Abstract

Background:

Muktā Bhasma (MB) is a traditional Ayurvedic preparation for cough, breathlessness, and eye disorders and is a powerful cardiac tonic, mood elevator, and known to promote strength, intellect, and semen production.

Objectives:

The present research work was conducted to generate fingerprint for raw and processed MB for quality assessment and standardization using classical and other techniques.

Setting and Design:

Three samples of MB were prepared by purification (śodhana) of Muktā (pearl) followed by repeated calcinations (Māraṇa). Resultant product was subjected to organoleptic tests and Ayurvedic tests for quality control such as rekhāpūrṇatā, vāritaratva, and nirdhūmatva.

Materials and Methods:

For quality control, physicochemical parameters such as loss on drying, total ash value, acid insoluble ash, specific gravity, pH value, and other tests using techniques such as elemental analysis with energy dispersive X-ray analysis (EDAX), Structural study with powder X-ray diffraction, particle size with scanning electron microscopy (SEM) were carried out on raw Muktā, Śodhita Muktā, and triplicate batches of MB.

Results:

The study showed that the raw material Muktā was calcium carbonate in aragonite form, which on repeated calcinations was converted into a more stable calcite form. SEM studies revealed that in raw and purified materials the particles were found scattered and unevenly arranged in the range of 718.7–214.7 nm while in final product, uniformly arranged, stable, rod-shaped, and rounded particles with more agglomerates were observed in the range of 279.2–79.93 nm. EDAX analysis revealed calcium as a major ingredient in MB (average 46.32%) which increased gradually in the stages of processing (raw 34.11%, Śodhita 37.5%).

Conclusion:

Quality control parameters have been quantified for fingerprinting of MB prepared using a particular method.

KEYWORDS: Energy dispersive X-ray analysis, Muktā Bhasma, Quality, scanning electron microscopy, X-ray diffraction

INTRODUCTION

Ancient health systems have long used metals, minerals etc., as sources for their medicinal formulas. However, with changing times, they require greater scientific validation with reference to their safety, pharmacokinetics, etc. With this evolved a requirement for further studies with respect to the determination of the minute structures of these complex compounds. Structure of any material may be examined at many levels. Macroscopic and microscopic findings are convenient ways to determine the structure. However, the examination need not stop there. The crystalline structure, elements present, elemental groups, as well as molecular structure, is ultimately essential to truly understand these ancient formulas. With reports of concerns regarding the safety of traditional medicines[1] surfacing in literature from all parts of the world, it is imperative for the practitioners of indigenous systems of medicine including Ayurveda to update themselves about the latest methods and techniques of structural analysis and use them as tools to validate efficacy and safety.

In Ayurveda, the variation in the collection process, timing and procedure of making Bhasma may yield same Bhasma with different qualities. In many cases, wrong manufacturing process may lead to production of inferior-quality products, which reduces efficacy and safety. In order to minimize variability and to strengthen the quality of Ayurvedic products, standardization of a Bhasma is essential.[2,3]

Muktā Bhasma (MB) is a calcium-rich Ayurvedic preparation which is in use since long and is claimed to be effective in very small doses. It chiefly alleviates the diseases caused by vitiated Pitta and Kapha and is widely used in treatment of various diseases such as śvāsa (dyspnoea), kāsa (cough), kṣaya (Phithesis), netraroga (eye disorders),[4] asthiśoṣa (bone disorders),[5] etc. It is a well-known drug to promote strength, intellect, and enhances semen production. It is also a powerful cardiac tonic, antitoxic, and mood elevator.[6] Being mild in nature it is predominantly used in pregnant females, aged persons, and others who cannot tolerate strong medicines. Recent studies have scientifically validated its role in calcium absorption,[7,8] antiulcer activity,[9] and even in enhancing the effectiveness of antibiotics.[10] Although several scientific studies have been carried out to answer structural analysis of other calcium containing Ayurvedic Bhasmas there have not been studies on MB. It is thus essential to prepare quality control parameters of this product. In the present research work, Muktā has been analyzed with a focus on preparing a standard operating procedure (SOP) required for Bhasmīkaraṇa (process of calcination) and also to set up quality control parameters both based Ayurvedic and modern parameters.

Aims and objectives

The present study is planned with the following aims and objectives:

To establish SOP for preparation of MB

To analyze Muktā Bhasma by adopting Ayurvedic and advanced analytical techniques for quality assessment.

MATERIALS AND METHODS

Raw materials

Muktā the chief raw material used in this study was purchased from professional suppliers of Hyderabad and got authenticated by the subject experts. Cūrṇodaka used in purification (~śodhana) was prepared using lime powder purchased from a local chemical shop. For calcination, (~Māraṇa) gulāba arka was prepared using fresh flowers of roses (Rosa sinensis) procured from the local market. Māraṇa process of Muktā was done traditionally using cow-dung cakes procured from the local market.

