Abstract

Introduction

Little is known about the transfer into the workplace of interventions designed to reduce the physical demands of sheet metal workers.

Methods

We reviewed videos from a case series of 15 sheet metal worksite assessments performed in 2007–2009 to score postures and physical loads, and to observe the use of recommended interventions to reduce physical exposures in sheet metal activities made by a NIOSH stakeholder meeting in 2002.

Results

Workers showed consistent use of material handling devices, but we observed few uses of recommended interventions to reduce exposures during overhead work. Workers spent large proportions of time in awkward shoulder elevation and low back rotation postures.

Conclusions

In addition to the development of new technologies and system designs, increased adoption of existing tools and practices could reduce time spent in awkward postures and other risks for musculoskeletal disorders in sheet metal work.

Keywords: intervention study, musculoskeletal injuries, technology transfer

1. Introduction

Construction workers across all trades are at high risk for work-related musculoskeletal disorders (MSD), with incidence rates higher than the national average for all industries as reported by the U.S. Bureau of Labor Statisitics (2013). Sheet metal workers are at particularly high risk for developing MSD, with one of the highest rates of overexertion injuries among all construction trades (Albers et al., 2005; Fredericks et al., 2002; U.S. Bureau of Labor Statisitics, 2013; Welch et al., 1995). The rate of non-fatal lost time injuries and illnesses among sheet metal workers was 401.9 per 10,000 full time equivalents versus 160.6 among all construction trades from 2008 to 2010 (CPWR, 2013).

Specific MSD symptoms have been linked to exposures found in construction work. Engholm and Holmstrom showed strong body location-specific dose-response relationships with time spent working in awkward postures among construction workers (2005). Frequent working with hands above shoulders was associated with shoulder symptoms, while stooping and twisted postures showed stronger association to lower back and upper back symptoms. Among sheet metal workers, working overhead to hang ducts has been associated with neck and shoulder symptoms (neck odds ratio (OR) 7.9, p=0.08; shoulder OR 2.7, p=0.16) (Welch et al., 1995). In a more recent observational study, Mitropoulous et al. found that aligning ducts was the most time-consuming task, and creates prolonged periods of awkward postures (Mitropoulos et al., 2013). Despite these known associations between work tasks and injury risks, rates of MSD among sheet metal workers remain high.

To address this problem, the National Institute for Occupational Safety and Health (NIOSH) held stakeholder meetings in 2002 to gather information about perceived risk of work tasks, availability of ergonomic controls, and perceived barriers to controlling hazards (Albers et al., 2005; NIOSH, 2006). Stakeholders included researchers, contractors, and national union representatives from the mechanical and electrical trades. During trade-specific breakout sessions, stakeholders listed problematic work tasks in order of priority, and recommended interventions for each task. Most of the interventions could be implemented by the contractor although some interventions required support from the general contractor, or required long-term planning in the project design. These identified tasks and recommendations were made available to the public in a publication by Albers and colleagues (Albers et al., 2005) and a 2006 NIOSH document (NIOSH, 2006).

Tracking the diffusion and adoption of control measures is a recognized problem. There are no national mechanisms nor data available in the United States to track the transfer of recommendations, the implementation of voluntary control measures, the evaluation of the high-risk tasks for which control measures are needed, or the description of barriers to implementing hazard controls (Albers et al., 2005; Andersson, 1990; Wos et al., 1992). A workshop held by the Center for Construction Research and Training (CPWR) in 2012 brought together researchers, tool manufacturers, contractor associations, trade union representatives, and insurance industry representatives to explore the challenges of transferring technology to workers engaged in appropriate work tasks (Welch et al., 2015). The participants agreed that strong cultural norms within the construction industry can create barriers to change, and the constantly changing workplace makes implementation and evaluation of interventions very difficult. Different agents are responsible for the purchase and implementation of technologies at the worksite including the owner, contractor, project manager, and worker. Despite these challenges, some new safety technologies have been introduced successfully (CPWR, 2012).

Given the need for more controls in sheet metal tasks described in the NIOSH stakeholder meeting and the lack of monitoring transfer of technologies in the construction industry, this study was undertaken 1) to determine whether previously recommended voluntary control measures to reduce physical exposures in sheet metal tasks were being utilized in a sample of commercial heating, ventilating, and air conditioning (HVAC) installation projects between 2007 and 2009, and 2) to describe postures and loads associated with residual MSD risk that were observed for these jobs.

2. Materials and Methods

2.1 Case Selection

We analyzed data collected between 2007 and 2009 from sheet metal workers who participated in a study to monitor the natural history of carpal tunnel syndrome, the Predictors of Carpal Tunnel Syndrome study (PrediCTS) (Armstrong et al., 2008; Dale et al., 2010). An experienced ergonomist conducted worksite visits to examine tools, equipment, and materials used. Videos of workers were taken to characterize work postures and physical loads during normal work activities, and workers were interviewed to obtain an estimate of the time spent in each of the most common work activities. Fifty-eight videos were taken of sheet metal workers employed in residential and commercial duct installation, sheet metal assembly at the shop, architectural sheet metal installations, and HVAC service, of which 19 sampled commercial duct installation, the focus of the NIOSH recommendations. Four of the 19 videos on commercial duct installation projects were excluded from this study since at least 30% of the frames could not be coded due to blurring or obstructed views. The remaining 15 videos represented 10 sheet metal workers from 6 companies, with some workers observed on two separate construction projects. The workers, the union training center and the local union belonged to the Sheet Metal Workers’ International Association (SMWIA), and the contractors belonged to the Sheet Metal and Air Conditioning Contractors’ National Association (SMACNA). All participants provided written informed consent to participate. The Institutional Review Board of Washington University School of Medicine provided the approval for this study.

