Abstract

The present study investigated the effects of resistant starch concentration (0, 1, 2 %), aging time (2, 13, 24 h) and aging temperature (2, 4, 6 °C) on the physicochemical properties of frozen soy yogurt. The results showed that resistant starch increased viscosity because of its water binding properties. Resistant starch also increased foam stability, fat destabilization, and hardness, but it decreased overrun and meltdown rate. Viscosity, hardness and fat destabilization increased as aging time increased. An increase in aging temperature decreased viscosity, overrun, hardness and fat destabilization of frozen yoghurt, but increased the meltdown rate.

Keywords: Resistant starch, Frozen soy yogurt, Aging time, Aging temperature

Introduction

Frozen yogurt, or yogurt ice cream, is a complex of yogurt and ice cream. This dessert combines the flavor of yogurt and texture of ice cream. Consumers have a strong preference for functional foods containing specific ingredients and can reduce the threat of diseases such as cancer and heart diseases (Champagne et al. 2009). Soybean has been reported to contain a high concentration of isoflavones with potential health-enhancing properties (Chen et al. 2012). Also, Soy oil can reduce bad cholesterol due to its polyunsaturated fatty acid. The incorporation of soy and its products into the human diet is attractive because of its perceived nutritional properties (Rinaldoni et al. 2012).There has also been increasing demand for substitutes to cow’s milk for those who should avoid its consumption. Soy-based products also meet the needs of vegetarians and therefore interest in soy-based products has developed (Farnworth et al. 2007).

The addition of dietary fiber to dairy products is one of the fields of functional foods. Dietary fiber is a class of compounds that includes a mixture of plant carbohydrate polymers, oligosaccharides and polysaccharides, resistant starch, beta glucan and inulin (Elleuch et al. 2010). Dietary fibers have many health profits. They regulate bowel movement and help maintain bowel health. Fiber can modify and improve the texture and sensory properties of food because of its ability to bind with water, form gels, and its thickening properties (Soukoulis et al. 2009). Resistant starch (RS) is a fraction of starch that can resist digestion thus attains the colon (Fuentes-Zaragoza et al. 2011). Its physiological properties are similar to that of soluble fiber and it is fermented by useful microorganisms in the colon (Dundar and Gocmen 2013).

Aging is a key step in ice cream production. This step is defined as the time in the procedure where the mix will be cooled for a period of 2–24 h (Marshall et al. 2003). Aging improves the viscosity, whipping ability of mix, body and texture of the final product. It also decreases stabilization fat globules and causes fat crystallization (Issariachaikul 2008). The present study evaluated the effect of RS and aging time and temperature on the physicochemical properties of frozen soy yogurt.

Materials and Methods

Soy yogurt preparation

Soymilk blend containing 8 % soy flour, 4 % skim milk and 1 % food grade sodium citrate was prepared by dissolving in hot water (90–95 °C). Different amounts of RS (0, 1, 2 %) were then added. The mixture was stirred thoroughly so that the soy milk was homogenous and smooth. This mixture was heated to 85 °C for 30 min. After cooling the mixture to 42 °C, yogurt starter (YF-L812; CR-Hansen; Denmark) was added and the mixture was incubated at 42 °C. When acidity reached 80° Dornic, fermentation process was stopped and the yogurt was cooled to 10 °C.

Frozen yogurt mix

To prepare the frozen yogurt mix, sugar (16 %), stabilizer-emulsifier mix (0.5 %, Lux6700; Cargill; France) and skim milk powder (adjusted to total solids of 30 %) were dissolved in water and heated to 85 °C for 30 min. After cooling, the mixture was blended with yogurt and aged at different temperatures (2, 4, 6 °C) for different lengths of time (2, 13, 24 h). The aged mix was then frozen using a laboratory batch ice cream maker. After freezing, samples were distributed into plastic cups (50 ml) and hardened at −18 °C.

Frozen soy yogurt analysis

Overrun

Overrun was determined by measuring the weight of a specific volume of frozen yogurt mix and final frozen yogurt and is calculated as (Adapa et al. 2000):

| 1 |

Viscosity

Viscosity of the frozen soy yogurt mix was determined according to Pintor and Totosaus (2012) with some modifications. Measurements were carried out at 5 °C using a Brookfield DVII viscometer with RV spindle (#4) after aging. All measurements were recorded at 100 rpm.

