Abstract

This study investigated (1) the susceptibility of Bacillus anthracis (Ames strain), Bacillus subtilis (ATCC 19659), and Clostridium sporogenes (ATCC 3584) spores to commercially available peracetic acid (PAA)- and glutaraldehyde (GA)-based disinfectants, (2) the effects that heat-shocking spores after treatment with these disinfectants has on spore recovery, and (3) the timing of heat-shocking after disinfectant treatment that promotes the optimal recovery of spores deposited on carriers. Suspension tests were used to obtain inactivation kinetics for the disinfectants against three spore types. The effects of heat-shocking spores after disinfectant treatment were also determined. Generalized linear mixed models were used to estimate 6-log reduction times for each spore type, disinfectant, and heat treatment combination. Reduction times were compared statistically using the delta method. Carrier tests were performed according to AOAC Official Method 966.04 and a modified version that employed immediate heat-shocking after disinfectant treatment. Carrier test results were analyzed using Fisher's exact test. PAA-based disinfectants had significantly shorter 6-log reduction times than the GA-based disinfectant. Heat-shocking B. anthracis spores after PAA treatment resulted in significantly shorter 6-log reduction times. Conversely, heat-shocking B. subtilis spores after PAA treatment resulted in significantly longer 6-log reduction times. Significant interactions were also observed between spore type, disinfectant, and heat treatment combinations. Immediately heat-shocking spore carriers after disinfectant treatment produced greater spore recovery. Sporicidal activities of disinfectants were not consistent across spore species. The effects of heat-shocking spores after disinfectant treatment were dependent on both disinfectant and spore species. Caution must be used when extrapolating sporicidal data of disinfectants from one spore species to another. Heat-shocking provides a more accurate picture of spore survival for only some disinfectant/spore combinations. Collaborative studies should be conducted to further examine a revision of AOAC Official Method 966.04 relative to heat-shocking.

Keywords: Anthrax, Bacillus anthracis, disinfection, heat-shock, inactivation kinetics, spore, sporicide

Introduction

The decontamination efforts that followed the intentional release of Bacillus anthracis spores through the US Postal Service have generated significant interest in chemical disinfectants that are capable of inactivating spores from virulent strains of B. anthracis. In addition, sporicidal disinfectants are important in a variety of clinical settings. For example, dental instruments, surgical instruments, and endoscopes require treatment between uses that ensures sufficient spore inactivation to prevent cross-contamination (Angelillo et al. 1998; Rutala et al. 1998; Rutala and Weber 2004). Alkaline glutaraldehyde and peracetic acid are common high-level disinfectants that might be used after a biological attack or in a healthcare setting; both are commercially available and highly effective sporicides (Russell 1990; Spotts Whitney et al. 2003).

Glutaraldehyde is an effective sporicide that displays optimal antimicrobial activity under basic conditions (Hopwood et al. 1970; Power and Russell 1990; Russell 1990; Coates 1996; Angelillo et al. 1998; Tennen et al. 2000). Consequently, aqueous glutaraldehyde solutions are activated by the addition of alkalinizing agents. Glutaraldehyde inactivates spores by cross-linking outer proteins and blocking normal germination events (Power and Russell 1989; Tennen et al. 2000). CIDEX™ (Advanced Sterilization Products, Irvine, CA) is a 2.4% alkaline glutaraldehyde solution that has been available commercially for many years (Lane et al. 1966). CIDEX™ was investigated throughout this study because it is a frequently used high-level disinfectant and cold sterilant.

Peracetic acid is an effective disinfectant against a wide-variety of microorganisms such as viruses, fungi, vegetative bacterial cells, and bacterial endospores (Kline and Hull 1960; Hussaini and Ruby 1976; Baldry 1983; Leaper 1984; Marquis et al. 1995; Setlow et al. 2002). In fact, it has been shown to be an effective disinfectant against spores from B. anthracis (Hussaini and Ruby 1976). Its primary mechanism of action involves the generation of hydroxyl and organic radicals (Clapp et al. 1994; Marquis et al. 1995). These radicals lead to the oxidation of the double bonds found in carbohydrates, nucleic acids, lipids, and proteins (Marquis et al. 1995). STERIPLEX™ (SBIOMED LLC, Orem, UT) formulations contain peracetic acid and other proprietary active ingredients, which create a synergistic antimicrobial effect when combined. Preliminary studies in our laboratory indicated that STERIPLEX™ solutions have rapid sporicidal activity. In addition, oral toxicity studies in rats, conducted in other laboratories, demonstrated that these solutions are minimally cytotoxic and have relatively few corrosive properties (data not shown). STERIPLEX™ HC (0.25% peracetic acid) and STERIPLEX™ Ultra (1.3% peracetic acid) were the formulations used throughout this study.

Upon exposure to chemical disinfectants, bacterial endospores can be unaffected, sublethally injured, or irreparably damaged (i.e., inactivated or killed). Upon neutralization of the disinfectant and incubation in or on nutrient media, sublethally injured spores can recover and convert back to vegetative growth through the process of germination. The spores that fail to germinate are generally considered to be dead. However, treating spores with lysozyme or sodium hydroxide after disinfectant treatment can promote the germination of spores thought to be irreparably damaged (Gorman et al. 1983; Dancer et al. 1989). In addition, exposing spores to high heat (heat-shocking) after treatment with certain biocides has been shown to aid in the revival of injured spores (Spicher and Peters 1976, 1981; Gorman et al. 1983; Williams and Russell 1993).

Although the treatments described above are not typically practiced in clinical settings, the ability to revive spores that were supposedly killed by exposure to a chemical disinfectant should not be ignored. Experiments involving these harsh treatments have revealed the risk of overestimating the effectiveness of certain disinfectants against various spore species (Gorman et al. 1983; Power et al. 1989; Russell 1990; Williams and Russell 1993). In fact, the official method for determining the activity of sporicidal disinfectants, as published by AOAC International, requires spores to be heat-shocked at 80°C for 20 min after disinfectant treatment and incubation, to avoid overestimating the effectiveness of a given chemical disinfectant (AOAC Official Method 966.042006). However, the results of heat-shocking spores after peracetic acid treatment have not been investigated. In addition, previous studies on the effects of heat-shocking on spore viability have not included spores from virulent B. anthracis strains.