Preparation of MB was done in accordance to Rasa Tarangini. Process of fomentation (svedana) was adoped for śodhana,[11,12] while levigation (Bhāvana) followed by calcination was used for the preparation of MB.[13]

Preparation of Muktā Bhasma

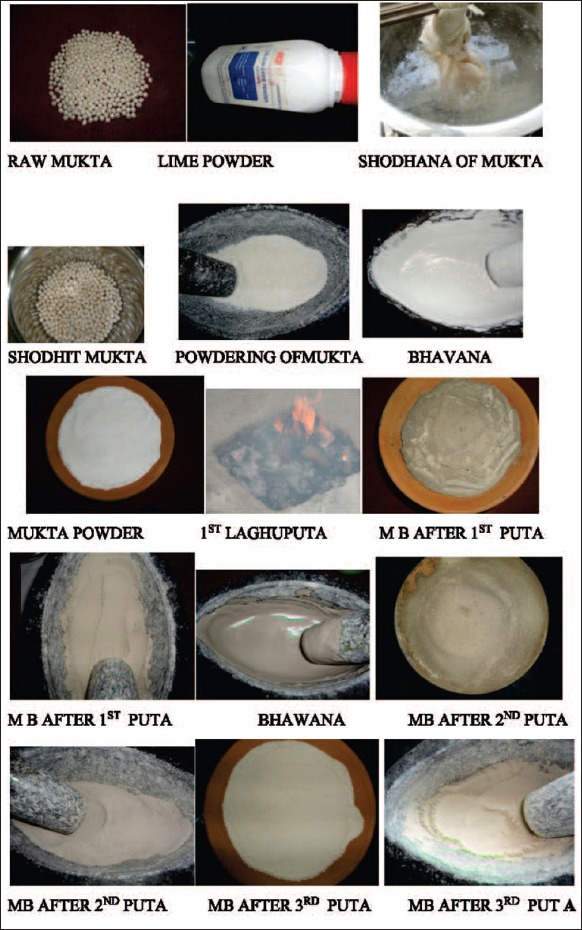

For the purpose of standardization, three different samples of MB were prepared in the Department of Rasashastra and B. Kalpana, Rishikul Government Ayurveda College, Haridwar, Uttarakhand, under similar condition. Preparation of MB includes following steps [Figure 1]. Three batches of MB viz., MB-1, MB-2, and MB-3 were prepared under similar environmental conditions for the purpose of standardization.

Figure 1.

Photograph showing raw material and pharmaceutical processing of Muktā Bhasma

Preparation of Cūrṇodaka

Lime powder (CaO) and potable water was mixed in the ratio of 1:240, kept aside undisturbed for 9 h. The supernatant layers of water were decanted and stored in a dark green colored bottle. The ratio used is as per Rasataraṅgiṇī,[11] which is used as a reference text in classical preparation of mineral based drugs.

Preparation of Gulāba arka

Roses were collected and cleaned. 6000 ml of water was added to 600 g rose for soaking and kept overnight. Next day it was mashed gently with hand, and it was kept in traditional distillation apparatus and heated on mild heat. In the beginning, the vapors consist of only steam and, therefore, were discarded. The process is completed in approximately 6 h and finally 2500 ml Gulāba arka is obtained.

Śodhana of Muktā

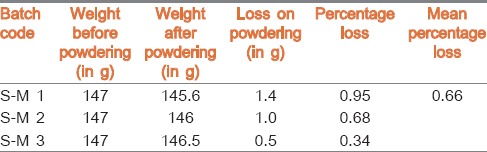

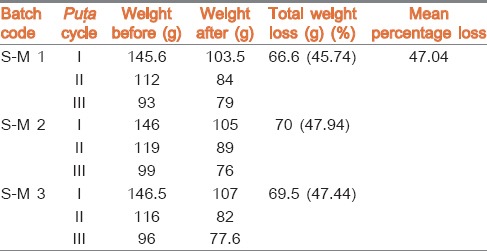

Raw Muktā was placed over a cloth and tied to make a poṭṭali. This poṭṭali was hung inside a stainless steel vessel with the help of a wooden stick. Cūrṇodaka was poured into the vessel till the poṭṭali got completely immersed. The vessel was put on low flame at 100°C continuously for 3 h. After completion of processing, the heating was stopped and the vessel was left for self-cooling.[12] The Poṭṭali was then opened and Muktā was washed with lukewarm water. It was then spread on a clean cloth and kept for drying. After drying, it was weighed, stored, and used for further procedure. All three batches namely RM-1, RM-2, and RM-3 were purified by the same process. There was no weight loss in all the three batches during purification [Table 1].

Table 1.