Meltdown rate

Meltdown tests were carried out on frozen soy yogurt samples stored at −18 °C. The samples were placed onto a stainless steel screen (hole diameter: 0.5 mm) over a beaker. The serum passing through the screen was weighed after 45 min at 20 °C (Akalin and Erisir 2008).

Fat destabilization

Fat destabilization was evaluated by spectroturbidometery. Briefly, an aliquot of frozen yogurt mix and final frozen yogurt were diluted at 1:500 with distilled water and their absorbance was measured using a spectrophotometer at 540 nm. Distilled water was used as a blank (Issariachaikul 2008). Equation (2) was used to determine the percentage of fat destabilization. The smaller the percentage of fat destabilization, the greater is the fat destabilization in the ice cream (Adapa et al. 2000).

| 2 |

Foam stability

To determine foam stability, 200 ml of the frozen yogurt mix was blended for 2 min in a domestic blender. The mix was then poured into a 250 ml graduated cylinder and the volume of foam produced was recorded. After 15 min, the final volume of foam was measured. The percentage of foam stability was expressed as the percentage of final volume of foam to initial volume of foam.

Color

The color was measured using an image processing method (Hashemi Shahraki et al. 2014). A digital camera adjusted to the top of a sample in a box (60 × 60 cm in size). The interior of the box was covered with dark cloth to prevent light scattering. The images were directly transferred to a computer for image processing using Image J software (Version 1.42, National Institutes of Health, USA). The color space of the images was converted from RGB to CIElab. The mean of each color parameter was expressed as L* (lightness), a* (redness) and b* (yellowness).

Texture (hardness)

Texture analysis was conducted using a texture analyzer (TA.XT plus, UK). The samples were stored in 50 mm plastic containers at −20 °C until analysis. Measurement was carried out using a cylindrical probe (P2). The penetration depth at the geometrical center of the sample was 10 mm and penetration speed was set at 2 mm/s. The hardness was determined as the peak compression force (g) during penetration (Rossa et al. 2012).

Statistical analysis

The parameters in the experimental design were RS concentration, aging time and aging temperature. Response surface methodology with a central composite design was used to evaluate the effects of these three variables. The independent variables were RS (0, 1, 2 %), aging time (2, 13, 24 h) and aging temperature (2, 4, 6 °C). Design-Expert software (Version 6.0.2, Stat-Ease) was used to design and arrange the experiments. All testing was carried out in triplicate.

Results and discussion

Overrun

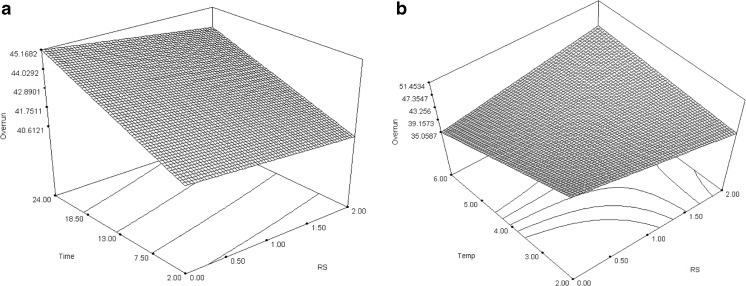

The results showed that the addition of RS decreased overrun, but not considerably (Fig. 1a). Whipping ability associated with overrun determines the simplicity of air integration into the mix and subsequent diffusion and the stability of air cells in the ice cream (Baer et al. 1999). It has been reported that viscous components could prohibit air incorporation and high viscosity systems do not support foaming ability (Adapa et al. 2000). The results also showed that overrun increased with aging time. This could be attributed to the increase in viscosity over aging time. An adequate level of viscosity is necessary to maintain air bubbles, although when viscosity increases considerably, the whipping ability decreased (Marshall et al. 2003). Increased aging temperature had a negative effect on overrun (Fig. 1b).

Fig. 1.