In this study, suspension tests were conducted, with and without heat-shocking, to obtain the inactivation kinetics for CIDEX™, STERIPLEX™ HC, and STERIPLEX™ Ultra against spores from a fully virulent strain of B. anthracis as well as spores from well-characterized strains of Bacillus subtilis and Clostridium sporogenes. These tests provided comparative data on the efficacy of the three disinfectants against the different spore species. They also allowed the investigation of the effects of heat-shocking (according to AOAC Official Method 966.04) on the viability of spores in suspension after treatment with glutaraldehyde and peracetic acid. In addition, these tests revealed the consequences of heat-shocking on virulent strains of B. anthracis after disinfectant treatment.

The disinfectants were also tested against spores from B. subtilis and C. sporogenes that were deposited on carriers. This was done according to AOAC Official Method 966.04 and a modified version that employed immediate heat-shocking after disinfectant treatment. This allowed for the evaluation of the effects of a 3-week incubation period prior to heat-shocking that is prescribed by AOAC Official Method 966.04.

Materials and Methods

Bacterial strains

Bacterial strains used in this study were B. anthracis A0462 (the virulent Ames strain), B. subtilis ATCC 19659, and C. sporogenes ATCC 3584. The identity of B. anthracis was confirmed by the gas chromatographic analysis of cellular fatty acids using an Agilent 6890 Series Gas Chromatograph (Santa Clara, CA) and software purchased from MIDI (Newark, DE). Real-time PCR assays targeting unique chromosomal and plasmid gene sequences (Tetracore Inc, Rockville, MD) were used to definitively identity the strain as B. anthracis and to confirm the presence of both virulence plasmids. Vegetative cultures of B. anthracis and B. subtilis were grown on Columbia agar (Becton, Dickinson and Company, Sparks, MD) and incubated under aerobic conditions, whereas vegetative cultures of C. sporogenes were grown on Reinforced Clostridial Agar (RCA, Becton, Dickinson and Company) and incubated under anaerobic conditions using an Anoxomat system (Advanced Instruments, Inc., Norwood, MA).

Laboratory conditions

Procedures involving B. anthracis were performed under Biosafety Level 3 (BSL-3) operating conditions. All other procedures were conducted under Biosafety Level 2 (BSL-2) operating conditions.

Disinfectants

The following common high-level disinfectants were tested against spores from B. anthracis, B. subtilis, and C. sporogenes: CIDEX™ Activated Dialdehyde Solution, STERIPLEX™ HC, and STERIPLEX™ Ultra. Disinfectants were tested as recommended by the manufacturer. Additionally, all disinfectants were activated immediately before testing.

Neutralizing agents

Controls were conducted to ensure adequate neutralization of the disinfectants by combining 100 μL of a spore suspension (containing approximately 1 × 104 spores mL−1) with 1 mL of disinfectant and 9 mL of the appropriate neutralizer. A 1% (w/v) glycine solution, prepared just prior to use, was used to neutralize the aldehyde-based disinfectant. The peracetic acid-based disinfectants were inactivated using a freshly prepared neutralizing solution which was formulated as follows: 500 mmol L−1 Tris pH 8.0, 12.72% Tween 80, 6% Tamol SN, 1.7% lecithin, 1.1% catalase, 1% cysteine, and 1% peptone. The neutralized solution (containing approximately 100 spores mL−1) was allowed to rest for 20 min before being assayed for the number of viable spores. Neutralizer controls were plated in triplicate using a membrane filtration system (E-Z Pak 0.45 μm, Millipore Corporation, Billerica, MA).

Spore suspensions

Aliquots of a saturated bacterial culture (100 μL) were used to inoculate flasks containing 250 mL of Leighton-Doi Broth (Leighton and Doi 1971). The flasks were incubated at 32°C with vigorous shaking for approximately 3–4 days, or until the culture exhibited >95% refractile spores. The percent of refractile spores was monitored on a daily basis by phase-contrast microscopy. The culture was transferred to 50 mL conical vials and heated for 30 min at 65°C to kill vegetative cells. The spores were pelleted by centrifugation at 5000g for 15 min at 4°C and suspended in 20 mL ice-cold sterile HPLC water. After incubating for 16–18 h at 4°C to promote the lysis of dead vegetative cells, the spore suspensions were centrifuged, as described above, and washed three times in 20 mL ice-cold sterile HPLC water to further purify the spore suspensions. Spore suspensions of B. anthracis and B. subtilis were prepared as described above, whereas a spore suspension of C. sporogenes was purchased from Presque Isle Cultures (Erie, PA). All spore suspensions were quantified using serial dilution and plated in triplicate using membrane filtration. The spore titers for each spore suspension are listed in Table1. All spore suspensions were stored at 4°C until used.

Table 1.

Spore suspension concentrations

| Organism | Concentration (spore mL−1) |

|---|---|

| Bacillus anthracis | 1.80 × 109–1.98 × 109 |

| Bacillus subtilis | 4.16 × 109–7.02 × 109 |

| Clostridium sporogenes | 1.24 × 107–3.12 × 107 |

Suspension tests

A spore suspension was vortexed for 2–3 min to ensure a homogenous mixture. Aliquots of the spore suspension (1 mL) were transferred to vials containing 9 mL of the chosen disinfectant (previously equilibrated to 20°C) at time zero. The vial was vortexed and placed back in a 20°C water bath.

Samples of the spore/disinfectant suspension were taken after various exposure times. The vial was removed from the water bath and vortexed before a 1 mL aliquot of the solution was removed to 9 mL of an appropriate neutralizing agent. The spore/neutralizer suspension was vortexed and allowed to stand for 20 min to allow complete neutralization of the active ingredient. The neutralized solution was serially diluted in physiological saline solution (PSS) and the viable spores of 1 mL aliquots from each dilution were quantified in triplicate using membrane filtration. After samples from each dilution were plated, the dilution tubes were heat-shocked in an 80°C water bath for 20 min. After heat-shocking, the viable spores of 1 mL aliquots from each dilution were again quantified in triplicate using membrane filtration. In the case of B. anthracis and B. subtilis, filter membranes were incubated on plates containing Columbia agar, whereas prereduced RCA plates were used for C. sporogenes. All plates were incubated at 37°C. B. anthracis and B. subtilis colonies were counted after incubating for 24 and 48 h, whereas C. sporogenes colonies were counted only after 48 h in order to ensure that anaerobic conditions were maintained. Assays were repeated in triplicate for each species-disinfectant combination.

