Abstract

A mixture of orange vesicle flour, commercial nixtamalized corn flour and potato starch was extruded using a Brabender Laboratory single screw extruder (2:1 L/D). The resulting pellets were expanded by microwaves. Expansion index, bulk density, penetration force, carotenoid content, and dietary fiber were measured for this third-generation snack and optimum production conditions were estimated. Response surface methodology was applied using a central composite rotatable experimental design to evaluate the effect of moisture content and extrusion temperature. Temperature mainly affected the expansion index, bulk density and penetration force, while carotenoids content was affected by moisture content. Surface overlap was used to identify optimum processing conditions: temperature: 128–130 °C; moisture content: 22–24 %. Insoluble dietary fiber decreased and soluble dietary fiber increased after extrusion.

Keywords: Third generation snacks, Extrusion, Orange by-products, Carotenoids, Dietary fiber

Introduction

Extrusion is a continuous cooking, mixing and shaping process carried out at high temperatures over short times (Kebede et al. 2010). It is a very versatile, low-cost and highly energy efficient technology for snack food production. During extrusion, raw materials experience chemical and structural transformations such as starch gelatinization, protein denaturation, complex formation between amylose, lipids and/or proteins, and degradation of pigments and vitamins (Ding et al. 2006). Extrusion of flours and other products containing starch in their structure (e.g., cereals) is widely used in the food industry to produce snack foods (Hernández-Díaz et al. 2007), a perennial element of the human diet.

The extrusion process allows production of low-fat snacks and induces the formation of resistant starch, which makes no caloric contribution and behaves physiologically like dietary fiber (Larrea et al. 2005). As a result, extrusion is increasingly popular for snack production using raw materials containing protein, starch and dietary fiber in an effort to create snacks with a more adequate nutritional value. Third generation (3G) snacks have become increasingly popular among producers and consumers. Pellets are very stable under storage; they have a high bulk density, and are normally expanded via infrared radiation or microwaves, before distribution and sale (Chen et al. 2002; Larrea et al. 2010).

Orange processing generates by-products such as juice, essential oils, aromatic liquids, pectins and flour. In Mexico, the citrus industry generates large amounts of residues that are normally discarded in landfills and left to decompose. Including these residues in technological processes can add value for industry and reduce contamination generated by residue decomposition; thus reducing their impact on ecosystems. The objective of this study was to evaluate the feasibility of using orange vesicle flour to enrich a third generation snack food produced by extrusion from potato starch and commercial nixtamalized corn flour, and subsequent microwave expansion.

Materials and methods

Raw material preparation

Residual vesicles produced by juicing oranges were dried and milled in a hammer mill (Laboratory Mill 3100 Perten, Ireland). Using a formula determined in preliminary studies, the resulting orange vesicle flour 10 % (OVF) was mixed with potato starch (PS), commercial nixtamalized corn flour 10 % (NCF), and monoglicerides 0.1 % to form a homogenous mixture.

Raw material characterization

Proximate analysis

Proximate analyses were made on the OVF, PS, NCF, and the extrusion mixture. For pellets and expanded products, they were evaluated only for the optimal conditions. Official methods (AOAC 1999) were used to determine protein (979.09), fats (923.05), ash (923.03), moisture (925.09) and crude fiber (962.09) contents. Carbohydrate content was calculated by difference.

Extrusion process

Extrusion was carried out with a laboratory extruder (Brabender 20DN, 8-235-00, Brabender OHG, Duisburg, Germany) fitted with a rectangular matrix (internal dimensions = 20 mm wide × 1.0 mm high × 100 mm long), a screw speed of 1.08 Hz (65 rpm), a 2:1 L:D screw ratio and the feed rate was averaged 33 g/min (dry matter), (0.42 Hz [25 rpm]). Temperatures in the feed zone and out zone were fixed at 60 and 75 °C. The transition zone temperature and moisture conditions were controlled according to the experimental design. The extruded material was cut manually into approximately 1.5 cm long pellets, and dried at room temperature for approximately 24 h until reaching 9–13 % moisture content.

Microwave expansion of pellets

To identify optimum time for maximum expansion, the pellets were expanded in a conventional microwave oven (LG®, R-501CW, 900 W, 2450 Hz) at different heating times (22, 25, 28, 31, and 34 s).

Physicochemical characterization

Expansion index (EI)

Expansion index was calculated as the average frontal area of the expanded product divided by the average frontal area of the extruded product. Extruded product area was calculated by multiplying product length and thickness (Aguilar-Palazuelos et al. 2006).

Bulk density (BD)

Bulk density was calculated by dividing product mass by volume and expressed as kg/m3 (Gujska and Khan 1991). Both, the extruded and expanded products were measured after drying at room temperature for approximately 24 h until reaching 9–13 % moisture content.

Penetration force (PF)

A texturemeter (TA-HDi Texture Analyzer, Vienna Court, Lammas Road, Godalming, Surrey, UK) was used to measure PF for both the extruded and expanded products, according to Aguilar-Palazuelos et al. (2006). Using the compression mode, the force (N) required to penetrate the products was measured. A 2 mm diameter, flat-tipped cylindrical probe was used at a descendent rate and penetration distance of 2 mm · s−1 and 2 mm, respectively. Samples were placed on a 25.5 mm thick platform and 25 samples per treatment were analyzed.