Effect of RS and aging on overrun: a time; b temperature

Viscosity

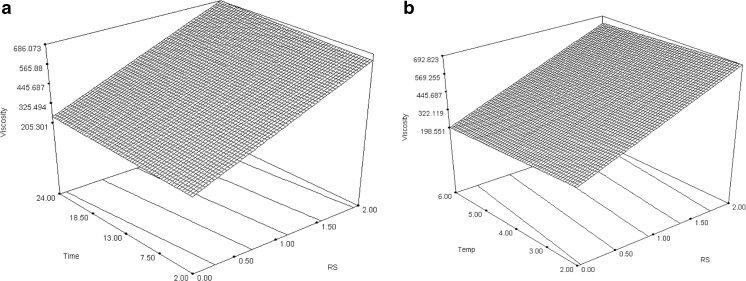

The addition of RS strongly increased the viscosity of the frozen soy yogurt mix (Fig. 2a). A similar result was obtained for aging time, but the effect was unimportant. Aging temperature decreased the viscosity of the mix (Fig. 2b). Dietary fibers such as RS can impart functional properties to foods such as increasing the water retention capacity that improves the viscosity (Elleuch et al. 2010).

Fig. 2.

Effect of RS and aging on viscosity: a time b temperature

The effect of the addition of RS on viscosity is the result of water retention by soluble fiber and the increase in serum concentration (Soukoulis et al. 2009). Rezaei et al. (2014) reported that inulin increased the viscosity of frozen yogurt significantly. They stated that the hygroscopic nature of inulin was responsible for the improvement of viscosity. During aging, hydration of components became complete, meaning that increased aging time increased viscosity, as expected.

Fat destabilization

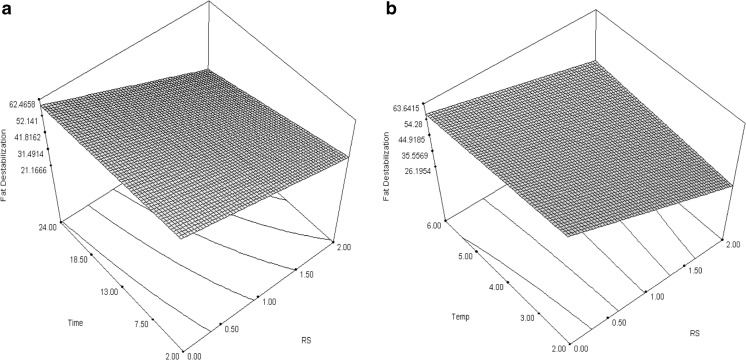

Fat acts as an important component in stabilization of the ice cream structure. Partly coalesced fat is responsible for stabilizing the air bubbles and foam formationx (Koxholt et al. 2001). Some experiments demonstrated that fat destabilization has significant effect on ice cream properties such as mouth feel, appearance, overrun and meltdown (Berger and White 1971; Koxholt et al. 2001). The results showed that an increase RS concentration decreased the percentage of fat destabilization (Fig. 3a). As stated, the smaller the fat destabilization value, the greater is the fat destabilization in ice cream. RS increased fat destabilization in frozen soy yogurt. This result could be attributed to the ability of RS to improve the stability of foam in the food system, which gives the emulsion destabilization power (Franck 2002). Issariachaikul (2008) also confirmed that the formulas for ice cream have been shown to influence fat destabilization. They reported that the addition of inulin significantly increased fat destabilization of ice cream. Aging temperature decreased fat destabilization (Fig. 3b).

Fig. 3.

