Abstract

Based on the electric rotating magnetoresistance method, the shape anisotropy of a Co microstrip has been systematically investigated. We find that the shape anisotropy is dependent not only on the shape itself, but also on the magnetization distribution controlled by an applied magnetic field. Together with micro-magnetic simulations, we present a visualized picture of how non-uniform magnetization affects the values and polarities of the anisotropy constants  and

and  . From the perspective of potential appliantions, our results are useful in designing and understanding the performance of micro- and nano-scale patterned ferromagnetic units and the related device properties.

. From the perspective of potential appliantions, our results are useful in designing and understanding the performance of micro- and nano-scale patterned ferromagnetic units and the related device properties.

Shape anisotropy, which originates from the dipole-dipole interactions that occur in ferromagnets, is a fundamental issue in magnetism1. For uniformly magnetized magnetic ellipsoids bodies, the shape anisotropy can be quantificationally described by the demagnetization tensor N which depends only on the shape. Thus, it provides a simple mechanism for designing the local effective anisotropy field of micro- and nano-scale magnetic units2,3,4. However, for an arbitrary magnet with a non-ellipsoid shape (such as the commonly used square and rectangle), it is difficult to realize uniform magnetization under a finite magnetic field5,6,7. As a consequence of nonuniform magnetization, the values of N that are estimated by uniformly magnetized ellipsoid approximation would be inaccurate and not suitable for describing shape anisotropy8,9. Moreover, a magnetic field-dependent shape anisotropy is expected. As more and more micro- and nano-scale patterned ferromagnetic units are used in spintronics devices, the shape anisotropy plays an increasingly important role in determining both the magnetic properties of local magnets and the related device performances10,11,12,13,14. Therefore, it is time to systematically investigate the shape anisotropy in micro- and nano-scale magnetic units, which is important in both physics and applications.

Methods

The universal method for describing magnetic anisotropy is to determine the anisotropy constants  (

( = 1, 2, …) in the expression of magnetic anisotropy energy

= 1, 2, …) in the expression of magnetic anisotropy energy  . For uniaxial anisotropy, Ek = K1

. For uniaxial anisotropy, Ek = K1  + K2

+ K2  , where

, where  is the angle of the magnetization with respect to a certain symmetry axis. Many methods have been explored to measure magnetic anisotropy. Some methods can only give the first-order term

is the angle of the magnetization with respect to a certain symmetry axis. Many methods have been explored to measure magnetic anisotropy. Some methods can only give the first-order term  or the effective anisotropy field

or the effective anisotropy field  to estimate the anisotropy, such as the intersection method15, the area method16, and the singular point detection (SPD) method17,18 but these methods are not sufficiently accurate for our experiments. There are also a few methods that can give higher-order terms, such as the torque method19,20,21 and the magnetic resonance method22,23. It is worth noting that the ferromagnetic resonance (FMR) method is one of the best methods for determining magnetic anisotropy with very high sensitivity24,25. There are two kinds of FMR experiments, frequency-swept FMR and magnetic field-swept FMR. To obtain accurate anisotropy values, angular resolved measurements are needed, and

to estimate the anisotropy, such as the intersection method15, the area method16, and the singular point detection (SPD) method17,18 but these methods are not sufficiently accurate for our experiments. There are also a few methods that can give higher-order terms, such as the torque method19,20,21 and the magnetic resonance method22,23. It is worth noting that the ferromagnetic resonance (FMR) method is one of the best methods for determining magnetic anisotropy with very high sensitivity24,25. There are two kinds of FMR experiments, frequency-swept FMR and magnetic field-swept FMR. To obtain accurate anisotropy values, angular resolved measurements are needed, and  can be obtained by fitting the angle dependent resonance position curves (

can be obtained by fitting the angle dependent resonance position curves ( for field swept,

for field swept,  for frequency swept). Such method can be realized using traditional cavity FMR, transmission line or co-planar waveguide26,27,28,29,30,31,32, and DC electrical detection of FMR33,34,35,36,37,38,39,40,41,42,43,44, and has been widely used in various magnetic materials. Note that, the field-swept FMR method is accurate only when the anisotropy itself is independent of the applied magnetic field, such as the magnetocrystalline anisotropy. If

for frequency swept). Such method can be realized using traditional cavity FMR, transmission line or co-planar waveguide26,27,28,29,30,31,32, and DC electrical detection of FMR33,34,35,36,37,38,39,40,41,42,43,44, and has been widely used in various magnetic materials. Note that, the field-swept FMR method is accurate only when the anisotropy itself is independent of the applied magnetic field, such as the magnetocrystalline anisotropy. If  is a function of the applied magnetic field (i.e., the shape anisotropy in our case), such a method becomes “inaccurate” because the relation between

is a function of the applied magnetic field (i.e., the shape anisotropy in our case), such a method becomes “inaccurate” because the relation between  and

and  is now hidden in

is now hidden in  and that relation cannot be directly obtained from the fitting. In this work, by taking the advantage of frequency-swept FMR and the torque method that determining anisotropy at a certain magnetic field, and the advantage of direct electrical detection which is its inherent high sensitivity, we used a similar but experimentally simpler DC electrical method to quantify the magnetic field-dependent shape anisotropy in a small magnetic unit.

and that relation cannot be directly obtained from the fitting. In this work, by taking the advantage of frequency-swept FMR and the torque method that determining anisotropy at a certain magnetic field, and the advantage of direct electrical detection which is its inherent high sensitivity, we used a similar but experimentally simpler DC electrical method to quantify the magnetic field-dependent shape anisotropy in a small magnetic unit.

