Abstract

Ipomoeassin F, a macrolide glycoresin containing an embedded disaccharide, possesses potent in vitro antitumor activity with an unknown mechanism of function. It inhibits tumor cell growth with single-digit nanomolar IC50 values, superior to many clinical chemotherapeutic drugs. To facilitate translation of its bioactivity into protein function for drug development, we report here a new synthesis for the gram-scale production of ipomoeassin F (3.8% over 17 linear steps) from commercially-available starting materials. The conformation-controlled subtle reactivity differences of the hydroxyl groups in carbohydrates were utilized to quickly construct the disaccharide core, which, along with judicial selection of protecting groups, made the current synthesis very efficient. The same strategy was also applied to the smooth preparation of the 11R-epimer of ipomoeassin F for the first time. Cytotoxicity assays demonstrated the crucial role of the natural 11S configuration. In addition, cell cycle analyses and apoptosis assays on ipomoeassin F and/or its epimer were conducted. This work has laid a solid ground for understanding the medicinal potential of the ipomoeassin family of glycolipids in the future.

INTRODUCTION

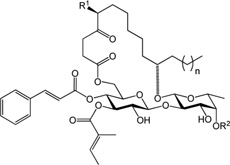

Resin glycosides (also called glycoresins) are a large collection of amphiphilic glycolipids consisting of a differently-acylated oligosaccharide glycosylated with a mono- or dihydroxy C14 or C16 fatty acid.1,2 The latter is usually folded back to form a macrolactone ring of various sizes spanning two or more sugar units. Resin glycosides are primarily isolated from the morning glory family (Convolvulaceae) of plants that have been extensively used as traditional herbal medicines for many diseases. Because of their unique macrocyclic architectures with embedded carbohydrates and a broad spectrum of biological activities, resin glycosides have attracted considerable attention from the synthetic community, but not much beyond.3–5

In 2005 and 2007, a new family of glycoresins, ipomoeassins A–F (Table 1), was isolated from the leaves of Ipomoea squamosa in the Suriname rainforest.6,7 These newly discovered natural glycoconjugates quickly inspired synthetic chemists to tackle their total syntheses8 because two members of the family, ipomoeassins D and F, exhibited exceptionally potent cytotoxicity with single-digit nanomolar IC50 values against several cancer cell lines (Table 1). More importantly, in the NCI 60-cell line screen, the naturally most abundant member of the family, ipomoeassin A, showed strong and selective growth inhibition of different cancer cells, and its pattern of activity was clearly distinguished from other known anticancer agents based on a COMPARE analysis.9 Therefore, it suggests that the ipomoeassins have novel molecular targets and can serve as promising new leads for developing a new class of anti-neoplastic agents.

Table 1.

IC50 values of ipomoeassin A–F.

With the long-term goal of utilizing underexploited natural glycoconjugates to study biological systems for drug development, our laboratory became enamored with the ipomoeassin family of glycolipids for both chemical and biological reasons. Chemically, it is still necessary to develop more scalable and flexible syntheses of the ipomoeassins and their analogs to offer solutions to the scarce availability. From a biological vantage point, we are interested in biological assessment of those chemical entities resulting from such efforts, which would open the door to understanding the mechanism of action of the ipomoeassins and may eventually lead to new therapeutic and/or preventative interventions. Ipomoeassin F was selected as a representative compound in this venture because it showed the highest activity in the family.

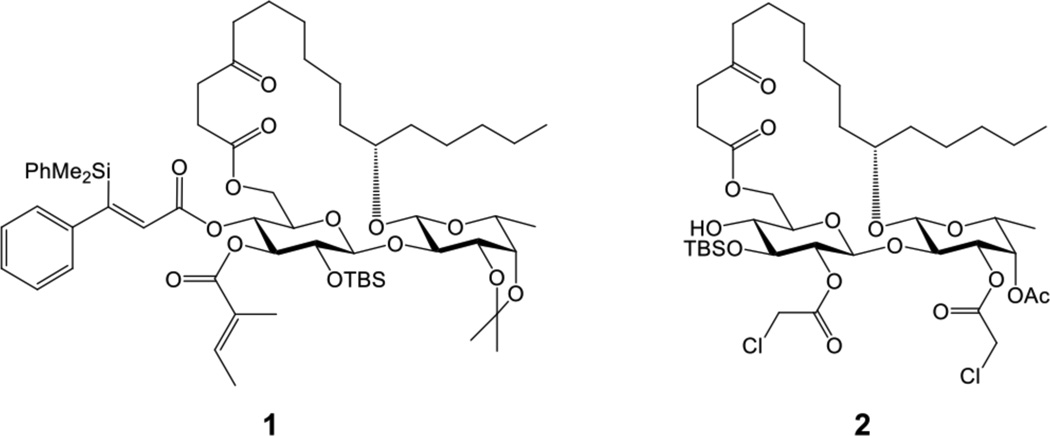

To date, two total syntheses of ipomoeassin F have been achieved independently by Postema10 and Fürstner.11 Given its favorable reactivity profile and high flexibility, RCM12,13 was adopted by both groups for the formation of the 20-membered macrolactone ring. RCM has demonstrated great success for the syntheses of many resin glycosides;4,5 however, incompatibility between two unsaturated ester groups (cinnamate and tiglate at 4-O-Glcp (glucosylpyranoside) and 3-O-Glcp, respectively) and common hydrogenation conditions presented a substantial challenge in protecting group maneuver for the ipomoeassin F syntheses. To solve this problem, the Fürstner group found that trisubstituted alkenes can well survive hydrogenation catalyzed by Wilkinson’s catalyst; therefore, they elegantly designed the key intermediate 1 (Chart 1) with a C-silylated cinnammic acid ester and achieved the total synthesis of ipomoeassin F in ~1.0% overall yield.11 By contrast, Postema and his coworkers decided to go through the orthogonally-protected intermediate 2 (Chart 1), thereby postponing the assembly of both cinnamate and tiglate to a later stage after RCM and hydrogenation. Intermediate 2 offers great flexibility for synthesizing ipomoeassin F analogs. Unfortunately, the total yield for this route is only ~0.4%.10

Chart 1.

Key intermediates in the previous total syntheses of ipomoeassin F (Fürstner and Postema).

Because of the critical role of the disaccharide core, the sequence for the installation of its peripheral ester functional groups, in particular the cinnamate moiety, is crucial to the overall efficiency for synthesizing ipomoeassin F. In addition, we were attracted by this sole aromatic functionality of cinnamate for two other reasons. First, cinnamoyl-containing compounds classified as phenylpropanoids have received significant attention in medicinal research as antitumor agents.14 Second, we hypothesized that the disubstituted α,β-unsaturated Michael system in the cinnamate group could be a covalent protein modifier through 1,4-nucleophilic addition.15 In order to conduct efficient SAR studies to clarify the role of the cinnamic ester in the future, it is essential to introduce this moiety as late as possible. Based on this principle, this full account traces the evolution of our studies that enabled the scalable synthesis and biological evaluation of ipomoeassin F and its 11R-epimer.

