Fluid catalytic cracking (FCC) is one of the major conversion technologies in the oil refinery industry, and the largest commercial catalytic process that uses zeolite materials.

Fluid catalytic cracking (FCC) is one of the major conversion technologies in the oil refinery industry, and the largest commercial catalytic process that uses zeolite materials.

Abstract

Fluid catalytic cracking (FCC) is one of the major conversion technologies in the oil refinery industry. FCC currently produces the majority of the world's gasoline, as well as an important fraction of propylene for the polymer industry. In this critical review, we give an overview of the latest trends in this field of research. These trends include ways to make it possible to process either very heavy or very light crude oil fractions as well as to co-process biomass-based oxygenates with regular crude oil fractions, and convert these more complex feedstocks in an increasing amount of propylene and diesel-range fuels. After providing some general background of the FCC process, including a short history as well as details on the process, reactor design, chemical reactions involved and catalyst material, we will discuss several trends in FCC catalysis research by focusing on ways to improve the zeolite structure stability, propylene selectivity and the overall catalyst accessibility by (a) the addition of rare earth elements and phosphorus, (b) constructing hierarchical pores systems and (c) the introduction of new zeolite structures. In addition, we present an overview of the state-of-the-art micro-spectroscopy methods for characterizing FCC catalysts at the single particle level. These new characterization tools are able to explain the influence of the harsh FCC processing conditions (e.g. steam) and the presence of various metal poisons (e.g. V, Fe and Ni) in the crude oil feedstocks on the 3-D structure and accessibility of FCC catalyst materials.

1. Introduction

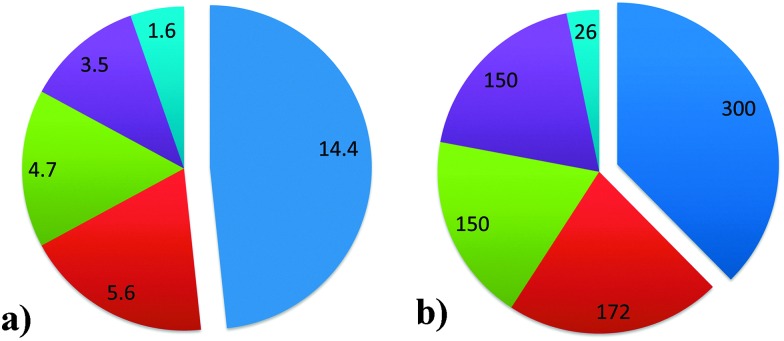

Fluid catalytic cracking (FCC) is one of the major conversion technologies in the oil refinery industry and produces the majority of the world's gasoline. The process is in operation at over 300 out of a total of 646 refineries, as of the beginning of 2014. It is important to note that FCC is not the only conversion process used in oil refineries, as there are also e.g. hydrocracking units. Fig. 1 provides an overview of the different conversion processes in use in oil refineries as of the beginning of 2014, expressed as both the number of barrels of crude oil processed per day and the number of refineries utilizing the processes.1 A number of oil refineries use multiple conversion technologies, and some refineries even have more than one FCC unit. Apart from producing gasoline, the FCC unit is also a major producer of propylene and, to a lesser extent, raw materials for petrochemical processes.

Fig. 1. (a) Installed capacities for the major conversion processes in refineries worldwide, in million barrels per day. (b) Number of refineries in which major conversion processes are installed. Refineries can have more than one technology installed. Data as of 2013, from ref. 1. Color-coding: fluid catalytic cracking (FCC): blue; hydrocracking: red; coking: green; thermal operations: purple; and resid hydrotreating: light blue.

It is estimated that ∼2300 metric tons of FCC catalyst are produced per day,2 or ∼840 000 metric tons per year.

This implies that, on average, approximately 0.16 kg of FCC catalysts are used for the conversion of a barrel of feedstock. This equals about 0.35 lbs per bbl, in units more conventionally used in the field, making use of vacuum gas oil (VGO). Heavier feedstocks, such as resid, require more catalyst material (0.4 lbs per bbl) while lighter feedstocks, such as heavy gas oil (HGO), require less catalyst (∼0.15 lbs per bbl).2 The leading worldwide FCC catalyst producers are W. R. Grace, Albemarle and BASF, while local producers like CCIC in Japan and Sinopec and Petrochina in China have smaller market shares.

In this review article, we will demonstrate that, in spite of the fact that FCC has been practiced for almost 75 years already, the field is still very active and still central in many research activities of both academia and industry. New developments in the availability of feedstocks, such as shale oil and gas and tight oil, the quest to increase the use of renewable resources, as well as changes in the demand for gasoline, result in a desire to change the selectivity of the FCC process. This development has led to a renewed interest in new molecular sieves, zeolites with hierarchical pore structure, and stabilization of the zeolites used in FCC. At the same time a rapid development in analytical tools has recently led to a substantial increase in the fundamental understanding of the integral FCC catalyst particle at sub-micrometer resolution. Reports on new spectroscopic tools used in the analysis of FCC catalyst materials are published in rapid succession. All in all, research in the field of FCC, the grand old lady of zeolite catalysis, is very much alive.

2. Fluid catalytic cracking: some background

2.1. A short history

Commercial production of petroleum dates back to 1859, when Colonel Edwin L. Drake found “rock oil” in Titusville (PA, USA). The initial petroleum products were refined in very simple refineries without conversion capability. At the beginning of the 20th century, the number of cars propelled by an internal combustion engine sharply increased, and a shortage of gasoline developed.

Thermal cracking, in which the unused fractions in the higher boiling range were converted to gasoline-range molecules, was first introduced in 1913, by Burton at Standard Oil of Indiana.3,4 However, the gasoline produced by this process was of relatively poor quality. Additives like tetra-ethyl lead, discovered in the 1920's by Midgley, could improve the “octane number” of gasoline,5 but other solutions were required. The first technical embodiment of catalytic cracking was introduced in 1915, when McAfee at Gulf Refining Company developed a catalyst based on aluminum chloride.6 However, this process was not economically feasible,7 and was abandoned.

In the 1920's, French engineer Houdry experimented with the conversion of lignite to useful products, and found that clay minerals could convert his lignite-based oil to a fuel similar to gasoline.3,8 This was the advent of catalytic cracking as we know it today. Houdry moved to the USA and developed his process with the Socony-Vacuum Oil company (which later became Mobil Oil Company), and eventually the first catalytic cracker operating the Houdry process, which processed 15 000 barrels of petroleum per day, was started up in 1936 in Paulsboro (NJ, USA). The first full-scale commercial plant went on-stream in 1937 at Sun Oil's refinery in Marcus Hook (PA, USA).8 The catalyst was replaced by a synthetic silica-alumina already in the early 1940's, and the process, which produced very high quality fuels, was very quickly developed to produce aviation fuel for the allied war effort in the Second World War. The original Houdry process made use of a fixed bed reactor.

In 1938, a consortium called Catalytic Research Associates (originally Standard Oil of New Jersey, Standard Oil of Indiana, M. W. Kellogg Co., and I. G. Farben) set out to develop a new cracking process.9 At the beginning of the 2nd World War, I. G. Farben was dropped from the Consortium, and Anglo-Iranian Oil Co. Ltd, Royal Dutch-Shell Co., The Texas Co. and Universal Oil Products Co. (UOP) joined. A pilot plant based on a powdered catalyst moving through a pipe coil reactor and a regenerator was built in Baton Rouge (LA, USA). The 100 barrels per day unit was called PECLA-1 (Powdered Experimental Catalyst, Louisiana). In about a year, the system was developed to commercial stage, and mid-1942, the first commercial FCC unit (PCLA-1) was started up.9,10 This system was based on an up-flow reactor and regenerator11 and used a clay-based catalyst.9 It was based on work of Lewis and Gilliland,12 working with Standard Oil Company of New Jersey, who suggested that a low velocity gas flow through a powder might “lift” it enough to cause it to flow in a manner similar to a liquid.13

The system was extremely successful, and with ongoing developments,14 at the end of the war, 34 FCC units were in operation in the USA. PCLA No. 3, which was the second unit at Baton Rouge, was started up in June, 1943. This unit is still in operation today, and is the oldest operating FCC unit, as the PCLA-1 unit was shut down in 1963.

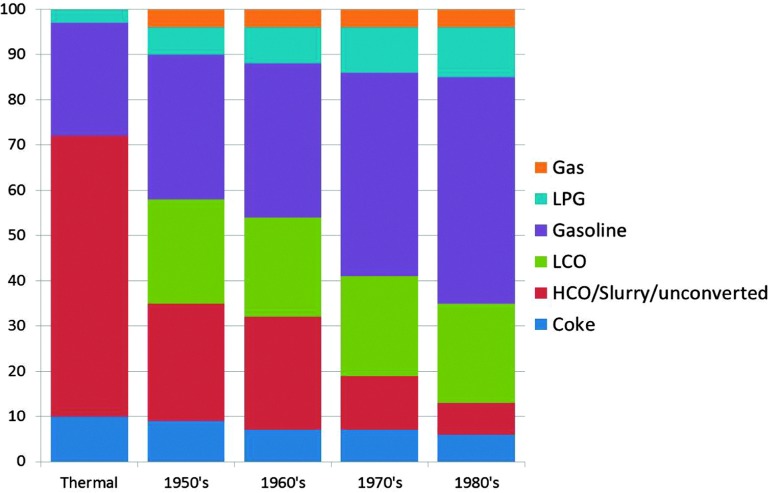

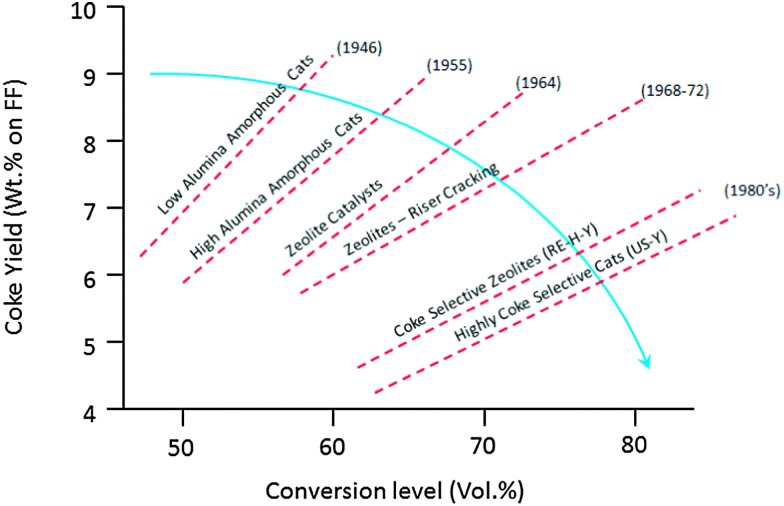

As mentioned before the initial FCC process used clay-based catalysts. Improvements were soon made, and synthetic amorphous SiO2–Al2O3 or SiO2–MgO-based catalysts were developed already in the 1940's.17 The reason for this was an improved selectivity to the desired products,18 as can be observed in Fig. 2 using data from ref. 15 and 16. The graph shows a combined effect of activity increase and selectivity improvement.

Fig. 2. The effect of improving reactor and catalyst technology on the product selectivity for the FCC process for four decades in the 1900's. Color-coding: gas: orange; LPG: light blue; gasoline: purple; LCO: green; HCO/slurry/unconverted: red; and coke: dark blue. Data are obtained from ref. 15 and 16.

In the early 1960's and 1970's, synthetic crystalline microporous aluminosilicates (i.e. zeolites) were invented at the laboratories of Union Carbide and Mobil Oil Corporation. The first of these relevant to FCC was synthetic faujasite (IUPAC structure code FAU19), or zeolite Y (Linde Y), invented by Breck at Union Carbide.20 Zeolite Y in various improved forms has been the main cracking component of FCC catalysts since 1964.21 The initial embodiment was Mg-stabilized, while the currently used rare earth (RE)-stabilized zeolite Y was introduced fairly quickly after that.21 A second zeolite that has found large-scale application in FCC is zeolite ZSM-5 (IUPAC structure code MFI19), which was invented in 1973 by Argauer and Landolt at Mobil Oil Corporation.22 The main application of zeolite ZSM-5 has been in FCC operation targeting an increased propylene yield. Fig. 2 clearly shows that the introduction of zeolite materials in FCC catalyst formulations resulted in a drastic increase in the gasoline yield in the 1970s and 1980s. The books by Venuto and Habib23 and Scherzer24 give good accounts of the history and backgrounds of the FCC process up to the 1980's.

2.2. Process and reactor design

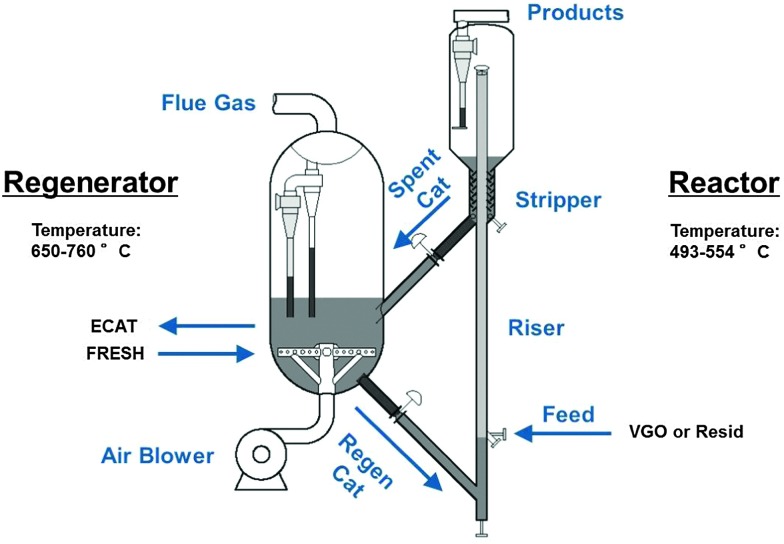

Although a number of different designs exist for the FCC process,25,26 a number of general principles can be described on the basis of Fig. 3. FCC, or at least the cracking reaction, is an endothermic process. The heat required for cracking is produced by sacrificing a small portion of the feedstock, and burning it in the regenerator.

Fig. 3. Schematic depiction of the fluid catalytic cracking (FCC) process, including reactor and regenerator.

Hot catalyst material is combined with pre-heated feedstock at the bottom of the riser reactor. The catalyst-to-oil ratio at the bottom of riser is larger than one, and a typical ratio is 5.5. The temperature at the bottom of the riser is typically in the range of about 550 °C. The reactant mixture expands due to the cracking reaction as gases are formed, and the catalyst/feedstock mixture is rapidly transported up the riser reactor, at speeds approaching 40 m s–1. The typical contact time in a riser is therefore in the order of seconds. At the top of the riser reactor, the temperature has dropped to about 500 °C as catalytic cracking is an endothermic process. The catalyst is separated from the product mixture and stripped of remaining useful product by steam treatment. The products are further refined downstream. The catalyst material, on which a certain amount of carbon, better known as coke, has been deposited during the cracking process, is transported to the regenerator, where the coke is burned off. The catalyst is thus regenerated and re-used continuously. Depending on the exact conditions (such as the oxygen availability), the regenerator temperature can reach up to 760 °C.16

The selectivity to gasoline is in the order of 50% (see also Fig. 2). The catalyst temperature cycles between about 500 °C and about 760 °C, while it is moving at great speed. It is clear that this means the catalyst is exposed to harsh reaction conditions. As a result of this, the catalyst deactivates. A conservative estimate is that a typical FCC catalyst particle has an average lifetime in the order of about 1 month. Since it is not possible in the present process to selectively remove the deactivated catalyst, refiners remove a small portion of the complete inventory of the regenerator at fixed intervals (typically daily), and replace the removed catalyst with fresh catalyst. When this practice is performed for a longer period, a more or less steady state is reached in the catalyst life-time distribution, which is called equilibrium catalyst, or E-cat. Depending on the size of the FCC unit and the operational parameters, catalyst withdrawal rates can be between 1 and 30 tons per day.

