Abstract

Background

The current typical drying methods for red ginseng are sun drying and hot-air drying. The purpose of this study was to investigate drying characteristics of red ginseng by using far-infrared drying.

Methods

The far-infrared drying tests on red ginseng were conducted at two drying stages: (1) high temperature for 24 h drying and (2) low temperature drying until the final moisture content was 13 ± 0.5% (wet basis). The high temperature drying stage included three drying chamber temperature conditions of 60°C, 65°C, and 70°C. The low temperature drying stage was conducted at temperatures of 45°C and 50°C. Drying characteristics were analyzed based on factors such as drying rate, color changes, energy consumption, and saponin content. The results were compared with those of the hot-air and sun drying methods.

Results

The results revealed that increases in drying temperature caused a decrease in drying time and energy consumption for far-infrared drying. The saponin content decreased under all drying conditions after drying, the highest value (11.34 mg/g) was observed at drying conditions of 60∼50°C. The sun drying condition showed the lowest color difference value when compared with far-infrared and hot-air drying.

Conclusion

The far-infrared drying showed a faster drying rate, higher saponin content, lower color difference value, and a decrease in energy consumption than seen in hot-air drying.

Keywords: drying characteristics, drying rate, far-infrared drying, red ginseng, saponin content

1. Introduction

Red ginseng is a type of ginseng that belongs to the Asteraceae family. The main components of red ginseng are saponin, phenolic compounds, and antioxidants. It is widely distributed in Eastern China, Japan, and North and South Korea. It is used both in food and for medicinal purposes [1], [2]. The typical drying methods used for red ginseng are sun drying and hot-air drying. Sun drying is the most natural method as it simply uses sunlight and wind. However, this method is weather dependent and there is a high potential for decay of the drying materials. In addition, long drying periods can easily degrade the quality and nutritional properties of red ginseng causing changes in color and the destruction of nutrients. By contrast, hot-air drying has the potential advantage of shorter drying times than those for sun drying. However, hot-air drying needs additional resources, and heat transfer efficiency is low in terms of energy cost [3], [4]. When drying materials are exposed to hot-air for extended periods, their surfaces harden and shrink considerably due to rapid water loss, which affects factors such as color, texture, and restoring force of the drying materials [5]. Therefore, an efficient alternative method for drying red ginseng that has a shorter drying time, higher drying quality, and less energy consumption needs to be explored.

The far-infrared ray is an electromagnetic wave with a wavelength of 4–1,000 μm. Radiation energy penetrates objects and stimulates them at their resonance wavelength [6]. Therefore, Far-infrared drying has some advantages over convective hot-air drying, including high heat transfer efficiency, faster drying rate, and low energy cost [7]. Moreover, drying of agricultural products by far-infrared radiation accelerates drying rates and enhances the quality of the dried products. There are many widely reported studies on (1) the photosynthetic characteristics and component analysis of various types of ginseng, (it is known that Korean ginseng contains 34 types of saponins, with ginsenosides Rb1 and Rg1 typically present in the highest amount [8]); and (2) the analysis of vitamins and general components in the leaves of red ginseng [9]. However, little is known on the drying characteristics of red ginseng. Therefore, this study was undertaken to investigate the far-infrared drying characteristics of red ginseng, to determine the effect of two stages of drying temperature on the variability of drying quality, and finally to determine the optimal drying conditions for the far-infrared drying of red ginseng.

2. Materials and methods

2.1. Experimental materials

The red ginseng, used in this study was obtained from the Geumsan ginseng factory. The initial color values of red ginseng were as follows: lightness (38.94–46.33), redness (5.31–7.84) and yellowness (16.92–20.59). The initial moisture content of red ginseng was 35.2∼39.0% [wet basis (wb)].