RESULTS AND DISCUSSION

Strategic Considerations

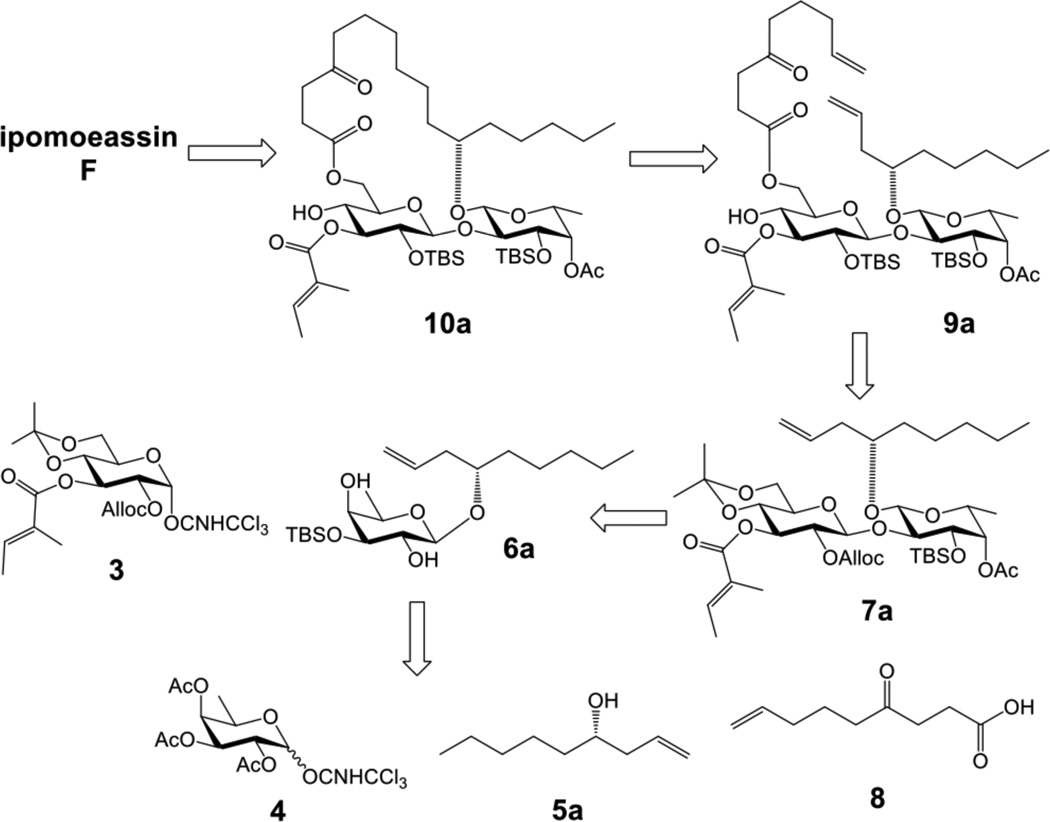

Because of the high efficiency of RCM in making macrocycles, we decided to continue to incorporate it in our strategy (Scheme 1). However, the requirement for hydrogenation after RCM along with the presence of a variety of ester moieties in ipomoeassin F makes the choice of protecting groups very limited because of orthogonality issues. Thus, TBS groups were selected and a new diene intermediate 9a with minimal transient protections was designed. Using 9a, the introduction of the cinnamate moiety could be postponed right after RCM and hydrogenation (intermediate 10a), which would lead to ipomoeassin F after the removal of TBS. To make the synthesis even more challenging, the β-(1→2) linkage further limits the choice of the protecting group on 2-O-Glcp to those with the neighboring group participation effect. Therefore, the monosaccharide building blocks, 3 and 6a, were proposed. In the glucosyl donor 3, tiglate was introduced in an early stage to minimize the number of protection and deprotection steps. The requirement of a participating group for β-glycosylation, which is also orthogonal to esters, made us opt for the allyloxycarbonyl (Alloc) group as a transient protection because its mild deprotection conditions could be well tolerated by many functional groups.16 To prepare 3, the reactivity difference between 2-OH-Glcp and 3-OH-Glcp was investigated and exploited.17 Similarly, by exploiting the reactivity differences of the hydroxyl groups in a pyranose ring,17 the fucosyl acceptor 6a was designed with minimal protection steps from fucosyl donor 418 and chiral alcohol 5a.11 The regioselective TBS protection on 3-OH-Fucp (fucosylpyranoside), followed by the regioselective glycosylation on the equatorial 2-OH-Fucp in 6a and then acetylation on the 4-OH-Fucp, afforded the disaccharide 7a, which led to the diene intermediate 9a after replacement of Alloc with TBS, followed by deisopropylidenation and consequent chemo-selective esterification of 6-OH-Glcp with 4-oxo-8-nonenoic acid 8.19

Scheme 1.

Retrosynthesis of Ipomoeassin F.

To the best of our knowledge, the stereochemistry for the fatty acid carbon that is connected to the carbohydrate core of a natural resin glycoside through the glycosydic bond is exclusively the S configuration. In ipomoeassin F, we believe that this sole stereogenic center of the aglycone has great influence on the overall conformation of the molecule, only second to the sugar core. Although it is a reasonable assumption that the naturally-occurring S configuration would be preferred for biological activities, no experimental evidence has been documented in literature as yet. Therefore, we also include the 11R–epimer of ipomoeassin F in our studies by using the same strategy.

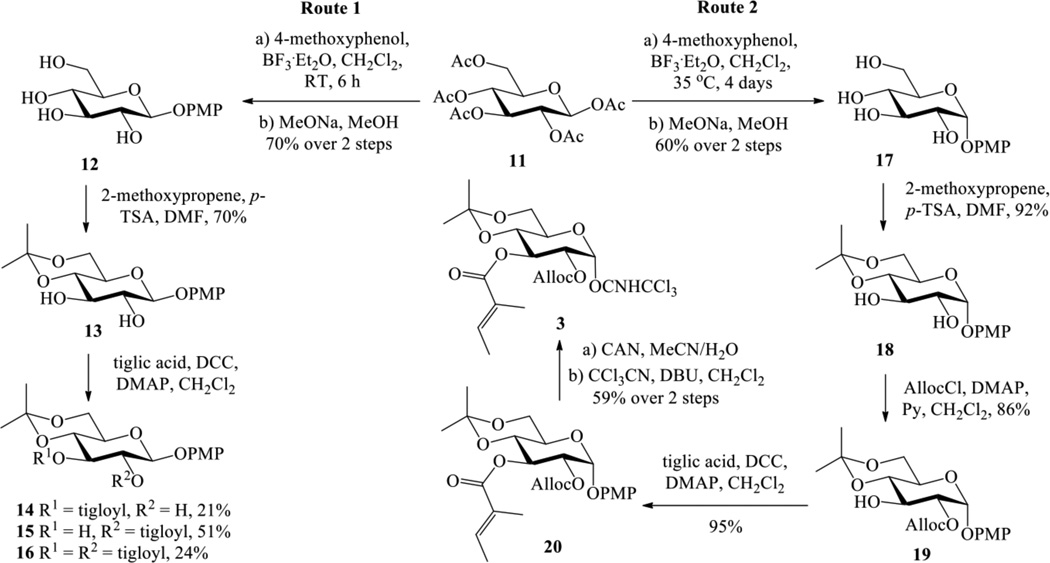

Synthesis of Glucosyl Donor 3

The synthesis commenced with the preparation of d-glucosyl donor 3 (Scheme 2). For esterification, it has been found that the 3-OH is more active than 2-OH in the case of β-d-glucopyranoside.17 Therefore, we first tried to introduce tiglate to the 3-O position of p-methoxyphenyl (PMP)-β-d-glucopyranoside (13)20,21 utilizing Steglich esterification.22 Unexpectedly, we got a mixture of products in which 2-O-tiglate was the major product in the ratio of 2.4:1 for 2-O-tiglate versus 3-O-tiglate. Because it has also been found that regioselective esterification favored 2-OH in an α-glucopyranoside,17 we next explored the selectivity for installing Alloc on the 2-OH of α-glucopyranoside 18, which was obtained through isopropylidenation of p-methoxylphenyl-α-d-glucopyranoside 17.23 To our delight, we got exclusive selectivity on 2-O-Glcp position with a yield of 86% when treated with AllocCl at low temperature (Scheme 2, Route 2). The resulting compound 19 was subsequently acylated with tiglic acid to give an excellent yield of glucosyl donor precursor 20 (95%). Cleavage of the 4- methoxyphenyl group in 20 with CAN, followed by the reaction with trichloroacetonitrile and DBU,24 gave the trichloroacetimidate donor 3 in 59% yield over two steps.

Scheme 2.

Regioselective Acylation at 2-OH and 3-OH of β-d-Glucoside (13) and α-d-Glucoside (18) and Synthesis of Glucosyl Donor 3

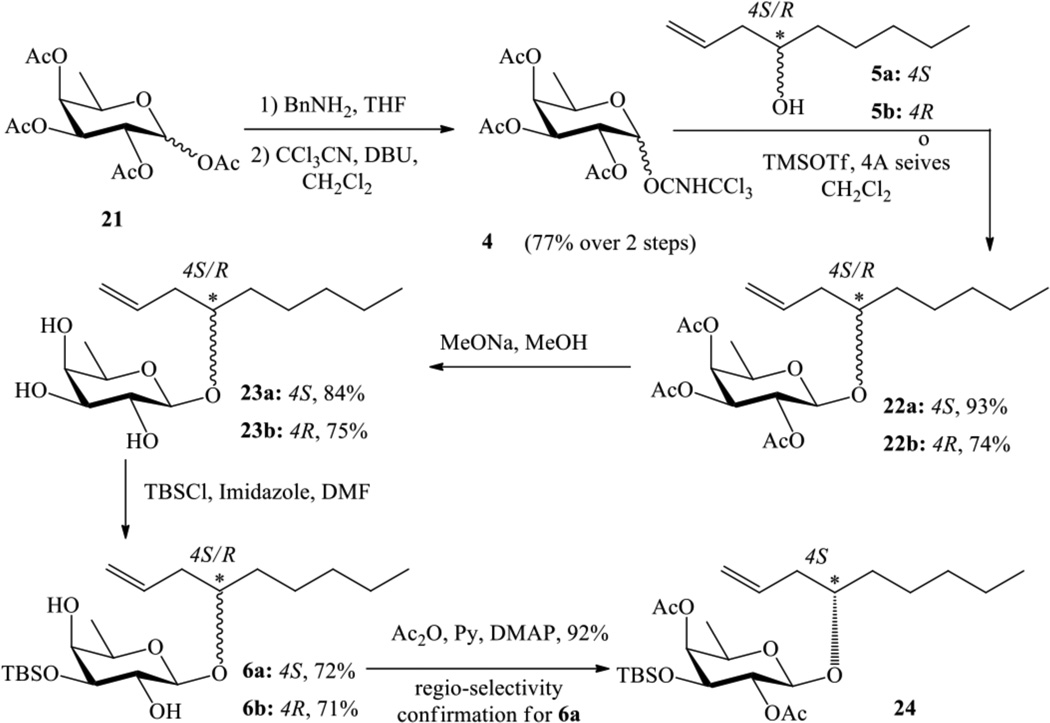

Synthesis of Fucoside Acceptor 6a/b

The synthetic route for fucoside acceptor 6a/b is outlined in Scheme 3. The known fucosyl donor 418 was prepared in 77% yield from compound 2125 using a two-step sequence involving selective removal of anomeric acetate followed by trichloroacetimidate formation. Glycosylation of fucosyl donor 4 with (S)- or (R)-4-hydroxy-1-nonene (5a11 or 5b) was accomplished by using TMSOTf as the catalyst in the presence of 4Å molecular sieves, which then underwent global deacetylation to give triol 23a10 or 23b in good to excellent yield over two steps. In the literature,17 it has been established that in the galacto-configuration, the reactivity order for the secondary hydroxyl groups is 3-OH > 2-OH > 4-OH. The 3-OH is most nucleophilic because of the hydrogen bonding with axial 4-OH. Therefore, we applied this rationale to 6-deoxy galactopyranose (d-fucose) to selectively protect 3-OH. Thankfully, regioselective silylation on 3-OH of the triol 23a/b with TBSCl provided the diol product in good yield (72% for 6a and 71% for 6b). The regioselectivity was confirmed by acetylation of 6a to give 24 (92%). Both 1H and COSY NMR spectra of 24 showed the signals for H-2 and H-4 moving downfield, while a doublet of doublet peak stays at δ 3.78 ppm with J2,3 = 9.6 and J3,4 = 3.6 Hz for H-3, when compared to that of 6a. This single-step regioselective silylation without using any other protecting groups significantly improved the overall efficiency of our synthesis.

Scheme 3.

