Abstract

Three varieties of paddy in brown, red (non-waxy) and black (waxy) forms were de-husked and milled before and after inducing retro-gradation and their physical properties were studied. Normalized grain weight, porosity of parboiled paddy (PP) and its de-husked rice (DR), were high compared to their respective native. True and bulk density were lowest for black variety, its DR, its raw and parboiled forms compared to other varieties of paddy. Angle of repose increased from raw paddy to PP whereas it decreased from raw DR to parboiled DR. Under similar conditions of milling of DR, raw and parboiled milled rice of black variety was the darkest. Raw husk showed higher EMC compared to husk of parboiled. Hardness followed the pattern: Raw: Paddy (~230–280 N) > DR (~120–260 N) > Milled rice (~110 N); for parboiled: DR (~270–480 N) > PP (~260–425 N) > Parboiled milled rice (~250–340 N). Cooking time was high for DR of parboiled ones and least for waxy raw milled rice. Results of this study will be helpful in understanding the quality of pigmented rice cultivars, design and fabrication of some of the equipments in rice processing industry.

Keywords: Normalized grain weight, Hardness, Equilibrium moisture content, De-husked rice, Retro-gradation

Introduction

Rice (Oryza sativa L) is one of the most important domesticated cereals in Asia, where over 60 % of the calories consumed by the population come from this cereal. Rice is categorised by their husk and endosperm colour into red, green, violet, black, and brown varieties that give coloured kernels on shelling and white rice on polishing for longer duration (Finocchiaro et al. 2007). The pigmented rice has been consumed in China, Japan, and Korea in de-husked form for a long time, and is widely known as naturally enriched rice for taste and health improvements (Simmons and Williams 1997). Coloured rice shows stronger antioxidants and free radical scavenging activities compared to brown rice. Property of this coloured rice originates from the seed capsule. Purple and black rice were superior compared to red pigmented rice, as the former retained higher amounts of phytochemicals and antioxidant capacities in the cooked rice and hence this rice could be used in food product preparation (Sangeeta et al. 2012).

In order to understand design of storage, manufacture of handling and processing equipments, physical and engineering properties of agricultural grains are essential (Varnamkhasti et al. 2007). Static coefficient of friction on plywood, galvanized steel, mild steel and glass surface increased with increase in moisture content of grains and highest static coefficient was found on galvanized steel (Abdul et al. 2011). Bulk densities of all varieties of rice increased to the extent of 51 % after processing (Correa et al. 2007). To prepare light coloured parboiled rice, higher yield milled rice, 55–80 N hardness to the grain, optimum condition of period and temperature of soaking were standardized (Rabiul et al. 2002). Buggenhout et al. (2013) reviewed the work on breakage of raw and parboiled rice. Fan et al. (2000) investigated the head rice yield reduction of long and medium grain rice cultivars in relation to various harvesting and drying conditions. Chitra et al. (2010) reported changes in the dimensions of rice before and after processing. The hardness of cooked germinated brown rice was less than that of cooked standard brown rice (Parnsakhorn and Langkapin 2013). The objective of the present work was to determine the influence of the rice processing operations on physical and hardness properties of different rice varieties (two pigmented and a non pigmented variety of rice in their rough, brown/ de-husked and milled form) before and after inducing retro-gradation.

Materials and methods

Procurement of paddy

Three paddy varieties viz. IR-64 (brown), Jyothi-red pigmented were procured from Agriculture Produce Marketing Co-operative (APMC), Bandipalya, Mysore, Karnataka, India. Black Thai Jasmine (BTJ) paddy was procured from Malavalli taluk, Mandya district, Karnataka. These samples were harvested during December, 2011. They were cleaned of foreign material, packed in polyethylene bags and placed inside jute bags, and stored at 4 °C. The paddy samples were then taken out from cold and brought to room temperature before analysis.

Methodology

Inducing retro-gradation

The paddy (2 kg) was soaked in hot water and the mix was stirred, floating chaff was removed and the vessel was covered with jute sacks and left overnight (Sashikala et al. 2005). After 12 h, water was drained off and the paddy was spread on small wire-mesh trays, and steamed in an autoclave at open atmospheric pressure for 20 min. The gelatinized starch in the paddy was retro-graded by air drying in the shade (1 to 2 days) at room temperature (25–30 °C) to attain the moisture level of 12 to 13 %. Thus retrograded or parboiled paddy prepared was used for further studies.

Shelling/de-husking

A weighed sample (100 g) of paddy, before and after parboiling, from each variety was de-husked using the Laboratory Satake Sheller (Satake Corporation Tokyo, Japan), with rubber rolls adjusted to grain size so as to minimize the breakage. The de-husked rice and husk were weighed separately.

Milling/polishing

The shelled rice (150 g) of each variety was subjected to milling/polishing using a Mc-Gill polisher for 2 min with a pressure of 88.85 kPa. It consists of a wire-mesh screen with slotted perforated enclosure in which a shaft rubs the grain against the casing (frictional). Collected bran was sieved through #22 mesh sieve and adhering bran was removed from the milled rice by sieving through the same sieve, and degree of polish was calculated on the weight of brown or de- husked rice basis.

Broken rice

The raw and parboiled de-husked and milled rice produced were a mixture of respective head rice and broken. Grading these into different categories, such as small, large broken and head rice were determined manually using rectangular perforated sheets with dimpled type holes of diameter 3, 4 and 5 mm respectively.

Colour values / colour changes

The L*, a* and b* values for color of the above materials along with husk of each rice variety were measured using Colour Measurement Spectrophotometer (M/S Hunter lab scan XE model) with a viewing angle of 2°. The instrument was calibrated with a standard white plate having L*, a* and b* values of 92.67, −0.92 and 0.72, respectively, where ‘L*’ indicates degree of lightness or darkness (L* = 0 indicates perfect black and L* = 100 indicates most perfect white); ‘a*’ indicates degree of redness (+) and greenness (−); whereas ‘b*’ indicates degree of yellowness (+) and blueness (Lamberts et al. 2006).