2.3. The FCC unit in the oil refinery

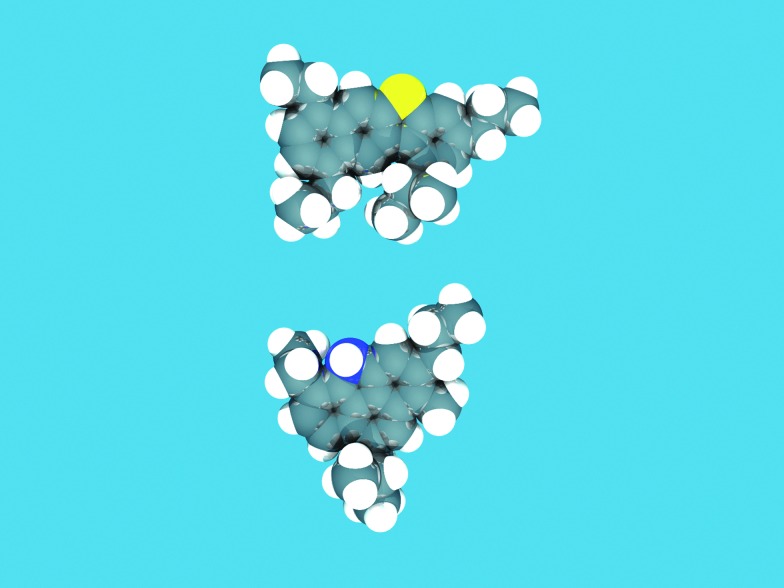

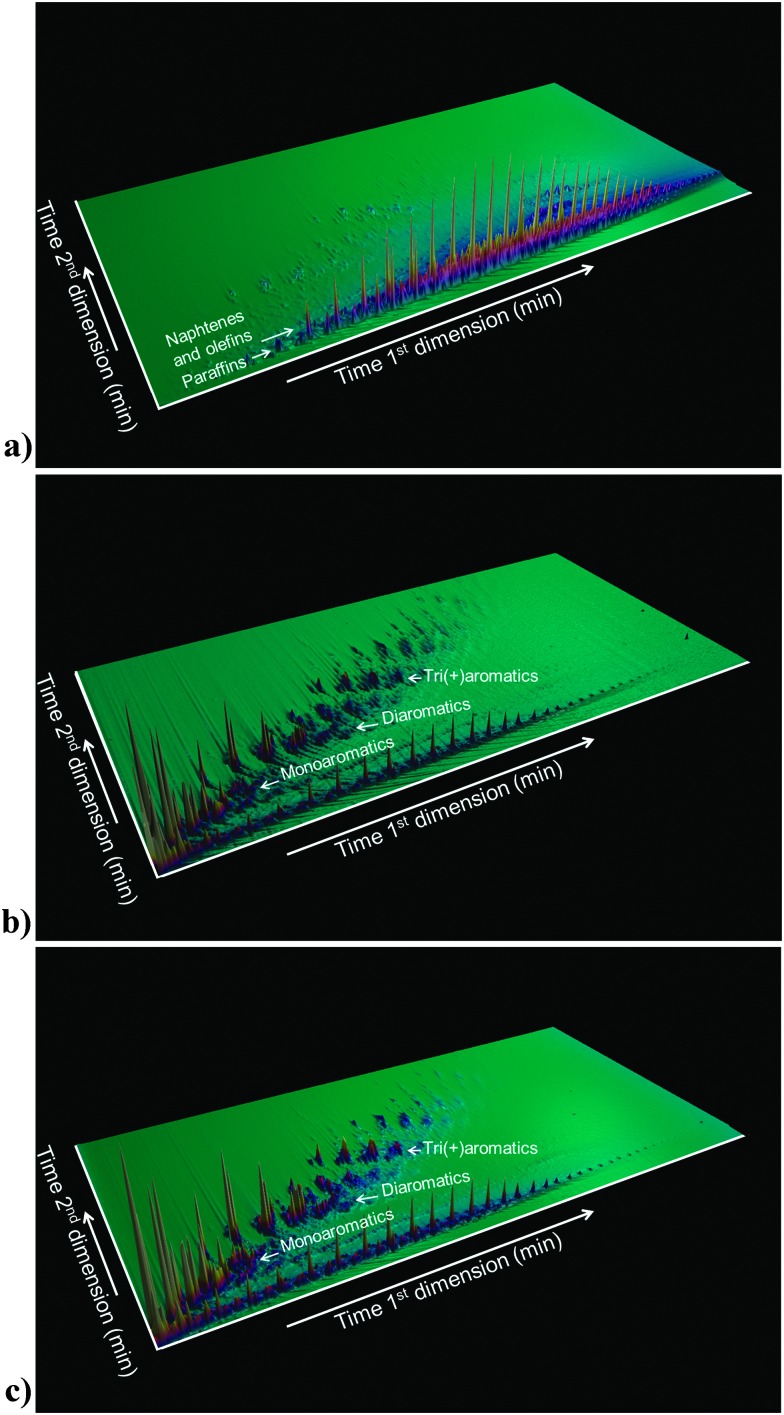

The function of the FCC unit in an oil refinery is to convert heavy gas oil (HGO), vacuum gas oil (VGO) or residue feedstocks into useful products. Fig. 4, based on models by Fu et al. and Ma et al.,27 provides an artist impression of molecules such as could be found in an FCC feedstock, depicting larger aromatic structures with alkyl side-chains, as well as sulfur and nitrogen impurities (oxygen would be present in similar molecules), while Fig. 5a illustrates the complexity of a typical VGO feedstock with a GC × GC plot. When applying a zeolite Y-containing FCC catalyst material the wide variety of molecules present in the VGO feedstock is converted into molecules with on average a lower molecular weight, as illustrated in Fig. 5b, including molecules in the gasoline range (i.e., the 150 °C boiling temperature range). A typical molecule in the gasoline range would be 2,2,3-trimethylpentane (i.e., iso-octane). VGO feedstocks typically boil at 340–540 °C30 while resid has a higher boiling range (>540 °C), and contains multi-layered systems of poly-aromatic rings.

Fig. 4. Typical molecules that could be found in an FCC feedstock, depicting larger aromatic structures with alkyl side-chains, as well as impurities: in this case sulfur (yellow) and nitrogen (blue). Structures based on VGO-molecule cores described in Fu et al. and Ma et al. 27 The structures were sketched in the ADF-builder, and energy-minimized using the built-in UFF force field in ADF.28 The resulting atomic positions were rendered with POV-Ray 3.6.29 .

Fig. 5. (a) GC × GC plot of a typical FCC feedstock (i.e., VGO). (b) GC × GC plot of the products of cracking the VGO in (a), making use of an FCC catalyst with zeolite Y. (c) GC × GC plot of the products of cracking the VGO making use of an FCC catalyst with zeolite Y in the presence of zeolite ZSM-5 as additive.

In addition to multi-aromatic ring structures, both VGO and resid, also contain impurities, such as sulfur and nitrogen, and Ni, Fe and V. These are typically remainders from the plant or animal life forms that originally made up the organic matter that decayed into fossil fuels over millions of years, although they can also originate from the interaction of the oil fractions with rock formations. Interestingly, by comparing the GC × GC plots of Fig. 5b and c one can appreciate the influence of the addition of zeolite ZSM-5 to an FCC catalyst material.

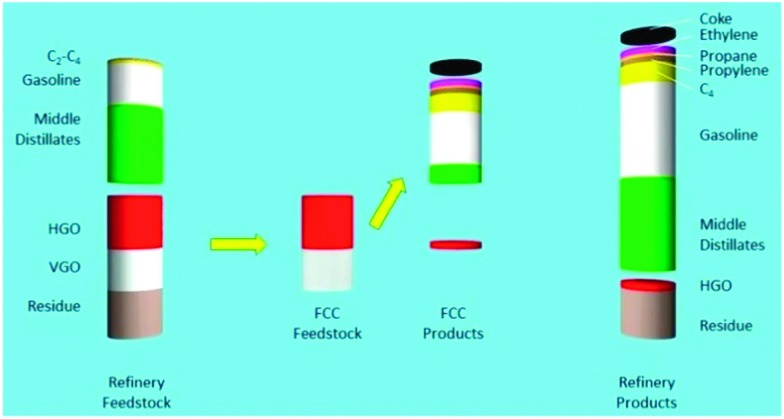

A more schematic way of illustrating the FCC conversion process is shown in Fig. 6.31 Approximately 45% of the original feedstock (i.e., middle distillates, naphtha, and C2–C4-range molecules) can be further processed without conversion e.g. in reforming and isomerization to increase their value, and will likely require some form of hydrotreatment (e.g. HDS) to remove impurities.

Fig. 6. The effect of FCC conversion on total refinery product. Left: Atmospheric distillation frees up about 50% of the feedstock (middle distillates, gasoline and light gases). Heavy gas oil (HGO) and vacuum gas oil (VGO) are converted in the FCC unit. The products from FCC are combined with the initial products from crude distillation in the column on the right. More recent FCC processes will also convert part of the residue. Data from ref. 31.

A major part of the remaining relatively low-value bottom-of-the-barrel fractions (HGO and VGO in this example) are converted to desired products by the actions of the FCC catalyst, in which molecules are cracked to form high-octane rating products. The residue is not converted by the FCC catalyst in this particular example,31 although present day FCC catalyst materials can certainly convert resid, and resid FCC has now become an important process and, consequently, a vast amount of research is directed to focus on resid conversion.

3. The FCC catalyst material

3.1. Structure and composition

The FCC process as described above sets a number of demands for catalyst parameters:16

• Activity, selectivity and accessibility: first of all, the catalytic properties to convert the large feedstock molecules to the desired molecules;

• Attrition resistance: the catalyst particles must be able to withstand the impacts with each other and the unit walls during circulation;

• Hydrothermal stability: the catalyst must be able to withstand the temperature and steam partial pressure in the regenerator;

• Metals tolerance: the catalyst must be able to withstand the actions of poisons in the (heavier) feedstock;

• Coke selectivity: the catalyst must make the minimum amount of coke at high cracking activity, especially when processing heavier feedstocks, such as resids; and

• Fluidizability: the catalyst components must be available in a form that allows fluidization in the regenerator.

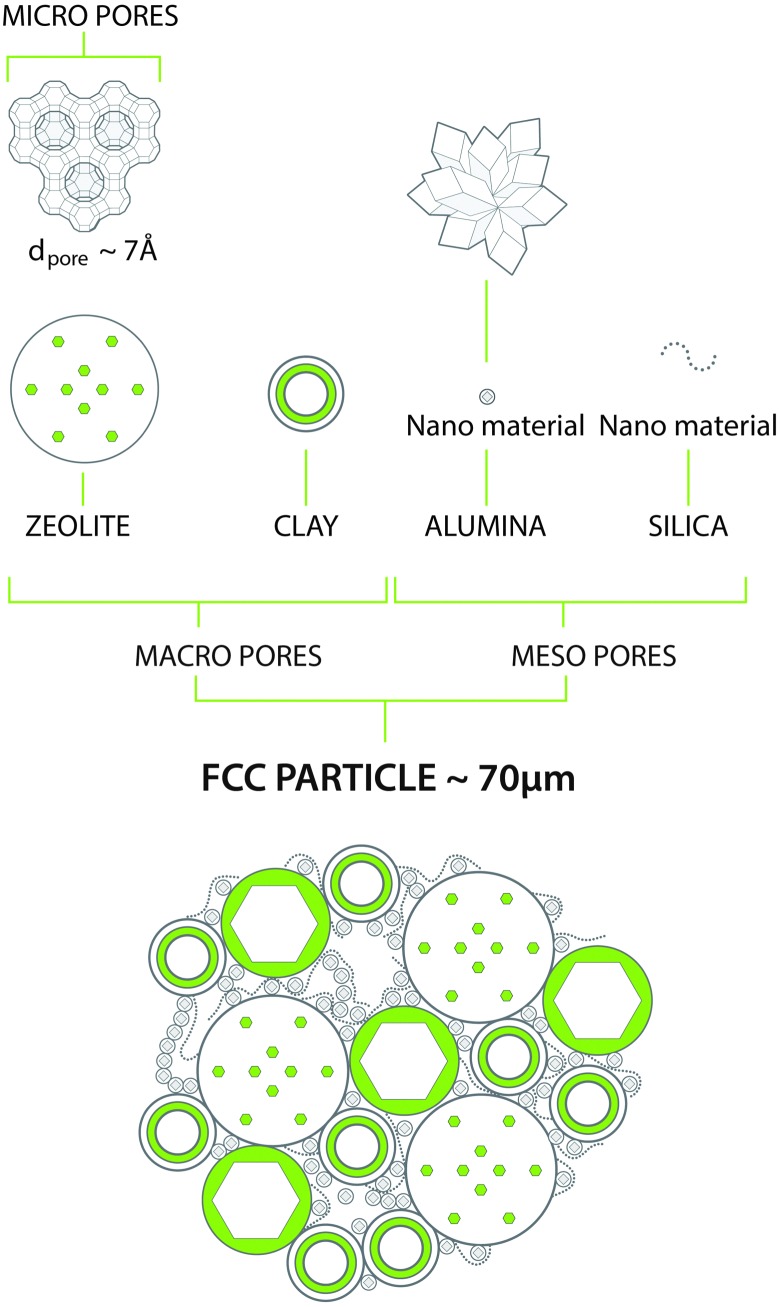

The above demands can be met in a catalyst system that combines a number of components, as depicted in Fig. 7. As described above, the main active component is a zeolite, usually a stabilized form of zeolite Y. This material contains an internal porous structure in which acid sites are present, which can convert larger molecules to the desired gasoline range molecules. Clay is added as filler, but also for heat-capacity reasons. Various alumina and silica sources are used to produce a meso- and macroporous matrix that allows access to, and pre-cracks the larger molecules in the feedstocks. In addition, these components are used to bind the system together. Additional components may comprise specific metal traps for trapping Ni and V. The components are typically mixed in aqueous slurry, and then spray-dried to form more or less uniform spherical particles that can be fluidized in the regenerator.

Fig. 7. Typical chemical and structural composition of a FCC particle. Artwork by RSK Communication.

