Abstract

Background:

Impression materials during impression procedure often get infected with various infectious diseases. Hence, disinfection of impression materials with various disinfectants is advised to protect the dental team. Disinfection can alter the dimensional accuracy of impression materials. The present study was aimed to evaluate the dimensional accuracy of elastomeric impression materials when treated with different disinfectants; autoclave, chemical, and microwave method.

Materials and Methods:

The impression materials used for the study were, dentsply aquasil (addition silicone polyvinylsiloxane syringe and putty), zetaplus (condensation silicone putty and light body), and impregum penta soft (polyether). All impressions were made according to manufacturer’s instructions. Dimensional changes were measured before and after different disinfection procedures.

Result:

Dentsply aquasil showed smallest dimensional change (−0.0046%) and impregum penta soft highest linear dimensional changes (−0.026%). All the tested elastomeric impression materials showed some degree of dimensional changes.

Conclusion:

The present study showed that all the disinfection procedures produce minor dimensional changes of impression material. However, it was within American Dental Association specification. Hence, steam autoclaving and microwave method can be used as an alternative method to chemical sterilization as an effective method.

Keywords: Autoclave, chemical, dimensional changes, elastomeric, impression material, microwave

Introduction

Impression procedures are required for various dental procedures to make accurate casts of oral structures. During impression procedure, impression materials often come in contact with saliva and blood, which may get infected with infectious diseases such as AIDS, herpes, hepatitis, or tuberculosis. Hence, disinfection of impression materials is important as dentist, oral hygienist, and dental laboratory person often expose to infectious diseases.1-4 In 1998, FDI guidelines suggested that all impression materials should be disinfected before sending to laboratory.3 Even American Dental Association (ADA) and center for disease control suggested disinfection of impression materials to prevent cross infection.5 Disinfection can be done by either immersion or spraying impression materials with disinfectants.4 Disinfectants used should be as effective as antimicrobial agents, and not adversely affect the dimensional accuracy of impression material.1 Various disinfectants are advised for disinfecting impression materials such as, sodium hypochlorite, glutaraldehyde, iodophor, and phenol.1,5 According to the organization for safety and asepsis procedures, 10-15 min exposure of disinfectants is recommended.5 These chemicals can kill bacteria but not spores, hence sterilization by means of autoclaving and microwave methods are suggested. Autoclaving is one of the most effective methods of sterilization. Studies related to the accuracy of elastomeric impression materials after autoclaving is very scares.2,4 Addition silicone elastomeric impression materials (polyvinylsiloxane) are widely used because of their excellent dimensional accuracy with minimal distortion.4 It has been thought that disinfectants can alter the dimensional accurate of impression materials. Hence, the purpose of this study was to evaluate and compare the dimensional accuracy of elastomeric impression materials when treated with autoclave, microwave, and chemical disinfection.

Materials and Methods

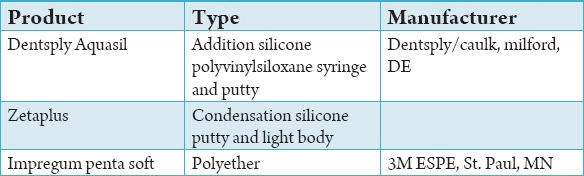

This study uses three different types of impression materials; dentsply aquasil (addition type), zetaplus (condensation type), and impregum penta soft (polyether type) (Table 1). 30 impressions with 10 for each group impression materials were made according to manufacturer’s instructions. The stainless steel die was used according to ADA specification no.19 and ISO International standard 4823 to fabricate specimens.4-6 The syringe material was dispensed directly from cartridge on surface, and the tray material was placed over light body material.

Table 1.

Elastomeric impression materials used in present study.

The mold consisted of a base was scored with 3 horizontal lines perpendicular to 2 vertical lines with each 0.050 mm wide. 3.8 mm internal diameter steel ring was positioned accurately on the base and perforated steel plate was used to apply pressure after loading elastomers. Initially, the metal ring was placed on the base of the mold fallowed by direct injection of light body material onto platform. Then tray material was mixed and loaded according to manufacturer instruction. Excess materials were removed through perforation. The specimens were allowed to set in thermostatically controlled water bath at 37°C to simulate oral condition. Total of 30 specimens with 10 for each group (materials) were fabricated. After fabricating the samples, the distance between the inner profiles of horizontal line was measured (0.005 mm) using microscope before and after subjecting to disinfection with autoclave (Group-1), chemical - 1% sodium hypochlorite (Group-2), and microwave (Group-3) methods by same examiner. Mean values were tabulated and analyzed using t-test and SPSS software IBM version 21. The percentage of dimensional change was assessed using formula; dimensional change % = (A-B)/A × 100, where “A” is distance between the inner profile of horizontal line before disinfection and “B” is after disinfection procedure.

