Abstract

Amla (Indian gooseberry) and its processed products are rich source of vitamin C, phenols, dietary fibre and antioxidants. In contrast, ice cream is a poor source of these phytochemicals and antioxidants; therefore, the present investigation was undertaken to enhance the functional properties and nutritional quality of ice cream with the incorporation of processed amla. Ice cream was prepared using amla shreds, pulp, preserve and candy at 5 to 20 % and powder at 0.5 to 2.0 % levels in ice cream mix prior to freezing. Inclusion of amla products at augmented levels resulted in significant changes in physico-chemical properties and phytochemical content of ice cream. The total solids decreased on addition of shreds and pulp and increased with preserve, candy and powder in ice cream at increasing levels. The functional constituents i.e. fibre, total phenols, tannins, ascorbic acid and antioxidant activity increased with greater level of inclusion. Incorporation of processed amla raised the melting resistance of ice cream and decreased the overrun. The samples with 5 % shreds and pulp, 10 % preserve and candy and 0.5 % powder were found to have highest overall acceptability scores. Inclusion of amla in all the forms i.e. shreds, pulp, preserve, candy and powder enhanced the functional properties and nutritional value of ice cream.

Keywords: Ice cream, Amla, Physico-chemical, Phytochemical, Functional, Sensory quality

Introduction

Ice-cream which was considered an indulgent category of food items in the past has now developed to a stage where it is largely and gladly perceived as a snacking alternative by consumers. It has been growing at a sound rate of 10–15 % (Garg 2014). The growing consumer base, product acceptability and stiff competition have pushed manufacturers to strive for furtherance through innovations with respect to product offerings and delivery of service. These days’ consumers are more inclined towards healthy and premium options (Shukla and Sharma 2014). Frozen products adapt most readily to nutrient fortification and inclusion of nutraceuticals. Frozen dairy desserts serve as good carriers of nutraceuticals because of their low storage temperature, ability to stabilize ingredients and popularity among consumers. With care, frozen dairy desserts can be used successfully to deliver unique additional and nutritional benefits to consumers beyond the basic nutrition. Therefore, new varieties of ice cream are coming out targeting the health conscious consumers, and also new manufacturing processes giving more value for money spent by the consumers (Garg 2014).

At present the focus of nutritional enrichment has shifted from the provision of nutrient deficiency to the pursuit of optimal health and dietary intake. The consumers are now more interested in healthy foods and looking for foods that have added beneficial compounds such as antioxidants, phenolics and phytosterols. Thus producers have to add functional ingredients to food products to attract the attention of health-conscious consumers (Shaviklo et al. 2011). Phenolics of certain fruits such as blueberry, blackcurrant, elderberry, and boysenberry have been shown to display antidiabetic properties (Cam et al. 2013).

Amla (Emblica officinalis) is one of the very good natural sources of nutraceuticals and functional components. After Barbados cherry, amla is second richest natural source of vitamin C (ascorbic acid) having approximately 600 to 700 mg per fruit. It also has high content of tannin which is responsible for its antioxidative property (Nath and Sharma 1998). Amla contains gallic acid which is a potent polyphenol and has been found to improve immunity (Singh et al. 2011). It is also a rich source of pectin, an important form of dietary fiber that regulates the bowel action, is anti-diabetic, and treats scurvy and pulmonary tuberculosis (Ganju et al. 2003; Yokozawa et al. 2007; Sidhu et al. 2011). Because of its excellent therapeutic values, it is extensively used in Ayurvedic medicines like Chyavanprash, Triphalahurna, Brahmi rasayan and Madhumehga (Anon 2003).

Amla has a sour and astringent taste and a sweet after taste. Because of its high acidity and astringecy, it is not popular as a dessert fruit. It is mostly used to prepare pickle, preserve, juice, candy and powder. It is a common ingredient in Ayurvedic medicines and has very good demand for the preparation of various health care products like hair oils, dye, shampoo, face creams and tooth powders. It has a great potential for inclusion into food products deficient in vitamin C and fiber. Ice cream is rich in carbohydrates, fats, proteins, some vitamins (A, D, E) and mineral calcium (Cam et al. 2013). However, the ice cream currently available commercially is generally poor in natural antioxidants like vitamin C, antioxidants and phenolics (Waterhouse et al. 2013). There is a definite consumer trend toward the purchase of improved products with strong inclination on health aspects. Blending of ice cream with amla will provide product diversification and benefits to the health conscious consumers which otherwise ice cream alone could not provide. Increasing preference of consumers towards natural ingredients has tempted the ice cream manufacturers to search for new innovations in components having favourable health effects (Patel et al. 2011). Scientific studies on the utilization of amla in combination with other foods are scanty. Therefore, the present study was carried out with the objective to assess the suitability of different levels of processed amla products and to evaluate their effect on the physicochemical properties, phytochemical content and sensory quality of ice cream.

Materials and methods

Fresh whole milk was obtained from Guru Angad Dev Veterinary and Animal Sciences University (GADVASU), Ludhiana. Cream, skim milk powder, sugar, sodium alginate, glycerol monostearate and amla (Emblica officinalis) were procured from the local market.

Processing of amla

Amla was processed into shreds, pulp, preserve, candy and powder. Raw amla berries were sorted, weighed and washed before the preparation of products. Shreds were prepared fresh from whole fruit using a hand grater. For the preparation of pulp, the berries were blanched at 83 °C for 7–10 min. Thereafter, destoned and crushed using an electric blender. Amla powder was prepared from pulp by drying in a cabinet drier at 50 °C for 6 h. After drying, the dried product was ground, packed in the polythene bags and stored in a refrigerator (3–4 °C).

Amla preserve was prepared by the method of Lal et al. (1986). Fruit to sugar ratio used for the preparation of preserve was 1:1.5. Berries were steeped in 2 % saline water for 3–4 days, changing water every day, till the green color disappeared. Thereafter, fruits were washed in fresh water and pierced mechanically. It was followed by blanching at 83 °C for 8 min, destoning, segment separation and weighing. For sugar syrup, 1.0 Kg of sugar was boiled in 1.5 L of water, filtered and cooled. The softened fruits were added to the syrup. The half of remaining sugar was sprinkled on the syrup and kept for 2 days. Thereafter, the syrup was drained and again boiled with the addition of more sugar. This process was repeated till 66–68 °B was achieved. Preserve was kept under observation for two days in order to ensure the constant TSS. It was packed in clean, sterilized and dry glass jars and stored under refrigeration. Amla candy was prepared from preserve by removing excess syrup and drying segments in a cabinet drier at 40 °C for 6 h. Dried segments were packed in polyethylene bags, sealed and stored in a refrigerator.

Preparation of ice cream mix

The mix ingredients were calculated using the formulae given by Arbuckle (1997). Plain ice cream mix having a composition of 11 % fat and SNF, 15 % sugar, 0.5 % emulsifiers and stabilizer (0.15 + 0.35) was prepared using fresh milk, cream, skim milk powder, sugar, glycerol monostearate and sodium alginate. After pre-heating and mixing the ingredients, the mix was homogenized at 65 °C using laboratory homogenizer (Taj, New Delhi) at 2000 psi and 500 psi in two stage process, pasteurized at 80 °C for 25 s, cooled and aged overnight at 5 °C.

Preparation of amla incorporated ice cream

Amla preparations were added into the cooled and aged ice cream mix prior to freezing. The mix was frozen in a batch type mechanical freezer of 5 kg capacity (Sigma Sales Corporation, New Delhi) for 8 min. The frozen ice cream was drawn at −4 ± 1 °C from freezer, filled in plastic cups, hardened in a cabinet freezer at −18 to −20 °C for 12 h and stored at this temperature for further studies.