Physical properties

Grain dimensions viz. Length (L), breadth (B) and thickness (T) were measured with Vernier calipers and L/B ratios were calculated. Weight of 1000 kernels of each sample was determined. The bulk density was determined by using a Bushel apparatus and the actual (true) density was determined by using the kerosene displacement method. Porosity, angle of repose and angle of friction of the raw, parboiled paddy, their respective de-husked rice and normalized grain weight [10 × Weight of grain (mg)] ÷ Length of grain (mm) were determined according to the method of Bhattacharya et al. (1972) and Sowbhagya et al. (1984).

Moisture content of the raw, parboiled paddy, husk, de-husked and milled rice was determined by drying at 130 °C for 2 h as per (AOAC 2000). Equilibrium moisture content on soaking at Room temperature (EMC-S) was estimated as per the procedure of Indudhara et al. (1971).

Cooking time

Cooking time was determined by parallel plate method (Desikachar and Subrahmanyan 1961; Ranghino 1966). The rice grains were cooked in excess water and few grains were withdrawn with a spatula at different intervals of time and pressed between two glass slides. The cooking time was recorded until the white opaque central core of the grain disappeared. In the case of parboiled rice, the rice was cooked in excess water and at different intervals of time; moisture content of the cooked grains was estimated. When moisture content reaches a value around 72 to 74 %, the cooking time was noted down.

Hardness

Universal Testing Machine (UTM) (Model: LR five series, M/s Llyod Instrument, England) was employed for measuring hardness of raw, as well as parboiled paddy and rice. The hardness was measured on compression mode, as the force required for 50 % compression of each grain which result in permanent deformation (breaking) of the grain and this parameter was recorded as breaking/crushing strength. Hardness value was measured for 50 individual grains and after eliminating the extreme and unmatched odd values, the mean of the remaining readings was calculated and are reported. Measurements were carried out using a 1 KN (One Kilo Newton) load cell and a 10 mm diameter probe at a cross head speed of 50 mm/min from a height of 2 mm from the base.

Statistical analysis

Data were analyzed using Graph Pad Instat statistical software (Graph Pad Software, Inc., La Jolla, CA, USA). Each experiment was performed in triplicate and the results were expressed as the mean values ± standard deviation. Results were analyzed and significance level was calculated using Tukey - Kramer multiple comparison test by means of one way ANOVA. Values with p < 0.05 were considered statistically significant.

Results and discussion

Moisture pick up while inducing retro-gradation

IR-64 and Jyothi (non-waxy) paddy varieties after soaking in hot water (overnight) picked up moisture of about 20 %, thus reaching total moisture content of around 33 % whereas Black Thai Jasmine (waxy) picked up about 27 %, thus reaching final moisture content of about 40 %. This difference was due to high branched component (amylo-pectin) in the Black variety which was in accordance with the observation made by Bharathi et al. (2012). After steaming for 20 min in open atmosphere, there was ~ 2 % increase in moisture content for non-waxy paddy varieties and ~1 % for waxy paddy, thus showing the differences that while steaming the branched component containing paddy could absorb less moisture.

Shelling/dehusking

Husk content of these three varieties varied from ~ 21 to 28 % before and after parboiling. There was less husk content after parboiling, because there was leach out from each variety during soaking step. The amount of husk reduced after parboiling was not remarkable, though not negligible. Highest husk content was noticed in black variety and almost same in other two (Fig. 1a). Chaff content varied from 0.2 to 0.8 % and after parboiling the content reduced, as during soaking step the floating chaff was removed by scooping. Before parboiling, the de-husked head rice in these varieties varied from 59 to 62 %. The content of head rice was 3 % less in black variety; otherwise all varieties showed almost same de-husked head rice content. In the de-husked rice broken, there were different sizes, 1/4th fell in a close range (~5 %) for Jyothi and Black variety, half and 1/4th were high in Black variety compared to other two, however, 3/4th broken were high and almost same in Jyothi and IR-64 (~8 %). Overall results on broken were about 15 to 16 % in IR-64 and Jyothi, in black variety the content was 3 % less than that of other two varieties. This was opposite to the observation made by Deepa and Singh (2010), Savitha and Singh (2011), where the broken percentage was high in Jyothi and was quite less in IR-64, indicating the varietal variation and processing conditions. The proportion of de-husked head rice and broken, depends on the method of harvesting, drying conditions, sheller used for dehusking.

Fig. 1.

a Shelling/de-husking, b Milling/polishing of IR-64, Jyothi and Black Thai Jasmine paddy

After parboiling, head rice increased from 59 to 79 % and broken reduced significantly in all varieties. It is well known that parboiling maximizes the head rice yield by minimizing the broken, and grains become hard. The starch gets completely gelatinized, apparently sufficient solubilization takes place in order to “cement” these cracks together, thus strengthening the kernel (Bhattacharya and Ali 1985; Savitha and Singh 2011 and Bharathi et al. 2012) and hence lesser breakage in the process of dehusking of parboiled paddy. The quantity of head rice in Black variety was around 69 %, which was less, as the husk content was high in this variety.

Milling/polishing

Under similar conditions of polishing of dehusked rice, parboiled rice showed less degree of polish (DOP) (6–7 %) compared to raw rice, which showed a high DOP (12 %), which indicates that bran layers consisting of aleurone, pericarp (consisting of nucellus, seed coat, endocarp and epicarp) on the endosperm in parboiled rice was highly resistant/or tightly bound because of parboiling process, also on the other hand, the bran layers on the caryopsis of raw rice were loose compared to that of parboiled rice such that they could fall easily while milling or polishing (Fig. 1b). Retentate on 22 # sieve was high in raw rice bran which varied from 6.6 to 8.5 % and it was least in the parboiled rice bran. This was because, in raw rice, the germ, pericarp layers were easily removable while milling and therefore the amount was high. On the other hand while parboiling operations (soaking, steaming and drying) these fractions on the caryopsis adhere/bound tightly, which will not fall easily while milling and therefore the amount of retentate on 22 # was less in the parboiled rice bran.

In raw de-husked rice, one fourth broken were high in black variety (~37 %) compared to other two varieties (~30 %); almost similar pattern existed in half and three fourth broken, though the percentages were less. Overall percentage of broken were highest in black variety (~62 %), other two were around 50 %, on polishing or milling of dehusked rice of respective varieties. This was also seen by Deepa and Singh (2010), Savitha and Singh (2011). As the broken were high, corresponding head rice in milled raw rice was less and least was seen in black variety.

