Abstract

Background:

Denture repair involves joining two parts of a fractured denture with a denture repair material. Hence, a substantial repairing system for denture base fracture should be there to elude frequent fracture.

Materials and Methods:

Surface treatment of conventional heat cure denture base resin with different surface treatments (chemical ethyl acetate, and mechanical roughening with bur), with control group formed without surface treatment. Specimens were repaired with auto polymerizing acrylic resin using sprinkle on technique. The testing of the transverse strength of the repaired specimens was evaluated with three-point bending test on universal testing machine.

Results:

The study revealed that surface chemical treatment with ethyl acetate improved the transverse strength of repaired heat cure denture base when compared with mechanical and control group. A two-way analysis of variance revealed that there was statistically significant difference in mean strengths of the three groups.

Conclusion:

Surface chemical treatment with ethyl acetate improved the transverse strength of the repaired heat cure denture base when compared with mechanical roughening with bur and group without surface treatment.

Keywords: Ethyl acetate, mechanical roughening, repaired resin, surface treatment, transverse strength

Introduction

Acrylic resin is an indispensable material in removable prosthodontics. Unfortunately, removable restorations that are made totally or partially of acrylic resin will fracture if dropped or stressed beyond their fracture strength.1 They may be fractured by an impact while outside the mouth, or it may crack or break while in service in the mouth. The latter is generally a fatigue failure caused by repeated flexure over a period of time.2 This type of fracture most often occurs on or close to the midline.3,4 Acrylic resin dentures have been shown to flex in function to a much greater degree than would be expected.5,6 Poor tissue adaptation permits greater flexure of dentures and often results in fatigue failure.3 Several techniques and materials have been used to repair fractured dentures. The ultimate goal is to restore the actual strength of the denture and to prevent further fracture. However, this goal cannot always be attained.7 Furthermore, the fracture of the repaired specimens often occurs at the junction of the old and new materials rather than through the center of the repair where the load is applied. This finding clearly indicates that the interface of the old and new materials is the location of stress concentration during transverse strength testing, regardless of the technique used.1

Denture repairs involve joining two parts of a fractured denture with a denture repair material. In essence, the success of denture repairs relies on the phenomenon of adhesion. Surface preparation of the sites to be joined is of paramount importance to assure a long service life.8

Correct surface preparation means a strong bonding interface, which can improve the repair strength and reduce stress concentration. Normally, the surfaces to be joined are ground with a handpiece to a desirable profile and cleaned; the surface is treated with monomer before the repair materials are inserted.3 Polymer surfaces can be etched by appropriate chemicals, a process, which changes considerably the morphology and chemical properties of the surface and promotes better adhesion.9

Aims and objectives

To evaluate and compare the transverse strength of repaired heat cure denture base resins without surface treatment and with chemical and mechanical surface treatment

To assess mode of failure of fractured denture base

To recommend combination having superior transverse strength in repair of denture base resins.

Materials and Methods

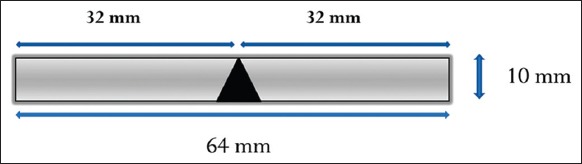

Acrylic resin specimen measuring 66 mm × 12 mm × 2.5 mm were fabricated from wax specimen of the same measurement by the process of acrylization. The prepared intact specimens were divided with the help of marker pen vertically into two equal parts, i.e. 32 mm each. 1 mm was marked on the right and left from the center line on the top, and 3 mm was marked on the right and left from the center line at the bottom respectively (Figure 1). The prepared intact specimens were then vertically cut in accordance with the marking on the specimen.

Figure 1.

Specimens were divided with the help of marker pen vertically into two equal parts of 32 mm each.

Repair method

Stone index: The intact acrylic resin specimens measuring 64 mm × 10 mm × 25 mm were invested in dental stone, and these formed the repaired indices. Final groups were formed according to surface chemical treatment:

Group 1:No surface pre-treatment (control).

Group 2:Ethyl surface pre-treatment (chemical).

Group 3: Roughening of the surface with straight fissure bur (mechanical).

After treatment of the cut surface, the heat polymerizing strips were fixed in mold to obtain a space for placing the resin to be repaired. Widths between strips were 2 mm at the top and 6 mm at the bottom. And no surface treatment was done in Group 1 (control group).