Two samples were used in the experiments. One was a 3 mm × 3 mm × 50 nm Co ferromagnetic film, and the other was a 3 mm × 50 μm  50 nm Co microstrip. Both samples were made of a Co film deposited on glass substrate using magnetron sputtering. The background pressure was lower than

50 nm Co microstrip. Both samples were made of a Co film deposited on glass substrate using magnetron sputtering. The background pressure was lower than  Pa and a pressure of 0.2 MPa of argon was used. The patterns were realized using laser exposure and the lift-off method. The magnetoresistance was measured by using lock-in techniques: a lock-in amplifier (SR830) provided a 2 V voltage with a modulation frequency of 1.31 kHz, and the sample was connected with a large resistance (20 kΩ) in series. At the same time, the lock-in amplifier measured the voltage

Pa and a pressure of 0.2 MPa of argon was used. The patterns were realized using laser exposure and the lift-off method. The magnetoresistance was measured by using lock-in techniques: a lock-in amplifier (SR830) provided a 2 V voltage with a modulation frequency of 1.31 kHz, and the sample was connected with a large resistance (20 kΩ) in series. At the same time, the lock-in amplifier measured the voltage  at both ends of the microstrip. Thus, the resistance of the microstrip can be calculated using the expression

at both ends of the microstrip. Thus, the resistance of the microstrip can be calculated using the expression  k

k . The magnetic hysteresis loops were measured using a vibrating sample magnetometer (VSM; EV9, MicroSense, Westwood, MA, USA).

. The magnetic hysteresis loops were measured using a vibrating sample magnetometer (VSM; EV9, MicroSense, Westwood, MA, USA).

Results and Discussions

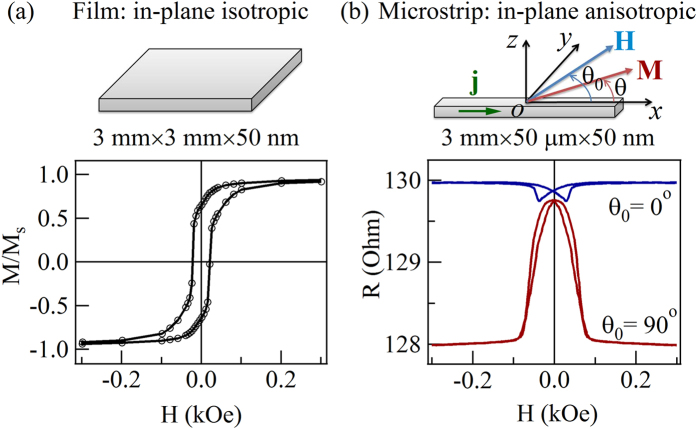

First, we measured the magnetic hysteresis loops of Co film with in-plane applied magnetic field  along different directions. All of the in-plane hysteresis loops were the same as shown in Fig. 1(a), which indicated that the Co film is in-plane isotropic. The saturation magnetization

along different directions. All of the in-plane hysteresis loops were the same as shown in Fig. 1(a), which indicated that the Co film is in-plane isotropic. The saturation magnetization  = 16.5 kOe and coercivity

= 16.5 kOe and coercivity  = 27.5 Oe. However, because of the very small volume of the microstrip (approximately

= 27.5 Oe. However, because of the very small volume of the microstrip (approximately  cm3), the maximal signal was approximately

cm3), the maximal signal was approximately  emu, which is close to the resolution of the VSM. Then we used anisotropy magnetoresistance (AMR) curves (magnetoresistance as a function of magnetic field

emu, which is close to the resolution of the VSM. Then we used anisotropy magnetoresistance (AMR) curves (magnetoresistance as a function of magnetic field  ) to identify the in-plane anisotropy of the microstrip, as shown in Fig. 1(b) where

) to identify the in-plane anisotropy of the microstrip, as shown in Fig. 1(b) where  is the angle of the applied magnetic field with respect to the long axis of the Co micro-strip.The significant differences between the curves show that the Co micro-strip is magnetic anisotropic. Comparing the results of Fig. 1(a) with Fig. 1(b), we can conform that the anisotropy of the Co microstrip originated from the shape anisotropy, and that the effective anisotropy field is approximately 80 Oe. Then, the problem becomes the following: how do we get the accurate value of anisotropy field? As noted in the method section, the torque method can accurately measure anisotropy constants

is the angle of the applied magnetic field with respect to the long axis of the Co micro-strip.The significant differences between the curves show that the Co micro-strip is magnetic anisotropic. Comparing the results of Fig. 1(a) with Fig. 1(b), we can conform that the anisotropy of the Co microstrip originated from the shape anisotropy, and that the effective anisotropy field is approximately 80 Oe. Then, the problem becomes the following: how do we get the accurate value of anisotropy field? As noted in the method section, the torque method can accurately measure anisotropy constants  and

and  by fitting the torque curve. Can the rotating anisotropy magnetorsistance (RAMR)

by fitting the torque curve. Can the rotating anisotropy magnetorsistance (RAMR)  curves give the accurate value of the shape anisotropy? Before we introduce the experiment results, comprehension of the features of the RAMR curve is necessary.

curves give the accurate value of the shape anisotropy? Before we introduce the experiment results, comprehension of the features of the RAMR curve is necessary.

Figure 1. The magnetic properties of the Co film and Co strip.

(a) The magnetic hysteresis loop of Co film. (b) The magnetoresistance curves of a Co micro-strip at different  .

.

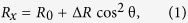

In the following, we calculate the RAMR curve at different magnetic field amplitudes by using the model shown in Fig. 1(b). The expression of AMR is given by11

|

where,  is ordinary resistance,

is ordinary resistance,  is the anisotropy magnetoresistance, and

is the anisotropy magnetoresistance, and  is the orientation of magnetization

is the orientation of magnetization  with respect to the current density

with respect to the current density  . Our first task is to determine

. Our first task is to determine  from the equilibrium condition when applying a magnetic field with amplitude

from the equilibrium condition when applying a magnetic field with amplitude  and direction

and direction  . Based on the coherent rotation model, the total energy is given by

. Based on the coherent rotation model, the total energy is given by

|

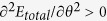

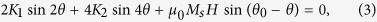

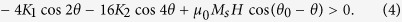

The equilibrium direction of magnetization is determined by the minimum of  with respect to

with respect to  , i.e.