The hardness of grains was greatly affected by the conditions of parboiling like moisture content, the extent of gelatinization and retro-gradation (Islam et al. 2004). Photographs of different forms of IR-64, Jyothi and Black Thai Jasmine paddy, are depicted in (Fig. 2a, b and c).

Fig. 2.

Photographs of different forms of raw and parboiled paddy, head de-husked and milled rice. a IR-64 (Non-pigmented), b Jyothi (Red-Pigmented) and c Black Thai Jasmine (Black pigmented)

Physical properties

IR 64 (brown rice)

Physical properties of IR-64 paddy and its de-husked rice/brown rice are shown in Table 1. In the paddy after parboiling, l, b, and t and l/b decreased marginally indicating linear dimensions changed negligibly while parboiling. Ratios of b and t, 1000 kernel weight and NGW increased marginally indicating the result of various steps involved during hydrothermal treatment. True density (TD) decreased to the extent of 2.4 % while bulk density decreased to an extent of ~ 13 %, indicating that there was an increase in volume after processing of paddy. It is also seen that bulk density (BD) will always be less than the true density. Porosity increases by ~ 10 %, indicating that in parboiled paddy, there was loose packing of grains compared to that of raw paddy. Angle of repose increased by about 15 %, indicating that the angle formed by the parboiled paddy with the horizontal surface had increased, which is because of increase in size of paddy after parboiling. Angle of friction with smooth and rough surface increased by ~ 12 and 4 % respectively indicating change in surface property of the retro-graded paddy.

Table. 1.

Physical properties of raw, parboiled, IR-64, Jyothi and Black Thai Jasmine paddy and their dehusked/brown rice

| Physical properties | IR-64 (Non-pigmented) | Jyothi (Red-pigmented) | Black Thai Jasmine (Black-pigmented) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| RIR-64p | PIR-64p | RIR-64BR | PIR-64BR | RJp | PJp | RJDR | PJDR | RBTJp | PBTJp | RBTJDR | PBTJDR | |

| Length (mm) | 9.7 ± 0.05a | 9.6 ± 0.01a | 7.1 ± 0.08b | 7.0 ± 0.08b | 8.9 ± 0.10a | 8.9 ± 0.14a | 6.8 ± 0.08b | 6.9 ± 0.08bc | 9.2 ± 0.09a | 9.1 ± 0.08a | 6.7 ± 0.08b | 7.2 ± 0.05c |

| Breadth (mm) | 2.7 ± 0.01a | 2.7 ± 0.05a | 2.4 ± 0.09b | 2.4 ± 0.00b | 3.0 ± 0.05a | 3.0 ± 0.01a | 2.5 ± 0.09b | 2.5 ± 0.01bc | 3.2 ± 0.05a | 3.0 ± 0.03b | 2.3 ± 0.06c | 2.5 ± 0.01d |

| Thickness (mm) | 2.4 ± 0.04a | 2.3 ± 0.01b | 2.1 ± 0.02c | 2.2 ± 0.01d | 2.5 ± 0.20a | 2.4 ± 0.01a | 1.9 ± 0.01b | 2.3 ± 0.02a | 2.1 ± 0.01a | 2.4 ± 0.01b | 1.8 ± 0.01c | 1.7 ± 0.01d |

| L/B | 3.6 ± 0.05a | 3.6 ± 0.05a | 3.0 ± 0.06b | 2.9 ± 0.02b | 2.9 ± 0.07a | 3.0 ± 0.05a | 2.7 ± 0.08b | 2.8 ± 0.03abc | 2.9 ± 0.05a | 3.0 ± 0.03a | 2.9 ± 0.10a | 2.9 ± 0.02a |

| B/T | 1.1 ± 0.06a | 1.2 ± 0.01b | 1.1 ± 0.04a | 1.1 ± 0.01a | 1.2 ± 0.09a | 1.2 ± 0.01a | 1.3 ± 0.06a | 1.1 ± 0.01ab | 1.5 ± 0.06a | 1.3 ± 0.01b | 1.3 ± 0.05bc | 1.5 ± 0.01a |

| 1000 kernel weight (g) | 27.9 ± 0.22a | 28.2 ± 0.81a | 22.4 ± 0.05b | 23.9 ± 0.14c | 29.9 ± 0.24a | 30.2 ± 0.94a | 23.4 ± 0.07b | 24.3 ± 0.17bc | 24.2 ± 0.23a | 24.8 ± 0.09b | 18.3 ± 0.07c | 18.6 ± 0.05c |

| NGW (mg/cm) | 28.8 ± 0.21a | 29.3 ± 1.04a | 31.5 ± 0.08b | 34.2 ± 0.22c | 33.5 ± 0.27a | 34 ± 1.06ab | 34.5 ± 0.10ab | 35.4 ± 0.24b | 26.4 ± 0.25a | 27.2 ± 0.09b | 27.3 ± 0.11bc | 25.9 ± 0.08d |

| True density (kg/m3) | 1250 ± 0.01a | 1220 ± 0.01b | 1409 ± 0.01c | 1429 ± 0.01d | 1202 ± 5.39a | 1174 ± 0.01b | 1399 ± 4.09c | 1400 ± 0.01cd | 1035 ± 3.01a | 934.1 ± 0.01b | 1399 ± 8.60c | 1392 ± 0.01d |

| Bulk density (kg/m3) | 611 ± 1.76a | 532 ± 0.01b | 848 ± 0.01c | 848 ± 0.01c | 633 ± 0.01a | 550 ± 0.01b | 848 ± 0.01c | 877 ± 0.01d | 533 ± 0.01a | 459 ± 0.01b | 835.5 ± 0.01c | 769.5 ± 0.01d |

| Porosity (%) | 51.1 ± 0.14a | 56.4 ± 0.01b | 39.8 ± 0.01c | 40.7 ± 0.01d | 47.3 ± 0.24a | 53.2 ± 0.01b | 39.4 ± 0.18c | 37.3 ± 0.01d | 48.5 ± 0.15a | 50.9 ± 0.01b | 40.3 ± 0.37c | 44.7 ± 0.01d |