Results

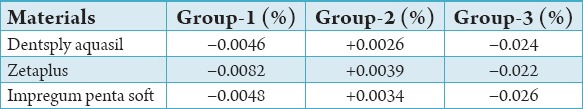

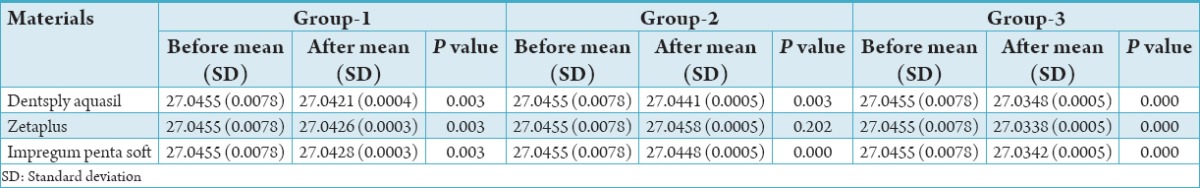

The Tables 2 indicates % of linear dimensional change of different elastomeric materials after different disinfection procedures dentsply aquasil showed smallest dimensional change (−0.0046%) and impregum penta soft highest linear dimensional changes (−0.026%). With chemical disinfection linear expansion occurred. Highest contraction occurred with microwave method compared to autoclave and chemical type. The Tables 3 indicates dimensional change of different elastomeric materials after different disinfection procedures. All the tested elastomeric impression materials showed some degree of dimensional changes (Table 3).

Table 2.

Linear dimensional changes (%) of impression materials after disinfection procedure.

Table 3.

Mean and standard deviation of elastomeric materials after disinfection.

Discussion

Accurate reproduction of surface details of the oral structure is must after impression making. Disinfection of impression materials is advised to avoid cross infection. Impression materials may show dimensional changes after disinfection. Chemical disinfection alone is insufficient hence autoclave at high temperature is necessary to kill microbes and their spores. Microwave sterilization is used as an alternative approach, where electromagnetic energy from the microwave is considered to be alternative to the conventional method.4 This study measures the dimensional changes of impression materials after chemical, autoclave, and microwave sterilization.

In the present study, microwaving method showed highest dimensional changes followed by autoclave method and chemical sterilization (Tables 2 and 3). This could be because of elastomer fluid intake in microwave method and dry nature of microwave. Results of our studies are similar to studies by Ramakrishnaiah et al. 2012 and Cynthia et al. 2003.4,7 Warden et al. from their study concluded that steam autoclaving of impression is a safe method of microbial reduction.8 Thota et al. from their study suggested that autoclave disinfection is effective for addition and condensation silicon, compare to polyether since polyether is hydrophilic which has to be disinfected by chemical means.2

Chemical disinfection produced minimal dimensional changes compared to other two methods. Tullner et al. observed no clinical significant dimensional changes with disinfection using 2% gluteraldehyde.9 Ivanis et al. (2000) concluded that polyether expanded with chlorhexidine 0.5% disinfection compared to addition and condensation type.10 Ahila and Subramanian. (2012) observed no significant dimensional changes after disinfecting impression materials with glutaraldehyde, povidone, and sodium hypochlorite.3 Katyayan et al. (2011) and Walker et al. (2007) concluded that dimensional changes of elastomer was within ADA specification after disinfection with phenol and 0.5% sodium hypochlorite.5,11 Similar results were observed by Guiraldo et al. (2012); Dorner et al. (2014); Garrofé et al. (2011).1,12,13

It has been observed that elastomer expand with chemical sterilization and contract with autoclave and microwave method.4 All of the tested impression materials were quite accurate before disinfection, but showed some degree of dimensional changes after disinfection. These dimensional changes is well below the ADA specification slandered <0.5%.

