Abstract

In present study, influence of grinding (hammer and pin mills) and moisture content (range: 6.4–13.6 % dry basis) on the quality traits of coriander powder were investigated. These include grinding parameters, colour parameters, specific heat, thermal conductivity, thermal diffusivity, glass transition temperature, essential oil, total phenolic content, total flavonoid content and DPPH scavenging (%) of coriander powder. For coriander seed, the geometric properties such as major, medium, minor dimensions, geometric mean diameter, arithmetic mean diameter, sphericity, surface area and volume of coriander seeds increased significantly with increasing moisture (6.4–13.6 % db). For coriander powder, the grinding parameters such as average particle size, volume surface mean diameter and volume mean diameter increased significantly with increasing moisture (6.4–13.6 % db). With the grinding method, the colour attributes of coriander powder such as L-value, a-value, b-value, hue angle and browning index varied significantly. It was observed that the specific heat followed second order polynomial relationship with temperature and moisture whereas thermal conductivity varied linearly with temperature and moisture content. The variation of glass transition temperature with moisture can be best represented in quadratic manner. Total flavonoid content (mg QE/g crude seed extract) and DPPH scavenging % activity of coriander powder is significantly affected by grinding methods. A lower value of specific heat was observed for hammer ground coriander powder as compared to pin mill ground coriander powder. The thermal conductivity of hammer mill ground coriander powder was higher as compared to pin mill ground coriander. It was observed that hammer mill yields more fine coriander powder in comparison to pin mill. The browning index was more in hammer mill ground coriander powder.

Keywords: Coriander, Hammer mill, Pin mill, Grinding parameters, Thermal properties, Antioxidant properties

Coriander (Coriander sativum L.) is a major seed spice crop, grown in throughout the Asian sub continent, for either green leaf or seeds. It has prime position in flavouring foods. The major coriander growing states are Rajasthan, Gujarat, Andhra Pradesh, Uttar Pradesh, Madhya Pradesh, Himachal Pradesh etc. The most common use of coriander seed is in curry powders, where it is the bulkiest constituent, often rough ground to give a crunchy texture. The most important constituents of coriander seeds are the essential oil and fatty oil. The essential oil content of dried coriander seeds varies between 0.03 and 2.60 % and fatty oil content varies between 9.9 and 27.7 %. Other constituents such as crude protein, fat, crude fibre and ash contents vary from 11.5–21.3 %, 17.8–19.15 %, 28.4–29.1 % and 4.9–6.0 %, respectively (Akgul 1993; Diederichsen 1996; Kaya et al. 2000; Ramadan and Morsel 2002). Apart from this, coriander has medicinal properties, known for thousands of years which largely depend upon genetic constitution and environmental factors.

Grinding is an important unit operation in processing of spices in which the size of the spices is reduced and hence surface area increased. When increasing surface area of particles, the availability of constituents such as oil inside the cells, fragrance and flavouring components increases which are available in the material. Power consumption in grinding, size of the particles and increase in the surface area depend on the initial size, shape and strength of the particle (material); the kind of grinder or mill used for the unit operation and the fixing of operating parameter to run the grinder (mill) such as temperature, size of sieve, number of rotor ribs etc. (Das 2005). The colour of spice powder is an important quality attribute to accept or reject the spices because it has direct appealing effect in the mind of consumer.

Knowledge of thermal properties viz. specific heat, thermal conductivity and thermal diffusivity are essential for simulation and modelling of heat transfer phenomenon in the grinder (Singh and Goswami 2006). The temperature and moisture content of agricultural materials greatly affect its thermal properties. Using differential scanning calorimetry (DSC) technique, the specific heat of agricultural materials can be measured as a function of temperature. Various researchers have investigated the thermal properties of agricultural materials using DSC such as for cumin seed (Singh and Goswami 2000), gram (Dutta et al. 1988), borage seeds (Yang et al. 2002) etc. The variations in specific heat, thermal conductivity and diffusivity with moisture content have been reported in published literature. The glass transition temperature is the temperature where the material goes from a hard, glass like state to a rubber like state. DSC defines the glass transition as a change in the heat capacity as the solidified oil goes from the glass state to the rubber like viscous state. This is a second order endothermic transition, requires heat to go through the transition (Goula et al. 2008).

The pin and hammer mills are used in spice milling industries. The comparative evaluation of pin and hammer mills on quality attributes such as grinding parameters, colour parameters, thermal properties and antioxidant properties of ground spices e.g. coriander etc. are rarely available in published literature. Also, moisture content is one of the most important parameters in processing operations e.g. grinding etc. Therefore, in present study, influence of grinding methods (hammer and pin mills) at different moisture content on quality attributes of coriander powder were investigated.

Material and methods

Sample preparation

Coriander seeds were procured from local market of Ludhiana, India. The seeds were cleaned manually to remove all foreign matter, dust, dirt, broken and immature seeds. The initial moisture content of the seeds was determined by vacuum oven method (temperature 70 °C and pressure 100 mm Hg) until a constant mass was obtained (Singh and Goswami 2000) and found as 8.7 % dry basis (db). The moisture content of coriander seeds were conditioned to 6.4, 8.7, 11.1, 13.6 % db to determine the geometric properties of coriander seed and grinding parameters, thermal properties and antioxidant properties of ground coriander powder. The coriander seeds were dried in a tray dryer at 55 °C, recording moisture content at every 15 min interval, to achieve 6.4 % moisture content (db). The samples of the high level desired moisture contents were prepared by adding the amount of distilled water, Q, as calculated from the following relationship (Chakraverty 1988):

| 1 |

where Q is the mass of water to be added (kg); Wi is the initial mass of the sample (kg); M0 is the initial moisture content of the sample (%, db); and Mf is the desired moisture content of the sample (% db). Samples were packed in low density polyethylene (LDPE) pouches and kept at 5 °C for 48 h in a refrigerator for uniform distribution of moisture throughout the seed (Sahay and Singh 2004). Prior to experiment, required quantities of the samples were taken out of the refrigerator and allowed to equilibrate with room temperature for about 2 h.

Geometric properties of coriander seed

For each moisture content, the major (L), medium (W) and minor (T) dimensions of coriander seeds were measured using a digital vernier calliper (accuracy: 0.01 mm) for randomly selected 100 seeds. The arithmetic mean diameter (da) and geometric mean diameter (dg) of the seeds were calculated by using the following relationship (Mohsenin 1986):

| 2 |

| 3 |

The sphericity, Ф, of coriander seeds was calculated by using the following relationship (Mohsenin 1986)

| 4 |

The surface area and volume of coriander seeds were determined using the following relationships (Jain and Bal 1997):

| 5 |

| 6 |

where

| 7 |

Grinding parameters of coriander powder

A laboratory grinder (M/s Hosakowa Alpine, Germany, Model: 100UPZ, three-phase motor, 3 HP, 10,000 rpm) was employed for the grinding of coriander seeds. The samples of coriander seeds were divided into two lots: one lot was ground in the grinder using hammer mill whereas another lot was ground using pin mill at ambient conditions.

Particle size distribution of hammer and pin mills ground coriander was determined in duplicate using a vibratory sieve shaker with a set of Bureau of Indian Standards (BIS) sieves. Average particle size (Dp), volume surface mean diameter (Dvs), mass mean diameter (Dm) and volume mean diameters (Dv) of hammer and pin mil ground coriander powders were evaluated as follows (Sahay and Singh 2004):

| 8 |

| 9 |

| 10 |

| 11 |

where FM, mi, and Dpi are fineness modulus, mass retained and mean diameter in each increment, respectively.