Physicochemical analysis

For each parameter, samples were analysed in three replicates. The total solids/moisture, protein, ash and titratable acidity were determined according to AOAC (2000) method. Fat content of milk and cream was estimated using Gerber’s method (BIS 1981) and that of amla and its products using Soxtec (Foss instrument, Sweden). The pH of samples was determined using pocket pH meter (IQ Scientific USA, Model IQ 125). The fibre content was determined using Fibertec (Foss instrument, Sweden). The color of mix was recorded on Hunter Color Lab (Ultra Scan, Hunter Lab, USA) in terms of ‘L’, ‘a’, ‘b’ values. Ascorbic acid was determined by the method given by Ranganna (1997) by titration against dye (2,6-dichlorophenol indo-phenol). Tannins were estimated using the method of Ruck (1969). Total phenols were determined using Folin-Ciocalteu reagent according to the modified method of Swain and Hillis (1959). Antioxidant activity was estimated as per the method of Shimada et al. (1992). Free radical scavenging activity was measured using 1,1- diphenyl-2-picryl- hydrazil (DPPH). Five g of amla product ((one g in case of amla powder) and ice cream sample was extracted with 50 ml of 80 % methanol for 2 h, filtered and was again extracted for 1 h with same amount and strength of methanol. It was then filtered and final volume made to 100 ml with methanol. One ml of sample solution was then mixed with 1 ml tris buffer and 2 ml of DPPH. The reaction mixture was incubated for 30 min in dark at room temperature. The absorbance of the resulting solution was measured at 517 nm. Methanol was used as control. DPPH scavenging activity of samples was measured as a decrease in the absorbance and was calculated using the following equation:

Specific gravity of ice cream samples was calculated as the method described by Winton (1958) at 20 °C by filling a cup of known weight and volume, with the resultant ice cream and recording weight. Overrun of the ice cream was calculated on weight basis using the following formula.

The melting property of ice cream was analysed at 20 ± 1 °C using the method of Akesowan (2008). Hardened ice cream was placed on a sieve (2 mm wide, square openings). The time of first drop on melting of ice cream was recorded as first dripping time and melting rate was expressed as % W/W.

Sensory evaluation

Control ice cream along with experimental samples incorporating variable levels of processed amla products were evaluated by a semi trained panel of eight judges for attributes of appearance, flavor, body and texture and overall acceptability scores on a 9- point hedonic scale (Larmond 1982).

Statistical analysis

The experimental data was analyzed for analysis of variance (ANOVA) using CPCS-1 software developed by Department of Mathematics and Statistics, Punjab Agricultural University, Ludhiana. Each value was a mean of three observations. The means were compared using Duncan's multiple range test (Duncan 1955).

Results and discussion

Proximate composition of raw and processed amla

The proximate composition values of raw amla and its processed products are presented in Table 1. The moisture, protein, fat, and ash content was similar to those reported in literature by Premi et al. (1999), Ranote et al. (2002), Vijayanand et al. (2007) and Nayak et al. (2012). Fresh amla was found to have 2.74 % fibre content which increased. Fibre content was maximum in powder. Kalra (1988) reported the range of fibre from 2.38 to 3.4 % in fresh fruit. Total sugar was highest in candy followed by preserve due to processing in sugar syrup. Nayak et al. (2012) found that total sugar varies from 64.3 to 66.6 % in candy. The acidity was observed as 2.52 % in raw amla which was reduced in processed preparations. Ascorbic acid content in fresh amla was 430.1 mg/100 g which was lower than that observed by Premi et al. (1999) and higher than Vijayanand et al. (2007). The values of tannic acid were lower than that of Ranote et al. (2002). The processed preparations were found to retain high antioxidant activity due to concentration effect. The tannic acid and total phenol content was lower in processed than raw amla due to handling and processing effects.

Table 1.

Proximate composition and functional components of processed amla

| Parameters | Raw amla | Shreds | Pulp | Candy | Preserve | Powder |

|---|---|---|---|---|---|---|

| Moisture, % | 85.06 ± 0.21 | 86.06 ± 0.04 | 90.06 ± 0.12 | 17.76 ± 0.88 | 33.57 ± 0.08 | 6.56 ± 0.08 |

| Total solids, % | 14.94 ± 0.21 | 13.94 ± 0.49 | 9.93 ± 0.15 | 82.24 ± 1.02 | 66.43 ± 0.1 | 93.44 ± 0.09 |

| Fat, % | 0.11 ± 0.01 | 0.10 ± 0.04 | 0.10 ± 0.03 | 0.12 ± 0.01 | 0.11 ± 0.01 | 0.52 ± 0.02 |

| Protein, % | 0.70 ± 0.01 | 0.71 ± 0.01 | 0.68 ± 0.02 | 0.90 ± 0.04 | 0.73 ± 0.04 | 5.60 ± 0.43 |

| Ash, % | 1.54 ± 0.13 | 1.47 ± 0.02 | 0.99 ± 0.01 | 1.75 ± 0.06 | 1.31 ± 0.03 | 9.31 ± 0.39 |

| Fibre, % | 2.74 ± 0.02 | 2.76 ± 0.04 | 2.09 ± 0.04 | 8.55 ± 0.04 | 2.03 ± 0.03 | 16.98 ± 0.04 |

| Total sugar, % | 4.58 ± 0.07 | 4.48 ± 0.03 | 4.11 ± 0.02 | 66.01 ± 0.03 | 61.02 ± 0.01 | 45.19 ± 0.04 |

| Acidity, % Citric acid | 2.52 ± 0.14 | 2.31 ± 0.89 | 1.6 ± 0.01 | 0.54 ± 0.08 | 0.36 ± 0.02 | 4.48 ± 0.07 |

| Ascorbic acid, mg/100 g | 430.1 ± 1.10 | 421.0 ± 1.22 | 112.4 ± 1.74 | 13.1 ± 0.10 | 18.2 ± 0.65 | 241.3 ± 1.41 |

| Tannins, % tannic acid | 1.95 ± 0.04 | 1.90 ± .035 | 0.12 ± 0.04 | 0.20 ± 0.08 | 0.19 ± 0.04 | 0.41 ± 0.02 |

| Antioxidant activitya, % inhibition of DPPH | 83.73 ± 12.01 | 83.72 ± 11.91 | 82.16 ± 3.19 | 79.7 ± 1.23 | 80.03 ± 3.11 | 55.88 ± 0.98 |

| Total phenols, g/100 g GAE | 3.50 ± 0.26 | 3.09 ± 0.04 | 1.48 ± 0.04 | 1.02 ± 0.05 | 0.94 ± 0.04 | 2.04 ± 0.04 |

n = 3, Values are Mean ± Standard Deviation

aSample weight 5 g for each except in powder (1 g)

Effect of incorporation of processed amla on proximate composition of ice cream

Incorporation of processed amla preparations in ice cream at different levels significantly (p < 0.01) affected the total solids, fat, protein, ash, fibre, acidity, pH, ascorbic acid, antioxidant activity, phenol, tannins, specific gravity and overrun (Table 2).

Table 2.

