Abstract

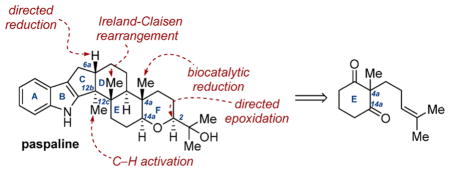

An enantioselective synthesis of the indole diterpenoid natural product paspaline is disclosed. Critical to this approach was the implementation of stereoselective desymmetrization reactions to assemble key stereocenters of the molecule. The design and execution of these tactics are described in detail, and a thorough analysis of observed outcomes is presented, ultimately providing the title compound in high stereopurity. This synthesis provides a novel template for preparing key stereocenters in this family of molecules, and the reactions developed en route to paspaline present a series of new synthetic disconnections in preparing steroidal natural products.

INTRODUCTION

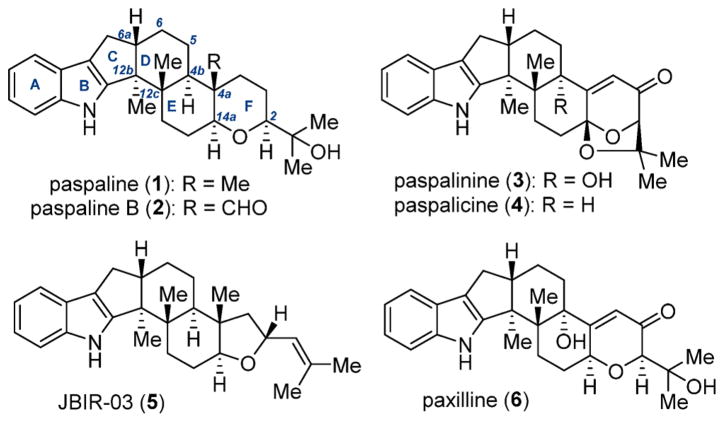

Production of novel metabolites by the ergot fungus has been well-documented.1 Most notably, those produced by Claviceps purpurea have long been implicated in the contamination of various grains.2 Claviceps paspali, another species in this genus, has been linked to “paspalum stagger” poisoning in livestock,3 and it was from this fungus that Arigoni and co-workers isolated paspaline (1, Figure 1) and paspalicine (4), the first of a now extensive family of indole diterpene alkaloid natural products.4 A diverse range of related structures have since been reported including paspaline B (2),5 paspalinine (3),6 JBIR-03 (5),7 and paxilline (6).8

Figure 1.

Paspaline and related indole diterpenoid natural products.

The varied biological profiles of these compounds have rendered them particularly attractive to the chemical industry. The recently discovered JBIR-03 has displayed significant inhibition of Valsa ceratosperma (MIC = 128 μg/mL) while showing no cytotoxic effects to the human fibrosarcoma cell line HT-1080 at 100 μM.7 Moreover, paspalinine and its derivatives have demonstrated marked activity as Maxi-K channel antagonists and, as a result, are under examination as treatments for Alzheimer’s disease and other neurological disorders.9 Paxilline is currently under study for its properties as a BK channel antagonist toward the suppression of seizures in postnatal mammals.10 From a standpoint of structure–activity, prior work by Cole has underscored the significance of the axial tert-hydroxyl functionality (C4b, paspaline numbering) as an important source of activity for these structures, evidenced by the lack of tremorgenicity demonstrated by paspaline and paspalicine.11

The absolute structure of 1 was confirmed in 1980 by Springer and Clardy on the basis of X-ray diffraction studies.11a Paspaline and its related compounds are characterized by their unique indole and tetrahydropyran (or derivatives thereof) ring fusions. Furthermore, grafted onto the D/E decalin core, three all-carbon quaternary atoms are encountered (C4a, C12b, C12c). These salient features necessitate careful planning for endeavors in total synthesis. These challenges were first addressed by the Smith laboratory,12 whose body of work in this area has defined the state of the art for the synthesis of paspaline and its related structures. Subsequent partial13 and total14 synthetic studies of these molecules have since been disclosed, building on these advances. As an extension to previous work in our laboratory in developing total synthesis platforms for complex molecular frameworks,15 we sought to develop an expedient synthesis of 1, particularly of the key C4a, C12b, and C12c stereocenters, which could serve as a template for assembly of the remaining structures in this family. Our work toward this goal culminated in a highly stereocontrolled total synthesis of paspaline.16 Herein, we disclose the entirety of our efforts, ultimately leading to the conception and implementation of two critical stereoselective desymmetrization reactions for facile target assembly. These studies have laid the groundwork for future investigations in this family of natural products.

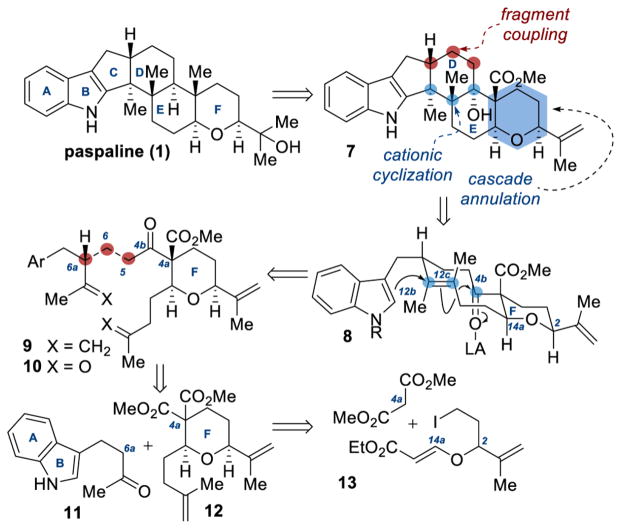

Our preliminary synthetic plan for 1 began with translation to hydroxyalkene 7 (Scheme 1). The decalin functionality (D and E rings) in 7 would be constructed via a transannular ketone addition/Friedel–Crafts alkylation cascade arising from cyclodecenone 8,17 establishing the vicinal C12b and C12c quaternary centers in a single operation. The tetrasubstituted (E)-alkene in 8 would be prepared via intramolecular coupling of the corresponding diene 9 or dicarbonyl 10 via a metathesis18 or McMurry process.19 Synthesis of this ketone would rely on the union of fragments 11 and 12 to assemble the C6a, C6, and C5 carbon–carbon bonds. Access to the tetrahydropyran 12 was envisioned via an alkylation/Michael addition cascade between dimethylmalonate and 13 inspired by methodology developed by Gharpure.20

Scheme 1.

Preliminary Synthesis Plan for Paspaline

RESULTS AND DISCUSSION

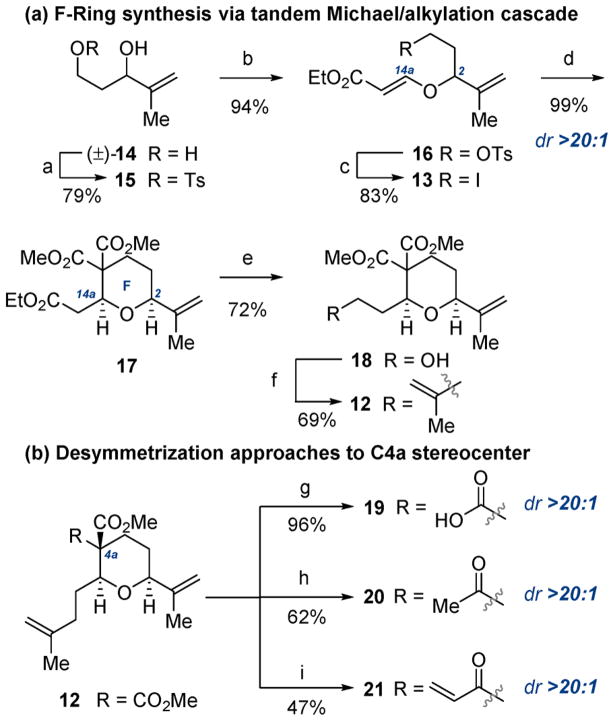

In accordance with the above strategy, initial focus was placed on synthesizing the tetrahydropyranyl F ring and C2/C14a stereodiad in 1 (Scheme 2). In a forward sense, tosylation of the previously reported diol 14 followed by oxy-Michael addition and iodination furnished the requisite iodoalkene 13 in 62% yield over three steps,21 setting the stage for the proposed annulation. Thus, treatment of 13 with CH2(CO2Me)2 and Cs2CO3 in DMF provided exclusively the desired 2,6-cis-pyran in 99% yield and >20:1 dr. Selective reduction of the ethyl ester in 17 proceeded smoothly to give alcohol 18 in 72% yield, and subsequent iodination and alkylation installed the requisite alkene in 12. With this compound in hand, we turned our attention to desymmetrization of the C4a gem-diester in 12 via nucleophilic addition. Experiments with this compound revealed a strong diastereotopic group bias for the equatorial ester, giving the desired relative stereochemistry at C4a.22 To enable maximum flexibility in the downstream strategy, the corresponding carboxylic acid 19, methyl ketone 20, and enone 21 were prepared.

Scheme 2. Synthesis of Tetrahydropyranyl F Ring and C4a Stereocentera.

aReagents and conditions: (a) TsCl, NEt3, DMAP (10 mol %), CH2Cl2, 0 °C; (b) N-methylmorpholine, ethyl propiolate, CH2Cl2, rt; (c) NaI, acetone, rt; (d) CH2(CO2Me)2, Cs2 CO3, DMF, rt; (e) DIBAL-H, THF, 0 °C; (f) (i) I2, PPh3, imidazole, CH2Cl2, 0 °C to rt; (ii) (isopropenyl)2CuLi, Et2O, −78 to 0 °C; (g) KOH, THF/MeOH (1.75:1), rt; (h) MeLi, THF, −78 °C; (i) (i) EtLi, THF, −78 °C; (ii) LDA, THF, −78 °C, then PhSeBr; (iii) H2O2(aq), CH2Cl2, 0 °C.

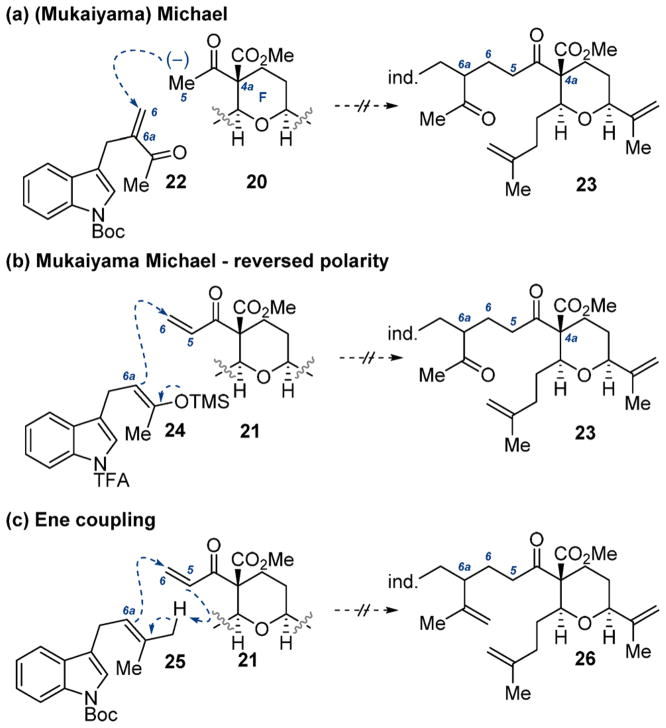

With the pyran subunit in place, the next challenge became introduction of the indole fragment bearing the atoms necessary for cyclodecenone synthesis (Scheme 3); however, we found this union to be significantly more challenging than first expected. In the first iteration, Michael addition of the enolate of 20 to the indole-derived enone 2223 using a variety of bases (LDA, LHMDS, NaOMe) showed no productive reactivity, presumably due to low reactivity of enone 22. Mukaiyama Michael addition to 22 using the enolsilane derived from 20 resulted in rapid desilylation prior to engaging 22 under all conditions examined. Methyl vinyl ketone also failed to react with 20 under these conditions. An alternative strategy explored reversal of the nucleophile/electrophile identities via the reaction of enolsilane 24 and pyranyl enone 21. However, exposure of these compounds to Lewis acidic conditions (BF3·OEt2, TiCl4, Cu(OTf)2, etc.) resulted only in desilylation of 24 and decomposition of enone 21. Finally, a Lewis acid promoted ene reaction was examined as a method for the union of enone 21 and nucleophilic alkene 25; unfortunately, the inherent instability of enone 21 remained problematic in this approach. These failed efforts led us to conclude that direct intermolecular coupling methodologies of these fragments to 1 from the C4a functionality were prohibitively challenging, and as a result, this approach was abandoned.

Scheme 3.