2.2. Experimental apparatus

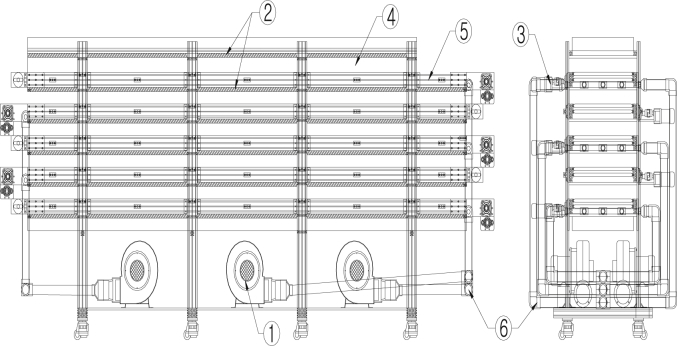

A schematic diagram of the experimental apparatus is shown in Fig. 1. The dimensions of the dryer used in this experiment were 5,500 × 1,800 × 900 mm [length (L) × height (H) × width (W)]. The dryer consisted of drying chamber [5,340 × 620 × 90 mm (L × H × W)], a far-infrared heater (MEP-550, Restoration, Korea), blast fan (DTB-402, belt conveyer, Dongkun Industrial Co. Ltd, Incheon, Korea), and a control box to control the belt speed, drying temperature of the far-infrared heater, and air velocity.

Fig. 1.

Schematic diagram of a far-infrared dryer: (1) blast fan, (2) far-infrared heater, (3) motor, (4) drying chamber, (5) belt conveyer, and (6) blast pipe.

2.3. Experimental procedure

Each drying condition used a 180-g sample of red ginseng for the experiment; samples were dried until the final moisture content was 13 ± 0.5% (wb). On the basis of results of the preliminary experiment, far-infrared drying was tested at the high temperature drying stage which included three drying chamber temperature conditions of 60°C, 65°C, and 70°C for 24 h drying, and at the low temperature drying stage which was conducted at temperatures of 45°C and 50°C and air velocities of 0.6 m/s, in order to increase the drying rate and prevent cracks and holes appearing on the surface and inside the ginseng. In this study, drying rate, surface color, energy consumption, and saponin contents were used as quality parameters for the dried red ginseng.

2.4. Analysis

2.4.1. Drying rate

The air-oven method was used to measure the initial moisture content. A sample of about 20 g of red ginseng was taken and dried in an experimental dryer (WFO-600ND, TokyoRi-kakai, Japan) at 105°C for 24 h. The moisture content was determined from the ratio of the weight changes before and after drying. The drying rate was represented by the moisture ratio. The moisture content that was measured at each drying time point was converted into the moisture ratio by using the following equations [10], [11]:

| (1) |

| (2) |

where Mt indicates moisture content at any drying time point and Me, M0, Mm, and Mf indicate equilibrium, initial, middle, and final moisture contents, respectively.

2.4.2. Surface color

The surface color of red ginseng was measured using a colorimeter (JX777, C.T.S. Co., Tokyo, Japan). Surface color was measured on the basis of lightness (L), redness (a) and yellowness (b) values from three parts of the red ginseng body before and after drying, six samples were used to measure the color values. Total color difference (ΔE) was calculated using the following equation [12], [13]:

| (3) |

where ΔE is total color difference and ΔL, Δa, and Δb are changes in lightness, redness, and yellowness, respectively, before and after drying.

2.4.3. Saponin measurement

Approximately 2 g of finely ground sample was extracted with 75% methanol and then dried after dissolution. The dried powder was mixed with 60 mL of ether solution. Any undissolved substance was removed before 50 mL of butanol was added. Subsequently, the extracted saponin solution was dried at 50°C, before being mixed with 10 mL of methanol. Finally the saponin content was analyzed using HPLC (2690, Waters, USA) [14], [15].

