brown rice during the process of germination. The process of water addition in brown rice could be divided into three stages according to different water absorption speeds in soaking process. Water was added with three different speeds in three stages to get the optimal water adding rate in the whole process of germination. Thus, the technology of segmented moisture conditioning which is a method of adding water gradually was put forward. Germinated brown rice was produced by using segmented moisture conditioning method to reduce the loss of water-soluble nutrients and was beneficial to the accumulation of gamma aminobutyric acid. The effects of once moisture adding amount in three stages on the gamma aminobutyric acid content in germinated brown rice and germination rate of brown rice were investigated by using response surface methodology. The optimum process parameters were obtained as follows: once moisture adding amount of stage I with 1.06 %/h, once moisture adding amount of stage II with 1.42 %/h and once moisture adding amount of stage III with 1.31 %/h. The germination rate under the optimum parameters was 91.33 %, which was 7.45 % higher than that of germinated brown rice produced by soaking method (84.97 %). The content of gamma aminobutyric acid in germinated brown rice under the optimum parameters was 29.03 mg/100 g, which was more than two times higher than that of germinated brown rice produced by soaking method (12.81 mg/100 g). The technology of segmented moisture conditioning has potential applications for studying many other cereals.

Keywords: Germinated brown rice, Segmented moisture conditioning, Soaking process, GABA content, Germination rate

Introduction

Germination is widely used for cereals and legumes. A number of studies have shown that the nutrition is enriched after germination of cereal such as barley (Bamforth and Barclay 1993; Iimure et al. 2009), wheat (Yang and Ooraikul 2001), rice (Saman et al. 2008), oats and rye (Price 1988; Moongngarm and Saetung 2010), which is beneficial to human health. Germinated brown rice (GBR) as one of healthy foods becomes more and more popular in the world, especially in Asian countries. The texture of GBR is much softer than that of ungerminated brown rice (UBR) (Zhang et al. 2015). Moreover, GBR has been reported to contain more bioactive substances than UBR and white rice, such as dietary fiber, minerals, proteins, vitamins, especially gamma aminobutyric acid (GABA) (Kayahara 2001; Moongngarm and Saetung 2010). The content of GABA in GBR was noticed to be ten times more as compared to milled white rice and two times more than that of brown rice (Patil and Khan 2011).

Recently, researches have focused on producing GBR by soaking method and improving GABA content in GBR (Suzuki and Maekawa 1999; Morita et al. 2007). Saikasa et al. 1994 described the accumulation characteristics of GABA in ten rice cultivars with water soaking. Komatsuzaki et al. 2007 reported that GBR with high GABA content could be produced by soaking and gaseous treatment. Many other attempts have been made for producing GBR with high GABA content by stress treatment, such as cytosolic, acidification and water stress (Oh 2003). However, few studies have tried to find out the optimal water adding rate in the whole process of germination to improve quality characteristics of GBR. The technology of segmented moisture conditioning (SMC), a method of un-soaking, was applied in this study. In this method, water was added in a small amount every hour rather than soaking in excessive water. This new process can reduce the loss of water-soluble substances including GABA and decrease the number of cracks emerging on the kernels, which may affect the edible quality of GBR.

The purpose of this study was to find the optimal water adding rate which was suitable for germination of brown rice by using SMC method. Water was added to brown rice in three stages at three different once moisture adding amount (OMAA) (the increasing percentage of moisture content in brown rice) until the water content of brown rice reached 29 % (the optimum water content to germination), and then brown rice was transferred to a container for germination under certain temperature and humidity. The effects of OMAA in three stages on the GABA content in GBR and germination rate of brown rice were investigated by response surface methodology.

Materials and methods

Brown rice samples

The Dongnong 419 paddy used in this study was harvested in 2012, and provided by the experiment station of the Northeast Agricultural University (Harbin, China). Brown rice samples were obtained after hulling by a sheller (THU-35B type, Satake, Tokyo, Japan), cleaning and removing impurities. Samples were stored in airtight containers at ambient temperature (20 °C ± 2 °C) with the initial moisture content 12 % (w. b.).

Soaking test

The brown rice was packed with gauze and soaked in distilled water between 20 °C and 40 °C in 250 mL glass beakers. About 15 g brown rice samples were put into each beaker that contains 200 mL distilled water. Beakers were placed into the thermostat water bath to control temperature. The samples were taken out after achieving the required time. Then the water on the surface of brown rice was dried by using filter paper. The samples were then moved to a plastic cup and weighed on analytical balance to an accuracy of ± 0.1 mg. The moisture content of brown rice was calculated based on the initial moisture content previously determined. All soaking tests were done in triplicate.