Unsuccessful Approaches to C5–C6a Bond Construction

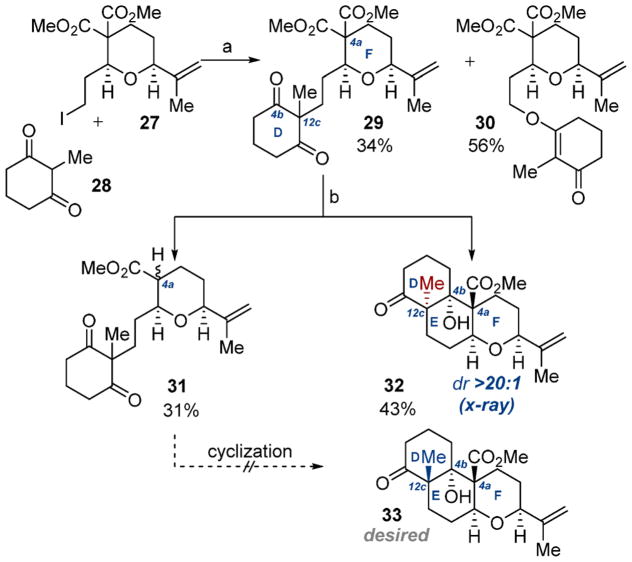

In an effort to circumvent the issues associated with the above strategy, we postulated that an intramolecular approach to the critical bond disconnection might be more facile (Scheme 4). This process would be enabled via appendage of the appropriate functionality to the iodide 27 (which had been synthesized previously in the described route to alkene 12). We selected 2-methyl-1,3-cyclohexanedione 28 as this nucleophile, anticipating that Krapcho decarboxylation of the corresponding alkylation product 29 might initiate an intramolecular aldol addition process to assemble the D,E ring decalin moiety as well as the C12c and C4b stereocenters (33). In practice, alkylation of iodide 27 with 28 gave a ~1:2 mixture of diketone 29 and the undesired O-alkylation product 30 in 34 and 56% yields, respectively.23 While this issue of regiochemistry rendered material throughput challenging, we carried on in the interest of validating the proposed downstream reactivity. Operating first on small scale (15 mg), treatment of diketone 29 with NaCl in DMSO afforded a ~1:1 ratio of the Krapcho adduct 31 and the cyclization product 32 as a single diastereomer. However, a single-crystal X-ray diffraction study revealed 32 to be the undesired cis-decalinone product (e.g., epimeric at C12c). Fortunately, formation of 32 was suppressed when the reaction was further scaled (70 mg), giving exclusively the Krapcho adduct 31 in 43% yield. In hopes that a stepwise Krapcho/aldol process might proceed with selectivity orthogonal to 32, we began screening conditions for the conversion of 31 to 33. Toward this aim, treatment of 31 with Brønsted or Lewis acidic conditions gave either no reaction or starting material decomposition upon heating. Alternatively, exposure to basic conditions resulted in no reaction or retro-Dieckmann decomposition of the dione functionality.

Scheme 4. Decarboxylative Annulation Approach to Paspaline D,E Ringsa.

aReagents and conditions: (a) Cs2CO3, DMF, 65 °C; (b) NaCl, DMSO, 150 °C.

Having arrived at another critical impasse, we began to question the viability of this route in providing access to 1. While the alkylation/Michael cascade sequence (13 → 17) provided expedient access to the F ring tetrahydropyran stereochemistry and desymmetrization of the C4a stereocenter proceeded as planned, further elaboration of this material to 1 seemed an unlikely venture. At this critical stage in our studies, we began to examine alternative points of initiation for our synthesis (Scheme 5).

Scheme 5.

Revised Approach to 1 via Enantioselective Desymmetrization

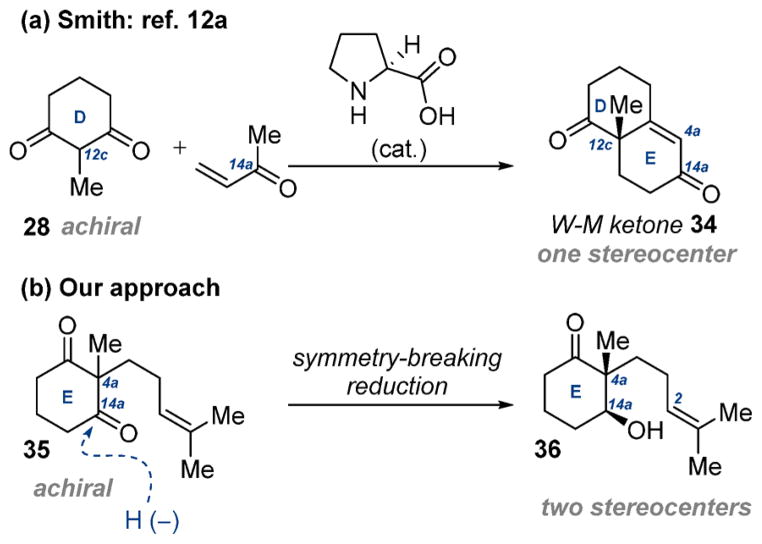

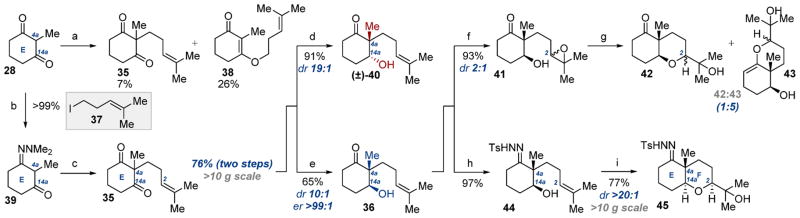

Guided by our previous work in developing symmetry-breaking processes to enable rapid construction of complex natural products,15g,h we surmised that a synthesis beginning from desymmetrization of a paspaline E ring precursor might circumvent the problems associated with our initial strategy. It is important to note at this juncture that Smith’s synthesis of 1 also commences via a symmetry-breaking process;12a namely, the Wieland–Miescher ketone synthesis (28 → 34) assembles the D–E ring fusion of 1 concomitant with the C12c quaternary stereocenter. While this reaction is a classic “single stereocenter” desymmetrization, we envisioned an alternative E ring desymmetrization arising from stereoselective monoreduction of functionalized diketone 35. Reduction of this compound would establish the stereochemical identity of C4a and C14a in 36 in a single operation while supplying the needed functional handles for tetrahydropyran assembly and synthesis completion. Armed with this new hypothesis, we refocused our efforts in the synthesis of 1 via this approach.

The first challenge in our revised synthesis plan was preparation of the desymmetrization precursor 35 via alkylation of dione 28 or its derivatives (Scheme 6). In the event, deprotonation of 28 with NaH followed by addition of iodide 37 provided the desired cycloalkanone 35 in 7% yield along with 26% of the undesired O-alkylation product 38. This result was not entirely unexpected: challenges associated with regioselective C-alkylation of cyclic α-dicarbonyls have been well-documented.24 In hopes of enhancing C-nucleophilicity of this structure, we prepared hydrazone 39.24 Screening of conditions revealed that enolization with KH followed by addition of iodide 37 provided exclusively the corresponding C-alkylation adduct which, following hydrazone deprotection, afforded functionalized diketone 35 in 76% yield over two steps. Of particular importance is the scalability of this process: diketone 35 can be prepared in >10 g scale in a single batch. This reaction represents a useful advance over prior art in preparing this compound,25 and the scope of this method is currently under study.

Scheme 6. Desymmetrization Approach to 1: E,F Ring Synthesisa.

aReagents and conditions: (a) NaH, DMF, 0 °C, then 37, rt; (b) H2NNMe2, TsOH (3.0 mol %), C6H6, 100 °C; (c) (i) KH, THF, 0 °C, then 37, −78 °C to rt; (ii) Cu(OAc)2, THF/H2O (1:1), rt; (d) NaBH4, MeOH, 0 °C; (e) YSC-2, H2O/DMSO (10:1), 30 °C; (f) m-CPBA, CH2Cl2, 0 °C; (g) PPTS (20 mol %), CH2Cl2, rt; (h) TsHNNH2, C7H8, 70 °C; (i) m-CPBA, CH2Cl2, 0 °C, then PPTS.

With the critical desymmetrization precursor in our possession, we began investigating selective monoreduction of 35 to access the C4a–C14a stereodiad. Treatment of 35 with NaBH4 provided the racemic monoreduction product 40 with excellent yield and diastereoselectivity (19:1), albeit the opposite diastereomer to that desired. It is reasonable to expect formation of this diastereomer under strictly substrate-controlled conditions, although we were surprised by the magnitude of selectivity for this diastereomer. We were encouraged, however, by the recent reports of Nakada26 and Node27 which demonstrated access to the diastereomer needed for our synthesis on similar cyclic diketones using biocatalytic reducing conditions. In experimenting with our compound, we were pleased to find that monoreduction of 35 with yeast from Saccharomyces cerevisiae type 2 (YSC-2) proceeded with virtually complete reagent control, giving the desired alcohol diastereomer 36 in 65% yield, 10:1 dr, and >99:1 er. The success of this transformation provided encouragement to the viability of our revised synthesis plan and set the stage for further manipulation to 1.

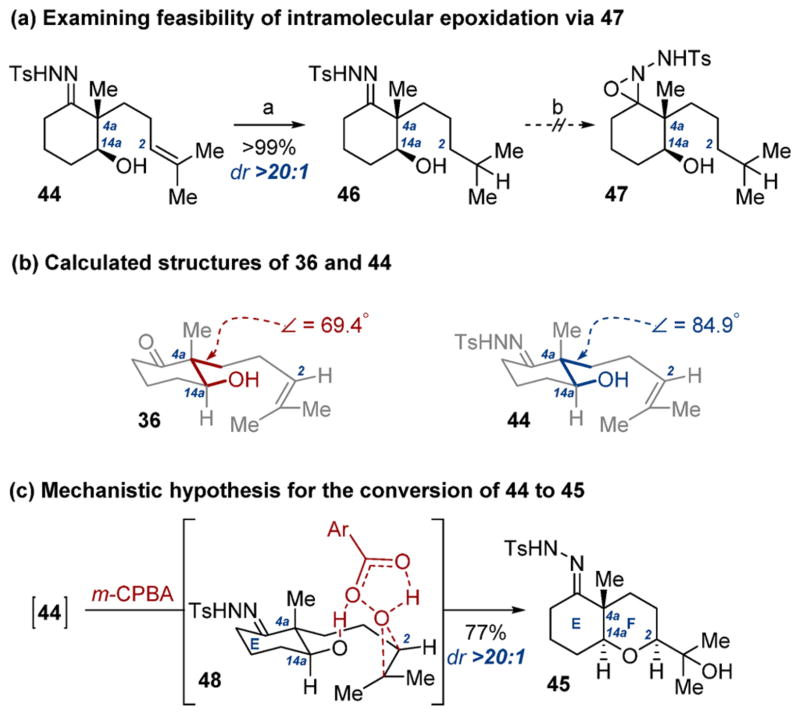

From hydroxy olefin 36, we anticipated assembly of the tetrahydropyranyl F ring via an oxidative cyclization sequence. With this goal in mind, treating the alkene in 36 with m-CPBA provided the corresponding epoxide 41 in 93% yield and poor diastereoselectivity (2:1). While any number of asymmetric epoxidation methods could likely enhance this selectivity, of greater concern was that treatment of this diastereomeric mixture 41 with conditions requisite for ring closure (PPTS) gave an inseparable 5:1 mixture of products with the desired tetrahydropyran 42 as the minor product. The major material was identified as alcohol 43, the result of epoxide trapping by the enol tautomer of the ketone in 41. To circumvent this issue, we envisaged that masking the ketone in 36 would preclude this undesired mode of ring closure. Since it translated well to our downstream strategy for D ring construction, 36 was converted to the corresponding tosyl hydrazone 44 in 97% yield. To our surprise, the reaction of this compound with m-CPBA followed by PPTS initiated an epoxidation/cyclization cascade, providing the desired tetrahydropyran 45 directly in 77% yield and >20:1 dr. This reaction gave expedient preparation of the paspaline F ring in a single operation.

We were unaware of any previously reported directing effects of tosyl hydrazones on analogous systems (Scheme 7). To provide understanding to this difference in reactivity between hydroxyketone 36 and hydrazone 44, we carried out the following experiments. First, the alkene in hydrazone 44 was removed via hydrogenation to give alcohol 46. Treatment of 46 with the exact reaction conditions used in the epoxidation of 44 resulted in quantitative starting material recovery. This datum excluded the possibility of intramolecular oxygen delivery in the reaction via a transient oxazidirine such as 47. Concluding that the reactivity may be a consequence of underlying conformational differences between 36 and 44, we calculated both structures using density functional theory (DFT) at the level of B3LYP/6-311G(d).28 Interestingly, the optimized structures of 36 and 44 showed a significant difference in the dihedral angle about the C14a C–OH bond and the C4a C–CH2R bond (69° for 36 and 85° for 44). On the basis of these facts, we hypothesize that the observed selectivity is a consequence of the hydrazone in 44 imposing a favorable reactive conformation (48) on the cyclohexane such that the C14a hydroxyl is in close proximity to the alkene during the oxidation. It follows that this would enhance transfer of the substrate’s chiral information to C2 during the oxidation, giving the observed pyran 45 following ring closure. To the best of our knowledge, this reaction is the first example of an alkene epoxidation stereoselectivity being influenced by the presence of a tosyl hydrazone.29

Scheme 7. Mechanistic Investigations in the Conversion of 44 to 45a.

aReagents and conditions: (a) H2 (1 atm), Pd/C (1.50 mass equiv), MeOH, rt; (b) m-CPBA, CH2Cl2, 0 °C.

