Abstract

Ultrafiltered milk (UF1 and UF2), ultrafiltrate retentate added milk (UF3 and UF4) and SMP added milk (UF0) were used for dahi preparation in the present study. Treatments were evaluated for rheological, textural and sensorial characteristics. Significant increase (p < 0.01) in values of firmness, stickiness, work of shear, work of adhesion and sensory scores, but significant decrease (p < 0.01) in whey syneresis values were observed with treatments UF1, UF2, UF3 and UF4 as compared to UF0. Principal component analysis (PCA) revealed that first four principal components (PC) explained 87.39 % relationship between samples and attributes. PC1 accounted for 48.34 % of data variance was characterized by protein content, firmness, work of shear, body & texture and opposed by total carbohydrates, stickiness, syneresis and work of adhesion. Total carbohydrates content (r = −0.982, P < 0.01), whey syneresis (r = −0.783, P < 0.01), stickiness (r = −0.729, P < 0.01) and work of adhesion (r = −0.684, P < 0.01) are negatively while body and texture (r = +0.600, P < 0.01), firmness (r = +0.574, P < 0.05) and work of shear (r = +0.538, P < 0.05) of dahi are highly positively correlated with protein content.

Keywords: Dahi, Firmness, PCA, Syneresis, Ultrafiltration

Introduction

Dahi is an age-old indigenous fermented milk product. It can be made from cow milk, buffalo milk or mixed milk but it should have the same percentage of fat and solids-non-fat as the milk from which it is prepared (Kurien and Mishra 2008). About 6.9 % of total milk produced in India is utilized for making dahi, intended for direct consumption (Khurana and Kanawjia 2007). Dahi with good quality should have a homogeneous body and smooth glossy surface; while the cut surface is trim and free from cracks, gas bubbles and whey pockets. It should be firm, solid and uniform with no whey separation (IS: 9617–1980). However, dahi available in local markets has several quality problems like whey syneresis, loose body, lumpiness, etc. Textural defects in set gel type products, like ‘lumpiness’, ‘granular’ or the presence of ‘nodules’ are objectionable, as consumers expect a smooth, fine-bodied product (Bodyfelt et al. 1988). Lumpiness usually refers to the presence of large protein aggregates in the product. These variations in the quality of dahi could be due to the differences in their total solids and fat contents, apart from optional treatments like homogenization and varying heat treatments given to milk. The level of total solids and protein plays a significant role in the development of desirable aroma and consistency of dahi (Garg and Jain 1980). Whey syneresis, also known as spontaneous separation of whey on the surface of dahi (set type yoghurt) is generally regarded as one of the major defects which could be eliminated by increasing the level of total milk solids (Amatayakul et al. 2006). Overall quality of dahi can be improved by pre-concentrating the proteins (up to a certain level) in milk through ultrafiltration (UF) process. Ultrafiltration is a sieving process that employs a membrane with definite pores that are large enough to permit the passage of water and small molecules. When a pressure is applied to a fluid, the semi-permeable membrane allows small species to pass through as permeate and larger species are retained and concentrated as retentate. In ultrafiltration of milk, non-protein nitrogen and soluble components such as lactose, salts, and some vitamins pass through the membrane, whereas milk fat, protein and insoluble salts are retained by the membrane (Glover 1985; Rollema and Muir 2009). The commercial UF membranes with nominal molecular weight cut-off size of 20,000 to 25,000 exclude all fat and almost all protein while permitting water, lactose, non-protein nitrogen compounds and soluble salts to pass through. Reported retention percentage for fat, protein, ash, not-protein nitrogen and total solids in ultrafiltration of milk, is 100, 93, 29, 62 and 54 %, respectively (Yan et al. 1979). UF concentrated milk has higher protein content; higher concentration of casein particles that leads to the reinforcement of protein matrix density and to the improvement of the firmness and water holding capacity of the gel (Sodini et al. 2004). Application of UF process has an advantage of controlled acidity development in the product due to reduced lactose content of milk and special advantage for the lactose intolerant people who cannot digest milk as excess lactose in milk leads to cramps or other digestive discomforts. To overcome quality related defects of dahi, present investigation was undertaken to produce good quality buffalo milk dahi employing UF technique.

Materials and methods

Materials

Milk

Fresh buffalo whole milk was procured from the Experimental Dairy of the National Dairy Research Institute, Karnal. Skim milk and cream were obtained by cream separation of buffalo milk by a laboratory cream separator (Chadha Electro Industries, Delhi) having capacity of 110 l/h.

Skim milk powder

Medium heat skim milk powder (SMP) made from mixed cow and buffalo milk having 3–4 whey protein nitrogen index (as per manufacturer’s report) was procured from M/s Modern Dairies Ltd., Karnal.

Starter culture

Mesophilic mixed starter culture strains of Lactococcus lactis ssp. Lactis, L. lactis ssp. Cremoris, L. lactis ssp. Diacetylactis and Leuconostoc citrovorum (NCDC-167) was procured from National Collection of Dairy Cultures, NDRI, Karnal. The starter culture was maintained by propagating in sterilized reconstituted skimmed milk (12 g 100 mL−1) by sub-culturing once in fortnight.

Packaging materials

Polystyrene cups of 100 mL with lids were obtained from Experimental Dairy of the National Dairy Research Institute, Karnal and used for packaging and storage of dahi.

Pretreatment of milk for dahi making

Cream separation

Buffalo whole milk was fore-warmed to 45–50 °C and separated in a cream separator to obtain cream (65–70 % fat) and skim milk (0.1–0.5 % fat).

