Abstract

The effect of everlasting pea in combination with wheat on physical properties and microstructure of extrudates were studied. The share of everlasting pea (Lathyrus sativus) was variable, at 35, 50 and 65 %, respectively. The everlasting pea-wheat mixtures were moistened to the required level (18, 21, and 24 %), homogenized, conditioned and extruded in twin-screw extruder with counter-rotating conical screws. All of the obtained extrudates were characterised by a slow degree of radial expansion and high specific density. The Pearson correlation analysis indicated a statistically significant linear Pearson correlation (p < 0.05) between chemical compositions of the blends and physical properties of the extrudates. The expansion ratio increased as the concentration of the fibers and proteins increased, while specific density and hardness decreased. Inverse relationship was observed for crude fat. The microstructure of the extrudates was determined by both the moisture of the blend and the process temperature. The differences observed in the size, number of air cells and in the cell wall shapes and thickness indicate possibilities of the modification of physical properties of everlasting pea-wheat extrudates. The extrudates produced from everlasting pea-wheat blends (50:50) at higher barrel temperature (110/140/180/170/130 °C) were characterised by more numerous air cells of smaller diameters. Increasing moisture content of extruded blends results in extrudates with a higher porosity. No significant effect was shown in the chemical compositions on the level of metal contamination in the extrudates. The application of a counter-rotating twin-screw extrusion-cooker in the study permitted the production of compact, hard everlasting pea-wheat extrudates for use in vegetarian lunch dishes.

Keywords: Extrusion, Everlasting pea, Wheat, Physical properties, Microstructure, Metal contamination

Introduction

Extrusion-cooking, due to unique features of the final products, is a technology that is commonly used in food processing, especially in the production of “ready to eat” food products (Repo-Carrasco-Valencia et al. 2009; Thymi et al. 2005). Despite increased use of extrusion processing, extrusion is still a complicated process that has yet to be explored. Specific properties of extrudates e.g. porous structure, texture, expansion, specific density, can be created through the composition of the blend material (moisture, content of starch, protein, lipids and dietary fibre) and parameters of the extrusion process, such as extruder type, profile of barrel temperature and pressure distribution, configuration and speed of the extruder screws, size and shape of the die aperture (Ding et al. 2005; Kaur et al. 2013; Liu et al. 2011; Sobota and Rzedzicki 2009; Wang and Ryu 2013; Zarzycki et al. 2010).

Except for the taste enjoyment, today’s consumer wishes healthy, natural ingredients with higher nutritional and physiological values (Yanniotis et al. 2007). Blends subjected to extrusion must be characterised by a high nutritive value, e.g. increased contents of proteins and dietary fibre. Everlasting pea (Lathyrus sativus) is an interesting plant which may have a broad application in food production. The seed of everlasting pea is characterized by high content of protein and dietary fibre, oligosaccharides and biologically active compounds, and by attractive taste values (Kasprzak and Rzedzicki 2007; Lisiewska et al. 2003; Monsoor and Yusuf 2002; Rybiński et al. 2006).

Extrusion technology enables obtaining a variety of products - from fragile light snacks, suitable for direct consumption, to compact, hard extrudates to be used for the production of vegetarian lunch meals (Kasprzak et al. 2013). The research demonstrated a highly significant role of microstructural analyses in modelling new products and elaborating technologies of their production (Rzedzicki and Błaszczak 2005; Yanniotis et al. 2007; Zarzycki et al. 2010). According to Rzedzicki and Błaszczak (2005) microstructure affects the major physical properties of extrudates.

Considering the advantages following the application of the technology, one cannot neglect the fact that it is a technology of highly intensive processing of materials. The extrusion process can result in an increase of the total iron content of the materials. This phenomenon has already been described by some researchers and must be taken into account (Alonso et al. 2001; Cardoso-Santiago and Arêas 2001; Zarzycki and Rzedzicki 2007). Intensive action of shear stresses in the extruded material may lead to increased wear of the structural elements of the extruder (screw, barrel, head, dies), thus to an increase in the content of metals in the final product (Camire 2001). The level of metals transition from the structural elements to the final product depend both on the type of material processed and on the technological parameters (Alonso et al. 2001; Cardoso-Santiago and Arêas 2001; Zarzycki and Rzedzicki 2007). According to some research, materials with high dietary fiber content appear to produce the greatest screw wear and may lead to increasing the level of metal contamination (Camire 1998, 2001).

The objective of this work was to investigate the effect of everlasting pea wholemeal in combination with wheat wholemeal on physical properties and mictrosturcture of extrudates, under specific moisture content and barrel temperature conditions. The influence of process parameters on the level of metal contamination in extrudates was also investigated. The literature does not provide any data on the simultaneous application of a mixture of wholemeal everlasting pea -wheat in the extrusion technology, therefore, this issue has been undertaken in the present study.

