Abstract

Purpose:

to evaluate the shrinkage, polymerization stress, elastic and bulk modulus resulting from composites formulated by siloranes, 2nd generation ormocers, and dimethacrylates.

Materials and Methods:

The bonded disc method was used to evaluate volumetric shrinkage. The polymerization stress was evaluated by mean of the Bioman. Cylindrical specimens (5 mm thickness and 6 mm diameter) were submitted to gradual loading. Young's and bulk modulus were obtained from the slope of the stress/strain curve. Data were analyzed using one-way analysis of variance and Tukey's test (5%).

Results:

Grandio and ormocer showed significant higher elastic and bulk modulus. Silorane presented significant lowest bulk modulus and maximum shrinkage. Ormocer and silorane presented lower values for the maximum rate of shrinkage. Extra-low shrinkage (ELS) composite presented the greatest maximum shrinkage. The higher maximum rate of shrinkage was attained by Grandio and ELS, statistically similar from each other. The silorane showed lower values of maximum stress and maximum rate of stress. The higher values of maximum stress were presented by ELS and Grandio, statistical similar between them. Grandio showed the significantly greatest maximum rate of stress.

Conclusion:

Silorane showed to promote lower shrinkage/stress among the composites, with the lowest elastic modulus. Ormocer showed lower shrinkage/stress than methacrylates despite of its high modulus.

Keywords: Composite resin, polymerization stress, volumetric shrinkage

INTRODUCTION

The stress resulted from the polymerization process is considered one of the most important determinants for the failure of dental composite restorations. The stress development is caused by a multifactorial process.[1,2] The volumetric shrinkage occurs simultaneously with the increase in the elastic modulus, as the density of cross-linked ligations among the polymeric chains increases.[3,4] Thus, the polymerization reaction, the material's composition and the surrounding conditions around the restoration (bonding integrity, C-factor, and deformation of the adjacent structures) are important factors which deal with the development and transmission of stress to the bonded interface and to dental structures.[5,6,7,8,9,10,11] In order to reduce the stress generated, several clinical techniques were developed and surveyed such as step-wise light exposure methods, incremental technique, and the use of stress-relieving materials. However, almost all methods presented controversial results.[12,13,14,15]

Specific methods of light exposure have been proposed as an alternative to reduce the polymerization rate thereby decreasing the rate of stress development as well.[16,17] Theoretically, it would be possible to obtain stress release by viscous flow before the vitrification stage without compromising the final polymer properties.[18,19] Thus, initial light exposure at lower irradiance might lead to the formation of a reduced number of polymer growth centers, reducing the reaction rate and decreasing stress development due to the increased opportunity for resin flowing before the vitrification stage. Although some studies suggest that the light exposure protocols are not able to affect the properties of the polymerized composite, other studies disagree regard the advantages of these methods, either in the stress reduction or in the final formation of the polymer. The theories concerning the incremental technique or the application of layering stress-relieving materials, which would act as “stress absorbing layers” are also controversial.[1,20,21]

In fact, the employment of clinical techniques arises controversial outcomes among the several in vitro studies[12,13,14,15] and as a result, materials with the capacity to develop lower stress are required, which would indeed simplify the application technique and the variability of the outcomes. Consequently, changes in the material's composition have been proposed both by the scientific community and by the manufacturers. In this regard, it might be highlighted the materials developed relying on silorane and ormocer technologies. Likewise, few studies were realized dealing with the stress reduction and the resistance to degradation in such materials. Thus, the aims of the present study were to evaluate the shrinkage, stress, and mechanical properties (elastic and bulk modulus) resulting from composites formulated by siloranes, 2nd generation ormocers, and dimethacrylates. The resistance to degradation of these materials was already evaluated, and the same materials and parameters were employed here.[22]

The hypotheses of this study were that materials formulated by siloranes and ormocers would produce:

Lower shrinkage,

Lower stress and

Similar mechanical properties to those produced by composite formulated with dimethacrylates.

MATERIALS AND METHODS

Materials

Four restorative composite materials were evaluated in this study: Filtek silorane (3M ESPE, St. Paul, MN, USA), one experimental 2nd generation ormocer, and dimethacrylates (Extra-low shrinkage [ELS], Voco, Cuxhaven, Germany; and Grandio, Saremco Dental AG, Rebstein, Switzerland).