Nutritional characterization

Total carotenoid content

Carotenoid content was analyzed according to 941.15 official methods (AOAC 1999). A spectrophotometer (DU-65, Beckman, Fullertone, USA) was used with a quartz cell, and a 436 nm absorbance level. Results were expressed as μg/100 g product (d. s.).

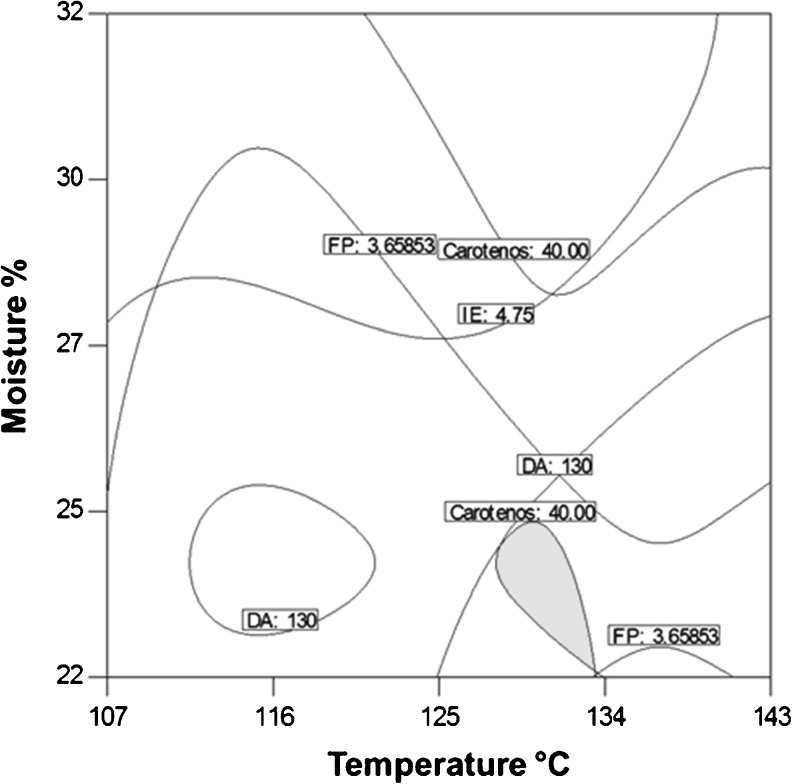

Optimization

A rotatable central composite design for response surface methodology was applied using the Design Expert ® Software (Stat-Ease, Inc., Minneapolis, MN, USA). Four response variables (EI, BD, PF and carotenoid content) were used to evaluate the effect of moisture content and extrusion temperature (Table 1). These responses were selected as EI, BD, and PF are physicochemical properties related to acceptability degree for snacks, and carotenoid content is an indicator of nutritional quality. The main criteria for determining overlap area were to identify the processing conditions that would provide the highest EI and carotenoid content values and lowest BD and PF values. Reference values were taken from commercial 3G products: minimum EI (4.75) and PF (3.65 N), and maximum BD (130 kg/m3). Minimum acceptable carotenoid content was selected as 40 μg carotenoids/100 g of sample for providing a snack with high nutritional quality.

Table 1.

Central, composite, rotatable experimental design for response surface methodology of two factors: temperature (°C) and moisture (%)

| Assay | Factors | |

|---|---|---|

| Temperature (°C) | Moisture (%) | |

| 1 | 107 | 22 |

| 2 | 143 | 22 |

| 3 | 107 | 32 |

| 4 | 143 | 32 |

| 5 | 99.54 | 27 |

| 6 | 150.45 | 27 |

| 7 | 125 | 19.92 |

| 8 | 125 | 34.07 |

| 9 | 125 | 27 |

| 10 | 125 | 27 |

| 11 | 125 | 27 |

| 12 | 125 | 27 |

| 13 | 125 | 27 |

Functional characterization

Soluble dietary fiber

Soluble, insoluble, and total dietary fiber, were evaluated for the optimal conditions. Following the official method (958.29; AOAC 1999), soluble dietary fiber (SDF) content was quantified for both, extruded and expanded products. Briefly, one gram of flour was weighted in triplicate, placed in a 500 mL matrass, and 50 mL phosphate buffer (pH 6) plus 0.1 mL thermostable α-amylase. This mixture was placed in a boiling water bath until reaching an internal temperature of 95–100 °C and agitated every 5 min for 30 min. It was then cooled, pH adjusted to 7.5; 5 mg protease was added and then incubated for 30 min at 60 °C under constant agitation. The mixture was cooled at room temperature, pH was adjusted to 4.0–4.6, 0.1 mL amyloglucosidase was added and the resulting mixture incubated for 30 min at 60 °C under constant agitation. After incubation, the mixture was cooled, filtered, placed in a stove at 40 °C overnight (until reaching constant weight), transferred to a dryer and weighted. The filtrate and water were saved to determine insoluble dietary fiber content.