Carriers

Polyester suture loops and porcelain penicylinders were used throughout the investigation. Polyester suture loops were used instead of the typical silk suture loops, because the latter have been shown to interact with peracetic acid (McDonnell 2003). All carriers were prepared by, and purchased from Presque Isle Cultures. Preparation of the carriers was done according to AOAC Official Method 966.04 and included (1) inoculation with spores of B. subtilis ATCC 19659 or C. sporogenes ATCC 3584, (2) spore enumeration, and (3) verification of spore resistance to hydrochloric acid.

Presque Isle Cultures reported spore titers that exceeded 1 × 106 spores per carrier. As described below, these titers were confirmed prior to use. Five carriers were randomly selected from each lot number. Each carrier was transferred to a different 50 mL conical vial containing 10 mL nutrient broth (Becton, Dickinson and Company) and 2% Tween. The vials were sonicated for 10 min in a Sonicor™ SC-200 ultrasonic cleaner (Sonicor, Wallingford, CT) in order to dislodge spores from the carrier material. Following sonication, the vials were vortexed for 2 min to further remove spores from the carrier. The spore suspensions were serially diluted in PSS and the number of viable spores in each dilution was quantified by membrane filtration of 1 mL samples. Samples from each dilution were plated in triplicate. In the case of B. subtilis, filter membranes were incubated on plates containing Columbia agar, whereas prereduced RCA plates were used for C. sporogenes. All plates were incubated at 37°C. B. subtilis colonies were counted after incubating for 24 and 48 h, whereas C. sporogenes colonies were counted after 48 h. Plate counts were used to determine the average spore titer for each lot number. The average spore titers are listed in Table2.

Table 2.

Concentrations of spores dried onto carriers from recovery experiments

| Bacillus subtilis | ||

| Lot 0321071 | Carrier | Average titer (cfu) |

| Porcelain penicylinder | 1.05 × 106 | |

| Polyester suture loop | 1.46 × 106 | |

| Lot 0525072 | Carrier | Average titer (cfu) |

| Porcelain penicylinder | 1.12 × 106 | |

| Polyester suture loop | 1.00 × 106 | |

| Clostridium sporogenes | ||

| Lot 0402071 | Carrier | Average titer (cfu) |

| Porcelain penicylinder | 1.21 × 106 | |

| Polyester suture loop | 3.05 × 106 | |

| Lot 0526072 | Carrier | Average titer (cfu) |

| Porcelain penicylinder | 1.61 × 106 | |

| Polyester suture loop | 5.27 × 106 | |

Lots used for CIDEX™ and STERIPLEX™ Ultra tests.

Lots used for STERIPLEX™ HC.

Carrier tests

Polyester suture loops and porcelain penicylinders were used to evaluate the effectiveness of the disinfectants against spores deposited on solid surfaces. Experiments were performed according to AOAC Official Method 966.04 (Fig.1). Aliquots of a disinfectant (10 mL) were transferred to 50 mL conical vials and placed in a 20°C water bath. After equilibrating in the water bath for 10 min, two polyester suture loops or two porcelain penicylinders were placed in each vial using a flamed metal hook. Once the specified contact time had elapsed, the carriers were removed using a flamed metal hook and placed in separate vials containing Sodium Thioglycolate Broth (STB, Becton, Dickinson and Company). After the initial transfer had been completed, each carrier was again transferred to a second vial of STB. Vials were incubated at 37°C for 21 days. After the initial incubation period, the vials were heat-shocked at 80°C for 20 min and incubated at 37°C for an additional 72 h, after which vials were assessed for growth. Thirty polyester suture loops and 30 porcelain penicylinders were tested, as described above, for each spore species-disinfectant combination.

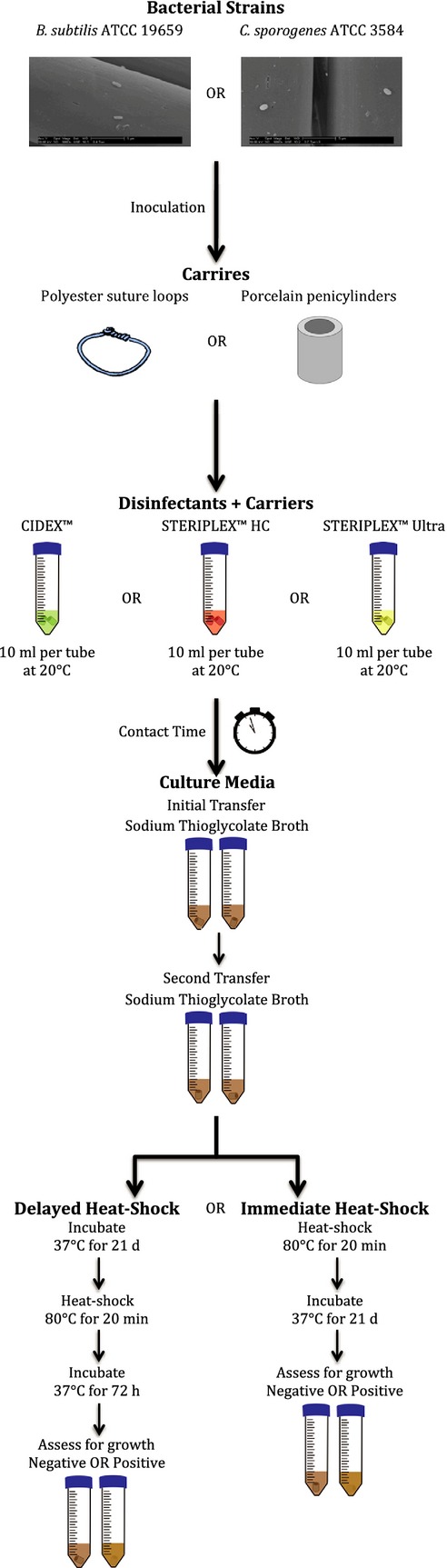

Figure 1.