, i.e.  and

and  ,

,

|

|

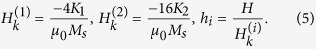

Considering  (i.e., the easy axis lies along the

(i.e., the easy axis lies along the  axis), the anisotropy field

axis), the anisotropy field  and reduced magnetic field

and reduced magnetic field  (

( = 1, 2, 3

= 1, 2, 3 ) can be defined as:

) can be defined as:

|

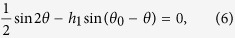

If we ignore  temporarily for a simple case, Eqs. (3) and (4) can be simplified as

temporarily for a simple case, Eqs. (3) and (4) can be simplified as

|

|

Based on Eqs. (6) and (7), we can calculate the relation of  with any selected

with any selected  value. Putting

value. Putting  into Eq. (1), the angular dependence of the magnetoresistance (i.e., the RAMR curve

into Eq. (1), the angular dependence of the magnetoresistance (i.e., the RAMR curve  ) can be obtained. Supposing

) can be obtained. Supposing  = 100

= 100  ,

,  = 2

= 2  , the

, the  curves have been calculated at different

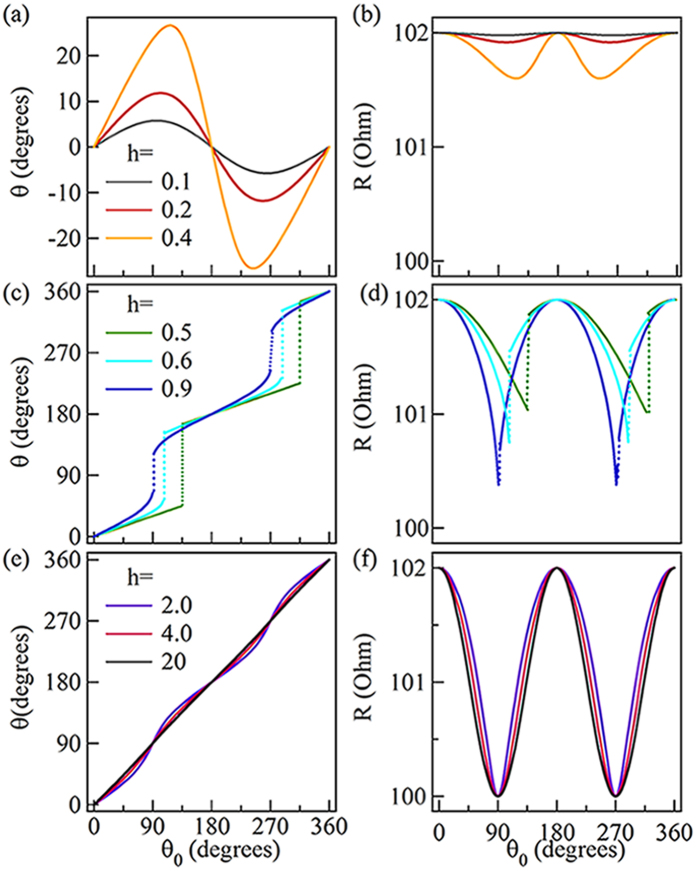

curves have been calculated at different  ; as shown in Fig. 2. Those curves can be divided into three groups with quite different features. Group 1:

; as shown in Fig. 2. Those curves can be divided into three groups with quite different features. Group 1:  , as shown in Fig. 2(a,b), both the

, as shown in Fig. 2(a,b), both the  curves and

curves and  curves are continuous, and have a period of

curves are continuous, and have a period of  , which indicates that the magnetization process is reversible under small applied magnetic fields. Group 2:

, which indicates that the magnetization process is reversible under small applied magnetic fields. Group 2:  ; as shown in Fig. 2(c,d), the curves are obtained at relatively high applied fields. It is found that the periods of these curves are

; as shown in Fig. 2(c,d), the curves are obtained at relatively high applied fields. It is found that the periods of these curves are  rather than

rather than  , and that two “jumps” appear, which makes the curves discontinuous. The “jumps” results from an irreversible rotation of magnetization from current state to a more steady equilibrium state at critical values of

, and that two “jumps” appear, which makes the curves discontinuous. The “jumps” results from an irreversible rotation of magnetization from current state to a more steady equilibrium state at critical values of  45. Group 3:

45. Group 3:  ; as plotted in Fig. 2(e,f), although the period is

; as plotted in Fig. 2(e,f), although the period is  , the curves become continuous again, which indicates that the magnetization is approaching the saturation state.

, the curves become continuous again, which indicates that the magnetization is approaching the saturation state.

Figure 2. The calculated  curves and RAMR curves.

curves and RAMR curves.

(a,c,e) The calculated  curves at different

curves at different  . (b,d,f) The magnetoresistance (

. (b,d,f) The magnetoresistance ( ) as a function of

) as a function of  at different

at different  .

.