Effect of addition of processed amla on the proximate composition of ice cream

| Level % |

Total solids % |

Fat % |

Protein % |

Ash % |

Fibre % |

|---|---|---|---|---|---|

| Shreds | |||||

| 0 | 37.49a ± 0.08 | 11.03a ± 0.01 | 5.34a ± 0.03 | 0.728e ± 0.006 | NDe |

| 5 | 36.28b ± 0.14 | 10.70b ± 0.09 | 5.18b ± 0.01 | 0.772d ± 0.006 | 0.132d ± 0.004 |

| 10 | 35.03c ± 0.04 | 10.33c ± 0.01 | 4.98c ± 0.04 | 0.815c ± 0.001 | 0.275c ± 0.003 |

| 15 | 33.76d ± 0.76 | 9.94d ± 0.03 | 4.72d ± 0.01 | 0.831b ± 0.001 | 0.408b ± 0.003 |

| 20 | 32.60e ± 0.04 | 9.63e ± 0.03 | 4.54e ± 0.01 | 0.850a ± 0.003 | 0.484a ± 0.003 |

| CD, 5 % | 0.137 | 0.068 | 0.013 | 0.007 | 0.008 |

| Pulp | |||||

| 0 | 37.49a ± 0.09 | 11.03a ± 0.02 | 5.23a ± 0.02 | 0.730e ± 0.003 | NDe |

| 5 | 36.19b ± 0.04 | 10.64b ± 0.01 | 5.07b ± 0.04 | 0.752d ± 0.001 | 0.107d ± 0.003 |

| 10 | 34.64c ± 0.03 | 10.30c ± 0.02 | 4.85c ± 0.01 | 0.786c ± 0.002 | 0.193c ± 0.001 |

| 15 | 33.56d ± 0.02 | 9.91d ± 0.01 | 4.64d ± 0.01 | 0.801b ± 0.002 | 0.291b ± 0.002 |

| 20 | 32.52e ± 0.02 | 9.60e ± 0.02 | 4.32e ± 0.01 | 0.820a ± 0.002 | 0.420a ± 0.006 |

| CD, 5 % | 0.137 | 0.079 | 0.153 | 0.008 | 0.004 |

| Preserve | |||||

| 0 | 37.49e ± 0.09 | 11.03a ± 0.01 | 5.21a ± 0.03 | 0.730e ± 0.002 | NDe |

| 5 | 38.73d ± 0.04 | 10.72b ± 0.01 | 5.01b ± 0.03 | 0.754d ± 0.001 | 0.105d ± 0.002 |

| 10 | 39.90c ± 0.03 | 10.34c ± 0.01 | 4.81c ± 0.02 | 0.778c ± 0.003 | 0.187c ± 0.004 |

| 15 | 41.28b ± 0.04 | 9.97d ± 0.04 | 4.63d ± 0.01 | 0.805b ± 0.001 | 0.290b ± 0.001 |

| 20 | 43.03a ± 0.02 | 9.65e ± 0.02 | 4.28e ± 0.02 | 0.834a ± 0.003 | 0.419a ± 0.006 |

| CD, 5 % | 0.142 | 0.046 | 0.177 | 0.001 | 0.042 |

| Candy | |||||

| 0 | 37.49e ± 0.06 | 11.03a ± 0.01 | 5.31ab ± 0.03 | 0.730e ± 0.002 | NDe |

| 5 | 39.42d ± 0.04 | 10.72b ± 0.01 | 5.38a ± 0.01 | 0.764d ± 0.002 | 0.421d ± 0.005 |

| 10 | 41.60c ± 0.04 | 10.35c ± 0.01 | 5.26b ± 0.03 | 0.831c ± 0.003 | 0.852c ± 0.003 |

| 15 | 43.35b ± 0.05 | 10.01d ± 0.02 | 5.12c ± 0.01 | 0.870b ± 0.004 | 1.300b ± 0.016 |

| 20 | 45.87a ± 0.02 | 9.67e ± 0.01 | 4.97d ± 0.03 | 0.906a ± 0.003 | 1.690a ± 0.004 |

| CD, 5 % | 0.137 | 0.068 | 0.013 | 0.007 | 0.008 |

| Powder | |||||

| 0 | 37.49e ± 0.03 | 11.03a ± 0.01 | 5.31 ± 0.03 | 0.730e ± 0.003 | NDe |

| 0.5 | 37.80c ± 0.05 | 10.73b ± 0.01 | 5.35 ± 0.02 | 0.787d ± 0.003 | 0.080d ± 0.008 |

| 1.0 | 38.11b ± 0.06 | 10.37c ± 0.02 | 5.37 ± 0.02 | 0.841c ± 0.003 | 0.152c ± 0.002 |

| 1.5 | 38.36a ± 0.02 | 9.97d ± 0.04 | 5.40 ± 0.03 | 0.891b ± 0.003 | 0.247b ± 0.001 |

| 2.0 | 37.70d ± 0.04 | 9.66e ± 003 | 5.43 ± 0.01 | 0.990a ± 0.004 | 0.328a ± 0.006 |

| CD, 5 % | 0.076 | 0.050 | NS | 0.008 | 0.007 |

n = 3, Values are Mean ± Standard Deviation, Values in a column of a block with different superscripts differ significantly

ND Non detectable, NS Non significant

Total solids play an important role in controlling the ice cream quality. The total solid content decreased as the level of shred and pulp was raised. This decrease was due to lower solids and higher moisture content of the shreds and pulp than ice cream mix. These results are in accordance with Pinto et al. (2004, 2006) who reported that ginger shreds and ginger juice addition at increased levels lowered the total solid content of ice cream. On the other hand the total solid content of ice cream samples increased on inclusion of preserve, candy and powder due to their high dry matter content. Similar results were earlier reported by Bajwa et al. (2003) and Murtaza et al. (2004) in strawberry pulp and fig paste ice cream.

The fat content decreased progressively as the level of amla incorporation increased. This was due to the very low (0.1 %) fat in amla berries. Fruits contain less fat so their incorporation leads to decrease in fat content. The results are in concordance with Bajwa et al. (2003), Murtaza et al.(2004), Pinto et al. (2004) and Temiz and Yesilsu (2010), who observed that fat content in ice cream decreased on addition of strawberry pulp, fig paste, ginger shreds and grape and mulberry pekmez, respectively. The addition of amla preparations significantly (p < 0.01) reduced the protein content except for powder. Temiz and Yesilsu (2010) found the reduction in protein content of the ice cream with increased levels of mulberry and grape pekmez. Earlier, Pinto et al. (2004, 2006) also reported similar results with ginger shreds and juice ice cream. A non-significant increase was noticed in protein content of ice creams with amla powder. Incorporation of black tea into the milk increased the protein content of the mix due to the diffusion of its substances (Karaman and Kayacier 2011). Abdullah et al. (2003) and Choo et al. (2010) described similar results on addition of soymilk blends and coconut virgin oil in ice cream at higher levels. Ash content of all ice cream samples increased with augmentation of processed amla product at higher levels. Addition of strawberry pulp, fig paste, ginger shreds and juice, grape and mulberry pekmez in ice cream increased the ash content (Bajwa et al. 2003; Murtaza et al. 2004; Pinto et al. 2004, 2006; Temiz and Yesilsu 2010). In control ice cream fibre was not detected because milk and its products are deficient in this component. Incorporation of amla preparations significantly (p < 0.01) increased the fibre content of ice cream.

Effect of incorporation of processed amla on the physico-chemical properties of ice cream

Incorporation of processed amla caused significant (p < 0.01) rise in acidity and drop in pH of all ice cream samples (Table 3). Ice cream with higher inclusion had greater titratable acidity while least was observed in the control sample. This was due to the presence of ascorbic acid and phenolic substances in amla. Sagdic et al. (2011) reported that the addition of phenolic rich substances, like elagic acid and gallic acid, enhanced the acidity of ice cream due to acidic nature of these. The results are in accordance with those of earlier workers as reported by Hwang et al. (2009) with grape wine lees, Temiz and Yesilsu (2010) with mulberry and grape pekmez and Bajwa et al. (2003) with strawberry pulp.

Table 3.