| Angle of repose (°) | 46 ± 0.42a | 52.7 ± 0.48b | 34 ± 0.21c | 31.6 ± 0.37d | 48 ± 0.47a | 54.7 ± 0.47b | 35 ± 0.24c | 32.3 ± 0.47d | 46 ± 0.24a | 50 ± 0.01b | 34 ± 0.47c | 29.3 ± 0.47d |

| AF (°) on smooth surface | 24 ± 0.46a | 26.8 ± 0.43b | 25.8 ± 0.84bc | 26.8 ± 0.45db | 25 ± 0.47a | 26.3 ± 0.47ab | 26 ± 0.82a | 27.7 ± 0.47b | 24 ± 0.47a | 25 ± 0.01ac | 33 ± 0.82b | 26 ± 0.82cd |

| AF (°) on rough surface | 43.8 ± 0.48a | 45.7 ± 0.47b | 36.8 ± 0.82c | 37.5 ± 0.42dc | 44 ± 0.47a | 46.7 ± 0.47b | 37 ± 0.82c | 37.7 ± 0.47cd | 42 ± 0.47a | 45.3 ± 0.47b | 33 ± 0.82c | 34 ± 0.82cd |

Values are mean ± standard deviation of three independent determinations (n = 3)

Values within the same row with different letters are significantly different at p < 0.05

RIR-64p-Raw IR-64 paddy, PIR-64p-Parboiled IR-64 paddy, RIR-64BR-Raw IR-64 Brown Rice, PIR-64BR-Parboiled IR-64 Brown Rice

RJp-Raw Jyothi paddy, PJp-Parboiled Jyothi paddy, RJDR-Raw Jyothi De-husked Rice, PJDR-Parboiled Jyothi De-husked Rice

RBTJp-Raw Black Thai Jasmine paddy, PBTJp- Parboiled Black Thai Jasmine paddy, RBTJDR-Raw Black Thai Jasmine Rice, PBTJDR-Parboiled Black Thai Jasmine De-husked Rice

NGW Normalized Grain Weight, AF Angle of Friction

In brown rice, parboiling reduces length, remains almost same in breadth, thickness increases marginally. Ratio of l and b, b and t decreases after parboiling, indicating the result of parboiling on marginal changes in breadth and thickness of the dehusked rice. One thousand kernel weight increased by ~ 7 % and normalized grain weight (NGW) increased by about 9 % indicating the changes in the properties of starch and other components while processing, thus gaining weight and increases the true density by ~ 1.4 % and bulk density remained almost same. Porosity increased marginally in brown rice indicating increase in space between the grains after inducing retro-gradation or parboiling similarly angle of friction on smooth and rough surface increased marginally.

Jyothi (red pigmented)

Physical properties of Jyothi paddy and its de-husked rice are summarized in Table 1. In the paddy, after parboiling, length, breadth and thickness decreased marginally. Both l/b and b/t ratios increased marginally. NGW and 1000 kernel weight increased marginally indicating the effect of parboiling. TD and BD decreased by ~2 and 13 % respectively indicating that the volume of paddy increased after parboiling. Even porosity increased by about 13 % indicating the fact that the parboiled grains had become bulky and therefore the space between the grains was high and hence the porosity increased. Angle of repose increased by about 14 % indicating parboiled grains of this paddy formed larger angle with the horizontal surface compared to its raw paddy. Angle of friction on smooth and rough surface increased by five and 13 % respectively indicating the behavior of parboiled paddy especially on the rough surface the friction was high compared to smooth surface.

In the case of the dehusked rice, length and thickness increased marginally but breadth remained almost same. l/b remained almost same and b/t ratio decreased to the extent of ~ 19 % indicating the increased thickness of de-husked grains after parboiling. One thousand kernel weight also increased marginally by ~ 4 %, NGW increased marginally (2.6 %) indicating the physicochemical changes brought about by hydrothermal treatment might have increased both forms of weight. Even NGW indicated that the grain belongs to coarse in nature. TD remained almost same, however, bulk density increased by about 4 % indicating the change in volume of the parboiled rice compared to the raw dehusked rice. Porosity decreased by ~ 5 % and angle of repose decreased by ~ 8 % indicating the fact that the de-husked parboiled rice compacted to a greater degree compared to its raw de-husked rice. Angle of friction of the parboiled dehusked rice on smooth surface was high compared to that of rough surface indicating the adherence property of the parboiled dehusked rice was high.

Black Thai Jasmine (black pigmented)

Physical properties of the black waxy paddy and its de-husked rice are shown in Table 1. After parboiling, length and breadth decreases marginally indicating during this process, shrinkage of grain occurs, while thickness of the paddy increases by about 13 %. Ratio of l and b increases indicating the breadth has decreased during the process of parboiling. Similarly ratio of breadth to thickness decreases indicating the fact that the thickness of the paddy increased during the process. Marginally 1000 grain weight and NGW increases, which may be due to swelling and shrinkage of grain during parboiling. True density and bulk density reduces by ~ 10 % and about 14 % respectively indicating the fact that for a known volume, the weight of the grain decreases, which will help during manufacturing vessels of larger capacity. Porosity increases marginally indicating the space between the parboiled grains was high when packed compared to its native paddy. Angle of repose increases by about 9 % showing the fact that the angle formed with a normal surface by the parboiled paddy was high. Similarly angle of friction on rough and smooth surface increased marginally thus showing the effect of processing.

In the case of black de-husked rice, the length and breadth increased marginally while thickness decreased indicating leaching of water soluble components from the grain while parboiling l/b ratio values indicate that they were of medium sized grains. As the thickness has reduced the ratio of b/t increased marginally. One thousand kernel weight changed and NGW decreased marginally, indicating the leaching of soluble from the kernels while soaking and draining. TD and BD were high for raw dehusked rice, but they decreased after parboiling as their volume increased after processing. Porosity increased after parboiling indicating that the space between the de-husked grains were more. Angle of repose decreased informing that the retro-graded grains spreads more when dropped on the surface and accordingly the steaming tank are to be fabricated. Because the surface of the grain was not smooth, friction on the rough surface was high.