Colour attributes of ground coriander powder

Colour (L, a and b) values of hammer and pin mill ground coriander powders were determined by using Hunter Colorimeter (model no. 45/0 L, U.S.A). ‘L’ is known as the lightness and extends from 0 (black) to 100 (white). The other two coordinates ‘a’ and ‘b’ represents redness (+a values) to greenness (−a values) and yellowness (+b values) to blueness (−b values), respectively. Hue angle (h0) is the attribute of the colour by means of which the colour is perceived. Chroma (C*) is the attribute of colour used to indicate the degree of departure of the colour from gray of the same lightness. Browning index (BI) is the intensity of pure brown colour. The values of h0, C* and BI were computed by using the following formulae:

| 12 |

| 13 |

| 14 |

| 15 |

where b = b values, a = a values.

Thermal properties of ground coriander powder

The specific heat of hammer and pin mill ground coriander powder was determined by using the Differential Scanning Calorimeter (DSC 6000 Perkin Elmer, USA) operated by Pyris software. Before conducting the experiments, the DSC was calibrated using indium at scanning rate of 10 °C/min. For determination of specific heat, the hammer and pin mill ground coriander powder samples were kept in an aluminium crucible (capacity: 10 μL) in small quantity (5–5.5 mg). The aluminium crucible was sealed and run in the DSC for the temperature range of −100 °C to +100 °C. The DSC provided thermogram, in which ordinate shows the heat flow rate (mW mg−1) as a function of time and temperature. Specific heat and glass transition temperature (Tg) were determined from the thermogram according to the procedure given in software. All experiments were conducted in triplicate and the mean values were reported.

The bulk thermal conductivity was measured by using portable thermal conductivity meter (Model: KD-2 PRO, Decagon Devices, Inc. USA). The hammer and pin mill ground coriander powder were filled separately into 100 ml beakers and completely tapped, then the beakers were covered using aluminium foils and stored over night in deep freezer (Model: U 410–86, New Brunswick Scientific, England) at −50 °C for the conditions of below 0 °C. For the higher temperature i.e. above 0 °C, the powder samples were kept in recirculation type tray dryer (M/s BTPL, Kolkata, India) at 60 °C for 4 h. The thermal conductivity meter was calibrated with glycerine. After calibration, the powder sample was taken out from the deep freezer and immediately a single needle probe (Model: KS-1, 1.3 mm diameter × 60 mm long) of thermal conductivity meter was inserted in the sample and reading was recorded at intervals of 2 min.

The average bulk density (ρb, kg m−3) of hammer and pin mill ground coriander powder was determined by using standard method as described by Mohsenin (1986) and it was expressed as the ratio of mass by volume.

The bulk thermal diffusivity of hammer and mill ground coriander powder was calculated from the obtained values of bulk thermal conductivity, specific heat and bulk density of hammer and pin mill ground coriander powder using the Eq. (16) (Singh and Goswami 2000):

| 16 |

where, αb is the bulk thermal diffusivity (m2 s−1), Cp is the specific heat in (kJ kg−1 K−1), kb is the thermal conductivity in (W m−1 K−1) and ρb is the bulk density (kg m−3).

Chemical properties

Volatile oil was extracted from the hammer and pin mill ground coriander powder by hydro-distillation using Clevenger apparatus lighter than water type. Oil was quantified as volume by weight percentage (Saxena et al. 2015).

Oleoresin content was extracted using Accelerated Solvent Extraction System (Dionex India Pvt. Ltd.). The Accelerated Solvent Extraction system accelerates the traditional extraction process by using solvent at elevated temperatures and pressures. Pressure is maintained in the sample cell to maintain the heated solvent in a liquid state during the extraction. After heating, the extract is rinsed from the sample cell into a collection vessel. Oleoresin was obtained after evaporating the solvent in rotary evaporator.

Hammer and pin mill ground coriander powder (10 g) was extracted with 50 ml methanol twice. Supernatant from both extraction were pooled and methanol was evaporated in rotary evaporator. This crude extract was used for determination of the total phenol and flavonoids concentration, as well as antioxidant activities. Total phenol concentrations were determined using a Folin-Ciocalteu assay (Amin et al. 2006). An aliquot of 0.1 ml from 1000 ppm crude methanol extract was taken in a test tube and made the volume 1 ml by adding solvent. Three ml of 10 % sodium carbonate was added. Previously 10-fold diluted Folin-Ciocalteu reagent was added to the mixture. The mixture was allowed to stand at room temperature for 90 min and then absorbance was measured at 710 nm. Gallic acid was used as the standard reference phenol. The amount of phenolic content was calculated by using the standard curve of standard reference phenol i.e. Gallic acid (R2 = 0.96 to 0.99) and was expressed as mg Gallic Acid Equivalents/g crude seed extract.

Total flavonoid concentration was determined by using standard method (Chang et al. 2002). One ml of crude extract was taken in a test tube and 100 μl aluminum chloride (1 M) solution was added carefully from the side wall of the test tube followed by addition of 100 μl potassium acetate. The total volume was made 4 ml by adding 2.8 ml of solvent in the test tube. After 30 min incubation of reaction mixture at room temperature, stable yellow colour was developed. Absorbance was measured at 415 nm. Quercetin was used as the standard reference flavonoid. The amount of flavonoid was calculated by using the standard curve of standard reference flavonoid i.e. quercetin having R2 value ranged from 0.96 to 0.99 and was expressed as mg Quercetin Equivalents/g crude seed extract.

The antioxidant activity of crude seed extract was evaluated on the basis of its activity in scavenging the stable DPPH radical using standard method (Shimada et al. 1992). Crude seed extract was diluted in methanol to give at least 5 different concentrations. An aliquot (1, 1.5, 2, 2.5 ml) of the extract of each concentration was mixed with 1 ml of 1 M DPPH solution. The mixture was then homogenized and left to stand for 30 min in the dark. The absorbance was measured at 517 nm against a blank of methanol using a spectrophotometer. DPPH solution plus methanol was used as control and Butyl hydroxyl toluene (BHT) was used as a standard reference synthetic antioxidant with R2 value ranged from 0.95 to 0.99. Results were expressed as mg Butyl hydroxyl toluene (BHT) Equivalent/g crude seed extract. Results were expressed as a mean standard deviation from three replicate measurements. The percent scavenging effect was calculated as follows:

Statistical analysis

Analysis of variance for geometric properties, grinding parameters, thermal properties and antioxidant properties were carried out using LSD of AgRes Statistical software (Version 3.01, Pascal International Software Solution, USA). Regression analysis was carried out using Microsoft Excel 2003 software to determine the relationship between temperature and thermal properties and moisture content and thermal properties.

Results and discussion

Geometrical properties of coriander seed

All geometric properties such as major, medium and minor dimension, geometric mean diameter, arithmetic mean diameter, sphericity, surface area and seed volume increased significantly from 4.95 ± 0.26–5.34 ± 0.15 mm, 2.85 ± 0.18–3.28 ± 0.10 mm, 2.77 ± 0.20–3.20 ± 0.08 mm, 3.39 ± 0.17–3.83 ± 0.08 mm, 3.52 ± 0.15–3.92 ± 0.05 mm, 68.52 ± 0.04–71.68 ± 0.01 %, 30.53 ± 3.00–39.01 ± 1.57 mm2 and 14.36 ± 2.28–21.08 ± 1.31 mm3, respectively with increasing moisture content (range: 6.4–13.6 % db) (Table 1). Similar trend for geometric properties such as axial dimensions, geometric mean diameter, surface area, sphericity and kernel volume were reported for bay laurel seeds and fenugreek seeds (Yurtlu et al. 2010; Altuntas et al. 2005).

Table 1.