Polyester suture loops and porcelain penicylinders were prepared and tested according to AOAC Official Method 966.04 (See “Delayed Heat-Shock”) and a modified version (See “Immediate Heat-Shock”). Spores from B. subtilis had an exposure time of 4 h when tested against CIDEX™, whereas spores from C. sporogenes had an exposure time of 1 h when tested against CIDEX™. Regardless of spore species, the exposure times for STERIPLEX™ HC and STERIPLEX™ Ultra were 25 min and 15 min, respectively. Exposure times were determined experimentally by previous testing (data not shown) to be at the end of the kill curve for each spore species-disinfectant combination. Thirty polyester suture loops and 30 porcelain penicylinders were tested, for each spore type, disinfectant, and heat-treatment combination.

Spores from B. subtilis had an exposure time of 4 h when tested against CIDEX™, whereas spores from C. sporogenes had an exposure time of 1 h when tested against CIDEX™. Regardless of spore species, the exposure times for STERIPLEX™ HC and STERIPLEX™ Ultra were 25 min and 15 min, respectively. Exposure times were determined experimentally by previous testing (data not shown) to be at the end of the kill curve for each spore species-disinfectant combination.

A modified version of AOAC Official Method 966.04 was performed with the following alteration: the vials were heat-shocked at 80°C for 20 min immediately following transfer to the second tube of STB instead of incubating for 21 days before being heat-shocked (Fig.1). It is important to note that the vials were not heat-shocked a second time after 21 days. Thirty polyester suture loops and 30 porcelain penicylinders were tested, as described above, for each spore species-disinfectant combination.

Statistical methods

Suspension tests

Suspension tests were used to obtain the inactivation kinetics for the three disinfectants against spores from B. anthracis, B. subtilis, and C. sporogenes, with and without heat-shocking. On each test day, a different combination of spore species and disinfectant was selected at random until each combination was repeated three times. Each dilution assayed for viable spores was plated in triplicate and these counts were averaged to obtain an estimate for each dilution.

A generalized linear-mixed model (GLMM) was fitted to the viable spore count data for each of the three spore species using the GLIMMIX procedure of the SAS® software (SAS Institute Inc, Cary, NC). The GLMMs were specified with the Poisson distribution as the basic distribution, the logarithm as the link function, and the dilution factor of each count as an offset. For each spore species, the logarithm of the expected bacterial count was modeled as a linear or quadratic function of time, with distinct polynomial coefficients for all combinations of disinfectants and heat-shock treatments. For each of the heat-shock treatments, a common intercept was specified for all disinfectants. Samples and triplicate determinations within samples were modeled as random effects in the GLMMs.

Estimated parameters of the GLMMs were combined to estimate 6-log10 reduction times along with their standard errors and covariances for each spore species, disinfectant, and heat-shock combination. Six-log10 reduction times were compared statistically among spore species, disinfectants, and heat-shock treatments using the delta method.

Carrier tests

The number of positive tests after delayed heat-shock was compared to the number of positive tests after immediate heat-shock using the FREQ procedure of the SAS® software. For this data, Fisher's exact test was used.

Results and Discussion

Suspension tests

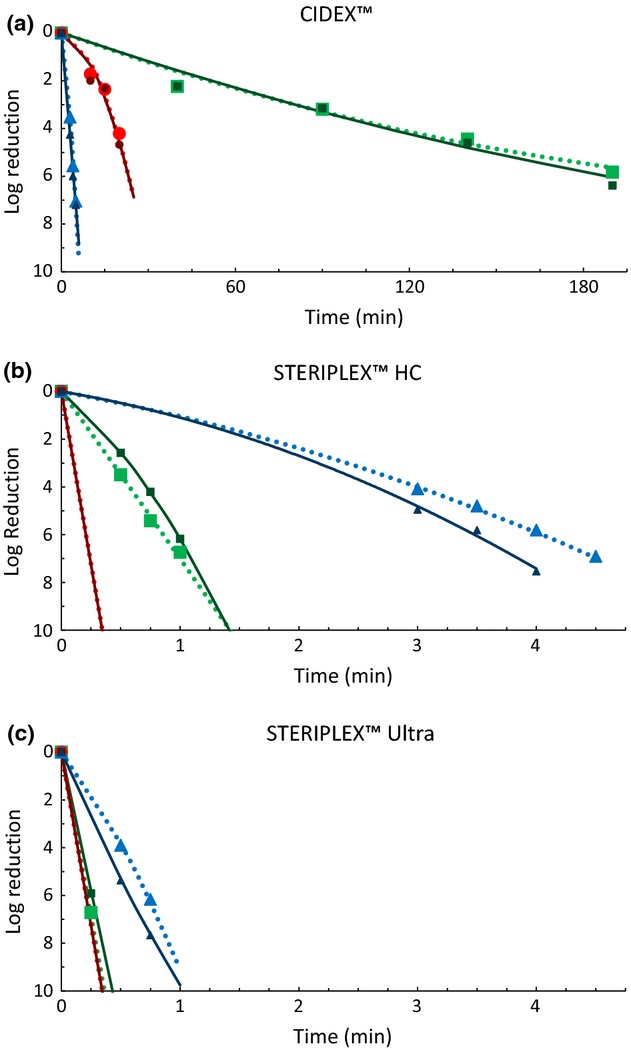

The first objective of this study was to investigate the effects of heat-shocking (as described in AOAC Official Method 966.04) on the viability of spores from B. anthracis, B. subtilis, and C. sporogenes in suspension after treatment with CIDEX™, STERIPLEX™ HC, and STERIPLEX™ Ultra. This was accomplished in part by comparing the inactivation kinetics for the disinfectants against each of the three spore species, with and without heat-shocking (Fig.2A–C). Additionally, generalized linear-mixed models were used to estimate 6-log10 reduction times for each spore type, disinfectant, and heat treatment combination. The 6-log10 reduction times and the approximate standard errors for each of the combinations are shown in Table3. A comparison of 6-log10 reduction times from each spore species, with and without heat-shocking, within each disinfectant is shown in Figure3A–C.

Figure 2.