Colour values / colour changes

L, a, b and ∆E are the parameters measured in light measuring spectrophotometer. L and ∆E values are inversely proportional. Our studies indicated that higher the L value, lower will be the ∆E (Table 2), a and b values decreased from paddy to brown rice and brown rice to milled rice, indicating increased brightness, similarly in parboiled paddy, the L values increased but the values were lower than that of raw rice and the values of a and b were higher than that of raw paddy, brown and milled rice, indicating that parboiling induced the dark color because of Maillard reaction between sugars and amino acids during the process of parboiling. In terms of figures or numbers/values, for raw paddy of IR-64, the L value increased from ~ 53 to ~ 69 (paddy to brown rice and brown rice to milled rice) whereas ∆E decreased from ~ 49 to ~ 30, however, in parboiled paddy the L value increased from ~ 48 to ~57 and ∆E changed from ~ 53 to ~ 44 indicating the color of the paddy and rice became dark after parboiling.

Table. 2.

Colour values of IR-64, Jyothi and Black Thai Jasmine before and after parboiling for their different forms

| Sample ID | L* | a* | b* | DE |

|---|---|---|---|---|

| STD | 92.8 ± 0.01a | −0.9 ± 0.02a | 0.7 ± 0.01a | – |

| Raw, IR - 64 | ||||

| Paddy | 52.8 ± 0.39b | 8.2 ± 0.02b | 29.1 ± 0.17b | 48.7 ± 0.31a |

| Brown rice | 59.3 ± 0.33c | 4.4 ± 0.32c | 20.0 ± 0.09c | 40.8 ± 0.34b |

| Milled rice | 68.7 ± 0.17cd | 0.6 ± 0.04d | 14.7 ± 0.11d | 30.3 ± 0.18c |

| Parboiled, IR - 64 | ||||

| Paddy | 47.7 ± 0.02de | 8.3 ± 0.02be | 29.2 ± 0.07be | 52.8 ± 0.10d |

| Brown rice | 50.5 ± 0.35f | 5.6 ± 0.09f | 22.6 ± 0.06f | 49.4 ± 0.31e |

| Milled rice | 56.7 ± 0.07g | 3.3 ± 0.03g | 21.9 ± 0.04g | 43.5 ± 0.07f |

| Raw Jyothi | ||||

| Paddy | 50.2 ± 0.01fh | 8.3 ± 0.20bh | 29.4 ± 0.16bh | 50.8 ± 0.05g |

| De-husked rice | 35.9 ± 0.08i | 14.2 ± 0.17i | 18.4 ± 0.05i | 62.5 ± 0.09h |

| Milled rice | 68.3 ± 0.02dj | 3.5 ± 0.02j | 15.4 ± 0.12j | 31.0 ± 0.01ci |

| Parboiled, Jyothi | ||||

| Paddy | 47.8 ± 0.03ek | 8.4 ± 0.06bk | 29.1 ± 0.09bk | 52.9 ± 0.04dj |

| De-husked rice | 25.8 ± 0.08l | 8.2 ± 0.03bl | 8.0 ± 0.20l | 69.4 ± 0.06k |

| Milled rice | 45.1 ± 0.13m | 9.8 ± 0.06m | 18.0 ± 0.01im | 54.1 ± 0.12l |

| Raw, Black Thai Jasmine | ||||

| Paddy | 54.8 ± 0.07n | 5.4 ± 0.03n | 23.0 ± 0.20n | 45.6 ± 0.05m |

| De-husked rice | 23.5 ± 0.01° | 6.5 ± 0.04° | 4.8 ± 0.08° | 71.0 ± 0.01n |

| Milled rice | 51.9 ± 0.53p | 5.0 ± 0.16p | 5.0 ± 0.11p | 46.3 ± 0.53° |

| Parboiled, Black Thai Jasmine | ||||

| Paddy | 48.2 ± 0.07eq | 6.3 ± 0.06oq | 21.0 ± 0.18gq | 51.3 ± 0.04p |

| De-husked rice | 20.4 ± 0.08r | 3.1 ± 0.14gr | 1.6 ± 0.17r | 73.2 ± 0.06q |

| Milled rice | 20.8 ± 0.06rs | 3.0 ± 0.15hrs | 2.3 ± 0.09s | 72.9 ± 0.05qr |

Values are mean ± standard deviation of three independent determinations (n = 3)

Values within the same column with different letters are significantly different at p < 0.05

In Jyothi raw paddy, the color of husk being dark, the L value of paddy was ~ 50, after removing the husk i.e., after shelling, the value decreased to 36 indicating the fact that the endosperm was much darker than the rough rice. However, after polishing, where the dark colored bran layers were removed, the endosperm became bright and therefore the L value increased to 68. Parboiled paddy became darker, because of several changes taking place between proteins or amino acids and sugars, fat globules moving towards outward layers as aleurone, pericarp, protein bodies moving outward, even because of Maillard reaction probably the husk becomes darker and darker and therefore the L value decreases by ~ 2 units compared to raw paddy. Because of so many physico-chemical changes, the endosperm became very dark and therefore the color became dark and hence L value decreased to 26, which was almost 50 % less in comparison to raw Jyothi paddy. This dehusked rice was milled and still the color of the milled rice was dark and the L value was 45. These could clearly be seen from the photographs of the grains shown in Fig. 2b.

In the case of Black Thai Jasmine a pigmented waxy paddy, the husk was dark and the L value was ~ 55 which was higher than Jyothi paddy and somewhat brighter than Jyothi. On dehusking the L value was ~ 24 which was much lower value or darker than that of Jyothi dehusked rice, indicating the pigment layers consisted of several coloured ones as informed above, is much thick. On the milling of this endosperm, the value of L was ~52, which was less than that of milled rice of Jyothi, indicating the fact that under similar conditions of polishing the milled rice of BTJ was much dark. On parboiling the husk became dark and almost same as that of parboiled Jyothi paddy and the value was ~ 48. On dehusking, the endosperm was dark and the value was ~ 20 which was less than that of de-husked parboiled Jyothi rice, indicating the clear variation among the pigmented varieties. On milling of this parboiled endosperm, the color of the milled rice was almost same as that of parboiled de-husked endosperm. It was an interesting observation that before and after polishing of parboiled dehusked rice, the grain color remains same which was because of the movement of fat globules, protein bodies to the surface and also because of Maillard reaction the colour remains same as that of unpolished parboiled endosperm. Because of parboiling the grain becomes hard, various layers on the endosperm were impregnated, the bran layers will not fall, and therefore the degree of polish was less. Under similar conditions of milling, parboiled rice showed the lesser degree of polish and raw rice showed the higher degree of polish (Savitha and Singh 2011). In both colored rice, parboiled milled rice were much darker and hence the L values were less. This study indicated that there are differences among the varieties of pigmented paddy. The dehusked rice of parboiled BTJ and its milled rice were dark, which was an interesting observation.