Materials and methods

Raw materials

The raw materials used in the study included wholemeal of everlasting pea (Lathyrus sativus), cv. Derek (Agropol, Motycz, Poland) and wholemeal of high-gluten wheat (wet gluten 36.5 %), cv. Henika (Agropol, Motycz, Poland). The chemical composition of raw materials used in the study is given in Table 1. Seeds of everlasting pea and wheat were ground by means of a universal impact mill type H-111/3 (Agromet, Jawor, Poland) until obtaining the required level of mean diameter (respectively 0.62 and 0.96 mm) and share rate of fractions <0.5 mm (not less than 20 %). The degree of fragmentation of the material was estimated by means of sieve analysis (Sieve analyzer, ZBPP, Bydgoszcz, Poland).

Table 1.

Chemical composition of the everlasting pea wholemeal and wheat wholemeal

| Ash | Crude protein | Crude fat | Soluble dietary fibre | Insoluble dietary fibre | Total dietary fibre | Fe | |

|---|---|---|---|---|---|---|---|

| (% dm) | (mg/kg dm) | ||||||

| Everlasting pea wholemeal | 3.41 ± 0.15 | 28.0 ± 1.4 | 1.14 ± 0.04 | 4.34 ± 0.19 | 28.96 ± 0.09 | 33.30 ± 0.55 | 66.3 ± 3.1 |

| Wheat wholemeal | 3.74 ± 0.17 | 16.2 ± 1.2 | 3.25 ± 0.09 | 3.69 ± 0.13 | 14.74 ± 0.11 | 18.43 ± 0.67 | 48.8 ± 2.7 |

Values are averages of triplicate determination with standard deviations

dm dry matter

The wholemeal of everlasting pea and wheat were used to prepare blends in accordance with the adopted model of experiment (Table 2). The ratio of everlasting pea was variable, at 35, 50 and 65 %. The blends were moistened to the required moisture content (18, 21, and 24 %), mixed in a drum mixer, and conditioned for 12 h at room temperature to ensure a proper water diffusion within the material. Blends prepared as above were subjected to extrusion. The process parameters and the shares of the components of the blend were selected on the basis of earlier research (Kasprzak and Rzedzicki 2007).

Table 2.

Model of experiments

| Sample | Ratio of composition (%) | Extrusion process parameter | ||

|---|---|---|---|---|

| Everlasting pea wholemeal | Wheat wholemeal | Material blend moisture (%) | Barrel temperature distribution profile (°C) | |

| 1 | 35 | 65 | 18 | 90/120/150/140/130 |

| 2 | 50 | 50 | ||

| 3 | 65 | 35 | ||

| 4 | 35 | 65 | 21 | |

| 5 | 50 | 50 | ||

| 6 | 65 | 35 | ||

| 7 | 35 | 65 | 24 | |

| 8 | 50 | 50 | ||

| 9 | 65 | 35 | ||

| 10 | 35 | 65 | 18 | 110/140/180/170/130 |

| 11 | 50 | 50 | ||

| 12 | 65 | 35 | ||

| 13 | 35 | 65 | 21 | |

| 14 | 50 | 50 | ||

| 15 | 65 | 35 | ||

| 16 | 35 | 65 | 24 | |

| 17 | 50 | 50 | ||

| 18 | 65 | 35 | ||

Chemical analysis

Moisture, ash, protein and crude fat analysis of raw materials were carried out using standard procedures of AOAC (1990). The fractional composition of dietary fibre was determined with the enzymatic method :AOAC, Method 991.43; AACC, Method 32-07; AACC, Method 32-21; AOAC, Method 985.29; AACC, Method 32-05 (2000), using Megazyme enzymes and methodological procedures. The determinations included total dietary fibre (TDF), insoluble dietary fibre (IDF), and soluble dietary fibre (SDF). All analyses are expressed as the mean (±SD) of triplicate analysis.

Extrusion cooking

The extrusion process was conducted using a 2S-9/5 twin-screw extruder with counter-rotating conical screws (Metalchem Gliwice, Poland, L/D ratio of 12:1). Two profiles of barrel temperature distribution were applied: 90/120/150/140/130 °C and 110/140/180/170/130 °C. The extruder used in the experiments was equipped with a die of 3 × 6 mm in diameter. Constant screw speed of 75 rpm was applied throughout. The process parameters were selected on the basis of earlier research (Kasprzak and Rzedzicki 2007).

Degree of radial expansion

The degree of radial expansion of the extrudate (RE) was determined as described by Kasprzak et al. (2013). The RE is the ratio of the extrudate cross-sectional area (cm2) to the cross sectional area of the die aperture (cm2). Extrudates diameters were measured using a Vernier caliper.