Ultrafiltration

Skim milk was flash heated to 80 °C, cooled to about 55 °C and transferred into the balance tank (having capacity of 200 l) of a pilot ultrafiltration plant (Tech-Sep., France, tubular module) having ZrO2 membrane with surface area of 1.68 m2 and molecular weight cut off of 50,000 Da. Further, this skim milk was ultrafiltered to different desired UF concentrations (1.28 fold, 1.55 fold and 3.87 fold). Each fold was calculated on the basis of water removal from skim milk. During UF operation, the inlet and outlet pressures on the retentate side were maintained at 4.6 kg/cm2 and 3.6 kg/cm2, respectively. The permeate side pressure was kept at 1 kg/cm2 (Trans Membrane Pressure was 3.1 kg/cm2).

Standardization

Buffalo milk standardized to 3 % milk fat and 13.75 % total solids using previously separated skim milk and cream. The quality of dahi prepared at 3 % fat and 13.75 % total solids level was better than the dahi prepared at the same fat level but at 12.83 and 14.83 % total solids level (Meena et al. 2014). However, the levels of protein were varied by adding ultrafiltered retentate. UF retentate was added to four experimental batches or UF treatments viz. UF1 (1.28 fold ultrafiltered skim milk and cream); UF2 (3.87 fold ultrafiltered skim milk and cream); UF3 (1.55 fold ultrafiltered skim milk, cream and potable water) and UF4 (3.87 fold ultrafiltered skim milk, cream and potable water). The dahi batch made by recombining buffalo skim milk, skimmed milk powder and cream to contain 3 % milk fat and 13.75 % total solids was treated as control (UF0).

Production of dahi

Each batch of standardized milks was pre-heated to 65–70 °C and homogenized in a two-stage homogenizer (M/s Goma Engineers, Mumbai) at 13.78 and 3.44 MPa pressure in 1st and 2nd stage, respectively. Homogenized batches was heated to 85 °C for 30 min and then cooled to 30 °C. Starter culture (2 g per 100 mL) was added to each batch and filled into pre-sterilized polystyrene cups (100 mL−1). Incubation was carried out at 30 °C till the titratable acidity reached about 0.70 % lactic acid. Once the desired titratable acidity was achieved, without disturbing, set dahi cups were transferred to refrigerated storage (4 ± 1 °C). All the trials were carried out in triplicate.

Compositional analysis

Fat content of skim milk and ultrafiltered milks were determined by Gerber method (IS: 1224 part I-1977) and fat content of dahi was determined by Rose-Gottlieb method (IS: 1479 part II-1961). Protein content of skim milk, ultrafiltered milks and dahi were determined by semi-micro Kjeldahl method described by Menefee and Overman (1940) using Kjeltec digestion (2300, Kjeltec Analyzer, FOSS) and laboratory distillation equipment followed by manual method. Total solids content of skim milk, ultrafiltered milks and dahi were determined by Gravimetric method as described by Indian standards (IS: 12,333–1997). Ash content of skim milk, ultrafiltered milks and dahi was determined by Gravimetric method (IS: 1479 part III-1961). Total carbohydrates content of skim milk, ultrafiltered milks and dahi was determined by subtracting fat, protein and ash contents from the total solids content. Titratable acidity of dahi (as percent of lactic acid) was determined by adopting the standard method (IS: 1166–1973) with some modifications (addition of 30 ml warm distilled water in about 10 g of the dahi sample and addition of 1 ml of phenolphthalein indicator before titration). Micro processed pH meter (PHAN LABINDIA Model, Labtek Engg. Pvt. Ltd. India) was used for pH determination of dahi at 20 °C. All the analysis were carried out in triplicate.

Whey syneresis

Spontaneous whey syneresis of undisturbed set dahi was determined using a siphon method. In this study, 100 mL polystyrene cup containing 80 mL dahi was used for determining spontaneous whey separation. Dahi cups were taken out from the refrigerated storage (4 ± 1 °C), tempered to 20 °C and kept at an angle of approximately 45° to allow the whey on the surface to collect on the side of the cup. A needle connected to a syringe was used to siphon the liquid whey from the surface of the sample. Siphoning was carried out within 10 s to prevent further leakage of whey from the dahi gel. The syneresis was expressed as the volume of whey in mL. Average values of 3 replicates from three trails were calculated.

Texture analysis

Texture analysis of dahi was carried out with slight modifications in the method of Raju and Pal (2009). For determining the textural attributes, 80 mL quantity of control and standardized milk samples were incubated with starter culture in 100 ml pre-sterilized glass beakers. Texture analyser (TA-XT2i, M/s Stable Micro Systems, UK) was fitted with a 25-kg load cell and calibrated with a 5-kg standard dead weight prior to use. Texture analysis of set dahi samples was carried out at a temperature of 20 ± 0.5 °C by compression test using a 25 mm perplex cylindrical probe that generated plot of force (N) versus time (s). During the analysis, samples were compressed up to 20 mm of their original depth. The speed of the probe was 0.5 mm s−1 during the compression and 2 mm s−1 during pre-test and relaxation of the samples. From the resulting force-time curves, firmness, stickiness, work of shear and work of adhesion were calculated using the Texture Expert Exceed software (version 2.55) supplied by the manufacturer along with the instrument. Average values of 4 replicates from three trails were calculated.

Sensory evaluation

Dahi cups were randomly drawn from the refrigerator (4 ± 1 °C) and tempered to 20 °C by keeping at room temperature before presenting them for sensory evaluation. All the samples were evaluated by a panel of six discriminative and trained judges for the sensory attributes such as flavour (out of maximum score 45), body and texture (out of maximum score 30), acidity (out of maximum score 10), colour and appearance (out of maximum score 10) and overall acceptability (out of maximum score 100) using a 100 point score card suggested by Ranganadham and Gupta (1987).