Moisture content and equilibrium moisture content (EMC-S) on soaking at RT

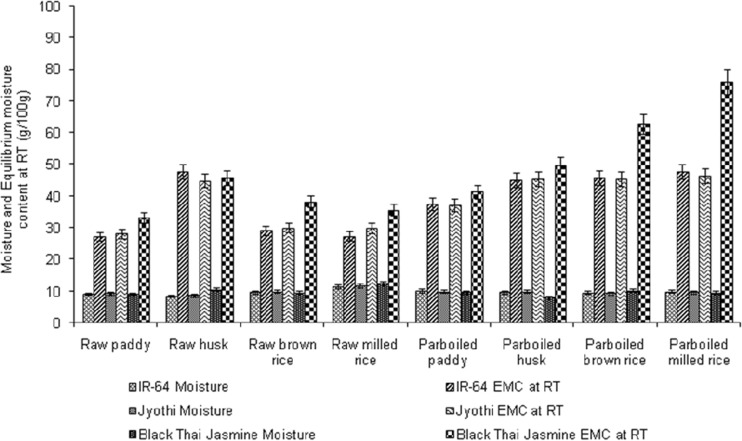

Moisture content (MC) and EMC-S at RT are shown in (Fig. 3). The MC of paddy, husk, dehusked and milled rice and their parboiled forms, for three varieties, varied from 9 to 12 %, which mainly depends on the climatic conditions or RH and temperature of the environment, where these samples were stored. As the humidity was around 65 %, environmental temperature varied between 25 and 28 °C, the moisture variations were not much in all samples.

Fig. 3.

Moisture content and Equilibrium moisture content on soaking at RT (EMCS) of raw, parboiled, brown/de-husked and milled rice of IR-64, Jyothi and Black Thai Jasmine

EMC-S at RT of natives

EMC-S at RT in paddy of IR-64 and Jyothi was between 28 and 29 %, however, in BTJ it was around 32–33 %, as this paddy is made up of full of amylopectin or less amylose or waxy paddy which bears the property of absorbing more moisture. In the case of raw husk, the EMC-S values were slightly different. Husk of IR-64 showed highest (~48 %), in Jyothi it was around 47 % and in the husk of waxy paddy, it was around 47–48 %. Here the absorption of moisture was by the hemicellulose of the respective variety of the husk. As it was cellulosic material, at RT the absorption variations were seen. EMC-S in brown or de-husked rice i.e., red or black, the values were almost equivalent to that of paddy in the case of IR-64 and Jyothi. However in the case of BTJ black rice, the value was ~ 38 %, which was mainly because of the branched molecule in the starch granules of black rice, which holds high moisture. In the milled rice of these varieties, the values were almost similar to paddy, brown rice in the case of IR-64 and Jyothi, but in the case of milled black rice the value was less than that of its black rice (de-husked rice). Probably the residual bran layers of this absorbed more moisture and hence the EMC-S may be high and that of its milled rice was less by 2–3 %.

EMC-S at RT after inducing retro-gradation

Parboiled paddy showed higher EMC than raw paddy. This was due to gelatinization and retro-gradation of starch in the endosperm of each variety during parboiling process. The higher EMC was obstructed by the outside husk of each paddy variety. The values further increased in husk of each parboiled paddy, however, that of the raw husk of IR-64 was higher by 2 % compared to husk of parboiled. That of raw husk of Jyothi and husk of its parboiled were almost same. Husk of parboiled black rice, showed about 1–2 % higher value compared to its raw form. Thus, parboiling induced some changes in the β1→ 4 linkages of glucose in the silicious cellulosic or hemi-cellulosic husk, thus making it absorb little high moisture. In the case of husk of parboiled Jyothi the chemical structure of beta glucose might not have altered and therefore the EMC values were almost same. Parboiled rice of brown or colored has shown higher values compared to their respective raw dehusked rice, which was because of gelatinization of starch followed by retro-gradation of the linear portion of amylose, as well as retro-gradation lengthiest linear chains of amylopectin molecule. The dehusked rice of BTJ showed very high EMC, which was around 60 %, which was because of gelatinized and retrograded starch. In the milled rice of parboiled ones, the EMC was almost same as that of brown rice of non-waxy parboiled ones. The value was high in milled form of parboiled BTJ, as there was negligible bran layer, the absorption of moisture by the branched molecules in starch granules was very high and therefore the value was ~ 70–72 %. This is similar to the observation made by Sashikala et al. (2005) as well as Bharathi et al. (2012).