2.2 Data Collection Framework

We structured the data extraction from our videos based on the published findings from the 2002 NIOSH stakeholder meeting (NIOSH, 2006). Stakeholder groups for the sheet metal trade identified the most common work activities and for each activity, determined the associated tasks, type of work-related physical exposures, risk level (High, Moderate, Low) and body region potentially affected by each risk, and suggested interventions to address the risk in each task (Albers et al., 2005; Everett, 1997; NIOSH, 2006); see Table 1. As described in the NIOSH proceedings, “activities were defined as ‘all the field work which results in a recognizable, completed unit of work with spatial limits and/or dimensions.’ Tasks were defined as the ‘fundamental building blocks of construction field work, each representing one in a series of steps that comprise an activity’” (NIOSH, 2006). We restricted our analysis to the four activities identified with a moderate to high risk level: pack, support system, prep, and install. The pack activity involved moving material or equipment to or within the worksite. The support system activity involved installing hangars into the concrete or metal roof sheeting to hold the duct or equipment. The prep activity involved assembling duct sections, installing duct pieces, or cutting /trimming duct joists in preparation to install. The install activity involved raising the duct sections or equipment into the air close to the ceiling and attaching them to the hanging support system.

Table 1.

Summary of activities, tasks, and associated risk for sheet metal workers.

| Activities | Tasks a | NIOSH Risk Level | WMSD Risk Factors b | Body Regions affected b |

|---|---|---|---|---|

| Pack: Move material/ equipment to and within jobsite |

Carry materials to work location and move equipment |

High/Moderate | Force Awkward postures Contact Stress |

Back Distal upper extremities |

| Support System: Install duct hangers |

Carry materials to work location |

Moderate | Force Awkward postures Contact Stress |

Back Distal upper extremities |

| Drill Holes | High | Force Sustained non-neutral postures Repetition Vibration Contact stress |

Back Distal upper extremities Shoulders Knees |

|

| Screw/shoot into ceiling |

High | Force Sustained non-neutral postures Repetition |

Shoulders Distal UEs |

|

| Prep: Assemble duct pieces in the field |

Carry materials to work location |

Moderate | Force Awkward postures Contact Stress |

Back Distal upper extremities |

| Assemble duct sections (not detailed) |

High | Not Detailed | Not Detailed | |

| Cut and trim duct joints | High | Force Sustained non-neutral postures Vibration Repetition |

Distal upper extremities |

|

| Weld | High | Sustained non-neutral postures Repetition Contact Stress |

Neck Back Distal upper extremities |

|

| Install: Install ductwork/ equipment |

Carry materials to work location |

Moderate | Force Awkward postures Contact Stress |

Back Distal upper extremities |

| Connect ductwork to hanger/ceiling |

High/Moderate | Force Sustained non-neutral postures Repetition Contact Stress |

Shoulders Back Distal upper extremities |

|

| Demo: Demolition |

Cut and remove duct (not detailed) |

High | Not Detailed | Not Detailed |

| Other: Detail Work and Field Design |

Measure, layout, inspect work, formulate work sequence |

Low | Not Detailed | Not Detailed |

Tasks with risk factors identified in Tables 8 & 9 of (Albers et al., 2005)

Risk factors identified from NIOSH narrative following p. 109 (NIOSH, 2006)

2.3 Identification of Interventions

We reviewed each video to determine the activity, task, and whether an intervention was in use by the worker. If a physical exposure or recommended intervention was observed on video but did not fit into any of the NIOSH categories, it was noted to be a researcher addition. In our analysis, we identified the problems and associated solutions that could be observed related to awkward postures and forceful loads. We excluded problems or potential solutions related to work organization that could not be observed by video (such as work pace, work schedules, rest breaks, task coordination with other trades, planning and communication, job rotation, worker training, preventive maintenance on tools, shop work, and stretching programs). We summarized the interventions observed in each activity and then the residual exposures for the same activities in the series of cases for this review.

2.4 Video Posture and Load Analysis

The physical exposures for awkward posture and load were evaluated using Multimedia-Video Task Analysis (MVTA) software (Ergonomics Analysis and Design Research Consortium, 2003; Yen et al., 1995). The program allows coding of continuous video for time studies and single frames for worker postures. Each video was coded for the following data: 1) duration of time in each activity, location of work relative to the worker (ground, overhead), and primary material used, 2) postures for six body parts (low back flexion/extension and/or rotation, right and left knee position, and right and left shoulder elevation/extension), and 3) type of load: no load, light load (lifting or holding items weighing <20 pounds, such as hand tools, pieces and light material, small equipment), or heavy load (20 pounds or more, such as large rectangular duct, small insulated pre-assembled duct, large equipment).

We conducted time studies using continuous coding of the activity observed at each frame of the video and described the average proportion of time spent in each activity from all videos. Task samples coded as null or not working were excluded from exposures for posture and load. Postures and load were coded within each activity from randomly sampled frames, using methods similar to those described in our previous study of postures and loads among construction floorlayers (McGaha et al., 2014). “Null” codes were assigned for frames with blurry images or obstructed views, and for frames with body angles not aligned with the axis of joint rotation (Lau et al., 2011; Paul et al., 1993). We computed the proportion of frames for each body part that exceeded a threshold previously defined by the literature as potentially harmful. The selected threshold for low back forward flexion was greater than or equal to 30 degrees (Washington State Ergonomic Checklist, 2009; Punnett et al., 1991), low back rotation was the presence of any observable rotation (Washington State Ergonomic Checklist, 2009; Punnett et al., 1991), knee flexion was greater than or equal to 45 degrees regardless of contact with the floor (Washington State Ergonomic Checklist, 2009; Jensen, 2005; Jensen et al., 2000; Jensen et al., 2000), and shoulder elevation was greater than or equal to 90 degrees (Punnett et al., 2000). The threshold for heavy load was set at 20 pounds (American Conference of Governmental Industrial Hygienists, 2007). The data was summarized to determine the average percentage of samples coded within eligible videos for each of the posture categories for each activity, and the proportion of samples in heavy or light load within the awkward posture categories.