Statistical analysis

Results obtained in the present study (mean value of three replicates) were subjected to one-way analysis of variance (ANOVA) using SAS Enterprise guide (5.1, 2012) developed by SAS Institute Inc., North Carolina, USA (SAS 2008) and represented by using Duncan’s Multiple Range Test values (Duncan 1955).

Results and discussion

Chemical composition

Chemical composition of buffalo skim milk, its retentate as obtained by 1.28, 1.55 and 3.87 folds UF concentration and dahi prepared with various treatments (UF0, UF1, UF2, UF3 and UF4) has been grossly reported in Table 1. It was observed that fat, protein and ash content increased, but total carbohydrate content decreased progressively with increase in UF concentration of milk. The content of total solids increased to a lesser extent compared with protein and fat, reflecting the loss of lactose and other soluble small molecular weight components. Similar findings were earlier reported by Patel and Mistry (1997) for the composition of 1.33, 2.0, 2.85 and 4.34 folds buffalo skim milk UF retentates. They observed that, during UF after 77 % weight reduction in buffalo skim milk the retention coefficients for the total solids, proteins, fat and ash in retentate were 52.52, 94.65,100 and 52.04 %, respectively. Gross chemical composition of dahi, prepared with different UF treatments met IS: 9617 (1980) specifications in all cases. Fat, total solids, titratable acidity and pH levels were maintained approximately same in all the treatments of dahi. It was observed that protein and ash contents increased and total carbohydrate content decreased progressively in dahi manufactured with the increase in UF concentration (UF1 and UF3) and UF retentate addition (UF2 and UF4). Lower amounts of total carbohydrate and ash content in UF1 compared UF2 and UF3 compared to UF4 could be due to their removal in larger amounts during UF (concentration) process. Renner and Abd El-Salam (1991); Atra et al. (2005) also reported that during ultrafiltration, the protein and fat of milk were retained completely in the retentate, whereas lactose, minerals and vitamins are partitioned between the retentate and permeate depending on the degree of concentration.

Table 1.

Chemical composition* of skim milk, UF retentates and dahi prepared with different treatments

| Components | TS (%) | Fat (%) | Protein (%) | Lactose (%) | Ash (%) | T.A. (% LA) | pH |

|---|---|---|---|---|---|---|---|

| Skim milk* | 9.98 ± 0.08 | 0.26 ± 0.03 | 3.80 ± 0.02 | 5.11 ± 0.04 | 0.79 ± 0.01 | 0.13 ± 0.004 | 6.65 ± 0.01 |

| UF retentate | |||||||

| 1.28 fold UF retentate | 10.99c ± 0.04 | 0.29b ± 0.04 | 4.78 ± 0.04 | 5.04a ± 0.04 | 0.87c ± 0.01 | 0.13b ± 0.00 | 6.67c ± 0.01 |

| 1.55 fold UF retentate | 12.07b ± 0.13 | 0.37b ± 0.05 | 5.78b ± 0.09 | 4.97b ± 0.03 | 0.95b ± 0.01 | 0.13ab ± 0.01 | 6.71b ± 0.00 |

| 3.87 fold UF retentate | 22.17a ± 0.35 | 0.97a ± 0.18 | 14.21a ± 0 0.38 | 4.48c ± 0.04 | 2.20a ± 0.02 | 0.14a ± 0.01 | 6.83a ± 0.01 |

| Standardized milk samples | |||||||

| UF0 | 13.75ns ± 0.03 | 3.06ns ± 0.00 | 4.25e ± 0.02 | 5.64a ± 0.04 | 0.85d ± 0.00 | 0.75ab ± 0.00 | 4.71ab ± 0.01 |

| UF1 | 13.79ns ± 0.01 | 3.07ns ± 0.00 | 4.83c ± 0.02 | 5.09c ± 0.05 | 0.88c ± 0.01 | 0.75a ± 0.00 | 4.71b ± 0.01 |

| UF2 | 13.8 ns ± 0.04 | 3.03ns ± 0.00 | 4.58d ± 0.01 | 5.28b ± 0.04 | 0.95a ± 0.01 | 0.74b ± 0.00 | 4.73a ± 0.00 |

| UF3 | 13.77ns ± 0.01 | 3.08ns ± 0.00 | 5.02a ± 0.02 | 4.85d ± 0.03 | 0.91b ± 0.01 | 0.75ab ± 0.00 | 4.72ab ± 0.00 |

| UF4 | 13.74ns ± 0.01 | 3.07ns ± 0.00 | 4.88b ± 0.01 | 4.89d ± 0.01 | 0.96a ± 0.02 | 0.75ab ± 0.00 | 4.73a ± 0.00 |

*Mean value of 3 trials ± S.E.; ns = non-significant at (p < 0.05), values for a particular column followed by different letters differ significantly (p < 0.05)