Preparation of GBR

Lots of brown rice (100 g) was put in culture dishes (15 cm diameter) after weighting. Water was added onto the surface of brown rice grains by means of spraying water as mist on the basis of OMAA (once moisture adding amount) in three stages. Three stages were divided as, stage I: rapid water absorption stage, stage II: slow water absorption stage and stage III: flat water absorption stage, according to different water absorbing rates. Water was added once an hour until the water content reached 29 %, and the brown rice grains were conducted conditioning under 95 % humidity at 30 °C during the whole process of adding water. Then the samples were put in a temperature-humidity chamber (CTHI-150 (A) B type, temperature fluctuation ± 0.2 °C, Shi Dukai Equipment Co., Ltd., Shanghai, China) at 25 °C for 36 h to germination.

Experimental design and statistical analysis

The factors selected for water addition rate were once moisture adding amount of stage I (OMAA I) (x1), once moisture adding amount of stage II (OMAA II) (x2) and once moisture adding amount of stage III (OMAA III) (x3). The selected independent variables and their levels in the form of coded variables were shown in Table 1, which were determined according to the results from preliminary experiments and previous study (Arora et al. 2007; Jia et al. 2012). Experiments of brown rice were performed by a central composite design (CCD) employing Design Expert software program (V6. 0. 4) of the Stat-Ease software (Stat-Ease, Inc., Minneapolis, MN, USA) with five levels of each parameter (Zheng et al. 2011). A multiple regression analysis of the data was carried out for obtaining an empirical model, which related the measured responses to the independent variables. The significant probability was at p < 0.05. The value of various responses at different experimental combinations for coded variables was given in Table 2.

Table 1.

Factors and levels of experiment factors

| Code Value | x 1 (%/h) | x 2 (%/h) | x 3 (%/h) |

|---|---|---|---|

| 1.682 | 1.5 | 2.0 | 1.6 |

| 1 | 1.3 | 1.8 | 1.4 |

| 0 | 1 | 1.5 | 1.1 |

| -1 | 0.7 | 1.2 | 0.8 |

| -1.682 | 0.5 | 1.0 | 0.6 |

x 1 represents once moisture adding amount of stage I; x 2 represents once moisture adding amount of stage II; x 3 represents once moisture adding amount of stage III

Table 2.

Design and result of the experiment

| Treatment | x 1 (%/h) | x 2 (%/h) | x 3 (%/h) | y 1 (%) | y 2 (mg/100 g) |

|---|---|---|---|---|---|

| 1 | -1 | -1 | -1 | 86.33 | 22.14 |

| 2 | 1 | -1 | -1 | 89.67 | 25.28 |

| 3 | -1 | 1 | -1 | 83.33 | 19.88 |

| 4 | 1 | 1 | -1 | 86.33 | 23.02 |

| 5 | -1 | -1 | 1 | 89.67 | 24.86 |

| 6 | 1 | -1 | 1 | 83.33 | 26.02 |

| 7 | -1 | 1 | 1 | 86.67 | 22.60 |

| 8 | 1 | 1 | 1 | 89.67 | 24.74 |

| 9 | -1.682 | 0 | 0 | 90.00 | 19.47 |

| 10 | 1.682 | 0 | 0 | 86.67 | 23.37 |

| 11 | 0 | -1.682 | 0 | 88.33 | 23.17 |

| 12 | 0 | 1.682 | 0 | 83.33 | 18.77 |

| 13 | 0 | 0 | -1.682 | 86.67 | 23.01 |

| 14 | 0 | 0 | 1.682 | 86.33 | 27.44 |

| 15 | 0 | 0 | 0 | 83.67 | 27.01 |

| 16 | 0 | 0 | 0 | 86.67 | 28.21 |

| 17 | 0 | 0 | 0 | 89.00 | 26.35 |

| 18 | 0 | 0 | 0 | 91.33 | 27.56 |

| 19 | 0 | 0 | 0 | 89.33 | 27.12 |

| 20 | 0 | 0 | 0 | 91.00 | 27.97 |

| 21 | 0 | 0 | 0 | 90.67 | 27.67 |

| 22 | 0 | 0 | 0 | 92.00 | 28.10 |

| 23 | 0 | 0 | 0 | 92.33 | 27.34 |

x 1 represents once moisture adding amount of stage I; x 2 represents once moisture adding amount of stage II; x 3 represents once moisture adding amount of stage III; y 1 represents germination rate of brown rice; y 2 represents GABA content of germinated brown rice

According to the theory of a multiple regression analysis, a second order polynomial equation for a three factor system is as follows:

| 1 |

Where βk0, βki, βkii, βkij are the constant coefficients and xi, xj are coded independent variables.

Both of the two models were tested for their adequacy using ANOVA technique. The validity of the models was confirmed by F-values for the lack of fit nonsignificant (p > 0.05).

Variance analysis of the single factor was calculated using SPSS software, version 18 (Inc., Chicago, IL, USA).

Determination of germination rate

The brown rice was considered to be germinated when the germ reached 0.5–1.0 mm. One hundred grains of rice were taken out randomly after 48 h of germination, and grains which reached the standard of germination were counted. The germination rate was calculated based on the total 100 grains (Chung et al. 2009). Each sample was counted three times and calculated the mean as the result.