Preparation of Fucoside Acceptor 6a

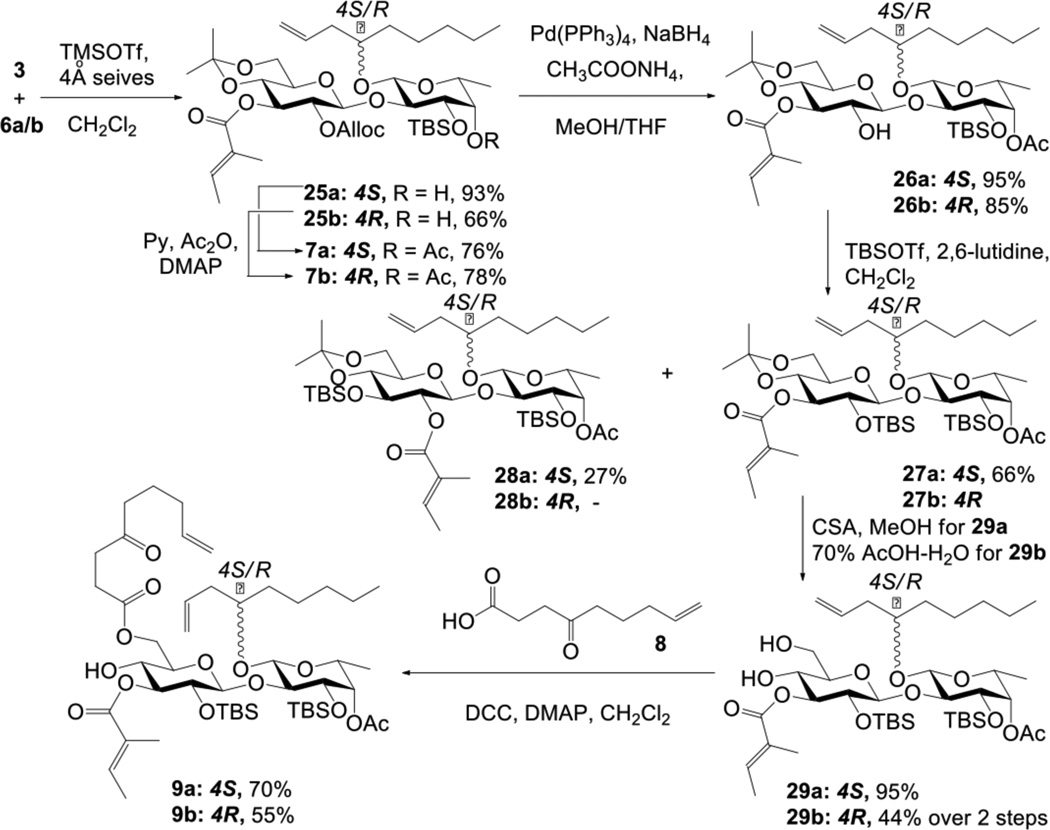

Synthesis of Diene Intermediate 9a/b

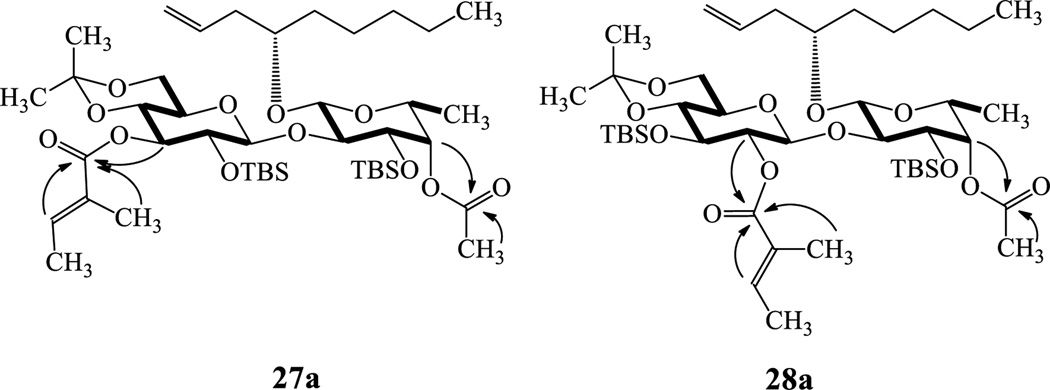

With the glucosyl donor 3 and the fucoside acceptor 6a/b in hand, the diene 9a/b was prepared efficiently as outlined in Scheme 4. The regioselective Schmidt glycosylation24 of acceptor 6a/b and donor 3 in dichloromethane at −60 °C in presence of TMSOTf, followed by acetylation of the remaining hydroxyl group, showed excellent regio- and stereoselectivity, giving exclusively β-(1→2)-linked disaccharide 7a in 71% yield or 7b in 51% yield over 2 steps. The configuration of the glycosyl bond and the regioselectivity of the coupling reaction were confirmed by the 1H, COSY and HSQC NMR spectra. Using 7a as the example, although the signal for H-1-Glcp overlapped with the signals for the terminal alkenes of the Alloc and the lipophilic tether, the coupling constant for H-2-Glcp (J = 9.6, 8.0 Hz) indicates the β-linkage; a signal at 3.90 ppm (dd, 1H, J1,2 = 9.2, 8.0 Hz, 2-H-Fucp) and a signal at 5.00 ppm (m, 1H, H-4-Fucp, 4-O-Fucp acetylated) confirmed the (1→2)-linkage of the disaccharide. The subsequent selective removal of the Alloc group was achieved in the presence of CH3COONH4, Pd[P(C6H5)3]4, and NaBH4 in 95% yield within 4 min.16 The treatment of the resulting alcohol with TBSOTf and 2,6-lutidine afforded the desired silyl ether 27a as the major product (66%), and also a byproduct 28a, in which the tigloyl group in glucose migrated from 3-O-Glcp to 2-O-Glcp and the TBS group was introduced to the 3-O-Glcp position. The structure of each isomer was confirmed by the 1H, 13C, COSY, HSQC and HMBC NMR spectra (Figure 1). The separation of 27b from 28b was not possible. The removal of the isopropylidene group using camphor-10-sulfonic acid (CSA) followed by the chemoselective esterification of 6-OH-Glcp with 4-oxo-8-nonenoic acid 819 in the presence of DCC and DMAP, gave diene as the RCM precursor (70% for 9a and 55% for 9b) over 2 steps.

Scheme 4.

Synthesis of Diene 9a/b

Figure 1.

Key COSY (bold) and HMBC (arrows) correlations in 27a and 28a.

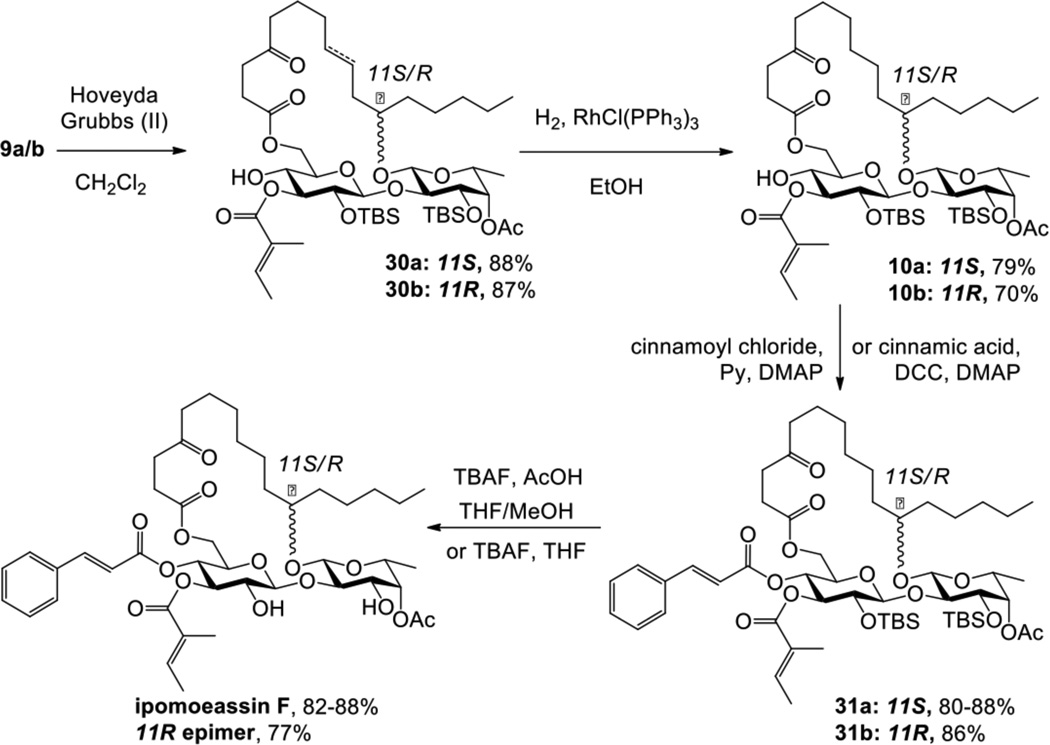

Total Synthesis of Ipomoeassin F and its 11R-Epimer

Treatment of the diene 9a/b with Hoveyda-Grubbs catalyst (II)26,27 (10 mol%) furnished macrolide a/b as a mixture of E/Z isomers, which was subjected to hydrogenation over Wilkinson’s catalyst to give 10a/b as the major product (79%) (Scheme 5). In the penultimate step, the cinnamate moiety was introduced in 80% yield by reacting 10a/b with cinnamoyl chloride in a pyridine solution promoted by DMAP. We also tried to use Steglich esterification to introduce the cinnamate moiety and found that increasing concentration of the reactants could further improve the synthesis up to 88% yield in 12 h for 10a. The final removal of the TBS groups was achieved by treating 31a either with TBAF and AcOH at room temperature to give ipomoeassin F in 88% yield or with TBAF alone at low temperature to give ipomoeassin F in 82% yield. Its 1H and 13C NMR spectra are consistent with the published literature data.7,10,11 Thus, ipomoeassin F was synthesized in 3.8% overall yield over 17 steps of the longest linear sequence from commercially available starting materials 11 and 21, which is more efficient (9- and 4-fold) than the previously reported two syntheses (ca. 0.4%10 and 1.0%11 overall yield, respectively, calculated based on the non-commercially available starting materials). In our route, three highly regioselective reactions were developed: a) selective allyloxycarbonylation of the 2-OH-Glcp in diol 18; b) selective silylation of the 3-OH-Fucp in triol 23a; and c) selective glycosylation of 2-OH-Fucp in diol 6a. To our delight, all of them were accomplished in good to excellent yield (86%, 72% and 93%, respectively). Using this route, ipomoeassin F can be synthesized on a gram scale since the key intermidiate 10a was prepared on a scale of 1.6 grams. Similarly, the 11R-epimer of ipomoeassin F was prepared from 31b.