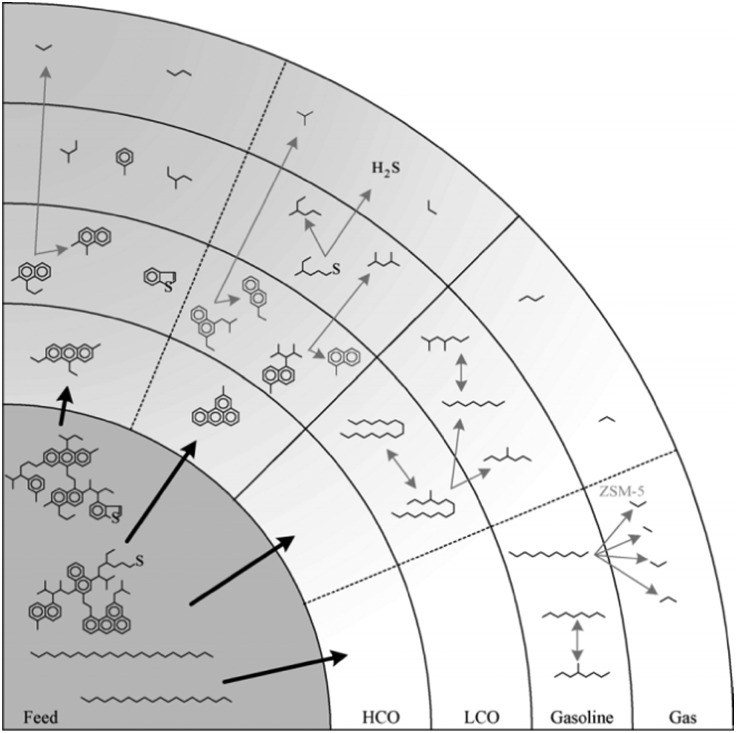

3.2. Reactions

Fig. 8, reproduced from the work of Dupain et al.,32 provides a schematic overview of the reactions occurring in the conversion of FCC feedstocks to gasoline range or gas products. It is clear that the conversion occurs in stages, and gasoline is not the primary reaction product, which should be obvious, since the large molecules in the feedstock cannot enter the (∼7.3 Å) pores of zeolite Y. Rather, the large molecules are pre-cracked in the matrix on their way to the zeolites. The cracking reactions are likely a combination between thermal and catalytic reactions, in which the catalytic reaction becomes more important as the molecules get smaller. The catalytic cracking reaction is acid-catalyzed.

Fig. 8. Consecutive cracking reactions of complex feedstock leading to the final FCC products. (Reproduced from ref. 32 with permission, Copyright Elsevier, 2005).

Acidity can be found both at the surface of matrix particles (for instance, Brønsted acidity at silica-alumina interfaces, or Lewis acidity at Al2O3 surfaces), or in the zeolite. The basic structure for zeolites is a tetrahedrally linked silicate. In some lattice positions, the silicon is replaced by aluminum. Since aluminum is present as a trivalent cation, this induces a local negative charge in the lattice, which can be compensated with a proton to form a Brønsted acid site. Lewis acid sites can be formed when the aluminum sites are coordinatively unsaturated when the framework is damaged (e.g. by steaming).

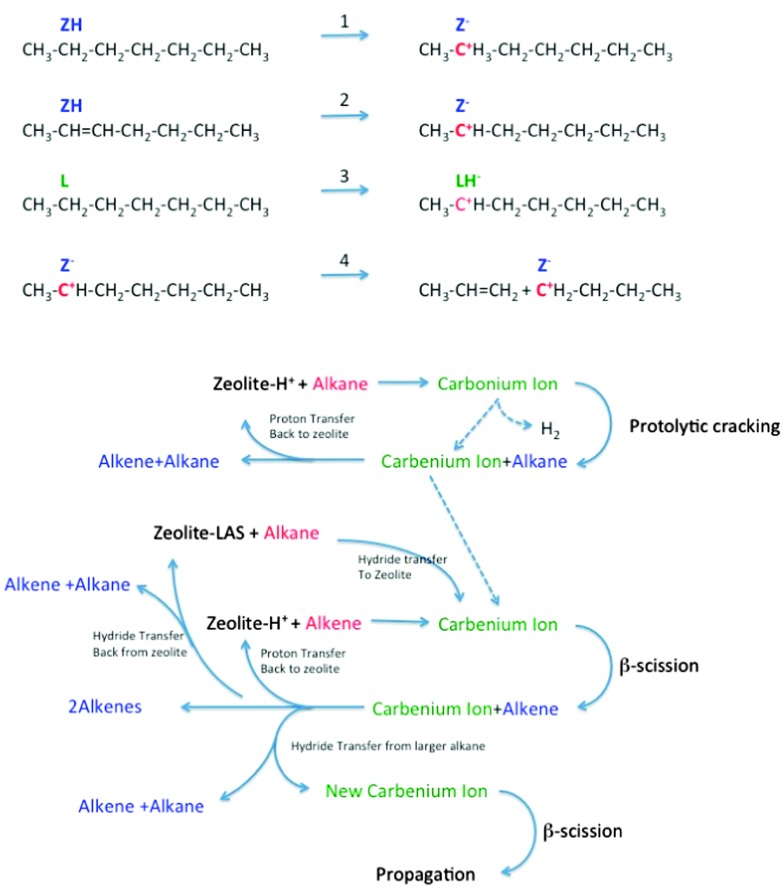

The subject of the cracking mechanism was discussed from the early days of catalytic cracking.33 It is now generally accepted that catalytic cracking involves the formation of carbenium ions.34 As depicted in Fig. 9, there is variety of ways these can be created:35,36

Fig. 9. Reaction network in zeolite-assisted cracking of hydrocarbon molecules. Reaction 1: proton transfer from zeolite Brønsted site to alkane to form carbonium ion. Reaction 2: proton transfer from zeolite to alkene to form carbenium ion. Reaction 3: hydride transfer from alkane to zeolite to form carbenium ion. Reaction 4: Beta scission of a carbenium ion to form a new carbenium ion and an alkene.

(1) Brønsted acid sites can donate a proton to an alkene. This alkene must than have been formed by thermal cracking beforehand. Dupain et al. describe that the initial stages of the FCC process involve mostly thermal (radical) cracking on the outer surface.32

(2) Lewis acid sites can abstract a hydride from an alkane, and the same can occur on strong Brønsted sites (forming dihydrogen).

(3) Alternatively, a Brønsted acid site can donate a proton to an alkane, forming a penta-coordinated carbonium ion. When the carbonium ion cracks protolytically (monomolecular, Haag–Dessau), an alkane and a carbenium ion remain.37

Isomerization reactions can yield branched molecules, in which the tertiary carbenium ions are more stable. The carbenium ions formed in steps 1–3 crack through β-scission, forming a smaller alkene and a smaller carbenium ion. Hydride abstraction from a larger alkane molecule allows the smaller carbenium ion to desorb from the acid site as an alkane, leaving a new larger carbenium ion on the zeolite acid site to propagate the reaction. Alternatively, the carbenium ion can donate the proton back to the acid site, and desorb as an alkene.

Corma et al. 34 conclude that both pathways, involving initial carbenium ion formation on Lewis sites and initial carbonium ion formation on Brønsted sites, occur in parallel.

3.3. FCC catalyst testing

One of the major problems in designing improved FCC catalysts is that it is very difficult to scale down the commercial FCC process with its short residence time and rapid deactivation processes. The feedstocks are complex and contain various impurities that can have a major effect on performance, such as Conradsen carbon, metals like Ni and V, oxygenates, and nitrogen- and sulfur-containing molecules. Resid feedstocks require a different operation than VGO, and diesel- or propylene-selective applications again are completely different.38

Over the years, various more or less standard methods have been developed for testing FCC catalysts. The first was the “MAT”-test, or Micro Activity Test, according to ASTM D-3907. In this test, a small sample of catalyst is tested in fixed bed. Conversion can be influenced by changing the catalyst-to-oil (CTO) ratio. The test has various drawbacks,38 but has nevertheless been very popular over the years. The test contacts the catalyst and feed for prolonged periods, during which deactivation of the FCC catalyst proceeds, and coke- and temperature profiles may develop over the catalyst bed. As a result of the prolonged exposure to feedstock, also the amount of coke deposited on the catalyst material may be unrealistic. The same holds for the observed gas selectivities.

The major drawbacks, concerning contact time and feed vaporization were addressed in various protocols.39,40 Kayser41 developed the so-called ACE (Advanced Cracking Evaluation) units, a catalytic fixed fluid bed system, in which a small catalyst sample (typically about 1 g) is fluidized in a gas stream, and a brief pulse of atomized VGO is passed through the fluidized bed at 538 °C (1000 °F). Another solution capable of handling the heavier feedstock is the Short Contact Time Resid Test, described by Imhof et al. 42 MAT and its refinements (e.g. SCT-MAT and AUTOMAT43) and ACE protocols can show ranking differences amongst each other, but also with pilot plant results.

To overcome this, more realistic simulations or even downscaled versions of the riser reactor, like Pilot Riser Units (PRU), have to be applied. The closest approximation on lab scale may be the Micro-riser simulation based on a coiled reactor developed by Dupain et al.,32 and the Micro-downer developed by Corma et al.,44 a moving bed system with short contact time, which also allows testing with heavier feedstocks.

While FCC catalyst testing is already complicated, the protocol will also have to take into account the deactivation of the catalyst during its lifetime of cracking and regeneration cycles. The deactivation of the catalyst is caused by steaming during the regeneration and assisted by the presence of metals like Ni and V (but also Fe, Na and Ca). Deactivated commercial catalysts may contain thousands of ppms of Ni and V, depending on the operation. Mitchell Impregnation (MI)45 is used to deposit Ni and V on the catalyst particle, usually prior to steaming. The metals are impregnated throughout the catalyst particle, which is maybe (in part) correct for V, but certainly not for Ni. Simple steaming of the catalyst (with or without metals) at increased temperatures mimics the effect of the regenerator in vary crude way.

More realistic procedures mimic the cracking-regeneration cycles, e.g. cyclic propane steaming (CPS),48 in which the catalysts are exposed to multiple cycles of (propane) cracking, stripping and steaming prior to the actual activity tests. A more elaborate deactivation procedure is the cyclic deactivation (CD) procedure,49 in which actual feedstock cracking, depositing metals every cycle, is combined with regeneration for many (up to over 50) cycles to create a more realistic metals profile. Improvements are the two-step CD (2s-CD) and advanced CPS protocols, as described by Psarras et al. 50

3.4. Zeolite framework stabilization

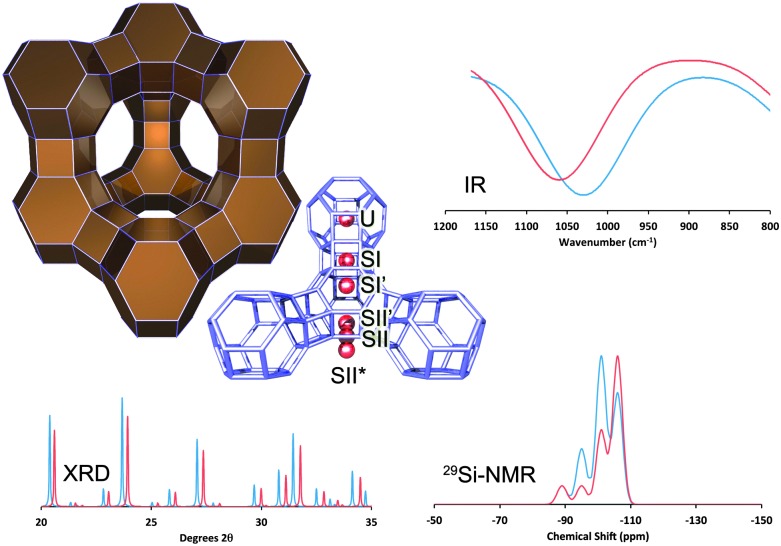

As mentioned above, the main cracking component in FCC catalysts responsible for the production of gasoline-range molecules is zeolite Y.19 The structure of zeolite Y, shown in Fig. 10, has a 3-D pore system, in which pores of ∼7.3 Å connect larger (13 Å in diameter) cages, which are known as the supercages of this zeolite.

Fig. 10. The structure of zeolite Y (Faujasite), with the most relevant ion-exchange sites highlighted. The effect of RE-introduction: XRD: comparing RE-stabilized (blue) with non-stabilized Y-zeolite (red), we observe a shift to lower angles (i.e. larger unit cell size, lower SAR, less dealumination), as well as higher crystallinity in the RE-stabilized material; IR: we observe a shift to lower frequency (lower SAR, less dealumination) for the RE-stabilized form; NMR: we observe larger contributions from Si-species with multiple Al-neighbors (i.e., a lower SAR, less dealumination). All spectra are simulated based on literature data from Roelofsen46 and Scherzer et al. 47 .

The addition of solid acids to the catalyst improves both the conversion as well the product selectivity towards gasoline. The original FCC catalyst contained clay, and later amorphous silica-alumina and silica-magnesia. The advent of zeolite-based catalytic cracking was seen shortly after their discovery at Union Carbide,20,21 in the early 1960's. Zeolite Y combines high surface area/pore volume solid acidity (both Brønsted and Lewis) with sufficient room to allow bimolecular (carbenium ion) cracking. The preparation of the zeolite is relatively simple, no organic Structure Directing Agents (SDAs) or even autoclaves are required. However, the as-prepared zeolite is not very stable towards hydrothermal conditions. The stability can be improved by controlled steaming and washing/leaching cycles (to make the so-called ultra stable Y, or US-Y).

A well-known way to improve the effectiveness of the zeolite (i.e. to retain activity longer) is to exchange part of the counter-ions with rare earth (RE) ions. There is a lot of literature on the effect of RE ions on zeolite stability and reaction characteristics. A large body of work in this area was already performed in the 1970's and 1980's.

For example, Rees et al. 51 show that the exothermic peak in differential thermal analysis, which is interpreted as a collapse of the framework, shifts towards higher temperature for RE-exchanged faujasite versus Na-exchanged faujasite. This framework collapse occurs in the range of 800–1000 °C, so outside of the temperature range relevant for FCC. Nevertheless, the effect is an indication for increased lattice thermal stability.

Flanigen et al. 52 provide an assignment of the IR vibrations observed for zeolite Y. Roelofsen et al. 46 explain that the symmetric stretch vibration at around 790 cm–1 is the most suited to derive the framework silicon-to-aluminum ratio, shortened as SAR, because other IR peaks are more sensitive to the type and amount of cations in the framework, crystallinity, as well as water content. The peak frequency of the IR band at around 790 cm–1 has found to be linearly proportional to the Al/(Al + Si)-ratio.

Rabo et al. 53 describe two IR peaks related to hydroxyl groups in RE-Y. The first peak, at 3640 cm–1, shows strong hydrogen bonding with water, benzene and ammonia, and can thus be interpreted as a Brønsted acid site exposed in the supercage. The other OH-vibration, centered at 3524 cm–1, does not bind with ammonia or benzene, and is thus hidden inside the sodalite cage. Rabo et al. assume these hydroxyls are associated with OH-groups retained between two RE-cations as an electrostatic shield.

Roelofsen et al. 46 investigated the dealumination of zeolite Y with varying loading of RE2O3 (mixed rare earths) with IR, XRD, and 29Si MAS NMR. They find a good correlation between the framework SAR derived from IR and from 29Si MAS NMR. However, the correlation with the SAR derived from the unit cell size using the Breck–Flanigen relation54 does not hold in this case. The unit cell size is significantly larger than would be expected from the Breck–Flanigen relation. This indicates that the unit cell size is not a good indicator for lattice stabilization.