2.4.4. Antioxidant level

2.4.4.1. Preparation of red ginseng extract

Sample extraction was performed by placing approximately 5 g of finely ground sample with 100 mL of distilled water in a shaker for 24 h at room temperature. Subsequently, the extract was centrifuged at 10,000 rpm for 5 min, and supernatants were filtered through Toyo No. 2 filter paper. The filtrate was diluted with 100 mL of distilled water and then stored at −20°C until analysis [3].

2.4.4.2. Determination of total phenolic content

The samples were analyzed spectrophotometrically to quantify total phenolic content. The extracts (100 μL) were mixed with 2 mL of 2% Na2CO2, followed by 100 μL of 50% Folin-Ciocalteu reagent. After 3 min of reaction, absorbance was detected at 720 nm by using a UV visible spectrophotometer (UV-1650 PC; Shimadzu, Japan). These measurements were compared to a standard curve for gallic acid and were expressed as milligrams of gallic acid equivalents per gram of red ginseng [16].

2.4.4.3. Determination of antioxidant activity

Antioxidant activity was determined using the ABTS radical cation decolorization assay method described by Re et al [17]. The ABTS radical cation was generated by adding 7.4 Mm ABTS to 2.6 Mm potassium persulfate solution, the mixture was left to stand overnight in darkness at room temperature. The ABTS radical cation solution was diluted with distilled water to obtain an absorbance of 1.4–1.5 at 414 nm (molar extinction coefficient ε = 3.6 × 104 M−1·cm−1) [18]. The diluted ABTS radical cation solution (1 mL) was added to 50 μL of the extract and ascorbic acid standard solution. After 90 min, absorbance was measured at 414 nm by using the spectrophotometer. ABTS radical scavenging activity was expressed as AEAC.

| AEAC = (ΔA/ΔAaa) × ΔCaa × V × (100/W), | (4) |

where AEAC is milligrams of ascorbic acid equivalents per 100 g fresh weight of sample, ΔA is change in absorbance in the presence of sample extracts, ΔAaa is change in absorbance after the addition of ascorbic acid standard solution, Caa is concentration of ascorbic acid standard solution (mg/mL), V is sample extracts volume (mL), and W is sample weight (g).

2.5. Energy consumption

An energy monitor (Energy Monitor 2720, SOAR, Italy) was used to measure the energy consumption of the dryer. The energy consumption measured was converted into the energy required to evaporate 1 kg of water.

2.6. Statistical analysis

Statistical analysis was conducted using SAS version 8.2 (SAS Institute Inc., Cary, NC, USA). Differences among mean values of experimental data were determined using Duncan's multiple range test and one-way analysis of variance (ANOVA) with a significance level of 0.05.