Effect of RS and aging on fat destabilization: a time b temperature

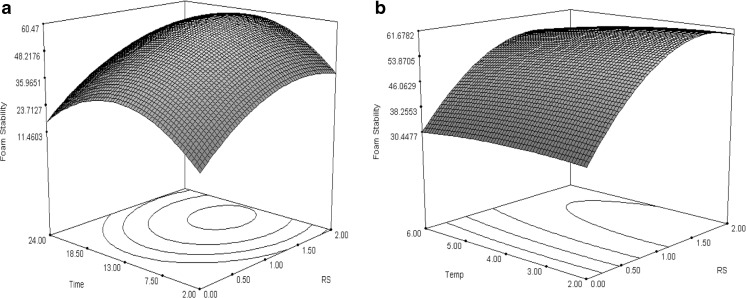

Foam stability

Results showed that increasing RS concentration increased the foam stability of the frozen yogurt mix (Fig. 4a). This was attributed to the heavy and soggy texture of the mix, which produced a comparatively low foaming ability and high foam stability (Alakali et al. 2009). Rossa et al. (2012) stated that high viscosity does not favor the formation of foam, but does contribute somewhat to the stability of foam. RS and aging time increased viscosity, which increased foam stability. Aging temperature decreased foam stability (Fig. 4b). Fat destabilization is another factor affecting foam stability. Fat that was destabilized by the addition of RS contributes to stabilization of the structure of the air and foam (Granger et al. 2005).

Fig. 4.

Effect of RS and aging on foam stability: a time b temperature

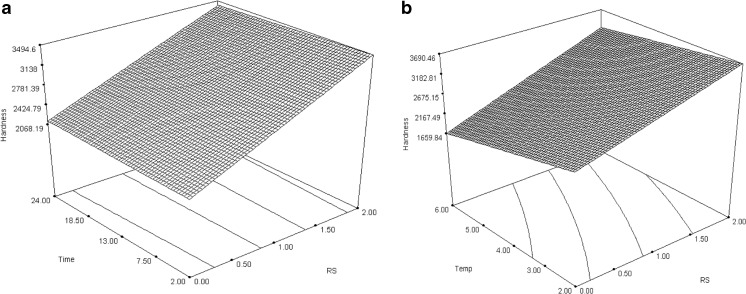

Hardness

The hardness of ice cream correlated with its resistance to deformation when an exterior force is applied (Muse and Hartel 2004). Hardness reveals the effect of the ingredients and processing conditions (Mahdian and Karazhian 2013). Overrun, the size of ice crystals and fat destabilization are factors that affect ice cream hardness. The results showed that hardness of samples corresponded with viscosity and hardness increased sharply when RS concentration and aging time increased (Fig. 5a). This result could be attributed to ability of RS to entrap water and form a gel network (Akalin and Erisir 2008).

Fig. 5.

Effect of RS and aging on hardness: a time b temperature

Muse and Hartel (2004) reported that rheological properties such as viscosity of ice cream mix could influence hardness and that samples were harder when their apparent viscosities were greater. They also confirmed that increased fat destabilization increased hardness because destabilized fat supplies a network between the air cells in the ice cream that can enhance the hardness of ice cream. The results of the present study showed that the hardness of frozen yogurt decreased when the aging temperature increased (Fig. 5b).

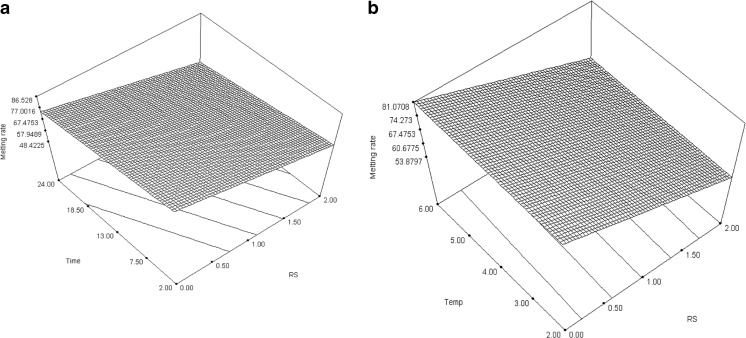

Meltdown rate

The meltdown rate of frozen soy yogurt was measured at 20 °C for 45 min. The results showed that samples with higher concentrations of RS melted more slowly (Fig. 6a). Increases in aging time decreased the meltdown rate of samples. The meltdown rate is an important characteristic of ice cream. Slow meltdown and good shape retention are some of the ideal quality parameters of ice cream (BahramParvar and Mazaheri-Tehrani 2011). Overrun, fat destabilization and viscosity of the ice cream mix influenced meltdown rate. An increase in coalesced fat increased resistance to flow of the liquid phase and resulted in slower melting (Nuernberg-Rossa et al. 2012). Botega et al. (2013) stated the increase in melting resistance was associated with the presence of larger fat aggregates. RS increased fat destabilization and decreased meltdown. Rezaei et al. (2011) reported arabic gum and guar gum can form sticky network that results in more resistance to melting.