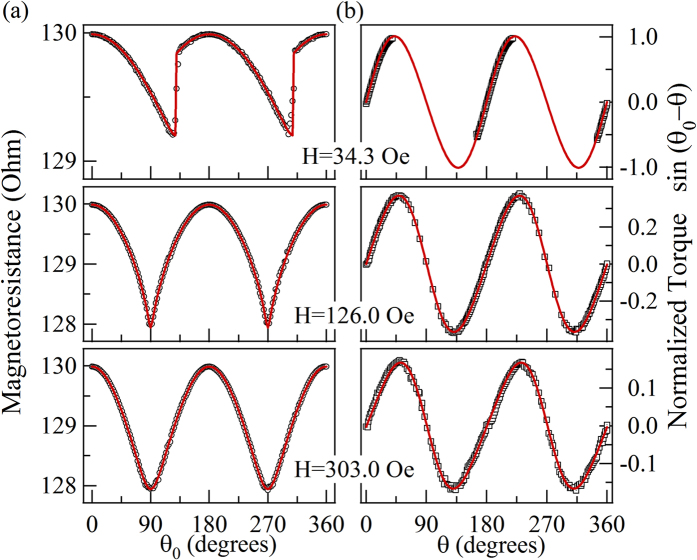

Immediately thereafter, we measured the RAMR curves of the Co micro-strip at different H, and the raw data (symbols) are shown in Fig. 3(a). The RAMR curve measured at H = 34.3 Oe has features similar to the second group’s theoretical curves shown in Fig. 2(d), wherein two obvious “jumps” can be observed. The curves measured at H = 126.0 Oe and 303.0 Oe look similar to those of the third group shown in Fig. 2(f). Therefore, our experimental results are basically consistent with the theory. We also measured the  curve at H = 22 Oe, which should be corresponding to the case of the first group. However, as the applied magnetic field is relative small, the magnetization switching mechanism is domain wall motion rather than coherent rotation as shown in supplementary material. Thus, the cases

curve at H = 22 Oe, which should be corresponding to the case of the first group. However, as the applied magnetic field is relative small, the magnetization switching mechanism is domain wall motion rather than coherent rotation as shown in supplementary material. Thus, the cases  are not suitable for determining the anisotropy constants, we did not add the cases

are not suitable for determining the anisotropy constants, we did not add the cases  in this letter.

in this letter.

Figure 3. The RAMR curves and normalized torque curves obtained in different magnetic fields.

(a) Symbols represent experimental  curves measured at

curves measured at  = 34.3 Oe, 126.0 Oe, and 303.0 Oe respectively; red lines are calculated curves used for corresponding fitted anisotropy constants. (b) The data of normalized torque curves

= 34.3 Oe, 126.0 Oe, and 303.0 Oe respectively; red lines are calculated curves used for corresponding fitted anisotropy constants. (b) The data of normalized torque curves  as a function of

as a function of  ; symbols are experimental data and the solid curves are fitting curves based on Eq. (8).

; symbols are experimental data and the solid curves are fitting curves based on Eq. (8).

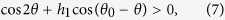

An accurate anisotropy field can be obtained by fitting the normalized torque curves  , as shown in Fig. 3(b). The angle

, as shown in Fig. 3(b). The angle  was calculated from the RAMR curves by using Eq. (1) with

was calculated from the RAMR curves by using Eq. (1) with  and

and  , as determined previously. The fitting function is a transformation of Eq. (3), given by

, as determined previously. The fitting function is a transformation of Eq. (3), given by

|

As shown in Fig. 3(b), the experimental results can be well fitted with that equation, which gives birth to the values of  and

and  . Moreover, the anisotropy constants

. Moreover, the anisotropy constants  and

and  can be calculated using Eq. (5), as shown in Table 1. However, the values of

can be calculated using Eq. (5), as shown in Table 1. However, the values of  (

( ) shown in the table differ from one another. To verify whether those values are correct, we took the values of

) shown in the table differ from one another. To verify whether those values are correct, we took the values of  ,

,  and

and  in the table back to Eq. (3) and (4), and then calculated the

in the table back to Eq. (3) and (4), and then calculated the  curves, i.e. the red curves shown in Fig. 3(a). The well matching between the experimental data and calculated curves indicates that all of the values shown in the table are correct. In the supplement, there is a discussion about the importance of higher-order terms in the fitting results, which is the circumstantial evidence of the accuracy of this method.

curves, i.e. the red curves shown in Fig. 3(a). The well matching between the experimental data and calculated curves indicates that all of the values shown in the table are correct. In the supplement, there is a discussion about the importance of higher-order terms in the fitting results, which is the circumstantial evidence of the accuracy of this method.

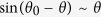

Table 1. The magnetic anisotropy parameters measured at different H.

|

|

|

|

|

|---|---|---|---|---|

| (Oe) | (Oe) | (Oe) | (kerg/cm3) | (kerg/cm3) |

| 34.3 | 68.8 | 7.3 | −22.58 | −0.60 |

| 126.0 | 92.0 | −13.6 | −30.20 | 1.12 |

| 303.0 | 99.0 | −20.8 | −32.50 | 1.71 |

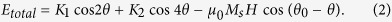

The difference between  and

and  determined under different

determined under different  unveils a fundamental issue in magnetism: the shape anisotropy not only is determined by the shape itself, but also depends on the applied magnetic field. It has been written in every textbook of magnetism that the shape anisotropy of any non-ellipsoid magnet is a complicated issue because of the non-uniform magnetization. Therefore, it is not surprising that the shape anisotropy is field dependent. However, because the non-uniform magnetization cannot be quantified simply, theoretical calculations of shape anisotropy in non-ellipsoid magnets are quite complicated. Because accurate anisotropy constants can now be experimentally determined, we systematically measured the shape anisotropy constants at different