The surface of test specimens facing each other were swabbed with chemical etchant - ethyl acetate in Group 2 for a period of 5 s, followed by rinsing with water and air drying. For Group 3, surface of test specimens facing each other were roughened by straight fissure bur. Specimens were repaired with auto polymerizing acrylic resin using “sprinkle on technique.” The joint space was slightly overfilled to allow for polymerization shrinkage and finishing. All specimens were stored in water at room temperature for 48 h before the test.

Testing

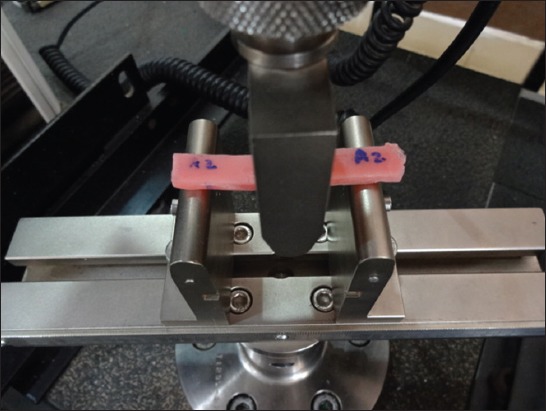

The testing of the transverse strength of the repaired specimen was carried out on the universal testing machine. The acrylic resin specimens were held in the fixture attached to the machine. Each specimen was subjected to the three-point bending test at a crosshead speed of 5 mm/min at a 20 mm distance (Figure 2). The load was applied perpendicular to the center of the repaired area. The direction of the load was similar to the load direction that affects repaired maxillary complete denture. The force required to fracture the denture base was recorded in kilograms. The transverse strength (S) of each specimen was calculated using the following formula:

Figure 2.

Testing of a specimen on three-point universal testing machine.

S = 3WL/2bd2

Where,

S = transverse strength

W = load at fracture

L = distance between end beams

b = width of specimen

d = thickness of the specimen.

The fractured specimens were examined visually to determine whether the fracture was adhesive or cohesive.

All statistical analyses were done with the help of the statistical package for social scientists (SPSS Version 20; Chicago Inc., USA) computer software for Windows version 8.

Results

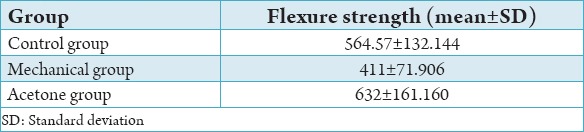

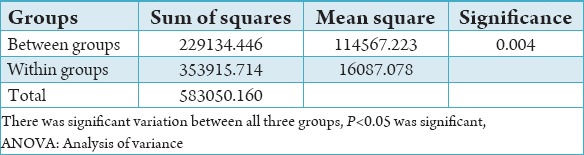

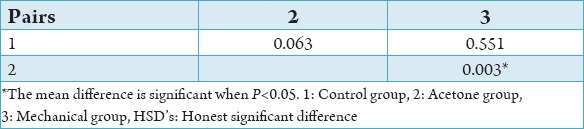

The mean strength with standard deviation for three comparative groups (control, ethyl acetate and mechanical) is presented in Table 1. One-way analysis of variance (ANOVA) for the transverse strength of different groups is presented in Table 2. A pairwise comparison via Tukey’s HSD (post-hoc analysis) test is presented in Table 3. The study revealed that surface chemical treatment with ethyl acetate improved the transverse strength of repaired heat cure denture base when compared with mechanical and control group. One-way ANOVA revealed that there was statistically significant difference in mean strengths of the three groups.

Table 1.

The mean strength with standard deviation for three comparative groups (control, ethyl acetate, and mechanical treatment).

Table 2.

One-way ANOVA for transverse strength of different groups.

Table 3.

Pairwise comparisons via Tukey HSD’s test.

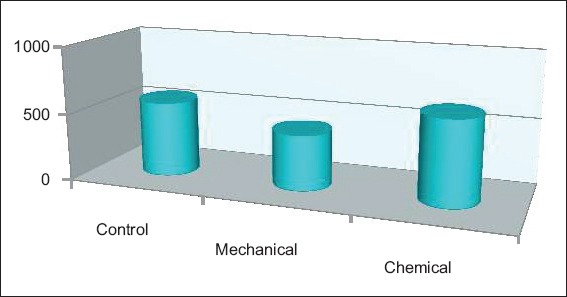

Further analysis was carried out to see if any significant difference existed between any pairs of groups by post-hoc analysis. Thus, the analysis suggested ethyl acetate surface treatment has the highest transverse strength, followed by no surface treatment (control group), and mechanical surface treatment has low mean transverse strength (Graph 1).