The inactivation kinetics of spores from Bacillus anthracis ( and

and  ), Bacillus subtilis (

), Bacillus subtilis ( and

and  ), and Clostridium sporogenes (

), and Clostridium sporogenes ( and

and  ) upon treatment with CIDEX™, STERIPLEX™ HC, and STERIPLEX™ Ultra. The bright shapes and dotted lines (

) upon treatment with CIDEX™, STERIPLEX™ HC, and STERIPLEX™ Ultra. The bright shapes and dotted lines ( ) represent the observed values and fitted curves for spores not heat-shocked. The dark shapes and solid lines (

) represent the observed values and fitted curves for spores not heat-shocked. The dark shapes and solid lines ( ) represent the observed values and fitted curves for heat-shocked spores.

) represent the observed values and fitted curves for heat-shocked spores.

Table 3.

Estimated 6-log10 reduction times and approximate standard errors for spores from Bacillus subtilis, Bacillus anthracis, and Clostridium sporogenes using the three different disinfectants

| Species | Disinfectant | Heat-shock | 6 log10 reduction time (min) | |

|---|---|---|---|---|

| Estimate | SE | |||

| Bacillus anthracis | CIDEX™ | − | 4.37 | 0.16 |

| + | 4.14 | 0.19 | ||

| STERIPLEX™ HC | − | 4.04 | 0.18 | |

| + | 3.50 | 0.14 | ||

| STERIPLEX™ Ultra | − | 0.72 | 0.04 | |

| + | 0.57 | 0.03 | ||

| Bacillus subtilis | CIDEX™ | − | 214.04 | 51.65 |

| + | 187.57 | 24.32 | ||

| STERIPLEX™ HC | − | 0.86 | 0.06 | |

| + | 0.98 | 0.07 | ||

| STERIPLEX™ Ultra | − | 0.22 | 0.01 | |

| + | 0.26 | 0.01 | ||

| Clostridium sporogenes | CIDEX™ | − | 23.22 | 1.40 |

| + | 23.20 | 1.43 | ||

| STERIPLEX™ HC | − | 0.21 | 0.01 | |

| + | 0.21 | 0.01 | ||

| STERIPLEX™ Ultra | − | 0.21 | 0.01 | |

| + | 0.21 | 0.01 | ||

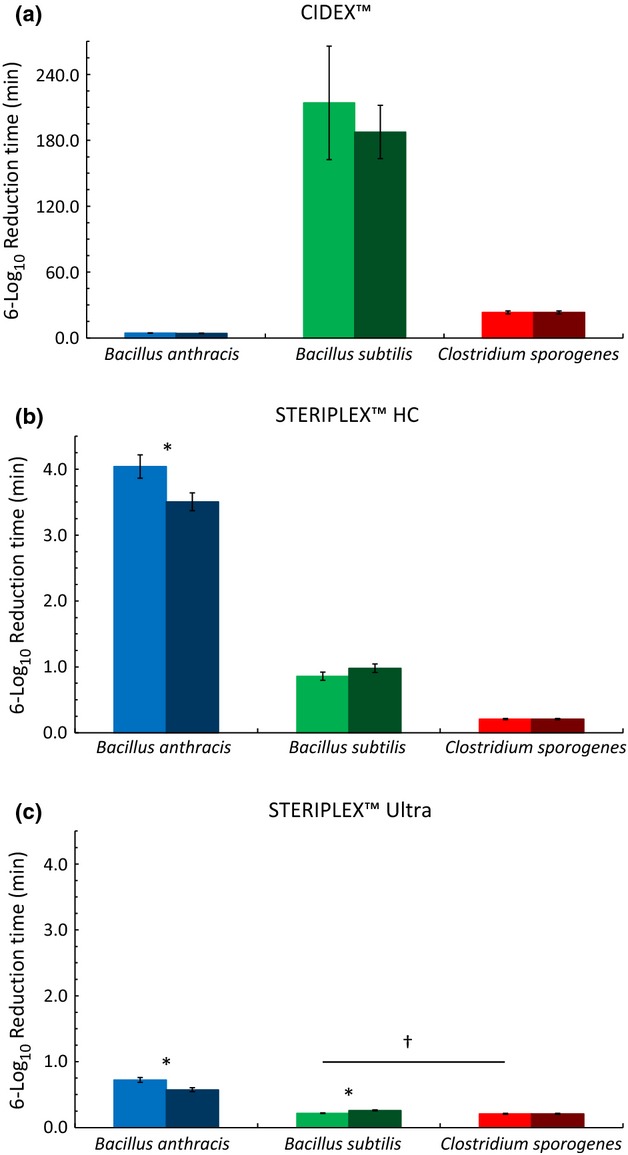

Figure 3.

The estimated 6-log10 reduction times for spores from Bacillus anthracis ( and

and  ), Bacillus subtilis (

), Bacillus subtilis ( and

and  ), and Clostridium sporogenes (

), and Clostridium sporogenes ( and

and  ) after treatment with CIDEX™, STERIPLEX™ HC, and STERIPLEX™ Ultra. The bright bars represent spores that were not heat-shocked, whereas the dark bars represent spores that were heat-shocked. Significant differences between heat treatments, but within the same spore species are denoted by (*). Differences across spore species that are not significant are denoted by (†).

) after treatment with CIDEX™, STERIPLEX™ HC, and STERIPLEX™ Ultra. The bright bars represent spores that were not heat-shocked, whereas the dark bars represent spores that were heat-shocked. Significant differences between heat treatments, but within the same spore species are denoted by (*). Differences across spore species that are not significant are denoted by (†).

All three spore species, regardless of heat treatment, differed significantly from each other in 6-log10 reduction times when exposed to CIDEX™ (Fig.3A). Additionally, heat-shocking the spore suspensions after treatment with CIDEX™ did not result in a significant change in any of the 6-log10 reduction times (Fig.3A). Upon exposure to CIDEX™, spores from B. anthracis had the shortest 6-log10 reduction times, whereas spores from B. subtilis had the longest (Fig.2A and Table3). In fact, spores from B. subtilis were approximately 50 times more resistant to CIDEX™ than were the spores from B. anthracis (Table3). Spores from C. sporogenes had 6-log10 reduction times that were significantly different from the other two species, but were more similar to B. anthracis than B. subtilis (Fig.2A and Table3). Spores from C. sporogenes were about five times more resistant to CIDEX™ than the spores from B. anthracis (Table3).