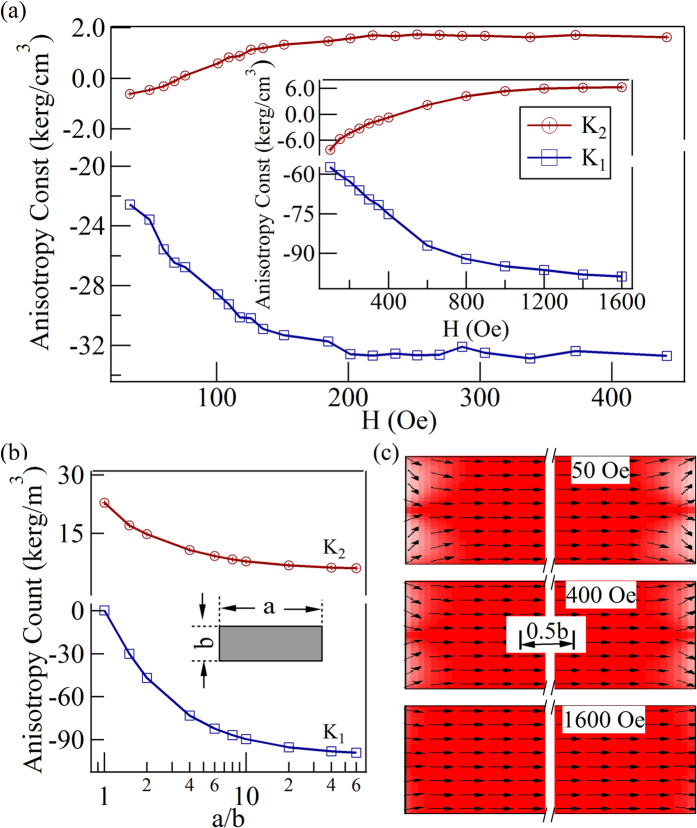

unveils a fundamental issue in magnetism: the shape anisotropy not only is determined by the shape itself, but also depends on the applied magnetic field. It has been written in every textbook of magnetism that the shape anisotropy of any non-ellipsoid magnet is a complicated issue because of the non-uniform magnetization. Therefore, it is not surprising that the shape anisotropy is field dependent. However, because the non-uniform magnetization cannot be quantified simply, theoretical calculations of shape anisotropy in non-ellipsoid magnets are quite complicated. Because accurate anisotropy constants can now be experimentally determined, we systematically measured the shape anisotropy constants at different  as shown in Fig. 4(a). It is found that when

as shown in Fig. 4(a). It is found that when  200 Oe, both the amplitudes of

200 Oe, both the amplitudes of and

and vary obviously with

vary obviously with  ; when H > 200 Oe,

; when H > 200 Oe,  and

and are saturated. Those experimental results can be further supported by the simulated

are saturated. Those experimental results can be further supported by the simulated  dependent

dependent  and

and  , as in the insert shown in Fig. 4(a). We calculated the angular dependent demagnetization energy curves and fitted them with

, as in the insert shown in Fig. 4(a). We calculated the angular dependent demagnetization energy curves and fitted them with  to determine the values of

to determine the values of and

and . The OOMMF46 was used to simulate the demagnetization energy of a Co strip. In the simulations, the Co strip had a length

. The OOMMF46 was used to simulate the demagnetization energy of a Co strip. In the simulations, the Co strip had a length  μm, and width

μm, and width  m, which has the same aspect ratio as our sample; the strip thickness was

m, which has the same aspect ratio as our sample; the strip thickness was  nm, and the unit cell size was 5 × 5 × 5 nm3. Material parameters used were typical for Co, namely, saturation magnetization

nm, and the unit cell size was 5 × 5 × 5 nm3. Material parameters used were typical for Co, namely, saturation magnetization  Am−1, and exchange stiffness constant

Am−1, and exchange stiffness constant  Jm−1 47. As shown in Fig. 4(a), the simulative curves (inset) have the same tendency as the experimental curves, which indicates that the measured results of

Jm−1 47. As shown in Fig. 4(a), the simulative curves (inset) have the same tendency as the experimental curves, which indicates that the measured results of  -dependent

-dependent  and

and  are reasonable.

are reasonable.

Figure 4. The magnetic field-and aspect ratio-dependent anisotropy constants.

(a) The relationship between anisotropy constants and magnetic field; the insert is the simulative result. (b) The simulative  and

and  as a function of the rate of a:b. (c) The distribution of magnetic moments at different magnetic fields obtained by the micro-magnetic simulation.

as a function of the rate of a:b. (c) The distribution of magnetic moments at different magnetic fields obtained by the micro-magnetic simulation.

To present a visualized picture of how the non-uniform magnetization affects the values and polarities of  and

and , the distributions of

, the distributions of  in a squareness ratio a/b = 60:1 Co strip were simulated with applied magnetic field

in a squareness ratio a/b = 60:1 Co strip were simulated with applied magnetic field  = 50 Oe, 400 Oe and 1600 Oe, as shown in Fig. 4(c). The arrows represent the direction of

= 50 Oe, 400 Oe and 1600 Oe, as shown in Fig. 4(c). The arrows represent the direction of  , and the color stands for the amplitude of the magnetic moment along the strip. Obviously, the non-uniformed magnetization emerges at the edge of the strip. With an increasing magnetic field, the magnetization distribution becomes uniform, which can be directly linked to the

, and the color stands for the amplitude of the magnetic moment along the strip. Obviously, the non-uniformed magnetization emerges at the edge of the strip. With an increasing magnetic field, the magnetization distribution becomes uniform, which can be directly linked to the  -dependent

-dependent  and

and  . Therefore, for non-uniformly magnetized magnets, the shape anisotropy depends not only on the shape, but also on the magnetization distribution controlled by the applied magnetic field. In the following, we want to discuss the polarity of the anisotropy constants. Both the experimental and simulation results show that

. Therefore, for non-uniformly magnetized magnets, the shape anisotropy depends not only on the shape, but also on the magnetization distribution controlled by the applied magnetic field. In the following, we want to discuss the polarity of the anisotropy constants. Both the experimental and simulation results show that  and

and  have opposite polarity (

have opposite polarity ( and

and  ) in the saturation status. The polarity actually represents the direction of the easy axis. To illustrate this argument, we simulated the values of

) in the saturation status. The polarity actually represents the direction of the easy axis. To illustrate this argument, we simulated the values of  and

and  as functions of the squareness ratio with a sufficiently large applied magnetic field

as functions of the squareness ratio with a sufficiently large applied magnetic field  = 1600 Oe as shown in Fig. 4(b). When the squareness ratio is 1:1,

= 1600 Oe as shown in Fig. 4(b). When the squareness ratio is 1:1,  = 0,

= 0,  , the anisotropy energy can be written as

, the anisotropy energy can be written as  , and the minimum of

, and the minimum of  appears at

appears at  =

=  i.e. the easy axis is along the cater-corner, which is consistent with the previously reported results47. When the squareness ratio

i.e. the easy axis is along the cater-corner, which is consistent with the previously reported results47. When the squareness ratio  ,

,  decreases slightly and

decreases slightly and  appears with negative values. The amplitude of

appears with negative values. The amplitude of  increases rapidly and becomes dominant, which means that the easy axis is along the strip.

increases rapidly and becomes dominant, which means that the easy axis is along the strip.