Effect of addition of processed amla on the physicochemical properties of ice cream

| Level, % | Acidity, % lactic acid | pH | Ascorbic acid, mg/100 g | Antioxidant activity, % inhibition of DPPH | Total Phenolic content, g/100 gGAE | Tannins, mg/100 g of tannic acid | Overrun, % | Specific gravity |

|---|---|---|---|---|---|---|---|---|

| Shreds | ||||||||

| 0 | 0.174a ± 0.002 | 6.64a ± 0.02 | NDe | 15.00e ± 0.19 | NDe | NDe | 68.04a ± 0.04 | 0.533c ± 0.002 |

| 5 | 0.389b ± 0.004 | 6.15b ± 0.03 | 25.52d ± 0.03 | 19.80d ± 1.44 | 0.183d ± 0.002 | 0.136d ± 0.004 | 60.70b ± 0.5 | 0.563bc ± 0.004 |

| 10 | 0.477c ± 0.004 | 5.76c ± 0.01 | 46.83c ± 0.03 | 23.50c ± 1.00 | 0.321c ± 0.003 | 0.190c ± 0.004 | 54.66c ± 0.05 | 0.585b ± 0.005 |

| 15 | 0.590d ± 0.004 | 5.66d ± 0.04 | 62.32b ± 0.02 | 26.20b ± 0.70 | 0.495b ± 0.002 | 0.299b ± 0.002 | 47.09d ± 0.09 | 0.616a ± 0.005 |

| 20 | 0.720e ± 0.004 | 5.28e ± 0.04 | 93.60a ± 0.04 | 31.70a ± 2.04 | 0.701‑a ± 0.002 | 0.387a ± 0.002 | 44.64e ± 0.06 | 0.628a ± 0.005 |

| CD, 5 % | 0.009 | 0.025 | 3.97 | 1.98 | 0.015 | 0.006 | 0.080 | 0.011 |

| Pulp | ||||||||

| 0 | 0.174a ± 0.001 | 6.63a ± 0.02 | NDe | 15.00e ± 1.0 | NDe | ND | 68.65a ± 0.03 | 0.532e ± 0.002 |

| 5 | 0.320b ± 0.004 | 6.41b ± 0.01 | 6.02d ± 0.02 | 19.5d ± 1.73 | 0.081d ± 0.002 | 0.006 ± 0.003 | 63.70b ± 0.53 | 0.547d ± 0.005 |

| 10 | 0.432c ± 0.003 | 6.10c ± 0.03 | 11.76c ± 0.05 | 23.00c ± 3.61 | 0.146c ± 0.002 | 0.013 ± 0.001 | 59.66c ± 0.02 | 0.566c ± 0.006 |

| 15 | 0.506d ± 0.004 | 6.00d ± 0.04 | 17.06b ± 0.02 | 27.40b ± 1.73 | 0.203b ± 0.003 | 0.073 ± 0.002 | 54.01d ± 0.05 | 0.588b ± 0.004 |

| 20 | 0.629e ± 0.004 | 5.75e ± 0.01 | 23.08a ± 0.04 | 31.33a ± 0.82 | 0.257a ± 0.003 | 0.021 ± 0.001 | 50.64e ± 0.03 | 0.602a ± 0.001 |

| CD, 5 % | 0.008 | 0.02 | 0.047 | 3.05 | 0.004 | NS | 0.051 | 0.010 |

| Preserve | ||||||||

| 0 | 0.171a ± 0.002 | 6.63a ± 0.03 | NDe | 15.00e ± 1.00 | NDe | NDe | 68.14a ± 0.04 | 0.533a ± 0.003 |

| 5 | 0.180b0.004 | 6.60a ± 0.04 | 0.82d ± 0.01 | 19.67d ± 1.04 | 0.052d ± 0.001 | 0.009d ± 0.001 | 61.21b ± 0.07 | 0.554a ± 0.002 |

| 10 | 0.189c ± 0.004 | 6.55b ± 0.03 | 1.69c ± 0.01 | 23.50c ± 1.00 | 0.092c ± 0.003 | 0.019c ± 0.004 | 56.14c ± 0.04 | 0.580a ± 0.004 |

| 15 | 0.243d ± 0.003 | 6.25c ± 0.04 | 2.31b ± 0.02 | 27.40b ± 0.44 | 0.153b ± 0.002 | 0.027b ± 0.004 | 51.29d ± 0.10 | 0.600ab ± 0.004 |

| 20 | 0.270e ± 0.004 | 5.92d ± 0.03 | 3.25a ± 0.01 | 30.83a ± 0.26 | 0.190a ± 0.002 | 0.037a ± 0.002 | 46.13e ± 0.03 | 0.622b ± 0.002 |

| CD, 5 % | 0.008 | 0.046 | 0.027 | 1.46 | 0.006 | 0.0004 | 1.357 | 0.009 |

| Candy | ||||||||

| 0 | 0.171a ± 0.002 | 6.65a ± 0.01 | NDe | 15.00e ± 1.025 | NDe | NDe | 68.54a ± 0.02 | 0.533e ± 0.003 |

| 5 | 0.175a ± 0.003 | 6.60b ± 0.03 | 0.66d ± 0.02 | 18.94d ± 0.53 | 0.046d ± 0.003 | 0.009d ± 0.004 | 57.43b ± 0.03 | 0.572d ± 0.002 |

| 10 | 0.193b ± 0.002 | 6.53c ± 0.02 | 1.10c ± 0.04 | 22.73c ± 0.62 | 0.085c ± 0.002 | 0.017c ± 0.001 | 51.21c ± 0.02 | 0.598c ± 0.002 |

| 15 | 0.247c ± 0.001 | 6.15d ± 0.03 | 1.76b ± 0.02 | 27.27b ± 0.36 | 0.144b ± 0.001 | 0.024b ± 0.002 | 46.02d ± 0.03 | 0.619b ± 0.003 |

| 20 | 0.279d ± 0.004 | 5.88e ± 0.03 | 2.20a ± 0.05 | 30.76a ± 0.95 | 0.197a ± 0.001 | 0.042a ± 0.001 | 40.29e ± 0.06 | 0.645a ± 0.004 |

| CD, 5 % | 0.008 | 0.02 | 0.037 | 1.75 | 0.004 | 0.001 | 0.102 | 0.010 |

| Powder | ||||||||

| 0 | 0.171a ± 0.001 | 6.65a ± 0.03 | NDe | 15.00e ± 1.00 | NDe | NDd | 68.70a ± 0.04 | 0.532e ± 0.001 |

| 0.5 | 0.203b ± 0.002 | 6.30b ± 0.01 | 3.08d ± 0.01 | 19.67d ± 0.53 | 0.018d ± 0.002 | 0.002c ± 0.001 | 66.12b ± 0.02 | 0.537d ± 0.004 |

| 1.0 | 0.319c ± 0.004 | 6.01c ± 0.01 | 6.17c ± 0.01 | 23.50c ± 1.00 | 0.024c ± 0.001 | 0.004b ± 0.002 | 64.53c ± 0.02 | 0.548c ± 0.006 |

| 1.5 | 0.454d ± 0.001 | 5.72d ± 0.01 | 8.80b ± 0.04 | 27.47b ± 0.36 | 0.038b ± 0.002 | 0.007a ± 0.002 | 60.21d ± 0.03 | 0.562b ± 0.001 |

| 2.0 | 0.544e ± 0.003 | 5.55e ± 0.04 | 12.20a ± 0.10 | 30.84a ± 0.17 | 0.051a ± 0.001 | 0.008a ± 0.001 | 56.05e ± 0.05 | 0.577a ± 0.004 |

| CD, 5 % | 0.008 | 0.056 | 0.055 | 1.31 | 0.004 | 0.002 | 0.157 | 0.009 |

n = 3, Values are Mean ± Standard Deviation, Values in a column of a block with different superscripts differ significantly

ND Non detectable, NS Non significant

Dietary intake of ascorbic acid is very important for humans as they are not able to synthesize these compounds but require them to neutralize reactive oxygen species (Rababah et al. 2005). Ascorbic acid was not detected in control ice cream, however, it increased significantly (p < 0.01) with the addition of each form of Amla. The ascorbic acid content of ice cream incorporated with Kiwi juice increased as the level of inclusion was raised (Waterhouse et al. 2013).