Graph 1.

Transverse strength of different groups.

The group with ethyl acetate surface treatment is recommended possessing the most superior transverse strength among the other groups. The mode of failure in ethyl acetate group is observed to be cohesive, suggesting tight adhesion of the auto polymerizing, and heat polymerizing acrylic resins; whereas in the control and mechanical group, adhesive type of fracture was noted.

Discussion

Different types of denture repair material are autopolymerizing acrylic resin i.e. heat-cure acrylic resin, visible light-polymerized resin, microwave polymerized acrylic resin. The material to be used for the repair of denture base depends on the working time of the material, the strength to be attained, and the dimensional stability achieved during and after repair.10,11 Dentures repaired with autopolymerizing acrylic resin have 60-65% of the original strength of the denture, when compared with heat cure acrylic which is 75-80%.12,13

While repairing the denture base, the bond strength desired between denture base and the repair material should be sturdy enough. The favorable result of denture repair, still, depends on the adhesion between the repair material and the denture base. Bonding between denture base and repair material can be enhanced by application of adequate chemicals to acrylic resin surfaces.10 To improve the surface adhesion, the repair surfaces can be dampened by methyl methacrylate monomer, which softens the polymethyl methacrylate and leads to change in the morphology and chemical properties of the surface. Chloroform,1,14 ethyl acetate15 and methylene chloride16,17 are used as softening agents in denture repair. Shen et al. observed that dampening the denture base resin surface with chloroform for 5 s produced a cleaner and more efficient site for bond which increased the strength of denture repairs. Since chloroform is recognized as toxic compound with mutagenic potential, so precautions are necessary to handle this material. Hence, chloroform was replaced by methylene chloride. Wetting of denture base with a methylene chloride on the surface causes crazing as well as the formation of numerous pits up to 2 µm in diameter.1,18

Surface treatment results in superficial crack propagation, as well as the formation of numerous pits. The resulting surface morphology with pitting and elevation is caused by dissolution of polymethyl methacrylate by ethyl acetate and methylene chloride. This enhances mechanical interlocking, further improving adhesion between surfaces to be joined. Toxicity of methylene chloride and ethyl acetate is low, which augments its role in surface chemical treatment for denture repair.10

Mechanical treatment involves grinding with burs, airborne particle abrasion and sandblasting, retention grooves to increase the surface area, and mechanical retention to raise Vander Waal force of attraction.16,19 Since monomer is not an efficient solvent for polymethyl methacrylate, painting or immersing the surface will not adequately dislodge the debris, and create particle free surface for bonding. Thus, treatment with chemicals is required.10 The study unveils that surface chemical treatment with ethyl acetate enhanced the transverse strength of repaired heat cure denture base when compared with the specimen treated with mechanical surface treatment and control group (no surface treatment). The improved transverse strength is due to tight adhesion, which is an outcome of monomer infiltration into pits and cracks. Surface treatment results in superficial crack propagation, and also the formation of innumerable pits. This increased the mechanical interlocking, which further improves the adhesion between surfaces to be repaired.10

There are two types of failures observed either adhesive or cohesive. Adhesive failure is observed when it gets fractured at the interface and cohesive failure is seen when a layer of repair resin was present on the test specimen. All samples were fractured at the interface of repair resin and heat-cure acrylic resin in the control group and group treated by roughening with straight fissure bur, so adhesive failure was observed. In the chemical group, cohesive failure was seen.

Conclusion

The study unveils that surface chemical treatment with ethyl acetate (acetone) enhanced the transverse strength of repaired heat cure denture base when compared with the control group and the one treated by roughening with straight fissure bur.

