Abstract

Clear thermoplastic retainers have been widely used in daily orthodontics; however, they have inherent limitations associated with thermoplastic polymer materials such as dimensional instability, low strength, and poor wear resistance. To solve these problems, we developed a new type of clear orthodontic retainer that incorporates multi-layer hybrid materials. It consists of three layers; an outer polyethylenterephthalate glycol modified (PETG) hard-type polymer, a middle thermoplastic polyurethane (TPU) soft-type polymer, and an inner reinforced resin core. The resin core improves wear resistance and mechanical strength, which prevent unwanted distortion of the bucco-palatal wall of the retainer. The TPU layer absorbs impact and the PETG layer has good formability, optical qualities, fatigue resistance, and dimensional stability, which contributes to increased support from the mandibular dentition, and helps maintain the archform. This new type of vacuum-formed retainer showed improved mechanical strength and rate of water absorption.

Keywords: Polyethylenterephthalate glycol modified, Retention, Thermoplastic, Thermoplastic polyurethane

INTRODUCTION

The vacuum-formed retainer (VFR) is one of the most common types of orthodontic retainers, and is preferred by patients because of its excellent esthetic characteristics, simplicity of use, superior formability, maintenance of good oral hygiene, and lesser discomfort compared to the Hawley retainers.1,2,3 However, from a clinical perspective, VFRs have major limitations related to their material properties. Thermoplastic retainers show poor wear resistance and durability along the incisal and occlusal surfaces with subsequent cracking after only a few months of use.4,5,6 To overcome these disadvantages, we designed a new VFR composed of multi-layer hybrid materials and performed mechanical tests to determine its physical characteristics.

APPLIANCE DESIGN

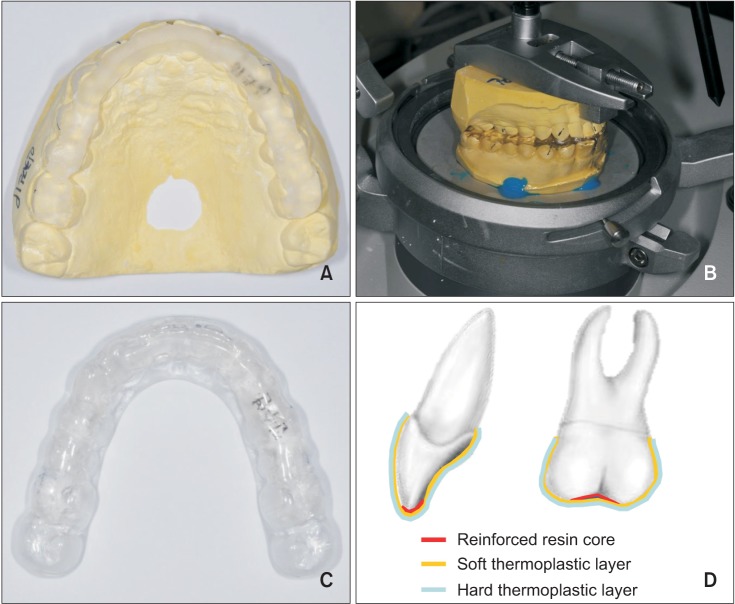

The new type of multi-layer VFR was fabricated as follows. The innermost layer consisted of a reinforced resin core that covered the incisal and lingual sides of the anterior teeth and occlusal surfaces (central fossa area) of the posterior teeth. The thickness of the resin core did not exceed 1 mm in the first molar area. The middle layer was made up of thermoplastic polyurethane (TPU) soft-type thermoplastic material, and the outer layer, which was made up of hard-type thermoplastic material (polyethylenterephthalate glycol modified, PETG), covered all the buccal, occlusal and palatal surface of upper arches (Figure 1). The resin core showed good mechanical retention with thermoplastic polymers, and delamination did not occur between layers. The total thickness of the appliance was less than 3 mm. Three-point occlusal contact with mandibular dentition was accomplished during the thermoforming procedure; therefore, minimal final adjustment of occlusion at the chair side was required.