Amla incorporated ice cream samples were found to have higher amount of antioxidant activity, total phenols and tannins than control sample. This remarkable increase in antioxidant activity was due to more total phenols and tannins infusion into the ice cream matrix. Teh et al. (2005) reported that frozen blueberry-soy dessert had higher antioxidant activity as compared to plain ice cream. Hwang et al. (2009) observed that addition of grape wine lee resulted in increment of total phenols and tannins in ice cream. The addition of phenolic rich substances increased the total phenols of the ice cream (Sagdic et al. 2011). Amla being a rich source of total phenols and tannins resulted in increase of these substances in ice cream on its inclusion.

Overrun is a measurement that relates to the increase in volume of ice cream during processing. It is related to yield and profit to the producer. As the level of processed amla product increased in the ice cream, it significantly (p < 0.01) decreased the overrun value. Control ice cream had higher overrun which was reduced on addition of processed amla. This was due to exertion of deleterious effect by weakening the air incorporation. The results are in accordance to ice cream mixes containing potato pulp (Das et al. 1989). Pinto et al. (2004) and Murtaza et al. (2004) found that addition of ginger shreds and fig paste at higher levels resulted in lower overrun values in ice cream. Similar results were reported by Temiz and Yesilsu (2010) in mulberry and grape pekmez ice cream. Addition of raw or processed products in ice cream mix restricts the air incorporation during freezing, which results in the drop of overrun values (Erkaya et al. 2012). Control ice cream had a lowest specific gravity of 0.533 and it highest for ice cream samples with high levels of processed amla product. Arbuckle (1997) reported that specific gravity of ice cream increased with decrease in overrun values. In the study of Samahy et al. (2009), overrun of cactus pear pulp ice cream decreased from 55.71 to 43.11 % when specific gravity increased from 0.71 to 0.86.

Effect of incorporation of processed amla on the color attributes (L*, a* and b*) of ice cream

Color is one of the most important qualities of foods and food colors constitute a major additive as it enhances the acceptance and appeal of a food item. ‘L’ value which designates whiteness of the product, decreased significantly (p < 0.01) as the level of amla incorporation increased (Table 4). It was due to the color of processed amla and also due to tannins. In grape and mulberry pekmez incorporated ice cream, Temiz and Yesilsu (2010) reported that the ‘L’ value decreased as the level of pekmez incorporation rose, which was due to the color of product and its oxidation that made product darker and in turn increased the absorption of light. Greenness of samples increased as the level of shreds increased, which is reflected in negative ‘a’ value. Ice cream with amla shreds showed more green color whereas samples with pulp, preserve, candy and powder had more red color when compared to control. Increase in levels of amla shreds decreased the ‘b’ values of ice cream; however, it increased with pulp, preserve, candy and powder. This indicated that yellowness of shred ice cream was reduced as the level of incorporation raised. Sagdic et al. (2011) reported that the addition of phenolic substance caused a significant change on the color properties of ice cream compared to control. Incorporation of grape wine lee resulted a significant increase in ‘a’ and ‘b’ values of ice cream samples (Hwang et al. 2009).

Table 4.

Effect of processed amla incorporation on color attributes (L, a* and b* values) of ice cream

| Levels, % | L | a* | b* |

|---|---|---|---|

| Shreds | |||

| 0 | 69.47a ± 0.04 | −1.55c ± 0.07 | 3.55a ± 0.04 |

| 5 | 67.34b ± 0.03 | −1.68bc ± 004 | 3.27a ± 0.02 |

| 10 | 64.23c ± 0.02 | −1.86b ± 0.02 | 3.08ab ± 0.05 |

| 15 | 60.10d ± 0.05 | −2.59a ± 0.06 | 2.75b ± 0.03 |

| 20 | 58.77e ± 0.02 | −2.70a ± 0.45 | 2.04c ± 0.03 |

| CD, 5 % | 0.072 | 0.325 | 0.787 |

| Pulp | |||

| 0 | 69.32a ± 0.05 | −1.53a ± 0.03 | 3.52e ± 0.03 |

| 5 | 69.37a ± 0.03 | −1.23b ± 0.04 | 4.35d ± 0.04 |

| 10 | 58.90b ± 0.96 | −0.89c ± 0.06 | 4.97c ± 0.04 |

| 15 | 53.82c ± 0.33 | −0.63d ± 0.02 | 5.88b ± 0.04 |

| 20 | 49.37d ± 0.07 | −0.48e ± 0.06 | 6.53a ± 0.04 |

| CD, 5 % | 0.179 | 0.054 | 0.030 |

| Preserve | |||

| 0 | 68.89a ± 0.04 | −1.44e ± 0.06 | 3.25e ± 0.05 |

| 5 | 62.85b ± 0.03 | −0.73d ± 0.03 | 4.66d ± 0.05 |

| 10 | 56.75c ± 0.02 | −0.21c ± 0.04 | 5.24c ± 0.02 |

| 15 | 52.15d ± 0.03 | 0.75b ± 0.05 | 5.97b ± 0.06 |

| 20 | 44.89e ± 0.07 | 1.18a ± 0.05 | 6.89a ± 0.05 |

| CD, 5 % | 0.062 | 0.051 | 0.071 |

| Candy | |||

| 0 | 69.45a ± 0.03 | −1.53e ± 0.03 | 3.55e ± 0.05 |

| 5 | 60.44b ± 0.03 | −0.67d ± 0.02 | 4.87d ± 0.04 |

| 10 | 53.55c ± 0.03 | −0.11c ± 0.03 | 5.60c ± 0.05 |

| 15 | 50.94d ± 0.05 | 0.82b ± 0.02 | 6.26b ± 0.06 |

| 20 | 41.64e ± 0.04 | 1.22a ± 0.02 | 7.02a ± 0.02 |

| CD, 5 % | 0.518 | 0.056 | 0.067 |

| Powder | |||

| 0 | 68.45a ± 0.04 | −1.48e ± 0.02 | 3.50e ± 0.05 |

| 0.5 | 68.01b ± 0.02 | −0.89d ± 0.07 | 3.64d ± 0.02 |

| 1.0 | 66.47c ± 0.05 | −0.57c ± 0.04 | 3.97c ± 0.02 |

| 1.5 | 64.93d ± 0.08 | −0.34b ± 0.03 | 4.50b ± 0.05 |

| 2.0 | 61.40e ± 0.1 | 1.03a ± 0.02 | 4.88a ± 0.04 |

| CD, 5 % | 0.359 | 0.045 | 0.108 |

n = 3, Values are Mean ± Standard Deviation, Values in a column of a block with different superscripts differ significantly

Effect of incorporation of processed amla on the first dripping time and melting properties of ice cream