Scheme 5.

Completion of the Total Synthesis

Cytotoxicity of Ipomoeassin F

By using the MTT (3-(4,5 dimethylthiazol-2-yl)-2,5-diphenyltetrazolium bromide) colorimetric assay28 with taxol as the positive control, the cytotoxicity of ipomoeassin F obtained through our total synthesis was evaluated against a small panel of cell lines, including five human tumor cell lines, one immortalized normal human mammary epithelial cell line (MCF-10A), and one immortalized normal mouse embryo fibroblast cell line (NIH/3T3). The U937 human leukemic monocyte lymphoma cell line was selected for comparison with the literature-reported cytotoxicity data.10,11 All the other cell lines, especially the two non-tumor cell lines, were screened for the first time. The results presented in Table 2 illustrate the concentrations required for 50% cell death (IC50 values) when compared to the vehicle-treated negative control. The IC50 values for ipomoeassin F range from 5.4 nM to 43.7 nM, close to taxol, whereas the 11R-epimer is significantly (20–80 fold) less active. In particular, the IC50 value (5.4 nM) for U937 cells is comparable to the literature-reported value (2.6 nM),10,11 which further confirms the success of our synthesis. The 2-fold difference could be explained by the longer treatment time in the literature conditions. In addition, ipomoeassin F exhibited markedly different toxicity (~8-fold) against two cancer cell lines (U937 and MCF7), suggesting that the cytotoxicity of ipomoeassin F is selective. Although taxol had lower IC50 values, the cell viability curves showed that ipomoeassin F could inhibit cell growth to a 20–30% greater extent than taxol at concentrations over 100 nM. One representative example is shown in Figure 2. Unfortunately, no selectivity between tumor and non-tumor cell lines was observed for ipomeassin F.

Table 2.

| MDA-MB- 231 |

MCF7 | HeLa | U937 | Jurkat | MCF-10A | NIH/3T3 | |

|---|---|---|---|---|---|---|---|

| Ipm F10,11 | –d | – | – | 2.6e | – | – | – |

| Ipm F | 6.5 | 43.7 | 16.4 | 5.4 | 6.1 | 5.4 | 16.8 |

| Epimer | 240.2 | 830.7 | 440.2 | 190.1 | 325.1 | 159.2 | 1370.5 |

| Taxol | 5.1 | 11.0 | 1.6 | 2.7 | 2.8 | 41.0 | 344.0 |

3-day treatment;

The data were obtained from at least two independent experiments, and the standard errors are within 20%

Ipm = ipomoeassin;

“–” = not tested;

4/5-day treatment.

Figure 2.

Cytotoxic Effect of Synthetic Ipomoeassin F and Taxol on MDA-MB-231 cells.

Ipomoeassin F Induces G1 Cell Cycle Arrest

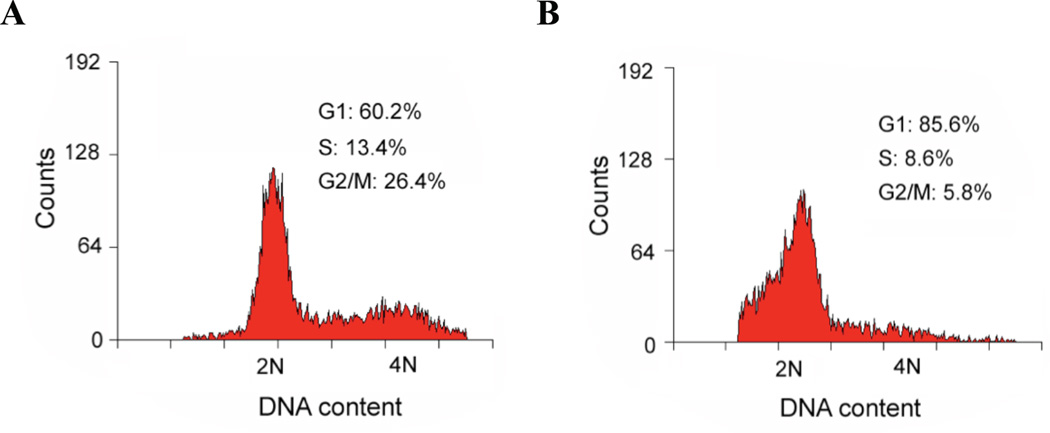

To date, very little is known about the functional mechanism of the ipomoeassins. The only related biological studies that have been performed are cell cycle analyses.11 The published data showed that a 24-hour treatment with the ipomoeassins led to the G1 arrest of mouse L-929 fibroblast cells, accompanied by a decreased cell number in the G2/M phase. The continued (48 h) exposure caused a significant number of sub-G1 cells and apoptosis. To explore the potential mechanism of action of ipomoeassin F in human cells, U937 cells were treated with ipomoeassin F (90 nM) for 48 h and then the cell cycle was analyzed by flow cytometry after the cells were stained by propidium iodide (PI). Consistent with the previous report, the ipomoeassin F treatment resulted in significant G1 arrest (~25%, Figures 3A and 3B), which was accompanied by a decreased cell population in both S and G2/M phase. In particular, the cell population in the G2/M phase was reduced by ~21%.

Figure 3.

Ipomoeassin F induces G1 arrest in U937 cells. Human U937 cells were (A) mock-treated or (B) treated with ipomoeassin F (90 nM). After 48 h, the cells were harvested, stained with propidium iodide (PI) and analyzed by flow cytometry.

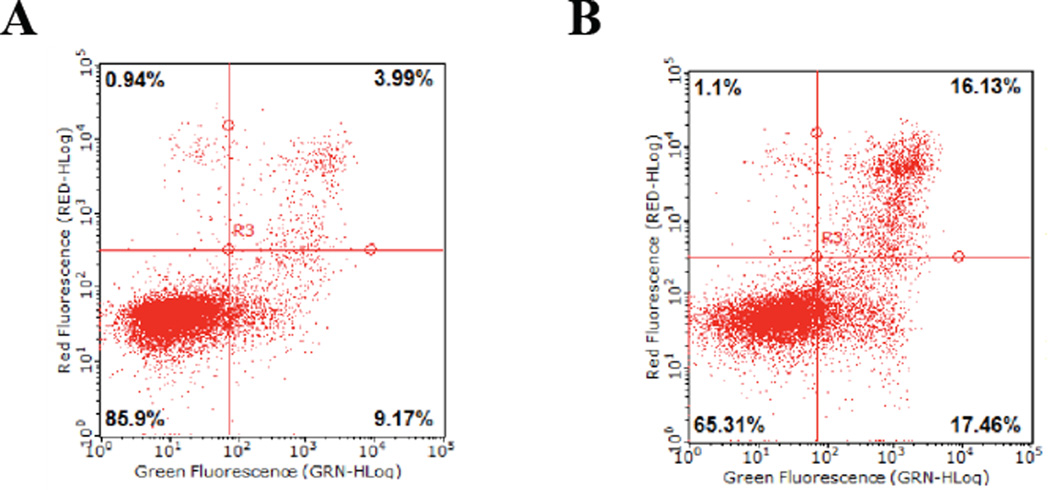

Ipomoeassin F Induces Apoptosis

To determine whether ipomoeassin F may kill cancer cells through apoptosis, the U937 cells treated with ipomoeassin F (90 nM) for 48 h were stained with both propidium iodide (PI) and FITC-conjugated annexin V, and then analyzed by flow cytometry. The results demonstrated that the ipomoeassin F treatment induced a substantial increase in cell apoptosis: the percentage of apoptotic cells increased from 13.2% (3.99% + 9.17%, Figure 4A) in control cells to 33.6% (16.13% +17.46%, Figure 4B) in the ipomoeassin F-treated cells.

Figure 4.

Ipomoeassin F induces apoptosis in U937 cells. Human U937 cells were (A) mock-treated or (B) treated with ipomoeassin F (90 nM). After 48 h, the cells were harvested, stained with PI and FITC-conjugated annexin V, and analyzed by flow cytometry.

To confirm the results obtained from the annexin V staining experiment, human MDA-MB-231 breast cancer cells were also treated with ipomoeassin F, followed by a DNA fragmentation assay. DNA fragmentation is an indicator of late apoptosis. Consistent with the flow cytometry results, it is clear that the treatment of MDA-MB-231 cells with ipomoeassin F (lane 3, Figure 5) at the concentration of IC90 (100 nM) resulted in smaller DNA fragments that were also present for the positive control (lane 4, staurosporine, Figure 5), but not in non-treated cells (lane 2, Figure 5).

Figure 5.

Ipomoeassin F induces DNA fragmentation in MDA-MB-231 cells. Lane 1: marker; lane 2: non-treated; lane 3: 100 nM ipomoeassin F; lane 4: 750 nM staurosporine (positive control).

CONCLUSIONS

In conclusion, by meticulous examination of subtle reactivity differences among various hydroxyl groups and careful selection of protecting groups, we introduced the peripheral ester functional groups to the disaccharide core in such a desired sequence that a much more efficient total synthesis of ipomoeassin F (3.8% overall yield for 17 linear steps) from commercially-available starting materials was accomplished. In our route, three highly regioselective reactions were developed: a) selective allyloxycarbonylation of the 2-OH-Glcp in diol 18; b) selective silylation of the 3-OH-Fucp in triol 23a/b; and c) selective glycosylation of 2-OH-Fucp in diol 6a/b. To our delight, all of them were accomplished in good to excellent yield. The synthesis can be easily scaled up to gram-scale. This new route secured a meaningful material supply and enabled several biological assessments for this scarce natural resin glycoside. Using the same synthetic strategy, the 11R-epimer of ipomoeassin F was prepared for the first time. The cytotoxicity screens of both compounds undoubtedly demonstrate that the 11S configuration is crucial for the cytotoxicity of ipomoeassin F. For the first time, we also confirmed that in human cells, ipomoeassin F can arrest cell cycle in the G1 phase and induce remarkable apoptosis.