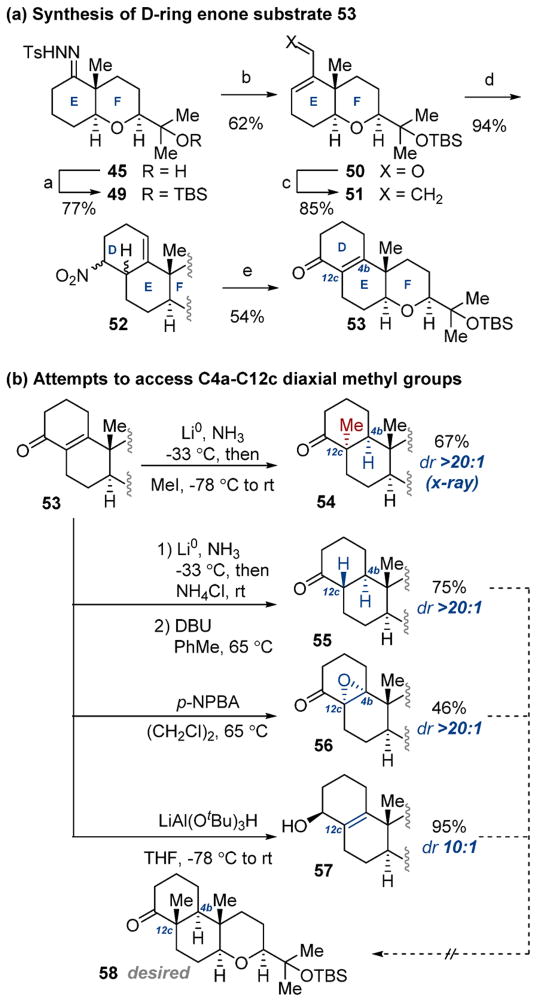

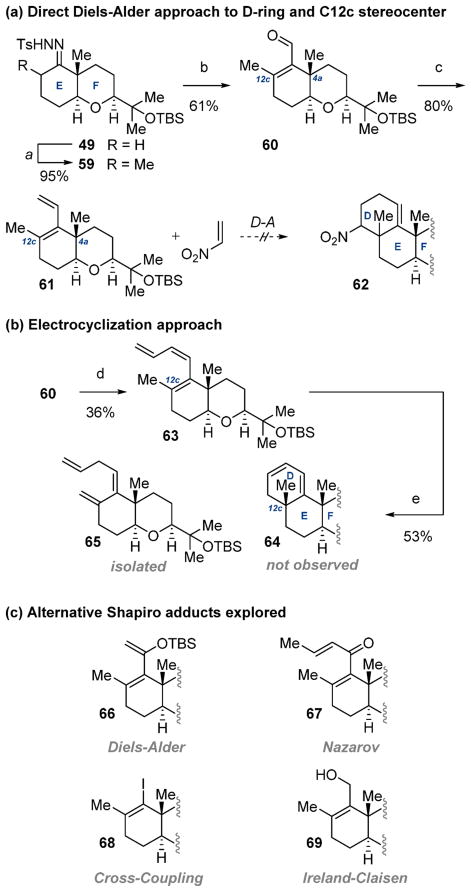

With assembly of the E and F rings complete, attention was directed to construction of the sterically congested D ring and C12c stereocenter (Scheme 8). We believed that the tosyl hydrazone in 45 would be engaged via the Shapiro reaction to produce a transient vinyllithium which, upon trapping with the appropriate electrophile, would provide the functionality required to meet these synthetic challenges.30

Scheme 8. Synthesis of Enone 53 and Attempts at D Ring Synthesisa.

aReagents and conditions: (a) TBSOTf, 2,6-lutidine, CH2Cl2, −50 °C; (b) n-BuLi, THF, −50 °C to rt, then DMF; (c) Ph3P=CH2, THF, 0 °C; (d) nitroethylene, CH2Cl2, 65 °C; (e) (i) KOH, MeOH, rt, then MsOH, 0 °C to rt; (ii) DBU, CH2Cl2, rt.

Thus, TBS protection of the tert-alcohol in 45 proceeded to give silyl ether 49 in 77% yield. Shapiro reaction of 49 followed by DMF trapping furnished unsaturated aldehyde 50 in 62% yield which, upon olefination, gave diene 51 poised for a Diels–Alder cycloaddition. Nitroethylene proved to be an effective dienophile in this reaction, giving the annulation product 52 in 94% yield and with complete regioselectivity under thermal conditions. Subsequent Nef reaction and alkene isomerization afforded the ketone 53, from which we envisioned manipulation of the alkene would complete D ring assembly to give 58. Accordingly, Birch reduction of 53 followed by electrophilic trapping with MeI furnished decalinone 54 in 67% yield and high stereoselectivity (>20:1). Unfortunately, this compound was identified as the undesired cis-decalinone (bearing the desired C4b stereochemistry and undesired C12c stereochemistry) via X-ray diffraction analysis of a derivative.31 After a screen of reducing metals, solvents, and addition methods showed no promise for over-riding this selectivity, we 2began exploring auxiliary methods for stereoselective introduction of the C12c methyl group. In the first iteration, Birch reduction of 53 followed by protic quenching and epimerization with DBU gave the trans-decalinone 55 as a single diastereomer. However, all attempts at thermodynamic methylation of this compound proved fruitless, giving either polymethylated products or starting material decomposition. We next examined whether the C12c methyl group could be introduced stereospecifically via an epoxidation/semipinacol reaction sequence. While epoxidation of 53 was achieved upon treatment with p-NPBA32 to give the desired oxirane 56 as a single diastereomer in 46% yield, the subsequent ketone methylation requisite for rearrangement consistently gave starting material recovery or decomposition under more forcing conditions. In a final case, the ketone in 53 was reduced upon treatment with LiAl(OtBu)3H to give alcohol 57 in 95% yield and 10:1 dr. From this compound, we pursued radical delivery of the C12c methyl group via tethering from the secondary hydroxyl.33 However, this approach also proved unsuccessful, as the alkene in 57 failed to engage all radical precursors bound to the alcohol.

Collectively, these reactions indicated that the inherent bias of enone 53 for the α-face of the D–E ring fusion (presumably influenced by the C4a angular methyl group) would preclude all attempts at late-stage introduction of the C12c methyl group. At this key juncture in our studies, we determined that if D ring assembly was preceded by introduction of this methyl group, then the subsequent annulation step might also proceed with α-face selectivity to give the requisite syn-diaxial methyl group relationship (Scheme 9). Thus, methylation of hydrazone 49 upon treatment with n-BuLi and MeI proceeded smoothly to give the monomethylated product 59 in excellent yield. In accordance with our Diels–Alder strategy, Shapiro reaction of 59 followed by trapping with DMF afforded aldehyde 60 in 61% yield, giving the diene 61 upon olefination. While we at first anticipated that the [4 + 2] annulation of 61 with nitroethylene would proceed in a manner similar to the previously described desmethyl cycloaddition (51 → 52), we quickly found the steric impact of the newly introduced methyl group to be much greater than expected. In our initial trials, the reaction of 61 with nitroethylene failed to produce cycloadduct 62 under both thermal and Lewis acidic conditions. An extensive screen of Diels–Alder dienophiles and promotors ensued, showing no further promise for D ring construction via this method. We then turned our attention to alternative annulation methods, making use of the flexibility of electrophile choice in the Shapiro reaction step and its subsequent intermediates. To bypass an intermolecular cycloaddition, we pursued an electrocyclization pathway to form the requisite D ring. Olefination of aldehyde 60 with the ylide derived from allyltriphenylphosphonium bromide gave the simplified triene 63 in 36% yield, and irradiation of 63 (Hg vapor lamp) gave complete conversion to a single product after 1 h. Unfortunately, this material was identified as the sigmatropic rearrangement product 65 and not the desired cyclization product 64. Suspecting that this rearrangement might predominate using any analogue of this triene, we abandoned this pathway in favor of alternative cyclization modes. Toward these aims, substrates 66–68 were prepared via modification of the electrophilic trap (and subsequent product manipulation) in the Shapiro reaction and examined for their viability in D ring synthesis. Electron-rich Diels–Alder diene 66 and Nazarov substrate 67 failed to participate in any productive reactivity, either giving no reaction or decomposing to complex mixtures. Iodide 68 was synthesized with the goal of completing D ring synthesis via cross-coupling; however, this approach also proved fruitless.

Scheme 9. Strategies Examined toward D Ring Synthesis via Methyl-Group-First Approacha.

aReagents and conditions: (a) n-BuLi, THF, −50 °C, then MeI; (b) n-BuLi, THF, −50 °C to rt, then DMF; (c) Ph3P=CH2, THF, 0 °C; (d) Ph3P=CHCHCH2, THF, 0 °C to rt; (e) hν, hexanes, rt.

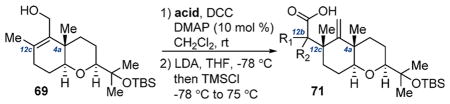

Our options diminishing, we prepared primary alcohol 69 via trapping the Shapiro intermediate of 59 with (HCHO)n (Table 1). We surmised that the appropriately selected ester of 69 would participate in an Ireland–Claisen rearrangement,34 influenced by the C4a stereocenter, to install the C12c (and potentially C12b) quaternary methyl group(s) while providing functional handles for D ring construction. We then began screening esters of 69 compatible with our synthetic manifold. In the simplest cases, acetate 70a (entry 1) and propionate 70b (entry 2) did not undergo rearrangement as the corresponding silyl ketene acetals were labile at elevated reaction temperatures. Isobutyrate 70c (entry 3) performed exceptionally to give 71a (80% yield, 6:1 dr, 4 g scale), although a downstream C–H activation at C12b would be required for this product to be a viable intermediate toward 1. With the reaction’s viability demonstrated, functionalized esters 70d–h were probed. Indole ester 70d or protected analogues thereof failed to rearrange, presumably due to a steric impact of the indole on silyl ketene acetal generation. Esters 70e–g (entries 5–7) likewise suffered from the same issue. We were excited to find promising reactivity, however, in the case of silyl-functionalized isobutyrate 70h (entry 8, 52% yield, 6.6:1.1:1 dr). The stereochemistry at C12c of this compound was assigned by analogy to rearrangement product 71a (vide infra). The identity of the C12b stereocenter could not be identified.

Table 1.

Ireland–Claisen Screenings for D Ring Assembly

| |||

|---|---|---|---|

| entry | acid | ester (yield)a | acid (yield, dr)a |

| 1 | Ac2O | 70a (82%)b | -- |

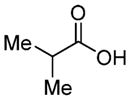

| 2 |

|

70b (83%) | -- |

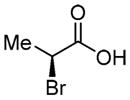

| 3 |

|

70c (73%) | 71a (80%, 6:1)c |

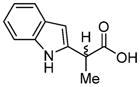

| 4 |

|

70d (93%) | -- |

| 5 |

|

70e (63%) | -- |

| 6 |

|

70f (74%) | -- |

| 7 |

|

70g (54%) | -- |

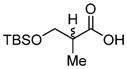

| 8 |

|

70h (87%) | 71b (57%, 6.6:1.1:1)c |

Isolated yields.

Conditions: Ac2O, NEt3, DMAP (10 mol %), CH2Cl2, rt.

Determined by 1H NMR analysis of crude mixtures.

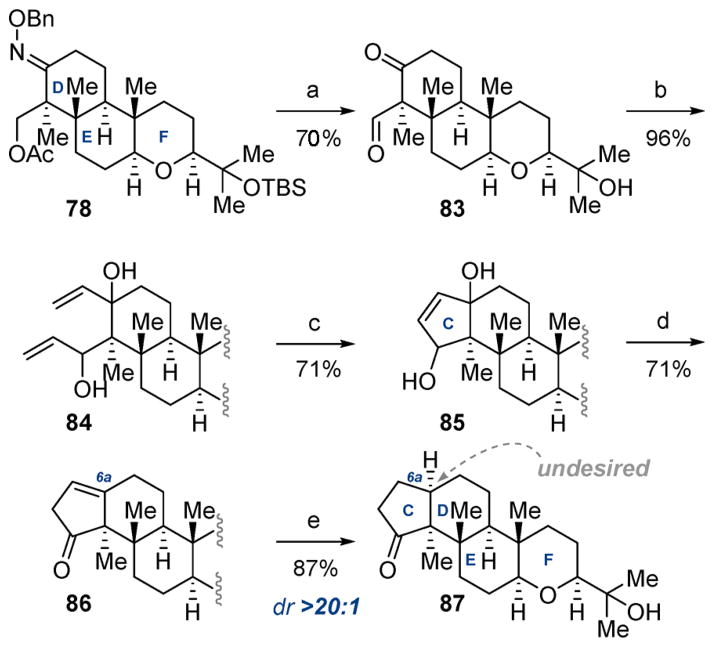

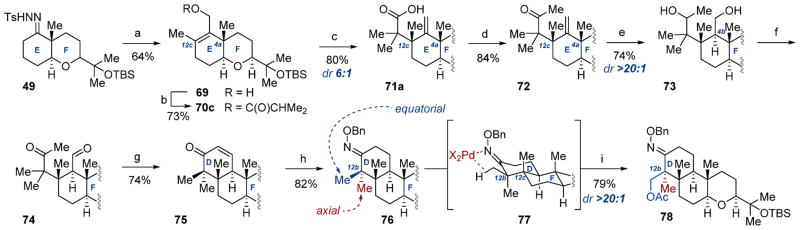

The next portion of our strategy involved conversion of the rearrangement product to its methyl ketone for subsequent ring closure (Scheme 10). After first reoptimizing the Shapiro reaction step to facilitate one-pot conversion of desmethylhydrazone 49 to alcohol 69, we moved forward in this approach. Unfortunately, conversion of silyl-functionalized isobutyrate product 71b to its derived methyl ketone proved unfeasible due to a significant steric impact at the α-position. In contrast, early returns on the simpler isobutyrate rearrangement product 71a showed that the methyl ketone synthesis worked well, and as a result, we moved forward in our synthesis with this compound. Thus, esterification of acid 71a with TMSCHN2 followed by treatment with MeLi furnished ketone 72 in 84% yield. The C4b stereocenter was established via hydroboration/oxidation of 72 to give diol 73 in 74% yield and >20:1 dr. After some experimentation, bisoxidation of 73 was accomplished via Swern conditions to give ketoaldehyde 74 poised for intramolecular condensation. Exposure of 74 to basic conditions cleanly afforded enone 75 in 74% yield over two steps, thereby completing D ring synthesis. The resultant alkene was removed via hydrogenation to give the corresponding ketone, which was converted to oxime 76 in 82% yield.

Scheme 10. D Ring Synthesis Completion and Symmetry-Breaking C–H Activation of C12b Stereocentera.

aReagents and conditions: (a) n-BuLi, THF, −50 °C, then MeI; n-BuLi, −50 °C to rt, then (HCHO)n; (b) isobutyric acid, DCC, DMAP (10 mol %), CH2Cl2, rt; (c) LDA, THF, −78 °C, then TMSCl, −78 to 75 °C; (d) (i) TMSCHN2, MeOH/C7H8 (2:1), rt; (ii) MeLi, Et2O, 0 °C to rt; (e) BH3T·HF, THF, 50 °C, then H2O2, NaOH, 0 °C to rt; (f) (COCl)2, DMSO, CH2Cl2, −78 °C, then DIPEA, −78 to 0 °C; (g) KOH(aq), THF/ MeOH (1:1), 0 °C to rt; (h) (i) H2 (1 atm), Pd/C (1.50 mass equiv), EtOAc, rt; (ii) NH2OBn·HCl, NaOAc, MeOH/H2O (5:1), 85 °C; (i) Pd(OAc)2 (15 mol %), PhI(OAc)2, AcOH/Ac2O (1:1), 100 °C.