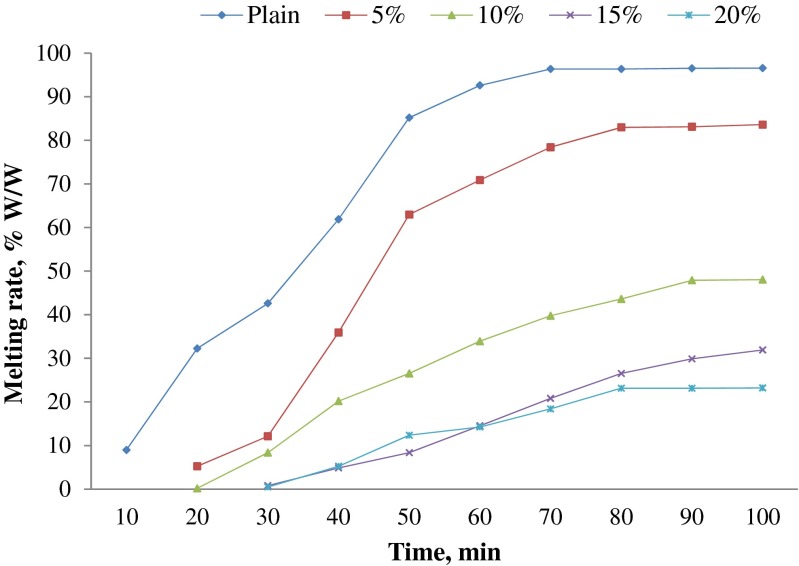

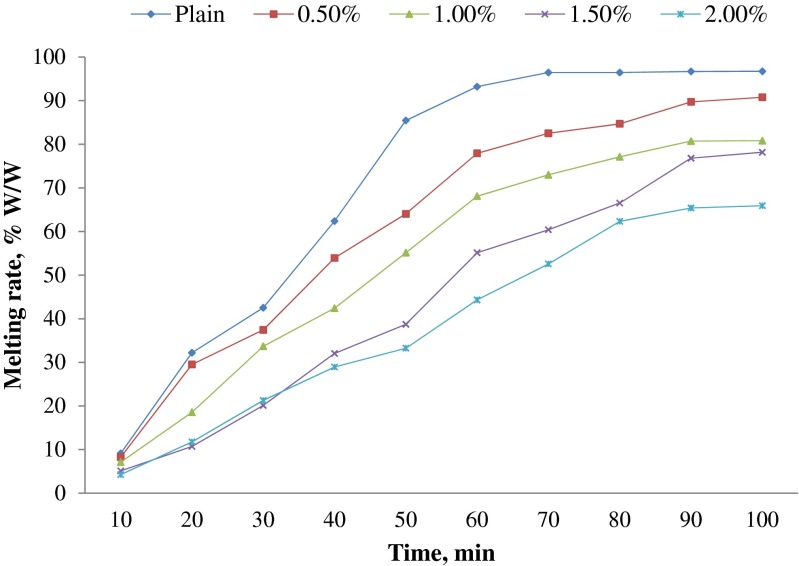

Addition of amla shreds and pulp had appreciable effect on the first dripping time of ice cream as shown in Table 5. The first dripping time of control was least which increased as the level of processed amla increased. Herald et al. (2008) reported that the first dripping time of control ice cream was 5 min. Melting rate, being an important factor of ice cream, is greatly influenced by its composition, additives used during manufacturing, amount of air incorporated (overrun), nature of ice crystals and network of fat globules formed during freezing (Moeenfard and Tehani 2008). The melting rate was maximum in control which decreased as the level of processed amla was raised (Figs. 1, 2, 3, 4 and 5). This was due to the additional solids alongwith pectin, a hydrocolloid, of amla. Incorporation of amla hindered air incorporation, thereby, reducing the overrun and caused decrease in melting rate of ice cream. Bajwa et al. (2003) and Gafour et al. (2007) reported that melting resistance was increased as the level of strawberry pulp and black mulberry and red pulp, respectively, was raised.

Table 5.

Effect of processed amla incorporation on the first dripping time of ice cream

| Level@, % | Shreds | Pulp | Preserve | Candy | Powder | |

|---|---|---|---|---|---|---|

| 0 | 4.28e ± 0.03 | 4.26e ± 0.56 | 4.27e ± 0.08 | 4.29e ± 0.07 | 4.29e ± 0.07 | |

| 5/0.5 | 16.50d ± 0.17 | 12.30d ± 0.43 | 15.53d ± 0.04 | 14.49d ± 0.04 | 4.80d ± 0.08 | |

| 10/1.0 | 19.00c ± 0.60 | 16.00c ± 0.62 | 18.50c ± 0.04 | 17.03c ± 0.04 | 4.52c ± 0.03 | |

| 15/1.5 | 22.00b ± 0.78 | 21.00b ± 0.70 | 21.48b ± 0.06 | 21.51b ± 0.05 | 5.18b ± 0.07 | |

| 20/2.0 | 25.00a ± 0.50 | 24.00a ± 0.78 | 24.18a ± 0.04 | 24.08a ± 0.06 | 5.39a ± 0.07 | |

| ANOVA | ||||||

| Source | df | MSS | ||||

| Treatment | 4 | 190.81** | 179.49** | 178.40** | 176.79** | 0.618** |

| Error | 35 | 0.75 | 1.71 | 0.0021 | 0.002 | 0.0027 |

n = 3, Values are Mean ± Standard Deviation, Values in a column with different superscripts differ significantly

@5, 10, 15 &20 % for shreds, pulp, candy, preserve and 0.5, 1.0, 1.5 & 2.0 % for powder

**Significant at p < 0.01

Fig. 1.

Effect of amla shreds incorporation on the melting rate of ice cream

Fig. 2.

Effect of amla pulp incorporation on the melting rate of ice cream

Fig. 3.

Effect of amla preserve incorporation on the melting rate of ice cream

Fig. 4.

Effect of amla candy incorporation on the melting rate of ice cream

Fig. 5.

Effect of amla powder incorporation on the melting rate of ice cream

Effect of incorporation of processed amla on the sensory scores of ice cream

Ice cream prepared with incorporation of processed amla was found to have variable sensory scores with different preparations (Table 6). The scores differed significantly for mouthfeel and overall acceptability in ice cream incorporating shreds; flavor and overall acceptability for pulp and flavor for preserve whereas and other sensory attributes did not differ significantly. As the level of shreds and pulp increased sweetness of ice cream was lowered due to dilution effect thereby lowering the sensory scores. The overall acceptability scores were highest at 5 % level of incorporation. On the other hand sensory scores of ice cream samples did not differ significantly with the inclusion of preserve, candy and preserve because the sweetness level increased which was perceived to be high and detrimental to overall acceptability scores which were comparable at all levels (5–20 %) of incorporation. Therefore, another trial was conducted in which the sugar content of the formulation was reduced by 1 and 2 %, respectively for 5 and 10 % level of both preserve and candy. In this trial the results of sensory scores came out to be similar and significant (p < 0.01) being significantly higher in 10 % formulation than 5 % (Table 7). Tutti-frutti which is candied raw papaya is commonly used in cold deserts and as toppings for the ice-creams and sundaes (Anon 2015). On incorporation of amla powder the scores for appearance/color improved and body and texture, mouthfeel and flavor scores dwindled with augmented level of powder incorporation.

Table 6.

Effect of addition of processed amla on the sensory scores of ice cream

| Level, % | Appearance/color | Body and texture | mouthfeel | Flavor | Overall acceptability |