Our posture coding procedures used the methods and definitions from our previous study (McGaha et al., 2014), with the addition of new coding definitions for describing the type of load. To ensure consistency of these codes, two reviewers independently rated a sample of the randomly selected posture frames (1,198 total frames) with discussion and consensus for discrepancies. Trial 1 included 12% of samples with computed intraclass correlation coefficients (ICC) using a two-way mixed effects model and absolute agreement for load=0.79; trial 2 included an additional 14% of samples with computed ICC for load=0.93. Coding definitions were refined between trials. Once agreement exceeded 90%, one reviewer coded all remaining samples for type of load using the refined coding definitions.

3. Results

The 10 sheet metal workers observed in the 15 video samples were all male, and predominately Caucasian (90%) and right handed (90%). Workers were young (mean age 29.3 years, standard deviation (SD) 7.1) with a mean tenure of 2.5 years (SD 1.5 years) in their trade. The total video time was 393.8 minutes. The average video length was 26.3 minutes (range 13.2–47.3). Workers’ average self-reported estimates of time spent in each activity across all commercial installation jobs were as follows: prep 33%, install and support system combined for a total of 57%, and pack 9%. The actual proportions of time in activities from all video samples used in the analysis were: prep 23%, install 48%, support system 22%, and pack 7%.

3.1 Interventions observed in each activity

Table 2 describes the type of interventions observed in use for physical exposures in each activity and task. Three videos of packing were available, 2 of which showed workers using NIOSH recommended interventions including manual material handling equipment and coworker assistance to reduce physical exposures from manually lifting/carrying heavy objects. NIOSH stakeholders identified several other potential interventions which were not observed in the case series, such as electrical chain falls or tuggers to lift large ducts, fabricated handles/magnets/suction cups, or levers.

Table 2.

Summary of video coding of NIOSH recommended interventions observed or not observed in use during high/moderate risk sheet metal tasks.

| Activities | Tasks a | Physical Exposures b | Recommended Interventions | Intervention observed (+=yes; −=no) |

|---|---|---|---|---|

| Pack: Move material/ equipment to and within jobsite |

Carry materials to work location and move equipment |

Manually lift and carry heavy objects without any assistive devicec |

Use mechanical material handling equipmentc Electrical chain fall or tugger to lift large ductc Use fabricated handles, magnets, or suction cupsc Use levers to assist movingc Co-worker assist with lift/carryc |

+ − − − + |

| Support System: Install duct hangers |

Drill holes and assemble system |

Drill holes with drill with excessive vibration and rotational forcec |

Use low vibration toolsc Use a side arm on a rotary hammerc Use beam clamps or caddy clipsc |

− − + |

| Work on floor (drill into floor/deck, any work on floor)c |

Use knee padsc Anti-fatigue matsc Work from elevated surfaced |

− − + |

||

| Screw/shoot into ceiling |

Operate powder actuated tool or rotary hammerc |

Embed concrete insertsc Use tool stand or inverse drill pressc Use tool counterweightc Use low-vibration toolsc |

+ − − + |

|

| Use hammer/wrench to set threaded rodc |

Embed concrete insertsc Use electric or pneumatic drill to set nut and wedge anchorc Use ratchet wrench with open socket to set nut and wedge anchorc |

+ + + |

||

| Use tools with arms overheadc |

Use extension pole and remote triggeringc Use drill bit extenderc Work on powered lift or scaffoldc Correct placement of ladder and liftc Predrill holes on duct before liftingd Place anchor on duct before liftingd |

− − + + + + |

||

| Prep: Assemble duct pieces in field |

Assemble duct sections |

Work with duct on floorc, d |

Work from elevated surfacec, d Preassembly of ductd Use drill bit extensiond |

+ + + |

| Work on floor without knee padsd |

Use knee padsd Anti-fatigue matsd |

− − |

||

| Intensive use of manual hand toolsd |

Use power tools when possibled | − | ||

| Cut and trim duct joints |

Use manual tin snipsc | Use electric snipsc Drill adapter to cut circlesc |

+ − |

|

| Use manual crimperd | Use power crimperd | − | ||

| Work on floor without knee padsc |

Use knee padsc Anti-fatigue matsc Work from elevated surfacec |

− − − |

||

| Use power tools with excessive vibrationc |

Use low-vibration toolsc Anti-vibration wraps on tool handlec |

− − |

||

| Use heavy power toolsc | Use tube cutter for small bore stainless steelc Use tools of appropriate weightc |

− − |

||

| Intensive use of manual hand toolsd |

Crank device to prepare drives in fieldd | + | ||

| Install: Install ductwork/ equipment |

Carry materials to work location |

Manually lift and carry heavy objects without any assistive devicec |

Use mechanical material handling equipmentc Electrical chain fall or tugger to lift large ductc Use fabricated handles, magnets, or suction cupsc Use jig attached to lift for spiral duct (within manufacturer weight restrictions)c Use levers to assist movingc Co-worker assist with lift/carryc |