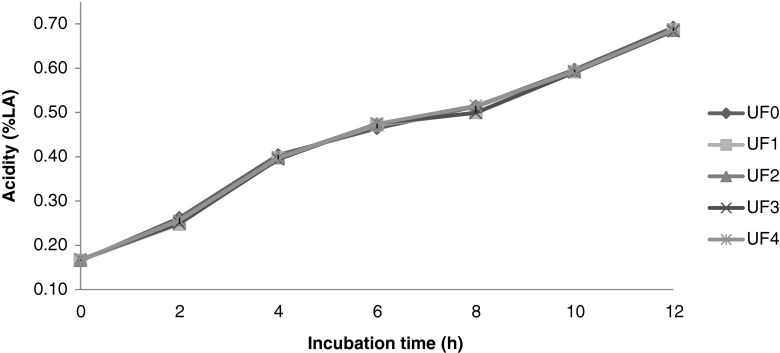

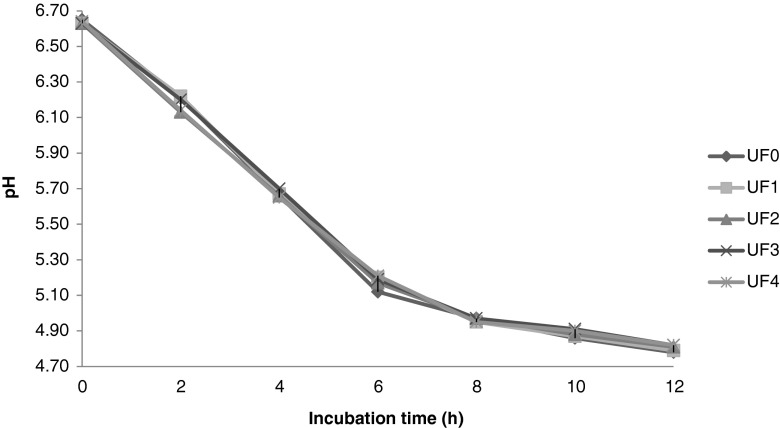

Acidity and pH

Average rate of titratable acidity development and related change in pH of dahi prepared with different treatments have been presented in Figs. 1and 2, respectively. It can observed that level of protein as well as total carbohydrates content of milk does not significantly affect the growth of microorganism and acidity development or decrease in pH, which may be due to lower difference in protein and lactose content. No difference in fermentation progress of yoghurt prepared with UF retentate and traditional method was also reported by Brazuelo et al. (1995). Isleten and Karagul-Yuceer (2006) also reported that fortification of yoghurt with skim milk powder did not have significant effect on pH development during fermentation.

Fig. 1.

Rate of acidity development in dahi prepared with different treatments

Fig. 2.

Rateof decrease in pH of dahi prepared with different treatments

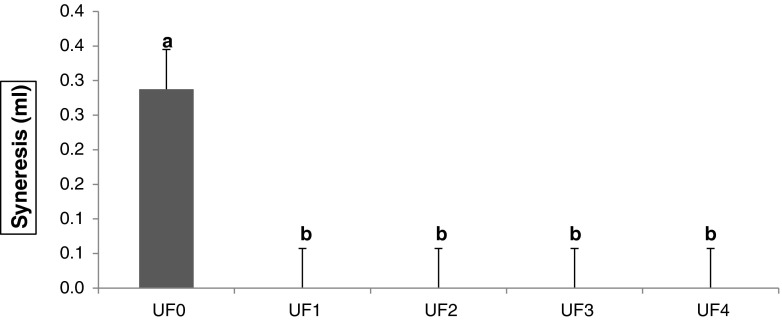

Whey syneresis

Whey syneresis is a common defect in set type fermented milk products such as yoghurt (Lucey 2001) and dahi. Dejmek and Walstra (1993) defines the syneresis as the shrinkage of gel and this occurs concomitantly with expulsion of liquid or whey separation and related to instability of the gel network resulting in the loss of the ability to entrap all the serum phase. The effect of different treatments on the syneresis values of dahi is shown in Fig. 3. Significant (p < 0.01) difference was observed between syneresis values of dahi prepared with control sample (UF0) and different ultrafiltration treatments (UF1, UF2, UF3 and UF4). It could be due to higher protein content in dahi prepared with ultrafiltration treatments. It has been shown in other studies that yoghurts prepared with protein-supplemented milk had low whey separation because of increasing water binding by protein. Garg and Jain (1980) also reported that whey syneresis decreased with increase in the protein content of curd. Savello and Dargan (1997) reported that concentration of milk for yoghurt with UF significantly diminished susceptibility of yoghurt to syneresis. Abd El-Khair (2009) concluded that yoghurts with added skim milk retentate displayed minimal free whey, whereas the control yoghurt was criticized for whey separation. Savello & Dargan, (1997) reported that, higher total solids content, particularly high protein content might be attributed to the less whey expulsion in yoghurt made with added skim milk retentate.

Fig. 3.

Effect of different treatments on the whey syneresis values of dahi. Abmean values of treatments within a graph with different letters significantly differ (p < 0.01)