Upon exposure to STERIPLEX™ HC, all three spore species, regardless of heat treatment, once again displayed significantly different 6-log10 reduction times from each other (Fig.3B). Heat-shocking the spore suspensions after treatment with STERIPLEX™ HC did not result in a significant change in the 6-log10 reduction times for spores from B. subtilis and C. sporogenes (Fig.3B). However, heat-shocking spores from B. anthracis after disinfectant treatment caused a significant decrease in the 6-log10 reduction times (Fig.3B). When tested against STERIPLEX™ HC, C. sporogenes spores had the shortest 6-log10 reduction times, whereas spores from B. anthracis had the longest reduction times (Fig.2B and Table3). In this case, spores from B. anthracis were approximately 20 times more resistant to STERIPLEX™ HC than were the spores from C. sporogenes (Table3). Spores from B. subtilis had 6-log10 reduction times that were significantly different from the other two species, but were more similar to those of C. sporogenes than those of B. anthracis (Fig.2B and Table3); spores from B. anthracis were roughly four times more resistant to STERIPLEX™ HC than were the spores from B. subtilis (Table3). It is also important to note that the reduction times for spores from B. anthracis, in the absence of heat-shocking, were not significantly different when comparing STERIPLEX™ HC to CIDEX™.

Upon exposure to STERIPLEX™ Ultra, spores from B. subtilis and C. sporogenes did not differ significantly in their 6-log10 reduction times prior to being heat-shocked (Fig.3C). After heat treatment, spores from C. sporogenes had significantly shorter reduction times than those from B. subtilis (Fig.3C). This was not due to a change in the reduction times of spores from C. sporogenes; rather heat-shocking caused a significant increase in the reduction times of spores from B. subtilis (Fig.3C). In either situation, with heat-shock or without heat-shock, spores from B. subtilis and C. sporogenes had significantly shorter reduction times than those from B. anthracis (Fig.3C). Although spores from B. anthracis had the longest reduction times for either heat condition, they once again showed a significant decrease in 6-log10 reduction times after being heat-shocked (Fig.3C). Also, the reduction times for spores from C. sporogenes, regardless of heat treatment, were not significantly different when comparing STERIPLEX™ HC to STERIPLEX™ Ultra.

In general, STERIPLEX™ HC and STERIPLEX™ Ultra displayed extremely rapid sporicidal activity (Fig.2A–C). STERIPLEX™ Ultra had the most rapid sporicidal activity across all spore species (Fig.2A–C and Table3), resulting in a 6-log10 reduction in as little as 15–45 sec (Fig.3C and Table3). CIDEX™ had comparable activity to STERIPLEX™ HC on spores from B. anthracis; however, it was generally much slower than the two peracetic acid-based disinfectants on the other spore species.

These results also showed important differences between the three spore species with respect to sporicide resistance. Spores from B. subtilis proved to be less resistant than those from B. anthracis to STERIPLEX™ HC and STERIPLEX™ Ultra. Greater exposure times (up to 3.5 times greater) were required for B. anthracis, to achieve the level of kill seen in B. subtilis (Figs.2B–C and 3B–C). However, the opposite is true of CIDEX™. In this case, B. subtilis spores were significantly more resistant than those from B. anthracis, requiring a 186 min longer exposure time to achieve a similar inactivation (Figs.2A and 3A).

C. sporogenes spores proved to be extremely susceptible to STERIPLEX™ HC and STERIPLEX™ Ultra, but less so to CIDEX™. A complete kill, or a >6-log10 reduction was always observed within 15 sec with the two peracetic acid-based disinfectants, whereas a 6-log reduction took approximately 23 min with CIDEX™. It is not surprising that spores from C. sporogenes, an anaerobic bacterium, are more susceptible to oxidative damage than those from aerobic bacteria such as B. subtilis and B. anthracis.

This study also provided important information regarding the effects of heat-shocking after disinfectant treatment on spore recovery. For example, heat-shocking did not significantly increase the 6-log10 reduction times of any of the spore species following exposure to CIDEX™, which suggests that heat does little to overcome or augment the damage mediated by glutaraldehyde. On the other hand, when B. subtilis spores were heat-shocked immediately following exposure to STERIPLEX™ Ultra, a significant level of spore resuscitation was observed. This result indicates that while peracetic acid causes rapid injury to bacterial spores, heat-shocking can aid in their recovery. Interestingly, the resuscitation observed when B. subtilis spores were heat-shocked after exposure to STERIPLEX™ Ultra was not observed in B. anthracis (Fig.3). In fact, after treatment with STERIPLEX™ HC or STERIPLEX™ Ultra, heat-shocking B. anthracis spores resulted in a significant decrease in spore recovery.

Taken together, these data indicate that spore species differ widely in their susceptibility to disinfectants and their response to heat-shocking following disinfectant treatment. These data showed a significant spore species-disinfectant-heat-shock interaction. Because these interactions are complex and unpredictable, tests with and without heat-shocking should be performed when evaluating the sporicidal properties of a disinfectant.

The differences in spore resistance and recovery may be influenced by many factors including, but not limited to, the presence or absence of additional genes on plasmids, chromosomal-based genetic differences between species, and by interactions between gene products of the plasmids and the chromosome. Further research is needed to more specifically determine the reasons for the highly significant species-disinfectant-heat-shock interactions seen in this study. Testing with a larger number of isolates and a wider range of disinfectants may help define the significant variables involved. In a clinical setting, it would be advisable to increase the disinfectant exposure times past the end-points tested here, to ensure complete kill. For disinfection of B. anthracis, however, these peracetic acid-based disinfectants are as effective as the glutaraldehyde-based disinfectant, and, in the case of STERIPLEX™ Ultra, much more so. In addition, the use of data from surrogate organisms to model inactivation kinetics of virulent B. anthracis strains may be misleading, and caution should be used when extrapolating sporicidal results from one spore species to another, depending on the disinfectant used.