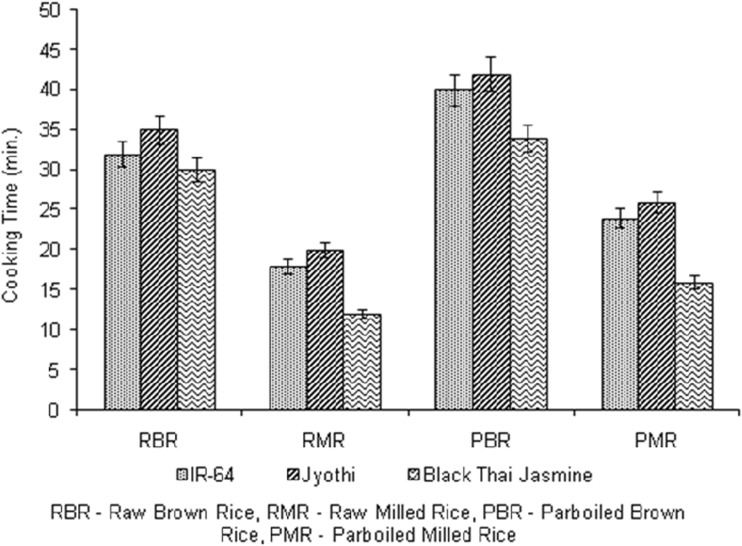

Cooking time

Cooking time (CT) is the time needed to make the opaque portion in the rice grain to disappear completely during cooking. The CT was highest for parboiled dehusked /brown, parboiled milled rice and least for raw de-husked as well as milled rice. In the case of parboiled rice, CT was judged by estimating the moisture content of cooked rice (72–74 %), the time taken to reach this moisture content was considered to be the CT of parboiled rice. CT of various brown and milled rice are shown by histograms (Fig. 4). Dehusked rice of Jyothi (red rice) showed 35 min. as the CT, for IR-64 it was 32 min. and for black rice it was 30 min. The long period of time for cooking of brown rice was because of the presence of pericarp and aleurone layers on the endosperm of grain. This is similar to the observation made by Deepa et al. (2008). When these layers were removed by polishing or milling, the CT decreases. Again highest CT was seen in milled Jyothi rice (~20 min), around 18 min for milled IR-64 rice and least was noticed in the case of milled waxy rice (~13 min). On parboiling, the CT increased because of gelatinized and retrograded starch. The CT of dehusked rice of Jyothi (parboiled) was ~ 42 min that of IR-64 was ~ 40 min, and that of BTJ parboiled rice was ~ 35 min. On the removal of bran or milling, the CT reduced to different extents. In the case of milled rice of Jyothi (parboiled) the CT was 27 min, that of IR-64 was 25 min and finally that of milled waxy rice was 17 min., thus showing higher CT in each milled parboiled rice than their respective raw milled rice.

Fig. 4.

Cooking time of brown/de-husked and milled rice of IR-64, Jyothi and Black Thai Jasmine in raw as well as parboiled forms

Probable reason for high CT of parboiled brown rice may be due to the bran layers impregnate on the endosperm and penetration of water takes a long time and to acquire 72–74 % moisture, longer duration was needed and hence the CT was high. Another reason may be due to the strong cohesion between the endosperm cells which are tightly packed. This makes the starch granules to hydrate at a slower rate, which leads to a decrease in water penetration into the grains, hence a longer cooking time (Otegbayo et al. 2001).

To conclude, raw brown rice showed high CT (30–35 min), brown rice of parboiled one showed higher CT (35 to 42 min). In milled rice, raw showed low CT (~13–21 min) and high CT was shown by milled parboiled rice (~15–25 min). Among the varieties, highest CT was seen in raw and parboiled dehusked or red rice of Jyothi and least was noticed in raw milled waxy rice (~12 min) and parboiled waxy brown rice.

Hardness

Hardness of raw and parboiled paddy and their different form are shown in (Fig. 5). The hardness varied from ~ 230 to ~ 280 N in raw paddy. In waxy paddy it was high, which may be due to unique starch amylopectin with the high proportion in this variety. The hardness increased from IR-64 to waxy paddy. The high hardness may also be due to the husk that may be considered as the barrier present on the endosperm of each variety. When the husk was removed, the hardness decreased by several fold. Lowest was observed in the brown rice of IR-64. Almost same were noticed in the case of the dehusked rice of both colored ones, thus showing no difference between non-waxy and waxy dehusked rice of coloured ones. The values are clear from the (Fig. 5). The hardness further decreased when these dehusked rice were milled and the values were ~ 100 N. The values were almost same in the case of milled rice of brown as well as coloured de-husked rice of both varieties.

Fig. 5.

Hardness of brown/de-husked and milled rice of IR-64, Jyothi and Black Thai Jasmine in raw as well as parboiled forms

On parboiling, the hardness in the paddy increased and the values showed a clear demarcation between 3 varieties. Lowest hardness was in IR-64, highest was in BTJ and in between was by Jyothi. The values varied from 256 to 425 N with ~ 380 N by Jyothi. This increase was because of gelatinization and retro-gradation of starch in the parboiled paddy. In the dehusked rice of the parboiled paddy, the hardness in IR-64 and Jyothi was almost same as that of their parboiled paddy. However, the value was high in black rice of BTJ which was around ~ 480 N, which may be because of its different chemical make up and retro-gradation. In milled rice of parboiled paddy, the hardness reduced compared to their parboiled paddy and brown rice. The hardness of milled rice followed the order BTJ > Jyothi > IR-64. Hence, the inference from this study is brown rice of parboiled paddy is much harder than parboiled paddy and milled parboiled rice. However in raw state, paddy is much harder than brown rice that is harder than their respective raw milled rice. Probably the husk becomes brittle and hence the hardness of parboiled paddy was less than that of their respective brown rice. Among the three varieties, raw waxy paddy was the hardest.

Conclusions

Two non-waxy varieties (non-pigmented and red pigmented) and one black waxy variety were shelled and milled before and after parboiling. Parboiling increased the NGW of their DR in non-pigmented varieties, in waxy variety it did not change much. True and bulk density was high in non-waxy varieties compared to waxy variety, parboiling reduced these properties. Porosity was high in all parboiled paddy and their DR compared to their respective raw ones. Angle of repose increased after parboiling in all three varieties whereas, in their DR, it decreased compared to their respective raw ones. Angle of friction on smooth and rough surfaces were high after parboiling and in their DR. Lowest values of TD, BD, angle of repose and angle of friction were noticed for the waxy variety in their raw and parboiled paddy as well as their shelled and milled forms, indicating the main reason may be chemical nature of this variety. Hardest was DR of parboiled waxy paddy and softest was all the milled rice of all three varieties. Under similar conditions of polishing, waxy milled rice was the darkest. Parboiling made all three paddy varieties almost of the same color. DR and MR of parboiled BTJ was the darkest. Cooking time was highest for parboiled DR and least was for raw milled rice. EMC-S at RT was highest in waxy parboiled as well as in its milled rice indicating the highest absorption by the variety. Results of this study could lead to a better appreciation of pigmented rice and assist food processors in selecting rice with unique characteristics for specialty food processing.

Acknowledgments

The authors thank Director, CSIR-Central Food Technological Research Institute, Mysore, India, for his support in the present study. Ms. HameedaBanu . N. Itagi wishes to gratefully acknowledge the financial support from ICMR, New Delhi, in carrying out this investigation.