Insoluble dietary fiber

To quantify insoluble dietary fiber (IDF), 298 mL 95 % ethanol at 60 °C was added to the filtrate remaining from the SDF analysis, mixed and allowed to rest overnight at room temperature (25 °C). This solution was filtered; the residue washed twice with 15 mL 78 % ethanol, twice with 15 mL 95 % ethanol and twice with 15 mL acetone. The residue was dried and weighted.

Total dietary fiber

Using the SDF and IDF results, total dietary fiber (TDF) was calculated as follows:

Where TDF = total dietary fiber; Rs = sample residue; Ps = sample protein; Cs = sample ash; B = blank; and Ws = sample dry weight.

The percentage of IDF was calculated in a manner similar to TDF, as follows:

Results and discussion

Raw material characterization

Orange vesicles are a promising ingredient in expanded snack products mainly due to their dietary fiber content. Chemical composition in the OVF (Table 2) was similar to previous reports (Martínez et al. 2008; Larrea et al. 2010), but its ether extract value (8.10 %) was higher than the 2.63 % (db) reported by Moreno-Álvarez et al. (2005). This difference in ether extract content can be attributed to orange variety and maturity and the fact that Moreno-Álvarez et al. (2005) used whole orange rind flour. The PS used in the present study had a composition similar to reported values (Aguilar-Palazuelos et al. 2006), but ether extract content (0.12 %) was lower than the 0.37 % reported by Alvis et al. (2008). This difference is probably due mostly to the use of different potato varieties and maturity, and also purification method. Chemical composition for the NCF was similar to that reported by Flores-Farías et al. (2002).

Table 2.

Proximate composition of materials in dry basis

| % Moisture | Protein+ | % Ether extract | % Ash | % Total fiber | % Carbohydratesa | |

|---|---|---|---|---|---|---|

| OVF | 8.7 (7.50 × 10−03) | 9.75 (0.14) | 8.10 (3.26 × 10−04) | 4.60 (1.86 × 10−26) | 26.67 (0.2) | 42.18 (–) |

| PS | 14.75 (1.86 × 10−02) | 0.17 (0.04) | 0.12 (5.33 × 10−04) | 0.46 (9.71 × 10−07) | 0.085 (0.05) | 84.585 (–) |

| NCF | 9.75 (1.00 × 10−02) | 9.41 (0.44) | 4.40 (4.16 × 10−05) | 1.46 (1.94 × 10−05) | 1.53 (0.05) | 73.45 (–) |

| Extrusion mixture | 12.91 (3.30 × 10−02) | 5.11 (0.19) | 6.80 (7.30 × 10−04) | 1.00 (1.75 × 10−06) | 6.3 (0.005) | 67.88 (–) |

| Pellet | 13.53 (1.06 × 10−02) | 4.87 (0.04) | 4.47 (2.61 × 10−02) | 0.99 (0.01) | 6.2 (0.01) | 76.13 (–) |

| Expanded | 11.60 (0.01) | 4.55 (0.02) | 3.4 (0.02) | 0.88 (0.01) | 6.09 (0.2) | 74.27 (–) |

+ factor: 6.25, () standard deviation

aCalculated by difference

Microwave pellet expansion

The pellet expansion kinetics showed that the highest expansion index was obtained at 28 s. This heating time produced uniformly expanded pellets and was thus chosen for the extrusion treatments. Pellets expanded for 22 and 25 s did not expand homogeneously, exhibiting unexpanded areas, mostly along the edges; and pellets expanded for 34 s showed burning zones, primarily in the center portion. Expanded pellets for 28 s were characterized as function of expansion index, bulk density, penetration force, and total carotenoid content before optimization.

Physicochemical properties of expanded pellets

Expansion index (EI)

Regression coefficients from the model showed that extrusion temperature and moisture had an effect (p < 0.0001) on the EI (Table 3). The temperature-moisture interaction affected (b12, p < 0.0001) expansion of the pellets. Overall, moisture had the greatest effect, with progressively higher EI values as moisture content decreased across the entire studied range (Fig. 1). Higher temperature also increased EI values. However, at low moisture content, a temperature increase from 107 to 116 °C produced a decrease in EI. This could be due to at low temperatures and moisture contents, the starch matrix shows a high resistance to flow, because temperature is low and there is insufficient plasticizer, causing increased pressure and therefore a high EI at 107 °C. These results are in agreement with those from Camacho-Hernandez et al. (2014) for third generation snacks obtained from blue corn. Maximum expansion was observed at low moisture content (22 %) and high temperature (143 °C). Changes in EI depended on temperature and moisture. This is probably due to the degree of starch degradation, which is closely related to the severity and degree of starch gelatinization during extrusion (Kebede et al. 2010). For getting a high expansion index in third generation snacks, it is necessary to obtain a partial starch gelatinization; letting extruded pellets to trap water, which will later be used during microwave expansion. However, over-processing lowers EI values at high temperatures, probably due to greater starch structure dextrinization caused by temperature and shear force during extrusion (Atienzo-Lazos et al. 2011). Furthermore, moisture in a mixture acts as a lubricant, reducing shear force and decreasing the heat released by friction, thus lowering temperature. As a result, amylose and amylopectin molecules do not deteriorate as much due to temperature and shear force, consequently favoring expansion.