Experiments

Volumetric shrinkage evaluation

The volumetric shrinkage evaluation was performed through the bonded-disc technique at room temperatures (25°C). Approximately 0.146 g of resin-composite (similar mass as used in the stress evaluation) was squeezed between a rigid glass plate and a coverslip to form a disc-shape uncured specimen. A peripheral brass ring with 0.8 mm thickness was used between the glass plate and the cover slip to standardize the sample thickness. The set was then fixed into a rigid platform holing a linear variable differential transformer (LVDT) (RDP Electronics, Wolverhampton, UK) and the light-curing unit (LCU, Optilux-500, Kerr, Orange, USA). The irradiation procedure (40 s at 550 mW/cm2) was performed through the rigid plate and the LVDT probe, which was positioned in contact with the coverslip, was able to detect continuously sample's deformation during the following 60 min (n = 3).

Polymerization stress evaluation

The Bioman stress measurement device has been described previously in detail.[9] The system is based on a cantilever load-cell (500 kg) fitted with a rigid integral clamp. The compliant end of the cantilever held a circular steel rod (10 mm diameter × 22 mm long) vertically and perpendicular to the load-cell axis. The counter-face consisted of a removable rigid glass plate that was held rigidly relative to the base-plate in a special clamp during measurement. The lower end of the steel rod and the glass plate were sandblasted and the resin-composite was introduced between them, forming an uncured specimen-disk of 10 mm diameter and 0.8 mm thickness (which represents a bonded to nonbonded surface area, i.e., C-factor, of 6.25). The composite specimen was irradiated through its thickness dimension from the bottom surface by the LCU (Optilux-500) for 40 s at 550 mW/cm2, as periodically measured with a power meter. The registered load (in Newton, N) was then divided by the disk area in order to obtain the stress values (MPa). Measurements were performed during 60 min after the photoactivation procedure (n = 3). Time zero was considered when the LCU turned on.

Mechanical properties

Cylindrical specimens 5 mm thickness and 6 mm diameter were built by injecting the resin-composite in a stainless steel mold and light activating during 60 s at 550 mW/cm2 each surface with the LCU (Optilux-500). Additional light exposure under vacuum was performed in a bench-curing-chamber during 7 min (Visio Beta Vario, 3M-Espe, St. Paul, USA) as soon as samples were removed from the mold. Samples were then stored dry at 25°C and loaded after 24 h. A digital caliper was used to measure the dimensions before and after loading.

A universal testing machine (Zwick/Roell Z02, Zwick GmbH and Co. KG, Ulm, Germany) was used to load the specimens. The compliance of the machine was measured prior to the performance of the actual tests by running a loading cycle using exactly the same attachments and adjustments, which would be used at the real experiment, but without placing samples. The resulting stress-strain curves (named correction curves) were uploaded to the software during the real test and the compliance of the machine was automatically subtracted to generate the corrected stress-strain curves from the overall measured displacement. Two correction curves were produced, one for the arrangement used for the determination of the Young's modulus and the other for the bulk modulus measurements.

For Young's modulus measurement, nonconstricted specimens were submitted to gradual loading up to 1000 N with a crosshead speed set at 1 mm/min (n = 6). On the other hand, for bulk modulus, the samples were constrained in a close-fitting rigid stainless steel ring and loaded between two pistons at 1 mm/min with a gradual load up to 10,000 N. Young's (E) and bulk (B) moduli were obtained from the slope of the stress/strain curve at the higher loads for the unconstrained and constrained specimens, respectively.

Statistical analyses

Data were explored using Statistical Package for Social Sciences (SPSS)® software (version 20; IBM, Armonk, NY, USA). The results for each test were analyzed by one-way analysis of variance, followed by Tukey's test (significance level of 5%).

RESULTS

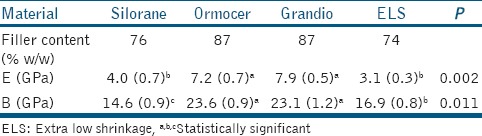

The mechanical properties of the evaluated materials are presented in Table 1. Grandio and ormocer composites presented the statistically significant higher elastic and bulk modulus than the silorane and ELS ones, which did not differ from each other on the elastic modulus. The silorane-based composite showed statistically significant lowest bulk modulus.

Table 1.

Filler content and mechanical properties of the evaluated materials

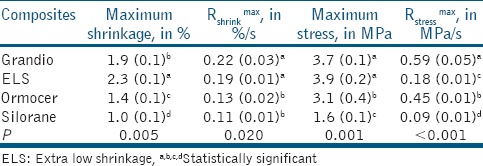

Regarding the shrinkage evaluation [Table 2], the silorane composite presented statistically significant lower values of the maximum shrinkage, followed by the experimental ormocer. Yet, both ormocer and silorane presented lower values for the maximum rate of shrinkage in comparison with the other composites. The ELS composite presented the greatest maximum shrinkage. The higher maximum rate of shrinkage was attained by Grandio and ELS, statistically similar from each other.