Specific density

The specific density was determined as described by Kasprzak et al. (2013). The specific density of the extrudates was calculated as the ratio of the mass of the extrudate to its volume (the volume included also the internal pores of the extrudate). In volume calculations, the results of cross sectional area of the extrudate were adopted from expansion measurement. The weight of extrudate was determined by weighing measured lengths (10 cm). The specific density was then calculated using the following formula, assuming a cylindrical shape of extrudate.

where ρs is specific density (kg m−3), m is the mass of a length L of cooled extrudate (kg), d is diameter of the extrudate (m), and L is the length of the extrudate (m).

Notch toughness

Notch toughness was determined with the Charpy impact test, which determines the amount of energy absorbed by the material during fracture. The absorbed energy was divided by cross sectional area of the extrudate (Antila et al. 1983).

Scanning electron microscopy

The microstructure of extrudate was determined as described by Kasprzak et al. (2013). Selected fragments were cut from the dehydrated extrudates with a blade. The approximate thickness of each sample was 1–2 mm. Samples were attached with silver paste to specimen circles. Specimens prepared in this manner were sprayed with carbon and gold in a vacuum sprayer, type JEOL JEE 4X (Japan). Microscopy analysis was examined with a scanning electron microscope (JEOL, type JSM 5200, JEOL Ltd., Japan) using accelerating voltage of 10 kV. Samples were viewed under a scanning electron microscope at different magnification (35× and 100×), and representative photomicrographs of each magnification have been taken.

Iron content

The content of iron in samples was determined with the method of atom absorption spectrophotometry (AAS) using the Unicam 939 apparatus, in accordance with the AOAC Method 975.03. The determinations were made at the Central Analytical Laboratory of the University of Life Sciences in Lublin. Inorganic elements, including iron, were dissolved in 10 mL HCl after dry ashing the grounded extrudate sample (4 g). The solution was then transfer quantitatively to 50 mL volumetric flask. The iron-containing solution was then atomized in an air-acetylene flame, and the absorption was measured at a specific wavelength (248 nm) to determine the iron concentration. Necessary dilutions (dilutions factor was equal 100) were made with 10 % HCl to obtain solutions within range of instrument.

Statistical analysis

For the results obtained, the mean values, standard deviations and coefficients of variation were calculated. In the cases when the values of the coefficient of variation exceeded the limits of the error of estimation for a given method, the results were rejected and the analyses were repeated. The results were subjected to a statistical analysis using the statistical program SAS ver. 9.1. One-factor analysis of variance was performed based on the Duncan test, adopting a significance level p ≤ 0.05. The Pearson coefficients of linear correlation between the physical properties of extrudates and chemical compositions of blends were also determined.

Results and discussion

Extrusion process and physical properties of extrudates

The process of extrusion was conducted for blends composed of wholemeal everlasting pea (35–65 %) and wholemeal wheat (35–65 %) in conformance with the model of the experiment (Table 2). The results of previous research show that such a composition of mixtures allows obtaining extrudates with high content of protein and dietary fibre (Kasprzak and Rzedzicki 2007). The process parameters i.e. barrel temperature and moisture content, were selected on the basis of earlier research within ranges that guaranteed stable operation of the extruder and enable to obtain a compact, hard extrudates to be used for the production of lunch meals (Kasprzak and Rzedzicki 2007).

All of the extrudates were characterised by a relatively slow degree of radial expansion (2.61–4.91) and high specific density (393–861 kg m−3) (Table 3). Independent on blend moisture and the barrel temperature, an increase in the value of radial expansion was observed with increasing wholemeal everlasting pea content. The analysis of chemical composition of the raw materials (Table 1) shows that the addition of the everlasting pea component caused an increase of dietary fibre content in blends. The Pearson correlation analysis indicated a statistically significant linear correlations between fibre content and radial expansion (r = 0.79, p < 0.05), also a statistically significant correlations exist between fibre content and specific density and notch toughness (r = −0.76, r = −0.71, p < 0.05, respectively). Moreover, radial expansion showed a high negative correlation with specific density (r = −0.95, p < 0.05) (Table 4). In the studies on extrudates with a content of other raw materials, inverse effects of the fibre content on the expansion were observed. Many authors report that the introduction of a fibre rich material contributes to the appearance of a more compact structure of extrudates, which causes a decrease of expansion (Mendonca et al. 2000; Wang and Ryu 2013; Yanniotis et al. 2007). Expansion of extrudate is related to the size, number and distribution of the air cells. Increasing fiber content reduce the cell size, probably by causing premature rupture of gas cells, what obviously reduces the overall expansion (Mendonca et al. 2000). That was not observed in the case of extrudates containing everlasting pea and wheat wholemeal. The expansion ratio increased both as the concentration of the fibers and proteins increased, while specific density and hardness decreased. Inverse relationship was observed for crude fat (Table 4). These results may indicate that wheat gluten plays an important role in expansion of everlasting pea-wheat extrudates. The effects of wheat proteins on functional characteristics of extrudates were reported by other researchers. Faubion and Hosney (1982) reported that expansion ratio decreased as the gluten content increased.