3. Results and discussion

3.1. Drying curves

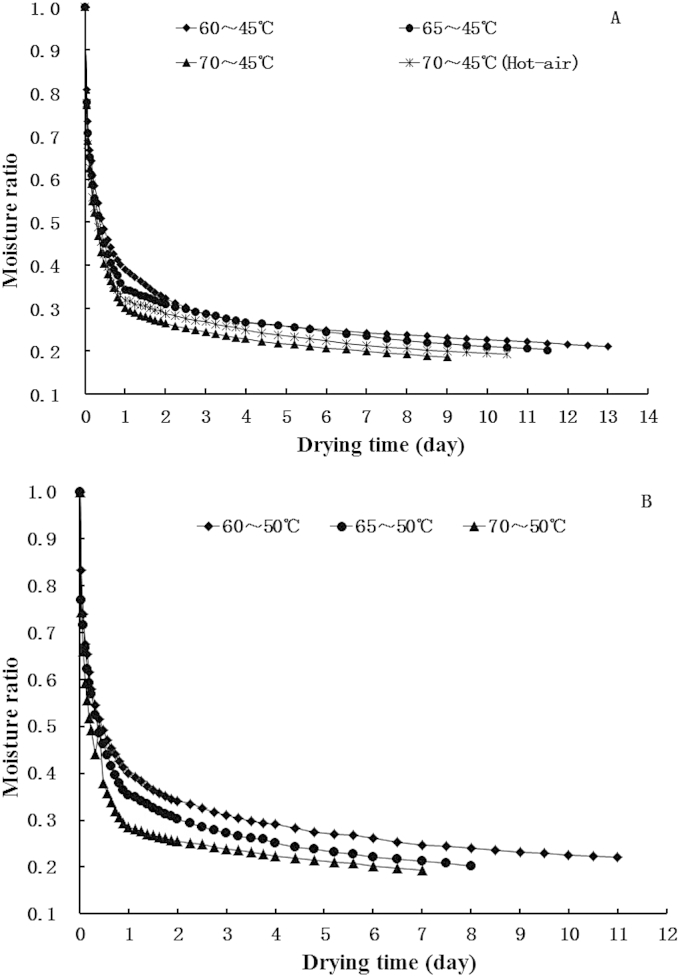

The moisture ratio with drying time is shown in Fig. 2. The drying times taken for red ginseng to reach the final moisture content required with drying conditions of 60∼45°C, 65∼45°C, and 70∼45°C were 13 d, 11.5 d, and 9 d, respectively. When the low drying stage temperature was increased to 50°C for each of these drying conditions, the drying times were 11 d, 8 d, and 7 d respectively. As expected for these drying curves, drying temperature had a pronounced effect on the drying rate of red ginseng. This demonstrated that an increase in drying temperature resulted in a decrease in drying time, which may be due to the increase of heat transfer between the air and the red ginseng, and the acceleration of water migration inside the ginseng [19]. A decrease in drying time with an increase in drying temperature has previously been observed by Kooli et al [20] for red pepper, by Li [4] for agricultural and fisheries products, and by Lee et al [21] for oak boxthorn. In addition, it was observed that the drying time of 70∼45°C for hot-air drying was 10.5 d, which was 1.5 d longer than that of far-infrared drying under the same conditions. In the case of hot-air drying, the heat efficiency is low, and heat was diffused into the drying matter by air convection, whereas, in the case of far-infrared drying, the rate is fast, the rate of heat loss is low, and heat efficiency is high. The quantity of radiation heat translation is significant as a result of direct heating of the drying matter [2], [6]. The drying efficiency for sun-drying is very low; the drying time was 58 d which was much longer than that of either far-infrared drying or hot air drying conditions.

Fig. 2.

Effect of drying temperature on moisture ratio.

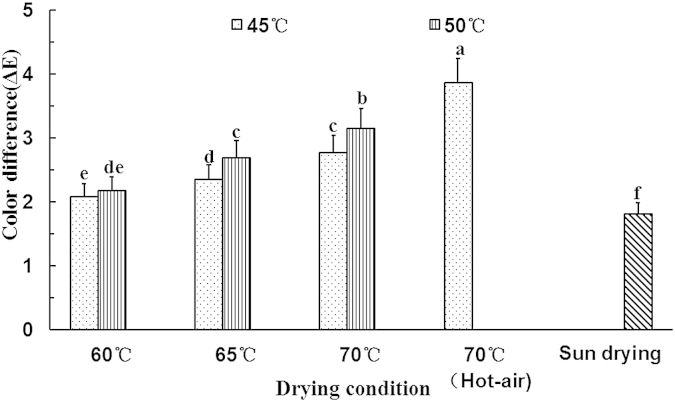

3.2. Determination of surface color

Fig. 3 shows the color changes in red ginseng before and after drying. At drying conditions of 60∼45°C, 65∼45°C, and 70∼45°C, total ΔE values were 2.08, 2.35, and 2.77 respectively. When the low drying stage temperature was 50°C, the total ΔE values were 2.18, 2.69, and 3.15 with drying conditions of 60∼50°C, 65∼50°C, and 70∼50°C, respectively. The ΔE seen at the 70°C values were higher than those seen at 65°C and 60°C values, and the ΔE seen at the 50°C values were higher than those seen at the 45°C values. This result indicates that drying temperature had a significant effect on color change in red ginseng (p < 0.05). Higher drying temperatures required shorter drying times and produced smaller color changes. These observations can be explained by the fact that the stability of pigments is reduced with increasing drying duration and temperature [22]. In the case of hot-air drying at the 70∼45°C drying condition, the ΔE value was 3.86, which was higher than that of the far-infrared drying under the same drying conditions.