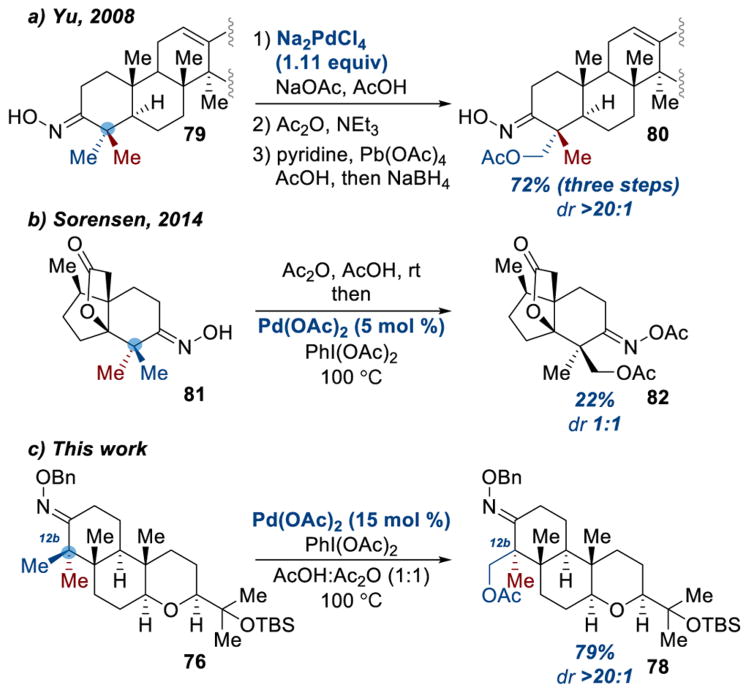

With D ring synthesis concluded, desymmetrization of the nonstereogenic C12b dimethyl group in 76 became compulsory for synthesis completion. The success of this transformation would require a selective functionalization of the equatorial methyl group at C12b over its axial counterpart to provide the diastereomer needed; we were aware that the lowest energy conformer of 76 places the oxime C–N double bond in the same plane as the equatorial methyl group and anticipated that the appropriate catalytic system would operate on 76 using the oxime as a directing group. We selected the catalytic C–H oxidation reaction developed by Sanford and co-workers,35 which had demonstrated applicability to substituted cyclohexanone oximes. In the event, treatment of oxime 76 with Sanford’s conditions provided acetate 78 in 79% yield (via 77) with complete diastereoselection, establishing the stereochemistry of the final quaternary center in 1 and providing the necessary functional handle for synthesis completion.

The yield and selectivity of this transformation are noteworthy; examples for the successful execution of this reaction as a platform for desymmetrization of achiral quaternary centers are scarce in recent literature (Scheme 11). In 2008, Yu and co-workers reported a stoichiometric desymmetrization of dimethyl oxime 79, proceeding in 72% yield and complete selectivity (assisted by the conformational rigidity of 79) en route to the synthesis of lobatoside E.36 Six years later, the Sorenson laboratory described the first symmetry-breaking implementation of Sanford’s catalytic reaction in their synthesis of jiadifenolide.37 In this reaction, treating oxime 81 with Pd(OAc)2 and PhI(OAc)2 afforded the desired acetate 82 in 22% yield and 1:1 dr. The poor selectivity in this transformation may be attributed to the oxime in 81 bisecting the two methyl groups. In our case, exposure of oxime 76 to Sanford’s conditions provided the desired acetate diastereomer 78 in 79% yield and >20:1 dr (presumably aided by the coplanar oxime and equatorial methyl group). That this reaction (76 → 78) provided the desired product diastereomer in such high yield illustrates the viability of this and related transformations in the late-stage pursuit of challenging quaternary stereocenters, particularly scenarios in which inherent structural biases may lend a degree of stereochemical predictability.

Scheme 11.

Recent Examples of Substrate-Directed sp3 C–H Oxidation/Desymmetrization

With acetate 78 in hand, we faced the remaining challenges of C ring installation, C6a reduction, and indolization to complete our synthesis (Scheme 12). Acetate 78 was subjected to global hydrolysis to remove the acetate, oxime, and silyl ether functionalities. The resulting primary alcohol was oxidized with Dess-Martin periodinane (DMP) to give ketoaldehyde 83 in 70% yield over two steps. From 83, we envisioned that bisvinylation followed by ring-closing metathesis (RCM) would install the needed carbon skeleton. Unfortunately, treatment of 83 with vinylmagnesium bromide at −78 °C gave predominantly retro-aldol decomposition products with only small amounts of 84. After some experimentation, we found that the CeCl3·2LiCl complex recently reported by Knochel aided in suppressing the retro-aldol product completely,38 giving diol 84 in 95% yield. Treatment of 84 with Grubb’s second generation catalyst provided allylic alcohol 85 in 71% yield. While an alcohol oxidation/hydroxyl elimination pathway was first pursued for the conversion of diol 85 to enone 86, we found that simply subjecting 85 to acidic conditions (TFA) resulted in direct elimination of the tert-hydroxyl to give nonconjugated enone 86 in 71% yield. This set the stage for hydrogenation of the resultant alkene to install the final stereocenter found in 1. In the event, catalytic hydrogenation of alkene 86 with Pd/C provided ketone 87 in 87% yield and >20:1 dr. However, 1H NMR spectral data of this compound were not consistent with that of the desired compound previously synthesized by Smith and co-workers,12d leading to the conclusion that this hydrogenation had delivered the opposite diastereomer to that required. In order to rationalize this result, we calculated the structure of nonconjugated enone 86. As anticipated, the DFT-optimized structure of 86 revealed a marked puckering of the C–D ring fusion; catalytic hydrogenation of this alkene to give the desired diastereomer at C6a would necessitate approach of H2 to the concave Re face of 86. This result is in accord with prior studies on similar steroidal systems39 which also describe convex surface hydrogenation on related enones.

Scheme 12. Paspaline C Ring Construction and Synthesis of C6a Epimeric Ketonea.

aReagents and conditions: (a) (i) HCl, H2O/MeOH/THF/acetone (10:10:10:1), 85 °C; (ii) DMP, CH2Cl2, rt; (b) vinylmagnesium bromide, CeCl3·2LiCl, THF, −78 °C; (c) Grubbs second generation catalyst (20 mol %), CH2Cl2, rt; (d) TFA, CH2Cl2, 0 °C to rt; (e) H2 (1 atm), Pd/C (1.50 mass equiv), EtOH, rt.

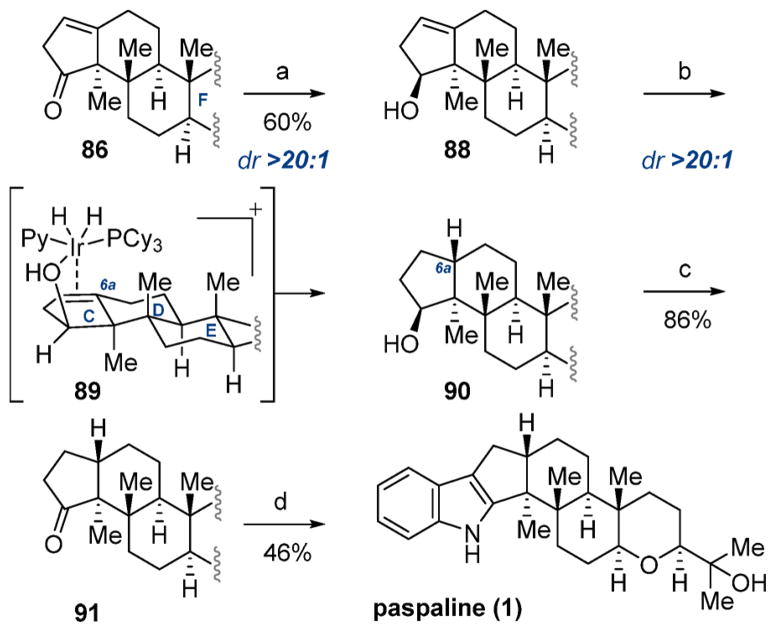

Upon assessing our available functional handles, we surmised that selective reduction of the ketone in 86 might alter the outcome of the ensuing alkene hydrogenation by virtue of the hydroxyl’s function as a directing group (Scheme 13). The use of Crabtree’s catalyst in alcohol-directed alkene hydrogenations has been well-documented40 and would presumably engage the alkene on the same face as the hydroxyl. To this end, treatment of ketone 86 with LiAlH4 afforded the desired (S)-alcohol 88 in 60% yield and >20:1 dr over two steps from diol 85. The steric impact of the C12c methyl group on the outcome of this reaction cannot be overstated; ketone reduction in analogous steroidal systems not bearing this methyl group generally proceed with the opposite sense of selectivity.39,41

Scheme 13. Substrate-Directed Control of the C6a Stereocenter and Completion of the Total Synthesis of Paspalinea.

aReagents and conditions: (a) LiAlH4, THF, 0 °C; (b) H2 (1 atm), C8H12IrP(C6H11)3C5H5N]PF6 (15 mol %), CH2Cl2, rt; (c) DMP, CH2Cl2, rt; (d) (i) LDA, THF, 0 °C, then HMPA, Me2S2; (ii) Nchloroaniline, CH2Cl2, −78 °C, then NEt3; (iii) Raney Ni, EtOH, rt; (iv) TsOH (66 mol %), CH2Cl2, 50 °C.

With this alcohol in hand, catalytic hydrogenation of 88 using Crabtree’s catalyst completely over-rode the inherent substrate bias, giving the corresponding alcohol 90 (via 89) in >20:1 dr and subsequently the ketone 91 in 86% over two steps after reoxidation of the alcohol. The stereochemistry of 91 was confirmed via 1H NMR comparison with Smith’s intermediate and an X-ray diffraction study.12d This left only indolization to complete our total synthesis of 1. The Gassman indolization utilized previously by Smith proved to be the method of choice in affording paspaline (1) in 46% yield from 91.12a,42 Synthetic 1 matched the reported analytical data for paspaline, and single-crystal X-ray analysis of this sample was in agreement with the reported structure.11a

CONCLUSIONS

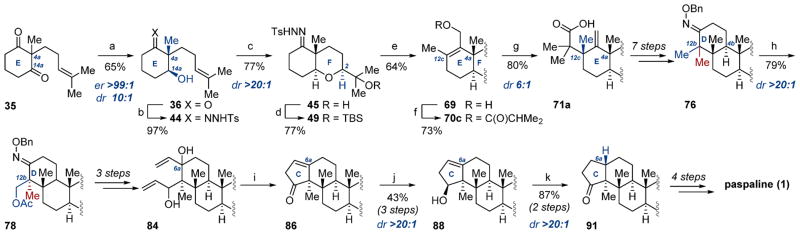

In conclusion, we have described the entirety of our efforts toward the synthesis of paspaline. The final route totals 28 steps from commercially available 28 in 0.4% yield (Smith synthesis: 24 steps from 28, 0.2% yield).12a Of particular note is the stereoselectivity of the described route: the least stereoselective reactions in our synthesis are the Ireland–Claisen rearrangement (70c → 71a, 6:1 dr) and the biocatalytic reduction (35 → 36, >99:1 er, 10:1 dr). All other stereodetermining transformations occur in >20:1 dr (Scheme 14). After initial approaches for the assembly of 1 via a cationic transannular cyclization were unsuccessful, a symmetry-breaking approach to paspaline was developed to complete construction of the E,F ring fusion within the first four steps of the synthesis. A novel tosyl hydrazone influenced epoxidation enabled excellent control of the C2 stereocenter (>20:1), and the Ireland–Claisen rearrangement provided access to the D ring and C12c stereocenter of 1. A substrate-directed symmetry-breaking C–H acetoxylation inspired by Sanford and co-workers provided control of the C12b stereocenter (>20:1). To override the inherent facial bias in the hydrogenation of enone 86, stereoselective reduction of the ketone followed by hydrogenation with Crabtree’s catalyst provided the final stereocenter in 1 with excellent selectivity (>20:1). Emphasis was placed throughout on expedient assembly of the critical C4a, C12b, and C12c quaternary methyl groups toward facile preparation of the remaining structures in this family of molecules. The route and methods described in this work present a number of complementary conceptual disconnections in the preparation of “steroid-like” natural products. Work in our laboratory in preparing these and related compounds is ongoing and will be reported in due course.

Scheme 14. Summary of Paspaline Total Synthesisa.

aReagents and conditions: (a) YSC-2, H2O/DMSO (10:1), 30 °C; (b) TsHNNH2, C7H8, 70 °C; (c) m-CPBA, CH2Cl2, 0 °C, then PPTS; (d) TBSOTf, 2,6-lutidine, CH2Cl2, −50 °C; (e) n-BuLi, THF, −50 °C, then MeI; n-BuLi, −50 °C to rt, then (HCHO)n; (f) isobutyric acid, DCC, DMAP (10 mol %), CH2Cl2, rt; (g) LDA, THF, −78 °C, then TMSCl, −78 to 75 °C; (h) Pd(OAc)2 (15 mol %), PhI(OAc)2, AcOH/Ac2O (1:1), 100 °C; (i) (i) Grubbs second generation catalyst (20 mol %), CH2Cl2, rt; (ii) TFA, CH2Cl2, 0 °C to rt; (j) LiAlH4, THF, 0 °C; (k) (i) H2 (1 atm), C8H12IrP(C6H11)3C5H5N]PF6 (15 mol %), CH2Cl2, rt; (ii) DMP, CH2Cl2, rt.