A variety of authors studied the stability of RE-exchanged zeolite Y in the 1960's and 1970's, mostly based on IR-analyses. Scherzer et al. 47 conclude that framework vibrations shift to higher frequencies, and the XRD unit cell size decreases, upon increased severity of the thermal treatment. In both cases there is more or less linear dependence of the effect with the RE-loading. In a subsequent paper, Scherzer and Bass55 look at the OH-stretching region of the same samples. They conclude that bands at 3600 and 3700 cm–1 indicate that the framework is dealuminated. Bands at 3650 and 3600 cm–1 are shown to be acidic (from interaction with ammonia, pyridine, and sodium hydroxide). They also observed a band at 3540 cm–1, which they ascribe to OH groups attached to lanthanum ions, although there also appears to be a framework band in the same IR region.

Fallabella et al. 56 study the effects of using different RE-ions in the ion exchange process of zeolite Y. The introduction of RE cations brought about no significant changes in the structural region of the zeolites. However, in the hydroxyl region, a band ranging from 3530 to 3498 cm–1 was observed.

This band, attributed to OH groups interacting with RE-cations (see also Scherzer and Bass55), is shifted to higher wavenumbers as the ionic radius of the cations increases. This hydroxyl is not acidic (or at least not active in catalysis), as it resides in the sodalite cages. The authors do note a clear effect of the radius of the RE-ion on the acidity as probed with pyridine and lutidine. Pyridine is capable of detecting both Brønsted and Lewis acid sites, whereas lutidine can only interact Brønsted acid sites due to sterical hindrances generated by the methyl groups. In their study, Dysprosium falls outside the plotted correlation, possibly because remaining chloride ions create extra activity.

Van Bokhoven et al. 57 report that high-charge octahedral extra-framework Al in US-Y, as well as La3+ ions in the ion exchange positions in La(x)NaY induce local polarization of the Al-atoms in the lattice. In addition, a long-range effect is observed which causes the T–O–T angles to increase (and thus the unit cell size to increase). The authors thus assume that although the type of ion is different, the origin of the enhanced activity in US-Y and RE-Y is identical. Most authors claim that rare earth elements stabilize the zeolites by moving into the hexagonal prisms (site S-I), and retaining the framework Al by some form of electrostatic interaction. Excess rare earth migrates from the hexagonal prism into the supercage (site S-II), and forms strong Brønsted acid sites in connection with framework Al.

Du et al. 58 claim that the ionic radius of different RE elements has an effect on the stability of the RE-Y zeolite and the framework stability increases with decreasing ionic radius for the set Ho3+, Dy3+, Nd3+, La3+. Ce3+ does not seem to move into the S-I positions, because under the conditions applied by Du et al. the cerium gets oxidized to Ce4+, and forms a larger complex that cannot migrate into the sodalite cages.

Schüßler et al. 59 investigated the nature and location of La-species in faujasite with a combination of techniques, including DFT calculations. In order to make full periodic calculations possible, they selected the rhombohedral primitive cell of faujasite. This reduces the number of framework atoms by a factor of 4, from 576 to 144. The authors find small amounts of [La(OH)]2+ and [La(OH)2]+-species in the S-II sites, but claim the majority of the La3+ is present in the sodalite cages in multinuclear OH-bridged aggregates. The formation of the hydroxylated clusters leads to the formation of Si–OH–Al groups at a distance to the La-clusters. However, the authors claim that isolated La3+ species in the S-II site are also able to polarize secondary and tertiary C–H bonds and thus activate alkanes, and point to these species as responsible for the enhanced activity and hydrogen transfer of RE-exchanged zeolites.

Noda et al. 60 performed a combination of temperature programmed desorption (TPD) of NH3 with DFT cluster calculations. They examined Ba-, Ca-, and La-exchanged zeolite Y and observe an increase in catalytic activity for all ion-exchanged zeolites with the Ba ones producing the lowest activity. They ascribe the formation of stronger acid sites to a removal of OH-sites in the sodalite cages and hexagonal prisms, and strengthening of the supercage-OH sites by a polarization effect induced by the cations.

From the above, it is clear that the presence of RE-cations in the structure provide some form of stabilization, to the extent that more aluminum is retained in the lattice as observed with IR and NMR. XRD unit cell size analysis does not correlate with IR and NMR measurements in the normal way for RE-containing zeolite Y.

The effect of the presence of RE in the lattice on performance is dramatic. Plank et al. 61 already in the early 1960's noted an appreciable increase in activity (more than 100 times as active as amorphous silica-alumina's) when using RE-stabilized Y zeolites, although they compared their materials to amorphous SiO2–Al2O3 and Na–Y. Although the activity increase is desirable, the incorporation of RE also increases the rate of hydrogen transfer, which leads to a less desirable drop in research octane number and olefinicity in the LPG range. Fallabella et al. 62 define a hydrogen transfer (HT) index derived from the ratio of different reaction rate constants in the cracking of cyclohexene, which correlates with the atomic ratio of the RE-ion and the acidity. Lemos et al. 63 studied heptane cracking on RE-exchanged Y-zeolites, and observed mainly paraffinic cracking products. The cracking activity seems to correlate with strong protonic acidity, as derived by reactivity comparison.

4. Improvements in FCC catalyst materials

4.1. General trends

Even though the FCC process has been with us for over 70 years now, the process is still being developed further. Changes in the demand for products, and changes in the feedstock drive constant development. Fletcher64 lists the following challenges for FCC catalysis:

• LCO maximization (i.e. diesel flexibility);

• Petrochemical feedstock maximization (i.e. propylene);

• Flue gas emissions control; and

• Enhanced metals tolerance.

On the one hand, conventional feedstocks are becoming heavier. Resid cracking in FCC gained popularity in the early 1990's, and has gained importance since. Heavier feedstocks imply that larger, more aromatic molecules need to be cracked, which calls for improved accessibility and improved metals tolerance. At the same time, there is a drive to increase activity, but at the same time limit the amount of coke produced to the absolute minimum required for heat balance of the unit. This is a continuous challenge in FCC since the early days, and various improvements have been made over the decades, as illustrated in Fig. 11.

Fig. 11. Effect of subsequent developments in active components on conversion and coke level. Redrawn from ref. 65.

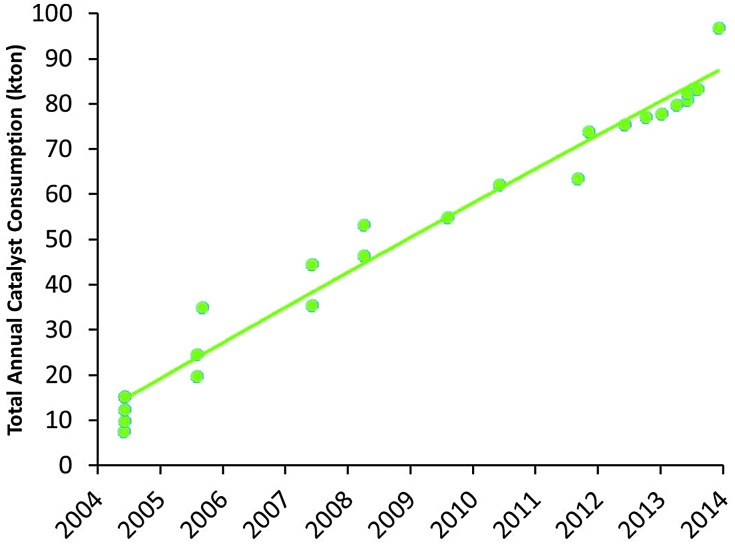

Apart from the conversion of heavier feedstocks, we have recently also seen an increased application of relatively light, paraffinic shale oil as the feedstock to the cracker. So the traditional feedstock of FCC, namely VGO, is replaced more and more by both heavier and lighter feedstocks. At the same time, a similar effect can be observed on the product side. Where (aviation) gasoline was the desired product for the initial FCC units, we have seen an increased demand for propylene over the last two decades. Propylene is the raw material for polypropylene, and the FCC unit can be one of the main sources to form propylene (the other would be steam cracking of naphtha). Propylene can be produced in the FCC unit as a product mostly of secondary cracking of gasoline range molecule, usually by specific additives containing ZSM-5 zeolite. Fig. 12 lists the market size for FCC catalyst specifically targeting propylene production, which has risen from about 10 000 metric tons per year in 2005 to almost 90 000 metric tons of catalyst in 2014.

Fig. 12. Development of the market for propylene-selective FCC catalysts (based on Albemarle market data).

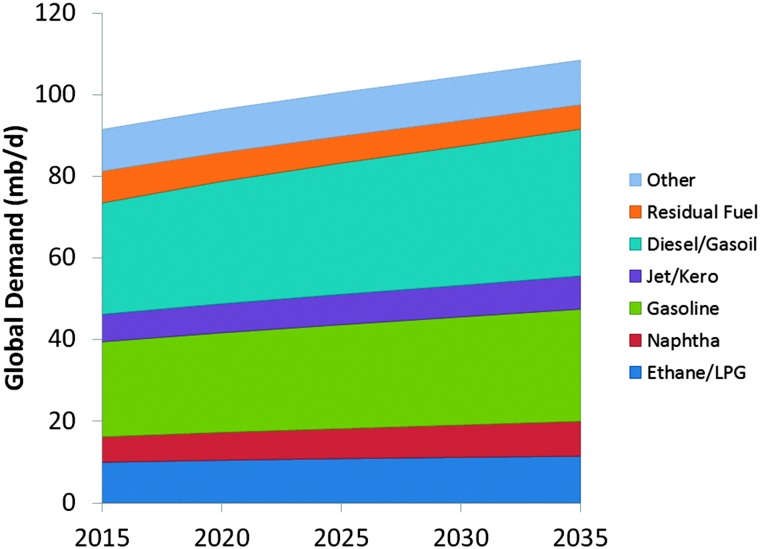

The development of specific FCC-propylene capacity follows the demand for olefins.66 It illustrates the clear expected increase in the propylene demand, which cannot be absorbed by steam cracking alone, and has to come from the FCC unit. On the other hand, as shown in Fig. 13, the world market for gasoline seems to flatten out, and developing countries and even the USA show an increasing demand for diesel as a transportation fuel.

Fig. 13. Projected evolution of the market for selected oil products. Color-coding: ethane/LPG: dark blue; naphtha: red; gasoline: green; jet/kero: purple; diesel/gasoil: blue; residual fuel: orange; other: light blue. Data taken from ref. 67.

The compiled information, based on data from the OPEC World Oil Outlook 2013,67 shows the ratio between gasoline and diesel demand over the next decades is projected to change in favor of diesel. Historically, the USA had a surplus in diesel, and the EU had a surplus in gasoline, which could be traded.68 With the new gasoline/diesel demand ratios predicted for the next decades, this is no longer possible, and this will no doubt have an impact on the desired products from the FCC unit as the main conversion process. The two developments combined require a shift from gasoline as the main product to both higher- and lower-boiling products, which is not possible at the same time.

4.2. Increasing propylene selectivity

Propylene is a minor product (<5% product yield) in normal FCC operation, but selectivity towards propylene can be enhanced by selectively cracking gasoline range molecules. Although increasing the riser temperature, increasing the catalyst-to-oil ratio, and increasing the residence time will increase the propylene yield,69 these options are limited. Corma et al. 70 show for cracking over Y-zeolites, that although propylene yield increases with conversion, propane yield increases faster, so the alkene/alkane ratio decreases at higher conversion. So rather than olefins, coke, dry gas and paraffinic LPG will be produced preferentially through so-called over-cracking. This is because the wide pore system of FAU allows for bimolecular cracking and hydrogen transfer reactions. In order to selectively produce lower olefins, refiners apply additives containing zeolite ZSM-5.66,71,72 These additives, complete FCC catalysts in themselves, usually contain ZSM-5 as the only active zeolite, in loadings of 25–50%. Combination of Y-zeolites and ZSM-5 in one catalyst is also possible, but removes (some) flexibility for the refiner. It is also possible to base the entire conversion on ZSM-5 based catalysts in dedicated processes, such as DCC,73 which operates at higher temperature than the conventional FCC process, and converts heavy feedstocks such as VGO, vacuum resid, or VGO mixed with DeAsphalted Oil, into light olefins or iso-olefins.

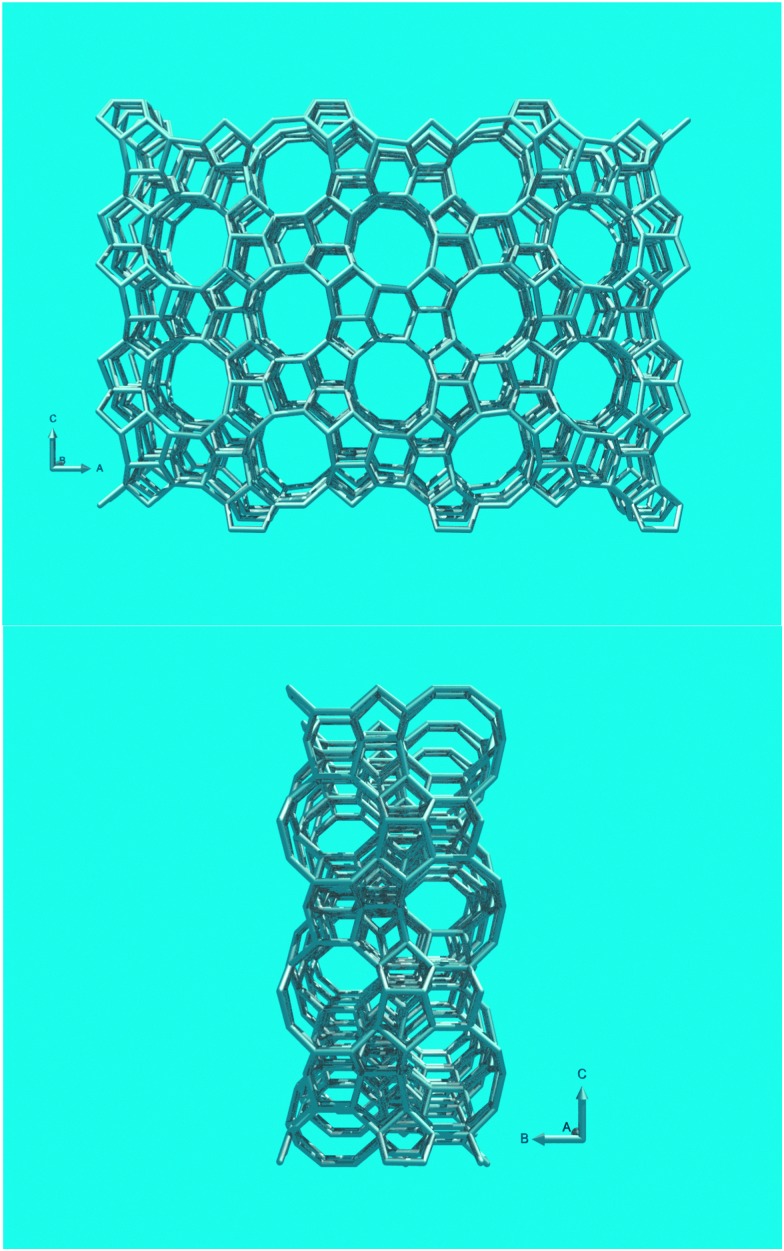

In this review paper, we will exclusively focus on ZSM-5-containing additives. Argauer and Landolt first reported ZSM-5, this structure shown in Fig. 14, as a synthetic molecular sieve in 1972.22 Although Kokotailo et al. solved the structure of ZSM-5 already in 1978,74 recent work has shed new light on this material. Even though zeolite ZSM-5 was first described as a synthetic material, a natural mineral form (named Mutinaite) also exists as it was discovered in Antarctica adjacent to deposits of natural zeolite Beta.75 Zeolite ZSM-5 can be prepared both in the presence and absence of organic SDAs. The typical SDA molecule is tetrapropylamine (TPA), which can be located in the pores of the synthetic material.76 Materials with a silica-to-alumina ratio (i.e., molar SiO2/Al2O3 ratio) up to about 25 can be synthesized without SDA, for higher silica-to-alumina ratios typically an SDA is required. The essentially all-silica form, known as silicalite, has a slightly different structure than the low-SAR material, it has a monoclinic unit cell, whereas the low SAR material crystallizes in an orthorhombic cell. The framework is exactly the same for both phases. The structure of ZSM-5 consists of a 3D pore system circumscribed by 10 T-atoms. The pores are slightly elliptical and have diameters of 5.1–5.6 Å. The structure has a straight 10-MR pore along the [010]-direction, and a zig-zag 10-MR pore along the [100]-direction. The pores intersect, and molecules (of the correct dimensions) can reach any point in the pore system from any other point. ZSM-5 normally crystallizes in lozenge- or coffin-shaped crystals that are frequently twinned.