Table 3.

Regression coefficients (coded factors) and level of significance for response variables: EI, PF and BD extruded and expanded by microwave

| Response | Coefficients | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Intercept | Lineal | Squared | Cubic | Fourth-grade | Interaction | |||||

| b0 | b1 | b2 | b1 2 | b2 2 | b1 3 | b2 3 | b1 4 | b2 4 | b12 | |

| EI | 4.77 | a | −1.11 | 1.13 | 0.31 | 0.35 | 0.44 | −0.71 | a | 0.36 |

| (<0.0001) | a | (<0.0001) | (<0.0001) | (<0.0001) | (<0.0001) | (<0.0001) | (<0.0001) | a | (<0.0001) | |

| BD | 158.89 | a | 71.38 | −46.15 | 26.46 | −28.37 | −28.39 | 39.09 | a | a |

| (<0.0001) | a | (<0.0001) | (<0.0001) | (<0.0001) | (<0.0001) | (<0.0001) | (<0.0001) | a | a | |

| PF | 3.54 | 3.65 | 2.82 | −0.78 | 0.44 | −3.68 | −1.25 | 1.92 | a | a |

| (<0.0001) | (<0.0001) | (<0.0001) | (<0.0001) | (<0.0001) | (<0.0001) | (<0.0001) | (<0.0001) | a | a | |

EI expansion index, BD bulk density (kg/m3), PF penetration force (N)

(): p value, b 0: intercept, b 1: temperature coefficient, b 2: moisture coefficient

aTerm not used

Fig. 1.

Effect of raw material extrusion temperature (°C) and moisture content (%) on expansion index (EI) of extruded products expanded by microwave heating

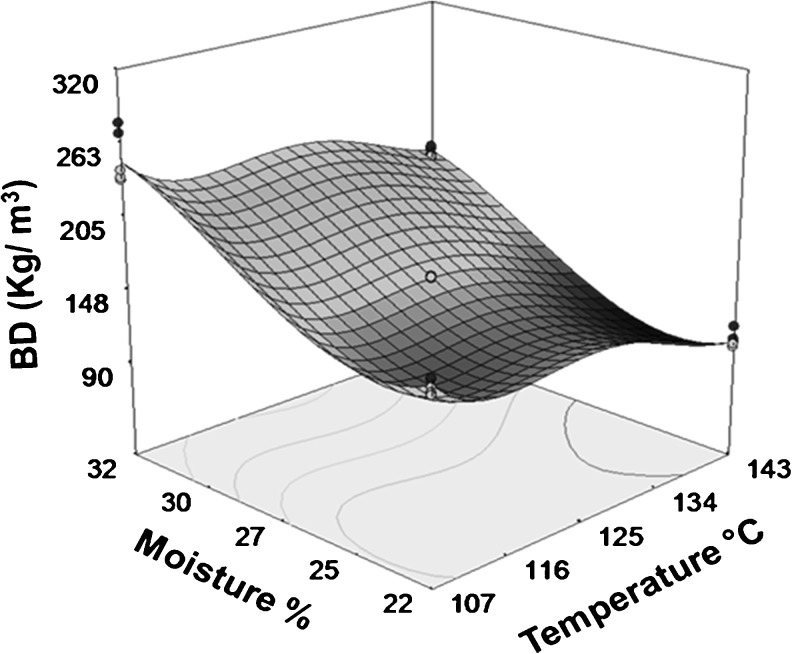

Bulk density (BD)

Expansion volume is the principal quality parameter associated with BD, extruded texture and other physicochemical properties (Meng et al. 2010). Regression coefficients, showed that extrusion temperature and moisture affected BD (p < 0.0001) (Table 3). Moisture content had a greater effect than extrusion temperature, with a clear reduction in BD as moisture content decreased within the studied temperature range (Fig. 2). Third-generation (i.e., pelleted) snack foods require only partial (≈50 %) gelatinization because greater degradation would reduce sugar chain size, leading to loss of product stability upon expansion. In contrast, a less degradation is insufficient to achieve the required opening of starch granules, thus reducing absorption of water that would then function as the means of expansion.

Fig. 2.

Effect of raw material extrusion temperature (°C) and moisture content (%) on bulk density (BD) of extruded products expanded by microwave heating

Generally, the lowest extruded BD values were observed in treatments with the highest EI values since the products with greater EI formed cells with thinner walls. This corresponds to a previous study in which BD in 3G snacks was inversely related to the degree of expansion and consequently to the degree of gelatinization (Meng et al. 2010; Atienzo-Lazos et al. 2011; Delgado-Nieblas et al. 2012). By correlating extrusion variables with degree of gelatinization, these authors found that the best product (i.e., that with the lowest BD) exhibited approximately 50 % gelatinization. This coincides with our results as products with the highest EI had the lowest BD. Starch degradation probably affects this dynamics because the amount of undegraded amylose is greater since water (a starch granule plastifier) does not allow granules to open, causing insufficient water adsorption and preventing optimum expansion. For instance, Rocha-Guzmán et al. (2006) reported decreased BD in 3G expanded products as starch degradation increased in response to higher extrusion temperature, results also similar to those from a more recent study (Delgado-Nieblas et al. 2012).