EXPERIMENTAL SECTION

Materials and Methods

General

Tetrahydrofuran (THF), diethyl ether (Et2O), dichloromethane (CH2Cl2), and toluene (C7H8) were dried by passage through a column of neutral alumina under nitrogen prior to use. Aniline, hexamethylphosphoramide (HMPA), and diisopropylamine were freshly distilled from calcium hydride prior to use. Compounds 14,43 37,44 and 3924 were prepared according to known procedures. All other reagents were purchased from commercial sources and were used as received unless otherwise noted. Proton and carbon magnetic resonance spectra (1H NMR and 13C NMR) were recorded with solvent resonance as the internal standard (1H NMR: CDCl3 at 7.26 ppm and C6D6 at 7.16 ppm; 13C NMR: CDCl3 at 77.0 ppm). 1H NMR data are reported as follows: chemical shift, multiplicity (s = singlet, br s = broad singlet, d = doublet, br d = broad doublet, t = triplet, q = quartet, m = multiplet), coupling constants (Hz), and integration. Mass spectra were obtained via Fourier transform mass spectromtetry (FTMS) with electrospray introduction (ESI) and external calibration in positive ion mode. All samples were prepared in methanol. Visualization for thin layer chromatography (TLC) was accomplished with UV light, KMnO4, and/or Seebach’s stain followed by heating. Purification of the reaction products was carried out by flash chromatography on silica gel. Unless otherwise noted, all reactions were carried out under an atmosphere of dry nitrogen in flame-dried glassware with magnetic stirring. Yield refers to isolated yield of analytically pure material unless otherwise noted. Yields are reported for a specific experiment and as a result may differ slightly from those found in figures, which are averages of at least two experiments.

Computation Analysis

High-level DFT calculations using the B3LYP28a,b approximate exchange-correlation energy density functional were performed with the standard Pople triple-ζ basis set 6-311G(d)28c,d for all elements when stable structures are optimized. Calculations were performed in the gas phase at 0 K with tight SCF convergence and ultrafine integration grids. All calculations were performed with the package of Gaussian 09 version D01.45 Cartesian coordinates of the studied systems are provided in the Supporting Information.

3-Hydroxy-4-methylpent-4-en-1-yl 4-Methylbenzenesulfonate (15)

A flame-dried, 1000 mL round-bottomed flask was charged with diol 14 (4.67 g, 40.2 mmol, 1.00 equiv) and CH2Cl2 (300 mL) under an atmosphere of N2. The solution was cooled to 0 °C, and NEt3 (14.0 mL, 100.5 mmol, 2.50 equiv), DMAP (0.49 g, 4.00 mmol, 0.10 equiv), and TsCl (8.43 g, 44.2 mmol, 1.10 equiv) were added sequentially. The resulting mixture was allowed to stir at this temperature until complete conversion of the starting material was observed by TLC analysis, typically 12 h. The mixture was then diluted with H2O (150 mL) and partitioned in a separatory funnel. The organic layer was separated, and the aqueous layer was extracted with CH2Cl2 (3 × 40 mL). The combined organic extracts were dried with sodium sulfate and concentrated in vacuo. The product was purified via flash chromatography (70:30 to 60:40 hexanes/EtOAc) to afford the tosylate 15 (8.75 g, 81% yield) as a pale yellow oil. Analytical data: 1H NMR (600 MHz, CDCl3) δ 7.79 (d, J = 8.4 Hz, 2H), 7.34 (d, J = 8.4 Hz, 2H), 4.91 (s, 1H), 4.82 (s, 1H), 4.22 (m, 1H), 4.16 (m, 1H), 4.09 (m, 1H), 2.44 (s, 3H), 1.91 (m, 1H), 1.79 (m, 1H), 1.75 (br s, 1H), 1.68 (s, 3H); 13C NMR (150 MHz, CDCl3) δ 146.4, 144.8, 132.9, 129.8, 127.9, 111.4, 71.5, 67.6, 34.1, 21.6, 17.6; HRMS (ESI+) calcd for C13H18O4S+Na, 293.0824; found 293.0815; IR (thin film, cm−1) 3545, 3055, 2984, 2686, 1652, 1616, 1456, 1360, 1266, 1189; TLC (80:20 hexanes/EtOAc) Rf = 0.14.

Ethyl (E)-3-((2-Methyl-5-(tosyloxy)pent-1-en-3-yl)oxy)acrylate (16)

A flame-dried, 500 mL round-bottomed flask was charged with alcohol 15 (8.75 g, 32.0 mmol, 1.00 equiv) and CH2Cl2 (160 mL) under an atmosphere of N2 at rt. N-Methylmorpholine (3.60 mL, 35.7 mmol, 1.10 equiv) and ethyl propiolate (3.92 mL, 35.7 mmol, 1.10 equiv) were added sequentially, and the mixture was allowed to stir until complete conversion of the starting material was observed by TLC analysis, typically 4 h. The reaction mixture was concentrated on a rotary evaporator, and the crude product was purified via flash chromatography (80:20 to 70:30 hexanes/EtOAc) to give the vinyl ether 16 (11.4 g, 97% yield) as a clear oil. Analytical data: 1H NMR (600 MHz, CDCl3) δ 7.77 (d, J = 8.4 Hz, 2H), 7.34 (d, J = 8.4 Hz, 2H), 7.28 (d, J = 12.6 Hz, 1H), 5.14 (d, J = 12.6 Hz, 1H), 4.97 (s, 1H), 4.93 (s, 1H), 4.31 (dd, J = 4.8, 4.2 Hz, 1H), 4.16–4.06 (m, 4H), 2.43 (s, 3H), 1.97 (m, 2H), 1.61 (s, 3H), 1.26 (t, J = 7.2 Hz, 3H); 13C NMR (150 MHz, CDCl3) δ 167.6, 160.5, 145.0, 141.5, 132.6, 129.9, 127.9, 115.4, 98.6, 81.5, 66.2, 59.8, 32.7, 21.6, 16.7, 14.3; HRMS (ESI+) calcd for C18H24O6S+Na, 391.1191; found 391.1181; IR (thin film, cm−1) 2980, 2916, 2849, 1706, 1644, 1488, 1362, 1189, 1097, 923; TLC (80:20 hexanes/EtOAc) Rf = 0.32.

Ethyl (E)-3-((5-Iodo-2-methylpent-1-en-3-yl)oxy)acrylate (13)

To a solution of tosylate 16 (11.4 g, 30.8 mmol, 1.00 equiv) in acetone (300 mL) at rt was added NaI (40.0 g, 308.0 mmol, 10.0 equiv) portionwise with vigorous stirring. The resulting suspension was allowed to stir 12 h at which point TLC analysis confirmed complete consumption of the starting material. The reaction mixture was diluted with brine (150 mL) and transferred to a separatory funnel. The aqueous layer was extracted with EtOAc (3 × 60 mL), and the combined organic extracts were dried with magnesium sulfate and concentrated in vacuo. The product was purified via flash chromatography (90:10 to 80:20 hexanes/EtOAc) to afford the alkyl iodide 13 (8.67 g, 87% yield) as a pale yellow oil. Analytical data: 1H NMR (600 MHz, CDCl3) δ 7.46 (d, J = 12.6 Hz, 1H), 5.27 (d, J = 12.6 Hz, 1H), 5.05 (s, 1H), 5.04 (s, 1H), 4.39 (dd, J = 4.8, 3.0 Hz, 1H), 4.14 (m, 2H), 3.17 (m, 2H), 2.21 (m, 1H), 2.07 (m, 1H), 1.67 (s, 3H), 1.25 (t, J = 7.2 Hz, 1H); 13C NMR (150 MHz, CDCl3) δ 167.7, 160.8, 141.5, 115.3, 98.6, 85.5, 59.8, 36.7, 17.0, 14.3, 0.9; HRMS (ESI+) calcd for C11H17IO3+Na, 347.0120; found 347.0111; IR (thin film, cm−1) 3078, 2978, 2916, 1707, 1644, 1456, 1322, 1171, 1006, 834; TLC (80:20 hexanes/EtOAc) Rf = 0.64.

Dimethyl 2-(2-Ethoxy-2-oxoethyl)-6-(prop-1-en-2-yl)dihydro-2Hpyran-3,3(4H)-dicarboxylate (17)

A 500 mL round-bottomed flask was charged with the iodide 13 (8.75 g, 27.00 mmol, 1.00 equiv) and DMF (130 mL) at rt. Dimethyl malonate (6.20 mL, 54.0 mmol, 2.00 equiv) and Cs2CO3 (26.4 g, 81.0 mmol, 3.00 equiv) were added sequentially, whereupon a bright orange color was observed. The resulting mixture was allowed to stir for 14 h and was subsequently diluted with H2O (50 mL) and Et2O (50 mL). The layers were partitioned in a separatory funnel, and the aqueous layer was extracted with Et2O (3 × 30 mL). The combined organic extracts were washed with brine (40 mL), dried with magnesium sulfate, and concentrated in vacuo to give the crude pyran as a single diastereomer (as determined by 1H NMR spectroscopic analysis of the crude mixture, which revealed a single compound). The product was purified via flash chromatography (90:10 to 80:20 hexanes/EtOAc) to afford tetrahydropyran 17 (8.85 g, 99% yield) as a clear, viscous oil. Analytical data: 1H NMR (600 MHz, CDCl3) δ 4.86 (s, 1H), 4.75 (s, 1H), 4.31 (dd, J = 9.0, 6.0 Hz, 1H), 4.11 (m, 2H), 3.83 (d, J = 12.0 Hz, 1H), 3.72 (s, 3H), 3.67 (s, 3H), 2.77 (m, 2H), 2.54 (m, 1H), 1.92 (m, 1H), 1.82 (m, 1H), 1.67 (br s, 1H), 1.65 (s, 3H), 1.20 (t, J = 6.6 Hz, 3H); 13C NMR (150 MHz, CDCl3) δ 171.4, 170.7, 169.0, 144.6, 110.7, 81.1, 77.3, 60.3, 55.8, 52.5, 52.2, 38.0, 31.7, 26.0, 18.8, 14.1; HRMS (ESI+) calcd for C16H24O7+Na, 351.1420; found 351.1409; IR (thin film, cm−1) 3446, 2955, 2849, 1733, 1652, 1455, 1267, 1186, 1072, 904; TLC (80:20 hexanes/EtOAc) Rf = 0.43.

Dimethyl-2-(2-hydroxyethyl)-6-(prop-1-en-2-yl)dihydro-2Hpyran-3,3(4H)-dicarboxylate (18)

A flame-dried, 500 mL roundbottomed flask was charged with ester 17 (6.00 g, 18.3 mmol, 1.00 equiv) and THF (150 mL) under an atmosphere of N2. The solution was cooled to 0 °C, and DIBAL-H (1 M solution in hexane, 18.3 mL, 18.3 mmol, 1.00 equiv) was added slowly. The reaction was then analyzed for reaction completion via TLC analysis, which indicated incomplete starting material conversion. Another 1.00 equiv of DIBAL-H was added, whereupon TLC analysis indicated complete conversion of the starting material. The reaction mixture was quenched via addition of acetone (30 mL), and the mixture was stirred 5 min at 0 °C. Saturated Rochelle’s salt(aq) (40 mL) was then added, and the mixture was transferred to a separatory funnel. The aqueous layer was extracted with Et2O (3 × 40 mL), and the combined organic extracts were washed with 1 M HCl(aq) (40 mL) and brine (40 mL), dried with magnesium sulfate, and concentrated in vacuo. The product was purified via flash chromatography (60:40 to 50:50 to 40:60 hexanes/EtOAc) to afford alcohol 18 (3.78 g, 72% yield) as a clear, viscous oil. Analytical data: 1H NMR (600 MHz, CDCl3) δ 4.92 (s, 1H), 4.81 (s, 1H), 4.01 (dd, J = 8.4, 1.8 Hz, 1H), 3.88 (m, 1H), 3.79–3.76 (m, 5H), 3.71 (s, 3H), 2.54 (m, 1H), 2.42 (d, J = 5.4 Hz, 1H), 2.14 (m, 1H), 1.93–1.88 (m, 3H), 1.70 (s, 3H), 1.67 (m, 1H); 13C NMR (150 MHz, CDCl3) δ 171.2, 169.3, 144.7, 111.1, 81.5, 81.1, 62.1, 56.2, 52.6, 52.1, 34.7, 31.9, 26.6, 18.7; HRMS (ESI+) calcd for C14H22O6+Na, 309.1314; found 309.1305; IR (thin film, cm−1) 3446, 3055, 2954, 2883, 1731, 1455, 1266, 1078, 906, 737; TLC (75:25 hexanes/EtOAc) Rf = 0.05.

Dimethyl-2-(2-iodoethyl)-6-(prop-1-en-2-yl)dihydro-2H-pyran-3,3(4H)-dicarboxylate (27)

A 500 mL round-bottomed flask was charged with CH2Cl2 (96 mL), and the solution was cooled to 0 °C. Imidazole (3.22 g, 47.4 mmol, 4.96 equiv) and PPh3 (5.14 g, 19.0 mmol, 2.05 equiv) were added followed by I2 (4.83 g, 19.0 mmol, 2.00 equiv). The mixture was allowed to stir at 0 °C for 10 min, whereupon a pale yellow suspension was observed. The alcohol 18 (2.73 g, 9.55 mmol, 1.00 equiv) was then added as a solution in CH2Cl2 (20 mL), and the mixture was allowed to warm to rt and stirred until complete consumption of the starting material was observed by TLC analysis, typically 12 h. The mixture was then quenched via addition of saturated Na2S2O3(aq) (50 mL) and transferred to a separatory funnel. The aqueous layer was extracted with CH2Cl2 (3 × 30 mL), and the combined organic extracts were washed with brine (30 mL), dried with magnesium sulfate, and concentrated in vacuo. The product was purified via flash chromatography (95:5 to 90:10 hexanes/EtOAc) to afford primary iodide 27 (2.64 g, 70% yield) as a white solid. Analytical data: mp 61–65 °C; 1H NMR (600 MHz, CDCl3) δ 4.93 (s, 1H), 4.83 (s, 1H), 3.88 (d, J = 10.2 Hz, 1H), 3.84 (d, J = 11.4 Hz, 1H), 3.75 (s, 3H), 3.72 (s, 3H), 3.36 (m, 1H), 3.28 (m, 1H), 2.56 (dt, J = 6.6, 3.0 Hz, 1H), 2.37 (m, 1H), 2.13 (m, 1H), 1.95 (m, 1H), 1.84 (m, 1H), 1.73 (s, 3H), 1.69 (m, 1H); 13C NMR (150 MHz, CDCl3) δ 171.0, 169.3, 144.8, 110.9, 81.4, 80.9, 56.4, 52.6, 52.2, 35.8, 32.0, 26.3, 19.0, 4.3; HRMS (ESI+) calcd for C14H21IO5+Na, 419.0326; found 419.0320; IR (thin film, cm−1) 2917, 2849, 1731, 1652, 1540, 1455, 1265, 1083, 905; TLC (75:25 hexanes/EtOAc) Rf = 0.50.