EXPERIMENTAL SECTION

General Methods

Reactions were carried out in oven-dried glassware. All reagents were purchased from commercial sources and were used without further purification unless noted. Unless stated otherwise, all reactions were carried out under a nitrogen atmosphere and monitored by TLC using Silica Gel GF254 plates with detection by charring with 5% (v/v) H2SO4 in EtOH or by visualizing in UV light (254 nm). Column chromatography was performed on silica gel (230 – 450 mesh). The ratio between silica gel and crude product ranged from 100 to 50:1 (w/w). 1H NMR spectra were obtained in deuteriochloroform (CDCl3) with chloroform (CHCl3, δ = 7.27 for 1H) as an internal reference. 13C NMR spectra were proton decoupled and were in CDCl3 with CHCl3 (δ = 77.0 for 13C) as an internal reference. Chemical shifts are reported in ppm (δ). Data are presented in the form: chemical shift (multiplicity, coupling constants, and integration). 1H data are reported as though they were first order. The errors between the coupling constants for two coupled protons were less than 0.5 Hz, and the average number was reported. Proton assignments, when made, were done so with the aid of COSY NMR spectra. For some compounds, HSQC and HMBC NMR were also applied to assign the proton signals. Optical rotations were measured at 25 ± 1 °C for solutions in a 1.0 dm cell. IR spectra were recorded on an FT-IR spectrometer. HRMS were obtained by electrospray ionization (ESI, FTMS) technique in positive or negative mode (as indicated).. The purity (>95%) of the obtained ipomoeassin F and its 11R-epimer was determined by HPLC analysis equipped with a C18 column (150 mm × 4.6 mm, 5 µm) measured at 280 nm. The mobile phase was a MeCN/H2O mixture. The tested compounds were at least 95% pure.

Chemistry: Synthetic Procedures and Analytical Data

p-Methoxyphenyl 3-O-tigloyl-4,6-O-isopropylidene-β-d-glucopyranoside (14)

Compound 13 was synthesized from penta-O-acetyl-β-d-glucopyranose (11) through three steps with an overall yield of 49% following the procedure reported in literature.21 DCC (850 mg, 4.12 mmol) was added in one portion to a cold (0°C) solution of compound 13 (1120 mg, 3.43 mmol), tiglic acid (412 mg, 4.12 mmol) and 4-dimethylaminopyridine (41.9 mg, 0.343 mmol) in CH2Cl2 (50 mL). The reaction was allowed to warm to ambient temperature and stirred overnight. At this point, TLC (silica, 1:2 EtOAc–hexanes) showed the reaction was complete. The precipitate formed was filtered thru a pad of Celite using CH2Cl2 (10 mL) as the eluent and the filtrate was concentrated in vacuo. The residue was purified by column chromatography (silica, EtOAc– hexanes, 1:6 → 1:1) gave 14 (298 mg, 21%), 15 (720 mg, 51%) and 16 (410 mg, 24%) as white amorphous solids.

Compound 14: [α]D25 −64.1 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 7.03 – 6.97 (m, 2H, 2 × ArH), 6.98 – 6.91 (m, 1H, Me-CH-C(Me)-C=O), 6.85 – 6.80 (m, 2H, 2 × ArH), 5.12 (t, J = 9.6 Hz, 1H, H-3), 4.93 (d, J = 7.6 Hz, 1H, H-1), 3.98 (dd, J = 10.8, 5.2 Hz, 1H, H-6), 3.85 – 3.75 (m, 6H, H-2, H-4, H-6, -OCH3), 3.48 – 3.41 (m, 1H, H-5), 3.21 (d, J = 3.6 Hz, 1H, OH), 1.90 – 1.80 (m, 6H, CH3-CH-C(CH3)-C=O), 1.48 (s, 3H, (CH3)2C), 1.39 (s, 3H, (CH3)2C). 13C NMR (100 MHz, CDCl3) δ 168.6, 155.6, 150.9, 138.7, 128.1, 118.68 (x2), 114.52 (x2), 102.9, 99.7, 74.8, 73.6, 71.1, 67.4, 62.1, 55.6, 28.9, 18.9, 14.5, 12.1.

Compound 15: [α]D25 −57.3 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 6.99 – 6.89 (m, 3H, Me-CH-C(Me)-C=O, 2 × ArH), 6.84 – 6.77 (m, 2H, 2 × ArH), 5.15 (dd, J = 9.2, 8.0 Hz, 1H, H-2), 4.99 (d, J = 7.6 Hz, 1H, H-1), 3.99 (dd, J = 10.8, 5.6 Hz, 1H, H-6), 3.90 – 3.80 (m, 2H, H-3, H-6), 3.78 – 3.72 (m, 4H, H-4, -OCH3), 3.43 – 3.35 (m, 1H, H-5), 2.89 (br, 1H, OH), 1.90 – 1.78 (m, 6H, CH3-CH-C(CH3)-C=O), 1.55 (s, 3H, (CH3)2C), 1.46 (s, 3H, (CH3)2C). 13C NMR (100 MHz, CDCl3) δ 167.7, 155.6, 151.1, 138.9, 127.9, 118.72 (x2), 114.48 (x2), 101.1, 99.9, 74.8, 73.5, 73.0, 67.2, 61.9, 55.6, 28.9, 19.0, 14.5, 12.2.

Compound 16: [α]D25 +8.2 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 6.96 – 6.88 (m, 2H, 2 × ArH), 6.86 – 6.76 (m, 4H, 2 × ArH, 2 × Me-CH-C(Me)-C=O), 5.38 – 5.27 (m, 2H, H-2, H-3), 5.10 – 5.00 (d, J = 7.2 Hz, 1H, H-1), 4.00 (dd, J = 11.2, 5.6 Hz, 1H, H-6), 3.94 – 3.80 (m, 2H, H-4, H-6), 3.76 (s, 3H, -OCH3), 3.54 – 3.46 (m, 1H, H-5), 1.82 – 1.73 (m, 12H, 2 × CH3-CH-C(CH3)-C=O), 1.49 (s, 3H, (CH3)2C), 1.39 (s, 3H, (CH3)2C). 13C NMR (100 MHz, CDCl3) δ 167.1, 166.5, 155.6, 151.1, 138.3, 138.0, 128.0, 127.8, 118.8 (x2), 114.5 (x2), 101.2, 99.7, 72.1, 72.0, 71.4, 67.6, 62.1, 55.6, 28.9, 18.9, 14.4, 14.4, 12.1, 12.1.

p-Methoxyphenyl 4,6-O -isopropylidene-α-d-glucopyranoside (18)

To a cold (0 °C) solution of the penta-O-acetyl-β-d-glucopyranose 11 (70.0 g, 179 mmol) and p-methoxyphenol (33.4 g, 269 mmol) in dry CH2Cl2 (800 mL) was added boron trifluoride diethyl etherate (111 mL, 897 mmol) in 30 min. Then, the mixture was heated to 35 °C and agitated for 4 days, at the end of which time TLC (EtOAc–hexanes, 1:2) indicated that the reaction was complete. The reaction mixture was poured into crushed ice, and the excess boron trifluoride diethyl etherate was neutralized by the careful addition of saturated aqueous NaHCO3 solution. The organic layer was washed with brine, dried (Na2SO4), and concentrated in vacuo to provide a yellowish syrup. The syrup was dried under high vacuum for 2 h before dissolved in MeOH (500 mL). Sodium methoxide (2 g) was added to the reaction mixture and stirred at room temperature for 2 h. The residue was purified by column chromatography (silica, EtOAc–MeOH, 1:20 → 1:5) to afford p-methoxyphenyl α-d-glucopyranoside 1723 (30.8 g, 60% over 2 steps) as a white solid. To a solution of compound 17 (28.8 g, 101 mmol) in DMF (200 mL) containing TsOH H2O (0.38 g, 2.0 mmol) was added 2-methoxypropene (11.6 mL, 121 mmol) under nitrogen atmosphere. The resulting mixture was stirred for 6 h at room temperature until completion (EtOAc–hexanes, 2:1). The reaction was quenched with Et3N (0.5 mL) and then diluted with EtOAc (400 mL), washed with water (400 mL × 3), brine (100 mL). The aqueous layer was extracted with EtOAc (400 mL × 2). The combined organic layer was dried over Na2SO4 and concentrated under reduced pressure. The residue was purified by column chromatography (silica, EtOAc–hexanes, 1:1 → 2:1) gave compound 18 (30.2 g, 92%) as a white foam. [α]D25 +124.7 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 7.02 – 6.96 (m, 2H, 2 × ArH), 6.84 – 6.79 (m, 2H, 2 × ArH), 5.41 (d, J = 3.6 Hz, 1H, H-1), 4.00 (td, J = 9.2, 2.0 Hz, 1H), 3.88 – 3.66 (m, 7H, H-2, H-5, 2 × H-6, −OCH3), 3.61 (t, J = 8.8 Hz, 1H), 3.45 – 3.40 (m, 1H, OH), 3.00 – 2.92 (m, 1H, OH), 1.52 (s, 3H, (CH3)2C), 1.44 (s, 3H, (CH3)2C). 13C NMR (100 MHz, CDCl3) δ 155.4, 150.2, 118.4 (x2), 114.6 (x2), 99.8, 98.6, 73.4, 72.8, 71.9, 64.0, 62.1, 55.6, 29.0, 19.1. IR (film): v = 3397, 2994, 2938, 1654, 1508, 1504, 1206, 1043, 847. HRMS (ESI) m/z calcd for C16H22NaO7 [M+Na]+ 349.1263. Found: 349.1260.

p-Methoxyphenyl 2-O-allyloxycarbonyl-4,6-O-isopropylidene-α-d-glucopyranoside (19)