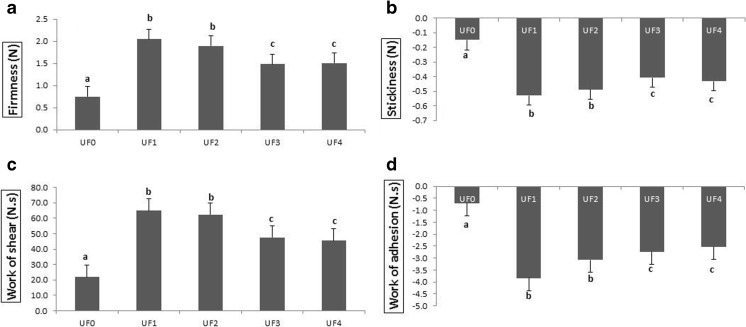

Textural properties

Effect of different treatments on the instrumental texture attributes such as, firmness, stickiness, work of shear and work of adhesion of dahi was given in Fig. 4. The force necessary to attain a given deformation, called as firmness, is a commonly evaluated parameter while determining the texture of set-type cultured dairy products. It is the height of the peak force on the first compression cycle. Stickiness is the negative force of the bite representing the work necessary to pull the compressing plunger away from the sample. Work of shear and work of adhesion are the area under the curve of positive peak (firmness) and negative peak (stickiness), respectively. There was a significant difference observed in firmness (p < 0.05), stickiness (p < 0.01), work of shear (p < 0.01) and work of adhesion (p < 0.01) values of dahi prepared with different treatments. Firmness of UF1 and UF2 treated dahi was observed to be significantly high (p < 0.05) compared to UF3, UF4 and control (UF0) samples. Also Firmness of dahi prepared with treatment UF3 and UF4 was observed to be significantly high (p < 0.05) compared to UF0. However, no statistical difference was observed in the firmness between UF3, UF4 and UF1 and UF2 dahi (p > 0.05). Stickiness of UF1 and UF2 treated dahi was significantly higher (p < 0.05) compared to UF3, UF4 and control (UF0). Moreover, stickiness of UF3 and UF4 treated dahi was significantly higher (p < 0.05) than UF0 treated dahi. However, the stickiness values of UF1 and UF2; UF3 and UF4 treated dahi samples were statistically not significant. Work of shear and work of adhesion of dahi had similar effects as that of firmness and stickiness. Lower firmness, stickiness, work of shear and work of adhesion of dahi prepared with treatments UF3 and UF4 may be due to the water addition for maintaining the same total solids level among all the treatments. Higher firmness, stickiness, work of shear and work of adhesion was observed in dahi prepared from ultrafiltration treatments, which could be due to the increase of protein content. Garg and Jain (1980) reported the same results and concluded that hardness and adhesiveness of curd increased with increase in the protein content. Abrahamsen and Holmen (1980) also reported that the yoghurt prepared with UF milk had higher firmness and viscosity compared to milk with added milk powder. Abd El-Khair (2009) reported that incorporation of skim milk retentate in yoghurt premix contributed to the increase of gel firmness when compared with the control yoghurt fortified only with skim milk powder. Each incremental increase in skim milk retentate required significantly greater force to penetrate the yoghurt gel, reflecting the effect of increased milk protein content (casein in particular) on gel firmness. Higher the protein content, the higher the firmness of yoghurts was observed. The reason for the somewhat lower firmness for yoghurt fortified only with skim milk powder, compared with that made with skim milk retentate added may be due to the partial denaturation of the whey proteins during the manufacture of milk powder. Increasing the total solids, especially milk protein, in yoghurt increased the density of the gel network and reduced pore size. Consequently, water is bound more firmly in the product, increasing the firmness of the yoghurt. White (1995) reported that increasing protein content in yoghurt resulted in an increase in the level of bound water (water of hydrated proteins) and led to firm and viscous yoghurts. Yoghurts made from milk concentrated by UF were firmer than those made from milk concentrated by evaporation or by the addition of skim milk powder (Becker and Puhan 1989; Savello and Dargan 1995) to similar protein levels.

Fig. 4.

Effect of different treatments on textural quality of dahi: a Firmness; b Stickiness c Work of shear; and b Work of adhesion. Abcmean values of treatments within a graph with different letters significantly differ (p < 0.05)

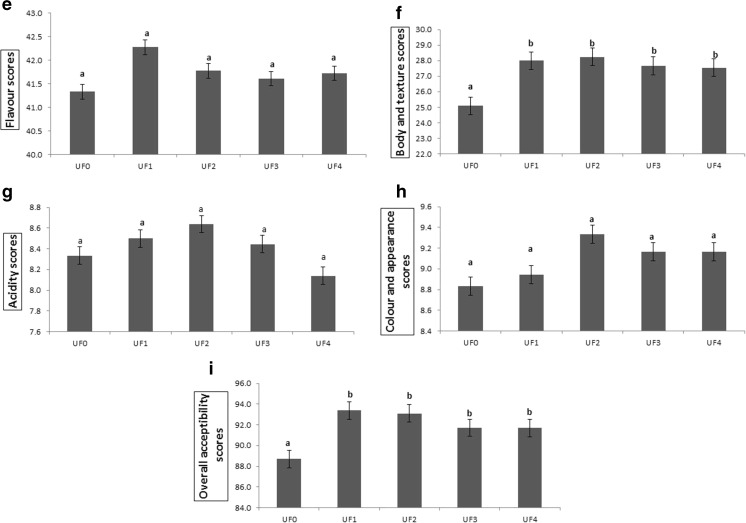

Sensory attributes

The effect of different treatments on the sensory attributes of prepared dahi has been presented in Fig. 5. Significant increase (p < 0.01) was observed between body and texture as well as overall acceptability scores of dahi prepared with different UF treatments (UF1, UF2, UF3 and UF4) than control sample (UF0). Statistical difference was not observed in flavour, colour and appearance and acidity scores of dahi prepared with different treatments. Also, body and texture and overall acceptability scores of dahi prepared with ultrafiltration treatment (UF1, UF2, UF3 and UF4) were not different from control (UF0). Better body and texture and overall acceptability scores of dahi prepared with ultrafiltration treatment may be due to higher level of protein content. Garg and Jain (1980) also reported that the dahi prepared from milk having higher protein content scored highest, but no significant difference was observed between the flavour and smoothness scores and concluded that higher the protein content, the better the overall quality of the dahi. Biliaderis et al. (1992) also reported that skim milk concentrated to 12 % total solids by UF process can yield yoghurt products of desirable flavour, constituent profiles, texture and other sensory attributes.

Fig. 5.