Fig. 3.

Comparison of drying temperature and color difference value in red ginseng under different drying conditions. a∼f Means with different letters are significantly different by Duncan's multiple range test (p < 0.05). Vertical bars represent the standard errors of three replicates.

3.3. Saponin content of red ginseng

Table 1 shows saponin content in red ginseng before and after drying. The results show that the saponin content decreased after drying in all cases of far-infrared, hot-air, and sun drying. The key saponin compounds of ginseng are triol (Rh2, Re, Rf, Rh1, and Rg1) and diol (Rc, Rb3, Rg3, and Rb1). Drying temperature had a significant effect on the saponin content (p < 0.05). After drying, triol and diol saponin contents were detected within the ranges of 3.14∼6.00, and 3.67∼5.40 under all drying conditions. For the far-infrared drying, the total saponin content, 8.04 mg/g [dry weight (dw)], 7.82 mg/g (dw), and 8.49 mg/g (dw) were observed with drying conditions of 60∼45°C, 65∼45°C, and 70∼45°C, respectively. When the low drying stage temperature was increased to 50°C, the total saponin contents were 11.34 mg/g (dw), 9.52 mg/g (dw), and 7.19 mg/g (dw) with drying conditions of 60∼50°C, 65∼50°C, and 70∼50°C, respectively. These results suggest that the 50°C low temperature drying conditions showed higher saponin content than 45°C low temperature drying conditions except at the 70∼50°C drying condition. At the 70∼50°C drying condition, although the drying time was shorter, the drying temperature was higher which resulted in more destruction of saponin components than in the lower drying conditions. Similar results have also been reported by Ning and Han [2] for taegeuk ginseng, and by Li et al [23] for tissue cultured mountain ginseng roots. These findings suggested that low drying temperature is beneficial for maintaining high saponin content in red ginseng.

Table 1.

Effect of drying temperature on saponin content in red ginseng

| Drying conditions (°C) | Triol (mg/g) | Diol (mg/g) | Total saponin (mg/g)1) | |

|---|---|---|---|---|

| Raw materials | 6.93 | 5.51 | 12.44a | |

| Far-infrared drying | 60∼45 | 4.00 | 4.04 | 8.04 |

| 60∼50 | 5.94 | 5.40 | 11.34b | |

| 65∼45 | 4.14 | 3.67 | 7.82e | |

| 65∼50 | 4.72 | 4.80 | 9.52c | |

| 70∼45 | 4.08 | 4.39 | 8.49d | |

| 70∼50 | 3.14 | 4.05 | 7.19f | |

| Hot-air drying | 70∼45 | 4.33 | 3.91 | 8.24d,e |

| Sun drying | 6.00 | 5.05 | 11.05bc | |

Totals with different letters are significantly different by Duncan's multiple range test (p < 0.05)

In the case of hot-air drying at 70∼45°C, the saponin content was 8.24 mg/g, which was somewhat less than that in the case of far-infrared drying under the same drying condition. For sun drying, the saponin contents were 6.00 mg/g (dw) and 5.05 mg/g (dw) for the triol and diol compounds, respectively, and total saponin content was 11.05 mg/g (dw). These values were higher than those of far-infrared drying and hot air drying conditions. During sun drying the drying temperature was lower and therefore the destruction of saponin components was less than that of far-infrared drying and hot-air drying.