Results of powdering procedure of Śodhita Muktā

Māraṇa of Muktā

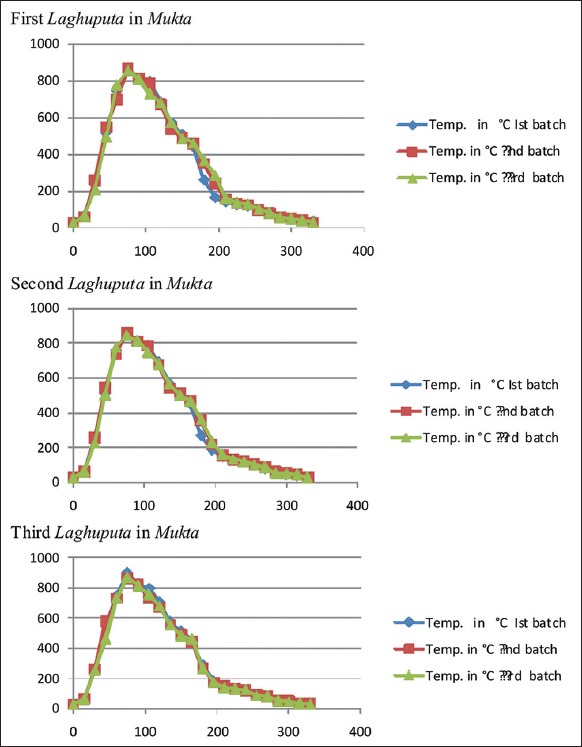

Muktā obtained after purification was made into fine powder and was passed through a sieve of 120 mesh size. Powdered Muktā was taken in a mortar and pestle and subjected to trituration with Gulāba arka. After complete drying of Śodhita Muktā powder, it was placed in an earthen pot (śarāva) and sealed forming a śarāvasaṃpuṭa, and subjected to first cycle of calcination (Laghupuṭa).[13] For this 2/3rd part of the pit (for Laghupuṭa) was filled with cow-dung cakes and śarāvasaṃpuṭa was placed over it. Thermocouple was placed vertically from the side of the pit at the junction of the upper 1/3rd of the pit near the śarāvasaṃpuṭa and previously ignited cow-dung cake were placed around the earthen pot. The remaining upper 1/3rd of the pit was filled with rest of the cow-dung cakes. During puṭapāka maximum temperature was in the range of 700–870°C [Figure 5]. After allowing it to cool on its own, the pot was opened and mārita Muktā powder was collected and again subjected for trituration with Gulāba arka. The trituration was done continuously till complete drying of powder and was subjected to second cycle of calcination (laghupuṭa). The process was repeated one more time until the sample showed positive traditional parameters of a Bhasma. All the three batches were prepared by the same method, and they were named as MB-1, MB-2, and MB-3. During Māraṇa, the mean percentage weight loss was 47.04% [Table 2].

Figure 5.

Temperature pattern of Muktā Bhasma

Table 2.

Variation in weight of Muktā during processing

Physicochemical evaluation

All the three samples of MB were analyzed by using different organoleptic parameters. Physicochemical tests were carried out as per Ayurvedic pharmacopeia[14] viz. Loss on drying, total ash value, acid insoluble ash, specific gravity, pH, and also by sophisticated techniques such as Elemental Analysis with Energy dispersive X-ray analysis (EDAX), structural study with powder X-ray diffraction (XRD), particle size with scanning electron microscopy (SEM) elemental analysis with EDAX,[15] was carried out in Carl Zeiss AG-Supra 40 WDS, manufactured by Zeiss Gemini, Carl Zeiss SMT, Oberkochen (Germany). For XRD,[16] Model–D8 Advance, manufactured by Bruker Corporation Pvt. Ltd., (Germany) was used. Surface analysis of particles was done using SEM. Classical tests such as rekhāpūrṇatā, vāritaratva, and nirdhūmatva[17] were also performed for quality check.

RESULTS AND DISCUSSION

Śodhana of Muktā was done with the help of dola yantra where heat is applied on the liquid. This procedure is used by modern pharmaceutics to prepare the solutions without stirring and by applying heat.[18] In śodhana process, there was no weight loss in Muktā, but its luster was reduced due to heat treatment as well as contact with the liquid media used [Table 1]. Traditional method for calcination (Māraṇa) adopted for MB was laghupuṭa which had a maximum temperature range up to 700-870°C[19] and was maintained for 30 min using 12 kg of cow dung cakes as fuel [Figure 5]. After each puṭa, there is a reduction in particle size, which leads to increased absorption. In Māraṇa process, the mean percentage loss was 47.04% [Table 2]. This loss might be due to evaporation of water, organic matter during the incineration process.

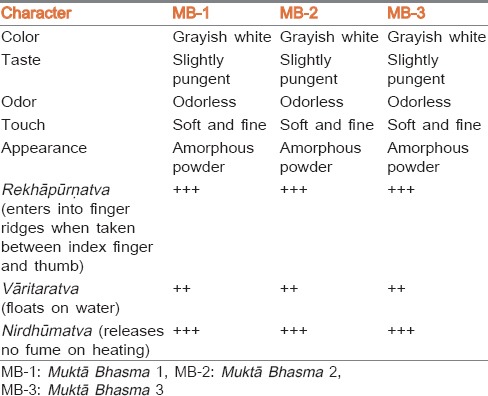

Organoleptical study

Organoleptically, MB was greyish white powder, soft and smooth on touch, tasteless, lusterless, odorless, and without any perceptible sound during chewing. Touch indicated smoothness, softness, and fineness of the Bhasma. Specific color and tastelessness indicates the formation of the particular inorganic compound. MB also complied of Ayurvedic parameters for quality control such as rekhāpūrṇatā, vāritaratva, and nirdhūmatva [Table 3].