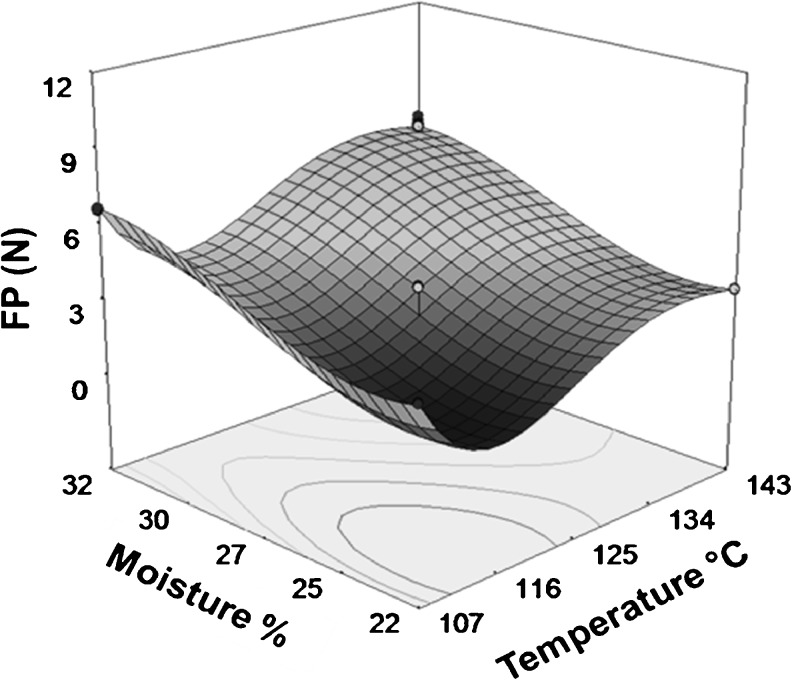

Penetration force (PF)

The maximum PF peak (N) indicates expanded product resistance to initial penetration, expressed as product hardness (Yağci and Göğüş 2009). Regression coefficients from the PF, showed that extrusion temperature and moisture affected PF (p < 0.0001) (Table 3). Penetration force decreased as moisture content decreased across the studied temperature range (Fig. 3). This has been reported previously in studies where texture is linked to extrudate hardness, which increased with moisture content (Atienzo-Lazos et al. 2011; Yu et al. 2012). The high PF values observed in the present study were related to high temperature and moisture content, probably due to degree of gelatinization and starch degradation (Meng et al. 2010), which in turn are highly dependent on temperature and moisture (Yu et al. 2012).

Fig. 3.

Effect of raw material extrusion temperature (°C) and moisture content (%) on penetration force (PF) of extruded products expanded by microwave heating

Partial gelatinization (≈50 %) is required in 3G products to produce high expansion and low texture values. This degree of gelatinization causes only a small opening in the starch granules, enough to allow water to enter for later expansion, but which maintains the granules’ capacity for reassociation during cooling and thus helping to trap water. High moisture content reduces starch granule opening, allowing less water into the amylaceous matrix, leading to less expansion and greater hardness in the final expanded product (Moraru and Kokini 2003). In addition, reduced starch conversion and air bubble compression result in a product with less crunchiness than observed in the present study. It is probable, therefore, that increases in temperature reduced extrudate viscosity, favoring growth of air bubbles, lowering density in the extrudates and expanded products, and producing greater crunchiness in the final product (Ferreira et al. 2011).