|---|---|---|---|---|---|

| Shreds | |||||

| 0 | 8.13 ± 0.63 | 8.00 ± 0.76 | 8.38a ± 0.76 | 7.75 ± 0.46 | 8.16a ± 0.72 |

| 5 | 8.25 ± 0.71 | 8.38 ± 0.74 | 8.63a ± 0.52 | 7.25 ± 0.71 | 8.37 a ± 0.56 |

| 10 | 8.00 ± 0.76 | 7.75 ± 0.71 | 7.62ab ± 0.56 | 7.62 ± 0.45 | 7.78 a ± 0.49 |

| 15 | 7.75 ± 0.71 | 7.50 ± 0.92 | 7.12b ± 0.68 | 7.25 ± 0.88 | 7.41ab ± 0.88 |

| 20 | 7.75 ± 0.92 | 7.25 ± 0.89 | 6.87b ± 0.71 | 7.00 ± 0.92 | 7.22b ± 0.90 |

| CD, 5 % | NS | NS | 0.793 | NS | 0.732 |

| Pulp | |||||

| 0 | 8.13 ± 0.83 | 8.37 ± 0.74 | 8.25 ± 0.71 | 8.00a ± 0.92 | 8.16a ± 0.70 |

| 5 | 8.50 ± 0.76 | 7.81 ± 0.71 | 8.37 ± 0.75 | 8.06 a ± 0.56 | 8.36a ± 0.74 |

| 10 | 8.38 ± 0.49 | 7.76 ± 0.58 | 7.81 ± 0.76 | 8.25 a ± 0.71 | 8.20a ± 0.54 |

| 15 | 7.88 ± 0.58 | 7.80 ± 0.75 | 7.62 ± 0.91 | 7.50ab ± 0.76 | 7.70ab ± 0.56 |

| 20 | 7.75 ± 0.65 | 7.75 ± 0.71 | 7.25 ± 0.89 | 6.25 b ± 0.53 | 7.29b ± 0.66 |

| CD, 5 % | NS | NS | NS | 0.901 | 0.655 |

| Preserve | |||||

| 0 | 8.13 ± 0.83 | 8.00 ± 0.92 | 7.63 ± 0.74 | 7.63ab ± 0.91 | 7.81 ± 0.72 |

| 5 | 8.00 ± 0.71 | 7.87 ± 0.83 | 8.12 ± 0.65 | 8.00a ± 0.53 | 8.25 ± 0.44 |

| 10 | 8.25 ± 0.71 | 8.13 ± 0.83 | 8.13 ± 0.83 | 8.25a ± 0.71 | 8.21 ± 0.62 |

| 15 | 8.37 ± 0.51 | 8.00 ± 0.53 | 8.00 ± 0.53 | 7.50b ± 0.53 | 7.93 ± 0.30 |

| 20 | 8.63 ± 0.44 | 7.63 ± 0.75 | 7.50 ± 0.76 | 7.00c ± 0.53 | 7.53 ± 0.52 |

| CD, 5 % | NS | NS | NS | 0.715 | NS |

| Candy | |||||

| 0 | 8.00 ± 0.76 | 8.00 ± 0.76 | 8.06 ± 0.73 | 8.00 ± 0.71 | 8.06 ± 0.62 |

| 5 | 8.13 ± 0.63 | 8.25 ± 0.71 | 8.03 ± 0.66 | 8.06 ± 0.56 | 8.10 ± 0.58 |

| 10 | 8.13 ± 0.35 | 8.25 ± 0.46 | 8.12 ± 0.57 | 7.93 ± 0.42 | 8.06 ± 0.67 |

| 15 | 8.25 ± 0.71 | 8.25 ± 0.46 | 8.00 ± 0.53 | 7.87 ± 0.83 | 8.03 ± 0.54 |

| 20 | 8.38 ± 0.52 | 8.05 ± 0.81 | 7.88 ± 0.64 | 7.56 ± 0.49 | 7.95 ± 0.59 |

| CD, 5 % | NS | NS | NS | NS | NS |

| Powder | |||||

| 0 | 8.13ab ± 0.83 | 8.62a ± 0.52 | 8.50a ± 0.52 | 8.38a ± 0.53 | 8.50a ± 0.51 |

| 0.5 | 7.25b ± 0.92 | 8.75a ± 0.46 | 8.62a + ±0.51 | 8.50a ± 0.53 | 8.62a + ±0.42 |

| 1.0 | 7.31a ± 0.59 | 8.25a ± 0.71 | 8.25a ± 0.71 | 7.75ab ± 0.65 | 8.09ab ± 0.63 |

| 1.5 | 8.50a ± 0.59 | 7.75ab ± 1.03 | 7.75ab ± 0.88 | 6.87b ± 0.99 | 7.42b ± 0.89 |

| 2.0 | 8.62a ± 0.52 | 7.25b ± 1.16 | 7.13b ± 1.46 | 6.50b ± 0.92 | 7.03b ± 1.06 |

| CD, 5 % | 0.781 | 0.838 | 0.903 | 0.762 | 0.748 |

n = 8, Values are Mean ± Standard Deviation, Values in a column of a block with different superscripts differ significantly

Table 7.

Effect of addition of different levels of amla candy on the sensory scores of ice cream with reduced sugar content

| Level,% | Appearance/color | Body and texture | mouthfeel | Flavor | Overall acceptability | |

|---|---|---|---|---|---|---|

| Control | 7.50b ± 0.53 | 7.50b ± 0.53 | 7.13b ± 0.35 | 7.37b ± 0.91 | 7.38b ± 0.33 | |

| 5 | 8.13ab ± 0.63 | 7.62ab ± 0.52 | 7.75ab ± 0.46 | 8.13ab ± 0.37 | 7.90ab ± 0.31 | |

| 10 | 8.56a ± 0.49 | 8.31a ± 0.46 | 8.62a ± 0.51 | 8.94a ± 0.17 | 8.60a ± 0.29 | |

| ANOVA | ||||||

| Source | df | MSS | ||||

| Treatment | 3 | 2.28** | 1.53** | 4.54** | 4.88* | 3.07** |

| Error | 20 | 0.314 | 0.254 | 0.202 | 0.332 | 0.094 |

n = 8, Values are Mean ± Standard Deviation, Values in a column with different superscripts differ significantly

**Significant at p < 0.01

Conclusion

Ice cream was manufactured by incorporation of amla fruit in the form of shreds, pulp, preserve, candy and powder in the mix during the freezing step of its manufacture. Inclusion of processed amla products significantly influenced the composition of ice cream. They reduced fat and protein content (except for powder) and increased ash and fiber content of resultant ice cream. The amount of functional components i.e. ascorbic acid, antioxidant activity, total phenols and tannins increased significantly. However, the overrun of ice cream was lowered and melting resistance increased with enhanced inclusion of amla preparations. The overall acceptability scores were highest at 5 % level of incorporation of shreds and pulp and 10 % preserve and candy and 0.5 % powder. The sensory acceptability of amla ice cream could be further enhanced by either augmenting or reducing the sugar content of ice cream formulae depending upon the inclusion of processed preparation and consumer preference for extent of sweetness.

References

- Abdullah M, Rehman S, Zubair H, Saeed H M, Kousar S, Shahid M. Effect of skim milk in soymilk blend on the quality of ice cream. Pak J Nutr. 2003;2:305–311. doi: 10.3923/pjn.2003.305.311. [DOI] [Google Scholar]

- Akesowan A. Effect of combined stabilizers containing Konjac flour and κ-carrageenan on ice cream. Aust J Technol. 2008;12:81–85. [Google Scholar]

- Anonymous (2003) http://www.jpn-virtualvarsity.org/TFL/agriculture/ cashcropsamla.htm, retrieved 24 Oct 2014

- Anonymous (2015) http://en.wikipedia.org/wiki/Tutti_frutti_(food), retrieved 2 Feb 2015

- AOAC . Official methods of analysis. Washington DC: Association of Official Analytical Chemists; 2000. [Google Scholar]

- Arbuckle WS. Ice cream. New York: AVI Publishing Company, Inc; 1997. [Google Scholar]

- Bajwa UA, Huma N, Ehsan B, Jabbar K, Khurrama A. Effect of different concentration of strawberry pulp on the properties of ice cream. Int J Agric Biol. 2003;l5:635–637. [Google Scholar]

- Bureau of Indian Standards (1981) ISI handbook of food analysis. IS : SP : 18 Part XI Dairy products. Manak Bhawan, New Delhi

- Cam M, Erdogan F, Aslan D, Dinc M. Enrichment of functional properties of ice cream with pomegranate by-products. J Food Sci. 2013;78:C1543–C1550. doi: 10.1111/1750-3841.12258. [DOI] [PubMed] [Google Scholar]

- Choo SY, Leong S K, Henna F S L. Physicochemical and sensory properties of ice cream formulated with virgin coconut oil. Food Sci Technol Intl. 2010;16:531–511. doi: 10.1177/1082013210367546. [DOI] [PubMed] [Google Scholar]

- Das TC, Rao MR, Reddy CR, Krishana N, Sudhakar K. Ice cream made by incorporation of different levels of potato pulp. Ind J Dairy Sci. 1989;42:295–296. [Google Scholar]

- Duncan DB (1995) New multiple range and multiple F tests. Biometrics 11:1–42

- Erkaya T, Dagdemir E, Sengul M. Influence of cape gooseberry (Physalis Perimiana) addition on the chemical and sensory characteristics and mineral concentration of ice cream. J Food Res Int. 2012;45:331–335. doi: 10.1016/j.foodres.2011.09.013. [DOI] [Google Scholar]