References

- Abdul RA, Lateef SO, Hameed OO, Olayinka KR. Effect of variety and moisture content on some engineering properties of paddy rice. J Food Sci Technol. 2011;48(5):551–559. doi: 10.1007/s13197-010-0173-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- AOAC . Official methods of analysis. 17. Washington, DC: Association of Official Analytical Chemists; 2000. [Google Scholar]

- Bharathi TV, Prasanna R, Shruthi S, Singh V. Changes in the properties of pigmented non-pigmented and waxy rice varieties before and after hydrothermal treatment, acid modification of starch from these. Trends Carbohydr Res. 2012;4(3):54–63. [Google Scholar]

- Bhattacharya KR, Ali SZ (1985) Changes in rice during parboiling, and properties of parboiled rice. In: Pomeranz Y (ed) Advances in cereal science and technology. American Association of Cereal Chemists, St. Paul, 8:105–167

- Bhattacharya KR, Sowbhagya CM, Indudhara SYM. Some physical properties of paddy and rice and their interrelations. J Sci Food Agric. 1972;23(2):171–186. doi: 10.1002/jsfa.2740230204. [DOI] [Google Scholar]

- Buggenhout J, Brijs K, Celus I, Delcour JA. The breakage susceptibility of raw and parboiled rice: a review. J Food Eng. 2013;117:304–315. doi: 10.1016/j.jfoodeng.2013.03.009. [DOI] [Google Scholar]

- Chitra M, Singh V, Ali SZ. Effect of processing paddy on digestibility of rice starch by in vitro studies. J Food Sci Technol. 2010;47(4):414–419. doi: 10.1007/s13197-010-0068-3. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Correa PC, Schwanz DSF, Jaren C, Afonso JPC, Arana I. Physical and mechanical properties in rice processing. J Food Eng. 2007;79:137–142. doi: 10.1016/j.jfoodeng.2006.01.037. [DOI] [Google Scholar]

- Deepa C, Singh V. Shelling, milling, nutritional and functional properties of rice varieties and some of their by-products. Oryza. 2010;47(2):110–117. [Google Scholar]

- Deepa G, Singh V, Akhilender NK. Nutrient, physicochemical properties of Indian medicinal rice: Njavara. Food Chem. 2008;106:165–171. doi: 10.1016/j.foodchem.2007.05.062. [DOI] [Google Scholar]

- Desikachar HSR, Subrahmanyan V. The formation of cracks in rice during wetting and its effect on the cooking characteristics of the cereal. Cereal Chem. 1961;38:356–364. [Google Scholar]

- Fan J, Siebenmorgen TJ, Yang W. The head rice yield reduction of long and medium grain rice varieties in relation to various harvested and drying conditions. Trans ASAE. 2000;436:1709–1714. doi: 10.13031/2013.3072. [DOI] [Google Scholar]

- Finocchiaro F, Ferrari B, Gianinetti A, Dall AC, Galaverna G, Scazzina F, et al. Characterization of antioxidant compounds of red and white rice and changes in total antioxidant capacity during processing. Mol Nutr Food Res. 2007;51:1006–1019. doi: 10.1002/mnfr.200700011. [DOI] [PubMed] [Google Scholar]

- Indudhara SYM, Ali SZ, Bhattacharya KR. Hydration of raw and parboiled rice at room temperature. J Food Sci Technol. 1971;8:20–22. [Google Scholar]

- Islam MR, Shimizu N, Kimura T. Energy requirement in parboiling and its relationship to some important quality indicators. J Food Eng. 2004;63:433–439. doi: 10.1016/j.jfoodeng.2003.09.002. [DOI] [Google Scholar]

- Lamberts L, Brijs K, Mohamed R, Verhelst N, Delcour JA. Impact of browning reactions and bran pigments on color of parboiled rice. J Agric Food Chem. 2006;54:9924–9929. doi: 10.1021/jf062140j. [DOI] [PubMed] [Google Scholar]

- Otegbayo BO, Osamuel F, Fashakin JB. Effect of parboiling on physicochemical qualities of two local rice varieties in Nigeria. J Food Technol Afr. 2001;6(4):130–132. [Google Scholar]

- Parnsakhorn S, Langkapin J. Changes in physicochemical properties of germinated brown rice and brown rice during storage at various temperatures. Agric Eng Int: CIGR J. 2013;15(2):293–303. [Google Scholar]

- Rabiul IM, Poritosh R, Naoto S, Toshinori K. Effect of processing conditions on physical properties of parboiled rice. Food Sci Technol Res. 2002;8(2):106–112. doi: 10.3136/fstr.8.106. [DOI] [Google Scholar]

- Ranghino F. Valuation of rice resistance to cooking. RISO. 1966;15:17–127. [Google Scholar]

- Sangeeta S, Himjyoti D, Daizi S, Charu LM. Quality characterisation and estimation of phytochemicals content and antioxidant capacity of aromatic pigmented and non-pigmented rice varieties. Food Res Int. 2012;46:334–340. doi: 10.1016/j.foodres.2011.12.021. [DOI] [Google Scholar]

- Sashikala IS, Singh V, Ali SZ. Changes in physicochemical properties of basmati paddy upon parboiling. Trends Carbohydr Chem. 2005;9:53–59. [Google Scholar]

- Savitha YS, Singh V. Status of dietary fiber contents in pigmented and non- pigmented rice varieties before and after parboiling. LWT Food Sci Technol. 2011;44:2180–2184. doi: 10.1016/j.lwt.2011.06.004. [DOI] [Google Scholar]

- Simmons D, Williams R. Dietary practices among Europeans and different South Asian groups in coventry. Br J Nutr. 1997;78:5–14. doi: 10.1079/BJN19970114. [DOI] [PubMed] [Google Scholar]

- Sowbhagya CM, Ramesh BS, Bhattacharya KR. Improved indices for dimensional classification of rice. J Food Sci Technol. 1984;21:15–19. [Google Scholar]

- Varnamkhasti GM, Mobli H, Jafari A, Rafiees S, Heidarysoltanabadi M, Kheiralipour K. Some engineering properties of paddy (var. Sazandegi) Int J Agric Biol. 2007;9:763–766. [Google Scholar]