Effect of different treatments on sensory quality of dahi: e Flavour; f Body and texture g Acidity; h Colour and appearance; and i Overall acceptability. Abmean values of treatments within a graph with different letters significantly differ (p < 0.05)

Correlation between chemical, instrumental texture and sensory attributes of dahi

Total carbohydrates content (r = −0.982, P < 0.01), whey syneresis (r = −0.783, P < 0.01), stickiness (r = −0.729, P < 0.01) and work of adhesion (r = −0.684, P < 0.01) are negatively while body and texture (r = +0.600, P < 0.01), firmness (r = +0.574, P < 0.05) and work of shear (r = +0.538, P < 0.05) of dahi are highly positively correlated with protein content. Whey syneresis (r = +0.780, P < 0.01), stickiness (r = +0.697, P < 0.01) work of adhesion (r = +0.620, P < 0.01) are highly but body and texture (r = −0.608, P < 0.01), ash content (r = − 0.537, P < 0.05) and firmness (r = −0.527, P < 0.01) are negatively correlated with total carbohydrates content of the product. Body and texture (r = +0.559, P < 0.05), firmness (r = +0.452, P < 0.05) and pH content (r = +0.627, P < 0.01) of the product are positively but both stickiness (r = −0.982, P < 0.05) and whey syneresis (r = +0.982, P < 0.01) are negatively correlated with ash. Sensorial acidity (r = +0.468, P < 0.01) and instrumental work of adhesion (r = −0.445, P < 0.01) are positively and negatively correlated with total solids of the product. Product pH and acidity are negatively correlated with each other. Whey syneresis of dahi is highly correlated with stickiness (r = +0.873, P < 0.01) and work of adhesion but negatively correlated with firmness (r = −0.801, P < 0.01), work of shear (r = −0.789, P < 0.01), body and texture (r = −0.687, P < 0.01) and overall acceptability (r = −0.982, P < 0.05). Body and texture (r = +0.796, P < 0.01), overall acceptability (r = +0.686, P < 0.01) and work of shear (r = +0.993, P < 0.01) are highly but stickiness (r = −0.916, P < 0.01) and work of adhesion (r = −0.938, P < 0.01) are negatively correlated with product firmness. Overall acceptability (r = +0.816, P < 0.01), color and appearance (r = +0.695, P < 0.01) highly while body and texture (r = +0.482, P < 0.01) and sensory acidity (r = +0.583, P < 0.01) are also well correlated with flavour of the product. Color and appearance is highly correlated with overall acceptability (r = +0.634, P < 0.01) of the product.

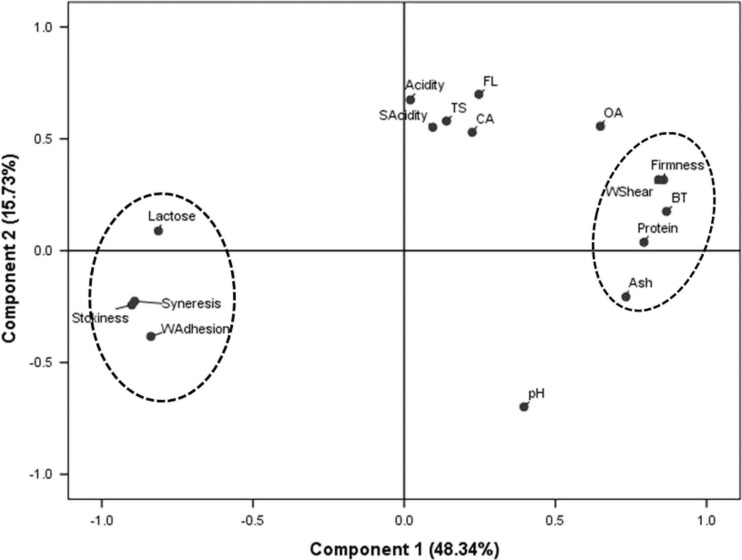

Principal component analysis (PCA)

PCA is a useful multivariate analysis procedure to describe interrelationships between multiple variables, which are achieved by reducing dimensions through lineal combinations of the original variables. PCA operation makes it possible to distinguish the fermented food samples and also identify the most important variables in a multivariate data set (Ghosh and Chattopadhyay 2012). In the present study, similarities and the differences among the sensory attributes, physico-chemical and instrumental textural attributes of 16 attributes were studied using PCA. PCA of the 16 variables from different treatments resulted in four principal components (Table 2) with eigenvalues greater than 1.0, a common statistical cut-off point (Frau et al. 1999; Chapman et al. 2001). In the present study, the first four principal components (PC) explained 87.39 % of the relationship between the samples and the attributes studied (Table 2). Figure 6 depicts the resulting biplot of the first two components of the attributes of dahi samples. PC1 which accounted for 48.34 % of the data variance was characterized by protein content, firmness, work of shear, body and texture and opposed by total carbohydrate, stickiness, syneresis and work of adhesion. PC2 explained 15.73 % of the variation and was defined by titratable and sensory acidity and total solids and opposed by pH. The literature pertaining to application of PCA in food science, which reveals that the variation attributed by PC1, could be as low as 47 %. In a study on the application of PCA for the characterization of desirable attributes of baker’s yeast, the PC1 and PC2 accounted for 47.1 and 30.6 % of the variance (Oda and Ouchi 1989). Hence, the variance observed in the PC1 of the present study is in line with reports. The correlation between a component and a variable estimates the information they share. In PCA, this correlation is called as loading. The sum of the squared coefficients of correlation between a variable and all the components is equal to 1 (Abidi and Williams 2010). In the present work, loadings with an absolute value greater than 0.600 (shown in bold type in Table 2) represents a strong influence. The absolute correlation or loading of syneresis, firmness, stickiness, work of shear and work of adhesion was found to be more than 0.900, while sensory body and texture and overall acceptability loading was found to be more than 0.800 in PC1 indicating the strong influence on the quality of UF dahi made.

Table 2.