+ − − − − − |

| Connect ductwork to hanger/ ceiling |

Work overheadc | Work on powered work platform or ladder platformc Use screwgun extensiond |

+ + |

|

| Intensive use of manual hand toolsc |

Use power tools when possiblec If screwing/bolting, use cordless screwdrivers that bend in centerc T-bar tool to remove drive between ductd |

+ − + |

||

| Manually position and hold system componentsc |

Use fixtures to hold and position work materialsc Use magnets or suction cups with handles to position ductc Use clamp to hold metal band around ductd Use mechanical material handling equipmentd |

+ − + + |

||

| Confined or cramped work spacesc |

Use one-person liftc Use baker scaffold (lower ceiling heights)c |

− − |

Eliminated Tasks if there was no video available: Carry materials to work location (Support system and Prep), Weld (Prep).

Restricted the NIOSH problems that could be observed related to postures/force but did not include problems related to work organization (pace of work, schedule of workers, rest breaks, task coordination with other trades, proper tool availability, planning and communication, job rotation, worker training, preventive maintenance on tools, shop work) and type of power tool used to determine vibration level.

Source document based on NIOSH proceedings from 2006 and the publication by Albers et al., 2005.

Source = Researcher addition.

More videos were available for support system tasks (n=7) than for packing. The support system activity showed several NIOSH stakeholder-suggested alternative hanging systems such as clamping the hangers to the I-beams and embedding inserts for anchors into the floor prior to pouring concrete. These solutions eliminated the tasks of drilling into concrete and did not require an impact device to shoot the anchors into the ceiling. The hanging system used clamps to hold the support system.

The prep activity involved the use of hand tools and work was often performed at the ground level. Ten videos of prep were available. Several workers were observed using an elevated work platform to reduce their time spent working on the floor. Some work with ducts on the floor was likely unavoidable due to the demands of the task for both duct assembly and cutting and trimming of duct joints; however, no workers were observed wearing knee pads or working on anti-fatigue mats during either task in the available video samples.

Overhead work to hang the support system and install the duct and equipment (e.g. air handlers) caused awkward shoulder postures. Most of the available videos captured these duct installation tasks (n=14). Workers were observed using powered lifts, scaffolds, and positioning ladders to reduce awkward body postures, although these devices were not observed on all sites. Workers often used power tools, such as powered screw guns or shears, rather than manual tools to assemble duct. Workers were not observed using power tools with excessive vibration or heavy weight. Few NIOSH stakeholder-suggested interventions were utilized for manually positioning and holding system components, and no interventions were observed to address working in confined spaces to install duct.

There were several interventions observed during the video review that were not suggested during the NIOSH meeting or in the publication by Albers and colleagues. These novel solutions included a drill bit extension to reduce awkward postures, a T-bar device to reduce upper extremity arm force during the removal of drives from duct, use of power tools to replace manual tools, availability of mechanical material handling equipment, and using clamps to hold metal bands around ductwork to reduce exposure to forceful gripping. Some of these interventions may be due to new technologies that have been developed since the time of the stakeholder meeting.