Table 3.

Physical properties of extrudates and Fe content

| Sample | Physical properties | Fe mg/kg d.b. |

|||

|---|---|---|---|---|---|

| Radial expansion | Specific density (kg m−3) |

Notch toughness (J cm−2) |

Extruded products | Non extruded mixtures* | |

| 1 | 3.26 e ± 0.11 | 753 b ± 19 | 0.087 b ± 0.004 | 97.3 bdc ± 9.7 | 55.0 |

| 2 | 4.28 c ± 0.19 | 559 f ± 20 | 0.067 ghf ± 0.002 | 101.8 bdac ± 1.9 | 57.6 |

| 3 | 4.69 ba ± 0.22 | 496 h ± 18 | 0.064 gh ± 0.004 | 115.0 a ± 12.5 | 60.2 |

| 4 | 2.61 f. ± 0.11 | 858 a ± 29 | 0.096 a ± 0.005 | 112.5 ba ± 11.3 | 55.0 |

| 5 | 3.02 e ± 0.14 | 732 b ± 26 | 0.081 c ± 0.002 | 96.3 bdc ± 6.2 | 57.6 |

| 6 | 3.55 d ± 0.15 | 635 ed ± 21 | 0.071 def ± 0.004 | 101.0 bdac ± 7.8 | 60.2 |

| 7 | 3.12 e ± 0.11 | 687 c ± 16 | 0.092 ba ± 0.004 | 86.8 d ± 4.8 | 55.0 |

| 8 | 3.29 e ± 0.14 | 628 ed ± 20 | 0.087 b ± 0.003 | 96.9 bdc ± 8.9 | 57.6 |

| 9 | 4.82 a ± 0.18 | 500 gh ± 18 | 0.058 i ± 0.003 | 101.2 bdac ± 3.2 | 60.2 |

| 10 | 2.64 f. ± 0.11 | 862 a ± 27 | 0.088 b ± 0.004 | 87.1 dc ± 0.4 | 55.0 |

| 11 | 3.63 d ± 0.14 | 652 d ± 13 | 0.072 def ± 0.002 | 92.2 dc ± 2.3 | 57.6 |

| 12 | 4.38 c ± 0.20 | 534 gf ± 19 | 0.067 ghef ± 0.003 | 100.3 bdac ± 4.2 | 60.2 |

| 13 | 3.55 d ± 0.12 | 654 d ± 15 | 0.076 dc ± 0.003 | 88.5 dc ± 4.7 | 55.0 |

| 14 | 3.76 d ± 0.14 | 605 e ± 17 | 0.069 gef ± 0.003 | 103.7 bac ± 5.8 | 57.6 |

| 15 | 4.42 bc ± 0.18 | 530 gfh ± 16 | 0.075 d ± 0.003 | 99.9 bdac ± 3.4 | 60.2 |

| 16 | 3.26 e ± 0.10 | 651 d ± 14 | 0.073 de ± 0.003 | 95.0 dc ± 0.9 | 55.0 |

| 17 | 4.46 bc ± 0.14 | 500 gh ± 11 | 0.062 hi ± 0.003 | 98.3 bdc ± 4.2 | 57.6 |

| 18 | 4.91 a ± 0.18 | 393 i ± 10 | 0.052 j ± 0.002 | 96.7 bdc ± 11.4 | 60.2 |

Means with different letter (a-j) on the same column are significantly different according to Duncan’s test, at p < 0.05, *-expected value, calculated in the mixes based on raw material analyses

Table 4.

Pearson correlation coefficients between the analysed physical and chemical properties of extrudates (n = 18)