3.4. Antioxidant level

Table 2 shows the polyphenolic content in red ginseng after drying. The results show that drying temperature had a significant effect on polyphenolic content (p < 0.05). For the far-infrared drying, polyphenolic contents of (195.5∼245.8 mg/100 g, 179.8∼209.9 mg/100 g, and 248.2∼269.6 mg/100 g) were observed with increasing drying temperatures of 60°C, 65°C, and 70°C, respectively. These results suggest that an increase in drying temperature caused an increase in polyphenolic content. The polyphenolic contents for the hot-air drying and sun drying conditions were 299.1 mg/100 g and 187.1 mg/100 g respectively, the hot-air drying showed the highest value overall.

Table 2.

Effect of drying temperature on polyphenolic and antioxidant activity in red ginseng

| Drying conditions (°C) | Polyphenolics content (mg/100g)1) | ABTS (AEAC)/100g1) | |

|---|---|---|---|

| Far-infrared drying | 60∼45 | 195.5de | 158.7e |

| 60∼50 | 245.8c | 200.4b,c | |

| 65∼45 | 209.9d | 175.9d | |

| 65∼50 | 179.8e | 140.4b | |

| 70∼45 | 248.2c | 194.7c | |

| 70∼50 | 269.6b | 209.3b | |

| Hot-air drying | 70∼45 | 299.1a | 235.6a |

| Sun drying | 187.1e | 151.3e | |

Means with different letters are significantly different by Duncan's multiple range test (p < 0.05)

For antioxidant activity, a similar phenomenon was observed and is presented in Table 1. After drying, ABTS scavenging activities were detected within the ranges of 151.3∼235.6 mg (AEAC)/100 g under all drying conditions. The highest ABTS [235.6 mg (AEAC)/100 g] activity was observed at a drying temperature of 70°C by hot-air drying. Consistent with the results of the current study, increases in drying temperatures caused increases in antioxidant content and antioxidant activity. It is possible that due to a Maillard reaction which occurred during the high temperature drying process, bound polyphenol was changed into free polyphenol, new phenolic compounds were formed or converted macromolecular polyphenol compounds into low molecular polyphenol compounds, and some antioxidant substances was formed [24]. Similar results were reported by Yang et al [24], Li et al [25], and Ning and Han [2], in which an increase in the drying temperature resulted in an increase in the polyphenol content and antioxidant activity of ginseng.

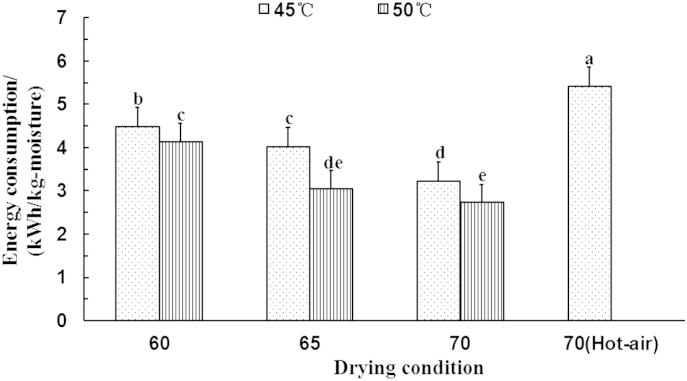

3.5. Energy consumption

Fig. 4 shows the energy consumption of red ginseng according to drying conditions. For the far-infrared drying, at drying conditions of 60∼45°C, 65∼45°C, and 70∼45°C, energy consumption was 4.48 kWh/kg-water, 4.01 kWh/kg-water, and 3.22 kWh/kg-water, respectively. When the low drying temperature was increased to 50°C, the energy consumption was 4.13 kWh/kg-water, 3.05 kWh/kg-water, and 2.73 kWh/kg-water with drying conditions of 60∼50°C, 65∼50°C, and 70∼50°C respectively. The far-infrared dryer requires minimal energy consumption (2.73 kWh/kg-water) at the drying condition of 70∼50°C. These results indicate that an increase in drying temperature resulted in a decrease in energy consumption, probably because higher temperatures facilitate the transfer of a significant amount of heat energy, which in turn increases the drying rate [2], [23]. For the hot-air drying at 45°C, energy consumption was 5.32 kWh/kg-water, this value was 2.10 kWh/kg-water and 65.2% higher than that of far-infrared drying under the same drying conditions. For far-infrared drying, the heat efficiency is high and the drying rate is faster than that of hot-air drying.