Fig. 6.

Effect of RS and aging on meltdown rate: a time; b temperature

Herald et al. (2008) found that increasing the viscosity of the ice cream mix decreased the melting rate. Increasing aging temperature slightly increased the meltdown rate (Fig. 6b), perhaps as a result of the considerable effect of temperature on overrun. According to the results of this study, higher aging temperature decreased overrun sharply; this decreased the air content of samples, which led to more heat delivery and increased meltdown (Phianmongkhol et al. 2012).

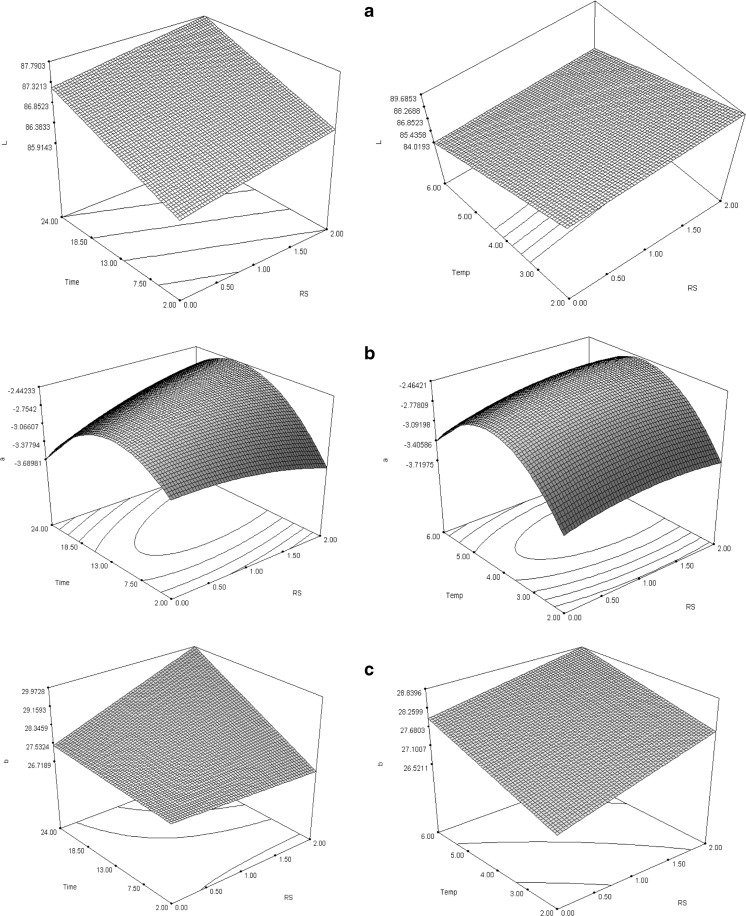

Color

Evaluation of color of samples revealed that the addition of RS increased whiteness (L*). Aging time had a similar effect on L*, but higher aging temperature decreased L* (Fig. 7a). The effect of RS on L* could be attributed to the white color of the RS, which decreased the color of the soy milk and increased whiteness.

Fig. 7.

Effect of RS, aging time and aging temperature on: a L* b a* c b*

All samples showed negative a* (greenness) values. Increasing the RS concentration up to 1 % increased a*, but after 1 %, a* was unaffected. Aging time (up to 13 h) and aging temperature (up to 4 °C) increased a* and then decreased it (Fig. 7b). RS concentration, aging time and aging temperature increased b* (yellowness) (Fig. 7c).

Conclusion

The best improvement in textural properties and appearance of frozen soy yogurt in terms of viscosity, hardness, meltdown rate, foam stability and color was obtained in samples with 2 % resistant starch. More investigation such as rheological, sensory and microstructure analysis of product are required for understanding effect of RS incorporation. Lower aging temperature (2 °C) and longer aging time (24 h) promoted quality of frozen soy yogurt.

Footnotes

Research highlights

1- Addition of resistant starch as a dietary fiber could modify textural properties of frozen soy yogurt.