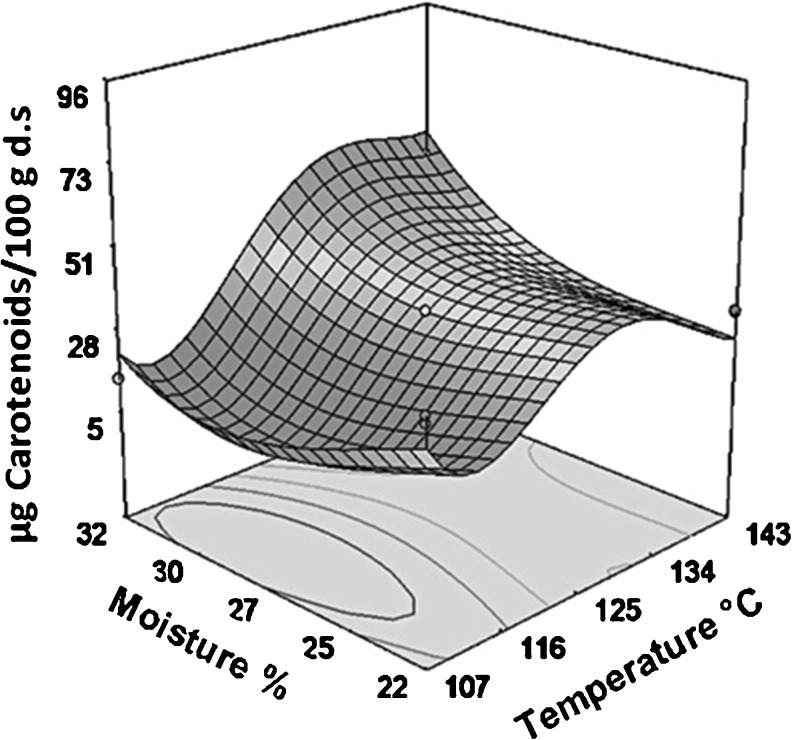

Nutritional characteristics

Total carotenoid content

As with the previous variables, temperature and moisture content affected total carotenoid content in the final 3G product (Table 3). Average carotenoid content in the mixture was 110 μg carotenoids/100 g of sample before extrusion, and then varied from 14 to 95 μg carotenoids/100 g of sample after extrusion and expansion. As temperature increased to approximately 134 °C, carotenoid content increased across the range of studied moisture content (Fig. 4). At higher temperatures, the total carotenoid content increased as moisture content increased, but the inverse occurred as moisture content increased at low temperatures. This may have resulted from the protective effect of water on the material during feeding into the extruder; a previously reported effect (Delgado-Nieblas et al. 2012).

Fig. 4.

Effect of raw material extrusion temperature (°C) and moisture content (%) on total carotenoids of extruded products expanded by microwave heating

Carotenoids are known to be unstable in response to oxidation, light, moisture, heat, minerals, acids and fats (Charlton and Ewing 2007). Because they are thermolabile, the decreases observed in carotenoid content in the extrudates may be explained as a function of residence time in the extruder barrel and the slower screw speed caused by low moisture content. As moisture content decreases, shear force and residence time increase, degrading carotenoid content (Lee et al. 1978). Indeed, thermal degradation is a significant contributor to carotenoid reduction during extrusion, with an approximately 40 % reduction in carotenoid content at temperatures ranging from 93.5 to 140 °C (Delgado-Nieblas et al. 2012).

Optimization

References values for the optimization analysis were taken from commercial 3G products: 4.75 for the EI (minimum value of 3G commercial product considered), 3.65 N for PF and 130 kg/m3 BD (maximum value of commercial product considered). The total carotenoid content was 40 μg carotenoids/100 g of sample; this was considered as the minimum value to obtain.

In our results, the highest EI values (>4.75) were produced at high temperatures and low moisture contents, whereas at temperatures <130 °C IE values dropped below 4.0. The overlap area shown in the analysis covers from 128 to 132 °C and 22 to 24 % moisture content (Fig. 5). The response values predicted by the model fell within these intervals: 4.48 to 5.06 for EI; 144 to 174 kg/m3 for BD; 22.8 to 44.5 μg carotenoids / 100 g of sample for total carotenoid content; and 3.03 to 4.05 N for PF.

Fig. 5.

Overlap area of responses as extrusion temperature (°C) and raw material moisture content (%) on the extrusion process of third-generation snacks expanded by microwave

The model was tested experimentally by producing an extrudate using the predicted optimum conditions, that is, the central point of the optimum conditions area. To this end, the premix (10 % OVF, 10 % NCF, 79.9 % PS, 0.1 % monoglycerides) was extruded at 130 °C and 23 % moisture content, and the resulting extrudate called best extrusion conditions (BEC). Average values (standard deviation) for the resulting extrudates were 5.44 (0.15) for the EI; 124.12 (0.002) for BD; 3.5 (0.03) for PF; and 43.3 μg carotenoids/100 g sample (0.30). Compared to predicted values, the experimental ones included EI and BD slightly better, and there was no difference (p = 0.05) between experimental and predicted PF. Therefore, the tested model exhibited an adequate fitness, predicting satisfactorily optimum temperature and moisture content for extrusion of a 3G snack food.

In addition, soluble and insoluble dietary fiber content was measured as an indicator of its functional properties.

Functional characteristics

Soluble and insoluble dietary fiber

The OVF had the highest TDF content (26.7 %) of the studied samples (Table 4). This content is comparable to previous reports for orange pulp flour (probably including albedo and seeds) (Grigelmo and Martin-Belloso 1998; Larrea et al. 2005). The main fraction in the OVF was IDF, which accounted for 73 % of TDF. In orange rind flour, IDF is reported to represent from 95 to 98 %, probably due to high cellulose content in rind cell walls since this fraction contains mostly cellulose, hemicellulose and lignin (De Moraes-Crizel et al. 2013). In the extrusion mixture, the main fiber-contributing component was the OVF. Extrusion increased SDF content, perhaps because the temperature, moisture content and screw speed degraded the starch in the mix, producing linear chains (Pérez-Navarrete et al. 2007). Increased SDF can also be attributed to partial solubilization of fiber components. For example, extrusion conditions (32.3–40.5 % moisture content) have been reported to reduce IDF content by 39.1 % and raise SDF by 80 %, probably due to production of small fragments from solubilization of pectic substances (Larrea et al. 2005). Furthermore, The NCF contained 1.5 % TDF, which may include fractions that have been retrograded by the nixtamalization, are resistant to enzyme attack and therefore behave physiologically like dietary fiber (Pérez-Navarrete et al. 2007). In this raw material, IDF consists mainly of pericarp, which contains cellulose, hemicellulose and lignin. Unlike the OVF and NCF, the PS did not contribute large quantities of TFD (Table 2), probably due to the chemical structure of its starch (Leivas et al. 2013).