| Radial expansion | Specific density | Notch toughness | Fe changes | |

|---|---|---|---|---|

| Radial expansion | 1 | −0.95342 p < .0001 |

−0.89130 p < .0001 |

– |

| Specific density | 1 | 0.88232 p < .0001 |

– | |

| Notch toughness | 1 | – | ||

| TDF | 0.79019 p < .0001 |

−0.76737 p = 0.0002 |

−0.71126 p = 0.0009 |

0.17927 p = 0.4766 |

| Protein | 0.79013 p < .0001 |

−0.76757 p = 0.0002 |

−0.71149 p = 0.0009 |

0.17933 p = 0.4765 |

| Fat | −0.79017 p < .0001 |

0.76746 p = 0.0002 |

0.71136 p = 0.0009 |

−0.17929 p = 0.4765 |

| Moisture content | 0.09228 p = 0.7157 |

−0.27658 p = 0.2665 |

−0.12487 p = 0.6215 |

−0.12922 p = 0.6093 |

TDF Total dietary fiber

As it is shown in Table 3 significance difference (p < 0.05) of radial expansion, specific density and notch toughness were observed for different moisture content and profile temperature. However, no significant correlations (Pearson, p > 0.05) between these extrusion conditions and physical properties of extrudates were found (Table 4). In case of many other materials, it was found that the expansion ratio increases with the barrel temperature and it decreases with feed moisture content (Ding et al. 2005; Thymi et al. 2005). Moreover, Saeleaw et al. (2012) found that increasing barrel temperature caused an increase in the expansion ratio and a decrease in density, independent of the feed moisture. In the presented study different influence of process temperature on physical properties of extrudates, depending on moisture content, was observed. At 18 % blend moisture level, decreasing expansion and increasing density with increasing extrusion temperature were observed. This trend was reversed with increasing moisture content (Table 3). The significant interactions shown by the results indicate that the effect of barrel temperature is dependent on the feed moisture content, and vice versa.

Extrusion process and microstructure of extrudates

Extrusion is a mechanical process of exposing a material to high temperature, shear and pressure, causing profound physical and chemical transformations of the material processed. The consequences of those transformations were a change in the structure of the material (Kasprzak et al. 2013; Lazou and Krokida 2010; Zarzycki et al. 2010; Rzedzicki and Błaszczak 2005).