Analysis of GABA in GBR

The GABA content of germinated brown rice was determined by following the procedure of Zhang et al. 2015. Firstly, the GBR samples were smashed into powder by using micro plant grinding machine (FZ-102, Taisite, Tianjin, China). And then about 2 g powder of each GBR sample was taken out to be measured by using an amino acid auto analyzer (L-8800, Hitachi, Hitachina ka, Japan) after processing by the solution. All of the samples solution and amino acids standard solution used in the determination were prepared by following the method of Zhang et al. 2015. The GBR samples were determined in triplicate.

Results and discussion

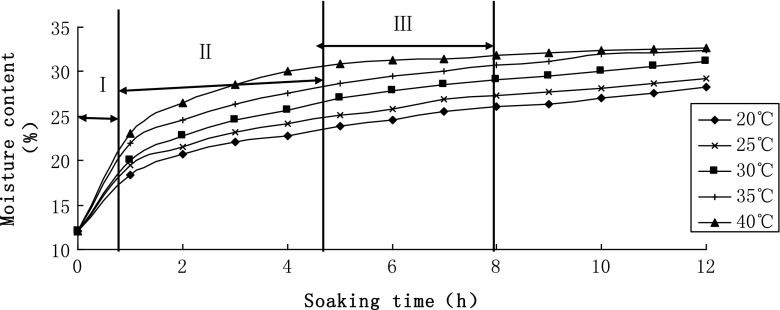

The relationship between moisture content of brown rice and soaking time at different temperatures were shown in Fig. 1. The values of various responses at different experimental combinations for coded variables were presented in Table 2. Analyses of variance (ANOVA) (Tables 3, 4 and 5) were conducted to investigate the statistical significance of independent variables on the germination rate and GABA content of GBR.

Fig. 1.

Effect of temperature and soaking time on mean moisture content of brown rice. I represents stage of rapid water absorption (12–18 % moisture content), II represents stage of slow water absorption (18–25 % moisture content) and III represents stage of flat water absorption (25–29 % moisture content)

Table 3.

Variance analysis of the effects of process variables on germination rate

| Origin of variance | Sum of squares | df | Mean square | F value | P value |

|---|---|---|---|---|---|

| x 1 | 14.95 | 1 | 14.95 | 8.64 | 0.0115* |

| x 2 | 16.79 | 1 | 16.79 | 9.71 | 0.0082** |

| x 3 | 11.6 | 1 | 11.6 | 6.71 | 0.0224* |

| x 1 x 2 | 0.22 | 1 | 0.22 | 0.13 | 0.7264 |

| x 1 x 3 | 2.75 | 1 | 2.75 | 1.59 | 0.2296 |

| x 2 x 3 | 0.22 | 1 | 0.22 | 0.13 | 0.7264 |

| x 1 2 | 48.27 | 1 | 48.27 | 27.91 | 0.0001** |

| x 2 2 | 48.27 | 1 | 48.27 | 27.91 | 0.0001** |

| x 3 2 | 8.72 | 1 | 8.72 | 5.04 | 0.0428* |

| Model | 150.57 | 9 | 16.73 | 9.67 | 0.0002** |

| Residual | 22.49 | 13 | 1.73 | ||

| Lack of fit | 13.88 | 5 | 2.78 | 2.58 | 0.1122 |

| Pure error | 8.6 | 8 | 1.08 | ||

| All terms | 173.06 | 22 |

x 1 represents once moisture adding amount of stage I; x 2 represents once moisture adding amount of stage II; x 3 represents once moisture adding amount of stage III. **extremely significant (p < 0.01), *significant (p < 0.05)

Table 4.

Variance analysis of the effects of process variables on GABA content

| Origin of variance | Sum of squares | df | Mean square | F value | P value |

|---|---|---|---|---|---|

| x 1 | 18.99 | 1 | 18.99 | 26.47 | 0.0002** |

| x 2 | 17.42 | 1 | 17.42 | 24.28 | 0.0003** |

| x 3 | 17.25 | 1 | 17.25 | 24.04 | 0.0003** |

| x 1 x 2 | 0.13 | 1 | 0.13 | 0.17 | 0.6832 |

| x 1 x 3 | 1.13 | 1 | 1.13 | 1.57 | 0.2325 |

| x 2 x 3 | 0.13 | 1 | 0.13 | 0.17 | 0.6832 |

| x 1 2 | 55.45 | 1 | 55.45 | 77.31 | <0.0001** |

| x 2 2 | 65.3 | 1 | 65.3 | 91.04 | <0.0001** |

| x 3 2 | 4.34 | 1 | 4.34 | 6.06 | 0.0286* |

| Model | 178.87 | 9 | 19.87 | 27.71 | <0.0001** |

| Residual | 9.32 | 13 | 0.72 | ||

| Lack of fit | 6.47 | 5 | 1.29 | 3.62 | 0.0522 |

| Pure error | 2.86 | 8 | 0.36 | ||

| All terms | 188.19 | 22 |

Note: x 1 represents once moisture adding amount of stage I; x 2 represents once moisture adding amount of stage II; x 3 represents once moisture adding amount of stage III. **extremely significant (p < 0.01), *significant (p < 0.05)

Table 5.