3.2 Exposures observed in each activity

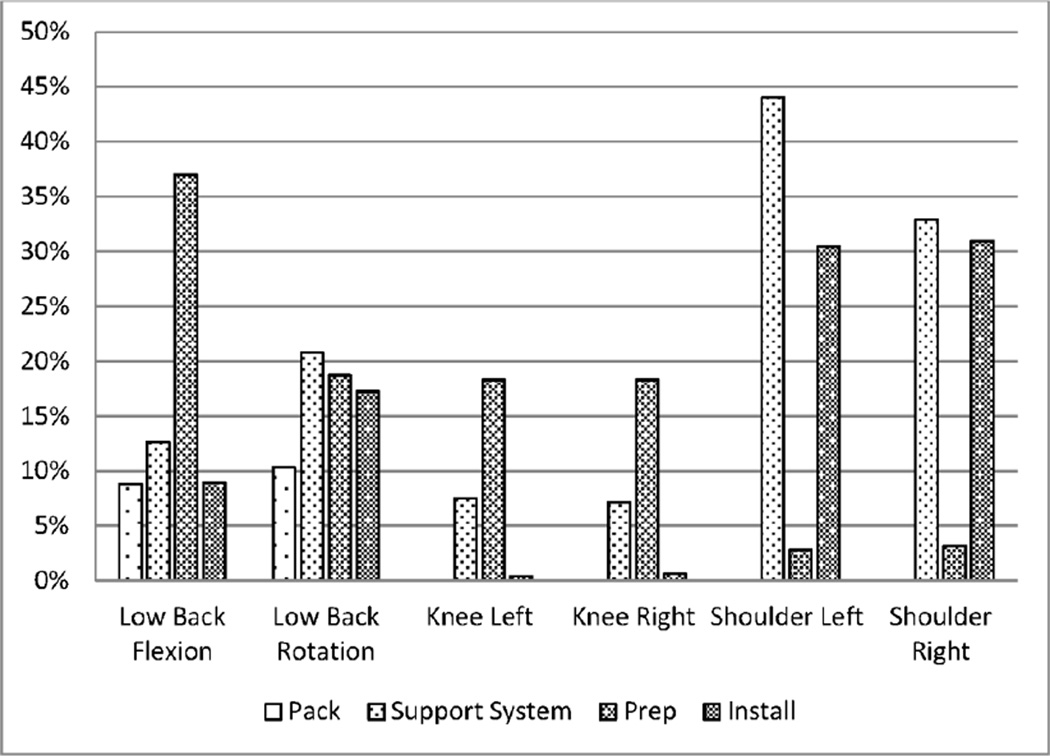

Despite the use of many intervention strategies, residual risk for MSD remained high across many sheet metal activities. Figure 1 describes the proportion of time workers were observed in awkward postures of the low back, knee, and shoulder during each of the four primary sheet metal work activities of pack, support system, prep, and install. Frames with the activity coded as null or not working were excluded from this analysis (excluded frames ranged from 16% to 28% for postures in activities, plus an additional 2% to 6% for load in activities). The prep activity, which accounted for approximately one-fourth of the daily work time, involved a large amount of time in awkward low back posture (37%). Since workers continued to perform many prep activities on the floor, bilateral awkward knee posture was present approximately 20% of the time. Workers used several of the stakeholder-suggested interventions to install the duct, but there still remained a large portion of time with shoulders overhead. Hanging support systems and installing duct activities involved overhead work and occurred approximately 30% to 45% of the time with the left shoulder having the highest exposure time. There were few frames with low back and shoulder in extension so these were not considered for further analysis.

Figure 1.

Average proportion of video time spent in awkward postures (by body part) during each activity

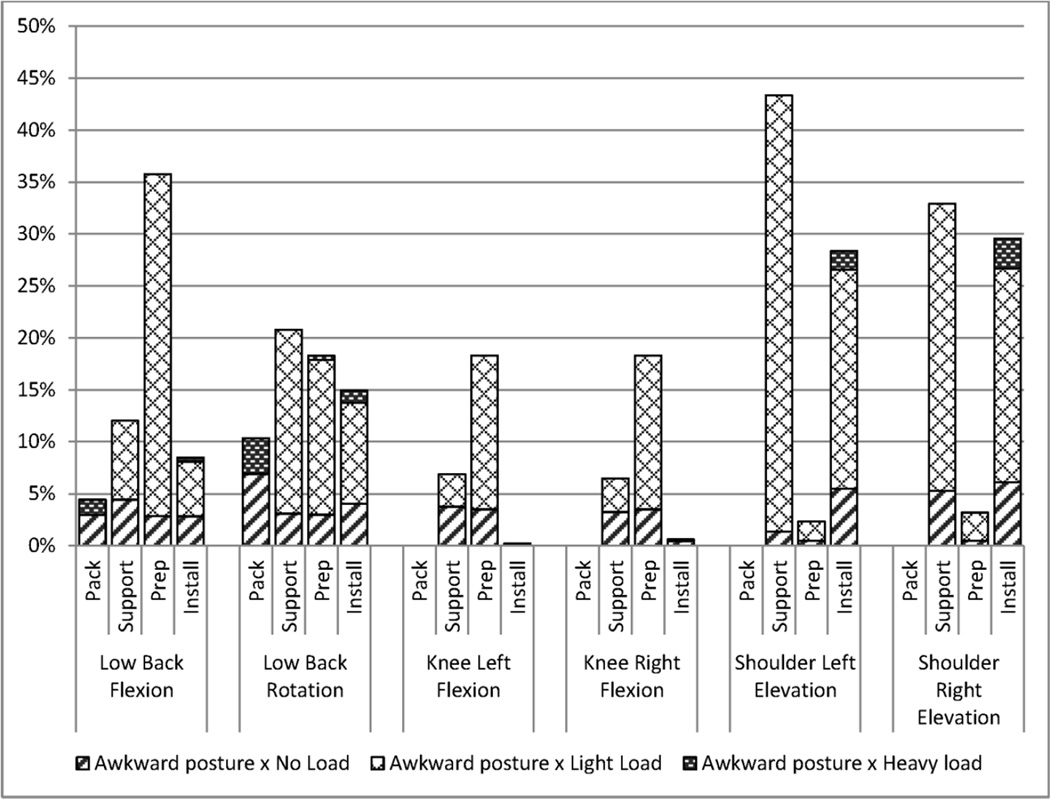

Workers handle different tools, equipment, and materials frequently throughout the day, potentially exposing them to significant loads on the body, and this stress may be increased if load is combined with awkward posture. Figure 2 shows the presence of a load while the worker was in an awkward body posture during each of the four activities. Load was described by the weight of the material or tool carried/held by the worker. High load (greater than 20 pounds) while in awkward body postures occurred most often during pack and install activities although the proportion of time was quite low. A large portion of work time involved carrying objects of lower weight such as tools, or pieces of duct. Heavy load occurred more frequently while in neutral body postures, for approximately 88% of time spent with heavy load during pack activities and 48% of time spent with a heavy load during install activities (results not shown).

Figure 2.

Proportion of time spent in each load for awkward postures by selected body parts during each activity

4. Discussion

Video analysis showed workers engaging in high to moderate risk tasks during four sheet metal activities including pack, support system, prep, and install. Some interventions suggested during the 2002 NIOSH stakeholder meeting were observed in use for each activity, although not for each task within the activity or physical exposure within the task. The most commonly observed interventions to reduce physical exposures were the use of mechanical handling equipment to pack heavy objects, power tool use in place of manual tools, and several examples of pre-assembly work processes at the ground level. There was also fairly consistent use of alternative support systems, and of power lifts to improve body positions during the installation activity. Several of the interventions that were observed, including preassembly work and proper body positioning, were low or no-cost solutions that workers often developed and employed themselves that required little or no involvement from the contractor.