Fig. 4.

Comparison of energy consumption according to drying condition. a∼e Means with different letters are significantly different by Duncan's multiple range test (p < 0.05). The vertical bars represent the standard errors of three replicates.

4. Conclusion

The current study investigated the far-infrared drying characteristics of red ginseng in order to determine optimum drying conditions. The results revealed that by increasing drying temperature a faster drying rate was achieved, the antioxidant activity and polyphenol content increased, and energy consumption decreased. However, a high drying temperature produced a larger color difference value and a loss of saponin content in red ginseng. Sun drying showed good drying quality, but the drying efficiency was very low and the drying time was much longer than those of far-infrared drying and hot air drying conditions. Hot-air drying showed poorer drying quality than that of the far-infrared drying at the same drying temperature. On the basis of these results, it can be suggested that the drying temperature of ginseng should not exceed 60°C during the drying process. Far-infrared drying increases the capacity and quality of red ginseng.

Conflict of interest

The authors declare no conflicts of interest.

Acknowledgments

This study was supported by the Korea Chungbuk National University, basic research project (LZ2014032) from the Educational Department, Liaoning Province China, and the Scientific Research Foundation for Doctors from the Scientific and Technological Department, Liaoning Province China (20141056).

Footnotes

This is an Open Access article distributed under the terms of the Creative Commons Attribution Non-Commercial License (http://creativecommons.org/licenses/by-nc-nd/4.0) which permits unrestricted non-commercial use, distribution, and reproduction in any medium, provided the original work is properly cited.

References

- 1.Chung T.Y., Eiserich J.P., Shibamoto T. Volatile compounds isolated from edible Korean Chamchwi (Aster scaber Thunb) J Agric Food Chem. 1993;41:85–91. [Google Scholar]

- 2.Ning X.F., Han C.S. Drying characteristics and quality of taegeuk ginseng (Panax ginseng C.A. Meyer) using far-infrared rays. Int J Food Sci Tech. 2013;48:477–483. [Google Scholar]

- 3.Choi Y.M., Jeong H.S., Lee J.S. Antioxidant activity of methanolic extracts from some grains consumed in Korea. Food Chem. 2007;103:130–138. [Google Scholar]

- 4.Li H. ChungBuk National University; Cheongju, South Korea: 2009. Drying and quality characteristics of agricultural and fishery products using far infrared rays. [PhD thesis] [Google Scholar]

- 5.Lee M.K., Kim S.H., Lee S.Y., Chung C.K., Kang I.J., Oh D.H. The effect of far infrared ray-vacuum drying on the quality changes of pimpinella bracycarpa. J Korean Soc Food Nutr. 2000;29:561–567. [Google Scholar]

- 6.Kang T.H., Hong H.K., Jeon H.Y., Han C.S. Drying characteristics of squids according to far infrared and heated air drying conditions. J Biosyst Eng. 2011;36:109–115. [Google Scholar]

- 7.Sakai C., Hanzawa T. Application and advances in far infrared heating in Japan. Trends Food Sci Tech. 1994;5:357–362. [Google Scholar]

- 8.Lee C.R., Wang W.K., Shin C.G., Ko S.K. Comparison of ginsenoside composition and contents in fresh ginseng roots cultivated in Korea, Japan, and China at various ages. Korean J Food Sci Tech. 2004;36:847–850. [Google Scholar]

- 9.Shin K.H., Lee S.H., Cho D.H., Park C.H. Analysis of vitamins and general components in the leaves of chwinamul. Korean J Plant Res. 1998;11:163–167. [Google Scholar]