Fig. 14. (Top) Structure of zeolite ZSM-5, viewed along the 10-MR straight channels. (Bottom) View along the zig-zag channels.

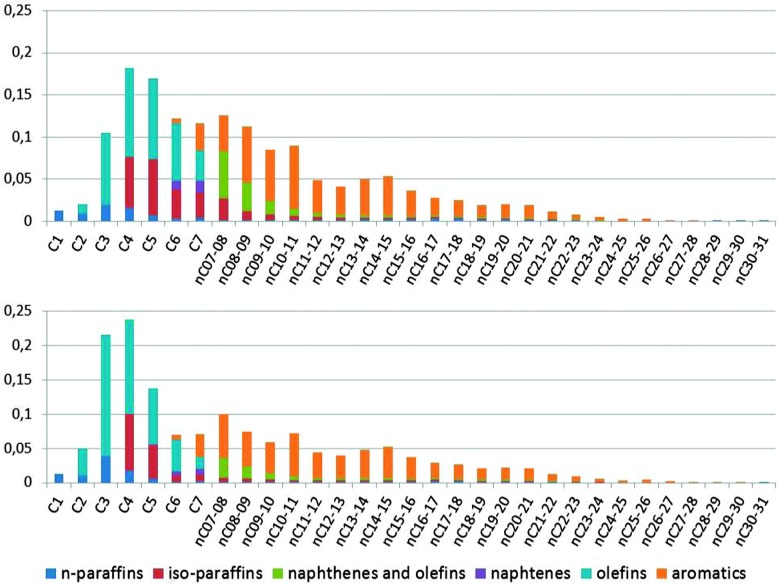

The limited room in the pore system of zeolite ZSM-5 compared to the supercages in zeolite Y implies that it is much more difficult to accommodate the larger bimolecular transition states. As a result, the secondary cracking of gasoline range molecules in ZSM-5 will produce more olefins. This is illustrated in Fig. 15.

Fig. 15. A comparison of the total products from the same runs as depicted in Fig. 4. The graphs are combinations of the GC × GC plot for total liquid product, PIANO analysis of the naphtha fraction, and GC analysis of the gases. Top: Products from a normal cracking run. Bottom: Products with ZSM-5 containing additive added to the catalyst. Color-coding: n-paraffins: dark blue; iso-paraffins: red; naphthenes and olefins: green; naphthenes: purple; olefins: blue; aromatics: orange.

Just like the primary cracking zeolites, also zeolite ZSM-5 is unstable towards the harsh environments of the FCC process. Dealumination by repeated contact with steam in the regenerator dislodges the aluminum from its framework position, thus removing the active acid sites, and in the process destroying the zeolite lattice. Although a partial destruction of the zeolite lattice may improve the diffusion characteristics of the zeolite by creating access to the interior through mesopores, this also creates larger pores, and hence the opportunity for bimolecular cracking.

To increase the stability of zeolite ZSM-5, a treatment with phosphorous is often applied. The trick has been used in ZSM-5 for various applications apart from FCC, such as methanol-to-olefins (MTO) conversion, alkylation, and ethanol dehydration.77 A very recent review on phosphorus promotion of zeolites covers the synthesis, characterization and catalysis aspects of phosphated ZSM-5.78 A variety of phosphorous sources has been used over the years to achieve the desired stabilization. For example, Xue et al. 77 mention organo-phosphorus compounds, such as trimethyl phosphite ((CH3O)3P) and others, and inorganic compounds, such as phosphoric acid (H3PO4) and ammonium phosphates ((NH4)3PO4, (NH4)2HPO4, (NH4)H2PO4) and others. Given the scale of the operation and ease of handling (e.g. by-products), especially the inorganic compounds are of relevance to FCC catalyst manufacturing.

The overall interaction between the phosphorous species and the zeolite lattice seems to be relatively independent of the phosphate source, although the overall effect of the treatment on activity strongly depends on parameters like Al/P ratio, Si/Al ratio, zeolite crystal size, and activation conditions.77,79 When phosphate species are introduced in a way that allows them to enter the pores and react with the bridging hydroxyls of the Si–OH–Al active sites in the zeolites, an adduct forms in which the phosphate ions force the aluminum in an octahedral coordination. This process, which is reversible under treatment with hot water, eliminates the bridging hydroxyls and thus the Brønsted acidity of the zeolite.78 However, when elution with hot water can be avoided during heat treatment, the octahedral Al–POx-species is more stable, and the lattice integrity is maintained to a larger extent then for untreated zeolites. Excess phosphorus used during the treatment will deposit on the external surface of the zeolite ZSM-5 crystals as a polyphosphate. If any aluminum is dislodged during the thermal treatment, it will very likely react with the available phosphate, and form an amorphous aluminophosphate. It should be noted that the ZSM-5-containing additive will generally also contain an alumina binder, which will react with excess phosphate to form an aluminophosphate species that may be beneficial for binding the system.

The effect of the treatment with phosphate on macroscopically observable parameters is

(1) Enhanced stability of the zeolite lattice;

(2) A decrease in the formation of bulky isomers;

(3) Formation of increased amounts of lights olefins in FCC, but also in MTO and ethanol dehydration; and

(4) A decrease in coke formation.

In view of the mechanistic relations described above, the latter two seem to hint at decreased hydrogen transfer, and the second seems to indicate decreased room in the lattice for the formation of bulky intermediates.

The phosphate treatment usually involves impregnation of solutions of phosphate sources, typically H3PO4, or the less acidic ammonium phosphates, followed by drying (70–120 °C) and calcination (450–650 °C) for 1 to 6 h. Although generally the catalysts will be exposed to steam after they were stabilized, some authors describe phosphate treatment after initial steaming. This may lead to the formation of extra-framework aluminum (EFAL) and hydroxyl nests, and dislodged aluminum still partially connected to the lattice.

Various characterization techniques have been used to study phosphated zeolites.78 XPS shows enhanced P-concentration at the surface of larger zeolite crystals, possibly because the initial stage P-species react with surface Si–OH groups before they can enter the pores. The optimal loading for the phosphate treatment seems to be an Al/P-ratio of about unity, although care must be taken to avoid diffusion problem during the impregnation stage. Excess of phosphate will remain on the external surface of the zeolite ZSM-5 crystals. Upon P-treatment, a decrease of porosity/surface area is observed, which is correlating with P-content. A decrease in surface area/porosity can be attributed to pore blockage by P-species, aggregation of zeolite crystals by the action of external polyphosphate, or dealumination.

Although porosity and accessibility are initially decreased, the bridging hydroxyl groups (and thus the acidity) appear to remain available at this stage. The zeolite crystals appear to lose some crystallinity after the calcination treatment following the phosphorous impregnation, but this could be due to scattering of the X-rays by P-species in the pores.

Although the Si/Al ratio as observed with 29Si MAS NMR seems to increase, this may just be caused by changes in the coordination spheres of the Si- or Al-species in the lattice, and not necessarily by removal of the framework Al. Depending on conditions for the calcination, the phosphate species may coordinate to the aluminum, and thus break the Si–OH–Al bridges. Although this would lower the number of strong acid sites, the Al–O–P(OH)3 and Si–OH species formed when this happens may lead to new acid sites, and partially connected Al may form additional Lewis acid sites.

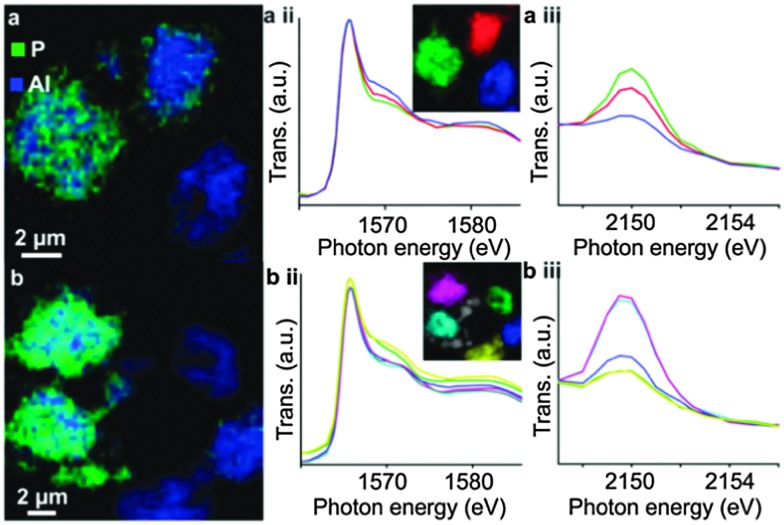

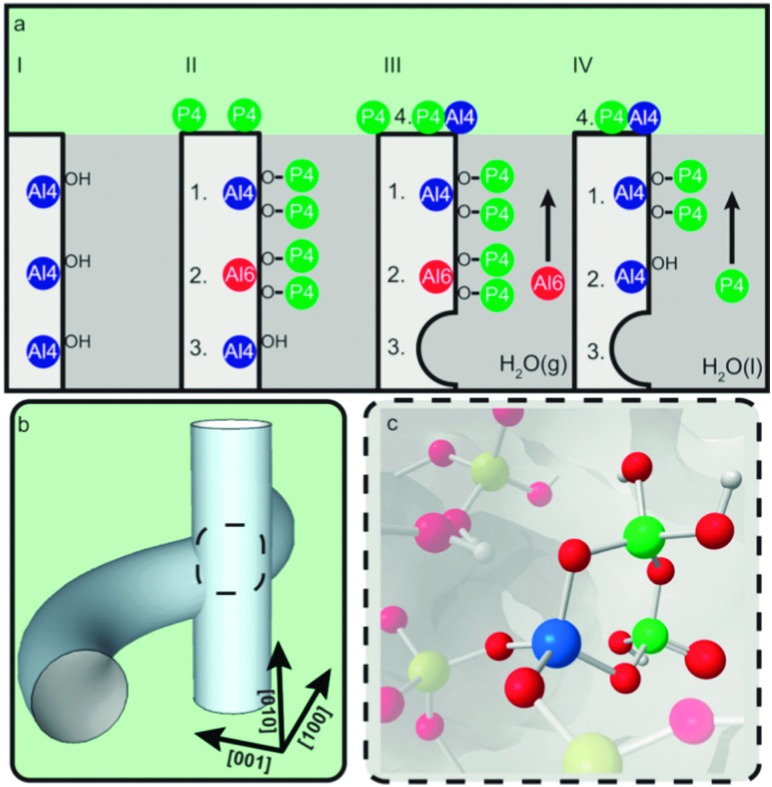

Upon phosphate treatment, the typical resonances for tetrahedral framework Al seem to decrease in 27Al MAS NMR. This does not necessarily mean that the Al is dislodged from its framework position. By using combined spectroscopy and scanning transmission X-ray microscopy (STXM), van der Bij et al. observed that there are two different interactions between the phosphate and aluminum (Fig. 16). Extra-framework aluminum reacts with the P-sources to form an extra-framework crystalline ALPO phase. When there is no EFAL to react with, the P reacts with framework Al, seriously distorting its coordination, but without forming EFAL species. These distorted sites were more or less immune to hydrothermal treatment. Excess phosphate was found on the external surface of the zeolite crystals.

Fig. 16. Chemical maps of phosphate-activated zeolite clusters, constructed from Al and P K-edge spectra stacks for two different samples. Blue color denotes Al, red denotes P, resolution is 60 × 60 nm. (a-ii) and (b-ii) Al K-edge XANES spectra; (a-iii) and (b-iii) P K-Edge XANES spectra, spectra in (ii) and (iii) colored according to the color in the inset. (Reproduced from ref. 80, Copyright PCCP Owner Societies, 2014).

Upon heat treatment, van der Bij et al. observed the formation of stable –(SiO)3–x–Al–(PO)x– type species (see Fig. 17), in other words SAPO species are connected to the framework, but with Al no longer in its original framework position.

Fig. 17. Schematic representation of the effect of phosphate on the stability of ZSM-5. (a) Stabilization effect of phosphorus on the framework of zeolite H-ZSM-5. (I) Unmodified H-ZSM-5 with three schematically drawn tetrahedrally coordinated framework aluminum (TFAl) atoms. (II) Phosphated and calcined H-ZSM-5, showing (1) local SAPO interfaces, (2) phosphates that induce a sixfold coordination on TFAl and (3) non-interacting TFAl. (III) During steam treatment non-interacting TFAl (3) is expelled from the framework and migrates to the surface where it reacts with phosphates to form AlPO4 (4). (1) Local SAPO interfaces and (2) physically coordinated phosphate aluminum are less affected, keeping aluminum fixed in the framework. (IV) Washing with hot water removes the physically coordinated phosphorus, returning six-coordinate aluminum (2) back into its original form as TFAl atoms, leading to acid site retrieval. (b) Part of the 3D channel system of H-ZSM-5 showing the straight and sinusoidal pores and their intersection. (c) Local silicon-alumino-phosphate (SAPO) interface located at channel intersections decrease the allowed dimensions of adsorbed species. (Reproduced with permission from ref. 81, Copyright Wiley-VCH, 2014).

The exact structure and position of these clusters, as well as mechanisms to form acid sites around these cluster remains as yet unsolved, although it is suggested that the bulky SAPO-species impede the formation of carbenium ions, and thus successfully suppress the bimolecular mechanism, resulting in an improved propylene selectivity for the treated samples.

4.3. Zeolites with hierarchical pore systems

Until recently, the job of operators working with an FCC unit was to make gasoline. Improved vehicle efficiency has led to a drop in the demand for gasoline in the USA, a trend that is more than likely to continue in view of the expected further efficiency increases demanded by greenhouse reduction emission limits. This implies the gasoline-to-diesel ratio in the refined product changes in favor of diesel, and the FCC unit, the main conversion unit in a large number of refineries, will have to respond. Hansen et al. 82 describe this can be tackled by a number of operational changes, such as minimizing the diesel fraction in the FCC feedstock, changing cutpoints and reducing the cracking severity. It is also possible to change the FCC catalyst to a more diesel-selective catalyst. Hansen et al. 82 describe that one option is to lower the zeolite content and increase matrix activity. However, this leads to an increased coke formation. They describe a series pathway as one of the cracking pathways: as conversion increases, first LCO, then gasoline, and finally LPG reach a maximum yield, and they propose that mass transfer limitations determine the outcome of this complex inter-conversion network to a great extent.