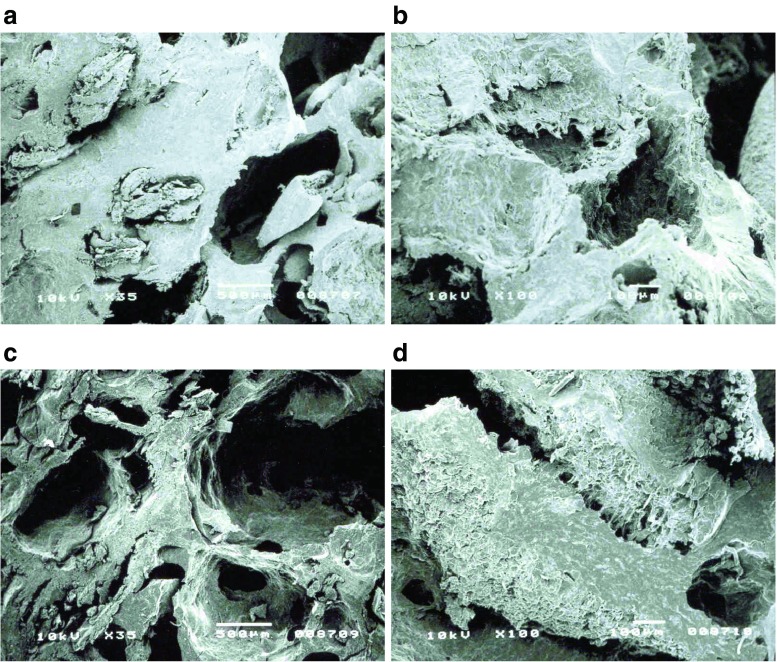

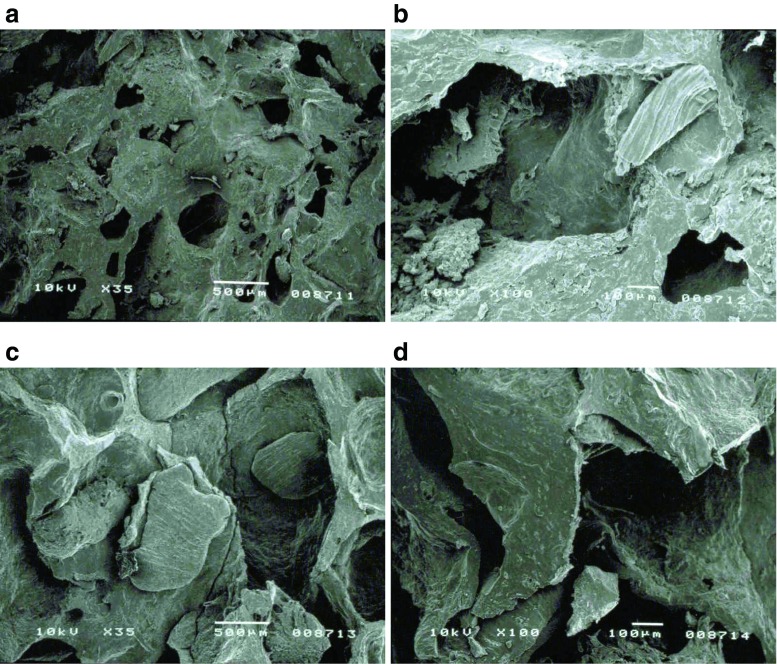

Microstructure analysis was performed to determine the effect of process parameters i.e. barrel temperature and moisture content, therefore the sample with a constant composition of the raw materials were selected. Comparative analysis was performed for extrudates with 50 % addition of wholemeal everlasting pea. The extrudates were produced at moisture content of 18 and 24 % and barrel temperature distribution profile of 90/120/150/140/130 °C and 110/140/180/170/130 °C. These products were characterised by high specific density and relatively low degree of radial expansion (Table 3). Such a high density and low expansion result from the product’s microstructure that was formed. As shown in the cross section of the samples (Figs. 1a–d and 2a–d), the products obtained the form of extruded, compact and pressed material and do not demonstrate the structure of a ‘honey comb’, typical for snack crisps (Rzedzicki and Błaszczak 2005).

Fig. 1.

Microstructure of everlasting pea-wheat extrudates (everlasting pea wholemeal 50 %, wheat wholemeal 50 %, barrel temperature distribution profile 90/120/150/140/130 °C): a, b material blend with moisture at 18 %, c, d material blend with moisture at 24 %

Fig. 2.

Microstructure of everlasting pea-wheat extrudates (everlasting pea wholemeal 50 %, wheat wholemeal 50 %, barrel temperature distribution profile 110/140/180/170/130 °C): a, b material blend with moisture at 18 %, c, d material blend with moisture at 24 %

A microscopic pictures of the extrudates obtained at 18 % moisture content and temperature of 90/120/150/140/130 °C are shown in Fig. 1a, b. As shown in the cross section of the samples, the obtained products attain the form of extruded, compact and pressed material. A careful analysis of the macrostructure may indicate some faults in processing the product. There is an observable absence of a distinct cellular structure of the extrudates, characteristic for expanded products. The extrudates have macrostructure with irregular air spaces and no clearly defined air cell walls. The air cells are differentiated, what is manifested in pores larger than 500 μm in size and a few small cells with the size of several μm (Fig 1a, b). Figure 1a presents visible not-liquefied particles which interrupt the structure of the material and may be responsible for lowering hardness (Table 3). Also at the higher barrel temperature (110/140/180/170/130 °C), and the same moisture level (18 %), the product appears to be not fully processed (Fig. 2a, b). Figure 2a, b still presents visible not-liquefied particles, but they are much smaller. Therefore, it seems that a key role in modeling the structure of these products is played by high content of dietary fibre. Similar relations were reported by Rzedzicki and Błaszczak (2005).

Figure 1c, d presents the structure of extrudates obtained at the temperature profile of 90/120/150/140/130 °C and 24 % moisture content. The analysis of the photographs reveals certain differences in the size of air cells and in cell wall thickness, compared to the products obtained at lower material moisture level (18 %). Extrudates obtained at material moisture of 24 % had air cells with larger diameters ranges between several and a few hundred μm (Fig. 1c, d). The air cells are surrounded by porous but relatively thick wall with small holes on the surfaces, which results in considerable hardness of these products (Table 3). In Fig. 1d some starch-protein bridges are visible. These bridges may be also responsible for hardness and compact structure of the product (Rzedzicki and Błaszczak 2005). However, such microstructure changes were not reflected in a lower density and higher expansion of the products. The extrudates were characterized by lower expandability and higher density, in comparison to analogical extrudates which were obtained at lower moisture level of the material (Table 3). In many cases, extrudates characterized by lower radial expansion and higher specific density should have smaller air cells with thicker walls, compared to extrudates with a higher degree of radial expansion (Zarzycki et al. 2010). That was not observed in the case of extrudates containing wheat and everlasting pea in their composition. The increase in porosity, observed for these samples (Figs. 1a–d and 2a–d), is probably an indication of longitudinal expansion. Similar observation for everlasting pea-corn extrudates was conducted earlier by Kasprzak and Rzedzicki (2007).