Optimization criteria for different factors and responses of SMC

| Name | Goal | Lower limit | Upper limit | Lower weight | Upper weight | Importance |

|---|---|---|---|---|---|---|

| x 1 | Is in range | 0.7 %/h | 1.3 %/h | 1 | 1 | 3 |

| x 2 | Is in range | 1.2 %/h | 1.8 %/h | 1 | 1 | 3 |

| x 3 | Is in range | 0.8 %/h | 1.4 %/h | 1 | 1 | 3 |

| y 1 | Maximize | 83.33 % | 100.00 % | 1 | 1 | 5 |

| y 2 | Maximize | 18.77 mg/100 g | 100 mg/100 g | 1 | 1 | 5 |

x 1 represents once moisture adding amount of stage I; x 2 represents once moisture adding amount of stage II; x 3 represents once moisture adding amount of stage III. y 1 represents germination rate of brown rice; y 2 represents GABA content of germinated brown rice

Water absorption characteristic

As Fig. 1 indicated, the moisture content of brown rice at different temperatures increased dramatically at first, then rised slowly and kept stable when reached moisture content of 32–33 %. The rate of water absorption increased with increasing temperature as demonstrated by the slopes of the absorption curves. For instance, the water content after soaking for 8 h reached 24, 29 and 32 % at 20, 30 and 40 °C respectively, because the higher temperature resulted in the faster motion of water molecule. The time decreased to reach saturation state with the increasing temperature. The result agreed well with reports about similar treatments on other cereals, such as steeping of sorghum grains (Dewar et al. 1997), and steeping and germinating of barley (Chung et al. 2009). The water absorption curves can be divided into three stages according to different water absorbing rates, namely stage I 12–18 % moisture content (stage of rapid water absorption), stage II 18–24 % moisture content (stage of slow water absorption) and stage III 24–29 % moisture content (stage of flat water absorption). Bamforth and Barclay (1993) reported that the barley grains soaked at 35 °C promoted mold growth on surface and resulted in an undesired flavor. The temperature below 35 °C for the water absorption process was recommended. However, relatively high temperature is helpful for the germination of brown rice. Based on above-mentioned consideration, 30 °C was selected as the temperature of water adding process.