Footnotes

Conflicts of Interest: None

Source of Support: Nil

References

- 1.Shen C, Colaizzi FA, Birns B. Strength of denture repairs as influenced by surface treatment. J Prosthet Dent. 1984;52(6):844–8. doi: 10.1016/s0022-3913(84)80016-5. [DOI] [PubMed] [Google Scholar]

- 2.Kelly E. Fatigue failure in denture base polymers. J Prosthet Dent. 1969;21(3):257–66. doi: 10.1016/0022-3913(69)90289-3. [DOI] [PubMed] [Google Scholar]

- 3.Beyli MS, von Fraunhofer JA. An analysis of causes of fracture of acrylic resin dentures. J Prosthet Dent. 1981;46(3):238–41. doi: 10.1016/0022-3913(81)90206-7. [DOI] [PubMed] [Google Scholar]

- 4.Darbar UR, Huggett R, Harrison A. Denture fracture – a survey. Br Dent J. 1994;176(9):342–5. doi: 10.1038/sj.bdj.4808449. [DOI] [PubMed] [Google Scholar]

- 5.Regli CP, Kydd WL. Preliminary study of the lateral deformation of metal base dentures in relation to plastic base dentures. J Prosthet Dent. 1953;3(3):26–330. [Google Scholar]

- 6.Lambrecht JR, Kydd WL. Functional stress analysis of the maxillary complete denture base. J Prosthet Dent. 1962;12(5):865–72. [Google Scholar]

- 7.Mc Croice JW, Anderson JN. Transverse strength of repairs with self-curing resins. Br Dent J. 1960;109:364. [Google Scholar]

- 8.Cagle CV, editor. 1st ed. Ch. 2,19. New York: McGraw-Hill Book Co; 1973. Handbook of Adhesive Bonding. [Google Scholar]

- 9.Mijovic JS, Koutsby JA. Etching of polymeric surfaces. Polym Plast Technol. 1997;9(2):139. [Google Scholar]

- 10.Siddesh CS, Aras MA. In vitro evaluation of transverse strength of repaired heat cured denture base resins with and without surface chemical treatment. J Indian Prosthodont Soc. 2008;8(2):87–93. [Google Scholar]

- 11.Seó RS, Neppelenbroek KH, Filho JN. Factors affecting the strength of denture repairs. J Prosthodont. 2007;16(4):302–10. doi: 10.1111/j.1532-849X.2007.00191.x. [DOI] [PubMed] [Google Scholar]

- 12.Leong A, Grant AA. The transverse strength of repairs in polymethyl methacrylate. Aust Dent J. 1971;16(4):232–4. doi: 10.1111/j.1834-7819.1971.tb03412.x. [DOI] [PubMed] [Google Scholar]

- 13.Stanford JW, Burns CL, Paffenbarger GC. Self-curing resins for repairing dentures: some physical properties. J Am Dent Assoc. 1955;51(3):307–15. doi: 10.14219/jada.archive.1955.0193. [DOI] [PubMed] [Google Scholar]

- 14.Anusavice KJ, Phillips RW. 10th ed. Philadelphia: Saunders; 1996. Phillips Science of Dental Materials; pp. 33–47. [Google Scholar]

- 15.Rached RN, Del-Bel Cury AA. Heat-cured acrylic resin repaired with microwave-cured one: Bond strength and surface texture. J Oral Rehabil. 2001;28(4):370–5. doi: 10.1046/j.1365-2842.2001.00666.x. [DOI] [PubMed] [Google Scholar]

- 16.Nagai E, Otani K, Satoh Y, Suzuki S. Repair of denture base resin using woven metal and glass fiber: Effect of methylene chloride pretreatment. J Prosthet Dent. 2001;85(5):496–500. doi: 10.1067/mpr.2001.115183. [DOI] [PubMed] [Google Scholar]

- 17.Minami H, Suzuki S, Minesaki Y, Kurashige H, Tanaka T. In vitro evaluation of the influence of repairing condition of denture base resin on the bonding of autopolymerizing resins. J Prosthet Dent. 2004;91(2):164–70. doi: 10.1016/j.prosdent.2003.10.023. [DOI] [PubMed] [Google Scholar]

- 18.Memariana M, Shayestehmajd M. The effect of chemical and mechanical treatment of the denture base resin surface on the shear bond strength of denture repairs. Rev Clín Pesqui Odontol. 2009;5(1):11–7. [Google Scholar]

- 19.George R, D’Souza M. Surface chemical treatment with ethylacetate and repair of fractured denture base resins: An in-vitro analysis of transverse strengths. J Indian Prosthodont Soc. 2001;1:41–4. [Google Scholar]