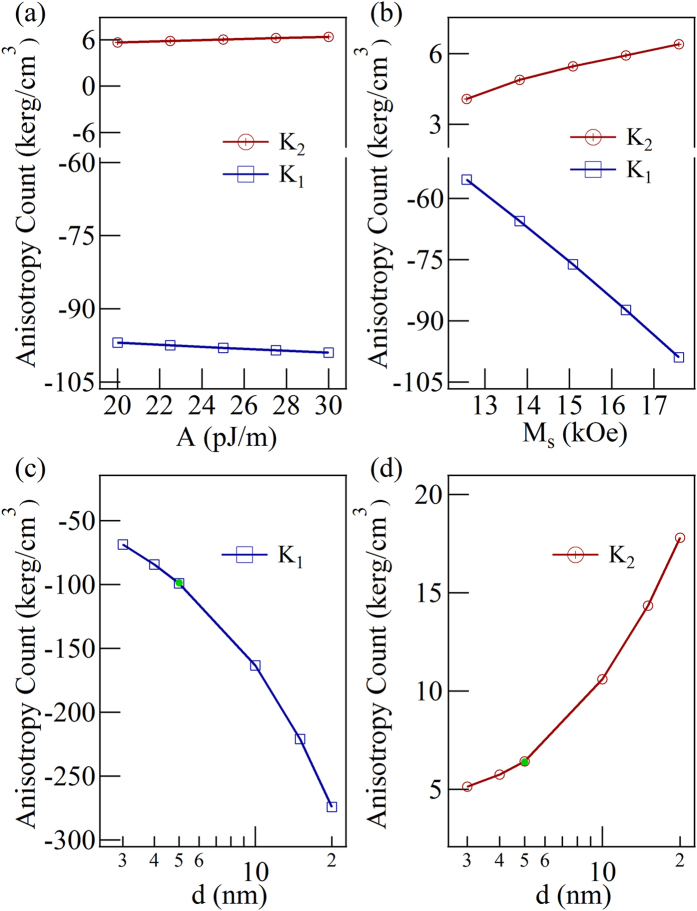

We studied the influences of effective exchange stiffness constant  , saturation magnetization

, saturation magnetization  , and film thickness

, and film thickness  on the values of the shape anisotropy obtained at saturation magnetized condition using simulation. We changed one parameter for the simulation while the other parameters remained the same as the previous ones. As show in Fig. 5(a), the anisotropy constants did not vary significantly while

on the values of the shape anisotropy obtained at saturation magnetized condition using simulation. We changed one parameter for the simulation while the other parameters remained the same as the previous ones. As show in Fig. 5(a), the anisotropy constants did not vary significantly while  changed from

changed from  Jm−1 to

Jm−1 to  Jm−1. As show in Fig. 5(b), while the

Jm−1. As show in Fig. 5(b), while the  changed from 12.6 kOe (

changed from 12.6 kOe ( Am−1) to 17.6 kOe (

Am−1) to 17.6 kOe ( Am−1), the amplitude of

Am−1), the amplitude of  and

and  increased almost linearly with

increased almost linearly with  , which is the nature of demagnetization energy. Moreover, the simulations with the cases where

, which is the nature of demagnetization energy. Moreover, the simulations with the cases where  = 3 nm (cell sizes =

= 3 nm (cell sizes =  nm3), 4 nm (cell sizes =

nm3), 4 nm (cell sizes =  nm3), 5 nm, 10 nm, 15 nm, and 20 nm (cell sizes =

nm3), 5 nm, 10 nm, 15 nm, and 20 nm (cell sizes =  nm3) were performed, as shown in Fig. 5(c,d). Additionally, the green points represented the simulated results of

nm3) were performed, as shown in Fig. 5(c,d). Additionally, the green points represented the simulated results of  = 5 nm using smaller cell size

= 5 nm using smaller cell size  nm3, which is consistent with previous case. Therefore, the influence of the unit cell size on the simulation results can be ignored. It should be noted that the simulated values for

nm3, which is consistent with previous case. Therefore, the influence of the unit cell size on the simulation results can be ignored. It should be noted that the simulated values for  (

( ) in Fig. 4(a) are different from the experimental ones, the main reason comes from the thickness we used for the simulations. The size of the experimental sample was 3 mm

) in Fig. 4(a) are different from the experimental ones, the main reason comes from the thickness we used for the simulations. The size of the experimental sample was 3 mm  50

50  m × 50 nm; to meet the proportion, the size of the simulated strip should be 30

m × 50 nm; to meet the proportion, the size of the simulated strip should be 30  m × 0.5

m × 0.5  m × 0.5 nm. However, if we use cell sizes =

m × 0.5 nm. However, if we use cell sizes =  nm3, the simulation would be far beyond our calculation ability. According to the tendency shown in Fig. 5(c,d), the value of

nm3, the simulation would be far beyond our calculation ability. According to the tendency shown in Fig. 5(c,d), the value of  (

( ) may reach −35 kerg/cm3 (2.2 kerg/cm3) when

) may reach −35 kerg/cm3 (2.2 kerg/cm3) when  = 0.5 nm, which is close to the experimental values.

= 0.5 nm, which is close to the experimental values.

Figure 5. The simulated anisotropy constants change with the exchange stiffness constant, saturation magnetization and thickness.

(a) The relationship between anisotropy constants and the amplitude of the exchange stiffness constant. (b) The simulated  and

and  as a function of the saturation magnetization. (c) The thickness dependent anisotropy constant

as a function of the saturation magnetization. (c) The thickness dependent anisotropy constant  . (d) The thickness dependent anisotropy constant K2.