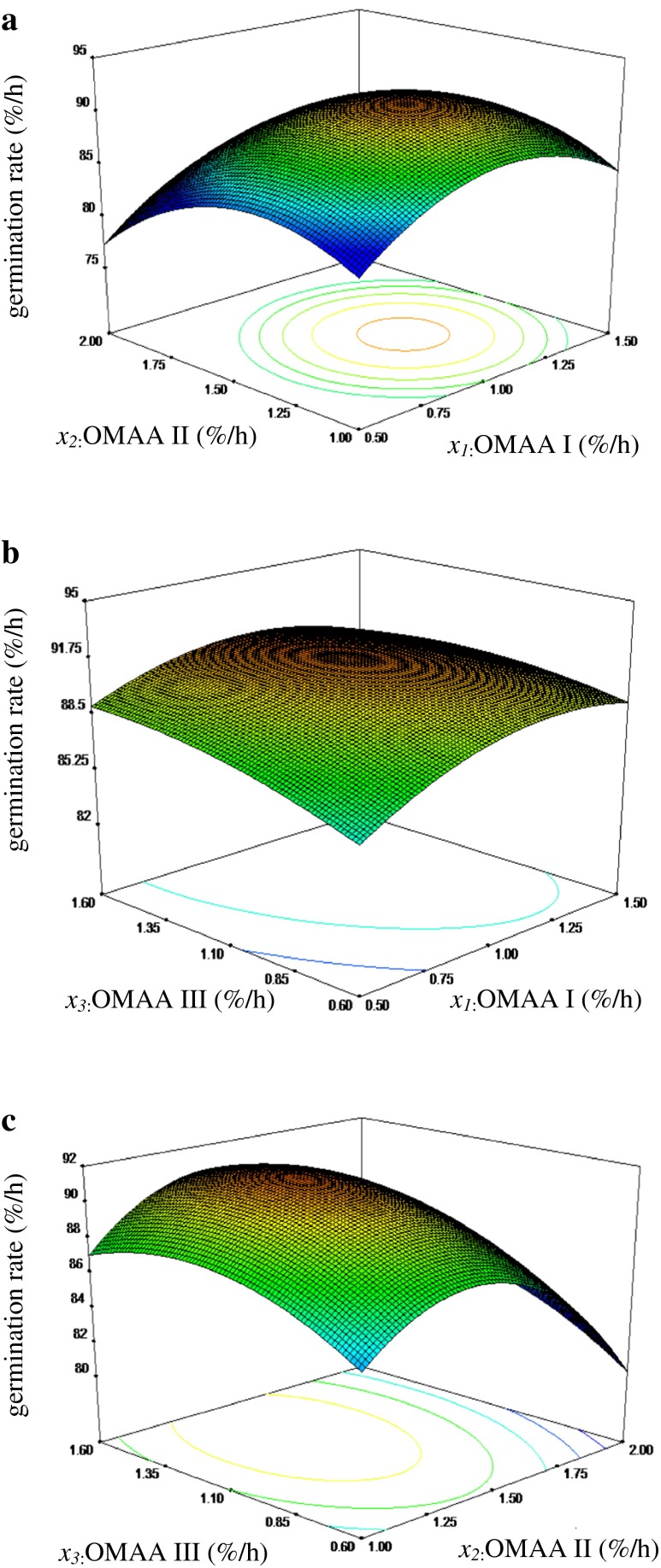

Effect of variables on germination rate

As shown in Table 2, the germination rate values of brown rice varied from 88.33 to 92.33 %. Table 3 indicated that the effect of OMAA II was very significant with a probability of over 99 % (p < 0.01). Effects of OMAA I and OMAA III were significant with a probability of over 95 % (p < 0.05). According to the F value in Table 3, OMAA I is the most important factor, followed by OMAA II, OMAA III is the least important. In Table 3, it was presented a regression equation of the relationship between germination rate and variables had high credibility (R2 of 0.8701, lack of fit of 0.1122). The quadratic regression model for germination rate was given in Eq. (2).

| 2 |

Figure 2a-c described the interaction of any two factors in the three factors. The interaction of OMAA I and OMAA II was shown in Fig. 2a. The germination rate varied significantly with OMAA I and OMAA II, which increased at the initial stage and then decreased with the increase of OMAA I and OMAA II. A similar trend of OMAA III was presented in Fig. 2b. When the once moisture adding amount (OMAA) of three stages was in lower level, water absorption of brown rice was not sufficient, resulting in low activation rate of kinds of enzyme in brown rice. Therefore, the germination rate during observation period was low. When the three factors were in higher level, a lot of cracks were caused by large humidity gradient between surface and inside of brown rice. Thus, the germinating process was restrained. In addition, since water was absorbed extremely slowly in stage III, the excessive water might lead to anoxic conditions which caused microbial proliferation and cell hypoxia (Chung et al. 2009).

Fig. 2.

a Effect of once moisture adding amount of stage I (OMAA I) and once moisture adding amount of stage II (OMAA II) on germination rate (OMAA III at 1.1 %/h) b Effect of once moisture adding amount of stage I (OMAA I) and once moisture adding amount of stage III (OMAA III) on germination rate (OMAA II at 1.5 %/h) c Effect of once moisture adding amount of stage II (OMAA II) and once moisture adding amount of stage III (OMAA III) on germination rate (OMAA I at 1.0 %/h)