The analysis of microscopic pictures of the extrudates (Figs. 1a–d and 2a–d) confirms also a significant impact of process temperature on the product structure. Extrudates at lower temperature show fewer cells which are larger in size, compared to those at higher temperature. The samples obtained at higher temperature (Fig. 2a–d) were also characterized by larger number of air cells and thinner cell walls. Such results, an increase of the number of air cells with increase in process temperature were also noted in other studies (Lazou and Krokida 2010; Rzedzicki and Błaszczak 2005). As pointed out above, the reverse influence of moisture content on physical properties of extrudates obtained at high barrel temperature (110/140/180/170/130 °C) was observed (Table 3). With increase in the feed moisture, up to 24 %, a statistically significant decrease in the degree of radial expansion and increase in specific density were observed, compared to the extrudates obtained at 18 % moisture level. The extrudates were characterised also by lower values of notch toughness (Table 3). The changes in the microstructure may be responsible for such changes in the physical properties. The increase in feed moisture content resulted in the formation of more air cells and thinner cell walls. Larger expansion reduced the thickness of the layer of starch molecules surrounding the air cells, so less force was required to break the extrudates. Also Lazou and Krokida (2010), in the case of extrudates with a content of lentils, observed that an increase in the moisture of the material blend contributed to an increase in the size of the air cells.

Extrusion process and iron content

The iron contents of raw materials and their extruded products are shown in Table 3. The iron levels of the extruded mixtures were significantly greater than the non-extruded ones. This phenomenon has been previously described (Alonso et al. 2001; Cardoso-Santiago and Arêas 2001; Zarzycki and Rzedzicki 2007) and it is most likely due to the wear of metallic pieces, mainly screws, of the extruder and subsequent contamination of processed samples. The phenomenon may influence both the quality of the products and the exploitation of the extruder. According to Camire (1998, 2001), materials with high dietary fibre content appear to produce the greatest screw wear and may lead to increasing the level of metal contamination. That was not observed in the case of extrudates containing wheat and everlasting pea in their composition. No significant effect was shown in the chemical compositions, especially in the dietary fibre content in the extruded material on the level of metal contamination in the extrudates (Table 4).

Conclusion

The application of a counter-rotating twin-screw extrusion-cooker (2S-9/5) in the study permitted the production of compact, hard everlasting pea-wheat extrudates for use in vegetarian lunch dishes. The extrudates obtained were characterised by high specific density and relatively low degree of radial expansion. A change in the moisture content of the material blends and in the process temperature had a notable effect on the microstructure of the products, causing changes in the thickness of walls of air pockets and in their dimensions, among other things. The extrudates produced from blends everlasting pea-wheat (50:50) at higher barrel temperature (110/140/180/170/130 °C) were characterised by more numerous air cells with smaller diameters. Increasing moisture content results in extrudates with higher porosity. The Pearson linear correlation analysis (p < 0.05) demonstrated a statistically significant Pearson correlation (p < 0.05) between chemical compositions of the blends and physical properties of extrudates. The expansion ratio increased as the concentration of the dietary fibers and proteins increased, while specific density and hardness decreased. Inverse relationship was observed for crude fat. No significant effect was shown of the chemical compositions of blends on the level of iron in the extrudates.

References

- AACC . American Association of Cereal Chemistry International. Minnesota, USA: St. Paul; 2000. [Google Scholar]

- Alonso R, Rubio LA, Muzuquiz M, Marzo F. The effect of extrusion cooking on mineral bioavailability in pea and kidney bean seed meals. Anim Feed Sci Technol. 2001;94:1–13. doi: 10.1016/S0377-8401(01)00302-9. [DOI] [Google Scholar]

- Antila J, Seiler K, Linko P. Production of flat bread by extrusion cooking using different wheat/rye ratios, protein enrichment and grain with poor baking ability. J Food Eng. 1983;2:189–210. doi: 10.1016/0260-8774(83)90010-9. [DOI] [Google Scholar]

- AOAC (1990) Official methods of analysis (15th ed.). Washington, DC: Association of Official Analytical Chemists

- Camire ME. Chemical changes during extrusion cooking. Adv Exp Med Biol. 1998;434:109–121. doi: 10.1007/978-1-4899-1925-0_11. [DOI] [PubMed] [Google Scholar]

- Camire ME. Extrusion and nutritional quality. In: Guy R., editor. Extrusion cooking. Cambridge: Woodhead Publishing Ltd; 2001. [Google Scholar]

- Cardoso-Santiago RA, Arêas JAG. Nutritional evaluation of snack obtained from chickpea and bovine lung blends. Food Chem. 2001;74:35–40. doi: 10.1016/S0308-8146(00)00335-6. [DOI] [Google Scholar]

- Ding Q-B, Ainsworth P, Tucker G, Marson H. The effect of extrusion conditions on the physicochemical properties and sensory characteristics of rice-based expanded snacks. J Food Eng. 2005;66:283–289. doi: 10.1016/j.jfoodeng.2004.03.019. [DOI] [Google Scholar]

- Faubion JM, Hosney RC. High temperature shorttime extrusion cooking of wheat starch and flour, II: Effect of protein and lipid on extrudate properties. Cereal Chem. 1982;59(6):533–537. [Google Scholar]