Figure 1. The fabrication process of multi-layer vacuum-formed retainers (VFRs). A, Inner reinforced resin core. B, Connection with thermoplastic dual layers. Threepoint occlusal contact is achieved during the vacuum forming procedure. C, Final product. D, Schematic diagram of multi-layer VFRs.

MECHANICAL TESTS

Tensile test

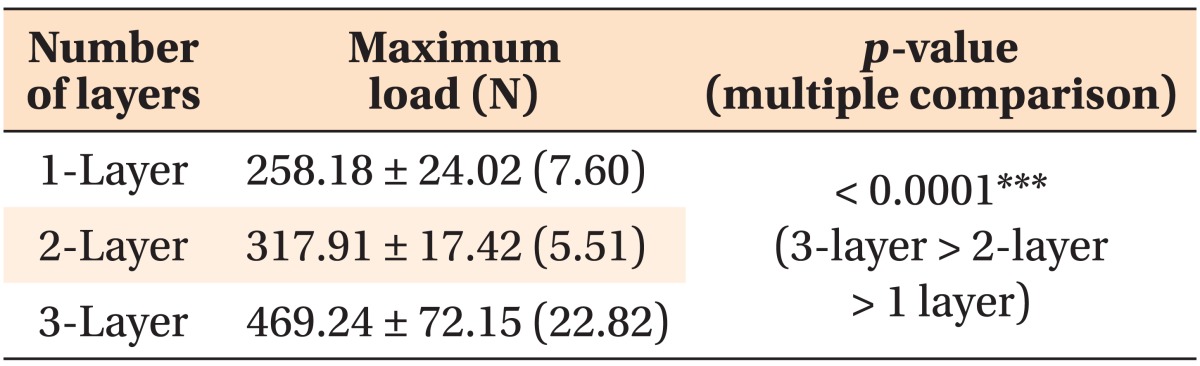

Ten rectangular specimens (length = 40 mm, width = 5 mm) were prepared for each group according to the number of layers; single- (1.0 mm, Track A; Forestadent, Pforzheim, Germany) and double-layer (2.0 mm, Track B; Forestadent) products available on the market were tested along with the newly designed three-layer retainer. The tensile test was performed using a universal mechanical testing instrument Instron 3367 (Instron Co., Norwood, MA, USA) with a load cell of 3 kN. Maximum tensile load with a loading rate of 1.5 mm/min was measured at room temperature. The data from mechanical test were analyzed using Bluehill® Lite version 2.0 software (Instron Co.). Comparisons between the specimens were performed by one-way analysis of variance (ANOVA) and Schéffe's test. The maximum tensile load increased with the increasing number of layers, and the three-layer specimen group yielded a significantly greater mean value (469 N) compared to the other groups (single-layer, 258 N; double-layer, 318 N; p < 0.001, Table 1).

Table 1. Tensional loading test according to the number of layers.

Values are presented as mean ± standard deviation (standard error).

One-way analysis of variance and multiple comparisons using Duncan test were performed.