Table 3.

Classical characteristics of MB

Physicochemical parameters

Physicochemical parameters of all three batches of MB showed identical value [Table 4]. On an average, % loss on drying value was found to be low that is, 0.60 which is indicative of the presence of a small amount of moisture content. Low % of ash value, that is, 1.64 indicates high percentage of calcium oxide and low percentage of calcium carbonate. Acid insoluble ash value shows insoluble inorganic content in MB (1.64). It may also predict the bioavailability of MB.

Table 4.

Physicochemical parameters of MB

The basic pH of MB is obvious due to the fact that all the batches were prepared using raw materials which decay to give calcium oxide at elevated temperature. This calcium oxide when dissolved in water produces calcium hydroxide. The variable amount of calcium oxide present in different Bhasmas yields the fluid of different concentrations and therefore, pH of all the solutions are different. pH also plays an important role in the solubility of the drugs. It has been found that the basic drugs are more soluble in solutions of low pH and they get precipitated if the pH is raised by the addition of an alkali.[18] pH meter was used to record pH. For this, 1% of each sample (1 g sample + 100 ml of distilled water) was prepared, then the tip of electrode was dipped and value was recorded. The average pH observed to be 12.04 in MB.

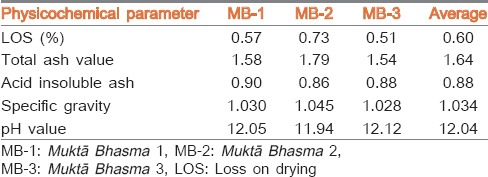

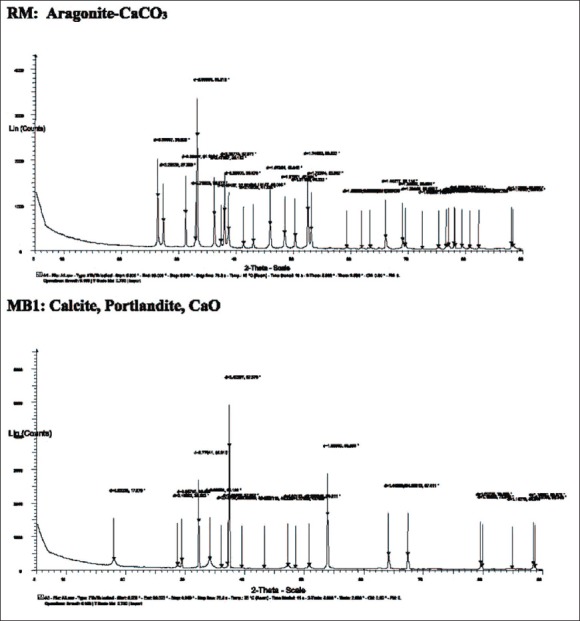

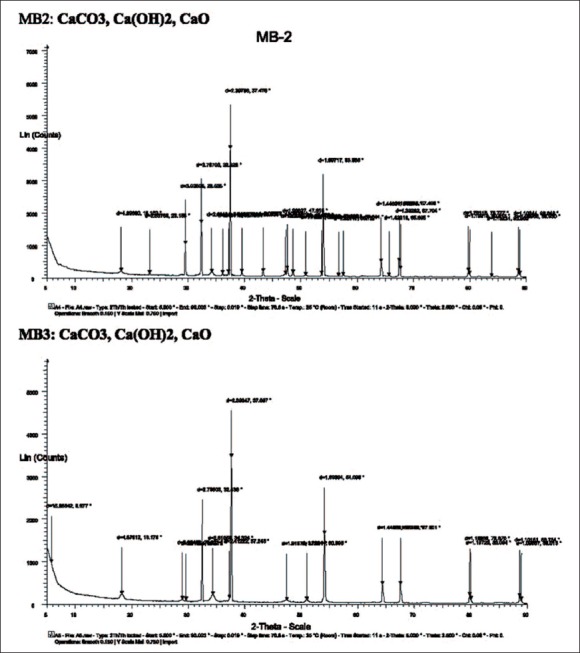

Crystalline phase identification of Muktā Bhasma by X-ray powder diffraction

The raw materials in the preparation of MB was powdered pearl showed characteristic peaks of Aragonite appearing at d = 2.86507 A° (2θ = 31.193), d = 2.72203 A° (2θ = 32.877), d = 2.69536 A° (2θ = 33.212), d = 2.47997 (2θ = 36.192) X-ray powder diffraction graph of pearl (RM) [Figure 2]. Identification of samples of MB was done by matching the d-spacing with the standard JCPDS database. All the three samples of MB showed peaks at [Figure 3].