Dimethyl-2-(3-methylbut-3-en-1-yl)-6-(prop-1-en-2-yl)dihydro-2H-pyran-3,3(4H)-dicarboxylate (12)

A flame-dried, 50 mL roundbottomed flask was charged with 2-bromopropene (0.67 mL, 7.57 mmol, 3.00 equiv) and Et2O (13 mL) under an atmosphere of N2. The mixture was cooled to −78 °C, and tBuLi (1.70 M solution in pentane, 8.91 mL, 15.14 mmol, 6.00 equiv) was added dropwise. The reaction mixture was allowed to stir 30 min at −78 °C, then warmed to rt and stirred for 1 h. During this time period, a second flame-dried, 100 mL round-bottomed flask was charged with CuI (0.72 g, 3.79 mmol, 1.50 equiv) and Et2O (12 mL) and was cooled to −78 °C. The isopropenyllithium solution was then cooled to −78 °C and transferred via cannula to the CuI suspension over a period of ~1 min. The resulting suspension was then warmed to −45 °C and stirred 1 h, upon which a color change from pale brown to dark gray to dark yellow-green was observed. The mixture was cooled to −78 °C, and a solution of iodide 27 (1.00 g, 2.52 mmol, 1.00 equiv) in Et2O (5 mL) was added. The reaction was then warmed to 0 °C and stirred until complete conversion of the starting material was observed by TLC analysis, typically 30 min. The reaction was then quenched via addition of saturated NH4Cl(aq) (20 mL), and the mixture was transferred to a separatory funnel. The aqueous layer was extracted with Et2O (3 × 20 mL), and the combined organic extracts were washed with saturated NH4Cl(aq) (20 mL), dried with magnesium sulfate, and concentrated in vacuo. The product was purified via flash chromatography (100:0 to 95:5 to 90:10 hexanes/EtOAc) to afford the alkene 12 (0.77 g, 99% yield) as a clear oil. Analytical data: 1H NMR (600 MHz, CDCl3) δ 4.93 (s, 1H), 4.81 (s, 1H), 4.72 (s, 1H), 4.69 (s, 1H), 3.75 (br s, 4H), 3.70 (br s, 4H), 2.53 (m, 1H), 2.21 (m, 1H), 2.12 (m, 1H), 1.94–1.78 (m, 4H), 1.74 (s, 3H), 1,72 (s, 3H), 1.67 (m, 1H); 13C NMR (150 MHz, CDCl3) δ 171.6, 169.7, 154.4, 145.1, 110.6, 110.3, 81.0, 80.5, 56.6, 52.4, 52.0, 34.9, 32.2, 30.1, 26.2, 22.2, 19.2; HRMS (ESI+) calcd for C17H26O5+Na, 333.1678; found 333.1669; IR (thin film, cm−1) 3446, 3056, 2953, 2849, 1731, 1669, 1636, 1520, 1455, 1203, 1266; TLC (75:25 hexanes/EtOAc) Rf = 0.52.

3-(Methoxycarbonyl)-2-(3-methylbut-3-en-1-yl)-6-(prop-1-en-2-yl)tetrahydro-2H-pyran-3-carboxylic Acid (19)

A 20 mL scintillation vial was charged with diester 12 (0.10 g, 0.32 mmol, 1.00 equiv) and THF (3 mL) with stirring at rt. KOH (1 M in MeOH, 1.70 mL, 1.70 mmol, 5.27 equiv) was added, and the resulting mixture was allowed to stir at rt until complete consumption of the starting material was observed by TLC analysis. This time period varied widely for each experiment (from 12 h to 6 days dependent on scale; in this iteration, 5 days were required to reach complete conversion). Once complete, the reaction mixture was concentrated on a rotary evaporator. The residue was diluted with H2O (10 mL), transferred to a separatory funnel, and extracted with Et2O (2 × 5 mL). The aqueous layer was acidified to pH = 1 with 1 M HCl(aq) and extracted with EtOAc (3 × 5 mL). The combined EtOAc extracts were dried with magnesium sulfate and concentrated in vacuo to afford the crude monoacid 19 (0.094 g, >99% crude yield) as a pale yellow, viscous oil. The diastereomeric ratio was determined via 1H NMR spectroscopic analysis of this crude material, which revealed a single compound. Analytical data: 1H NMR (600 MHz, C6D6) δ 10.56 (br s, 1H), 5.02 (s, 1H), 4.90 (s, 1H), 4.84 (s, 1H), 4.80 (s, 1H), 3.84 (dd, J = 7.2, 1.8 Hz, 1H), 3.58 (d, J = 11.4 Hz, 1H), 3.31 (s, 3H), 2.56 (d, J = 13.2 Hz, 1H), 2.33 (m, 2H), 2.17 (m, 2H), 2.08 (m, 1H), 1.71 (s, 3H), 1.68–1.67 (m, 4H), 1.34 (d, J = 1.8 Hz, 1H); 13C NMR (150 MHz, CDCl3) δ 177.1, 169.6, 145.3, 145.0, 110.8, 110.4, 81.1, 80.3, 56.6, 52.2, 34.8, 32.2, 30.1, 26.1, 22.2, 19.2; HRMS (ESI+) calcd for C16H24O5+Na, 319.1521; found 319.1513; IR (thin film, cm−1) 3566, 3074, 2952, 2857, 2633, 1732, 1650, 1438, 1268, 1080, 891; TLC (75:25 hexanes/ EtOAc) Rf = 0.32.

Methyl-3-acetyl-2-(3-methylbut-3-en-1-yl)-6-(prop-1-en-2-yl)-tetrahydro-2H-pyran-3-carboxylate (20)

A flame-dried, 25 mL round-bottomed flask was charged with diester 12 (0.35 g, 1.13 mmol, 1.00 equiv) and THF (11 mL) under an atmosphere of N2. The solution was cooled to −78 °C, and MeLi (1.60 M in Et2O, 0.6 mL, 0.97 mmol, 2.00 equiv) was added over 5 s. The reaction was then checked via TLC analysis, which showed incomplete conversion of the starting material. Another 1.00 equiv of MeLi was added, whereupon TLC analysis showed complete conversion of the starting material. The reaction mixture was then quenched via addition of saturated NH4Cl(aq) (5 mL) and subsequently warmed to rt. The mixture was transferred to a separatory funnel, and the aqueous layer was extracted with Et2O (3 × 10 mL). The combined organic extracts were dried with magnesium sulfate and concentrated in vacuo to give the crude ketone as a single diastereomer (as determined via 1H NMR spectroscopic analysis of the crude product residue, which revealed a single stereoisomer in combination with overaddition products). The product was purified via flash chromatography (100:0 to 98:2 to 95:5 to 90:10 hexanes/EtOAc) to afford ketone 20 (0.22 g, 65% yield) as a clear, viscous oil. Analytical data: 1H NMR (600 MHz, CDCl3) δ 4.94 (s, 1H), 4.82 (s, 1H), 4.71 (s, 1H), 4.69 (s, 1H), 3.78–3.75 (m, 4H), 3.71 (d, J = 11.4 Hz, 1H), 2.45 (m, 1H), 2.22 (m, 1H), 2.12 (br s, 4H), 1.99 (m, 1H), 1.75 (br s, 4H), 1.73 (br s, 4H), 1.68 (m, 2H); 13C NMR (150 MHz, CDCl3) δ 205.1, 171.0, 145.6, 145.2, 110.6, 110.3, 80.8, 80.3, 62.3, 52.0, 34.9, 31.4, 30.2, 27.1, 26.4, 22.3, 19.3; HRMS (ESI+) calcd for C17H26O4+Na, 317.1729; found 317.1720; IR (thin film, cm−1) 3445, 3072, 2969, 2857, 1708, 1649, 1436, 1356, 1221, 1081; TLC (75:25 hexanes/EtOAc) Rf = 0.45.

Synthesis of Unsaturated Ketone 21

Methyl-2-(3-methylbut-3-en-1-yl)-6-(prop-1-en-2-yl)-3-propionyltetrahydro-2H-pyran-3-carboxylate (S1)

A flame-dried, 20 mL scintillation vial was charged with bromoethane (0.13 mL, 1.69 mmol, 3.50 equiv) and THF (5 mL) under an atmosphere of N2. The solution was cooled to −78 °C, and tBuLi (1.70 M in pentane, 1.99 mL, 3.38 mmol, 7.00 equiv) was added dropwise. The mixture was allowed to stir 30 min at −78 °C, whereupon a solution of the diester 12 (0.15 g, 0.48 mmol, 1.00 equiv) was added over ~10 s. The reaction progress was immediately checked via TLC analysis, which confirmed complete consumption of the starting material. The reaction was then quenched via addition of saturated NH4Cl(aq) (5 mL) and warmed to rt. The mixture was transferred to a separatory funnel, and the aqueous layer was extracted with Et2O (3 × 10 mL). The combined organic extracts were dried with magnesium sulfate and concentrated in vacuo to afford the crude ketone as a single diastereomer (as determined via 1H NMR spectroscopic analysis of the crude product residue, which revealed a single stereoisomer in combination with overaddition products). The product was purified via flash chromatography (100:0 to 98:2 to 95:5 to 90:10 hexanes/EtOAc) to afford ketone S1 (0.13 g, 89% yield) as a clear, viscous oil. Analytical data: 1H NMR (600 MHz, CDCl3) δ 4.93 (s, 1H), 4.82 (s, 1H), 4.71 (s, 1H), 4.68 (s, 1H), 3.79–3.77 (m, 4H), 3.71 (d, J = 3.6 Hz, 1H), 2.42 (m, 3H), 2.21 (m, 1H), 2.12 (m, 1H), 1.95 (m, 1H), 1.78 (m, 1H), 1.74 (s, 3H), 1.73 (s, 3H), 1.69 (m, 2H), 1.60 (br s, 1H), 1.03 (t, J = 7.2 Hz, H); 13C NMR (150 MHz, CDCl3) δ 208.0, 171.2, 145.6, 145.2, 110.6, 110.3, 80.8, 80.5, 62.4, 51.9, 34.9, 32.6, 31.7, 30.2, 26.4, 22.3, 19.3, 7.9; HRMS (ESI+) calcd for C18H28O4+Na, 331.1885; found 331.1876; IR (thin film, cm−1) 3446, 3073, 2970, 2855, 1739, 1650, 1455, 1342, 1159, 892; TLC (75:25 hexanes/EtOAc) Rf = 0.47.

Methyl 3-Acryloyl-2-(3-methylbut-3-en-1-yl)-6-(prop-1-en-2-yl)-tetrahydro-2H-pyran-3-carboxylate (21)

A flame-dried, 20 mL scintillation vial was charged with THF (4 mL) and diisopropylamine (0.08 mL, 0.55 mmol, 1.30 equiv) under an atmosphere of N2. The mixture was cooled to 0 °C, and nBuLi (1.74 M in hexanes, 0.32 mL, 0.55 mmol, 1.30 equiv) was added dropwise. After being stirred 30 min, the mixture was cooled to −78 °C, and a solution of ketone S1 (0.13 g, 0.42 mmol, 1.00 equiv) in THF (1 mL) was added. After being stirred 45 min at −78 °C, PhSeBr (0.11 g, 0.51 mmol, 1.10 equiv) was added, and the mixture was allowed to stir until complete consumption of the starting material was observed by TLC analysis, typically 45 min. The reaction mixture was diluted with H2O (10 mL), warmed to rt, and transferred to a separatory funnel. The organic layer was separated, and the aqueous layer was extracted with Et2O (3 × 10 mL). The combined organic extracts were dried with magnesium sulfate and concentrated in vacuo to give the crude α-selenide, which was used in the next step without further purification.

The intermediate selenide was dissolved in CH2Cl2 (2 mL), and the mixture was cooled to 0 °C. H2O2 (30% w/w in H2O, 0.80 mL) was added dropwise, and the mixture was stirred at 0 °C until complete consumption of the starting material was observed by TLC analysis, typically 15 min. The reaction mixture was diluted with H2O (7 mL) and transferred to a separatory funnel. The aqueous layer was extracted with EtOAc (3 × 7 mL), and the combined organic extracts were dried with magnesium sulfate and concentrated in vacuo. The product was purified via flash chromatography (100:0 to 98:2 to 95:5 hexanes/EtOAc) to afford unsaturated ketone 21 (0.079 g, 56%) as a pale yellow, viscous oil. Analytical data: 1H NMR (600 MHz, CDCl3) δ 6.39 (d, J = 3.0 Hz, 1H), 6.38 (s, 1H), 5.71 (dd, J = 4.2, 3.0 Hz, 1H), 4.95 (s, 1H), 4.84 (s, 1H), 4.72 (s, 1H), 4.70 (s, 1H), 3.84 (d, J = 10.2 Hz, 1H), 3.76 (s, 3H), 3.72 (d, J = 11.4 Hz, 1H), 2.43 (m, 1H), 2.22 (m, 1H), 2.17 (m, 1H), 2.08 (m, 1H), 1.81 (m, 1H), 1.77 (s, 3H), 1.74 (s, 3H), 1.72–1.66 (m, 3H); 13C NMR (150 MHz, CDCl3) δ 195.6, 170.9, 145.6, 145.2, 131.7, 129.7, 110.7, 110.4, 80.7, 79.9, 60.8, 52.0, 34.8, 31.0, 30.2, 26.2, 22.3, 19.4; HRMS (ESI+) calcd for C18H26O4+Na, 329.1729; found 329.1720; IR (thin film, cm−1) 3420, 3054, 2952, 2852, 1740, 1636, 1455, 1265, 1049, 894; TLC (75:25 hexanes/EtOAc) Rf = 0.63.