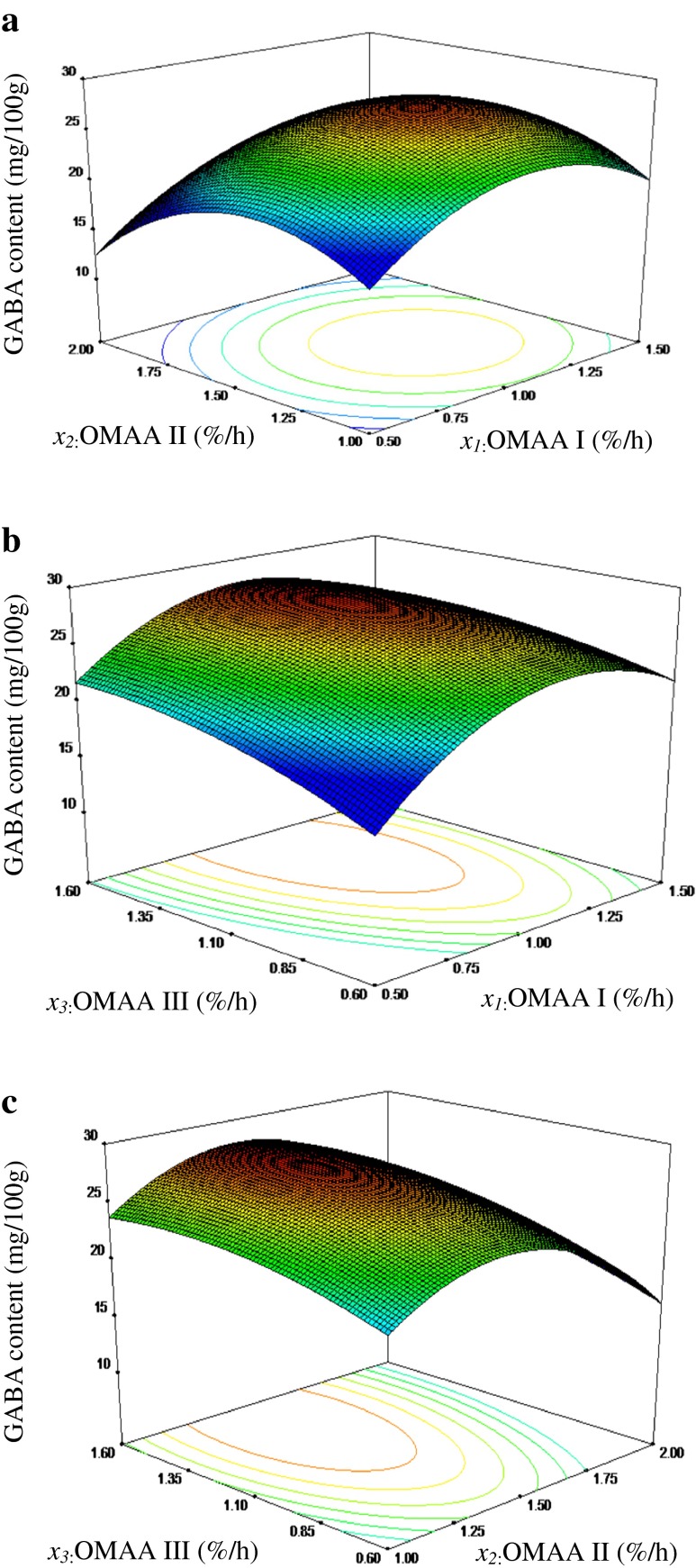

Effect of variables on GABA content

As shown in Table 2, the variations of GABA content varied from 18.77 mg/100 g to 28.21 mg/100 g. Table 4 indicated that the GABA content regression equation of R2 of 0.9505 and lack of fit of 0.0522 was high reliability. Table 4 showed that OMAA I, OMAA II and OMAA III were very significant with a probability of over 99 % (p < 0.01). The behavior of input variables on GABA content of GBR was described by Eq. (3).

| 3 |

Figure 3a-c was the response surface 3D plots which displayed the effect of interaction between any two factors while the other parameter was kept at its center point. As shown in Fig. 3a-c, the GABA content first increased with the increase of OMAA I, OMAA II and OMAA III, and then decreased. It was noticed that GABA generating system was affected by glutamate, GAD, calcium, calmodulin, etc. (Crawford et al. 1994). When parameters of OMAA I, OMAA II and OMAA III were in lower level, the activation of all kinds of enzyme including GAD was slow. Thus, the concentration of GABA was found to be less. When the three factors were in higher level, cracks caused by absorbing water rapidly hindered the accumulation of GABA (Jia et al. 2012). In addition, the excessive water adding amount in OMAA III might lead to anoxic conditions which hindered the germinating process, resulting in decrease of GABA content.

Fig. 3.

a Effect of once moisture adding amount of stage I (OMAA I) and once moisture adding amount of stage II (OMAA II) on GABA content (OMAA III at 1.1 %/h) b Effect of once moisture adding amount of stage I (OMAA I) and once moisture adding amount of stage III (OMAA III) on GABA content (OMAA II at 1.5 %/h) c Effect of once moisture adding amount of stage II (OMAA II) and once moisture adding amount of stage III (OMAA III) on GABA content (OMAA I at 1.0 %/h)

Determination and validation of the experimental model of the optimal parameters

With the target of getting high germination rate and high GABA content, a set of solutions were given by the software to determine the optimum conditions of germination characteristic. The upper ⁄ lower bounds, different weights and importance for factors and responses of SMC treatment were shown in Table 5. The optimal conditions were generated by running the solutions menu of the numerical optimization program in the Design Expert software. The optimum parameter values were as follows: OMAA I of 1.06 %/h, OMAA II of 1.42 %/h and OMAA III of 1.31 %/h. The optimum results were germination rate of 91.51 % and GABA content of 28. 21 mg/100 g.

At the optimal conditions mentioned above, three experimental results of germination rate were 90.33, 91.33 and 91.67 % respectively, whose average value was 91.11 %, close to the estimated value 91.51 % according to the equation. Three experimental results of GABA content were 27.56 mg/100 g, 27.12 mg/100 g and 28.01 mg/100 g, whose average value was 27.56 mg/100 g, 2.3 % lower than prediction value. The above-mentioned results demonstrated that both of two regression equations were fitted well.