Figure 2.

X-ray diffraction pattern of raw Muktā

Figure 3.

X-ray diffraction pattern of Muktā Bhasma

MB-1: D = 2.40397 A° (2θ = 37.378), d = 2.77641 A° (2θ = 32.215)

MB-2: D = 2.39786 A° (2θ = 37.476), d = 2.76703 A° (2θ = 32.328),

MB-3: D = 2.75803 A° (2θ = 32.436), d = 2.39047 A° (2θ = 37.597).

The diffraction pattern clearly indicates Calcite as the major crystalline phase present in MB. Peaks in the graph confirm the presence of calcite as the major crystalline phase in the samples. In the samples of MB, the lines of Aragonite disappeared and the product contains only the Calcite form of Calcium carbonate. Low intensity lines indicate the presence of Ca (OH)2 in Portlandite form. This may be attributed to the hydrolysis of calcium oxide formed due to partial decomposition of calcite during calcination cycles [Table 5].

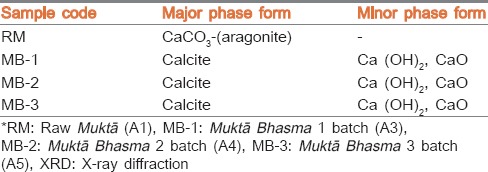

Table 5.

XRD analysis of MB

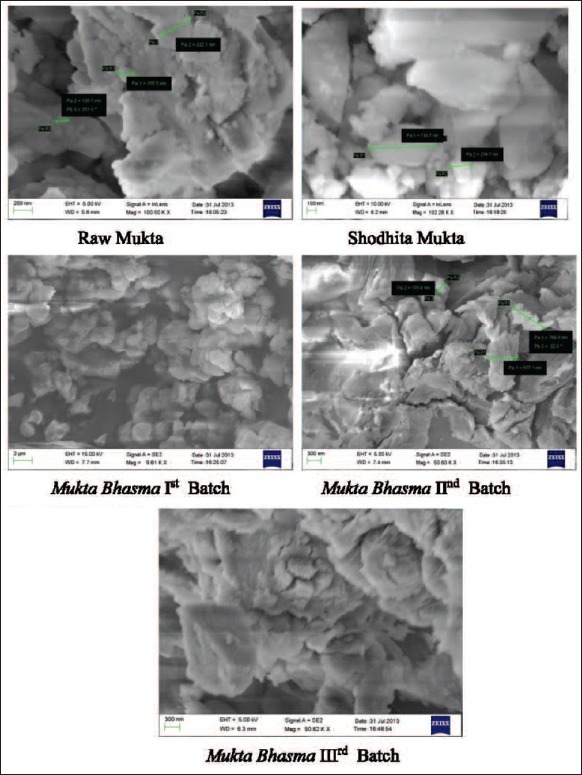

Particle size with scanning electron microscopy

Raw sample of Muktā, Śodhita Muktā, and MB at different cycles of puṭa were analyzed using SEM technique which revealed the information of external morphology, chemical composition, crystalline structure, and orientation of materials making up the sample.[20] The photomicrograph of bulk particles showed a wide distribution of size in the sample. We also observe that the particles were present in aggregated form. Shape and surface morphology was different. SEM photographs of raw and purified Muktā showed small and platy crystals of size 718.7–214.7 nm, respectively. On repeated calcinations, reduction in particle size was seen. Particles in all three batches of MB were found to be in the range of 279.2–79.93 nm. The particles in the raw and purified samples were not uniformly arranged, while in the final product the particles were uniformity arranged. In the final product, more agglomerates of particles were observed. Whereas, in the raw and purified materials, the particles were found to be scattered. Samples at different stages of calcinations showed even greater degree of agglomeration than those of standard calcite. After first puṭa, the particles were found to be more compact aggregates converted into a uniform, rod-shaped, and rounded particles after last Puṭa [Figure 4].

Figure 4.

Scanning electron microscopy images of Muktā Bhasma

Bhasma is almost nanocrystalline materials. Nanocrystalline materials are those solids a composed of crystallites with size <100 nm in at least one direction.[21] Morphology and distribution of particles in SEM photographs not only revealed a decrease in particle size to nano-level, but it also showed the stability of the product from beginning to the final stage. When the particles change from centimeter size to nanometer size, the surface area, and the surface energy increase seven orders of magnitude.[22] These nanoparticles are very easily absorbed through ion channels as they can diffuse readily inside the cells making them effective in absorption, thus avoiding the need for large doses.[23]