Table 4.

Dietary fiber content in the raw materials used in the extrusion mixture as well as the extruded product (pellet) and expanded by microwaves

| FDT (%) | FDI (%) | FDS (%) | |

|---|---|---|---|

| HSN | 26.67 (0.2) | 19.47 (0.05) | 7.20 (0.03) |

| HMNC | 1.53 (0.05) | 1.42 (0.02) | 0.11 (0.03) |

| AP | 0.085 (0.05) | 0.065 (0.01) | 0.02 (0.03) |

| Extrusion mixture | 6.3 (0.005) | 3.8 (0.03) | 2.5 (0.01) |

| Pellet | 6.2 (0.01) | 2.01 (0.02) | 4.19 (0.01) |

| Expanded | 6.09 (0.01) | 1.99 (0.03) | 4.1 (0.01) |

FDT total dietary fiber, FDI insoluble dietary fiber, FDS soluble dietary fiber

(): standard deviation

Approximately 2 % SDF is required for colonic fermentation. Eating SDF helps to reduce blood cholesterol and glucose levels, increases bile acid elimination and promotes bacterial growth and development (Larrea et al. 2010). In functional terms, SDF determines solubility, swelling capacity, water holding capacity and fiber viscosity, all of which affect how it can be added to foods. Based on the present results, the studied OVF is a potential dietary fiber source in the formulation of new food products such as 3G snacks.

Conclusions

Temperature significantly affected EI, BD and PF values, while moisture content affected carotenoid content. Optimum extrusion conditions for a third generation extruded snack food were determined with the optimum area: temperature 128–132 °C and moisture content 22 to 24 %. Products produced under these conditions had EI and BD values similar to commercial products but with the potential nutritional contribution provided by the OVF and NCF, and the functional benefit provided by soluble and insoluble dietary fiber. Optimum extrusion conditions decreased insoluble dietary fiber by 47 % and increased soluble dietary fiber by 2.5 to 4.2 %, due to partial solubilization of fiber components.

References

- Aguilar-Palazuelos E, Zazueta-Morales JJ, Martínez-Bustos F. Preparation of high-quality protein-based extruded pellets expanded by microwave oven. Cereal Chem. 2006;83:363–369. doi: 10.1094/CC-83-0363. [DOI] [Google Scholar]

- Alvis A, Vélez CA, Villada HS, Rada-Mendoza M. Análisis físico-químico y morfológico de almidones de ñame, yuca y papa y determinación de la viscosidad de las pastas. Inf Tecnol. 2008;19:9–28. [Google Scholar]

- AOAC . Official methods of analysis. 15. Arlington: Association of Official Analytical Chemists Inc; 1999. [Google Scholar]

- Atienzo-Lazos M, Delgado E, Ochoa-Martínez A, Aguilar-Palazuelos E, Martínez BF, Ramirez-Wong B, Gallegos-Infante A, Medrano-Roldan H, Solis-Soto A. Effect of moisture and temperature on the functional properties of composite flour extrudates from beans (Phaseolus vulgaris) and nixtamalized corn (Zea mays) J Anim Prod Adv. 2011;1:9–20. [Google Scholar]

- Camacho-Hernandez IL, Zazueta-Morales JJ, Gallegos-Infante JA, Aguilar-Palazuelos E, Rocha-Guzmán NE, Navarro-Cortez RO, Jacobo-Valenzuela N, Gómez-Aldapa CA. Effect of extrusion conditions on physicochemical characteristics and anthocyanin content of blue corn third-generation snacks. CyTA J Food. 2014;12:320–330. doi: 10.1080/19476337.2013.861517. [DOI] [Google Scholar]

- Charlton SJ, Ewing WN. The vitamin directory. England: Context Products, Ltd; 2007. [Google Scholar]

- Chen KHJ, Dogan E, Rizvi SSH. Supercritical fluid extrusion of masa-based snack chips. Cereal Foods World. 2002;47:44–51. [Google Scholar]

- De Moraes-Crizel T, Jablonski A, De Oliveira-Rios A, Rech R, Flôres SH. Dietary fiber from orange byproducts as a potential fat replacer. LWT-Food Sci Technol. 2013;53:9–14. doi: 10.1016/j.lwt.2013.02.002. [DOI] [Google Scholar]

- Delgado-Nieblas C, Aguilar-Palazuelos E, Gallegos-Infante A, Rocha-Guzmán N, Zazueta-Morales J, Caro-Corrales J. Characterization and optimization of extrusion cooking for the manufacture of third-generation snacks with winter squash (Cucurbita moschata D.) Flour Cereal Chem. 2012;89:65–72. doi: 10.1094/CCHEM-02-11-0016. [DOI] [Google Scholar]

- Ding QB, Ainsworth P, Plunkett A, Tucker G, Marson H. The effect of extrusion conditions on the functional and physical properties of wheat-based expanded snacks. J Food Eng. 2006;73:142–148. doi: 10.1016/j.jfoodeng.2005.01.013. [DOI] [Google Scholar]