Table 2.

Maximum shrinkage and maximum rate of shrinkage, maximum stress and maximum rate of stress

The silorane composite showed statistical significant lower values of maximum stress and maximum rate of stress, followed by the ormocer in the maximum stress and by the ELS in the maximum rate of stress. The higher values of maximum stress were presented by ELS and Grandio composites, statistical similar between them. Grandio also showed the significantly greatest maximum rate of stress. All data of stress are shown in Table 2.

DISCUSSION

The shrinkage and stress evaluation of the composite resins in this study showed silorane with the statistical lower values, followed by ormocer, which was statistically different from the methacrylate composites (Grandio and ELS). Previous reports found that methacrylate-based materials, induce volumetric shrinkage in the range of 1–5%[23,24] compatible with the present outcomes for methacrylate-based composites (1.9% and 2.3%, for Grandio and ELS, respectively). Moreover, the organic matrix of siloranes formed by the mixture of siloxane and oxirane components, polymerizes through a ring-opening cationic strategy and exhibits a low volumetric shrinkage of approximately 1%,[25] corroborating with the findings of this study. Thus, the results are in agreement with the literature that polymerization process of siloranes leads to lower shrinkage and stress in relation to methacrylates. Ormocers were initially used together with dimethacrylates, but a recent material formulated with a pure-ormocer-based resin matrix has been developed. An ormocer is a hybrid molecular structure. This combines organic and inorganic components at nanoscopic scale through the sol-gel method, and the main characteristic of this type of material is the incorporation of organic groups linked to the inorganic backbone.[26,27] Once the inorganic component of the ormocer structure presents no shrinkage during polymerization, the expected contraction and stress would be reduced which could explain the lower shrinkage of the ormocer in comparison with methacrylate-based materials. According to these considerations, the first and second hypotheses of this study, that materials formulated by siloranes and ormocers would produce lower shrinkage and lower stress than methacrylate-based composites, must be accepted.

Regarding the mechanical properties evaluated, Grandio and the ormocer composites presented statistically higher elastic and bulk modulus, in comparison to silorane and ELS. The silorane showed the statistically lowest bulk modulus. Hence, the third hypothesis was partially accepted. These outcomes show a positive correlation of modulus with the filler content, as the bulk and elastic modulus were increased in materials with a higher percentage of fillers. A correlation of higher elastic and bulk modulus with increased shrinkage and stress seems to be valid in the present study for the methacrylate-based composites, as Grandio attained lower volumetric shrinkage than ELS, but the resulting stress was similar due to the influence of higher modulus.

Furthermore, between the two methacrylates evaluated, although the different filler content, Grandio has its organic matrix based on BisGMA and TEGDMA while ELS is based on BisGMA and BisEMA to reduce the shrinkage. BisGMA has a very high molecular weight, which provides lower polymerization shrinkage than other monomers and superior mechanical qualities,[3] what explain its high usage as the main monomer for composite resins. TEGDMA presents a lower viscosity than BisGMA and thus, their association compensates the rigidity and polymerization difficulty of BisGMA and thus, the addition of TEGDMA results in resins with the higher conversion.[28] However, as negative effects, the addition of TEGDMA to the resin formulation tends to increase the water sorption as well as the shrinkage due to its lower molar weight. BisEMA differs from BisGMA because it does not present the pendant hydroxyl groups that form the hydrogen bonds among molecules and has significantly lower viscosity.[29] Aiming to develop composite resins with low shrinkage, manufacturers replaced monomers such as TEGDMA with monomers with increased molecular weight, for instance, BisEMA.[30] A previous report[31] showed that composites containing BisEMA have less shrinkage than those based on TEGDMA as a diluent monomer. These outcomes are in contrast with those of this study. Therefore, it could be suggested that the amount of filler was most important for the shrinkage than these two components associated to BisGMA on methacrylate-based materials.

Silorane composite showed the lower shrinkage and stress values in this study, followed by ormocer which was also statistical superior to methacrylates. Silorane also showed lower elastic modulus and the lowest bulk modulus, suggesting the low stress also related to these properties. The material's composition also showed influence on the shrinkage/stress in restorative composites, once ormocer had bulk and elastic modulus higher than ELS and similar to Grandio and presented significant lower shrinkage and stress. For the two methacrylate-composites evaluated, the filler amount seemed to be most important than the organic matrix and mechanical properties for volumetric shrinkage, as Grandio showed lower values than ELS, although the higher elastic and bulk modulus of Grandio might have led to the similar polymerization stress in these materials.