Geometric properties of coriander seeds and colour and chemical properties of ground coriander powder

| Details of geometric, colour and chemical properties | Moisture content, (% d.b.) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 6.4 | 8.7 | 11.1 | 13.6 | ||||||

| Geometric properties of coriander seeds | F-values | CD0.05 | |||||||

| i) L, mm | 4.95 ± 0.26a | 5.12 ± 0.11b | 5.28 ± 0.14c | 5.34 ± 0.15c | 33.78* | 0.08 | |||

| ii) B, mm | 2.85 ± 0.18a | 3.10 ± 0.12b | 3.19 ± 0.06c | 3.28 ± 0.10d | 58.74* | 0.07 | |||

| iii) T, mm | 2.77 ± 0.20a | 2.99 ± 0.13b | 3.11 ± 0.07c | 3.20 ± 0.08d | 67.66* | 0.06 | |||

| iv) GMD, mm | 3.39 ± 0.17a | 3.62 ± 0.10b | 3.74 ± 0.06c | 3.83 ± 0.08d | 99.13* | 0.05 | |||

| v) AMD, mm | 3.52 ± 0.15a | 3.73 ± 0.09b | 3.86 ± 0.06c | 3.92 ± 0.05d | 105.57* | 0.05 | |||

| vi) Sphericity, % | 68.52 ± 0.04a | 70.70 ± 0.02b | 70.91 ± 0.02c | 71.68 ± 0.01d | 9.03* | 0.01 | |||

| vii) Surface area, mm2 | 30.53 ± 3.00a | 34.80 ± 1.95b | 37.21 ± 1.17c | 39.01 ± 1.57d | 106.52* | 1.00 | |||

| viii Volume,mm3 | 14.36 ± 2.28a | 17.67 ± 1.64b | 19.54 ± 0.94c | 21.08 ± 1.31d | 105.50* | 0.79 | |||

| Colour attributes of coriander powder | F-values | CD0.05 | |||||||

| t | m | t | m | ||||||

| i) L -value | Hammer | 60.21 ± 1.45a | 59.93 ± 1.05a | 59.04 ± 1.60b | 58.76 ± 1.59c | 20.55* | 8.72* | 0.65 | 0.92 |

| Pin | 59.97 ± 1.25a | 58.26 ± 1.75c | 56.92 ± 0.53b | 56.90 ± 1.67b | |||||

| ii) a -value | Hammer | 6.16 ± 0.37 | 6.33 ± 0.21 | 6.15 ± 0.50 | 6.30 ± 0.50 | 35.44* | 1.30NS | 0.18 | 0.25 |

| Pin | 5.97 ± 0.32 | 5.61 ± 0.14 | 5.50 ± 0.16 | 5.72 ± 0.38 | |||||

| iii) b -value | Hammer | 23.51 ± 1.57a | 24.69 ± 0.77a | 24.50 ± 1.74a | 24.45 ± 1.65a | 4.47* | 3.70* | 0.92 | 1.31 |

| Pin | 24.09 ± 1.29a | 27.20 ± 2.97b | 25.11 ± 2.45a | 24.65 ± 1.61a | |||||

| iv) Hue (°) | Hammer | 75.31 ± 0.54a | 75.61 ± 0.35ab | 75.90 ± 0.65b | 75.55 ± 0.90ab | 64.32* | 7.56* | 0.40 | 0.56 |

| Pin | 76.07 ± 0.48a | 78.23 ± 1.36b | 77.57 ± 1.04c | 76.93 ± 0.28d | |||||

| v) Chroma | Hammer | 24.30 ± 1.67 | 25.48 ± 1.78 | 25.26 ± 0.78 | 25.25 ± 1.60 | 3.22NS | 3.46* | 0.92 | 1.31 |

| Pin | 24.82 ± 1.32a | 27.78 ± 2.90b | 25.70 ± 2.41a | 25.30 ± 1.65a | |||||

| vi) Browning index | Hammer | 57.74 ± 5.21a | 62.39 ± 8.84ac | 63.10 ± 7.18c | 70.65 ± 9.59b | 5.98* | 3.89* | 3.44 | 4.86 |

| Pin | 56.22 ± 6.01 | 59.76 ± 3.62 | 60.37 ± 7.24 | 60.77 ± 6.74 | |||||

| Chemical properties of ground coriander powder | |||||||||

| i) Essential oil | Hammer | 0.14 ± 0.02 | 0.14 ± 0.02 | 0.06 ± 0.01 | 0.11 ± 0.02 | 0.04NS | 3.21NS | 0.04 | 0.06 |

| Pin | 0.13 ± 0.03 | 0.15 ± 0.03 | 0.08 ± 0.02 | 0.11 ± 0.03 | |||||

| ii) Total phenolic content (mg GAE/g crude seed extract) | Hammer | 34.65 ± 0.14a | 27.02 ± 0.36b | 21.83 ± 0.73c | 21.35 ± 0.89c | 0.03NS | 413.84* | 0.76 | 1.08 |

| Pin | 35.99 ± 0.28a | 26.76 ± 0.58b | 21.62 ± 0.28c | 20.70 ± 1.01c | |||||

| iii) Total flavonoid content (mg QE/g crude seed extract) | Hammer | 0.08 ± 0.02 | 0.06 ± 0.02 | 0.08 ± 0.01 | 0.07 ± 0.01 | 10.27* | 2.05NS | 0.05 | 0.06 |

| Pin | 0.12 ± 0.03 | 0.10 ± 0.02 | 0.10 ± 0.01 | 0.21 ± 0.02 | |||||

| iv) DPPH scavenging % | Hammer | 24.69 ± 3.11 | 20.38 ± 0.59 | 17.86 ± 0.88 | 22.90 ± 3.26 | 9.49* | 2.77NS | 2.86 | 4.05 |

| Pin | 20.38 ± 0.60 | 32.15 ± 1.80 | 27.73 ± 2.07 | 20.49 ± 3.40 | |||||

Mean values with same lowercase superscripts do not differ significantly

t grinding method, m, moisture content, NS non significant;* significant at p ≤ 0.05