- Ferreira RE, Chag YK, Steel CJ. Influence of wheat bran addition and of thermoplastic extrusion process parameters on physical properties of corn-based expanded extruded snacks. Alim Nutr Araraquara. 2011;22:507–520. [Google Scholar]

- Flores-Farías R, Martínez-Bustos F, Salinas-Moreno Y, Ríos E. Caracterización de harinas comerciales de maíz nixtamalizado. Rev Agrociencia. 2002;36:557–567. [Google Scholar]

- Grigelmo NM, Martin-Belloso O. Characterization of dietary fiber from orange juice extraction. Food Res Int. 1998;31:355–361. doi: 10.1016/S0963-9969(98)00087-8. [DOI] [Google Scholar]

- Gujska E, Khan K. Effect of temperature on properties of extrudates from high starch fractions of navy, pinto bean meal (Phaseolus vulgaris L) J Food Sci. 1991;55:466–469. doi: 10.1111/j.1365-2621.1990.tb06788.x. [DOI] [Google Scholar]

- Hernández-Díaz JR, Quintero-Ramos A, Barnard J, Balandran-Quintana RR. Functional properties of extrudates prepared with blends of wheat flour/pinto bean meal with added wheat bran. Food Sci Technol Int. 2007;13:301–308. doi: 10.1177/1082013207082463. [DOI] [Google Scholar]

- Kebede L, Worku S, Bultosa G, Yetneberek S. Effect of extrusion operating conditions on the physical and sensory properties of tef (Eragrostis tef [Zucc.] Trotter) flour extrudates. Ethiop J Appl Sci Technol. 2010;1:27–38. [Google Scholar]

- Larrea CMA, Martínez-Bustos F, Yoon KC. The effect of extruded orange pulp on enzymatic hydrolysis of starch and glucose retardation index. Food Bioprocess Technol. 2010;3:684–692. doi: 10.1007/s11947-008-0166-7. [DOI] [Google Scholar]

- Larrea MA, Chang YK, Martinez-Bustos F. Effect of some operational extrusion parameters on the constituents of orange pulp. Food Chem. 2005;89:301–308. doi: 10.1016/j.foodchem.2004.02.037. [DOI] [Google Scholar]

- Lee TC, Chen T, Alid G, Chichester CO. Stability of vitamin A and pro-vitamin A (carotenoids) in extrusion cooking processing. AICHE Symp Ser. 1978;74:172–192. [Google Scholar]

- Leivas CL, Da Costa FJOG, De Almeida RR, De Freitas RJS, Stertz SC, Schnitzler E. Structural, physico-chemical, thermal and pasting properties of potato (Solanum tuberosum L.) flour. J Therm Anal Calorim. 2013;111:2211–2216. doi: 10.1007/s10973-012-2395-2. [DOI] [Google Scholar]

- Martínez OL, Román MO, Gutiérrez EL, Medina GB, Cadavid M, Flórez OA. Desarrollo y evaluación de un postre lácteo con fibra de naranja. Rev Fac Quím Farmac. 2008;15:219–225. [Google Scholar]

- Meng X, Threinen D, Hansen M, Driedger D. Effects of extrusion conditions on system parameters and physical properties of a chickpea flour-based snack. Food Res Int. 2010;43:650–658. doi: 10.1016/j.foodres.2009.07.016. [DOI] [Google Scholar]

- Moraru CI, Kokini JL. Nucleation and expansion during extrusion and microwave heating of cereal foods. Compr Rev Food Sci Food Saf. 2003;2:120–138. doi: 10.1111/j.1541-4337.2003.tb00020.x. [DOI] [PubMed] [Google Scholar]

- Moreno-Álvarez MJ, Belén DR, García D, Mendoza L. Evaluación del contenido de carotenoides totales en cáscaras de algunas variedades de naranjas venezolanas. Rev Fac Agro. 2005;23:301–309. [Google Scholar]

- Pérez-Navarrete C, Betancur-Ancona D, Casotto M, Carmona A, Tovar J. Efecto de la extrusión sobre la biodisponibilidad de proteína y almidón en mezclas de harina de maíz y frijol lima. Arch Latinoam Nutr. 2007;57:145–155. [PubMed] [Google Scholar]

- Rocha-Guzmán NE, Gallegos-Infante JA, González-Laredo RF, Castillo-Antonio PA, Delgado-Lincoln E, Ibarra-Peréz F. Functional properties of three common bean (Phaseolus vulgaris) cultivars stored under accelerated conditions followed by extrusion. LWU Technol. 2006;39:6–10. [Google Scholar]

- Yağci S, Göğüş F. Development of extruded snack from food by‐products: a response surface analysis. J Food Process Eng. 2009;32:565–586. doi: 10.1111/j.1745-4530.2007.00232.x. [DOI] [Google Scholar]

- Yu L, Hosahalli S, Ramaswamy BJ. Twin-screw extrusion of corn flour and soy protein isolate (SPI) blends: a response surface analysis. Food Bioprocess Technol. 2012;5:485–497. doi: 10.1007/s11947-009-0294-8. [DOI] [Google Scholar]