- Gafour WA, Essawy EA, Salem AS. Incorporation of natural antioxidants into ice cream. Egypt J Dairy Sci. 2007;35:117–123. [Google Scholar]

- Ganju L, Karan D, Chanda S, Srivastava KK, Sawhney RC, Selvamurthy W. Immunomodulatory effects of agents of plant origin. Biomed Pharmacother. 2003;57:296–300. doi: 10.1016/S0753-3322(03)00095-7. [DOI] [PubMed] [Google Scholar]

- Garg A (2014) Ice cream market in India: opportunities and challenges. http://www.indiafoodbrief.com/index.php/food-a-beverage/114923ice%20cream%20market%20in%india-%20opportunities%20?challenges= retrieved 28 Apr 2015

- Herald HJ, Aramouni M, Ghoush MHA. Comparison study of egg yolks and egg alternatives in French vanilla ice cream. J Texture Stud. 2008;39:284–295. doi: 10.1111/j.1745-4603.2008.00143.x. [DOI] [Google Scholar]

- Hwang JY, Shyu YS, Hsu CK. Grape wine lees improves the rheological and adds antioxidant properties to ice cream. LWT Food SciTechnol. 2009;42:312–318. doi: 10.1016/j.lwt.2008.03.008. [DOI] [Google Scholar]

- Kalra CL. The chemistry and technology of amla (Phyllanthus emblica)- a resume. Indian Food Packer. 1988;42:67–83. [Google Scholar]

- Karaman S, Kayacier A. Rheology of ice cream mix flavored with black tea or herbal teas and effect of flavoring on the sensory properties of ice cream. Food Bioproc Technol. 2011 [Google Scholar]

- Lal G, Siddappa GS, Tandon GL. Preservation of fruits and vegetables. New Dehli: Publication and information division, ICAR; 1986. [Google Scholar]

- Larmond E (1982) Laboratory methods for sensory evaluation of food. Publication No 1637. Department of Agriculture, Ottawa

- Moeenfard M, Teharni MM. Effect of some stabilizers on the physicochemical and sensory properties of ice cream type frozen yogurt. American-Eurasian J Agric Environ Sci. 2008;4:584–589. [Google Scholar]

- Murtaza MA, Huma GN, Din MU, Shabbir MA, Mahmood SD. Effect of fat replacement by fig addition on ice cream quality. Int J Agric Biol. 2004;l6:68–70. [Google Scholar]

- Nath V, Sharma RK. Screening of anola (Emblica officinalis Gaert.) cultivars for processing. Progress Hortic. 1998;30:76–77. [Google Scholar]

- Nayak P, Tandon DK, Bhatt DK. Study on changes of nutritional and organoleptic quality of flavored candy prepared from aonla (Emblica officinalis G.) during storage. Intl J Nutr Meta. 2012;4:100–106. [Google Scholar]

- Patel A, Jana A, Aparnathi K, Pinto S. Evaluating sago as a functional ingredient in dietetic mango ice cream. J Food Sci Technol. 2011;47:582–585. doi: 10.1007/s13197-010-0119-9. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Pinto SV, Jana AH, Solanky MJ. Ginger juice based herbal ice cream and its physicochemical and sensory characteristics. Indian J Dairy Sci. 2004;57:315–319. [Google Scholar]

- Pinto S, Rathour AK, Jana AH, Parjapati JP, Solanky MJ. Ginger shreds as flavoring in ice cream. Nat Prod Radiance. 2006;5:15–18. [Google Scholar]

- Premi BR, Sethi V, Maini SB. Effects of steeping preservation on the quality of anola fruit during storage. J Food Sci Technol. 1999;36:244–247. [Google Scholar]

- Rababah TM, Ereifey KT, Howard L. Effect of ascorbic acid and dehydration on the concentration of total phenolics, anti-oxidant capacity, anthocyanins and color in fruits. J Agric Food Chem. 2005;53:4444–4447. doi: 10.1021/jf0502810. [DOI] [PubMed] [Google Scholar]

- Ranganna S. Handbook of analysis and quality control for fruit and vegetable products. New Delhi: TataMcGraw Hill Pub Co. Ltd; 1997. [Google Scholar]

- Ranote PS, Hothe RK, Bawa AS. Preperation evaluation and storage of preserve made from amla cultivars grown in kandi area of Punjab state. J Sci Indian Res. 2002;61:461–465. [Google Scholar]

- Ruck JA. Chemical methods for analysis of fruit and vegetable products. Summerland: Research branch Canada, Department of Agriculture; 1969. pp. 1–68. [Google Scholar]

- Sagdic O, Ozturk I, Cankurt H, Tornuk F. Interaction between some phenolic compounds and probiotic bacterium in functional ice cream production. Food Bioprocess Technol. 2011 [Google Scholar]

- Samahy SK, Youssef KM, Moussa TE (2009) Producing ice cream with concentrated cactus pear pulp: a preliminary study. J Professional Assoc Cactus Dev 11:1–12

- Shaviklo GR, Thorkelsson G, Sveinsdottir K, Rafipour F. Chemical properties and sensory quality of ice cream fortified with fish protein. J Sci Food Agric. 2011;91:1199–1204. doi: 10.1002/jsfa.4299. [DOI] [PubMed] [Google Scholar]

- Shimada K, Fujikawa K, Yahara K, Nakamura T (1992) Antioxidative properties of xanthin on autoxidation of soybean oil in cyclodextrin emulsion. J Agric Food Chem 40:945–948

- Shukla R, Sharma V (2014). Ice cream market in India. http://www.technopak.com/files/ice-cream%20market%20in%20india.pdf retrieved 22 Oct 2014

- Sidhu S, Pandhi P, Malhotra S, Vaiphei K, Khanduja KL. Beneficial effects of emblica officinalis in l-arginine-induced acute pancreatitis in rats. J Med Food. 2011;14:147–155. doi: 10.1089/jmf.2010.1108. [DOI] [PubMed] [Google Scholar]

- Singh E, Sharma S, Pareek A, Dwivedi J, Yadav S, Sharma S. Phytochemistry, traditional uses and cancer chemo preventive activity of Amla (Phyllanthusemblica): the sustainer. J Appl Pharm Sci. 2011;02:176–183. [Google Scholar]

- Swain T, Hillis WE. The phenolic constituents of Prunusdomestica I. The quantitative analysis of phenolic constituents. J Sci Food Agric. 1959;10:63–68. doi: 10.1002/jsfa.2740100110. [DOI] [Google Scholar]

- Teh YH, Dougherty MP, Camrie ME. Frozen blueberry soy dessert quality. J Food Sci. 2005;70:119–122. doi: 10.1111/j.1365-2621.2005.tb07115.x. [DOI] [Google Scholar]

- Temiz H, Yesilsu AF. Effect of pekmez addition on the physical, chemical and sensory properties of ice cream. Czech J Food Sci. 2010;28:538–546. [Google Scholar]

- Vijayanand P, Kulkarni SG, Reena P, Aksha M, Ramana KVR. Effect of processing on gooseberry fruits and quality changes in dehydrated gooseberry powder during storage. J Food Sci Technol. 2007;44:591–594. [Google Scholar]

- Waterhouse SD, Edmonds L, Wadhwa SS, Wibisono R. Producing ice cream using a substantial amount of juice from kiwifruit with green, gold or red flesh. Food Res Int. 2013;50:647–656. doi: 10.1016/j.foodres.2011.05.030. [DOI] [Google Scholar]

- Winton A L (1958) Analysis of Foods. 3rd printing. John Wiley and Sons Inc, New York, p 78–80

- Yokozawa T, Kim HY, Kim HJ. Amla (Emblica officinalis Gaertn) attenuates age-related renal dysfunction by oxidative stress. J Agric Food Chem. 2007;55(19):7744–7752. doi: 10.1021/jf072105s. [DOI] [PubMed] [Google Scholar]