Compound 18 (20.4 g, 62.5 mmol) was dissolved in CH2Cl2 (300 mL) containing pyridine (20 mL, 250 mmol) and DMAP (0.76 g, 6.3 mmol), then under an N2 atmosphere, allyl chloroformate (7.3 mL68.8 mmol) in CH2Cl2 (50 mL) was added drop wise to the solution at −35 °C in 30 min. Then the reaction mixture was allowed to gradually warm to 0 °C in 30 min, at the end of which time TLC (silica, 1: 2 EtOAc–hexanes) showed it was complete. Then the reaction mixture was quenched with MeOH (0.5 mL) and washed with 1M HCl (200 mL), saturated aqueous NaHCO3 (100 mL) and brine (100 mL). The aqueous layer was extracted with CH2Cl2 (200 mL). The combined organic layer was dried over Na2SO4 and concentrated under reduced pressure. The residue was purified by column chromatography (silica, EtOAc–hexanes, 1:4→ 1:3) gave compound 19 (22.1 g, 86%) as a white foam. [α]D25 +153.2 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 7.01 – 6.94 (m, 2H, 2 × ArH), 6.85 – 6.77 (m, 2H, 2 × ArH), 5.96 – 5.85 (m, 1H, CH2=CH-CH2-), 5.65 (d, J = 3.6 Hz, 1H, H-1), 5.38 – 5.22 (m, 2H, CH2=CH-CH2-), 4.72 (dd, J = 9.6, 3.6 Hz, 1H, H-2), 4.66 – 4.59 (m, 2H, CH2=CH-CH2-), 4.26 (t, J = 9.2 Hz, 1H, H-3), 3.92 – 3.81 (m, 2H, H-5, H-6), 3.81 – 3.74 (m, 4H, H-6, −OCH3), 3.75 – 3.64 (m, 1H, H-4), 3.04 (br, 1H, OH), 1.54 (s, 3H, (CH3)2C), 1.45 (s, 3H, (CH3)2C). 13C NMR (100 MHz, CDCl3) δ 155.3, 154.4, 150.3, 131.1, 119.2, 118.2 (x2), 114.5 (x2), 100.0, 95.8, 76.7, 73.7, 68.97, 68.8, 63.7, 62.1, 55.6, 28.9, 19.1. IR (film): v = 3462, 2994, 2941, 1744, 1508, 1205, 1024. HRMS (ESI) m/z calcd for C20H26NaO9 [M+Na]+ 433.1475. Found: 433.1466.

p-Methoxyphenyl 2-O-allyloxycarbonyl-3-O-tigloyl-4,6-O-isopropylidene-α-d-glucopyranoside (20)

DCC (8.60 g, 41.7 mmol) was added in one portion to a 0°C CH2Cl2 (100 mL) solution of 19 (11.4 g, 27.8 mmol), tiglic acid (4.17 g, 41.7 mmol) and 4-dimethylaminopyridine (0.34 g, 2.78 mmol). The reaction was allowed to warm to ambient temperature and stirred overnight. At this point, TLC (silica, 1:2 EtOAc–hexanes) showed the reaction was complete. The reaction mixture was diluted with ether (100 mL) and hexanes (50 mL), stirred for 20 minutes then filtered thru a pad of Celite using ether (50 mL) as the eluent and the filtrate was concentrated in vacuo. The residue was purified by column chromatography (silica, EtOAc–hexanes, 1:6 → 1:5) gave 20 (13.1 g, 95%) as a colorless syrup. [α]D2 +127.9 (c 1 CHCl3). 1H NMR (400 MHz, MeOD) δ 7.05 – 6.99 (m, 2H, 2 × ArH), 6.93 – 6.83 (m, 3H, Me- CH-C(Me)-C=O, 2 × ArH), 5.94 – 5.75 (m, 1H, CH2=CH-CH2-), 5.67 (d, J = 3.6 Hz, 1H, H-1), 5.57 (t, J = 10.0 Hz, 1H, H-3), 5.29 – 5.15 (m, 2H, CH2=CH-CH2-), 4.97 (dd, J = 10.0, 3.6 Hz, 1H, H-4), 4.65 – 4.51 (m, 2H, CH2=CH-CH2-), 4.01 – 3.79 (m, 4H, H-4, H-5, 2 × H-6), 3.75 (s, 3H, -OCH3), 3.75 (d, J = 4.7 Hz, 3H), 1.86 – 1.78 (m, 6H, CH3-CH-C(CH3)-C=O), 1.50 (s, 3H, (CH3)2C), 1.34 (s, 3H, (CH3)2C). 13C NMR (100 MHz, MeOD) δ 168.4, 157.0, 155.6, 151.7, 139.6, 132.8, 129.2, 119.4 (x2), 118.9, 115.7 (x2), 101.2, 97.7, 75.9, 73.1, 70.8, 69.8, 65.7, 63.1, 56.0, 29.3, 19.4, 14.5, 12.2. IR (film): v = 2994, 2940, 1747, 1718, 1653, 1510, 1277, 1247, 1211, 1042. HRMS (ESI) m/z calcd for C25H32NaO10 [M+Na]+ 515.1893, found: 515.1891.

2-O-Allyloxycarbonyl-3-O-tigloyl-4,6-O-isopropylidene-α-d-glucopyranosyl trichloroacetimidate (3)

To a solution of compound 20 (10.9 g, 22.1 mmol) in acetonitrile (120 mL) and water (30 mL) was added a solution of CAN (24.3 g, 44.3 mmol) in water (30 mL) in 5 min at −10 °C. The mixture was stirred for 15 min at the same temperature, at the end of which time TLC (silica, 1:2 EtOAc–hexanes) indicated that the reaction was complete. The reaction was quenched with saturated aqueous NaHCO3 and extracted with EtOAc (400 mL × 2). The combined organic phase was dried over Na2SO4 and concentrated. The obtained residue was purified by column chromatography (silica, EtOAc–hexanes, 1:4 → 1:2) to afford the desired hemiacetal. To a solution of the obtained hemiacetal in CH2Cl2 (100 mL) was added trichloroacetonitrile (8.9 mL, 88 mmol), and DBU (0.33 mL, 2.2 mmol). The mixture was stirred overnight at room temperature and then was concentrated. The residue was purified by column chromatography (silica, EtOAc–hexanes, 1:5 → 1:3) to afford the glucosyl donor 3 (6.93 g, 59% over 2 steps) as a colorless syrup. [α]D25 +59.6 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 8.65 (s, 1H, CNHCCl3), 6.90 – 6.83 (m, 1H, Me-CH-C(Me)-C=O), 6.57 (d, J = 4.0 Hz, 1H, H-1), 5.93 – 5.76 (m, 1H, CH2=CH-CH2-), 5.61 (t, J = 9.6 Hz, 1H, H-3), 5.36 – 5.17 (m, 2H, CH2=CH-CH2-), 5.03 (dd, J = 9.6, 4.0 Hz, 1H, H-2), 4.65 – 4.54 (m, 2H, CH2=CH-CH2-), 4.05 – 3.72 (m, 4H, H-2, H-4, H-5, 2 × H-6), 1.90 – 1.76 (m, 6H, CH3-CH-C(CH3)-C=O), 1.49 (s, 3H, (CH3)2C), 1.41 (s, 3H, (CH3)2C). 13C NMR (100 MHz, CDCl3) δ 166.6, 161.2, 154.2, 138.0, 131.1, 128.0, 118.8, 100.0, 93.6, 74.0, 71.7, 69.07, 68.97, 66.2, 62.0, 28.8, 18.9, 14.4, 12.1.

1-Nonen-4S/R-yl 2,3,4-tri-O-acetyl-β-d-fucopyranoside (22a/b)

Fucosyl donor 418 was synthesized from tetra-O-acetyl-d-fucopyranose through two steps with an overall yield of 77% following the procedure reported in literature. (S)-4-hydroxy-1-nonene (5a)11 and (R)-4-hydroxy-1-nonene (5b) was synthesized from (S)-(+)-Epichlorohydrin and (R)-(−)-Epichlorohydrin through three steps with an overall yield of 68%, 58%, respectively.

Compound 22a

A mixture of acceptor 5a (3.21 g, 22.5 mmol), donor 4 (9.80 g, 22.5 mmol), and 4 Å molecular sieves (5 g) in anhydrous, redistilled CH2Cl2 (200 mL) was stirred under an N2 atmosphere for 30 min and then cooled to −10 °C. TMSOTf (408 µL, 2.3 mmol) was added to the mixture. Then the reaction mixture was allowed to gradually warm to ambient temperature with the cold bath in place and was stirred for 1 h. TLC (silica, 1:3 EtOAc–hexanes) indicated that the reaction was complete. Then the reaction mixture was quenched with Et3N (320 µL) and filtrated. The filtrate was evaporated in vacuo to give a residue, which was purified by silica gel column chromatography (silica, EtOAc–hexanes, 1:7 → 1:5) to give compound 22a (8.68 g, 93%) as a yellowish syrup. [α]D25 −9.9 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 5.81 – 5.71 (m, 1H, CH2=CH-CH2-), 5.23 – 5.11 (m, 2H, H-4-Fucp, H-2-Fucp), 5.09 – 4.94 (m, 3H, H-3-Fucp, CH2=CH-CH2-), 4.47 (d, J = 7.6 Hz, 1H, H-1-Fucp), 3.80 – 3.73 (m, 1H, H-5-Fucp), 3.65 – 3.58 (m, 1H, -CH2-CH-CH2-), 2.25 – 2.20 (m, 2H), 2.16 (s, 3H, CH3-C=O), 2.02 (s, 3H, CH3-C=O), 1.98 (s, 3H, CH3-C=O), 1.62 – 1.44 (m, 2H), 1.38 – 1.21 (m, 6H), 1.20 (d, J = 6.4 Hz, 3H, H-6-Fucp), 0.88 (t, J = 6.8 Hz, 3H). 13C NMR (100 MHz, CDCl3) δ 170.8, 170.3, 169.4, 134.4, 117.0, 100.5, 80.2, 71.5, 70.3, 69.3, 68.9, 38.4, 34.4, 31.7, 24.6, 22.5, 20.9, 20.7, 20.6, 16.1, 14.0. The 1H, 13C NMR data were in accordance with the literature.10

Compound 22b

Compound 22b (2.80 g, 74%) was prepared by coupling of acceptor 5b (1.32 g, 9.3 mmol) with donor 4 (4.28 g, 9.8 mmol) under the same conditions as described for the synthesis of 22a by coupling of 5a with 4. [α]D25 +9.7 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 5.88 – 5.75 (m, 1H, CH2=CH-CH2-), 5.25 – 5.13 (m, 2H, H-4-Fucp, H-2-Fucp), 5.09 – 4.96 (m, 3H, H-3-Fucp, CH2=CH-CH2-), 4.49 (d, J = 7.6 Hz, 1H, H-1-Fucp), 3.84 – 3.74 (m, 1H, H-5-Fucp), 3.65 – 3.56 (m, 1H, -CH2-CH-CH2-), 2.51 – 2.27 (m, 2H), 2.18 (s, 3H, CH3-C=O), 2.04 (s, 3H, CH3-C=O), 1.99 (s, 3H, CH3-C=O), 1.50 – 1.40 (m, 2H), 1.40 – 1.23 (m, 6H), 1.24 (d, J = 6.4 Hz, 3H, H-6-Fucp), 0.89 (t, J = 6.8 Hz, 3H). 13C NMR (100 MHz, CDCl3) δ 170.8, 170.3, 169.4, 134.7, 116.9, 101.2, 81.0, 71.5, 70.3, 69.3, 69.0, 39.7, 33.5, 31.9, 24.7, 22.6, 20.8, 20.7, 20.7, 16.1, 14.0. IR (film): v = 2936, 2856, 1755, 1600, 1368, 1254, 1229, 1078. HRMS (ESI) m/z calcd for C21H34NaO8 [M+Na]+ 437.2151, found: 437.2148.