Hence, it is clear that particles become fine by extensive grinding and pounding in wet state with various herbs using mortar and pestle and by repeated puṭas applied during the Māraṇa process to increase the dissolution as well as the absorption of drug. Indeed, materials and devices of nanometric dimensions (1–100 nm) are already approved for clinical use and numerous products are being evaluated in clinical trials.[24] It is this significant reduction of size which is confirmed by rekhāpūrṇatva and vāritaratva, which facilitates absorption and assimilation of the Bhasma.[25]

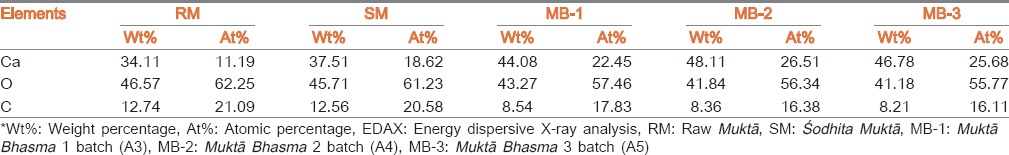

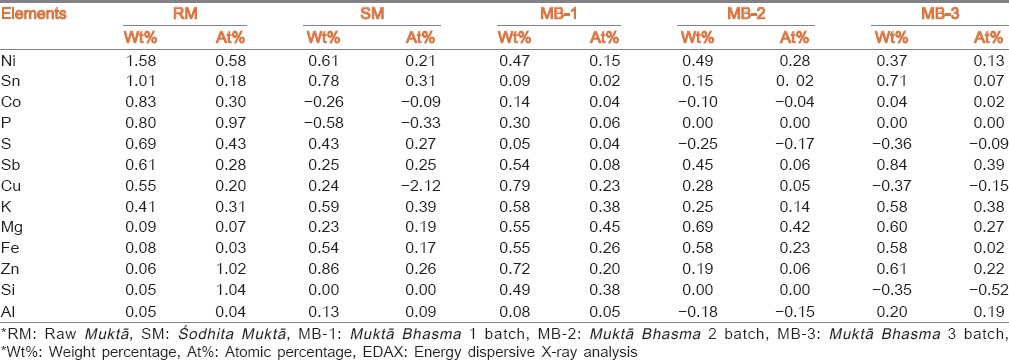

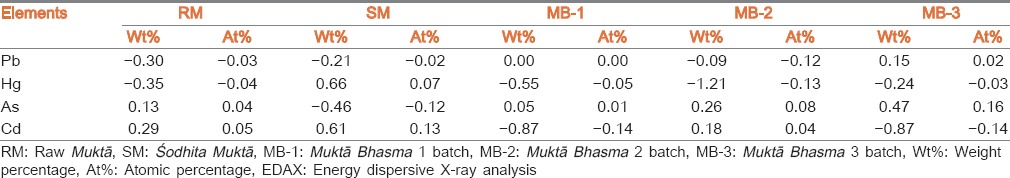

Chemical composition analysis by energy dispersive X-ray analysis

Quantitative determination and bulk elemental composition in the aliquot was carried out by EDAX, which was attached with field environmental scanning electron microscope. Raw sample of Muktā, Śodhita Muktā, and all the three samples of MB were analyzed. Composition of chief elements that is, Ca, O, C in different samples of Muktā detected by EDAX is shown in Table 6. EDAX analysis revealed Calcium to be the major element in all three batches of MB. The percentage of Calcium was greater in Bhasma than in raw and purified Muktā. In raw sample, it was 34.11% and was slightly increased to 37.51% in purified Muktā. Average Calcium percentage was increased up to 46.32% in MB. It might be due to loss of organic matter on repeated calcinations. The second highest element was oxygen that is, 42.09% in MB whose percentage also increased in the final product as compared to raw material. The percentage of Carbon element was decreased when compared to raw material.

Table 6.

Composition of Ca, O, C in different samples of Muktā detected by EDAX method

Elements analysis also showed the presence of several other essential micronutrient elements such as Mg, Al, K, Fe, Zn, etc., in the final product [Table 7] as trace elements. Trace elements serves many physiological role and are required in a small amounts but for very important functions.[26] This study proves that, these Bhasmas are also a good source of essential micronutrients. Among trace elements, MB was found to be good a source of Magnesium as detected by its percentage (0.61%) followed by Iron. Heavy metals such as As, Hg, Cd, Pd were detected below the permissible limits[27] [Table 8]. Hence, MB prepared by the method followed in the study is not only quite safe, but also a natural source that provides essential micronutrients on internal administration.

Table 7.

Trace elements in different samples of Muktā detected by EDAX method

Table 8.