Eigen values, percentage variances and variable loadings for the four principal components

| Parameter | PC1 | PC2 | PC3 | PC4 |

|---|---|---|---|---|

| Eigen values | 7.73 | 2.52 | 2.37 | 1.36 |

| Variance (%) | 48.34 | 15.73 | 14.82 | 8.45 |

| Cumulative variance (%) | 48.34 | 64.07 | 78.89 | 87.39 |

| Loadings | ||||

| Protein | 0.753 * | −0.252 | −0.379 | −0.275 |

| Lactose | −0.726 | 0.377 | 0.301 | 0.359 |

| Ash | 0.609 | −0.458 | 0.342 | −0.081 |

| Total solids | 0.340 | 0.490 | −0.144 | 0.577 |

| pH | 0.116 | −0.794 | 0.528 | 0.137 |

| Acidity | 0.263 | 0.621 | −0.677 | −0.239 |

| Syneresis | −0.913 | 0.112 | 0.209 | 0.182 |

| Firmness | 0.914 | −0.016 | −0.086 | 0.301 |

| Stickiness | −0.928 | 0.100 | 0.219 | −0.135 |

| Work of shear | 0.899 | −0.009 | −0.048 | 0.301 |

| Work of adhesion | −0.920 | −0.054 | 0.263 | −0.220 |

| Flavour | 0.483 | 0.562 | 0.482 | −0.311 |

| Body and texture | 0.872 | −0.151 | 0.311 | 0.016 |

| Sensory acidity | 0.288 | 0.480 | 0.601 | 0.291 |

| Colour and appearance | 0.401 | 0.412 | 0.448 | −0.517 |

| Overall acceptability | 0.806 | 0.283 | 0.449 | −0.100 |

*Loadings with an absolute value greater than 0.600 are shown in bold type

Fig. 6.

Principal component analysis

Conclusions

In the present investigation, quality attributes of dahi manufactured from standardized milk obtained from different UF treatments (UF1, UF2, UF3, and UF4) were studied. Whey syneresis, textural properties and sensory attributes of these dahi samples were greatly improved compared to control sample. Among four UF treatments, UF1 and UF2 had significantly (p < 0.05) better quality compared to other UF treatments (UF3 and UF4). Dahi prepared with UF treatments obtained better sensory scores than control sample for firmness, body and texture as well as overall acceptability. Moreover, UF treated samples (UF1, UF2, UF3, and UF4) did not show any whey syneresis. Increase in the protein contents did not hamper the growth of starter microorganisms and fermentation process. Hence, it could be concluded that good quality dahi can be manufactured by employing ultrafiltration technique which was also observed to overcome its quality problems like loose body, whey syneresis, high acidity, lumpiness etc.

Acknowledgments

Thankful acknowledgement to the Director, ICAR-National Dairy Research Institute for providing economic assistance in the form of Institute Research Project and other amenities for conducting the presented research work.

References

- Abd El-Khair AA. Production and evaluation of a high protein version of Non-fat yoghurt. Res. J. Agri. Biol. Sci. 2009;5(4):310–316. [Google Scholar]

- Abidi H, Williams LJ. Principal component analysis. Wiley Interdiscip Rev Comput Stat. 2010;2(4):433–459. doi: 10.1002/wics.101. [DOI] [Google Scholar]

- Abrahamsen RK, Holmen TB. Yoghurt from hyperfiltred and evaporated milk and from milk added milk powder. Milchwissenschaft. 1980;35:399–402. [Google Scholar]

- Amatayakul T, Sherkat F, Shah G. Syneresis in set yoghurt as affected by EPS starter cultures and levels of solids. Int J Dairy Technol. 2006;59:216–221. doi: 10.1111/j.1471-0307.2006.00264.x. [DOI] [Google Scholar]

- Atra R, Vatai G, Molnar EB, Balint A. Investigation of ultra- and nanofiltration for utilization of whey protein and lactose. J Food Eng. 2005;67:325–332. doi: 10.1016/j.jfoodeng.2004.04.035. [DOI] [Google Scholar]

- Becker T, Puhan Z. Effect of different processes to increase the milk solids non-fat content on the rheological properties of yoghurt. Milchwissenschaft. 1989;44:626–629. [Google Scholar]

- Biliaderis CG, Khan MM, Blank G. Rheological and sensory properties of yoghurt from skim milk and ultrafiltered retentate. Int Dairy J. 1992;2:311–323. doi: 10.1016/0958-6946(92)90035-K. [DOI] [Google Scholar]

- Bodyfelt FW, Tobias J, Trout GM. Yoghurt. In: Bodyfelt FW, editor. The sensory evaluation of dairy products. New York: Van Nostrand Reinhold; 1988. pp. 227–299. [Google Scholar]

- Brazuelo A, Suarez E, Riera FA, Alvarez R. Protein enriched yoghurt by ultrafiltration of skim milk. J. Sci. Food Agr. 1995;69:283–290. doi: 10.1002/jsfa.2740690304. [DOI] [Google Scholar]

- Chapman KW, Lawless HT, Boor KJ. Quantitative descriptive analysis and principal component analysis for sensory characterization of ultrapasteurized milk. J Dairy Sci. 2001;84:12–20. doi: 10.3168/jds.S0022-0302(01)74446-3. [DOI] [PubMed] [Google Scholar]

- Dejmek P, Walstra P. The syneresis of rennet-coagulated curd. In: Fox PF, editor. Cheese: chemistry, physics and microbiology. London: Chapman & Hall; 1993. pp. 141–191. [Google Scholar]

- Duncan DB. Multiple range and multiple F-test. Biometrics. 1955;11:1–42. doi: 10.2307/3001478. [DOI] [Google Scholar]