Conclusion

The present study showed that all the disinfection procedures produce minor dimensional changes of impression material. However, it is within ADA specification. Hence, steam autoclaving and microwave method can be used as an alternative method to chemical sterilization as an effective method.

Footnotes

Conflicts of Interest: None

Source of Support: Nil

References

- 1.Guiraldo RD, Borsato TT, Berger SB, Lopes MB, Gonini A, Jr, Sinhoreti MA. Surface detail reproduction and dimensional accuracy of stone models: influence of disinfectant solutions and alginate impression materials. Braz Dent J. 2012;23(4):417–21. doi: 10.1590/s0103-64402012000400018. [DOI] [PubMed] [Google Scholar]

- 2.Thota KK, Jasthi S, Ravuri R, Tella S. A comparative evaluation of the dimensional stability of three different elastomeric impression materials after autoclaving – An in vitro study. J Clin Diagn Res. 2014;8(10):ZC48–50. doi: 10.7860/JCDR/2014/9768.5036. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 3.Ahila SC, Subramanian E. Comparative evaluation of dimensional stability and surface quality of gypsum casts retrieved from disinfected addition silicone impressions at various time intervals: An in vitro study. J Dent Oral Hyg. 2012;4(4):34–43. [Google Scholar]

- 4.Ramakrishnaiah R, Kheraif AA, Qasim SS. The effect of chemical disinfection, autoclave, microwave sterilization on the dimensional accuracy of polyvinylsiloxane elastomeric impression materials. World Appl Sci J. 2012;17(1):127–32. [Google Scholar]

- 5.Walker MP, Rondeau M, Petrie C, Tasca A, Williams K. Surface quality and long-term dimensional stability of current elastomeric impression materials after disinfection. J Prosthodont. 2007;16(5):343–51. doi: 10.1111/j.1532-849X.2007.00206.x. [DOI] [PubMed] [Google Scholar]

- 6.Reports of Councils and Bureaus. Revised American Dental Association Specification No. 19 for Aqueous, Elastomeric Dental Impression Materials. 1878. Oct 4, [Last accessed on 2011 Jun 13]. Available from: http//www.132.248.225.10/posgrado/materials/normas/norma_19.pdf . [DOI] [PubMed]

- 7.Cynthia SP, Walker MP, O’mahony AM, Spencer P. Dimensional accuracy and surface detail reproduction of two hydrophilic vinyl polysiloxane impression materials tested under dry, moist, and wet conditions. J Prosthet Dent. 2003;90(4):365–72. doi: 10.1016/s0022-3913(03)00515-8. [DOI] [PubMed] [Google Scholar]

- 8.Warden J, Chorbaji Monzer R. Method of microbial reduction and/or sterilization of impression materials. Patent abstract of Japan. 1995 Feb 5; 07112910 A. [Google Scholar]

- 9.Tuller JB, Commette JA, Moon PC. Linear dimensional changes in dental impressions after immersion in different solutions. J Prosthet Dent 1988. 1998;60(6):725–8. doi: 10.1016/0022-3913(88)90407-6. [DOI] [PubMed] [Google Scholar]

- 10.Ivanis T, Zivko-Babie J, Lazie B, Pandurie J. Dimensional stability of elastomeric impression materials disinfected in a solution of 0.5% chlorhexidine gluconate and alcohol. Acta Stomatol Croat. 2000;34(1):11–4. [Google Scholar]

- 11.Katyayan PA, Kalavathy N, Katyayan M. Dimensional accuracy and detail reproduction of two hydrophilic vinyl polysiloxane impression materials tested under different conditions. Indian J Dent Res. 2011;22(6):881–2. doi: 10.4103/0970-9290.94697. [DOI] [PubMed] [Google Scholar]

- 12.Dorner AR, da Siva JM, Uemura ES, Borges AL, Fernandes Junior VV, Yamamto ET. Effect of disinfection of irreversible hydrocolloid impression materials with 1% sodium hypochlorite on surface roughness and dimesnsional accuracy of dental stone casts. Eur J Gene Dent. 2014;3(2):113–9. [Google Scholar]

- 13.Garrofé AB, Ferrari BA, Picca M, Kaplan AE. Linear dimensional stability of elastomeric impression materials over time. Acta Odontol Latinoam. 2011;24(3):289–94. [PubMed] [Google Scholar]