Despite the adoption of some of the technology recommended by stakeholders, several of the stakeholder-suggested interventions were not adopted in the workplaces that we observed; residual risk of MSD remained high for these work tasks. Although preassembly work likely reduced the time spent in overhead work during installation tasks, few other stakeholder-suggested interventions were utilized for drilling and overhead work during support system tasks. As a result, the proportion of time in awkward shoulder postures remained high. Despite the use of mechanical equipment during some tasks, workers spent a large proportion of time handling heavy loads during packing and installation activities, which suggests that equipment may not be readily available to workers at the worksite when it is needed, or that workers do not perceive the benefit in utilizing the equipment. Workers continue to work on the floor during prep activities with resulting awkward low back and knee postures. Working on the floor without knee pads or anti-fatigue matting was observed for multiple prep tasks.

There were several limitations to the study. The findings are based on the analysis of a case series of available videotapes from a longitudinal cohort study that were recorded for the purpose of analyzing upper extremity postures. This sample may not have captured all interventions that were utilized by workers at the time of data collection. As in our previous study (McGaha et al., 2014), we reviewed all videos for clarity to ensure all included videos could be appropriately coded and we used large samples of randomly selected video frames for coding postures and load (Bao et al., 2006). Random frame sampling and computing average exposure times for awkward postures and loads may have caused some exposure misclassification; however, our case series still showed high residual risk to sheet metal workers particularly during prep and installation tasks. In addition, the video case series is not representative of all sheet metal workers, of all contractors, or of all commercial HVAC installation projects. We found one similar study: Hunting et al. (2010) observed 100 sheet metalworkers in the Washington D.C. metro area and assessed time spent in different tasks. The sheet metal tasks described in this prior study were very similar to those seen in our study. The workers observed by Hunting et al. had worked in the sheet metal trade for a median of 12 years, considerably longer than the median of 2.5 years of our sample. These findings suggest that our results may be generalizable beyond our small sample of relatively young workers in one geographic region. Furthermore, the workers in our study belonged to SMWIA and the contactors to SMACNA, so would have had a greater chance of exposure to information from the NIOSH symposium and other sources through their national organizations than would unaffiliated workers and contractors. This suggests that adoption of control technologies may be even lower in other work settings.

The strengths of this study include the importance of examining the recommendations made by a national body, such as the NIOSH stakeholder meeting, and measuring their subsequent adoption in the workplace. The NIOSH stakeholder meeting identified a wide range of intervention strategies to address ergonomic risk factors in sheet metal work activities; however, few studies have examined the feasibility or the transfer of these new technologies in the sheet metal industry. Given the continued high injury rates among sheet metal workers, additional controls and tracking mechanisms are still needed. The observation of workers utilizing novel intervention strategies is promising; technology in the sheet metal industry is advancing and new tools and equipment that were not available at the time of the stakeholder meeting were observed in use just a few years later.

The CPWR technology transfer symposium in 2012 concluded that successful diffusion of new tools and equipment requires effective stakeholder involvement, development of a business case, testing for usability before introduction, an understanding of the culture of construction, and an appreciation for external factors such as regulation and the economy. The participants agreed that a long-term commitment is needed; change often requires sustained attention over a long time (Boatman et al., In Press; Welch et al., 2015). Contractors will avoid new technologies that decrease worker productivity, reduce job quality, require frequent or costly maintenance, require large capital investment, or change the nature of the job so dramatically that it is assumed by another trade or requires added supervision. Adoption of new tools or practices in the construction industry is more likely if a tool has a clear relative advantage, is easy to use, if the benefits are readily observable, if use reduces complexity, and if it can be tried before purchase (Weinstein et al., 2007). The barriers to implementing more solutions will require the participation and cooperation of all levels of the industry, contractors, unions and workers (Carlan et al., 2012). CPWR recently evaluated dissemination strategies that have been successful in other areas of public health, such as social marketing campaigns and partnerships. A comprehensive campaign to improve ergonomics in construction has not been undertaken to date (Baker et al., In Press).

Another barrier to the adoption of new tools or work practices to reduce physical exposures is that chronic MSD are not yet considered an important problem throughout the construction industry (Boatman et al., In Press). A series of informational interviews and focus groups with construction contractors and workers in California found that workers care deeply about the impact MSD have on their lives and their ability to continue working, yet at the same time many workers hold the belief that MSD are somewhat inevitable or acceptable as part of the job. The study found that the construction industry has been changing over time and that awareness of ergonomic hazards and solutions exists and has been increasing, particularly over the last 10–15 years. For each major obstacle to implementation of ergonomics in the industry identified, the construction professionals interviewed offered a variety of solutions. Kramer (2009; 2010) also found that a lack of awareness of the significance of MSD in the industry and a lack of confidence to manage MSD were barriers to adoption of interventions to reduce them. Van Der Molen et al. (2006) reported that among employers, those who were aware of the risk of MSD and understood the benefit of the interventions, were in turn more likely to buy and institute interventions to improve ergonomics.

Ergonomic solutions exist and are already helping the construction industry protect workers and reduce injuries (Entzel et al., 2007; Hess et al., 2010; Kramer et al., 2010). However, if the principles of ergonomics are integrated into all phases of construction (bidding, engineering, pre-planning, purchasing, materials handling, job site management, training of supervisors and workers), we can take the burden off of workers and mitigate hazards to reduce MSD.

5. Conclusions

Sheet metal workers are utilizing some available technologies to reduce physical exposures, particularly to reduce exposures due to manual material handling. Some improvements in designs and work processes have reduced the time spent in awkward overhead work postures although there remains a substantial risk for awkward postures of the low back and shoulders. Future work should focus on the design of installation and support systems that reduce or eliminate time spent in overhead work. In addition, a targeted dissemination campaign is needed to increase focus and attention by contractors and workers on chronic MSD and the more widespread adoption of the available effective solutions to reduce physical exposures (Boatman et al., In Press).