Grinding parameters of ground coriander powder

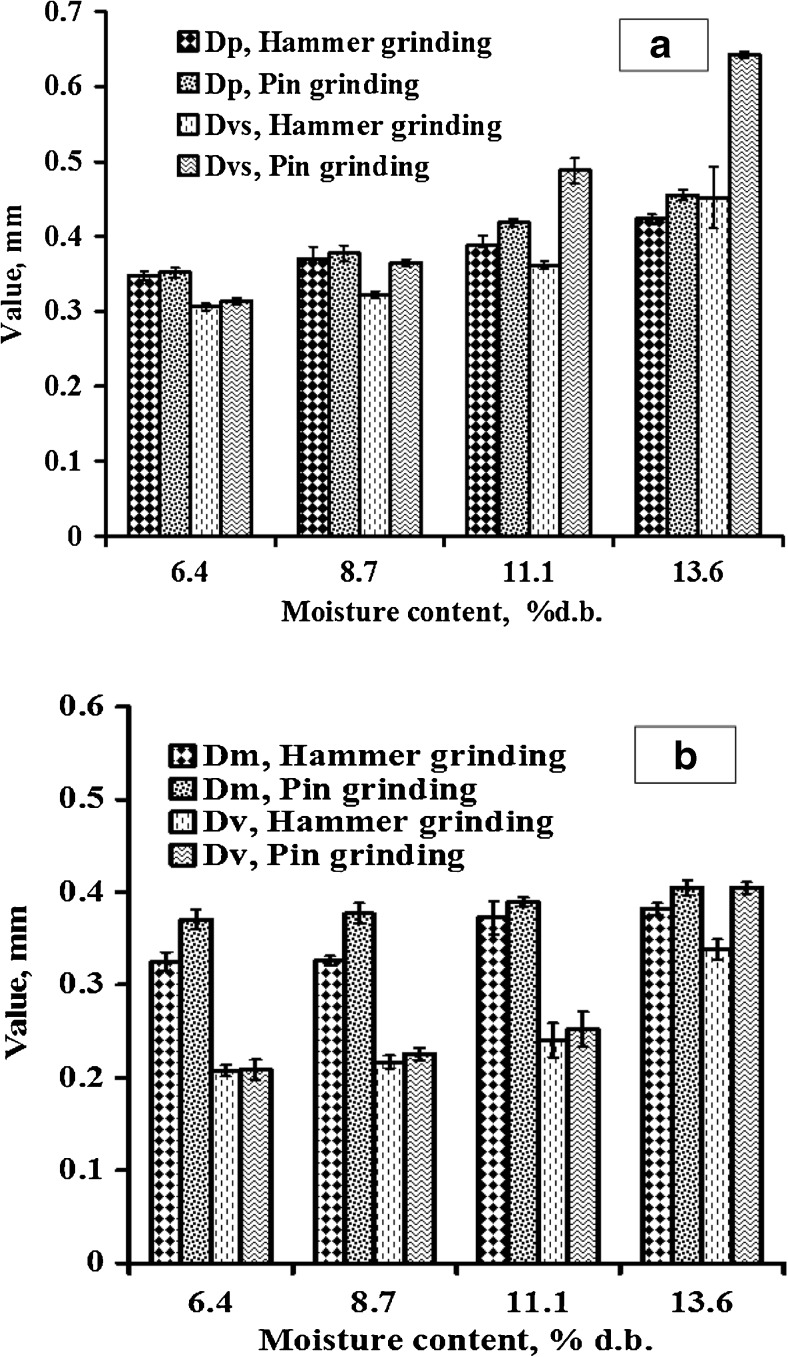

The variation of average particle size (Dp) and volume surface mean diameter (Dvs) of coriander powder with moisture content and grinding method is shown in Fig.1. It was observed that the average particle size and volume surface mean diameter of coriander powder were found to be increased with increasing moisture content for both hammer and pin mill grinding. This may be due to the fact that moisture sorption is often coupled with increased cohesiveness, mainly because of inter particle-liquid bridge formation. Moisture content thus affects the cohesive strength and arching ability of bulk materials. As the moisture content of seeds increases, the adhesion and cohesion tend to increase which results in coarser grinding at higher moisture levels and hence increased average particle size and volume surface mean diameter of the powder with increasing moisture content of seed. Similar findings were reported by Jha and Verma (1999) and Balasubramanian et al. (2011) for makhana and pearl millet, respectively. The average particle size and volume surface mean diameter of coriander powder were significantly affected by moisture content and grinding method (Table 2). Furthermore, the average particle size and volume surface mean diameter of hammer ground coriander powder were found to be lower as compared to pin mill grinding. The lower values of these parameters may be attributed due to presence of screen in hammer mill grinding which maximizes the residence time in the grinding zone until the desired particle size is achieved. The values of average particle size and volume surface mean diameter of hammer and pin mill ground coriander powder varied from 0.34 ± 0.003–0.46 ± 0.002 mm and 0.31 ± 0.004–0.64 ± 0.002 mm, respectively in moisture range of 6.4–13.6 % db.

Fig. 1.

Effect of moisture content on grinding parameters of hammer mill and pin mill ground coriander powder a average particle size and volume surface mean diameter b mass mean diameter and volume mean diameter

Table 2.

Analysis of variance for grinding parameters and thermal properties of coriander powder

| Source | Degrees of freedom | Mean square | F-value | p-value |

|---|---|---|---|---|

| Grinding parameters | ||||

| Average particle size | ||||

| Grinding method | 1 | 13.53 × 10−4 | 20.80* | 0.00 |

| Moisture content | 3 | 60.23 × 10−4 | 92.60* | 0.00 |

| Volume surface mean diameter | ||||

| Grinding method | 1 | 0.03 | 122.38* | 0.00 |

| Moisture content | 3 | 0.04 | 161.37* | 0.00 |

| Mass mean diameter | ||||

| Grinding method | 1 | 46.70 × 10−4 | 8.69* | 0.02 |

| Moisture content | 3 | 19.90 × 10−4 | 3.70NS | 0.07 |

| Volume mean diameter | ||||

| Grinding method | 1 | 19.66 × 10−4 | 8.30* | 0.02 |

| Moisture content | 3 | 223.72 × 10−4 | 94.50* | 0.00 |

| Thermal properties | ||||

| Specific heat | ||||

| Grinding method | 1 | 245.74 | 318.54* | 0.00 |

| Moisture content | 3 | 174.53 | 226.24* | 0.00 |

| Temperature | 5 | 111.40 | 144.41* | 0.00 |

| Thermal conductivity | ||||

| Grinding method | 1 | 1.57 × 10−4 | 38.24* | 0.00 |

| Moisture content | 3 | 4.82 × 10−4 | 117.63* | 0.00 |

| Temperature | 5 | 5.74 × 10−4 | 139.97* | 0.00 |

| Thermal diffusivity | ||||

| Grinding method | 1 | 532.45 | 102.26* | 0.00 |

| Moisture content | 3 | 17.70 | 3.40* | 0.03 |

| Temperature | 5 | 37.20 | 7.14* | 0.00 |

| Glass transition temperature | ||||

| Grinding method | 1 | 420.42 | 100.07* | 0.00 |

| Moisture content | 3 | 474.77 | 113.01* | 0.00 |

*significant at p ≤ 0.05; NS non significant

The mass mean diameter (Dm) and volume mean diameter (Dv) were found to be increased with increasing moisture content for both hammer and pin mill grinding (Fig.1). This may be attributed to the fact that at higher moisture levels the material becomes soggy/tougher resulting in coarser grinding of the coriander during grinding operation. The volume mean diameter of coriander powder were significantly affected by grinding method and moisture content whereas mass mean diameter increased significantly with grinding method (Table 2). The values of mass mean diameter and volume mean diameter using hammer mill grinding varied from 0.35 ± 0.030–0.40 ± 0.008 mm and 0.21 ± 0.006–0.40 ± 0.008 mm, respectively, with moisture (range: 6.4–13.6 % db). In addition, it is found that the values of mass mean diameter and volume mean diameter were lower in hammer grinding as compared to pin mill ground coriander powder which may be due to fineness of coriander powder in hammer mill grinding due to presence of screen in hammer mill grinding which maximizes the residence time in the grinding zone until the desired particle size is achieved.

Colour parameters of ground coriander powder

Table 1 represents colour values (L, a and b values) of hammer and pin mill ground coriander powder. The ‘L’ value’ decreased with increasing moisture content at both the grinding conditions whereas ‘a’ and ‘b’ values did not show any particular trend with increasing moisture content in both grinding conditions. The decrease in ‘L’ value’ may be due to increase in temperature during grinding of coriander powder. However, ‘L’ and ‘b’ values were found to vary significantly with moisture content and grinding method whereas ‘a’ value varied significantly with grinding method (Table 1). The hue and browning index (BI) were found to be varied significantly with moisture content and grinding method. However, grinding methods do not have any significant effect on chroma values whereas moisture content has significant effect on chroma values. The browning index increased with increase in moisture content irrespective of grinding method. However, the browning index was more in hammer mill ground coriander powder (Table 1) which may be due to more residence time during grinding in hammer mill. The values of colour parameters of hammer and pin mill ground coriander powder i.e L, a, b, hue, chroma and browning index varied from 56.90 ± 1.67–60.21 ± 1.45, 5.50 ± 0.16–6.33 ± 0.21, 23.51 ± 1.57–27.20 ± 2.97, 75.31 ± 0.54–78.23 ± 1.36°, 24.30 ± 1.67–27.78 ± 2.90 and 56.22 ± 6.01–70.65 ± 9.59, respectively (Table 1). Furthermore, it was observed that hue angle and chroma values were higher for pin mill ground coriander powder.