***p < 0.001.

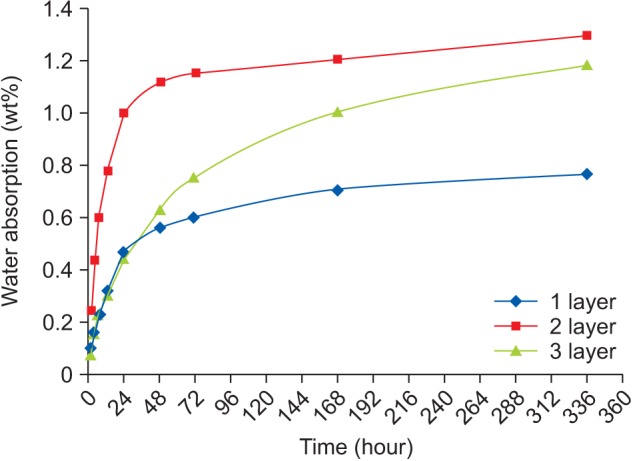

Water absorption test

Five circular specimens (diameter 5 cm) were prepared for each group according to the number of layers. The specimens were stored in a desiccator until they reached a constant weight (M1), and then immersed in distilled water at 37.8℃. After the beginning of immersion, the weight (M2) of each specimen was measured at 1, 3, 6, 12, 24, 48, 72, 168, and 336 hours. The water absorption rate was calculated as (M2-M1) × 100/M1 (wt%).7 Comparisons of water absorption rates at 336 h between groups were evaluated using the Kruskal-Wallis test. Figure 2 shows the changes in water absorption rates for up to 2 weeks. Water absorption of all specimen groups increased with time, and the double-layer specimen group showed the highest water absorption at all time points. The single-layer specimen group had the lowest water absorption value, with a rate of 0.77 wt% after 336 hours. The three-layer specimen group showed water absorption rates similar to that of the single-layer specimen group up to 24 hours, and gradually increased. The water absorption rates after 336 hours was significantly different between groups (p < 0.001).

Figure 2. The change in water absorption rates for up to 2 weeks according to the number of layers in the vacuum-formed retainers.

DISCUSSION

Various types of polymers have been used for VFRs, and they have different wear resistance and durability characteristics according to their molecular structure. Generally, polymers used in orthodontic fields are divided into amorphous polymers, including polycarbonate, PETG, and polyurethane (Invisalign; Align Technology, Inc., San Jose, CA, USA), and partly crystalline polymers, including polypropylene, polyethylene, and ethylene vinyl acetate.7 The mechanical properties of these thermoplastic polymers during real-world usage are not same as those provided by the manufacturers, because they are affected by environmental factor during intraoral use; the changes in surface characteristics are accelerated after intraoral exposure. Therefore, to ensure maintenance of the final treatment outcome through the retention periods, a critical understanding of the mechanical properties of the different thermoplastic materials is essential.

Our newly designed multi-layer retainer consists of three layers; an outer PETG hard thermoplastic layer, middle TPU soft thermoplastic layer, and an inner reinforced resin core. The resin core shows good wear resistance, mechanical strength and dissipates the occlusal force, which prevents unwanted distortion of the buccopalatal lateral wall during fitting and use. TPU is a ductile elastomer, which aids in improving elasticity,8,9 and absorbs impact while providing good wear sensation. The outer layer, PETG has good formability, optical qualities, fatigue resistance, and dimensional stability,10 which contributes to increased support from the mandibular dentition, and helps maintain the archform.

The primary mechanism of surface changes after intraoral exposure is hydrolytic degradation.11,12 The polymer material absorbs water, which induces polymer swelling and dimensional change, and eventually, its backbone chain is irreversibly degraded by hydrolysis.11 Therefore, the ideal thermoplastic materials for VFRs should have low water absorption properties. Generally, as the number of layers in the VFR increases, the water absorption rate is expected to increase. However, in our study, the water absorption rate of three-layer VFRs was lesser than that of the double-layer VFRs at all time points, and at 24 hours, it was similar to that of single-layer VFRs.

The retainer is subjected to long-term loading forces exerted intermittently during meals. A low level of resistance against fracture and wear due to its mechanical properties is the most critical limitation of VFRs during daily use.13 These deficiencies result from the susceptibility of thermoplastic polymers to environmental factors such as heat, humidity, and moisture.7,14 In addition, thermoforming procedures and intraoral uses have marked effects on their mechanical properties. In our study, multi-layer VFRs showed a significantly increased maximum load in the tensile test. We propose that this improved mechanical strength could result in better wear resistance and durability. In our cases with bruxism, the multi-layer VFRs were in good condition after 1-year use (Figure 3). In particular, the bucco-palatal lateral wall was not flared or distorted, and maintained good dimensional stability. Further studies should focus on the long-term clinical applications of these new and improved VFRs. We expect that this design can be widely applied not only to orthodontic retainers and aligners but also to other removable dental appliances such as splints, mandibular advancement devices, night guards, and bleaching trays.

Figure 3. Clinical application of the multi-layer vacuum-formed retainer (VFR) in a patient with bruxism. A, Debonding (delivery of the multilayer VFR). B, One-year after retention. The form and function of the VFR was well maintained.

CONCLUSIONS

Newly designed multi-layer VFRs that are composed of a reinforced resin core and hard/soft dual thermoplastic polymers showed improved mechanical strength and water absorption rate. This new type of VFR has the potential to overcome the limitations of conventional clear thermoplastic retainers.