Synthesis of Unsaturated Ketone 22

tert-Butyl 3-(3-oxopropyl)-1H-indole-1-carboxylate (S2)

A flame-dried, 50 mL round-bottomed flask was charged with 3-(1H-indol-3-yl)propanal46 (0.37 g, 2.10 mmol, 1.00 equiv), CH2Cl2 (14 mL), NEt3 (0.44 mL, 3.15 mmol, 1.50 equiv), and DMAP (0.005 g, 0.21 mmol, 0.10 equiv) at rt under an atmosphere of N2. Boc2O (0.55 g, 2.52 mmol, 1.20 equiv) was added in one porition, and the resulting mixture was allowed to stir until complete consumption of the starting material was observed by TLC analysis, typically 5 h. The mixture was then diluted with H2O (10 mL) and transferred to a separatory funnel. The organic layer was separated, and the aqueous layer was extracted with CH2Cl2 (3 × 10 mL). The combined organic extracts were dried with magnesium sulfate and concentrated in vacuo. The product was purified via flash chromatography (100:0 to 90:10 to 80:20 hexanes/ EtOAc) to afford the protected indole S2 (0.24 g, 42% yield) as a clear, viscous oil. Analytical data: 1H NMR (600 MHz, CDCl3) δ 9.87 (s, 1H), 8.13 (br s, 1H), 7.51 (d, J = 7.8 Hz, 1H), 7.38 (br s, 1H), 7.33 (t, J = 7.2 Hz, 1H), 7.25 (t, J = 7.2 Hz, 1H), 3.04 (t, J = 7.2 Hz, 2H), 2.87 (t, J = 7.8 Hz, 2H), 1.67 (s, 9H); 13C NMR (150 MHz, CDCl3) δ 201.5, 124.5, 122.6, 122.4, 119.1, 118.7, 115.3, 43.1, 28.2, 17.4; HRMS (ESI+) calcd for C16H19NO3+Na, 296.1263; found 296.1256; IR (thin film, cm−1) 3446, 2977, 2916, 1731, 1670, 1636, 1455, 1373, 1256, 1158, 1018, 746; TLC (80:20 hexanes/EtOAc) Rf = 0.53.

tert-Butyl 3-(2-formylallyl)-1H-indole-1-carboxylate (S3)

A flame-dried, 50 mL round-bottomed flask was charged with aldehyde S2 (0.16 g, 0.60 mmol, 1.00 equiv) and CH2Cl2 (12 mL) at rt under an atmosphere of N2. NEt3 (0.84 mL, 6.00 mmol, 10.0 equiv) was added followed last by dimethylmethylideneiminium iodide (0.33 g, 1.8 mmol, 3.00 equiv). The mixture was allowed to stir at rt until complete conversion of the starting material was observed by TLC analysis, typically 12 h. The reaction was then concentrated on a rotary evaporator and purified via flash chromatography (95:5 to 90:10 hexanes/EtOAc) to afford unsaturated aldehyde S3 (0.08 g, 45% yield) as a yellow, viscous oil. Analytical data: 1H NMR (600 MHz, CDCl3) δ 9.67 (s, 1H), 8.13 (br s, 1H), 7.42 (br s, 1H), 7.39 (d, J = 7.8 Hz, 1H), 7.32 (t, J = 8.4 Hz, 1H), 7.22 (t, J = 7.8 Hz, 1H), 3.65 (s, 2H), 1.67 (s, 9H); 13C NMR (150 MHz, CDCl3) δ 194.0, 149.7, 147.9, 135.3, 130.1, 124.4, 124.1, 122.5, 119.1, 116.8, 115.3, 83.6, 28.2, 23.3; HRMS (ESI+) calcd for C17H19NO3+Na, 308.1263; found 308.1255; IR (thin film, cm−1) 3446, 2916, 1732, 1685, 1488, 1455, 1370, 1255, 1158, 1083, 959; TLC (80:20 hexanes/EtOAc) Rf = 0.60.

tert-Butyl 3-(2-methylene-3-oxobutyl)-1H-indole-1-carboxylate (22)

A flame-dried, 20 mL scintillation vial was charged with aldehyde S3 (0.04 g, 0.12 mmol, 1.00 equiv) and THF (2 mL) under an atmosphere of N2. The solution was cooled to 0 °C, and MeMgBr (3 M in Et2O, 0.12 mL, 0.37 mmol, 3.00 equiv) was added over a period of ~1 min. The mixture was allowed to stir until complete consumption of the starting material was observed by TLC analysis, typically 30 min. The reaction was then quenched via addition of saturated NH4Cl(aq) (5 mL), and the mixture was transferred to a separatory funnel. The aqueous layer was extracted with Et2O (3 × 10 mL), and the combined organic extracts were dried with magnesium sulfate and concentrated in vacuo to give the crude alcohol, which was used in the next step without further purification.

The crude residue was dissolved in CH2Cl2 (2 mL) and transferred to a 20 mL scintillation vial. Dess-Martin periodinane (0.10 g, 0.25 mmol, 2.00 equiv) was added to the vial, and the resulting mixture was allowed to stir until complete consumption of the starting material was observed by TLC analysis, typically 20 min. The reaction mixture was then quenched via a 1:1 mixture of saturated NaHCO3(aq) and saturated Na2S2O3(aq) (5 mL) and allowed to stir 5 min. The mixture was then transferred to a separatory funnel, and the aqueous layer was extracted with Et2O (3 × 5 mL). The combined organic extracts were dried with magnesium sulfate and concentrated in vacuo. The product was purified via flash chromatography (95:5 to 90:10 hexanes/EtOAc) to afford enone 22 (0.026 g, 71% yield) as a yellow viscous oil. Analytical data: 1H NMR (600 MHz, CDCl3) δ 8.12 (br s, 1H), 7.41 (d, J = 9.0 Hz, 1H), 7.39 (br s, 1H), 7.31 (t, J = 9.0 Hz, 1H), 7.21 (t, J = 9.0 Hz, 1H), 6.10 (s, 1H), 5.72(s, 1H), 3.67 (s, 2H), 2.39 (s, 3H), 1.67 (s, 9H); 13C NMR (150 MHz, CDCl3) δ 199.4, 146.8, 126.5, 124.3, 124.0, 122.4, 119.2, 117.8, 115.2, 36.6, 28.2, 25.9; HRMS (ESI+) calcd for C18H21NO3+Na, 322.1419; found 322.1411; IR (thin film, cm−1) 3445, 3054, 2980, 2930, 1731, 1680, 1628, 1454, 1368, 1256, 1158, 1082; TLC (80:20 hexanes/EtOAc) Rf = 0.60.

Synthesis of Enol Silane 24

4-(1-(2,2,2-Trifluoroacetyl)-1Hindol-3-yl)butan-2-one (S4)

A flame-dried, 100 mL round-bottomed flask was charged with TFAA (1.51 mL, 10.7 mmol, 4.00 equiv) and CH2Cl2 (25 mL) under an atmosphere of N2. 4-(1H-Indol-3-yl)butan-2-one47 (0.50 g, 2.67 mmol, 1.00 equiv) was dissolved in CH2Cl2 (2 mL) and added dropwise to the TFAA solution. Once the addition was complete, the mixture was allowed to stir at rt until complete consumption of the starting material was observed by TLC analysis, typically 12 h. The reaction was quenched via addition of saturated NaHCO3(aq) (10 mL) and transferred to a separatory funnel. The aqueous layer was extracted with EtOAc (3 × 10 mL), and the combined organic extracts were dried with sodium sulfate and concentrated in vacuo. The product was purified via flash chromatography (90:10 to 80:20 hexanes/EtOAc) to afford TFAprotected indole S4 (0.54 g, 71% yield) as a pale yellow solid. Analytical data: mp 55–58 °C; 1H NMR (600 MHz, CDCl3) δ 8.43 (d, J = 7.8 Hz, 1H), 7.55 (d, J = 7.8 Hz, 1H), 7.42 (m, 2H), 7.25 (br s, 1H), 2.99 (t, J = 7.8 Hz, 2H), 2.87 (t, J = 7.8 Hz, 2H), 2.20 (s, 3H); 13C NMR (150 MHz, CDCl3) δ 207.0, 136.2, 130.5, 126.4, 125.5, 125.2, 120.3, 120.2, 119.2, 117.0, 42.2, 30.0, 18.6; HRMS (ESI+) calcd for C14H12F3NO2+Na, 306.0718; found 306.0709; IR (thin film, cm−1) 2917, 1717, 1459, 1419, 1292, 1207, 1155, 880; TLC (80:20 hexanes/ EtOAc) Rf = 0.48.

2,2,2-Trifluoro-1-(3-(3-((trimethylsilyl)oxy)but-2-en-1-yl)-1Hindol-1-yl)ethan-1-one (24)

A flame-dried, 20 mL scintillation vial was charged with ketone S4 (0.05 g, 0.267 mmol, 1.00 equiv) and CH2Cl2 (3 mL) under an atmosphere of N2. The mixture was cooled to −10 °C, and HMDS (0.17 mL, 0.801 mmol, 3.00 equiv) was added followed by TMSI (0.02 mL, 0.267 mmol, 1.00 equiv) dropwise. The reaction mixture was warmed to rt and stirred until TLC analysis confirmed complete consumption of the starting material, typically 45 min. The reaction mixture was then quenched via addition of saturated NaHCO3(aq) (5 mL) and transferred to a separatory funnel. The organic layer was separated, and the aqueous layer was extracted with CH2Cl2 (3 × 5 mL). The combined organic extracts were dried with magnesium sulfate and concentrated in vacuo to afford the crude enol silane as a ~3:1 mixture of alkene isomers as determined by 1H NMR analysis. This material was unstable to further purification and was used directly in reaction screenings. The crude 1H NMR spectrum is included in the Supporting Information.

tert-Butyl 3-(3-Methylbut-2-en-1-yl)-1H-indole-1-carboxylate (25)

A flame-dried, 20 mL scintillation vial was charged with 3-(3-methylbut-2-en-1-yl)-1H-indole48 (0.05 g, 0.27 mmol, 1.00 equiv), NEt3 (0.06 mL, 0.41 mmol, 1.50 equiv), DMAP (0.003 g, 0.027 mmol, 0.10 equiv), and CH2Cl2 (3 mL) at rt under an atmosphere of N2. Boc2O (0.07 mL, 0.32 mmol, 1.20 equiv) was added, and the mixture was allowed to stir at rt until TLC analysis confirmed complete consumption of the starting material, typically 12 h. The mixture was diluted with H2O (5 mL) and transferred to a separatory funnel. The aqueous layer was extracted with CH2Cl2 (3 × 5 mL), and the combined organic extracts were washed with H2O (5 mL), dried with sodium sulfate, and concentrated in vacuo. The product was purified via flash chromatography (100:0 to 98:2 hexanes/EtOAc) to afford protected indole 25 (0.06 g, 73% yield) as a yellow viscous oil. Analytical data: 1H NMR (600 MHz, CDCl3) δ 8.11 (d, J = 9.0 Hz, 1H), 7.53 (d, J = 7.8 Hz, 1H), 7.35–7.31 (m, 2H), 7.25 (t, J = 7.8 Hz, 1H), 5,41 (t, J = 7.2 Hz, 1H), 3.39 (d, J = 7.2 Hz, 2H), 1.78 (br s, 6H), 1.68 (s, 9H); 13C NMR (150 MHz, CDCl3) δ 133.0, 124.2, 123.1, 122.3, 122.2, 121.5, 120.6, 120.5, 119.1, 115.2, 107.1, 28.2, 25.7, 23.9, 17.8; HRMS (ESI+) calcd for C18H23NO2+Na, 308.1626; found 308.1619; IR (thin film, cm−1) 3421, 3053, 2980, 2931, 1730, 1454, 1371, 1265, 1158, 855; TLC (80:20 hexanes/EtOAc) Rf = 0.95.

Dimethyl 2-(2-(1-Methyl-2,6-dioxocyclohexyl)ethyl)-6-(prop-1-en-2-yl)dihydro-2H-pyran-3,3(4H)-dicarboxylate (29)

A flame-dried, 20 mL scintillation vial was charged with iodide 27 (0.60 g, 1.51 mmol, 1.00 equiv), 2-methyl-1,3-cyclohexanedione (0.27 g, 2.12 mmol, 1.4 equiv), and DMF (3 mL) at rt under an atmosphere of N2. Cs2CO3 (0.74 g, 2.27 mmol, 1.50 equiv) was added, and the mixture was warmed to 65 °C. The reaction was allowed to stir at this temperature until complete consumption of the starting material was observed by TLC analysis, typically 5 h. The reaction mixture was cooled to rt, diluted with H2O (6 mL) and Et2O (5 mL), and transferred to a separatory funnel. The organic layer was separated, and the aqueous layer was extracted with Et2O (3 × 10 mL). The combined organic extracts were washed with brine (10 mL), dried with magnesium sulfate, and concentrated in vacuo. The mixture was purified via flash chromatography (70:30 to 60:40 to 50:50 hexanes/ EtOAc) to afford diketone 29 (0.20 g, 34% yield) as a clear, viscous oil and enol ether 30 (0.34 g, 56% yield) as a clear, viscous oil. Analytical data: O-alkylation product 30: 1H NMR (600 MHz, CDCl3) δ 4.90 (s, 1H), 4.79 (s, 1H), 4.09 (m, 2H), 3.92 (d, J = 10.8 Hz, 1H), 3.77 (d, J = 11.4 Hz, 1H), 3.74 (s, 3H), 3.69 (s, 3H), 2.55–2.51 (m, 3H), 2.31 (t, J = 6.6 Hz, 2H), 2.21 (m, 1H), 2.09 (m, 1H), 1.96–1.90 (m, 3H), 1.79 (m, 1H), 1.70 (s, 3H), 1.68 (s, 3H), 1.66 (m, 1H); 13C NMR (150 MHz, CDCl3) δ 198.8, 171.5, 110.9, 169.3, 144.8, 115.0, 110.8, 81.3, 77.1, 64.6, 56.4, 52.6, 52.1, 36.2, 32.7, 31.9, 26.4, 25.3, 20.9, 18.8, 7.3; HRMS (ESI+) calcd for C21H30O7+Na, 417.1889; found 417.1879; IR (thin film, cm−1) 2953, 1731, 1635, 1455, 1377, 1355, 1262, 1095, 921; TLC (75:25 hexanes/EtOAc) Rf = 0.10. C-alkylation product 29: 1H NMR (600 MHz, CDCl3) δ 4.90 (s, 1H), 4.79 (s, 1H), 3.73–3.70 (m, 4H), 3.68 (s, 3H), 3.61 (m, 1H), 2.76 (m, 2H), 2.56–2.48 (m, 3H), 2.12 (m, 1H), 2.04 (m, 1H), 1.85–1.74 (m, 4H), 1.69 (s, 3H), 1.63 (m, 1H), 1.59 (m, 2H), 1.18 (s, 3H); 13C NMR (150 MHz, CDCl3) δ 210.0, 209.8, 171.3, 169.2, 145.0, 110.6, 81.1, 80.9, 66.1, 56.2, 52.5, 52.0, 37.5, 35.5, 32.0, 27.6, 26.4, 18.8, 17.8, 17.0; HRMS (ESI+) calcd for C21H30O7+Na, 417.1889; found 417.1879; IR (thin film, cm−1) 3403, 3057, 2954, 2872, 1729, 1696, 1455, 1266, 1084, 905; TLC (75:25 hexanes/EtOAc) Rf = 0.13.