Thermal properties of ground coriander powder

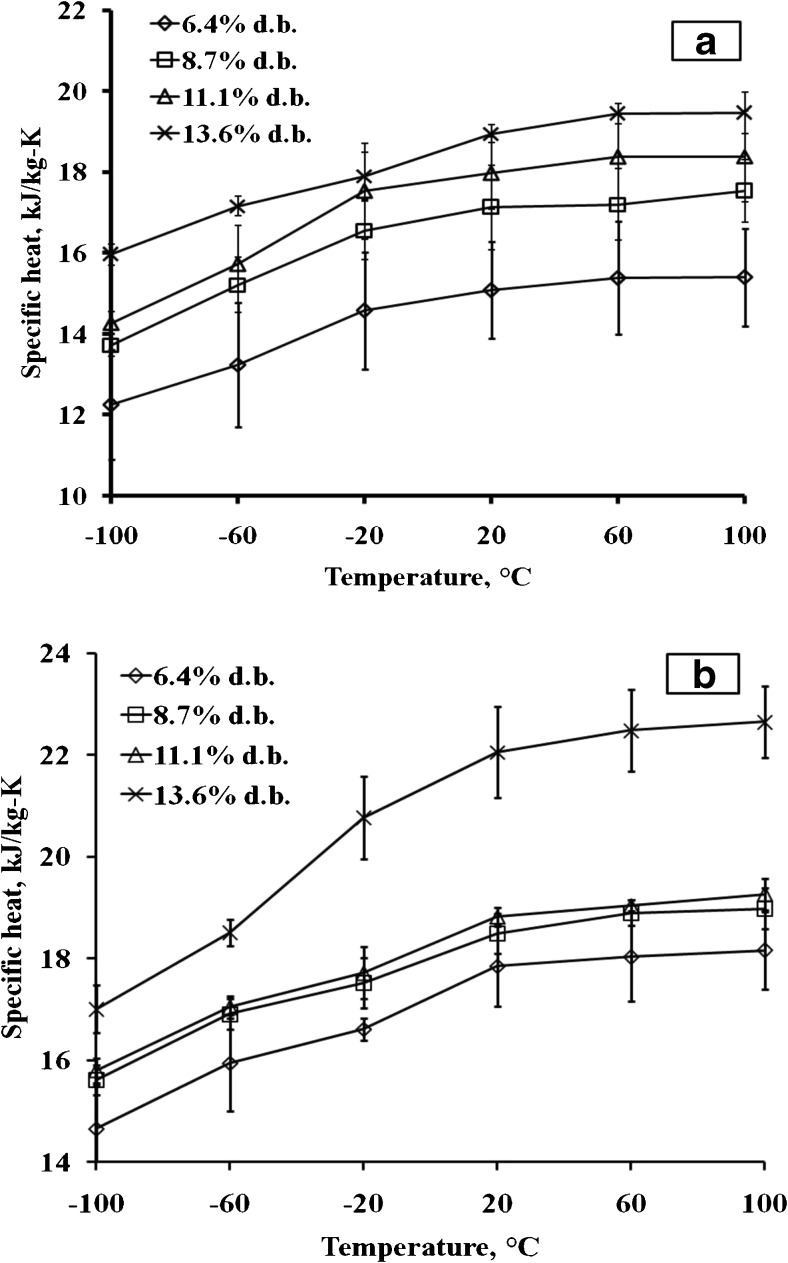

Specific heat of hammer and pin mill ground coriander powders were found to increase with increasing temperature (range: -100 °C to +100 °C) irrespective of moisture content (Fig. 2a, b). Though, a lower value of specific heat was observed for hammer ground coriander powder as compared to pin mill ground coriander powder. This may be due to the fact that as the particle size decreases, its surface-to-volume ratio increases and the melting temperature decreases as a consequence of the improved free energy at the particle surface leading to lower specific heat. The specific heat followed a second order polynomial relationship with temperature irrespective of grinding method (Table 3). Nevertheless other research workers (Tang et al. 1991; Wang and Brennan 1993) observed linear relations of specific heat with temperature for other agricultural materials. Specific heat was found to be increased with increase in moisture content regardless of grinding conditions and followed second order polynomial for all the moistures (Table 4). Hsu et al. (1991) also reported non linear correlation for pistachios. The values of specific heat of hammer and pin mill ground coriander powder increased from 12.25 to 22.64 kJ kg−1 K−1 in temperature range of −100 °C to +100 °C. The analysis of variance for specific heat showed that grinding conditions, temperature and moisture content significantly affected the specific heat of coriander powder at 5 % level (Table 2).

Fig. 2.

Effect of temperature on specific heat of ground coriander powder a hammer mill and b pin mill

Table 3.

Regression analysis of thermal properties of coriander powder with respect to temperature for different grinding methods

| Parameter | Grinding method | Moisture content, % d.b | Regression equation | R2 |

|---|---|---|---|---|

| Specific heat | Hammer | 6.4 | Cp = −10.051E-05 T2 + 0.016 T + 14.794 | 0.99 |

| 8.7 | Cp = −12.082E-05 T2 + 0.018 T + 16.792 | 0.98 | ||

| 11.1 | Cp = −14.321E-05 T2 + 0.0216 T + 17.712 | 0.99 | ||

| 13.6 | Cp = −7.698E-05 T2 + 0.018 T + 18.506 | 0.99 | ||

| Pin | 6.4 | Cp = −8.668E-05 T2 + 0.017 T + 17.279 | 0.98 | |

| 8.7 | Cp = −7.689 E-05 T2 + 0.016 T + 18.092 | 0.99 | ||

| 11.1 | Cp = −7.691E-05 T2 + 0.017 T + 18.305 | 0.99 | ||

| 13.6 | Cp = −15.645E-05 T2 + 0.029 T + 21.309 | 0.98 | ||

| Thermal conductivity | Hammer | 6.4 | kb = 14.6E-05 T + 0.049 | 0.94 |

| 8.7 | kb = 15.8E-05 T + 0.052 | 0.99 | ||

| 11.1 | kb = 16E-05 T + 0.055 | 0.98 | ||

| 13.6 | kb = 14.6E-05 T + 0.049 | 0.94 | ||

| Pin | 6.4 | kb = 14.2E-05 T + 0.051 | 0.96 | |

| 8.7 | kb = 14E-05 T + 0.055 | 0.99 | ||

| 11.1 | kb = 14.4E-05 T + 0.058 | 0.98 | ||

| 13.6 | kb = 15.8E-05 T + 0.063 | 0.99 | ||

| Thermal diffusivity | Hammer | 6.4 | αb = 12.862E-05 T2 + 0.021 T + 10.880 | 0.97 |

| 8.7 | αb = 17.334E-05 T2 + 0.022 T + 10.009 | 0.98 | ||

| 11.1 | αb = 17.085E-05 T2 + 0.016 T + 9.264 | 0.99 | ||

| 13.6 | αb = 12.821E-05 T2 + 0.018 T + 9.140 | 0.99 | ||

| Pin | 6.4 | αb = 1.82E-05 T2 + 0.021 T + 10.408 | 0.99 | |

| 8.7 | αb = 14.763E-05 T2 + 0.016 T + 9.847 | 0.99 | ||

| 11.1 | αb = 15.301E-05 T2 + 0.016 T + 9.764 | 0.99 | ||

| 13.6 | αb = 3.411E-05T2 + 0.012 T + 8.982 | 0.99 |

Table 4.