Acknowledgments

We would like to thank the workers and contractors who made the collection of data presented in this manuscript possible. We would also like to thank Anna Kinghorn and Kaleigh Sills for their work in formatting and preparing the manuscript for publication.

Role of the funding source

This study was supported by research funding from the Centers for Disease Control / National Institute of Occupational Safety and Health (R01 OH008017-01 and U60OH009762-01). Its contents are solely the responsibility of the authors and do not necessarily represent the official view of NIOSH. These funds were used by the research team in order to design the study, and to perform the data analysis and interpretation, and to prepare this manuscript. The study sponsors had no specific involvement in this manuscript.

Footnotes

Disclosure Statement

No authors in this study have actual or potential conflict of interest including any financial, personal or other relationships with other people or organizations within three (3) years of beginning the work submitted that could inappropriately influence this work.

References

- Albers J, Estill C, MacDonald L. Identification of ergonomics interventions used to reduce musculoskeletal loading for building installation tasks. Applied Ergonomics. 2005;36(4):427–439. doi: 10.1016/j.apergo.2004.07.005. [DOI] [PubMed] [Google Scholar]

- American Conference of Governmental Industrial Hygienists. TLVs and BEIs: Threshold limit values for chemical substances and physical agents and biological exposure indices. Cincinnati, OH: 2007. [Google Scholar]

- Andersson RE. The adoption process for an ergonomic intervention [Abstract] Swedish Council for Building Research (Byggforskningsradet), Stockholm. 1990 Report No. R76, 50pp. [Google Scholar]

- Armstrong T, Dale AM, Franzblau A, Evanoff BA. Risk factors for carpal tunnel syndrome and median neuropathy in a working population. Journal of Occupational and Environmental Medicine. 2008;50(12):1355–1364. doi: 10.1097/JOM.0b013e3181845fb1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Baker R, Chang CY, Bunting J, Betit E. Triage for action: Systematic assessment and dissemination of construction health and safety research. In Press doi: 10.1002/ajim.22477. [DOI] [PubMed] [Google Scholar]

- Bao S, Silverstein B, Howard N, Spielholz P. The Washington state SHARP approach to exposure assessment. In: Karwowski WS, Marras W, editors. Occupational Ergonomics. Boca Raton, FL: CRC Taylor and Francis Group; 2006. [Google Scholar]

- Boatman L, Chapman D, Teran S, Welch L. Creating a Climate for Ergonomic Changes in the Construction Industry. American Journal of Industrial Medicine. In Press doi: 10.1002/ajim.22499. [DOI] [PubMed] [Google Scholar]

- Carlan NA, Kramer DM, Bigelow P, Wells R, Garritano E, Vi P. Digging into construction: Social networks and their potential impact on knowledge transfer. Work. 2012;42(2):223–232. doi: 10.3233/WOR-2012-1345. [DOI] [PubMed] [Google Scholar]

- CPWR. Best practices for health and safety technology transfer in construction. Silver Springs, MD: 2012. pp. 1–19. [DOI] [PubMed] [Google Scholar]

- CPWR. The Construction Chart Book: The U.S. Construction Industry and Its Workers. Silver Spring, MD: CPWR - The Center for Construction Research and Training; 2013. [Google Scholar]

- Dale AM, Strickland J, Gardner BT, Symanzik J, Evanoff BA. Assessing agreement of self-reported and observed physical exposures of the upper extremity. International Journal of Occupational and Environmental Health. 2010;16(1):1–10. doi: 10.1179/107735210800546227. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Engholm G, Holmström E. Dose-response associations between musculoskeletal disorders and physical and psychosocial factors among construction workers. Scandinavian Journal of Work, Environment & Health. 2005;2005;31(Suppl 2):57–67. [PubMed] [Google Scholar]

- Entzel P, Albers J, Welch L. Best practices for preventing musculoskeletal disorders in masonry: Stakeholder perspectives. Applied Ergonomics. 2007;38(5):557–566. doi: 10.1016/j.apergo.2006.08.004. [DOI] [PubMed] [Google Scholar]

- Ergonomics Analysis and Design Research Consortium. User’s manual for Multimedia Video Task Analysis™ (MVTA™) Wisconsin: Wisconsin Alumni Research Foundation (WARF); 2003. [Google Scholar]

- Everett JG. NIOSH grant 5 R03 OH03154–02 Technical Report UMCEE 96–27. Ann Arbor, MI: University of Michigan, Center for Construction Engineering and Management, Department of Civil and Environmental Engineering; 1997. Ergonomic analysis of construction tasks for risk factors for overexertion injuries. [Google Scholar]

- Fredericks T, Abudayyeh O, Palmquist M, Torres HN. Mechanical contracting safety issues. Journal of Construction Engineering and Management-Asce. 2002;128(2):186–193. [Google Scholar]

- Hess J, Weinstein M, Welch L. Ergonomic Best Practices in Masonry: Regional Differences, Benefits, Barriers, and Recommendations for Dissemination. Journal of Occupational and Environmental Hygiene. 2010;7(8):446–455. doi: 10.1080/15459624.2010.484795. [DOI] [PubMed] [Google Scholar]

- Hunting KL, Haile E, Nessel L, Welch LS. Validity Assessment of Self-Reported Construction Tasks. Journal of Occupational and Environmental Hygiene. 2010;7(5):307–314. doi: 10.1080/15459621003717847. [DOI] [PubMed] [Google Scholar]