- 10.Altan A., Maskan M. Microwave assisted drying of short-cut (ditalini) macaroni: drying characteristics and effect of drying processes on starch properties. Food Res Inter. 2005;38:787–796. [Google Scholar]

- 11.Ning X.F., Han C.S., Li H. A mathematical model for color changes in red pepper during far infrared drying. J Biosyst Eng. 2012;37:327–334. [Google Scholar]

- 12.Feng H., Tang J. Microwave finish drying of diced apples in a spouted bed. J Food Sci. 2006;63:679–683. [Google Scholar]

- 13.Lee S.K., Park W.J., Kim W., Kang M.H., Jeon M.J., Paik S.W., Han J.W. Analysis of the drying characteristics of Lycii fructus with drying plates. J Biosyst Eng. 2010;35:250–256. [Google Scholar]

- 14.William A.C., John G.H., Jama E. Reversed phase high performance liquid chromatographic determination of ginsenosides of Panax quinquefolium. J Chromatography A. 1996;755:11–17. [Google Scholar]

- 15.Ha T.S., Choi J.Y., Park H.Y., Nam J.A., Seong S.B. Ginseng total saponin modulates the changes of α-action-4 in podocytes induced by diabetic. J Ginseng Res. 2014;38:233–238. doi: 10.1016/j.jgr.2014.05.004. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Liu H.Y., Qiu N.X., Ding H.H., Yao R.Q. Polyphenols contents and antioxidant capacity of 68 Chinese herbals suitable for medical or food uses. Food Res Inter. 2008;41:363–370. [Google Scholar]

- 17.Re R., Pellegrini N., Proteggente A., Pannala A., Yang M., Rice-Evans C. Antioxidant activity applying an improved ABTS radical cation decolorization assay. Free Radic Biol Med. 1999;26:1231–1237. doi: 10.1016/s0891-5849(98)00315-3. [DOI] [PubMed] [Google Scholar]

- 18.Forni L.G., Mora-Arellano V.O., Packer J.E., Willson R.L. Nitrogen dioxide and related free radicals: Electron-transfer reactions with organic compounds in solutions containing nitrite or nitrate. J Chem Soc. Perkin Trans. 1986;2:1–6. [Google Scholar]

- 19.Sacilik K., Elicin A.K. The thin layer drying characteristics of organic apple slices. J Food Eng. 2006;73:281–289. [Google Scholar]

- 20.Kooli S., Fadhel A., Farhat A., Belghith A. Drying of red pepper in open sun and greenhouse conditions.: mathematical modeling and experimental validation. J Food Eng. 2007;9:1094–1103. [Google Scholar]

- 21.Lee S.K., Kim W., Kim H., Han J.W. Determination of boxthorn drying conditions and using agricultural dryer. J Biosyst Eng. 2011;36:273–278. [Google Scholar]

- 22.Gálvez A.V., Mondaca R.L., Sáinz C.B., Fito P., Andrés A. Effect of air drying temperature on the quality of rehydrated dried red bell pepper (var. Lamuyo) J Biosyst Eng. 2008;85:42–50. [Google Scholar]

- 23.Li H., Kwang T.H., Ning X.F., Cho S.C., Han C.S. Far infrared rays drying characteristics of tissue cultured mountain ginseng roots. J Biosyst Eng. 2009;34:175–182. [Google Scholar]

- 24.Yang S.J., Woo K.S., Yoo J.S., Kang T.S., Noh Y.H., Lee J.S., Jeong H.S. Change of Korean ginseng components with high temperature and pressure treatment. Korean J Food Sci Tech. 2006;38:521–525. [Google Scholar]

- 25.Li H., Choi Y.M., Yeon K.S., Han C.S. Drying and antioxidant characteristics of the shiitake mushroom in a conveyer-type far-infrared dryer. J Korean Soc Food Sci Nut. 2007;36:250–254. [Google Scholar]