Composition of heavy metals in different samples of MB detected by EDAX method

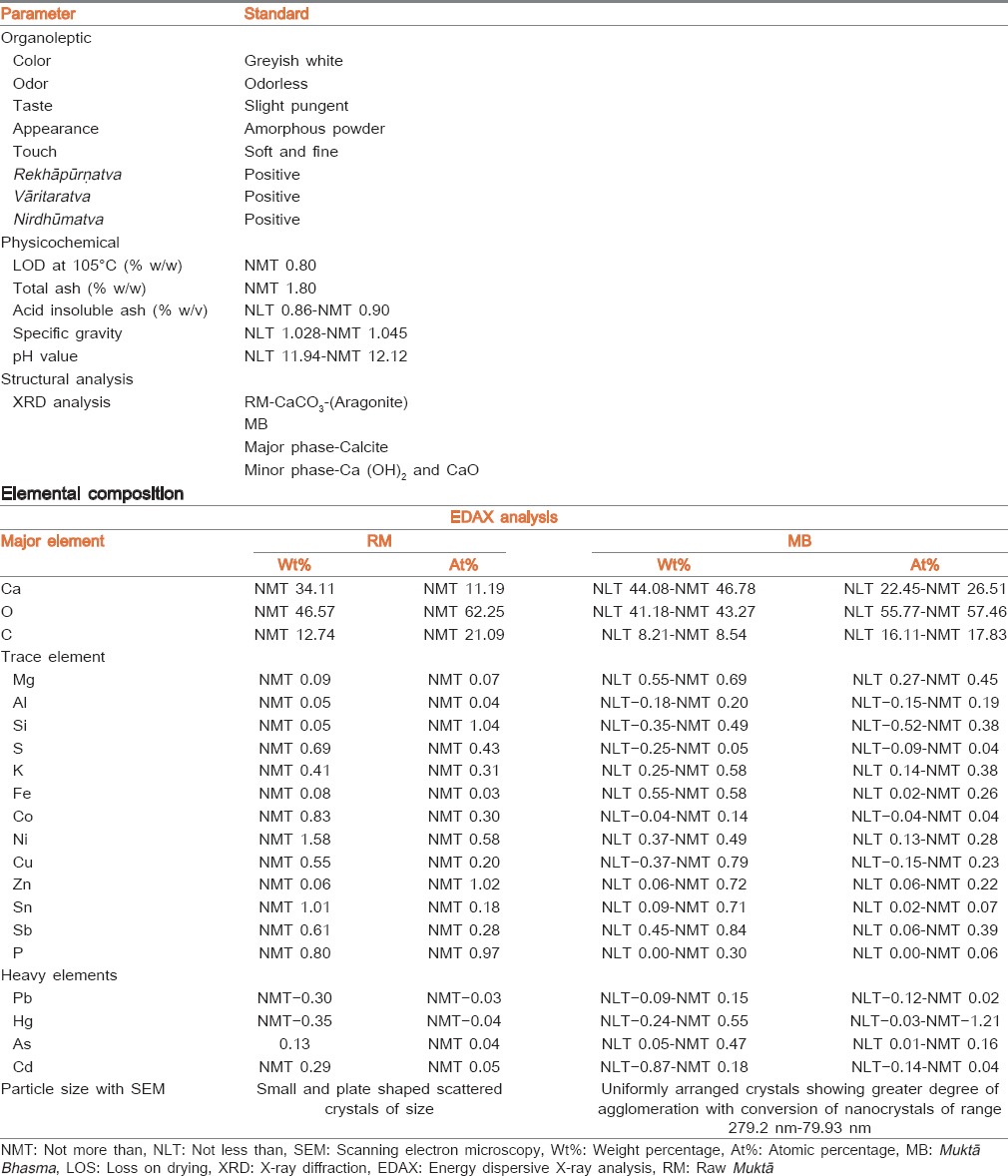

CONCLUSION

Raw Muktā is chemically calcium carbonate in aragonite form, which after Ayurvedic procedures of calcinations is converted into more stable form of calcite. SEM images clearly show reduced particle size of the Bhasma, which indicates absorption and assimilation of the drug into the body system at low doses. It can easily be concluded that Ayurvedic procedures of śodhana and Māraṇa, etc., are ancient techniques of nanoscience as the particles of final product MB comes under the range of 100 nm. Presence of essential micronutrients and permissible limits of heavy metals proves the compound to be safe as well as efficacious for internal administration. The observations in this study could be considered as fingerprints for quality control of MB based on both classical tests as well as modern sophisticated parameters. These parameters have been summarized in [Table 9].

Table 9.

QC specifications for MB

Financial support and sponsorship

Nil.

Conflict of interest

There are no conflicts of interest.

REFERENCES

- 1.Thatte UM, Rege NN, Phatak SD, Dahanukar SA. The flip side of Ayurveda. J Postgrad Med. 1993;39:179. [PubMed] [Google Scholar]

- 2.Tripathi YB. A multidisciplinary approach to standardize bhasmas (Ayurvedic metallic preparations) J Curr Sci. 2006;90:897–8. [Google Scholar]

- 3.Galib R, Kar AC, Narayana A. Standardization of bhasmas – Need of the hour. J Ayurveda. 2008;2:27–33. [Google Scholar]

- 4.Kulkarni SD, editor. Acharya Vagbhata, Rasa Ratna Samuchhaya, 4/14.15. New Delhi: ML Publication; 1998. p. 74. [Google Scholar]