Methyl 10a-Hydroxy-6a-methyl-7-oxo-3-(prop-1-en-2-yl)-decahydro-1H-benzo[f]chromene-10b(4aH)-carboxylate (32)

A 5 mL dram vial was charged with diketone 29 (0.015 g, 0.04 mmol, 1.00 equiv) and DMSO (2 mL), and NaCl (0.02 g, 0.38 mmol, 10.0 equiv) was added in one portion. The vial was sealed with a screw-cap, and the mixture was warmed to 150 °C and stirred 9 h. The mixture was cooled to rt, diluted with Et2O (2 mL), and transferred to a separatory funnel containing H2O (10 mL). The aqueous layer was extracted with Et2O (3 × 5 mL), and the combined organic extracts were washed with brine (5 mL), dried with magnesium sulfate, and concentrated in vacuo. Crude 1H NMR analysis revealed a ~1:1 mixture of the diastereomeric decarboxylation product 31 and annulation product 32. This mixture was purified via flash chromatography (70:30 to 60:40 hexanes/EtOAc) to afford annulation product 32 (0.006 g, 47% yield) as a clear, viscous oil and Krapcho adduct 31 (0.005 g, 39% yield) as a clear, viscous oil. Slow evaporation of 32 from acetone and hexanes provided crystals suitable for X-ray crystallographic analysis. (Note: when this reaction was conducted on 0.07 g, scale, only the Krapcho adduct 31 was isolated in 43% yield. No cyclization product 32 was detected on this scale.) Analytical data: Decarboxylation product 31: 1H NMR (600 MHz, CDCl3) δ 4.94 (s, 2H), 4.82–4.81 (m, 2H), 3.73–3.70 (m, 2H), 3.68–6.67 (m, 3H), 3.47–3.41 (m, 2H), 2.80–2.69 (m, 4H), 2.60–2.54 (m, 4H), 2.24 (m, 1H), 2.14–2.12 (m, 2H), 2.07–1.98 (m, 5H), 1.85–1.77 (m, 3H), 1.74–1.73 (m, 5H), 1.51–1.39 (m, 5H), 1.21 (s, 3H), 1.18 (s, 3H); 13C NMR (150 MHz, CDCl3) δ 210.3, 210.1, 210.0, 209.9, 174.3, 172.8, 145.8, 145.5, 110.6, 110.2, 81.5, 80.0, 78.0, 77.3, 66.1, 65.5, 51.7, 51.3, 46.7, 37.8, 37.7, 37.5, 34.0, 33.5, 29.7, 29.1, 28.9, 28.8, 27.7, 26.2, 25.7, 19.0, 18.8, 18.3, 17.9, 17.7, 16.4; HRMS (ESI+) calcd for C19H28O5+Na, 359.1834; found 359.1825; IR (thin film, cm−1) 3446, 2917, 2849, 1731, 1652, 1540, 1456, 1200, 901; TLC (75:25 hexanes/EtOAc) Rf = 0.17. Annulation product 32: 1H NMR (600 MHz, CDCl3) δ 4.91 (s, 1H), 4.78 (s, 1H), 3.86 (d, J = 12.0 Hz, 1H), 3.66 (dd, J = 7.8, 4.8 Hz, 1H), 3.59 (s, 3H), 2.47 (m, 2H), 2.31 (m, 2H), 2.16 (dd, J = 10.8, 6.0 Hz, 1H), 2.10–2.00 (m, 3H), 1.77 (m, 2H), 1.68 (s, 3H), 1.62 (m, 1H), 1.52 (br s, 1H), 1.45 (m, 1H), 1.35 (m, 1H), 1.18 (s, 3H); 13C NMR (150 MHz, CDCl3) δ 210.0, 172.5, 145.7, 110.9, 82.0, 80.0, 78.2, 53.5, 53.2, 50.5, 34.1, 29.1, 28.1, 27.5, 26.9, 25.9, 25.4, 18.4, 18.1; HRMS (ESI+) calcd for C19H28O5+Na, 359.1834; found 359.1825; IR (thin film, cm−1) 3446, 3055, 2950, 1718, 1456, 1339, 1265, 1073, 899; TLC (75:25 hexanes/EtOAc) Rf = 0.07.

2-Methyl-3-((4-methylpent-3-en-1-yl)oxy)cyclohex-2-en-1-one (38)

A flame-dried, 25 mL round-bottomed flask was charged with 2-methyl-1,3-cyclohexanedione (1.00 g, 7.93 mmol, 100 equiv) and DMF (8 mL) under an atmosphere of N2. The mixture was cooled to 0 °C, and NaH (60% dispersion in oil, 0.39 g, 10.3 mmol, 1.30 equiv) was added portionwise. The mixture was warmed to rt and stirred 10 min, whereupon the iodide 37 (2.16 g, 10.3 mmol, 1.30 equiv) was added. The mixture was allowed to stir 12 h, and the reaction mixture was poured into a separatory funnel containing H2O (20 mL). CH2Cl2 (20 mL) was added, and the aqueous layer was extracted with CH2Cl2 (3 × 10 mL). The combined organic extracts were washed with brine (20 mL), dried with magnesium sulfate, and concentrated in vacuo. The products were purified via flash chromatography (90:10 to 80:20 to 60:40 hexanes/EtOAc) to afford cycloalkanedione 35 (0.12 g, 7% yield) as a yellow oil and vinyl ether 38 (0.43 g, 26% yield) as a clear, viscous oil. Analytical data: 1H NMR (600 MHz, CDCl3) δ 5.11 (m, 1H), 3.93 (t, J = 6.6 Hz, 2H), 2.51 (m, 2H), 2.36 (q, J = 7.2 Hz, 2H), 2.30 (t, J = 6.6 Hz, 2H), 1.93 (m, 2H), 1.68 (s, 3H), 1.66 (t, J = 1.2 Hz, 3H), 1.61 (s, 3H); 13C NMR (150 MHz, CDCl3) δ 198.8, 171.4, 134.8, 118.9, 115.0, 67.4, 36.2, 28.7, 25.7, 25.4, 20.9, 17.7, 7.29; HRMS (ESI+) calcd for C13H20O2+Na, 231.1361; found 231.1354; IR (thin film, cm−1) 3446, 2926, 1732, 1646, 1472, 1376, 1238, 1096; TLC (70:30 hexanes/EtOAc) Rf = 0.26.

(E)-3-(2,2-Dimethylhydrazono)-2-methylcyclohexan-1-one (39)

A 250 mL round-bottomed flask was charged with 2-methyl-1,3-cyclohexanedione (12.0 g, 95.1 mmol, 1.00 equiv), C6H6 (150 mL), H2NNMe2 (8.70 mL, 114.2 mmol, 1.20 equiv), and TsOH (0.50 g, 2.63 mmol, 0.03 equiv). A Dean–Stark apparatus was connected to the flask, and the mixture was heated to 100 °C with vigorous stirring for 6 h. The mixture was cooled to rt and concentrated on a rotary evaporator. The crude residue was then recrystallized from C7H8 to afford ketohydrazone 39 (16.00 g, 99% yield) as a yellow powder. Analytical data for this compound matched that reported in the literature:24 1H NMR (600 MHz, CDCl3) δ 5.05 (br s, 1H), 2.64 (m, 2H), 2.53 (s, 6H), 2.32 (t, J = 7.2 Hz, 2H), 1.90 (m, 2H), 1.66 (s, 3H).

2-Methyl-2-(4-methylpent-3-en-1-yl)cyclohexane-1,3-dione(35)

A flame-dried, 500 mL round-bottomed flask was charged with THF (250 mL) under an atmosphere of N2. KH (10.40 g, 30% dispersion in oil, 78.50 mmol, 1.20 equiv) was washed free of oil three times with petroleum ether, suspended in THF (20 mL), and added to the flask with stirring. The reaction mixture was cooled to −78 °C, and a solution of ketohydrazone 39 (11.00 g, 65.42 mmol, 1.00 equiv) in THF (25 mL) was slowly added. The reaction was warmed to 0 °C and allowed to stir 4.5 h. The resulting dark-brown mixture was recooled to −78 °C, and iodide S2 (17.3 g, 78.50 mmol, 1.20 equiv) was added. The reaction mixture was allowed to stir while slowly warming to rt overnight, producing a cream-white suspension. The reaction was then quenched with saturated NH4Cl(aq) (50 mL), and the resulting mixture was partitioned in a separatory funnel. The aqueous layer was extracted with Et2O (3 × 50 mL), and the combined organic extracts were washed with brine (40 mL), dried with magnesium sulfate, and concentrated in vacuo to give the intermediate alkylation product, which was used in the next step without further purification.

Cu(OAc)2·H2O (26.00 g, 130.9 mmol, 2.00 equiv) was dissolved in H2O (300 mL) in a 1000 mL round-bottomed flask with vigorous stirring. The crude hydrazone was then dissolved in THF (300 mL) and added to the Cu(OAc)2·H2O solution, and the reaction mixture was allowed to stir until TLC analysis confirmed complete conversion of the starting material, typically 12 h. The resulting mixture was concentrated on a rotary evaporator to remove the THF, and the solution was then diluted with saturated NH4Cl(aq) (100 mL) and CH2Cl2 (100 mL). This mixture was transferred to a separatory funnel and extracted with CH2Cl2 (3 × 50 mL). The combined organic extracts were washed with brine (2 × 50 mL), dried with magnesium sulfate, and concentrated in vacuo. The product was purified via flash chromatography (90:10 to 80:20 hexanes/EtOAc) to afford diketone 35 (10.34 g, 76% yield) as an orange, viscous oil. Analytical data: 1H NMR (600 MHz, CDCl3) δ 4.99 (br s, 1H), 2.70 (m, 2H), 2.60 (m, 2H), 2.01 (m, 1H), 1.86–1.80 (m, 5H), 1.64 (s, 3H), 1.55 (s, 3H), 1.23 (s, 3H); 13C NMR (150 MHz, CDCl3) δ 210.3, 132.9, 122.9, 65.6, 37.9, 37.5, 25.6, 23.3, 18.9, 17.7, 17.6; HRMS (ESI+) calcd for C13H20O2+H, 209.1542; found 209.1537; IR (thin film, cm−1) 3400, 2967, 2929, 1725, 1695, 1602, 1451, 1280, 1169, 1026; TLC (80:20 hexanes/EtOAc) Rf = 0.40.

3-Hydroxy-2-methyl-2-(4-methylpent-3-en-1-yl)cyclohexan-1-one (40)

A 20 mL scintillation vial was charged with diketone 35 (0.1 g, 0.48 mmol, 1.00 equiv) and MeOH (10 mL), and the solution was cooled to 0 °C. NaBH4 (0.005 g, 0.12 mmol, 0.25 equiv) was added, and the mixture was allowed to stir at this temperature until complete consumption of the starting material was observed by TLC analysis, typically 10 min. The reaction was diluted with brine (5 mL) and CH2Cl2 (5 mL), and the mixture was transferred to a separatory funnel. The aqueous layer was extracted with CH2Cl2 (3 × 5 mL), and the combined organic extracts were dried with sodium sulfate and concentrated in vacuo to give the crude alcohol as a 19.4:1 mixture of diastereomers. The diastereomeric ratio was determined by 1H NMR spectroscopic analysis of the crude reaction mixture by comparison of the integration of the resonances at δ 1.14 (major diastereomer) and δ 1.09 (minor diastereomer). The product was purified via flash chromatography (80:20 to 70:30 hexanes/EtOAc) to afford hydroxyketone 40 (0.093 g, 93% yield) as a clear, viscous oil. Analytical data: 1H NMR (600 MHz, CDCl3) δ 5.05 (t, J = 6.0 Hz, 1H), 3.65 (d, J = 7.8 Hz, 1H), 2.39 (m, 1H), 2.32 (m, 1H), 1.99–1.88 (m, 5H), 1.73 (m, 1H), 1.66–1.63 (m, 4H), 1.55 (br s, 4H), 1.15 (s, 3H); 13C NMR (150 MHz, CDCl3) δ 214.1, 132.1, 123.9, 77.5, 54.7, 37.6, 31.5, 28.7, 25.6, 21.9, 20.7, 18.7, 17.6; HRMS (ESI+) calcd for C13H22O2+Na, 233.1518; found 233.1510; IR (thin film, cm−1) 3420, 2939, 2871, 1698, 1455, 1375, 1161, 1059, 993, 831; TLC (70:30 hexanes/EtOAc) Rf = 0.32.

(2R,3S)-3-Hydroxy-2-methyl-2-(4-methylpent-3-en-1-yl)-cyclohexan-1-one (36)