1-Nonen-4S-yl β-d-fucopyranoside (23a)

MeONa (224 mg, 4.15 mmol) was added in one portion to a solution of 22a (8.60 g, 20.7 mmol) in MeOH (200 mL) at room temperature. The reaction mixture was stirred at room temperature overnight. TLC (silica, 3:1 EtOAc–hexanes) showed the reaction was complete. Neutralization of the reaction mixture with acidic ion exchange resin (Amberlite IR-120 (H+), Alfa Aesar) and the organic phase was concentrated in vacuo. The residue was purified by column chromatography (silica, EtOAc–hexanes, 3:1 → 5:1) gave triol 23a (5.05 g, 84%) as a colorless syrup. [α]D25 −21.2 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 5.91 – 5.78 (m, 1H, CH2=CH-CH2-), 5.20 – 5.02 (m, 2H, CH2=CH-CH2-), 4.24 (d, J = 7.6 Hz, 1H, H-1-Fucp), 3.74 – 3.53 (m, 5H, H-2-Fucp, H-3-Fucp, H-4-Fucp, H-5-Fucp, -CH2-CH-CH2-), 3.36 (d, J = 4.8 Hz, 1H, OH), 2.97 (br, 1H, OH), 2.73 (d, J = 5.6 Hz, 1H, OH), 2.40 – 2.22 (m, 2H), 1.67 – 1.48 (m, 2H), 1.42 – 1.21 (m, 9H), 0.89 (d, J = 6.8 Hz, 3H, H-6-Fucp). 13C NMR (100 MHz, CDCl3) δ 135.0, 117.5, 102.3, 79.2, 73.9, 72.1, 71.6, 70.5, 38.6, 34.7, 31.8, 24.8, 22.6, 16.3, 14.1. The 1H, 13C NMR data were in accordance with the literature.10

1-Nonen-4R-yl β-d-fucopyranoside (23b)

Compound 23b (1.37 g, 73%, colorless syrup) was prepared by treating 22b (2.69 g, 6.49 mmol) with MeONa (80 mg, 1.48 mmol) under the same conditions as described for the synthesis of 23a. [α]D25 +2.0 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 5.91 – 5.78 (m, 1H, CH2=CH-CH2-), 5.11 – 4.99 (m, 2H, CH2=CH-CH2-), 4.25 (d, J = 7.6 Hz, 1H, H-1-Fucp), 3.76 – 3.54 (m, 5H, H-2-Fucp, H-3-Fucp, H-4-Fucp, H-5-Fucp, -CH2-CH-CH2-), 3.90 (br 1H, OH), 3.41 (br, 1H, OH), 3.24 (br, 1H, OH), 2.46 – 2.30 (m, 2H), 1.57 – 1.48 (m, 2H), 1.45 – 1.21 (m, 9H), 0.89 (d, J = 6.8 Hz, 3H, H-6-Fucp). 13C NMR (100 MHz, CDCl3) δ 135.0, 116.8, 102.6, 79.7, 73.9, 71.7, 71.6, 70.5, 39.6, 33.5, 31.9, 24.8, 22.6, 16.4, 14.0. IR (film): v = 3381, 2928, 2859, 1639, 1070, 995, 912, 756. HRMS (ESI) m/z calcd for C15H28NaO5 [M+Na]+ 311.1834, found: 311.1830.

1-Nonen-4S-yl 3-O-tert-butyldimethylsilyl-β-d-fucopyranoside (6a)

To a cold (0 °C) solution of triol 23a (5.05 g, 17.5 mmol) and 1H-Imidazole (3.58 g, 52.5 mmol) in DMF (100 mL) was added t-butyldimethylsilyl chloride (3.70 g, 24.5 mmol). The reaction was stirred at 0 °C for 30 min and then was allowed to warm to ambient temperature and stirred for a further 2 h. At this point, TLC (silica, 1:9 EtOAc–hexanes) showed the reaction was complete. The reaction mixture was diluted with ether (500 mL), washed with water (3 × 150 mL) and brine (100 mL). The aqueous layer was extracted with ether (200 mL). The combined organic layer was dried over Na2SO4, filtered and concentrated. The residue was purified by column chromatography (silica, EtOAc–hexanes, 1:30 → 1:20) to afford compound 6a (5.05 g, 72%) as a colorless syrup. [α]D25 −6.9 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 5.91 – 5.74 (m, 1H, CH2=CH-CH2-), 5.14 – 4.98 (m, 2H, CH2=CH-CH2-), 4.20 (d, J = 7.8 Hz, 1H, H-1-Fucp), 3.73 – 3.65 (m, 1H, -CH2-CH-CH2-), 3.63 (dd, J = 9.2, 3.6 Hz, 1H, H-3-Fucp), 3.59 – 3.48 (m, 3H, H-2-Fucp, H-4-Fucp, H-5-Fucp), 2.62 (br, 1H, OH), 2.38 – 2.21 (m, 2H), 2.17 (d, J = 1.6 Hz, 1H, OH), 1.67 – 1.47 (m, 2H), 1.39 – 1.22 (m, 9H), 0.96 – 0.84 (m, 12H), 0.15 (s, 3H, CH3-Si), 0.13 (s, 3H, CH3- Si). 13C NMR (100 MHz, CDCl3) δ 135.1, 117.4, 102.2, 78.9, 74.9, 72.1, 72.1, 70.0, 38.5, 34.7, 31.8, 25.8(3), 24.7, 22.6, 18.1, 16.4, 14.1, −4.4, −5.0. IR (film): v = 3537, 2930, 2857, 1655, 1109, 1066, 997, 910, 839, 781. HRMS (ESI) m/z calcd for C21H42NaO5Si [M+Na]+ 425.2699, found: 425.2696.

1-Nonen-4R-yl 3-O-tert-butyldimethylsilyl-β-d-fucopyranoside (6b)

Compound 6b (0.36 g, 71%, colorless syrup) was prepared by treating 23b (0.36 g, 1.2 mmol) with 1H–Imidazole (0.24 g, 3.5 mmol) under the same conditions as described for the synthesis of 6a. [α]D25 +7.8 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 5.91 – 5.74 (m, 1H, CH2=C-CH2-), 5.14 – 4.98 (m, 2H, CH2=CH-CH2-), 4.20 (d, J = 7.8 Hz, 1H, H-1-Fucp), 3.73 – 3.65 (m, 1H, -CH2-CH-CH2-), 3.63 (dd, J = 9.2, 3.6 Hz, 1H, H-3-Fucp), 3.59 – 3.48 (m, 3H, H-2-Fucp, H-4-Fucp, H-5-Fucp), 2.62 (br, 1H, OH), 2.38 – 2.21 (m, 2H), 2.17 (d, J = 1.6 Hz, 1H, OH), 1.67 – 1.47 (m, 2H), 1.39 – 1.22 (m, 9H), 0.96 – 0.84 (m, 12H), 0.15 (s, 3H, CH3-Si), 0.13 (s, 3H, CH3-Si). 13C NMR (100 MHz, CDCl3) δ 135.1, 117.4, 102.2, 78.9, 74.9, 72.1, 72.1, 70.0, 38.5, 34.7, 31.8, 25.8 (x3), 24.7, 22.6, 18.1, 16.4, 14.1, −4.4, −5.0. IR (film): v = 3379, 2930, 2856, 1653, 1074, 997, 800, 760. HRMS (ESI) mz calcd or C21H42NaO5Si [M+Na]+ 425.2699, found: 425.2693.

1-Nonen-4S-yl 2,4-di-O-acetyl-3-O-tert-butyldimethylsilyl-β-d-fucopyranoside (24)

To a solution of compound 6a (10 mg, 0.025 mmol) and DMAP (1 mg) in pyridine (1 mL) was added acetic anhydride (100 µL). The reaction mixture was stirred at room temperature overnight, at the end of which time TLC (silica, 1:6 EtOAc−hexanes) indicated that the reaction was complete. The mixture was concentrated under diminished pressure and then co-evaporated with toluene (2 × 3 mL) gave the crude product. The residue was purified by column chromatography (silica, EtOAc–hexanes, 1:10) to afford compound 24 (11 mg, 92%) as a colorless syrup. [α]D25 −1.1 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 5.84 – 5.69 (m, 1H, CH2=CH-CH2-), 5.11 – 4.99 (m, 4H, CH2=CH-CH2-, H-2-Fucp, H-4-Fucp), 4.36 (d, J = 8.0 Hz, 1H, H-1-Fucp), 3.78 (dd, J = 9.6, 3.6 Hz, 1H, H-3-Fucp), 3.70 – 3.63 (m, 1H, H-5-Fucp), 3.62 – 3.55 (m, 1H, -CH2-CH-CH2-), 2.28 – 2.18 (m, 2H), 2.15 (s, 3H, CH3-C=O), 2.05 (s, 3H, CH3-C=O), 1.65 – 1.21 (m, 8H), 1.18 (d, J = 6.4 Hz, 3H, H-6-Fucp), 0.88 (t, J = 6.8 Hz, 3H), 0.83 (s, 9H), 0.07 (s, 3H, CH3-Si), 0.06 (s, 3H, CH3-Si). 13C NMR (100 MHz, CDCl3) δ 170.9, 169.2, 134.7, 116.9, 100.6, 79.9, 72.9, 72.3, 71.5, 69.0, 38.4, 34.4, 31.8, 25.4 (x3), 24.7, 22.6, 21.3, 20.9, 17.8, 16.3, 14.1, −4.8, −5.1. IR (film): v = 2928, 2855, 1744, 1371, 1231, 1119, 1063, 837, 781.