- 5.Sharma S. Delhi: Motilal Banarasidas; 1970. Sadananda Sharma's Rasa Tarangini. 23/74; p. 614. [Google Scholar]

- 6.Kulkarni SD, editor. Acharya Vagbhat, Rasa Ratna Samuchhaya, 4/14-15. New Delhi: ML Publication; 1998. p. 74. [Google Scholar]

- 7.Chen HS, Chang JH, Wu JS. Calcium bioavailability of nanonized pearl powder for adults. J Food Sci. 2008;73:H246–51. doi: 10.1111/j.1750-3841.2008.00965.x. [DOI] [PubMed] [Google Scholar]

- 8.Gao H, Chen H, Chen W, Tao F, Zheng Y. Effect of nanometer pearl powder on calcium. Food Chem. 2013;140:1–370. [Google Scholar]

- 9.Dubey N, Mehta RS, Saluja AK, Jain DK. Antiulcer activity of a traditional pearl preparation: Mukta Bhasma. Res J Pharm Technol. 2009;2:287–90. [Google Scholar]

- 10.Kulkarni M, Deopujari JY, Purohit HJ. Synergistic effect of ayurvedic pearl preparation on enhancing effectiveness of antibiotics. Indian J Exp Biol. 2002;40:831–4. [PubMed] [Google Scholar]

- 11.Sharma S. Sadananda Sharma's Rasa Tarangini. 11/216. Delhi: Motilal Banarasidas; 1970. p. 280. [Google Scholar]

- 12.Sharma S. Sadananda Sharma's Rasa Tarangini. 23/69. Delhi: Motilal Banarasidas; 1970. p. 613. [Google Scholar]

- 13.Sharma S. Sadananda Sharma's Rasa Tarangini. 23/71. Delhi: Motilal Banarasidas; 1970. p. 613. [Google Scholar]

- 14.The Ayurvedic Pharmacopoeia of India. Part 2. 1st ed. Vol. 3. New Delhi: Govt. of India, Ministry of Health and Family Welfare; 2010. Govt. of India, Ministry of Health and Family Welfare. Appendix 2 (3.3, 2.2.8, 2.2.3, 2.2.4) [Google Scholar]

- 15.Goldstein J, Newbury DE, Joy DC. SEM and X-Ray Microanalysis. 3rd ed. New York: Springer Science; 2003. [Google Scholar]

- 16.Cullity BD. Elements of X-Ray Diffraction. 2nd ed. London, Palo Alto: Addison Wesley Publishing Company; 1978. [Google Scholar]

- 17.Kulkarni SD, editor. Acharya Vagbhat, Rasa Ratna Samuchhaya, 8/26-30. New Delhi: ML Publication; 1998. p. 148. [Google Scholar]

- 18.Carter SJ, editor. Cooper and Gunn's Tutorial Pharmacy. 6th ed. Delhi: CBS Publishers and Distributors; 1986. p. 10. [Google Scholar]

- 19.Chatterje I. Determination of Fuel and Temperature in Various Puta w.s.r. to Rasa Ratna Samucchaya (M.D. Ayu. Thesis HNB Univ., Uttrakhand) 2013 [Google Scholar]

- 20. [Last accessed on 2012 Jun 12]. Available from: http://www.serc.carleton.edu/research_education/geochemsheets/techniques/SEM.html .

- 21.Suryanarayana C, Forse FH. The structure and mechanical properties of metallic nanocrystals. Meter Trans. 1992;23:1071–81. [Google Scholar]

- 22.Behari J. Principles of nanoscience: An overview. Indian J Exp Biol. 2010;48:1008–19. [PubMed] [Google Scholar]

- 23.Satoskar RS, Bhandarkar SD, Rege NN. Pharmacology and Pharmacotherapeutics. 20th ed. Mumbai: Popular Prakashan; 2007. p. 13. [Google Scholar]

- 24.Zhang L, Gu FX, Chan JM, Wang AZ, Langer RS, Farokhzad OC. Nanoparticles in medicine: Therapeutic applications and developments. Clin Pharmacol Ther. 2008;83:761–9. doi: 10.1038/sj.clpt.6100400. [DOI] [PubMed] [Google Scholar]

- 25.Mohaptra S, Jha CB. Physicochemical characterization of Ayurvedic bhasma (Swarna makshika bhasma): An approach to standardization. Int J Ayurveda Res. 2010;1:82–6. doi: 10.4103/0974-7788.64409. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 26.Tudan C, Weber FX, Levine KE. The status of trace elements analysis in biological systems. Bioanalysis. 2011;3:1695–7. doi: 10.4155/bio.11.171. [DOI] [PubMed] [Google Scholar]

- 27.The Ayurvedic Pharmacopoeia of India. Part 2. 1st ed. Appendix 2. Vol. 3. New Delhi: Govt. of India, Ministry of Health and Family Welfare; 2010. Govt. of India, Ministry of Health and Family Welfare. [Google Scholar]