. (d) The thickness dependent anisotropy constant K2.

In fact, the shape anisotropy, which originates from the dipolar-dipolar interaction, is an old but fundamental problem in magnetism. The difficulty in calculating of shape anisotropy in non-ellipsoid magnets comes from the fact that non-uniform magnetization cannot be simply quantified. Because we can now quantify accurately the shape anisotropy which is closely related to the non-uniform magnetization, the magnetic field-dependent  and

and  determined by our method may be semi-quantificational parameters for describing non-uniform magnetization. From the application perspective, both shape anisotropy and non-uniform magnetization are important in designing and understanding the performance of micro- and nano-scale patterned ferromagnetic units as well as the related device properties.

determined by our method may be semi-quantificational parameters for describing non-uniform magnetization. From the application perspective, both shape anisotropy and non-uniform magnetization are important in designing and understanding the performance of micro- and nano-scale patterned ferromagnetic units as well as the related device properties.

Conclusions

In conclusion, based on the RAMR method, the shape anisotropy of a Co micro-strip was systematically studied. It was found that using only demagnetization factor is not sufficient to describe the shape anisotropy of non-ellipsoid magnets, and that non-uniform magnetization would result in an  -dependent anisotropy. These results have also been demonstrated through micromagnetic simulations.

-dependent anisotropy. These results have also been demonstrated through micromagnetic simulations.

Additional Information

How to cite this article: Fan, X. et al. Magnetic field-dependent shape anisotropy in small patterned films studied using rotating magnetoresistance. Sci. Rep. 5, 16139; doi: 10.1038/srep16139 (2015).

Supplementary Material

Acknowledgments

The project is supported by the National Basic Research Program of China (No.: 2012CB933101), NSFC (No.: 61102001), and the Program for Changjiang Scholars and Innovative Research Team in University (No.: IRT1251).

Footnotes

Author Contributions X.L.F. and H.A.Z. provide the idea and designed this study. H.A.Z. performed the experiments under the guidance of X.L.F. and D.S.X. J.W.R., X.B.Z., J.Z.H. and F.Z.Z. participated in the coordination of the study. D.S.X. and X.L.F. provide the fund support. All authors discussed the results. H.A.Z. and X.L.F. completed the manuscript. All authors read and approved the final manuscript.

References

- Holstein T. & Primakoff H. Field dependence of the intrinsic domain magnetization of a ferromagnet. Phys. Rev. 58, 1098 (1940). [Google Scholar]

- Pardavi-Horvath M., Yan J. & Peverley J. R. Nonuniform internal field in planar ferrite elements. IEEE Trans. Magn. 37, 3881 (2001). [Google Scholar]

- Kobayashi M. & Ishikawa Y. Surface magnetic charge distributions and demagnetizing factors of circular cylinders. IEEE Trans. Magn. 28, 1810 (1992). [Google Scholar]

- Osborn J. A. Demagnetizing factors of the general ellipsoid. Phys. Rev. 67, 351 (1945). [Google Scholar]

- Dubowik J. Shape anisotropy of magnetic heterostructures. Phys. Rev. B 56, 4088 (1996). [DOI] [PubMed] [Google Scholar]

- Jonsson T., Nordblad P. & Svedlindh P. Dynamic study of dipole-dipole interaction effects in a magnetic nanoparticle system. Phys. Rev. B 57, 497 (1998). [Google Scholar]

- Li Z. B., Zhang M., Shen B. G. & Sun J. R. Non-uniform magnetization reversal in nanocomposite magnets. Appl. Phys. Lett. 102, 102405 (2013). [Google Scholar]

- Chen D., Pardo E. & Sanchez A. Demagnetizing factors of rectangular prisms and ellipsoids. IEEE Trans. Magn. 38, 1742 (2002). [Google Scholar]

- Joseph R. I. & Schlämann E. Demagnetizing field in n onellipsoidal bodies. J. Appl. Phys. 36, 5 (1965). [Google Scholar]

- Fluitman J. H. J. The influence of sample geometry on the magnetoresistance of ni-fe films. Thin Solid Films 16, 269–276 (1973). [Google Scholar]

- Kima D. Y., Kimb C. G., Parkb B. S. & Parkc C. M. Thickness dependence of planar hall resistance and field sensitivity in nio(30 nm)/nife(t) bilayers. J. Magn. Magn. Mater. 215–216, 585–588 (2000). [Google Scholar]

- Lu Y. et al. Shape-anisotropy-controlled magnetoresistive response in magnetic tunnel junctions. Appl. Phys. Lett. 70, 2610 (1997). [Google Scholar]

- Kimura T. & Wakaya F. K. G. Control of magnetization rotation using submicron-wide cross geometry. J. Magn. Magn. Mater. 248, 286–291 (2002). [Google Scholar]

- Lin M., Fan X. L., Zhang Z. M., Guo D. W. & Xue D. S. In-plane uniaxial anisotropy induced by two-phase stripelike magnetic hybrid structure. J. Appl. Phys. 106, 123912 (2009). [Google Scholar]

- Fayling R. E. Relationship between coercive force and anisotropy field for oriented barium ferrite tapes and magnets. J. Appl. Phys. 49, 1823 (1978). [Google Scholar]

- Strnat K., Hoffer G., Olson J., Ostertag W. & Becker J. J. A family of new cobalt-base permanent magnet materials. J. Appl. Phys. 38, 1001 (1967). [Google Scholar]

- Scholl R., Elk K. & Jahn L. Application of the spd-method to crystalline and polycrystalline permanent magnetic materials. J. Magn. Magn. Mater. 82, 1–3 (1989). [Google Scholar]

- Nishioy H. et al. A comparison of magnetic anisotropy constants and anisotropy fields of permanent magnets determined by various measuring methods. J. Phys. D: Appl. Phys. 29, 2240 (1996). [Google Scholar]