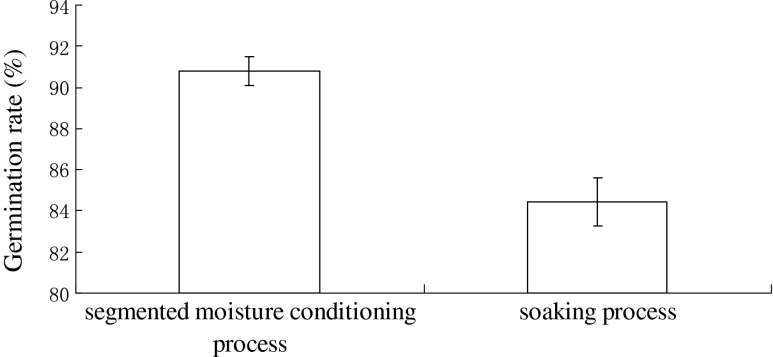

Comparison of germination rate in two methods

Figure 4 showed that the germination rate of brown rice by soaking process was 84.97 %, while that obtained under the optimum water addition rate was 91.33 %. ANOVA results in Table 6 indicated that there was significant difference in germination rate under different germination processes (p < 0.0001). On the one hand, in soaking process, a large amount of water-soluble nutrients was lost in water, resulting in the decrease of nutrients needed for germination to cause low germination rate. On the other hand, cracks were caused by excessive water which may affect the germination of brown rice. The technology of SMC was used to solve these problems. Thus, the germination rate of brown rice obtained under the optimum water addition rate was much higher than that by soaking process.

Fig. 4.

Comparison of germination rate between soaking method (soaking time of 12 h at 30 °C, germination time of 24 h at 25 °C) and segmented moisture conditioning (SMC) method (SMC treatment at 30 °C, germination time of 40 h at 25 °C). Data expressed as mean ± SD of triplicate determinations

Table 6.

Variance analysis of the single factor

| Origin of variance | Sum of squares | df | Mean square | F value | P value |

|---|---|---|---|---|---|

| Different-groups Interior-group Total |

60.293 1.886 62.179 |

1 4 5 |

60.293 0.471 |

127.88 | <0.0001** |

**Extremely significant at P < 0.01

Comparison of GABA content in two methods

As shown in Fig. 5, the GABA content in GBR by soaking process was 12.81 mg/100 g, while that obtained under the optimum water addition rate was 28.14 mg/100 g. ANOVA results in Table 7 indicated that there was significant difference in GABA content under different germination processes (p < 0.0001). GABA is a kind of water soluble substance which accumulated during germination of cereals, and is easy to dissolve in water under soaking process (Hill et al. 1996). In this new method, water can be absorbed completely because the amount of water was not excessive. Moreover, the optimum water adding rate is beneficial to germination of brown rice and the generation of GABA. Therefore, the GABA content of GBR obtained under the optimum water addition rate was much higher than that by soaking method.

Fig. 5.

Comparison of GABA content between soaking method (soaking time of 12 h at 30 °C, germination time of 24 h at 25 °C) and segmented moisture conditioning (SMC) method (SMC treatment at 30 °C, germination time of 40 h at 25 °C). Data expressed as mean ± SD of triplicate determinations

Table 7.

Variance analysis of the single factor

| Origin of variance | Sum of squares | df | Mean square | F value | P value |

|---|---|---|---|---|---|

| Different-groups Interior-group Total |

394.633 0.446 395.078 |

1 4 5 |

394.633 0.111 |

3542.483 | <0.0001** |

**Extremely significant at P < 0.01

Conclusions

The new method of segmented moisture conditioning (SMC) improved the germination rate and concentration of GABA in GBR. Optimum processing parameters, as well as close to optimal moisture adding rate, concluded in this study were as follows: once moisture adding amount of stage I (OMAA I) with 1.06 %/h, once moisture adding amount of stage II (OMAA II) with 1.42 %/h and once moisture adding amount of stage III (OMAA III) with 1.31 %/h. It was revealed that the method of SMC was superior to soaking process for germination of brown rice. The lower water adding amount avoided the loss of water-soluble nutrients including GABA, and reduced the number of cracks caused by soaking in water. GBR with higher quality characteristics can be produced under the optimum parameters. The method of SMC may be applicable to generation of other cereals rich in GABA, such as wheat and barley.

Acknowledgments

The authors express their acknowledgement to National Science and Technology supporting plan (2012BAD34B0205-2) and Heilongjiang Science and Technology plan (GC12B404) for financial support and all of the persons who assisted in this writing.