Regression analysis of thermal properties of coriander powder with respect to moisture contents for different grinding methods

| Parameter | Grinding method | Temperature, °C | Regression equation | R2 |

|---|---|---|---|---|

| Specific heat | Hammer | −100 | Cp = −0.006 M2 + 0.362 M + 9.790 | 0.97 |

| −60 | Cp = −0.025 M2 + 1.029 M + 7.846 | 0.96 | ||

| −20 | Cp = −0.073 M2 + 1.924 M + 5.301 | 0.99 | ||

| 20 | Cp = −0.050 M2 + 1.518 M + 7.488 | 0.98 | ||

| 60 | Cp = −0.037 M2 + 1.301 M + 8.617 | 0.98 | ||

| 100 | Cp = −0.049 M2 + 1.538 M + 7.681 | 0.99 | ||

| Pin | −100 | Cp = 0.009 M2 + 0.114 M + 13.63 | 0.94 | |

| −60 | Cp = 0.020 M2–0.076 M + 15.71 | 0.93 | ||

| −20 | Cp = 0.090 M2–1.284 M + 21.29 | 0.95 | ||

| 20 | Cp = 0.109 M 2–1.653 M + 24.10 | 0.96 | ||

| 60 | Cp = 0.109 M 2–1.621 M + 24.13 | 0.94 | ||

| 100 | Cp = 0.108 M 2–1.586 M + 24.06 | 0.95 | ||

| Thermal conductivity | Hammer | −40 | kb = 0.001 M + 0.036 | 0.97 |

| −15 | kb = 0.001 M + 0.034 | 0.99 | ||

| 10 | kb = 0.001 M + 0.038 | 0.99 | ||

| 35 | kb = 0.001 M + 0.046 | 0.99 | ||

| 60 | kb = 0.001 M + 0.047 | 0.99 | ||

| Pin | −40 | kb = 0.001 M + 0.038 | 0.99 | |

| −15 | kb = 0.002 M + 0.035 | 0.99 | ||

| 10 | kb = 0.001 M + 0.042 | 0.98 | ||

| 35 | kb = 0.001 M + 0.046 | 0.96 | ||

| 60 | kb = 0.001 M + 0.048 | 0.99 | ||

| Thermal diffusivity | Hammer | −40 | αb = −0.222 M + 11.52 | 0.95 |

| −15 | αb = −0.243 M + 11.97 | 0.88 | ||

| 10 | αb = −0.224 M + 12.17 | 0.90 | ||

| 35 | αb = −0.303 M + 13.85 | 0.95 | ||

| 60 | αb = −0.276 M + 14.22 | 0.93 | ||

| Pin | −40 | αb = −0.140 M + 10.63 | 0.82 | |

| −15 | αb = −0.138 M + 10.84 | 0.87 | ||

| 10 | αb = −0.200 M + 11.95 | 0.92 | ||

| 35 | αb = −0.233 M + 12.77 | 0.92 | ||

| 60 | αb = −0.229 M + 13.33 | 0.78 |

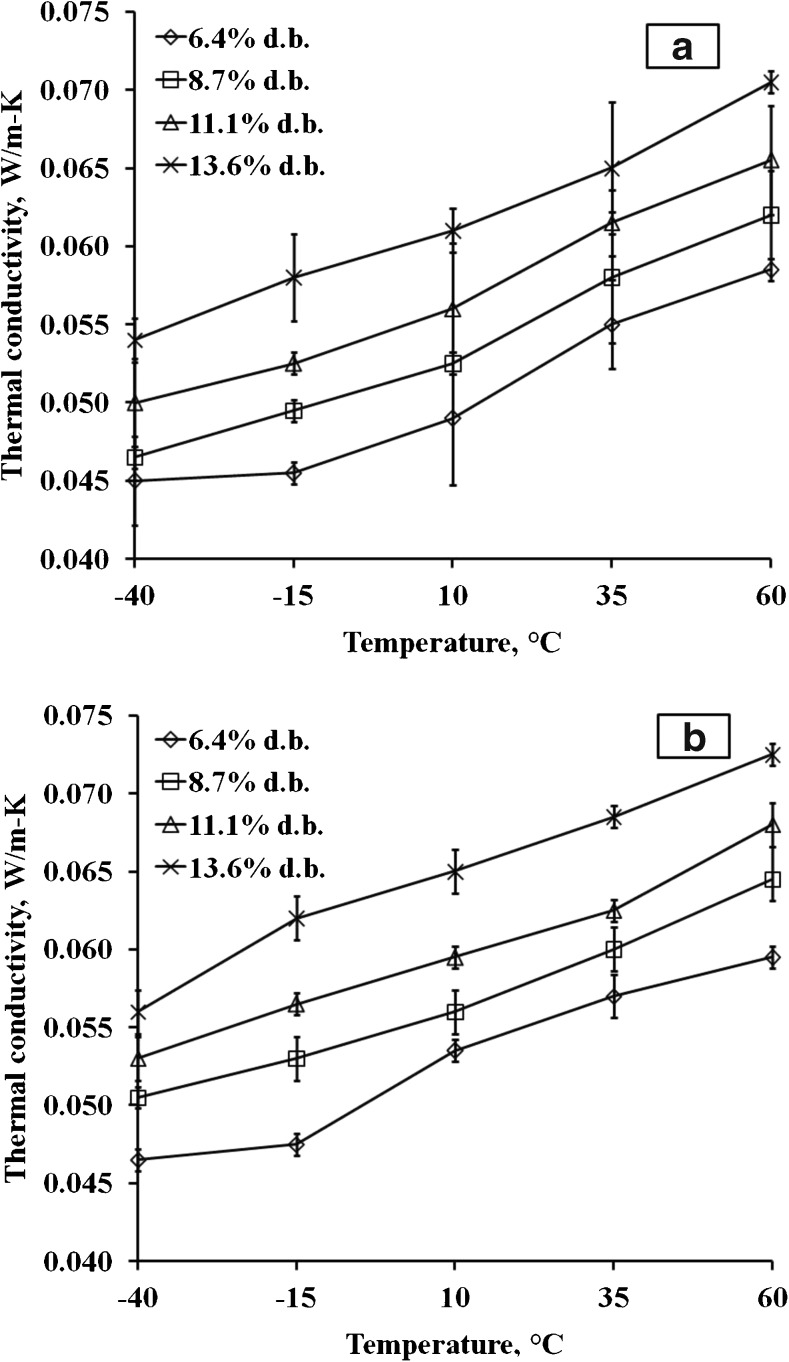

The variation of thermal conductivity with temperature of hammer and pin mill ground coriander powder is shown in Fig. 3. It may be observed that the thermal conductivity increased with temperature irrespective of the grinding method. However, thermal conductivity of hammer mill ground coriander powder was higher as compared to pin mill ground coriander despite the moisture content of coriander seeds. This may be accredited by lower particle size obtained in hammer mill grinding of coriander powder. As lower the particle size, larger surface to volume ratio, more particles will conduct heat leading to higher thermal conductivity. Similar increase in thermal conductivity with decreasing particles size of tomato powder was reported by Kadam et al. (2010). The thermal conductivity at given temperature, followed linear relationship regardless of grinding method (Table 4). Furthermore, it was found that thermal conductivity increased with increase in moisture content regardless of grinding method (Fig.3). The relationship was observed to be linear for all the moisture contents in hammer and pin mill grinding of coriander powder. Similarly, other research workers (Hsu et al. 1991; Aviara and Haque 2001) reported the existence of a linear relationship of thermal conductivity with moisture content for other agricultural materials. The values of thermal conductivity of hammer and pin mill ground coriander powders increased from 0.045 to 0.073 W m−1 K−1 for −40 to +60 °C. The analysis of variance for thermal conductivity showed that grinding method, moisture content and temperature significantly affected the thermal conductivity at 5 % level (Table 2).