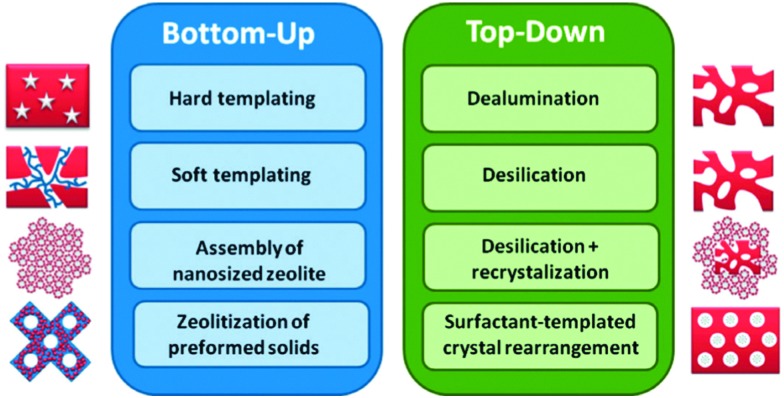

There are a number of ways to introduce a hierarchical pore structure, in which mesopores and micropores are connected, in zeolites. A review on hierarchical zeolites is presented by Li et al.,83 while other recent reviews on hierarchical zeolites are those by Na et al., Moliner, and Serrano et al. 84–86 Li et al. 83 describe, as summarized in Fig. 18, two approaches: bottom up, in which the hierarchical zeolite is synthesized directly from a silica-alumina gel, and top-down, in which existing zeolites are post-treated. In the bottom up-approach, extra-crystalline, hard, templates such as carbon black, 3-D ordered mesoporous carbon, or carbon aerogel can be used (e.g., ref. 87 and 88).

Fig. 18. Bottom-up and top-down approaches to hierarchical mesoporous zeolites. (Reproduced with permission from ref. 83, Copyright Wiley-VCH, 2014.).

The zeolites form within the structure of the hard template, which is then burnt off to create mesoporosity. Adaptations of the more standard templates, which introduce mesopore-structure direction in the same molecule, are called soft-templating. Here, different functionalities are combined in one template molecule that direct for micropores and mesopores. For instance, Ryoo et al. 89 describe hierarchical zeolites from randomly stacked MFI nanolayers, which are created by using special bifunctional organic structure directing agents. Rimer et al. 90 influence the crystallization kinetics by applying zeolite growth modifiers (ZGM), organic molecules that impede the growth of specific zeolite crystal planes. The conversion of amorphous cell walls of MCM-41 or SBA-15 type mesoporous materials towards crystalline zeolite structures (such as TUD-C,91 or zeolite Y encapsulated in TUD-192) is also considered bottom-up.

In the top-down approach to achieve hierarchical zeolites, the zeolites are post-treated after synthesis. The easiest way to introduce mesoporosity is by dealumination, which can be achieved by steaming and chemical treatments, such as acid leaching or reaction with EDTA or other chelating agents that remove the resulting extra-framework alumina. This approach was used in the development of Dow's 3DDM mesoporous mordenite catalyst for the production of cumene,93 and is also the basis of US-Y zeolites that are used in many applications nowadays.

Clearly, dealumination leads to a lower number of acid sites and at least an initial loss of framework integrity. However, these disadvantages are more than offset by the creation of new types of acidic sites and enhanced diffusion properties.94 The increased mesoporosity may give rise to increasing rates in bimolecular and oligomeric reaction pathways that require large transition states.95 Separating this effect from the modified acidity per site in explaining activity and selectivity differences can be a challenge. Janssen et al. provide a good insight in the formation of the mesopores in zeolite Y by applying 3D transmission electron microscopy (TEM) in combination with nitrogen physisorption and mercury porosimetry measurements.96 They find a large part of the mesopores in cavities within the crystal, and the creation of an interconnecting system of cylindrical mesopores requires special treatments.

Another way of producing mesopores is by desilication. Initial work in this field was published by Groen et al. 97,98 and expanded upon by Pérez-Ramírez et al. 99,100 The authors stress the need for a sustainable route, and note that most bottom-up approaches make use of exotic ingredients or larger amounts of organic templates than the original materials. Top-down approaches typically have low yields because they leach away either alumina or silica, and thus give rise to waste-streams. The authors note that a typical base leaching may remove as much as 30% of the parent material.101 They propose to use the silica-rich waste stream as a raw material in the original synthesis of the zeolite, thereby closing the material loop.99

Li et al. 102 compare mesoporous mordenites made with different synthesis methods. They applied soft and hard templating, as well as a combination of acid leaching and base treatment. Only the combination of acid leaching and base leaching yielded a material with improved accessibility and strong acidity, leading to optimal performance in the isomerization of 2-methyl-2-pentene and the alkylation of benzene with benzyl alcohol.

Park et al. 103 describe ZSM-5 based catalysts with hierarchical pore systems prepared with soft templating. When compared to normal ZSM-5 catalysts in the cracking of gas oil, they observe higher overall activity, and higher yield of lower olefins like propylene and butylene. The catalysts contain intracrystalline mesopores. The author assume that pre-cracking of larger molecules inside the mesopores provides the molecules that can be cracked inside the MFI micropores to give the desired products. Normal ZSM-5 would require conversion of gasoline range molecules to form the desired olefins, whereas the mesoporous catalysts described by the authors have similar or better gasoline yields compared to normal ZSM-5. However, the catalytic performance was tested on pure zeolite samples. The addition of matrix and binder, as well as the presence of a main Y-zeolite based FCC catalyst in the catalyst system, may cause the observed benefits to change, among others because this would supply a large concentration of gasoline molecules. The conversion and selectivity to propylene observed for the hierarchical ZSM-5 samples described by the authors is not high enough to warrant use by itself (see e.g. the performance characteristics of the DCC process104).

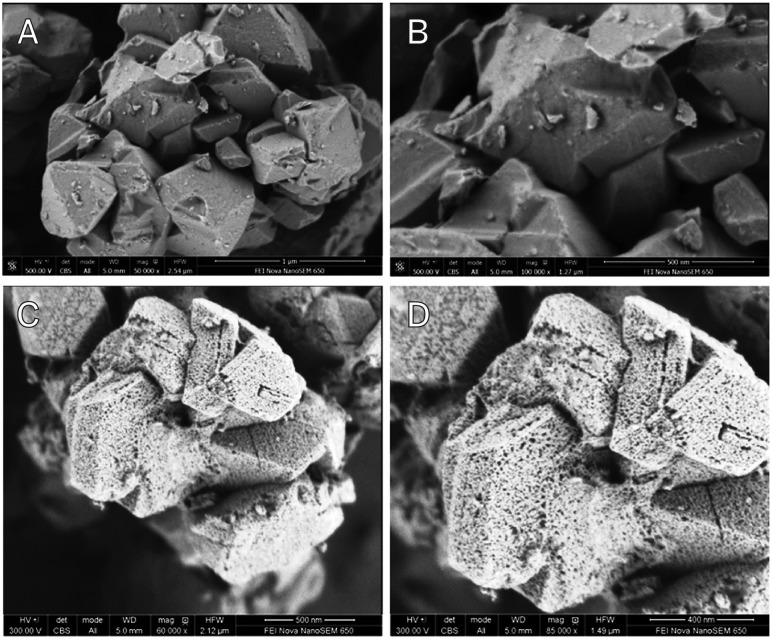

Hansen et al. 82 describe the introduction of uniform mesopores in the size range of about 4 nm, or about 6 times larger than the micropores in the host lattice of the zeolite (see Fig. 19), by a post-synthesis chemical treatment.83,105 We will expand a bit on this work, as it directly concerns an application in FCC. The authors observe a lower bottoms yield at constant coke, and improved middle distillate over bottoms selectivity in ACE testing. A similar effect is seen for the gasoline over LPG selectivity, since the optimum in the series pathway network is shifted to higher molecular weight. The post-synthesis treatment in this technology appears to amount to a re-crystallization of the zeolite in alkali (pH 9–11) in the presence of cetyl-trimethyl-ammonium-bromide (CTAB) at 150 °C. The starting zeolite in the original process already has a quite high silica-to-alumina ratio of about 30, lower SAR zeolites apparently need an acid pretreatment before they are suitable for post-treatment.106 Carbon residue from the template is removed by careful calcination at 550 °C. Following the treatment, the authors do not observe any octahedrally coordinated Al in the NMR spectrum, and terminal silanol vibrations at 3740 cm–1 also disappear, both indicating a lattice without too many irregularities. The vibration of the Brønsted acid site at 3640 cm–1 seems to increase compared to the parent material, as does a vibration at ∼3540 cm–1, on which the authors do not comment. TPD of ammonia shows that the mesostructured material has about the same number of acid sites as normal zeolite US-Y. The zeolites were tested after being introduced in FCC-matrices, and steam-deactivated. At constant conversion, lower bottoms- and coke-make, and higher gasoline and middle distillate yields are observed.

Fig. 19. FE-SEM images from untreated (top) and mesostructured (bottom) zeolite Y crystals. Scale bars: (a) 1 μm; (b and c) 500 nm; (d) 200 nm. (Reproduced with permission from ref. 83, Copyright Wiley-VCH, 2014).

García-Martínez et al. 107 describe a test with a commercial quantity of the material in a refinery. They tested the E-cat from the refinery in a FCC test unit before and at the end of the trial, and report lower coke make, higher LCO make and lower bottoms for the catalyst containing hierarchical zeolites.

4.4. New zeolites in fluid catalytic cracking

Although it is clear that improved mesoporosity in FCC catalysts improves the performance, this does not imply that ultra-large-pore zeolites are necessarily good active ingredients in FCC catalysts.108 In the cracking of model reactants like n-hexane, for instance, MCM-41 performs much poorer than zeolite US-Y. In the cracking of larger molecules, like gas oil cracking, the difference is smaller, but the low thermal stability of MCM-41 prevents its application under the severe FCC process conditions.

Early work by Derouane and co-workers109 explains this effect. The authors describe the role of the curvature of the zeolite pore surface and explain that the interaction between molecules and the zeolite surface is strongest when the radius of the molecule and the surface curvature are similar. At this exact fit, a number of phenomena are described that have a direct effect on the performance, e.g. a supermobility instead of Knudsen diffusion. The increased interaction leads to increased concentration of reactants near the acid sites, and expresses itself macroscopically as increased apparent acid strength. This implies that the 3D structure of the zeolite and its effect on sorption equilibria can play a large role in reaction kinetics; they directly influence the observed rate of reaction, especially when the sorption energetics are magnified by the surface curvature.110 This implies that the decreased rate of cracking of n-hexane in MCM-41 as compared to zeolite US-Y does not necessarily mean that the acid sites in MCM-41 are weaker than those in zeolite US-Y.

Apart from zeolite Y and ZSM-5, other zeolites have been tested in FCC catalysis. Zeolite Beta, for instance, has been studied extensively. Although economics and thermal stability have thus far prevented the application of zeolite Beta in large-scale FCC processes, it is known111–113 that (P-stabilized111) zeolite Beta improves C4-yields. Bonetto et al. describe an optimal crystallite size for stability, activity and selectivity for zeolite Beta in gas oil cracking.112 Mavrovouniotis et al. ascribe the higher olefinicity in the gases for zeolite Beta to a lower hydrogen transfer activity.113

The issue of cost and stability returns for many of the new structures proposed for FCC applications. Quite often, complicated organic SDAs, or exotic framework constituents (e.g. Ge and Ga), or fluoride-assisted syntheses are required to even synthesize (new) zeolite structures. These do not translate well to the scale of operation, catalyst consumption and the severity of the FCC process. Nevertheless, we will discuss some recent developments in the paragraphs below.

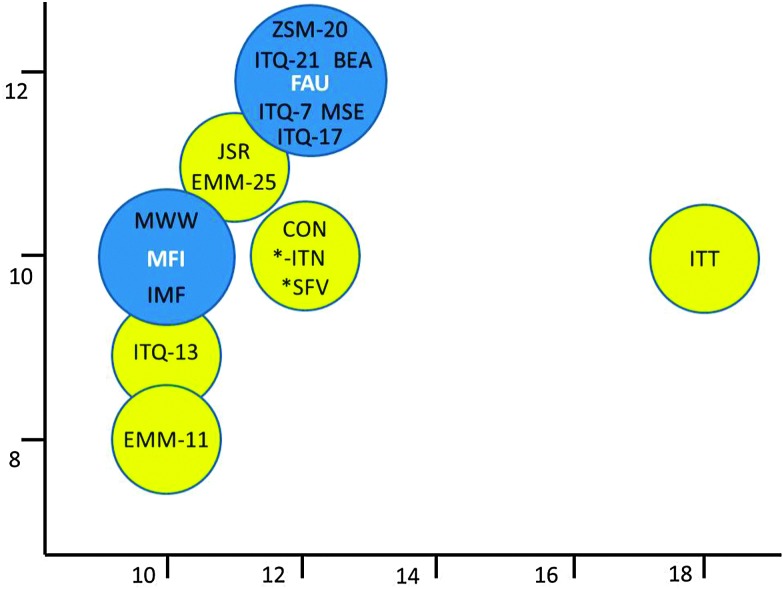

Fig. 20 gives an overview of some of the new zeolites tested in FCC as a function of their pore diameters. When examining the medium pore size zeolite MCM-22,114 Corma et al. observed little activity in the cracking of larger molecules. When using it in an additive similar to zeolite ZSM-5 additives, zeolite MCM-22 produces less gases (lower loss in gasoline yield), but with higher olefinicity (so higher propylene and butylene selectivity than ZSM-5). ZSM-5 is more active, though. ITQ-13115 with a 3D 9-MR × 10-MR pore system, presents acid sites that are similar in strength to those of ZSM-5, or stronger. The specific pore structure induces an increased yield of propylene in VGO cracking.

Fig. 20. New zeolites tried in FCC applications, ranked according to the size of their pore systems. Many of the new zeolites have mixed pore systems, allowing them to show performance in between the conventional zeolites ZSM-5 and Y.

Zeolite ITQ-7116 has a pore system similar to zeolite Beta, yet a higher gasoline yield and improved olefin selectivity are observed in FCC cracking, where an ITQ-7 containing additive was used.117 The authors conclude that the specific structure and tortuosity of the pore system favors β-scission over protolytic cracking and limits hydrogen transfer reactions.

Zeolite ZSM-20118 and ITQ-21119 both have structures that resemble zeolite Y, and pore openings that are similar in size to zeolite Y. Their cracking characteristics are similar to zeolite Y, except for a higher gas (LPG) and propylene yield but lower gasoline olefinicity in ITQ-21. Zeolite ZSM-20 shows good thermal stability compared to zeolite Y, but this does not directly translate into higher activity.

In their description of the new zeolite IM-5, Corma et al. 120,121 apply various cracking and isomerization tests (i.e., n-decane hydroisomerization–cracking, m-xylene isomerization–disproportionation, and n-hexadecane isodewaxing) and adsorption tests to study the pore morphology and suitability of the structure for cracking reactions. The structure is described as having 10-MR pores with side pockets, and performance of the material in some cases is close to ZSM-5, possibly with improved thermal stability.