- Frau M, Simal S, Femenia A, Sanjuan E, Rossello C. Use of principal component analysis to evaluate the phycial properties of Manhon cheese. Eur Food Res Technol. 1999;210:73–76. doi: 10.1007/s002170050536. [DOI] [Google Scholar]

- Garg AR, Jain SC. Studies on the textural characteristics of curd. I Effect on Time temperature Combination for Pasteurization and fat and Protein Content of Milk. Milchwissenschaft. 1980;35:738–742. [Google Scholar]

- Ghosh D, Chattopadhyay P. Application of principal component analysis (PCA) as a sensory assessment tool for fermented foods. J Food Sci Technol. 2012;49(3):328–334. doi: 10.1007/s13197-011-0280-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Glover FA. Ultrafiltration and reverse osmosis for the dairy industry. In: Glover FA, editor. Technical bulletin. England: National Institute for Research in Dairying; 1985. pp. 1–207. [Google Scholar]

- Indian Standard (1961) Methods of test for dairy industry-Part II: Chemical analysis of milk. Bureau of Indian Standards, IS-1479, Manak Bhavan, New Delhi: BIS

- Indian Standard (1973) Specification for condensed milk. Bureau of Indian Standards, IS-1166, Manak Bhavan, New Delhi: BIS

- Indian Standard (1977) Determination of fat by the Gerber method-Part I: Milk. Bureau of Indian Standards, IS-1224, Manak Bhavan, New Delhi: BIS

- Indian Standard (1980) Specification for dahi. Bureau of Indian Standards, IS-9617, Manak Bhavan, New Delhi: BIS

- Indian Standard (1997) Milk, Cream and Evaporated Milk-Determination of Total Solid Content (Reference method). Bureau of Indian Standards, IS-12333, Manak Bhavan, New Delhi: BIS

- Isleten M, Karagul-Yuceer Y. Effects of dried dairy ingredients on physical and sensory properties of nonfat yoghurt. J Dairy Sci. 2006;89:2865–2872. doi: 10.3168/jds.S0022-0302(06)72559-0. [DOI] [PubMed] [Google Scholar]

- Khurana HK, Kanawjia SK. Recent trends in development of fermented milks. Curr Nutr Food Sci. 2007;3:91–108. doi: 10.2174/1573401310703010091. [DOI] [Google Scholar]

- Kurien SV, Mishra HN. Modelling of acidification kinetics and textural properties in dahi (Indian Yoghurt) made from buffalo milk using response surface methodology. Int J Dairy Technol. 2008;6:284–289. [Google Scholar]

- Lucey JA. The relationship between rheological parameters and whey separation in milk gels. Food Hydrocoll. 2001;15:603–608. doi: 10.1016/S0268-005X(01)00043-1. [DOI] [Google Scholar]

- Meena PK, Gupta VK, Meena GS. Process optimization for protein enriched set dahi employing UF technique. Indian J Dairy Sci. 2014;67:114–121. [Google Scholar]

- Menefee SG, Overman OR. Semi micro kjeldhal method for determination of total nitrogen in milk. J Dairy Sci. 1940;23:1177–1185. doi: 10.3168/jds.S0022-0302(40)92829-6. [DOI] [Google Scholar]

- Oda Y, Ouchi K. Principal-component analysis of the characterisctis desirable in baker’s yeasts. App. Environ. Microbiol. 1989;55(6):1495–1499. doi: 10.1128/aem.55.6.1495-1499.1989. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Patel RS, Mistry VV. Physicochemical and structural properties of ultrafiltered buffalo milk and milk powder. J Dairy Sci. 1997;80:812–817. doi: 10.3168/jds.S0022-0302(97)76002-8. [DOI] [Google Scholar]

- Raju NP, Pal D. The physico-chemical, sensory and textural properties of misti dahi prepared from reduced fat buffalo milk. Food Bioproc Tech. 2009;2:101–108. doi: 10.1007/s11947-008-0137-z. [DOI] [Google Scholar]

- Ranganadham M, Gupta SK. Sensory evaluation of dahi and yoghurt. Indian Dairyman. 1987;39(10):493–497. [Google Scholar]

- Renner E, Abd El-Salam MII. Introduction. In: Renner E, editor. Application of ultrafiltration in the dairy industry. London: Elsevier Applied Science; 1991. pp. 112–152. [Google Scholar]

- Rollema HS, Muir DD. Casein and related products. In: Tamime AY, editor. Dairy powders and concentrated products. United Kingdom: Blackwell Publishing Ltd; 2009. pp. 235–252. [Google Scholar]

- SAS (2008) SAS/OR 9.2 user’s Guide: Mathematical programming. North Carolina: SAS Institute

- Savello PA, Dargan RA. Improved yoghurt physical properties using ultrafiltration and very-high temperature heating. Milchwissenschaft. 1995;50(2):86–90. [Google Scholar]

- Savello PA, Dargan RA. Reduced yoghurt syneresis using ultrafiltration and very high temperature heating. Milchwissenshaft. 1997;52(10):573–577. [Google Scholar]

- Sodini I, Remeuf F, Haddad S, Corrieu G. The relative effect of milk base, starter, and process on yoghurt texture: a review. Cr Rev Food Sci and Nutr. 2004;44:113–137. doi: 10.1080/10408690490424793. [DOI] [PubMed] [Google Scholar]

- White CH. Manufacture of high quality yoghurt. Cultured Dairy Prod J. 1995;30(2):18–26. [Google Scholar]

- Yan SA, Hill CG, Amundson CH. Ultrafiltration of whole milk. J Dairy Sci. 1979;62:23–40. doi: 10.3168/jds.S0022-0302(79)83197-5. [DOI] [Google Scholar]