Carrier tests

The second aim of this study was to evaluate the benefits of the 3-week incubation period prior to heat-shocking that is prescribed by AOAC Official Method 966.04. This was done according to AOAC Official Method 966.04 and a modified version that employed immediate heat-shocking after disinfectant treatment. Spores from B. anthracis were not used in these experiments because this organism is not specified for use in the AOAC Official Method 966.04. The results from the carrier tests are shown in Table4. In AOAC Official Method 966.04, results are based on a combined total of carriers (porcelain penicylinders and suture loops) that yielded growth; the results in Table4 are reported similarly.

Table 4.

Effect of immediate versus delayed heat-shock on the resuscitation of disinfectant-treated spores dried onto carriers

| Species | Disinfectant | Exposure time | Delayed heat-shock | Immediate heat-shock | P 1 |

|---|---|---|---|---|---|

| Bacillus subtilis | CIDEX™ | 4 h | 3/60 | 5/60 | 0.3585 |

| Clostridium sporogenes | CIDEX™ | 1 h | 3/60 | 4/60 | 0.5 |

| Bacillus subtilis | STERIPLEX™ HC | 25 min | 3/60 | 9/60 | 0.0627 |

| Clostridium sporogenes | STERIPLEX™ HC | 25 min | 1/60 | 1/60 | 0.7521 |

| Bacillus subtilis | STERIPLEX™ Ultra | 15 min | 2/60 | 7/60 | 0.0815 |

| Clostridium sporogenes | STERIPLEX™ Ultra | 15 min | 2/60 | 4/60 | 0.3397 |

Fischer's exact test used for this data.

For CIDEX™, a total of three B. subtilis carriers were positive when the test was performed according to the AOAC Official Method 966.04 (heat-shock after 3 weeks of incubation). However, five positive tests were observed when carriers were immediately heat-shocked, a 1.67-fold increase (P = 0.3585). Three C. sporogenes carriers were positive under AOAC guidelines, with four positives produced when carriers were immediately heat-shocked, a 1.33-fold increase (P = 0.5000).

For STERIPLEX™ HC, a total of three B. subtilis carriers were positive when the test was performed according to the AOAC Official Method 966.04. However, the group subjected to immediate heat-shock had nine positive carriers, a threefold increase (P = 0.0627). For C. sporogenes, only one carrier was positive in each group (P = 0.7521).

For STERIPLEX™ Ultra, two B. subtilis carriers were positive when the test was performed according to the AOAC Official Method 966.04, as opposed to seven after immediate heat-shock, a 3.5-fold increase (P = 0.0815). Two C. sporogenes carriers were positive under AOAC guidelines, and four were positive when subjected to immediate heat-shock, a twofold difference (P = 0.3397).

Taken together, these results indicate that, when testing STERIPLEX™ HC, STERIPLEX™ Ultra, and perhaps other peracetic acid-based disinfectants with B. subtilis, immediate heat-shock after disinfection may be a better indicator of the effectiveness of the sporicidal activity of a disinfectant than the current AOAC guidelines. In 2003, the Environmental Protection Agency initiated research to improve efficacy test methods for sporicides (Tomasino 2005). Since then, the AOAC Official Method 966.04 has been reevaluated several times (McDonnell and Russell 1999; Miner et al. 2001, 2004; Tomasino 2005; Tomasino and Hamilton 2006; Tomasino and Samalot-Freire 2007), but none of these evaluations addressed the effect of an immediate heat-shock. The findings of this study may warrant further evaluation of the AOAC Official Method 966.04, with regards to this parameter.

Acknowledgments

The authors thank Advanced Sterilization Products (Irvine, CA) for supplying the CIDEX™ and SBIOMED LLC (Orem, UT) for supplying the STERIPLEX™ HC and STERIPLEX™ Ultra.

Conflict of Interest

None declared.

References

- Angelillo IF, Bianco A, Nobile CG. Pavia M. Evaluation of the efficacy of glutaraldehyde and peroxygen for disinfection of dental instruments. Lett. Appl. Microbiol. 1998;27:292–296. [PubMed] [Google Scholar]

- Baldry MG. The bactericidal, fungicidal and sporicidal properties of hydrogen peroxide and peracetic acid. J. Appl. Bacteriol. 1983;54:417–423. doi: 10.1111/j.1365-2672.1983.tb02637.x. [DOI] [PubMed] [Google Scholar]

- Clapp PA, Davies MJ, French MS. Gilbert BC. The bactericidal action of peroxides; an E.P.R. spin-trapping study. Free Radic. Res. 1994;21:147–167. doi: 10.3109/10715769409056566. [DOI] [PubMed] [Google Scholar]

- Coates D. Sporicidal activity of sodium dichloroisocyanurate, peroxygen and glutaraldehyde disinfectants against Bacillus subtilis. J. Hosp. Infect. 1996;32:283–294. doi: 10.1016/s0195-6701(96)90039-0. [DOI] [PubMed] [Google Scholar]

- Dancer BN, Power EG. Russell AD. Alkali-induced revival of Bacillus spores after inactivation by glutaraldehyde. FEMS Microbiol. Lett. 1989;48:345–348. doi: 10.1016/0378-1097(89)90326-1. [DOI] [PubMed] [Google Scholar]

- Gorman SP, Hutchinson EP, Scott EM. McDermott LM. Death, injury and revival of chemically treated Bacillus subtilis spores. J. Appl. Bacteriol. 1983;54:91–99. doi: 10.1111/j.1365-2672.1983.tb01305.x. [DOI] [PubMed] [Google Scholar]

- Hopwood D, Callen CR. McCabe M. The reactions between glutaraldehyde and various proteins. An investigation of their kinetics. Histochem. J. 1970;2:137–150. doi: 10.1007/BF01003541. [DOI] [PubMed] [Google Scholar]

- Hussaini SN. Ruby KR. Sporicidal activity of peracetic acid against B. anthracis spores. Vet. Rec. 1976;98:257–259. doi: 10.1136/vr.98.13.257. [DOI] [PubMed] [Google Scholar]

- Kline LB. Hull RN. The virucidal properties of peracetic acid. Am. J. Clin. Pathol. 1960;33:30–33. doi: 10.1093/ajcp/33.1.30. [DOI] [PubMed] [Google Scholar]