2- Prolonged aging time could improve properties of this frozen dessert.

3- Higher aging temperature had negative effect on the quality of frozen soy yogurt.

References

- Adapa S, Dingeldein H, Schmidt KA, Herald TJ. Rheological properties of ice cream mixes and frozen ice creams containing fat and fat replacer. J Dairy Sci. 2000;83(10):2224–2229. doi: 10.3168/jds.S0022-0302(00)75106-X. [DOI] [PubMed] [Google Scholar]

- Akalin AS, Erisir D. Effects of inulin and oligofructose on the rheological characteristics and probiotic culture survival in low fat probiotic ice cream. J Food Sci. 2008;73(4):184–188. doi: 10.1111/j.1750-3841.2008.00728.x. [DOI] [PubMed] [Google Scholar]

- Alakali JS, Okonkwo TM, Uwu LU. Effect of food binders on the textual and sensory characteristics of ice cream. Afr J Biotechnol. 2009;8(12):2853–2856. [Google Scholar]

- Baer RJ, Krishnaswamy N, Kasperson M. Effect of emulsifiers and food gum on nonfat ice cream. J Dairy Sci. 1999;82:1416–1424. doi: 10.3168/jds.S0022-0302(99)75368-3. [DOI] [Google Scholar]

- Bahramparvar M, Mazaheri-Tehrani M. Application and functions of stabilizers in ice cream. Food Rev Int. 2011;27:389–407. doi: 10.1080/87559129.2011.563399. [DOI] [Google Scholar]

- Berger KG, White GW. An electron microscopical investigation of fat destabilization in ice cream. J Food Technol. 1971;6:285–294. doi: 10.1111/j.1365-2621.1971.tb01617.x. [DOI] [Google Scholar]

- Botega DCZ, Marangoni AG, Smith AK, Goff HD. Development of formulations and processes to incorporate wax olegels in ice cream. J Food Sci. 2013;78(12):1845–1851. doi: 10.1111/1750-3841.12248. [DOI] [PubMed] [Google Scholar]

- Champagne CP, Green-Johnson J, Raymond Y, Barrette J, Buckley N. Selection of probiotic bacteria for fermentation of a soy beverage in combination with Streptococcus thermophilus. Food Res Int. 2009;42:612–621. doi: 10.1016/j.foodres.2008.12.018. [DOI] [Google Scholar]

- Chen KI, Erh MH, Su NW, Liu WH, Chou CC, Cheng KC. Soy foods and soybean products: from traditional use to modern application. Appl Microbiol Biotechnol. 2012;96:9–22. doi: 10.1007/s00253-012-4330-7. [DOI] [PubMed] [Google Scholar]

- Dundar AN, Gocmen D. Effects of autoclaving temperature and storing time on resistant starch formulation and its functional and physicochemical properties. Carbohydr Polym. 2013;97:764–771. doi: 10.1016/j.carbpol.2013.04.083. [DOI] [PubMed] [Google Scholar]

- Elleuch M, Bedigian D, Roiseux O, Besbes S, Blecker C, Attia H. Dietary fiber and fibre-rich by-products of food processing: characterisation, technological functionality and commercial applications: a review. J Food Chem. 2010;124(2):411–421. doi: 10.1016/j.foodchem.2010.06.077. [DOI] [Google Scholar]

- Farnworth ER, Mainville I, Desjardin M, Gradner N, Fliss I, Chammpgne C. Growth of probiotic bacteria and Bifidobacteria in a soy yogurt formulation. Int J Food Microbiol. 2007;116:174–181. doi: 10.1016/j.ijfoodmicro.2006.12.015. [DOI] [PubMed] [Google Scholar]

- Franck A. Technological functionality of inulin and oligofructose. Br J Nutr. 2002;2:287–291. doi: 10.1079/BJNBJN/2002550. [DOI] [PubMed] [Google Scholar]

- Fuentes-Zaragoza E, Sanchez-Zapata E, Sendra E, Sayas E, Lope JF, Perez-Alvarez A. Resistant starch as prebiotic: a review. Starch J. 2011;63:406–415. doi: 10.1002/star.201000099. [DOI] [Google Scholar]