Moliner et al. 122 describe the synthesis of ITQ-39, a new zeolite with a three-directional channel system with interconnected large (12-MR) and medium pores (10-MR). The zeolite performs well in the alkylation of benzene to cumene. The authors claim the material would be a good additive for FCC since its pore system behaves as an intermediate between zeolites ZSM-5 and Beta. The silica-germanate ITQ-33, from the same group123 is another zeolite with a mixed pore system, in this case an intersecting 18-MR–10-MR system. This material was compared to ITQ-17, a material with the same composition but only 12-MR pores, as well as zeolite Beta (3D 12-MR pores). Cracking experiments were performed with 1,3-diisopropylbenzene (DIPB) and 1,3,5-triisopropylbenzene (TIPB), i.e. relatively large molecules that do not easily fit in small pores (DIPB can diffuse through 12-MR pores, TIPB cannot). The authors conclude the material behaves like a 12-MR, i.e. it has a medium-strong acid site strength. The material was also tested in VGO cracking, yielding more middle distillates than zeolite US-Y or Beta at the same conversion.124 A catalyst mixture of ITQ-33 and ZSM-5 yielded more middle distillate as well as significantly more propylene than zeolite US-Y, even when the US-Y was also tested with ZSM-5 additive. Economics and stability of the material may impede its widespread application, though.

There are other new or fairly recently described materials that could be of use for FCC, but these have not been extensively discussed, such as the 11-MR systems JU-64 (JSR125) and EMM-25,126 and the 12-MR system MCM-68 (MSE127). Other structures with mixed pore systems include EMM-11 (10-8MR),128 and the 10-MR/12-MR systems SSZ-57 (*SFV129) and CIT-1/SSZ-26/SSZ-33/EMM-22 (CON130–132).

5. Changes in feedstock and new applications of FCC catalysts

5.1. Co-processing biomass-derived oxygenates with FCC catalysts

Due to growing awareness of depleting crude oil resources, rising CO2 levels, global warming and securing energy supply it would be advantageous to use biomass-derived feedstock in existing petroleum refineries.133 As petroleum refineries are already in place the use of this infrastructure for the production of fuels and base chemicals, such as propylene, from biomass requires – in principle – relatively little investment costs. An attractive, and already explored option is the co-processing of biomass-derived oxygenates with petroleum-derived fractions, such as VGO.

FCC of biomass-derived oxygenates gives products with higher hydrogen content than the starting biomass-based feedstock by removing oxygen as carbon monoxide as well as carbon dioxide, next to an increased amount of water. In addition, higher amounts of carbon deposits are found on the FCC catalyst material, which then can be burned off in the regeneration to produce process heat. Alternatively, the coke deposits formed by co-processing biomass with VGO during FCC can be converted into synthesis gas (CO + H2), which can be used elsewhere in the oil refinery. Another important issue relates to the significant content of water in biomass-derived oxygenates, which may not dissolve into VGO, although some options have been discussed by Corma and co-workers.134

In this article we focus on the catalytic cracking of biomass-derived feedstocks mixed with petroleum-derived feedstocks making use of real-life FCC catalyst materials. This topic has been the subject of several review articles and we refer here the reader to the excellent articles of Huber & Corma and Stocker for the required background and the various possibilities for catalytic cracking of lignocellulosic- and triglycerides-based feedstocks.135,136 Examples include sugars (glucose and xylose), sugar alcohols (e.g. xylitol and glycerol), lignin as well as vegetable oils. Other more recent review papers are of the hands of Al-Sabawi and co-workers137 and Kubicka and Kikhtyanin.138

Active research groups include those of e.g. Schuurman & Mirodatos [e.g. ref. 139–142], Kersten & van Swaaij [e.g. ref. 143–145], Naik & Kumar [e.g. ref. 146 and 147], Corma [e.g. ref. 134 and 148] and Lappas & Vasalos [e.g. ref. 149 and 150].

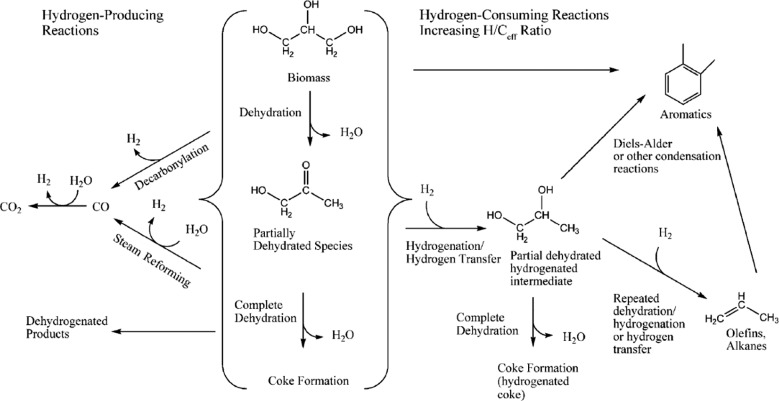

Fig. 21 summarizes the different reaction pathways for the catalytic cracking of biomass-derived oxygenates, which involves, according to Corma et al.,134 five different classes of reactions: (a) dehydration reactions, producing water; (b) cracking of large oxygenated biomass-based molecules into smaller molecules; (c) hydrogen-producing reactions; (d) hydrogen-consuming reactions; and (e) production of larger molecules by carbon–carbon bond formation. Although the FCC process in principle does not require hydrogen it can be produced through steam reforming and water–gas shift reactions as well as dehydrogenation and decarbonylation of biomass-derived molecules.

Fig. 21. Reaction pathways for the catalytic cracking of biomass-derived oxygenates. Reproduced with permission from ref. 135, Copyright Wiley-VCH, 2007.

A seminal mechanistic contribution in this field of research originates from the group of Schuurman and Mirodatos, who have explored the 14C technique – known to discriminate fossil carbon from bio-carbon since fossil fuel is virtually free of 14C, while biofuel contains the present-day amount of 14C – to determine how the carbon from the co-processed biomass re-distributes in the range of FCC products formed. This has been done by co-processing hydro-deoxygenated (HDO) bio-oil with VGO feedstock over an E-cat FCC catalyst. It was found that the bio-carbon was mainly concentrated in the gas fraction (10.6%) and in the coke deposits (15.8%), while the gasoline produced contains only around 7% of the bio-carbon. In other words, it was found that co-processing leads to a bio-carbon impoverished gasoline, and a bio-carbon enriched LPG product slate. Such an uneven bio-carbon distribution can be explained by the changes in the cracking routes during co-processing, arising essentially from the competitive adsorption of the polar oxygenated molecules and non-polar hydrocarbon molecules in the mesopore space of the FCC catalyst material. The HDO bio-oil molecules are preferentially cracked and deoxygenated into light gases, which seems to inhibit the production of bottom, LCO and gasoline from the VGO feedstock. The larger coke formation, which was noted to be richer in bio-carbon, could originate from the re-polymerization of phenolic compounds. Another part of the increased coke formation may originate from the depletion in hydrogen due to water formation.

A detailed study on the catalytic cracking of various bio-oil model compounds, which could be co-processed in an FCC unit, has been performed by Sedran and co-workers.151,152 This group has studied, making use of an E-cat FCC catalyst, the influence of various functional groups in biomass-derived molecules on the catalytic conversion, selectivity and coke levels, and compared them to those obtained for thermal cracking of the very same model compounds. More in particular, they have investigated the following biomass-derived model compounds: methanol (MEL), acetic acid (ACET), methyl acetate (MACET), furfural (FUR), 3-methyl-2-pentanone (MP), 2-hidroxy-3-methylcyclopenenone (HMCP), phenol (PHE), 2,6-dimethoxyphenol (SYR) and 1,2,4-trimethoxybenzene (TMBENZ). Table 1 summarizes the results of the thermal and catalytic cracking, including the conversion, as well as the yields of hydrocarbons, oxygenates, H2, CO2, CO, H2O and coke deposits.

Table 1. Thermal and catalytic conversion of various biomass-derived model compounds when using an E-cat FCC catalyst and a reaction temperature of 500 °C in a fixed bed laboratory reactor for 60 s. The selectivity is expressed as a distribution in wt% of the hydrocarbon products analysed. SiC was used as inert material in the reactor to simulate thermal cracking, while nr in the table implies not reported values.

| Model compound | Thermal or catalytic cracking | Conversion (%) | Yields (wt%) |

|||||||

| Hydrocarbons | Oxygenates | H2 | CO2 | CO | H2O | Coke | Unknown | |||

| Methanol | SiC | 22.6 | 0.2 | 5.4 | 2.4 | 0.8 | nr | 13.6 | 0.2 | nr |

| E-cat | 60.8 | 7.1 | 4.0 | 3.5 | 12.2 | nr | 27.0 | 5.5 | 1.7 | |

| Acetic acid | SiC | 45.0 | 10.4 | 5.0 | 17.5 | 8.2 | nr | 3.6 | 0.3 | nr |

| E-cat | 50.4 | 4.2 | 5.2 | 6.6 | 22.9 | nr | 9.9 | 1.6 | nr | |

| Methyl acetate | SiC | 95.3 | 0.4 | 81.6 | 5.2 | 3.0 | nr | 4.7 | 0.4 | nr |

| E-cat | 95.1 | 0.9 | 54.5 | 3.7 | 22.2 | nr | 6.4 | 7.4 | nr | |

| Furfural | SiC | 21.6 | 5.3 | 0.7 | 6.7 | 1.1 | nr | 6.8 | 1.0 | nr |

| E-cat | 78.2 | 32.1 | 9.0 | 5.7 | 9.6 | 1.8 | 12.8 | 7.2 | nr | |

| 3-Methyl-2-penta-none | SiC | 24.9 | 0.3 | 17.9 | 0.6 | 1.2 | nr | 3.1 | 0.1 | 1.7 |

| E-cat | 79.6 | 37.6 | 20.7 | 0.5 | 1.1 | nr | 13.7 | 5.9 | nr | |

| 2-Hidroxy-3-methyl-cyclopentenone | SiC | 37.7 | 5.0 | 14.4 | 3.7 | 1.9 | nr | 10.0 | 0.7 | 2.0 |

| E-cat | 84.5 | 14.0 | 9.4 | 8.1 | 35.7 | 1.2 | 2.3 | 12.8 | 1.0 | |

| Phenol | SiC | 8.2 | 0.2 | nr | 1.1 | 4.0 | nr | 2.8 | 0.1 | nr |

| E-cat | 54.9 | 34.9 | 2.0 | 1.6 | 4.0 | nr | 8.0 | 4.4 | nr | |

| Syringol | SiC | 56.7 | 0.4 | 39.0 | 3.0 | 7.5 | nr | 6.0 | 0.8 | nr |

| E-cat | 75.0 | 2.1 | 32.5 | 4.1 | 22.9 | nr | 4.9 | 8.5 | nr | |

| Trimethoxy-benzene | SiC | 97.1 | 57.8 | 3.4 | 2.3 | 32.9 | 0.3 | nr | 0.4 | nr |

| E-cat | 95.7 | 47.1 | 0.2 | 2.3 | 29.8 | 0.3 | nr | 16.0 | nr | |

It can be concluded from Table 1 that the catalytic cracking activity decreases in the order: TMB > MACET > HMPC > FUR > SYR > MET > PHE > ACET. These conversion levels are, with some exceptions (e.g. TMB), always higher for the catalytic cracking as compared to thermal cracking. Deoxygenation reactions, taking place via dehydration and decarboxylation, results in the production of CO2/CO and H2O, and was very important in all cases, but was very dominant for ACET, MACET, HMPC, SYR and TMB. Deoxygenation reactions were always much lower in the thermal conversions than in the catalytic conversions. The reverse was (almost) the case for coke deposit formation. The reaction products were also very different, ranging from mainly aromatics in the gasoline range for methanol and TMB, to C4-hydrocarbons of olefinic nature for PHE and SYR.