Fig. 3.

Effect of temperature on thermal conductivity of ground coriander powder a pin mill and b hammer mill

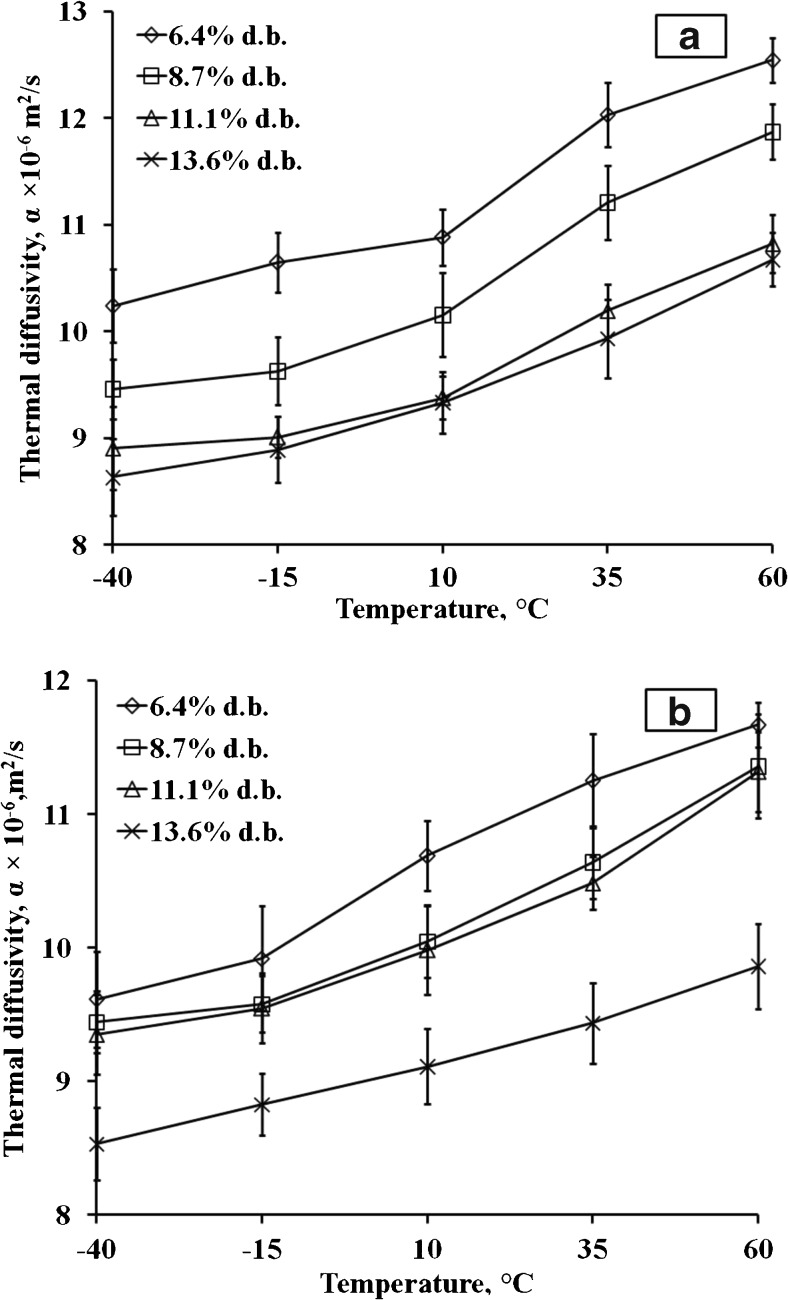

The relationship between temperature and thermal diffusivity of hammer and pin mill ground coriander powder is shown in Fig.4. The thermal diffusivity of coriander powder increased with increase in temperature irrespective of grinding method. The thermal diffusivity of hammer and pin mill ground coriander powder exhibited second order polynomial relationship with temperature (Table 3). In addition, the thermal diffusivity decreased with increase in moisture content despite the grinding method. The decrease in thermal diffusivity with moisture content may be due to increase in bulk density of coriander powder irrespective of grinding conditions. The thermal diffusivity of hammer and pin mill ground coriander powder increased from 8.53 × 10−6 to 12.54 × 10−6 m2s−1 with increase in temperature from −40 °C to 60 °C. However, the relationship between thermal diffusivity (αb), moisture content (M) and temperature have been reported in literature in both ascending [e.g. for gram (Dutta et al. 1988)] and descending [e.g. for borage seeds (Yang et al. 2002) and for cumin seed (Singh and Goswami 2000)] trends, as the magnitude of αb depends on the combined effect of kb, ρb and Cp. Nevertheless, a higher value of thermal diffusivity was found for pin mill ground coriander powder sample. This may be due to increased pore volume in pin mill ground coriander sample than that of hammer mill ground powder due to coarse particle size. The thermal diffusivity displayed linear relationship with moisture (Table 4). Similar trend was reported by Singh and Goswami (2000) for cumin seeds. The analysis of variance for thermal diffusivity showed that grinding method, moisture content and temperature significantly affected the thermal diffusivity of coriander powder at 5 % level.

Fig. 4.

Effect of temperature on thermal diffusivity of ground coriander powder a hammer mill and b pin mill

The glass transition temperature (Tg) of hammer mill and pin mill ground coriander powder decreased from 129.8 to 106.3 °C and 119.9 to 101.9 °C, respectively with an increase in moisture content irrespective of grinding method, which may be due to the plasticization effect of water. Similar observation was reported for osmo- dried apple, pear and tomato by Mrad et al. (2013) and Telis and Sobralb (2002), respectively. However, higher values of glass transition temperature were obtained for hammer mill ground coriander powder at all studied moisture contents. This increase in glass transition temperature of hammer ground coriander powder may be attributed due to smaller particle size (Paik and Kar 2009) obtained in hammer mill grinding. As the smaller particles agglomerates, more heat/temperature is required to change the phase. The regression equations showing the relationship between glass transition temperature and moisture content of hammer and pin mill ground coriander powder is shown in Eq. (17) and Eq. (18), respectively with high value of coefficient of determination.

| 17 |

| 18 |

Chemical properties of ground coriander powder

The essential oil content, total phenolic content (mg GAE/g crude seed extract), total flavonoid content (mg QE/g crude seed extract) and DPPH scavenging % of hammer and pin mill ground coriander powder at different moisture contents are shown in Table 1. The essential oil varied non-significantly with both grinding methods and moisture content whereas total flavonoid content (mg QE/g crude seed extract) and DPPH scavenging % were significantly varied with the grinding method. This may be due to particle size difference obtained in different grinding methods (Saxena et al. 2015). Total phenolic content (mg GAE/g crude seed extract) of coriander powder was decreased significantly with moisture content irrespective of grinding method (Table 1). The essential oil content, total phenolic content (mg GAE/g crude seed extract), total flavonoid content (mg QE/g crude seed extract) and DPPH scavenging % of hammer and pin mill ground coriander powder varied from 0.06 ± 0.01–0.15 ± 0.03, 20.70 ± 1.01 - 35.99 ± 0.28, 0.06 ± 0.02–0.21 ± 0.02 and 17.86 ± 0.88–32.15 ± 1.80, respectively. Furthermore, the values for these constituents were lower as compared to values obtained from cryo-ground coriander seeds of different genotypes (Saxena et al. 2015). This may be due to the fact that there is temperature rise in both the hammer and pin mill grinding methods at ambient conditions which resulted in loss of these essential constituents.