Financial support and sponsorship

Nil.

Conflicts of interest

There are no conflicts of interest.

REFERENCES

- 1.Braga RR, Ferracane JL. Alternatives in polymerization contraction stress management. J Appl Oral Sci. 2004;12:1–11. doi: 10.1590/s1678-77572004000500002. [DOI] [PubMed] [Google Scholar]

- 2.Ferracane JL. Developing a more complete understanding of stresses produced in dental composites during polymerization. Dent Mater. 2005;21:36–42. doi: 10.1016/j.dental.2004.10.004. [DOI] [PubMed] [Google Scholar]

- 3.Peutzfeldt A. Resin composites in dentistry: The monomer systems. Eur J Oral Sci. 1997;105:97–116. doi: 10.1111/j.1600-0722.1997.tb00188.x. [DOI] [PubMed] [Google Scholar]

- 4.Dauvillier BS, Feilzer AJ, De Gee AJ, Davidson CL. Visco-elastic parameters of dental restorative materials during setting. J Dent Res. 2000;79:818–23. doi: 10.1177/00220345000790030601. [DOI] [PubMed] [Google Scholar]

- 5.Davidson CL, de Gee AJ. Relaxation of polymerization contraction stresses by flow in dental composites. J Dent Res. 1984;63:146–8. doi: 10.1177/00220345840630021001. [DOI] [PubMed] [Google Scholar]

- 6.Feilzer AJ, De Gee AJ, Davidson CL. Setting stress in composite resin in relation to configuration of the restoration. J Dent Res. 1987;66:1636–9. doi: 10.1177/00220345870660110601. [DOI] [PubMed] [Google Scholar]

- 7.Miguel A, de la Macorra JC. A predictive formula of the contraction stress in restorative and luting materials attending to free and adhered surfaces, volume and deformation. Dent Mater. 2001;17:241–6. doi: 10.1016/s0109-5641(00)00077-4. [DOI] [PubMed] [Google Scholar]

- 8.Laughlin GA, Williams JL, Eick JD. The influence of system compliance and sample geometry on composite polymerization shrinkage stress. J Biomed Mater Res. 2002;63:671–8. doi: 10.1002/jbm.10386. [DOI] [PubMed] [Google Scholar]

- 9.Watts DC, Marouf AS, Al-Hindi AM. Photo-polymerization shrinkage-stress kinetics in resin-composites: Methods development. Dent Mater. 2003;19:1–11. doi: 10.1016/s0109-5641(02)00123-9. [DOI] [PubMed] [Google Scholar]

- 10.Lu H, Stansbury JW, Bowman CN. Towards the elucidation of shrinkage stress development and relaxation in dental composites. Dent Mater. 2004;20:979–86. doi: 10.1016/j.dental.2004.05.002. [DOI] [PubMed] [Google Scholar]

- 11.Watts DC. Reaction kinetics and mechanics in photo-polymerised networks. Dent Mater. 2005;21:27–35. doi: 10.1016/j.dental.2004.10.003. [DOI] [PubMed] [Google Scholar]

- 12.Van Ende A, De Munck J, Mine A, Lambrechts P, Van Meerbeek B. Does a low-shrinking composite induce less stress at the adhesive interface? Dent Mater. 2010;26:215–22. doi: 10.1016/j.dental.2009.10.003. [DOI] [PubMed] [Google Scholar]

- 13.Ilie N, Jelen E, Hickel R. Is the soft-start polymerisation concept still relevant for modern curing units? Clin Oral Investig. 2011;15:21–9. doi: 10.1007/s00784-009-0354-5. [DOI] [PubMed] [Google Scholar]

- 14.Campodonico CE, Tantbirojn D, Olin PS, Versluis A. Cuspal deflection and depth of cure in resin-based composite restorations filled by using bulk, incremental and transtooth-illumination techniques. J Am Dent Assoc. 2011;142:1176–82. doi: 10.14219/jada.archive.2011.0087. [DOI] [PubMed] [Google Scholar]

- 15.Bicalho AA, Pereira RD, Zanatta RF, Franco SD, Tantbirojn D, Versluis A, et al. Incremental filling technique and composite material - Part I: Cuspal deformation, bond strength, and physical properties. Oper Dent. 2014;39:E71–82. doi: 10.2341/12-441-L. [DOI] [PubMed] [Google Scholar]