ACKNOWLEDGEMENTS

The authors want to special thanks to Mr Hye-Woong Kim, Head Technician, Department of Orthodontics, School of Dentistry, Kyung Hee University, Seoul, Korea for supporting research data and technical assistance during manuscript preparation.

Footnotes

This research was supported by Basic Science Research Program through the National Research Foundation of Korea (NRF) funded by the Ministry of Science, ICT & Future Planning (NRF-2014R1A1A1038263).

The authors report no commercial, proprietary, or financial interest in the products or companies described in this article.

References

- 1.Mai W, He J, Meng H, Jiang Y, Huang C, Li M, et al. Comparison of vacuum-formed and Hawley retainers: a systematic review. Am J Orthod Dentofacial Orthop. 2014;145:720–727. doi: 10.1016/j.ajodo.2014.01.019. [DOI] [PubMed] [Google Scholar]

- 2.Rosvall MD, Fields HW, Ziuchkovski J, Rosenstiel SF, Johnston WM. Attractiveness, acceptability, and value of orthodontic appliances. Am J Orthod Dentofacial Orthop. 2009;135:276.e1–276.e12. doi: 10.1016/j.ajodo.2008.09.020. [DOI] [PubMed] [Google Scholar]

- 3.Demir A, Babacan H, Nalcacı R, Topcuoglu T. Comparison of retention characteristics of Essix and Hawley retainers. Korean J Orthod. 2012;42:255–262. doi: 10.4041/kjod.2012.42.5.255. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Sun J, Yu YC, Liu MY, Chen L, Li HW, Zhang L, et al. Survival time comparison between Hawley and clear overlay retainers: a randomized trial. J Dent Res. 2011;90:1197–1201. doi: 10.1177/0022034511415274. [DOI] [PubMed] [Google Scholar]

- 5.Raja TA, Littlewood SJ, Munyombwe T, Bubb NL. Wear resistance of four types of vacuum-formed retainer materials: a laboratory study. Angle Orthod. 2014;84:656–664. doi: 10.2319/061313-448.1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 6.Lindauer SJ, Shoff RC. Comparison of Essix and Hawley retainers. J Clin Orthod. 1998;32:95–97. [PubMed] [Google Scholar]

- 7.Hiromi R, Yoshikazu M, Akihiro F, Takashi M, Koutaro M. The mechanical properties of dental thermoplastic materials in a simulated intraoral environment. J Orthod Waves. 2006;65:64–72. [Google Scholar]

- 8.Frick A, Rochman A. Characterization of TPU-elastomers by thermal analysis (DSC) Polym Test. 2004;23:413–417. [Google Scholar]

- 9.Lu QW, Macosko CW. Comparing the compatibility of various functionalized polypropylenes with thermoplastic polyurethane (TPU) Polymer. 2004;45:1981–1991. [Google Scholar]

- 10.Dupaix RB, Boyce MC. Finite strain behavior of poly(ethylene terephthalate) (PET) and poly (ethylene terephthalate)-glycol (PETG) Polymer. 2005;46:4827–4838. [Google Scholar]

- 11.Boubakri A, Haddar N, Elleuch K, Bienvenu Y. Impact of aging conditions on mechanical properties of thermoplastic polyurethane. Mater Des. 2010;31:4194–4201. [Google Scholar]

- 12.Nair LS, Laurencin CT. Biodegradable polymers as biomaterials. Prog Polym Sci. 2007;32:762–798. [Google Scholar]

- 13.Schuster S, Eliades G, Zinelis S, Eliades T, Bradley TG. Structural conformation and leaching from in vitro aged and retrieved Invisalign appliances. Am J Orthod Dentofacial Orthop. 2004;126:725–728. doi: 10.1016/j.ajodo.2004.04.021. [DOI] [PubMed] [Google Scholar]

- 14.Göpferich A. Mechanisms of polymer degradation and erosion. Biomaterials. 1996;17:103–114. doi: 10.1016/0142-9612(96)85755-3. [DOI] [PubMed] [Google Scholar]