- Lane V, McKeever JD. Fallon M. Buffered glutaraldehyde (Cidex). A new disinfectant specially useful in urology. J. Ir. Med. Assoc. 1966;58:131–132. [PubMed] [Google Scholar]

- Leaper S. Synergistic killing of spores of Bacillus subtilis by peracetic acid and alcohol. Int. J. Food Sci. Tech. 1984;19:355–360. [Google Scholar]

- Leighton TJ. Doi RH. The stability of messenger ribonucleic acid during sporulation in Bacillus subtilis. J. Biol. Chem. 1971;246:3189–3195. [PubMed] [Google Scholar]

- Marquis RE, Rutherford GC, Faraci MM. Shin SY. Sporicidal action of peracetic acid and protective effects of transition metal ions. J. Ind. Microbiol. 1995;15:486–492. doi: 10.1007/BF01570019. [DOI] [PubMed] [Google Scholar]

- McDonnell G. Alternative AOAC sporicidal test carrier for evaluating peracetic acid-based sterilants (modification of AOAC official method 966.04) J. AOAC Int. 2003;86:407–411. [PubMed] [Google Scholar]

- McDonnell G. Russell AD. Antiseptics and disinfectants: activity, action, and resistance. Clin. Microbiol. Rev. 1999;12:147–179. doi: 10.1128/cmr.12.1.147. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Miner NA, Taylor MA, Bernal SE, Harris VL. Sichinga MJ. Culture age and drying time as variables of the AOAC Sporicidal Test. J. AOAC Int. 2001;84:1159–1163. [PubMed] [Google Scholar]

- Miner N, Harris V, Stumph S, Cobb A. Ortiz J. Studies of polyester fiber as carrier for microbes in a quantitative test method for disinfectants. J. AOAC Int. 2004;87:429–434. [PubMed] [Google Scholar]

- Official Methods of Analysis. AOAC International. 21st ed. Gaithersburg, MD: Official Method 966.04; 2006. [Google Scholar]

- Power EG. Russell AD. Glutaraldehyde: its uptake by sporing and non-sporing bacteria, rubber, plastic and an endoscope. J. Appl. Bacteriol. 1989;67:329–342. doi: 10.1111/j.1365-2672.1989.tb02502.x. [DOI] [PubMed] [Google Scholar]

- Power EG. Russell AD. Sporicidal action of alkaline glutaraldehyde: factors influencing activity and a comparison with other aldehydes. J. Appl. Bacteriol. 1990;69:261–268. doi: 10.1111/j.1365-2672.1990.tb01517.x. [DOI] [PubMed] [Google Scholar]

- Power EG, Dancer BN. Russell AD. Possible mechanisms for the revival of glutaraldehyde-treated spores of Bacillus subtilis NCTC 8236. J. Appl. Bacteriol. 1989;67:91–98. doi: 10.1111/j.1365-2672.1989.tb04959.x. [DOI] [PubMed] [Google Scholar]

- Russell AD. Bacterial spores and chemical sporicidal agents. Clin. Microbiol. Rev. 1990;3:99–119. doi: 10.1128/cmr.3.2.99. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rutala WA. Weber DJ. Disinfection and sterilization in health care facilities: what clinicians need to know. Clin. Infect. Dis. 2004;39:702–709. doi: 10.1086/423182. [DOI] [PubMed] [Google Scholar]

- Rutala WA, Gergen MF. Weber DJ. Comparative evaluation of the sporicidal activity of new low-temperature sterilization technologies: ethylene oxide, 2 plasma sterilization systems, and liquid peracetic acid. Am. J. Infect. Control. 1998;26:393–398. doi: 10.1016/s0196-6553(98)70034-3. [DOI] [PubMed] [Google Scholar]

- Setlow B, Loshon CA, Genest PC, Cowan AE, Setlow C. Setlow P. Mechanisms of killing spores of Bacillus subtilis by acid, alkali and ethanol. J. Appl. Microbiol. 2002;92:362–375. doi: 10.1046/j.1365-2672.2002.01540.x. [DOI] [PubMed] [Google Scholar]

- Spicher G. Peters J. Microbial resistance to formaldehyde. I. Comparative quantitative studies in some selected species of vegetative bacteria, bacterial spores, fungi, bacteriophages and viruses. Zentralbl. Bakteriol. Orig. B. 1976;163:486–508. [PubMed] [Google Scholar]

- Spicher G. Peters J. Heat activation of bacterial spores after inactivation by formaldehyde. Dependence of heat activation on temperature and duration of action (author's transl)] Zentralbl. Bakteriol. Mikrobiol. Hyg. B. 1981;173:188–196. [PubMed] [Google Scholar]

- Spotts Whitney EA, Beatty ME, Taylor TH, Jr, Weyant R, Sobel J, Arduino MJ, et al. Inactivation of Bacillus anthracis spores. Emerg. Infect. Dis. 2003;9:623–627. doi: 10.3201/eid0906.020377. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Tennen R, Setlow B, Davis KL, Loshon CA. Setlow P. Mechanisms of killing of spores of Bacillus subtilis by iodine, glutaraldehyde and nitrous acid. J. Appl. Microbiol. 2000;89:330–338. doi: 10.1046/j.1365-2672.2000.01114.x. [DOI] [PubMed] [Google Scholar]

- Tomasino SF. Efficacy testing of disinfectants. J. AOAC Int. 2005;88:355–358. [PubMed] [Google Scholar]

- Tomasino SF. Hamilton MA. Modification to the AOAC sporicidal activity of disinfectants test (method 966.04): collaborative study. J. AOAC Int. 2006;89:1373–1397. [PubMed] [Google Scholar]

- Tomasino SF. Samalot-Freire LC. AOAC method 966.04: preliminary evaluation of cooked meat medium with manganese sulfate for the cultivation of Clostridium sporogenes: precollaborative study. J. AOAC Int. 2007;90:825–833. [PubMed] [Google Scholar]

- Williams ND. Russell AD. Revival of biocide-treated spores of Bacillus subtilis. J. Appl. Bacteriol. 1993;75:69–75. doi: 10.1111/j.1365-2672.1993.tb03410.x. [DOI] [PubMed] [Google Scholar]