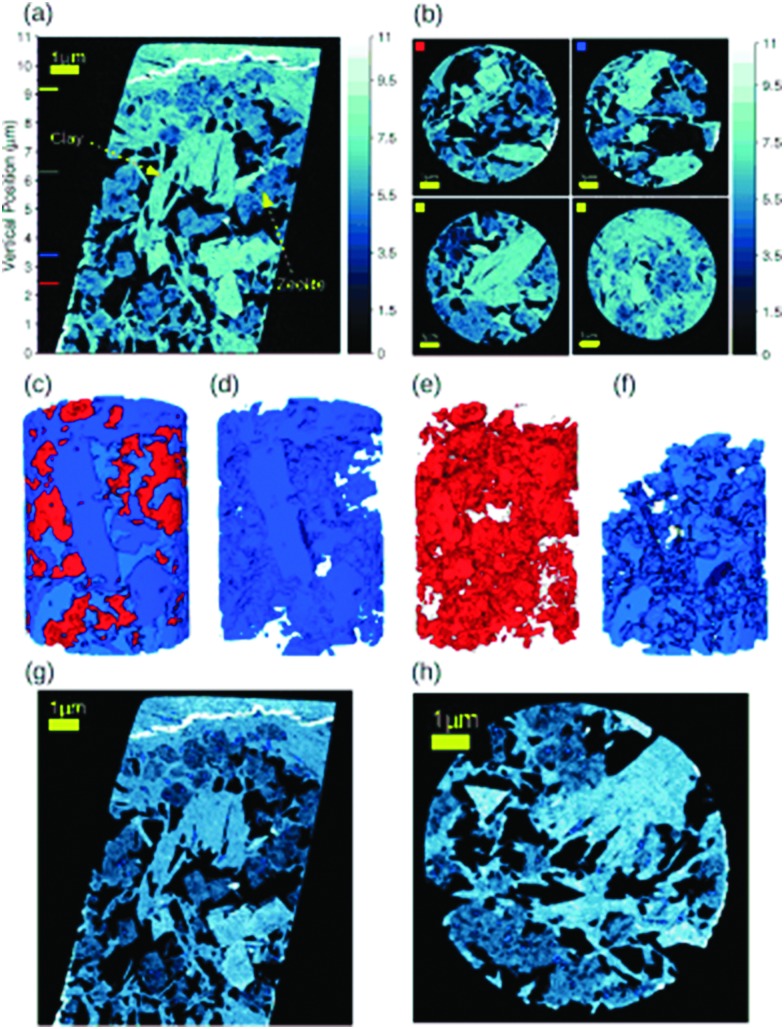

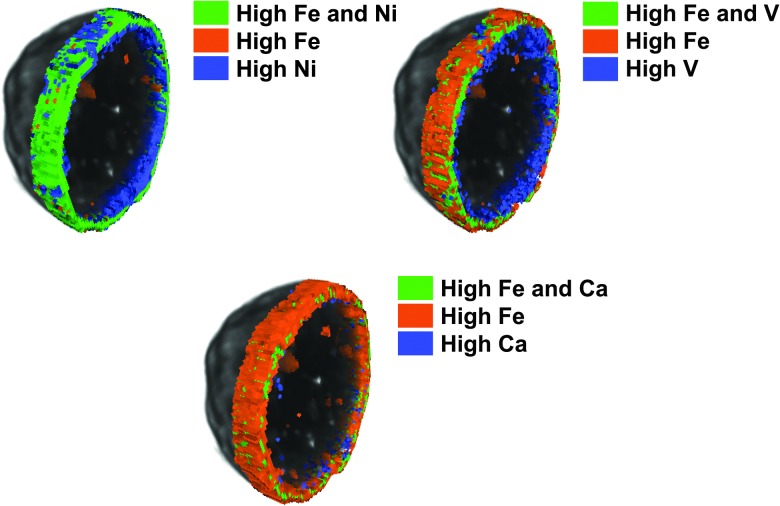

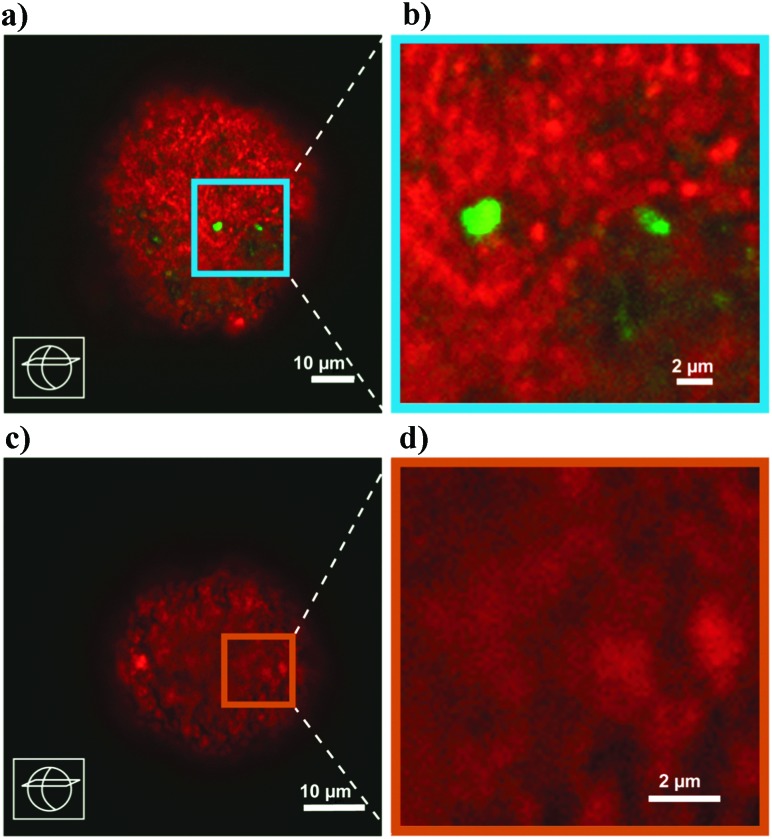

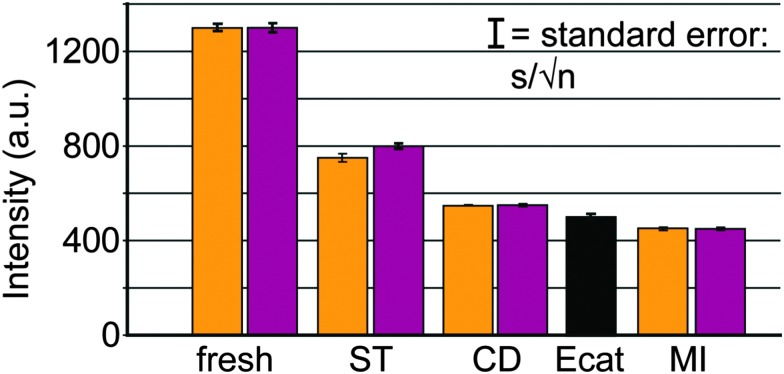

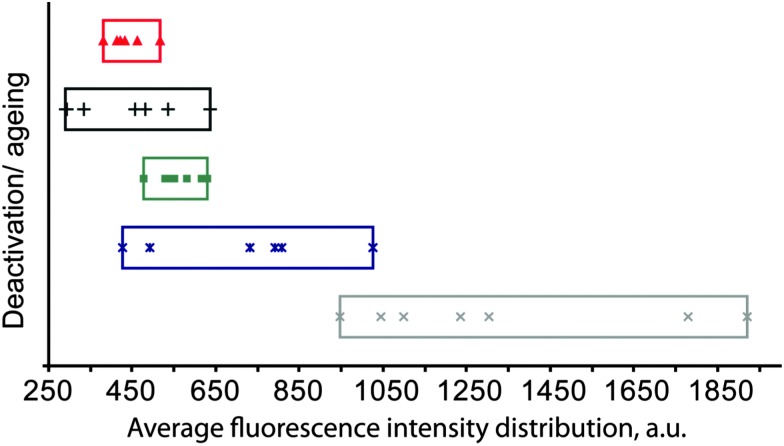

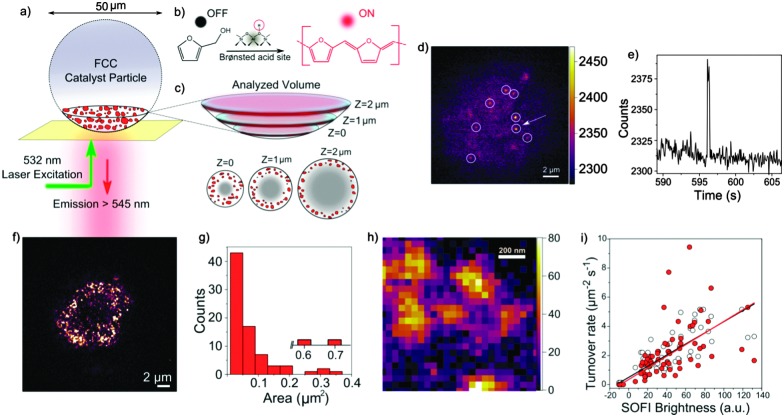

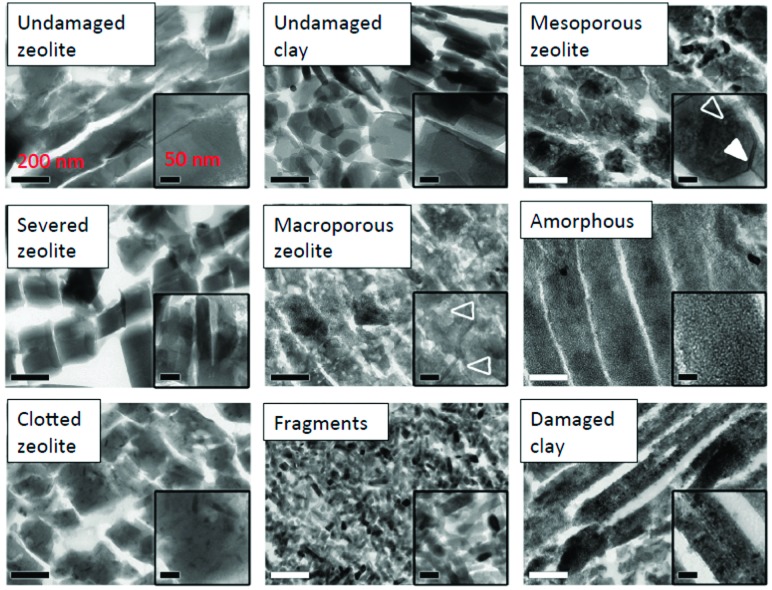

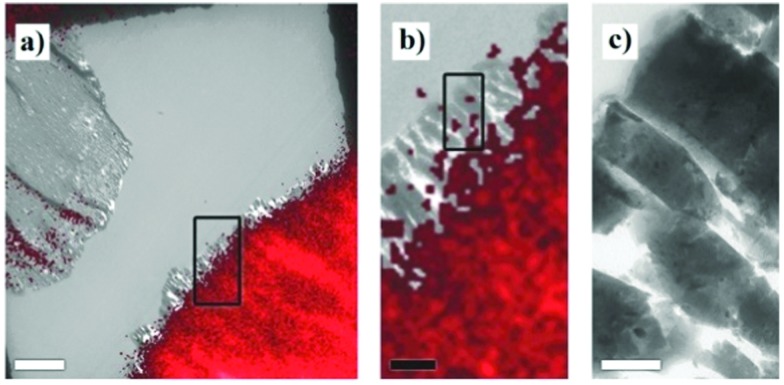

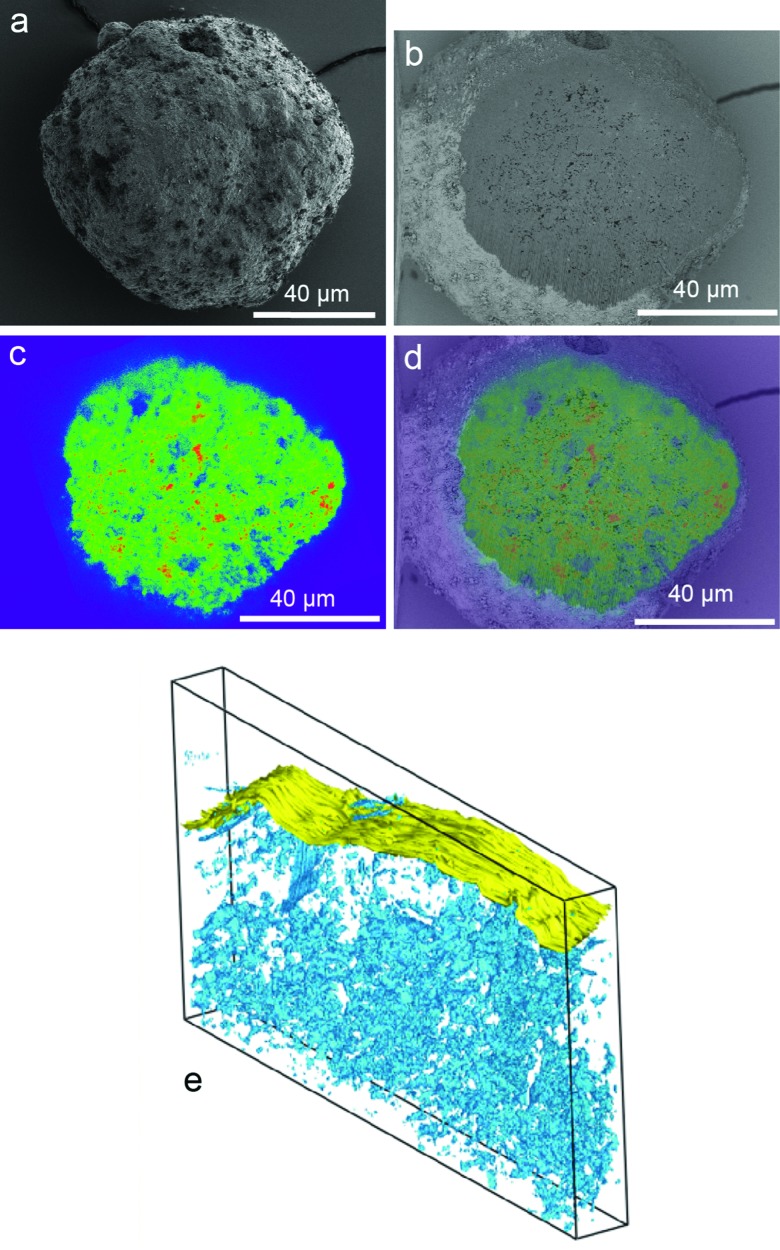

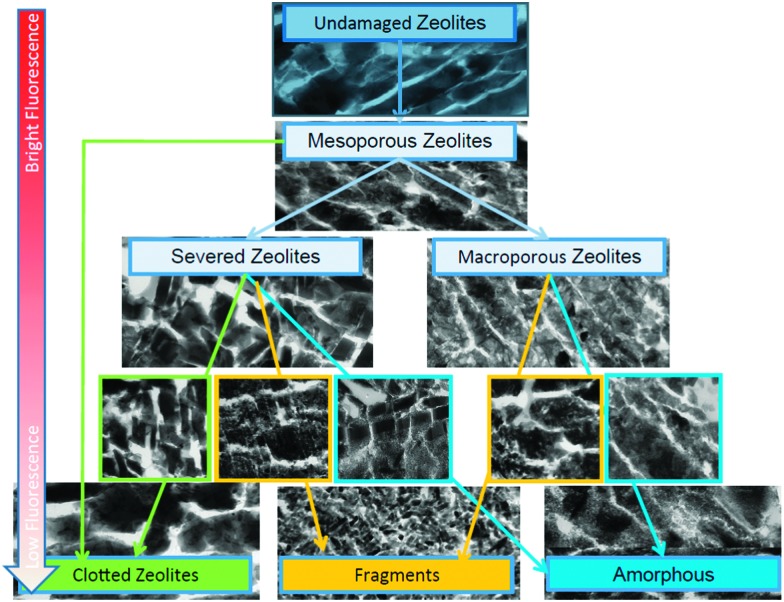

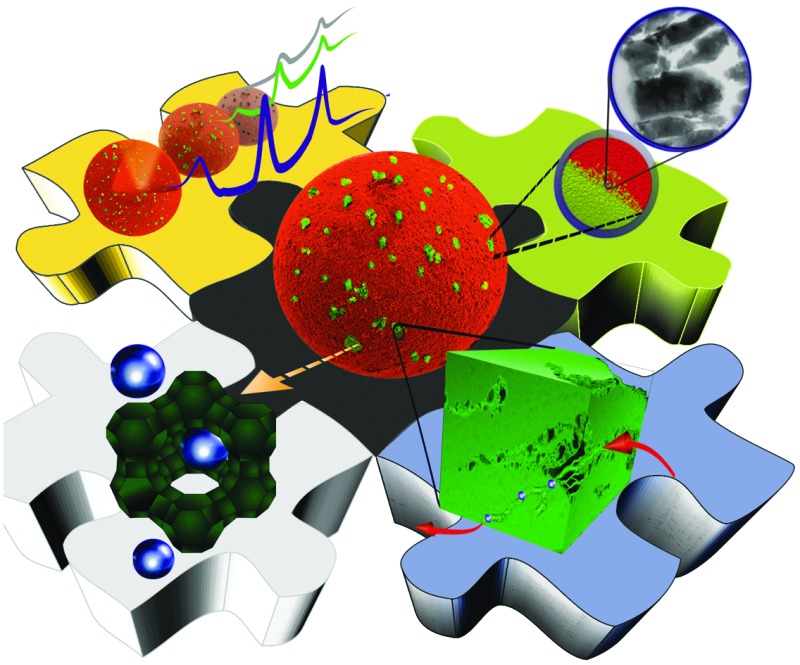

In a follow-up study, Bertero and Sedran have converted a raw and thermally processed pine sawdust bio-oil over an E-cat FCC catalyst and compared their findings with a synthetic bio-oil composed of MEL, ACET, MACET, FUR, HMCP, PHE, SYR and TMBENZ.153 It was found that with this biomass-derived feedstock mainly C4 olefins, oxygenates and coke were formed. In contrast, the synthetic bio-oil produced lesser hydrocarbons and more oxygenates and coke than the sawdust-derived feedstock. Thermal treatment of the raw bio-oil lead to an increased amount of hydrocarbons, and a decreased amount of coke deposits. As a side conclusion it was stated that the behavior of bio-oils over FCC-based catalysts could not be well-described by using mixtures of model compounds, indicating the need for real-life testing, including the use of a commercial FCC catalyst.