Conclusion

From present study, it was concluded that the geometric properties such as major, medium, minor dimension, geometric mean diameter, arithmetic mean diameter, sphericity, surface area and volume of coriander seeds increased significantly with increasing moisture (6.4–13.6 % db). The grinding parameters such as average particle size, volume surface mean diameter and volume mean diameter of coriander powder increased significantly with increasing moisture (6.4–13.6 % db). The L-value, a-value, b-value, hue angle and browning index varied significantly with the grinding method. The specific heat followed second order polynomial relationship with temperature and moisture whereas thermal conductivity varied linearly with temperature and moisture content. The variation of glass transition temperature with moisture can be best represented in quadratic manner. Total flavonoid content (mg QE/g crude seed extract) and DPPH scavenging % activity of coriander powder is significantly affected by grinding methods.

Acknowledgments

The financial assistance provided by NAIP, Component-4, ICAR, Government of India to carry out the study is highly acknowledged.

References

- Akgul A. Baharat Bilimi ve Teknolojisi, Gıda Teknolojisi Dernegi Yayınları Yayın. Ankara. 1993;15:113–114. [Google Scholar]

- Altuntas E, Ozgoz EO, Taser F. Some physical properties of fenugreek (Trigonella foenum-graceum L.) seeds. J Food Eng. 2005;71:37–43. doi: 10.1016/j.jfoodeng.2004.10.015. [DOI] [Google Scholar]

- Amin I, Norazaidah Y, Hainida KIE. Antioxidant activity and phenolic content of raw and blanched Amaranthus species. Food Chem. 2006;94:47–52. doi: 10.1016/j.foodchem.2004.10.048. [DOI] [Google Scholar]

- Aviara NA, Haque MA. Moisture dependence of thermal properties of sheanut kernel. J Food Eng. 2001;47:109–113. doi: 10.1016/S0260-8774(00)00105-9. [DOI] [Google Scholar]

- Balasubramanian S, Sharma R, Kumar SRV. Effect of moisture content and feed rate on size reduction of pearl millet. J Food Sci Eng. 2011;1:93–99. [Google Scholar]

- Chakraverty A. Post harvest technology of cereals, pulses and oilseeds. New Delhi: Oxford & IBH Publ. Co; 1988. [Google Scholar]

- Chang C, Yang M, Wen H, Chern J. Estimation of total flavonoid content in propolis by two complementary colorimetric methods. J Food Drug Anal. 2002;10:178–182. [Google Scholar]

- Das H. Food processing operation analysis, size reduction (chapter 1) New Delhi: Asian books private limited; 2005. pp. 1–20pp. [Google Scholar]

- Diederichsen A (1996) Coriander (Coriandrum sativum L.) promoting the conservation and use of underutilized and neglected crops, 3. Institute of Plant Genetics and Crop Plant Research, Gatersleben/International Plant Genetic Resources Institute, Rome, 1–82

- Dutta SK, Nema VK, Bhardwaj RK. Thermal properties of gram. J Agric Eng Res. 1988;39(4):269–275. doi: 10.1016/0021-8634(88)90148-5. [DOI] [Google Scholar]

- Goula AM, Karapantsios TD, Achilias DS, Adamopoulos KG. Water sorption isotherms and glass transition temperature of spray dried tomato pulp. J Food Eng. 2008;85:73–83. doi: 10.1016/j.jfoodeng.2007.07.015. [DOI] [Google Scholar]

- Hsu MH, Mannapperuma JD, Singh RP. Physical and thermal properties of pistachios. J Agric Eng Res. 1991;49:311–321. doi: 10.1016/0021-8634(91)80047-I. [DOI] [Google Scholar]

- Jain RK, Bal S. Properties of pearl millet. J Agric Eng Res. 1997;66:85–91. doi: 10.1006/jaer.1996.0119. [DOI] [Google Scholar]

- Jha SN, Verma BB. Effect of grinding time and moisture on size reduction ofmakhana. J Food Sci Technol. 1999;36:446–448. [Google Scholar]

- Kadam DM, Sharma M, Chadha S, Wilson RA. Effect of particle size of foam mat dried tomato juice powder on various physical and sensory attributes. St. Joseph: American Society of Agricultural and Biological Engineers; 2010. [Google Scholar]

- Kaya N, Yılmaz G, Telci I. Farklı zamanlarda ekilen kisnis (Coriander sativum L.) populasyonlarının agronomic ve teknolojik ozellikleri. Turk J Agric For. 2000;24:355–364. [Google Scholar]

- Mohsenin NN (1986) Thermal properties of foods and agricultural materials. (2nd ed.) Gordon and Breach New York

- Mrad ND, Bonazzia C, Courtosia F, Kechaouc N, Mihoubid NB. Moisture desorption isotherms and glass transition temperatures of osmo-dehydrated apple and pear. Food Bioprod Process. 2013;91(2):121–128. doi: 10.1016/j.fbp.2012.09.006. [DOI] [Google Scholar]

- Paik P, Kar KK. Thermal degradation kinetics and estimation of lifetime of polyethylene particles: effects of particle size. Mater Chem Phys. 2009;113(2–3):953–961. doi: 10.1016/j.matchemphys.2008.08.075. [DOI] [Google Scholar]

- Ramadan MF, Morsel JT. Oil composition of coriander (Coriandrum sativum) fruit seeds. Eur Food Res Technol. 2002;36:273–276. [Google Scholar]

- Sahay KM, Singh KK. Unit operations of agricultural processing, 2nd revised and enlarged edition. New Delhi: Vikas Publishing House Pvt. Ltd.; 2004. [Google Scholar]

- Saxena SN, Sharma YK, Rathore SS, Singh KK, Barnwal P, Saxena R, Upadhyaya P, Anwer MM. Effect of cryogenic grinding on volatile oil, oleoresin content and anti-oxidant properties of coriander (Coriandrum sativum L.) genotypes. J Food Sci Technol. 2015;52(1):568–573. doi: 10.1007/s13197-013-1004-0. [DOI] [Google Scholar]

- Shimada K, Fujikawa K, Yahara K, Nakamura T. Antioxidative properties of xanthin on autoxidation of soybean oil in cyclodextrin emulsion. J Agric Food Chem. 1992;40:945–948. doi: 10.1021/jf00018a005. [DOI] [Google Scholar]

- Singh KK, Goswami TK. Thermal properties of cumin seed. J Food Eng. 2000;45:181–187. doi: 10.1016/S0260-8774(00)00049-2. [DOI] [Google Scholar]

- Singh KK, Goswami TK. Determination of specific heat of cloves using Differential Scanning Calorimetry. J Agric Eng. 2006;43(3):114–117. [Google Scholar]

- Tang J, Sokhansanj S, Yannacopoulos Y, Kasap SO. Specific heat capacity of lentil seeds by Differential Scanning Calorimetry. Trans ASAE. 1991;34:517–522. doi: 10.13031/2013.31693. [DOI] [Google Scholar]

- Telis VRN, Sobralb PJA. Glass transitions for freeze-dried and air-dried tomato. Food Res Int. 2002;35:435–443. doi: 10.1016/S0963-9969(01)00138-7. [DOI] [Google Scholar]

- Wang N, Brennan JG. The influence of moisture content and temperature on the specific heat of potato measured by Differential Scanning Calorimetry. J Food Eng. 1993;19(3):303–310. doi: 10.1016/0260-8774(93)90049-P. [DOI] [Google Scholar]

- Yang W, Sokhansanj S, Tang J, Winter P. Determination of thermal conductivity, specific heat and thermal diffusivity of borage seeds. Biosyst Eng. 2002;82(2):169–176. doi: 10.1006/bioe.2002.0066. [DOI] [Google Scholar]

- Yurtlu YB, Yesiloglu E, Arslanoglu F. Physical properties of bay laurel seeds. Int Agrophys. 2010;24:325–328. [Google Scholar]