- Palmer W. Magnetocrystalline anisotropy of magnetite at low temperature. Phys. Rev. 131, 1057 (1963). [Google Scholar]

- Aubert G. Torque measurements of the anisotropy of energy and magnetization of nickel. J. Appl. Phys. 39, 504 (1968). [Google Scholar]

- Kouvel J. S. & Graham C. D. On the determination of magnetocrystalline anisotropy constants from torque measurements. J. Appl. Phys. 28, 340 (1957). [Google Scholar]

- Zhou H. et al. Electric field controlled reversible magnetic anisotropy switching studied by spin rectification. Appl. Phys. Lett. 104, 102401 (2014). [Google Scholar]

- Fan X. et al. Rapid characterizing of ferromagnetic materials using spin rectification. Appl. Phys. Lett. 105, 262404 (2014). [Google Scholar]

- Jalali-Roudsar A. A., Denysenkov V. P. & Khartsev S. I. Determination of magnetic anisotropy constants for magnetic garnet epitaxial films using ferromagnetic resonance. J. Magn. Magn. Mater. 288, 15–21 (2005). [Google Scholar]

- Heinrich B. & Cochran J. Ultrathin metallic magnetic films: magnetic anisotropies and exchange interactions. Adv. in Phys. 42, 15–21 (1993). [Google Scholar]

- Kittel C. On the theory of ferromagnetic resonance absorption. Phys. Rev. 73, 155 (1948). [Google Scholar]

- Chappert C., Dang K. L., Beauvillain P., Hurdequint H. & Renard D. Ferromagnetic resonance studies of very thin cobalt films on a gold substrate. Phys. Rev. B 34, 3192 (1986). [DOI] [PubMed] [Google Scholar]

- Farle M. Ferromagnetic resonance of ultrathin metallic layers. Rep. Prog. Phys. 61, 755 (1998). [Google Scholar]

- Bickford L. R. Ferromagnetic resonance absorption in magnetite single crystals. Phys. Rev. 78, 449 (1950). [Google Scholar]

- Heinrich B. et al. Ferromagnetic-resonance study of ultrathin bcc fe(100) films grown epitaxially on fcc ag(100) substrates. Phys. Rev. Lett. 59, 1756 (1987). [DOI] [PubMed] [Google Scholar]

- Liu X., Sasaki Y. & Furdyna J. K. Ferromagnetic resonance in ga1-xmnxas: Effects of magnetic anisotropy. Phys. Rev. B 67, 205204 (2003). [Google Scholar]

- Schlämann E., Green J. J. & Milano U. Recent developments in ferromagnetic resonance at high power levels. J. Appl. Phys. 31, 386 (1960). [Google Scholar]

- Costache M. V., Watts S. M., Sladkov M., van der Wal C. H. & van Wees B. J. Large cone angle magnetization precession of an individual nanopatterned ferromagnet with dc electrical detection. Appl. Phys. Lett 89, 232115 (2006). [Google Scholar]

- Harder M., Cao Z. X., Gui Y. S., Fan X. L. & Hu C.-M. Analysis of the line shape of electrically detected ferromagnetic resonance. Phys. Rev. B 84, 054423 (2011). [Google Scholar]

- Zhu X. F. et al. Dielectric measurements via a phase-resolved spintronic technique. Phys. Rev. B 83, 104407 (2011). [Google Scholar]

- Gui Y. S., Mecking N., Zhou X., Williams G. & Hu C. M. Realization of a room-temperature spin dynamo: The spin rectification effect. Phys. Rev. Lett. 98, 107602 (2007). [DOI] [PubMed] [Google Scholar]

- Wirthmann A. et al. Direct phase probing and mapping via spintronic michelson interferometry. Phys. Rev. Lett. 105, 017202 (2010). [DOI] [PubMed] [Google Scholar]

- Gui Y. S., Wirthmann A. & Hu C. C. Foldover ferromagnetic resonance and damping in permalloy microstrips. Phys. Rev. B 80, 184422 (2009). [Google Scholar]

- Gui Y. S., Wirthmann A., Mecking N. & Hu C.-M. Direct measurement of nonlinear ferromagnetic damping via the intrinsic foldover effect. Phys. Rev. B 80, 060402 (2009). [Google Scholar]

- Kiselev S. I. et al. Microwave oscillations of a nanomagnet driven by a spin-polarized current. Nature 425, 380 (2003). [DOI] [PubMed] [Google Scholar]

- Sankey J. C. et al. Spin-transfer-driven ferromagnetic resonance of individual nanomagnets. Phys. Rev. Lett. 96, 227601 (2006). [DOI] [PubMed] [Google Scholar]

- Sankey J. C. et al. Measurement of the spin-transfer-torque vector in magnetic tunnel junctions. Nat. Phys. 4, 67 (2008). [Google Scholar]

- Liu L., Moriyama T., Ralph D. C. & Buhrman R. A. Spin-torque ferromagnetic resonance induced by the spin hall effect. Phys. Rev. Lett. 106, 036601 (2011). [DOI] [PubMed] [Google Scholar]

- Sandweg C. W., Kajiwara Y., Ando K., Saitoh E. & Hillebrands B. Enhancement of the spin pumping efficiency by spin wave mode selection. Appl. Phys. Lett. 97, 252504 (2010). [Google Scholar]

- Fan X., Xue D., Jiang C., Gong Y. & Li J. An approach for researching uniaxial anisotropy magnet: Rotational magnetization. J. Appl. Phys. 102, 123901 (2007). [Google Scholar]

- Donahue M. & Porter D. Oommf user’s guide, version 1.0. interagency report nistir 6376. NIST (1999). [Google Scholar]

- Ren Y. et al. Tailoring coercivity and magnetic anisotropy of co nanowire arrays by microstructure. J. Mater. Sci. 46, 7545–7550 (2011). [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.