- 16.Bouschlicher MR, Rueggeberg FA, Boyer DB. Effect of stepped light intensity on polymerization force and conversion in a photoactivated composite. J Esthet Dent. 2000;12:23–32. doi: 10.1111/j.1708-8240.2000.tb00195.x. [DOI] [PubMed] [Google Scholar]

- 17.Cunha LG, Alonso RC, Pfeifer CS, Correr-Sobrinho L, Ferracane JL, Sinhoreti MA. Contraction stress and physical properties development of a resin-based composite irradiated using modulated curing methods at two C-factor levels. Dent Mater. 2008;24:392–8. doi: 10.1016/j.dental.2007.06.006. [DOI] [PubMed] [Google Scholar]

- 18.Sakaguchi RL, Berge HX. Reduced light energy density decreases post-gel contraction while maintaining degree of conversion in composites. J Dent. 1998;26:695–700. doi: 10.1016/s0300-5712(97)00048-1. [DOI] [PubMed] [Google Scholar]

- 19.Lim BS, Ferracane JL, Sakaguchi RL, Condon JR. Reduction of polymerization contraction stress for dental composites by two-step light-activation. Dent Mater. 2002;18:436–44. doi: 10.1016/s0109-5641(01)00066-5. [DOI] [PubMed] [Google Scholar]

- 20.Versluis A, Douglas WH, Cross M, Sakaguchi RL. Does an incremental filling technique reduce polymerization shrinkage stresses? J Dent Res. 1996;75:871–8. doi: 10.1177/00220345960750030301. [DOI] [PubMed] [Google Scholar]

- 21.Park J, Chang J, Ferracane J, Lee IB. How should composite be layered to reduce shrinkage stress: Incremental or bulk filling? Dent Mater. 2008;24:1501–5. doi: 10.1016/j.dental.2008.03.013. [DOI] [PubMed] [Google Scholar]

- 22.Schneider LF, Cavalcante LM, Silikas N, Watts DC. Degradation resistance of silorane, experimental ormocer and dimethacrylate resin-based dental composites. J Oral Sci. 2011;53:413–9. doi: 10.2334/josnusd.53.413. [DOI] [PubMed] [Google Scholar]

- 23.Palin WM, Fleming GJ, Nathwani H, Burke FJ, Randall RC. In vitro cuspal deflection and microleakage of maxillary premolars restored with novel low-shrink dental composites. Dent Mater. 2005;21:324–35. doi: 10.1016/j.dental.2004.05.005. [DOI] [PubMed] [Google Scholar]

- 24.Labella R, Lambrechts P, Van Meerbeek B, Vanherle G. Polymerization shrinkage and elasticity of flowable composites and filled adhesives. Dent Mater. 1999;15:128–37. doi: 10.1016/s0109-5641(99)00022-6. [DOI] [PubMed] [Google Scholar]

- 25.Weinmann W, Thalacker C, Guggenberger R. Siloranes in dental composites. Dent Mater. 2005;21:68–74. doi: 10.1016/j.dental.2004.10.007. [DOI] [PubMed] [Google Scholar]

- 26.Wolter H, Storch W, Ott H. New inorganic/organic copolymers (ORMOCER ® s) for dental applications. Mater Res Soc Symp Proc. 1994;346:143–9. [Google Scholar]

- 27.Haas KH, Wolter H. Synthesis, properties and applications of inorganic-organic copolymers (ORMOCER ® s) Curr Opin Solid State Mater Sci. 1999;4:571–80. [Google Scholar]

- 28.Asmussen E, Peutzfeldt A. Influence of pulse-delay curing on softening of polymer structures. J Dent Res. 2001;80:1570–3. doi: 10.1177/00220345010800061801. [DOI] [PubMed] [Google Scholar]

- 29.Schneider LF, Cavalcante LM, Silikas N. Shrinkage stresses generated during resin-composite applications: A review. J Dent Biomech. 2010;1:1–14. doi: 10.4061/2010/131630. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 30.Ferracane JL. Resin composite - State of the art. Dent Mater. 2011;27:29–38. doi: 10.1016/j.dental.2010.10.020. [DOI] [PubMed] [Google Scholar]

- 31.Chen MH. Update on dental nanocomposites. J Dent Res. 2010;89:549–60. doi: 10.1177/0022034510363765. [DOI] [PubMed] [Google Scholar]