References

- Arora G, Sehgal VK, Arora M. Optimization of process parameters for milling of enzymatically pretreated Basmati rice. J Food Eng. 2007;82:153–159. doi: 10.1016/j.jfoodeng.2007.01.023. [DOI] [Google Scholar]

- Bamforth CW, Barclay AHP (1993) Malting technology and the uses of malt. In: MacGregor AW, Bhatty RS (eds) Barley: chemistry technology. Am Assoc of Cereal Chem, St Paul, pp 297–354

- Chung HJ, Jang SH, Cho HY, Lim ST. Effects of steeping and anaerobic treatment on GABA (γ-aminobutyric acid) content in germinated waxy hull-less barley. LWT Food Sci Technol. 2009;42(10):1712–1716. doi: 10.1016/j.lwt.2009.04.007. [DOI] [Google Scholar]

- Crawford LA, Brown AW, Breitkreuze KE, Guinel FC. The synthesis of gamma-aminobutyric acid (GABA) in response to treatments reducing cytosolic pH. Plant Physiol. 1994;104:865–871. doi: 10.1104/pp.104.3.865. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Dewar J, Taylor JRN, Berjak P. Determination of improved steeping conditions for sorghum malting. J Cereal Sci. 1997;26(1):129–136. doi: 10.1006/jcrs.1996.0101. [DOI] [Google Scholar]

- Hill VC, Peters JA, Callachan H, Lambert JJ, Gemmell DK, Anderson A, Byford A, Hamilton N, Hill DR, Marshall RJ. The anaesthetic action and modulation of GABAA receptor activity by the novel water-soluble aminosteroid org 20599. Neuropharmacology. 1996;35(9):1209–1222. doi: 10.1016/S0028-3908(96)00069-X. [DOI] [PubMed] [Google Scholar]

- Iimure T, Kihara M, Hirota N, Zhou T, Hayashi K, Ito K. A method for production of γ-amino butyric acid (GABA) using barley bran supplemented with glutamate. Food Res Int. 2009;42(3):319–323. doi: 10.1016/j.foodres.2008.12.010. [DOI] [Google Scholar]

- Jia FG, Wang JT, Lan HP, Han S, Zhang Q, Fu Q. Effect of cycle humidification technology on GABA content in germinated brown rice. Trans CSAE. 2012;28(20):288–292. [Google Scholar]

- Kayahara H. Functional components of pre-germinated brown rice, and their health promotion and disease prevention and improvement. Wkly Agri For. 2001;1791:4–6. [Google Scholar]

- Komatsuzaki N, Tsukahara K, Toyoshima H, Suzuki T, Shimizu N, Kimura T. Effect of soaking and gaseous treatment on GABA content in germinated brown rice. J Food Eng. 2007;78(2):556–560. doi: 10.1016/j.jfoodeng.2005.10.036. [DOI] [Google Scholar]

- Moongngarm A, Saetung N. Comparison of chemical compositions and bioactive compounds of germinated rough rice and brown rice. Food Chem. 2010;122(3):782–788. doi: 10.1016/j.foodchem.2010.03.053. [DOI] [Google Scholar]

- Morita N, Maeda T, Watanabe M, Yano S. Pre-germinated brown rice substituted bread: dough characteristics and bread structure. Int J Food Prop. 2007;10(4):779–789. doi: 10.1080/10942910601183643. [DOI] [Google Scholar]

- Oh SH. Stimulation of gamma-aminobutyric acid synthesis activity in brown rice by a chitosan/glutamic acid germination solution and calcium/calmodulin. J Biochem Mol Biol. 2003;36(3):319–325. doi: 10.5483/BMBRep.2003.36.3.319. [DOI] [PubMed] [Google Scholar]

- Patil SB, Khan MK. Germinated brown rice as a value added rice product: a review. J Food Sci Technol. 2011;48(6):661–667. doi: 10.1007/s13197-011-0232-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Price TV. Seed sprout production for human consumption-a review. Can Inst J Food Sci Technol. 1988;21(1):57–65. doi: 10.1016/S0315-5463(88)70718-X. [DOI] [Google Scholar]

- Saman P, Vázquez JA, Pandiella SS. Controlled germination to enhance the functional properties of rice. Process Biochem. 2008;43(12):1377–1382. doi: 10.1016/j.procbio.2008.08.007. [DOI] [Google Scholar]

- Saikasa T, Horino T, Mori Y. Accumulation of γ-aminobutyric acid (Gaba) in the rice germ during water soaking. Bio Biotechnol Biochem. 1994;58(12):2291–2292. doi: 10.1271/bbb.58.2291. [DOI] [Google Scholar]

- Suzuki K, Maekawa T. Analysis on sprouting control of brown rice. J Soc Agric Struct. 1999;30(1):1–10. [Google Scholar]

- Yang TB, Ooraikul BF. Studies on germination conditions and antioxidant contents of wheat grain. Int J Food Sci Nutr. 2001;52(4):319–330. doi: 10.1080/09637480120057567. [DOI] [PubMed] [Google Scholar]

- Zhang Q, Jia FG, Zuo YJ, Fu Q, Wang JT (2015) Optimization of cellulase conditioning parameters of germinated brown rice on quality characteristics. J Food Sci Technol 52(1):465–471

- Zheng XZ, Liu CH, Zhou H. Optimization of parameters for microwave-assisted foam. Dry Technol. 2011;29(2):230–238. doi: 10.1080/07373937.2010.484112. [DOI] [Google Scholar]