- Granger C, Leger A, Barey P, Langendorff V, Cansell M. Influence of formulation on the structural networks in ice cream. Int Dairy J. 2005;15:255–262. doi: 10.1016/j.idairyj.2004.07.009. [DOI] [Google Scholar]

- Hashemi Shahraki M, Ziaiifar AM, Kashaninejad M, Ghorbani M. Optimization of pre-fry microwave drying of French fries using response surface methodology and genetic algorithm. J Food Process Preserv. 2014;38:535–550. doi: 10.1111/jfpp.12001. [DOI] [Google Scholar]

- Herald TJ, Aramouni FM, Abu-Ghoush MH. Comparison study of egg yolks and egg alternatives in French vanilla ice cream. J Texture Stud. 2008;39:284–295. doi: 10.1111/j.1745-4603.2008.00143.x. [DOI] [Google Scholar]

- Issariachaikul K (2008) Development of modified fat ice cream products using inulin as a fat replacer. M.Sc thesis, Mahidol University

- Koxholt MMR, Eisenmann B, Hinrichs J. Effect of the fat globule sizes on the meltdown of ice cream. J Dairy Sci. 2001;84(1):31–37. doi: 10.3168/jds.S0022-0302(01)74448-7. [DOI] [PubMed] [Google Scholar]

- Mahdian E, Karazhian R. Effects of fat replacers and stabilizers on rheological, physicochemical and sensory properties of reduced-fat ice cream. J Agric Sci Technol. 2013;15:1163–1174. [Google Scholar]

- Marshall RT, Goff HD, Hartel RW. Ice cream. New York: Kluwer Academic/Plenum Publishers; 2003. [Google Scholar]

- Muse MR, Hartel RW. Ice cream structural elements that affect melting rate and hardness. J Dairy Sci. 2004;87:1–10. doi: 10.3168/jds.S0022-0302(04)73135-5. [DOI] [PubMed] [Google Scholar]

- Nuernberg-Rossa P, Burin VM, Luiz MT. Effect of microbial transglutaminase on functional and rheological properties of ice cream with different fat contents. LWT Food Sci Technol. 2012;48:224–230. doi: 10.1016/j.lwt.2012.03.017. [DOI] [Google Scholar]

- Phianmongkhol A, Rongkom H, Wirjantoro I. Effect of fat replacer systems and maltitol on qualities of fat and calorie reduced dairy ice cream. Agric Nat Resour. 2012;11(1):193–204. [Google Scholar]

- Pintor A, Totosaus A. Ice cream properties affected by lambda-carrageenan or iota-carrageenan interactions with locust bean gum/carboxymethylcellulose mixtures. Int Food Res J. 2012;19(4):1409–1414. [Google Scholar]

- Rezaei R, Khomeiri M, Kashaninejad M, Aalami M. Effects of guar gum and Arabic gum on the physicochemical, sensory and flow behavior characteristics of frozen yogurt. Int J Dairy Technol. 2011;64:563–568. doi: 10.1111/j.1471-0307.2011.00705.x. [DOI] [Google Scholar]

- Rezaei R, Khomeiri M, Aalami M, Kashaninejad M. Effect of inulin on the physicochemical, flow behavior and probiotic survival of frozen yogurt. J Food Sci Technol. 2014;51(10):2809–2814. doi: 10.1007/s13197-012-0751-7. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Rinaldoni AN, Campderros M E, Padilla AP. Physicochemical and sensory properties of yogurt from ultrafiltrated soy milk concentrated added with inulin. LWT Food Sci Technol. 2012;45:142–147. doi: 10.1016/j.lwt.2011.09.009. [DOI] [Google Scholar]

- Rossa PN, Burin VM, Bordignon-Luiz MT (2012) Effect of microbial transglutaminase on functional and rheological properties of ice cream with different fat content. LWT Food Sci Technol 48:224–230

- Soukoulis C, Lebesi D, Tzia C. Enrichment of ice cream with dietary fiber: effects on rheological properties, ice crystallization and glass transition phenomena. Food Chem. 2009;115:665–671. doi: 10.1016/j.foodchem.2008.12.070. [DOI] [Google Scholar]