- Kasprzak M, Rzedzicki Z. Effect of bath temperature and soaking time on the dynamics of water holding capacity of everlasting pea-wheat extrudates. Int Agrophys. 2007;21:241–248. [Google Scholar]

- Kasprzak M, Rzedzicki Z, Wirkijowska A, Zarzycki P, Sobota A, Sykut-Domańska E, Błaszczak W. Effect of fibre-protein additions and process parameters on microstructure of corn extrudates. J Cereal Sci. 2013;58:488–494. doi: 10.1016/j.jcs.2013.09.002. [DOI] [Google Scholar]

- Kaur S, Sharma S, Singh B, Dar BN. Effect of extrusion variables (temperature, moisture) on the antinutrient components of cereal brans. J Food Sci Technol. 2013 doi: 10.1007/s13197-013-1118-4. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Lazou A, Krokida M. Structural and textural characterization of corn-lentil extruded snacks. J Food Eng. 2010;100:392–408. doi: 10.1016/j.jfoodeng.2010.04.024. [DOI] [Google Scholar]

- Lisiewska Z, Korus A, Kmiecik W. Changes in chemical composition during development of grass pea (Lathyrus sativus L.) seeds. Food. 2003;47(6):391–396. doi: 10.1002/food.200390088. [DOI] [PubMed] [Google Scholar]

- Liu C, Zhang Y, Liu W, Wan J, Wang W, Wu L, Zuo N, Zhou Y, Yin Z. Preparation, physicochemical and texture properties of texturized rice produce by improved extrusion cooking technology. J Cereal Sci. 2011;54:473–480. doi: 10.1016/j.jcs.2011.09.001. [DOI] [Google Scholar]

- Mendonca S, Grossmann MVE, Verhe R. Corn bran as a fibre source in expanded snacks. LWT Food Sci Technol. 2000;33:2–8. doi: 10.1006/fstl.1999.0601. [DOI] [Google Scholar]

- Monsoor MA, Yusuf HKM. In vitro protein digestability of lathyrus pea (Lathyrus sativus), lentil (Lens culinaris), and chickpea (Cicer arietinum) Int J Food Sci Technol. 2002;37(1):97–99. doi: 10.1046/j.1365-2621.2002.00539.x. [DOI] [Google Scholar]

- Repo-Carrasco-Valencia R, Peña J, Kallio H, Salminen S. Dietary fiber and other functional components in two varieties of crude and extruded kiwicha (Amaranthus caudatus) J Cereal Sci. 2009;49:219–224. doi: 10.1016/j.jcs.2008.10.003. [DOI] [Google Scholar]

- Rybiński W, Błaszczak W, Fornal J. Seed microstructure and genetic variation of characters in selected grass-pea mutants (Lathyrus sativus L.) Int Agrophys. 2006;20:317–326. [Google Scholar]

- Rzedzicki Z, Błaszczak W. Impact of microstructure in modelling physical properties of cereal extrudates. Int Agrophys. 2005;19:175–186. [Google Scholar]

- Saeleaw M, Dürrschmid K, Schleining G. The effect of extrusion conditions on mechanical-sound and sensory evaluation of rye expanded snack. J Food Eng. 2012;110:532–540. doi: 10.1016/j.jfoodeng.2012.01.002. [DOI] [Google Scholar]

- Sobota A, Rzedzicki Z. Effect of the extrusion process of corn semolina and pea hulls blends on chemical composition and selected physical properties of the extrudates. Int Agrophys. 2009;23:67–79. [Google Scholar]

- Thymi S, Krokida MK, Pappa A, Maroulis ZB. Structural properties of extruded corn starch. J Food Eng. 2005;68:519–526. doi: 10.1016/j.jfoodeng.2004.07.002. [DOI] [Google Scholar]

- Wang YY, Ryu GH. Physical properties of extruded corn grits with corn fibre by CO2 injection extrusion. J Food Eng. 2013;116:14–20. doi: 10.1016/j.jfoodeng.2012.10.041. [DOI] [Google Scholar]

- Yanniotis S, Petraki A, Soumpasi E. Effect of pectin and wheat fibers on quality attributes of extruded cornstarch. J Food Eng. 2007;80:594–599. doi: 10.1016/j.jfoodeng.2006.06.018. [DOI] [Google Scholar]

- Zarzycki P, Rzedzicki Z. Effect of extrusion process parameters on the level of metal contamination of corn-oat extrudates. Pol J Nat Sci. 2007;4(S):143–152. [Google Scholar]

- Zarzycki P, Rzedzicki Z, Błaszczak W. Application of oat whole-meal and protein components as modifiers of extrudates microstructure. Int Agrophys. 2010;24:397–406. [Google Scholar]