- Jensen LK. Knee-straining work activities, self-reported knee disorders and radiographically determined knee osteoarthritis. Scandinavian Journal of Work, Environment & Health. 2005;31(Supplement 2):68–74. [PubMed] [Google Scholar]

- Jensen LK, Eenberg W, Mikkelsen S. Validity of self-reporting and video-recording for measuring knee-straining work postures. Ergonomics. 2000;43(3):310–316. doi: 10.1080/001401300184422. [DOI] [PubMed] [Google Scholar]

- Jensen LK, Mikkelsen S, Loft IP, Eenberg W. Work-related knee disorders in floor layers and carpenters. JOEM. 2000;42(8):835–842. doi: 10.1097/00043764-200008000-00015. [DOI] [PubMed] [Google Scholar]

- Kramer D, Bigelow P, Vi P, Garritano E, Carlan N, Wells R. Spreading good ideas: A case study of the adoption of an innovation in the construction sector. Applied Ergonomics. 2009;40(5):826–832. doi: 10.1016/j.apergo.2008.09.006. [DOI] [PubMed] [Google Scholar]

- Kramer DM, Bigelow PL, Carlan N, Wells RP, Garritano E, Vi P, Plawinski M. Searching for needles in a haystack: Identifying innovations to prevent MSDs in the construction sector. Applied Ergonomics. 2010;41(4):577–584. doi: 10.1016/j.apergo.2009.12.003. [DOI] [PubMed] [Google Scholar]

- Lau MH, Armstrong TJ. The effect of viewing angle on wrist posture estimation from photographic images using novice raters. Applied Ergonomics. 2011;42(5):634–643. doi: 10.1016/j.apergo.2010.08.008. [DOI] [PubMed] [Google Scholar]

- McGaha J, Miller K, Descatha A, Welch L, Buchholz B, Evanoff B, Dale AM. Exploring physical exposures and identifying high-risk work tasks within the floor layer trade. Applied Ergonomics. 2014;45(4):857–864. doi: 10.1016/j.apergo.2013.11.002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Mitropoulos P, Houssain S, Guarascio-Howard L. Improving Productivity and Ergonomics in HVAC Installation; 49th ASC Annual International Conference Proceedings.2013. [Google Scholar]

- NIOSH. Proceedings of a meeting to explore the use of ergonomic interventions for the Mechanical and Electrical Trades. 2006 DHHS (NIOSH) Publication No.2006-119. [Google Scholar]

- Paul JA, Douwes M. Two-dimensional photographic posture recording and description: a validity study. Applied Ergonomics. 1993;24(2):83–90. doi: 10.1016/0003-6870(93)90079-o. [DOI] [PubMed] [Google Scholar]

- Punnett L, Fine LJ, Keyserling WM, Herrin GD, Chaffin DB. Back disorders and nonneutral trunk postures of automobile assembly workers. Scandinavian Journal of Work, Environment & Health. 1991;17(5):337–346. doi: 10.5271/sjweh.1700. [DOI] [PubMed] [Google Scholar]

- Punnett L, Fine LJ, Keyserling WM, Herrin GD, Chaffin DB. Shoulder disorders and postural stress in automobile assembly work. Scandinavian Journal of Work, Environment & Health. 2000;26(4):283–291. doi: 10.5271/sjweh.544. [DOI] [PubMed] [Google Scholar]

- U.S. Bureau of Labor Statisitics. Incidence rates of nonfatal occupational injuries and illnesses by industry and case types, 2011: Bureau of Labor Statistics, United States Department of Labor. 2013 from http://www.bls.gov/iif/oshwc/osh/os/ostb3191.pdf.

- Van Der Molen HF, Sluiter JK, Frings-Dresen MHW. Is the use of ergonomic measures associated with behavioural change phases? Ergonomics. 2006;49(1):1–11. doi: 10.1080/00140130500307455. [DOI] [PubMed] [Google Scholar]

- Washington State Ergonomic Checklist. [Retrieved: December 18, 2014];2009 from: http://www.ttl.fi/en/ergonomics/methods/workload_exposure_methods/table_and_methods/Documents/WashingtonStateErgonomicchecklist.pdf.

- Weinstein MG, Hecker SF, Hess JA, Kincl L. A roadmap to diffuse ergonomic innovations in the construction industry: There is nothing so practical as a good theory. International Journal of Occupational and Environmental Health. 2007;13(1):46–55. doi: 10.1179/107735207800245054. [DOI] [PubMed] [Google Scholar]

- Welch L, Hunting K, Kellogg J. Work-related Musculoskeletal Symptoms Among Sheet-Metal Workers. American Journal of Industrial Medicine. 1995;27(6):783–791. doi: 10.1002/ajim.4700270603. [DOI] [PubMed] [Google Scholar]

- Welch L, Russell D, Weinstock D, Betit E. Best Practices for Health and Safety Technology Transfer in Construction. American Journal of Industrial Medicine. 2015 doi: 10.1002/ajim.22456. [DOI] [PubMed] [Google Scholar]

- Wos H, Lindberg J, Jakus R, Norlander S. Evaluation of impact loading in overhead work using a bolt pistol support. Ergonomics. 1992;35(9):1069–1079. doi: 10.1080/00140139208967383. [DOI] [PubMed] [Google Scholar]

- Yen TY, Radwin RG. A video-based system for acquiring biomechanical data synchronized with arbitrary events and activities. IEEE Transactions on Biomedical Engineering. 1995;42(9):944–948. doi: 10.1109/10.412663. [DOI] [PubMed] [Google Scholar]