Disaccharide 25a

A mixture of acceptor 6a (4.30 g, 10.7 mmol), donor 3 (6.24 g, 11.7 mmol), and 4 Å molecular sieves (5 g) in anhydrous, redistilled CH2Cl2 (300 mL) was stirred under an N2 atmosphere or 30 min and then cooled to −60 °C. TMSOTf (193 µL, 1.07 mmol) was added the mixture. Then the reaction mixture was allowed to gradually warm to −20 °C over 2 h, at the end of which time TLC (silica, 1:6 EtOAc–hexanes) showed it was complete. Then the reaction mixture was quenched with Et3N (150 µL) and filtrated. The filtrate was evaporated in vacuo to give a residue, which was purified by silica gel column chromatography (silica, EtOAc– hexanes, 1:20 → 1:10) to give compound 25a (7.62 g, 93%) as a colorless syrup. [α]D25 −17.2 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 6.86 – 6.81 (m, 1H, Me-CH=C(Me)-C=O), 6.05 – 5.92 (m, 1H, CH2=CH-CH2-), 5.90 – 5.78 (m, 1H, CH2=CH-CH2-), 5.33 – 5.00 (m, 6H, 2 × CH2=CH- CH2-, H-3-Glup, H-1-Glup), 4.71 (dd, J = 9.6, 8.0 Hz, 1H, H-2-Glup), 4.65 – 4.45 (m, 2H, CH2=CH-CH2-O-), 4.29 (d, J = 7.6 Hz, 1H, H-1-Fucp), 3.97(dd, J = 11.2, 5.6 Hz, 1H, H-6-Glup), 3.85 – 3.68 (m, 4H, H-2-Fucp, H-3-Fucp, H-4-Glup, H-6-Glup), 3.68 – 3.59 (m, 1H), 3.55 – 3.45 (m, 2H), 3.30 (m, 1H, H-5-Glup), 2.38 (br, 1H, OH), 2.29 (t, J = 6.8 Hz, 2H), 1.87 – 1.72 (m, 6H, CH3-CH-C(CH3)-C=O), 1.56 – 1.47 (m, 2H), 1.45 (s, 3H), 1.42 – 1.18 (m, 12H), 1.02 – 0.83 (m, 12H), 0.17 (s, 3H, CH3-Si), 0.10 (s, 3H, CH3-Si). 13C NMR (100 MHz, CDCl3) δ 166.9, 154.2, 137.9, 135.6, 131.4, 128.0, 118.4, 116.3, 100.7, 99.6, 99.6, 79.3, 77.2, 76.1, 75.6, 72.4, 72.3, 71.7, 69.5, 68.4, 67.2, 62.1, 38.3, 34.3, 31.9, 28.9, 25.9 (x3), 24.6, 22.6, 18.8, 18.0, 16.4, 14.4, 14.1, 12.1, −4.6 (x2). IR (film): v = 3561, 2932, 2859, 1757, 1721, 1655, 1263, 1070, 980, 908, 835, 779. HRMS (ESI) m/z calcd for C39H66NaO13Si [M+Na]+ 793.4170, found: 793.4169.

Disaccharide 25b

25b (0.51 g, 66%, colorless syrup) was prepared by coupling of acceptor 6b (0.45 g, 1.1 mmol) with donor 3 (0.54 g, 1.0 mmol) under the same conditions as described for the synthesis of 25a by coupling of 6a with 3. [α]D25 −3.9 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 6.89 – 6.79 (m, 1H, Me-CH=C(Me)-C=O), 5.85 – 5.79 (m, 2H, 2 × CH2=CH-CH2-), 5.34 – 4.99 (m, 6H, 2 × CH2=CH-CH2-, H-3-Glup, H-1-Glup), 4.72 (dd, J = 9.6, 8.0 Hz, 1H, H-2-Glup), 4.62 – 4.49 (m, 2H, CH2=CH-CH2-O-), 4.28 (d, J = 7.6 Hz, 1H, H-1-Fucp), 3.97(dd, J = 11.2, 5.6 Hz, 1H, H-6-Glup), 3.86 – 3.67 (m, 4H, H-2-Fucp, H-3-Fucp, H-4-Glup, H-6-Glup), 3.68 – 3.59 (m, 1H), 3.56 – 3.47 (m, 2H), 3.31 (m, 1H, H-5-Glup), 2.37 (br, 1H, OH), 2.36 (t, J = 6.8 Hz, 2H), 1.83 – 1.75 (m, 6H, CH3-CH-C(CH3)-C=O), 1.55 – 1.46 (m, 2H), 1.46 (s, 3H), 1.41 – 1.20 (m, 12H), 1.00 – 0.82 (m, 12H), 0.18 (s, 3H, CH3-Si), 0.11 (s, 3H, CH3-Si). 13C NMR (100 MHz, CDCl3) δ 166.9, 154.2, 137.9, 135.2, 131.4, 128.1, 118.3, 116.5, 101.1, 99.6, 99.6, 79.9, 77.2, 75.8, 75.7, 72.4, 72.3, 71.8, 69.5, 68.4, 67.2, 62.2, 39.4, 33.5, 32.3, 28.9, 25.9 (x3), 24.7, 22.9, 18.8, 18.0, 16.5, 14.4, 14.0, 12.1, −4.6 (x2). IR (film): v = 3356, 2932, 2860, 1759, 1724, 1651, 1269, 1096, 839, 760. HRMS (ESI) m/z calcd for C39H66NaO13Si [M+Na]+ 793.4170, found: 793.4167.

Disaccharide 7a

To a cold (0 °C) solution of compound 25a (7.60 g, 9.86 mmol) and DMAP (120 mg, 0.99 mmol) in pyridine (20 mL) was added acetic anhydride (10 mL). The reaction mixture was heated to 60 °C and stirred for a further 24 h, at the end of which time TLC (silica, 1:6 EtOAc–hexanes) indicated that the reaction was complete. The mixture was concentrated under diminished pressure and then co-evaporated with toluene (2 × 20 mL) gave the crude product. The residue was purified by column chromatography (silica, EtOAc–hexanes, 1:20 → 1:10) to afford compound 7a (6.12 g, 76%, 83% based on recovered 25a) as a colorless syrup; recovered 25a (0.60g, 8%, 1H NMR, 400 MHz). [α]D25 −11.1 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 6.89 – 6.80 (m, 1H, Me-CH=C(Me)-C=O), 6.10 – 5.96 (m, 1H, CH2=CH-CH2-), 5.89 – 5.73 (m, 1H, CH2=CH-CH2-), 5.35 – 5.03 (m, 6H, 2 × CH2=CH-CH2-, H-3-Glup, H-1-Glup), 5.00 (m, 1H, H-4-Fucp), 4.75 (dd, J = 9.6, 8.0 Hz, 1H, H-2-Glup), 4.62 – 4.46 (m, 2H, CH2=CH-CH2-O-), 4.31 (d, J = 7.6 Hz, 1H, H-1-Fucp), 4.02 (dd, J = 10.8, 5.2 Hz, 1H, H-6-Glup), 3.90 (dd, J = 9.2, 8.0 Hz, 1H, H-2-Fucp), 3.82 – 3.70 (m, 3H, H-3-Fucp, H-4-Glup, H-6-Glup), 3.68 – 3.57 (m 2H), 3.33 (m, 1H, H-5-Glup), 2.34 (br, 2H), 2.12 (s, 3H, CH3-C=O), 1.84 – 1.74 (m, 6H, CH3-CH-C(CH3)-C=O), 1.62 – 1.48 (m, 2H), 1.46 (s, 3H, (CH3)2C), 1.40 – 1.22 (m, 9H), 1.13 (d, J = 6.4 Hz, 3H, H-6-Fucp), 0.94 – 0.83 (m, 12H), 0.12 (s, 3H, CH3-Si), 0.09 (s, 3H, CH3-Si). 13C NMR (100 MHz, CDCl3) δ 170.8, 166.8, 154.2, 137.9, 135.6, 131.4, 128.0, 118.3, 116.2, 101.3, 99.6, 99.5, 80.5, 77.1, 75.5, 73.5, 73.4, 72.3, 71.8, 68.9, 68.4, 67.3, 62.2, 38.4, 34.3, 31.8, 28.9, 25.8 (x3), 24.6, 22.6, 20.9, 18.9, 17.7, 16.5, 14.4, 14.1, 12.1, −4.3, −4.9. IR (film): v = 2932, 2859, 1759, 1744, 1653, 1649, 1253, 1069, 839, 758. HRMS (ESI) m/z calcd for C41H68NaO14Si [M+Na]+ 835.4276, found: 835.4270.

Disaccharide 7b

Compound 7b (321 mg, 78%, colorless syrup) was prepared by treating 25b (392 mg, 0.51 mmol) with acetic anhydride (1 mL) and DMAP (6.2 mg, 0.051 mmol) in pyridine (3 mL) under the same conditions as described for the synthesis of 7a. [α]D25 −0.6 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 6.89 – 6.80 (m, 1H, Me-CH=C(Me)-C=O), 5.91 – 5.78 (m, 2H, 2 × CH2=CH-CH2-), 5.33 – 5.02 (m, 6H, 2 × CH2=CH-CH2-, H-3-Glup, H-1-Glup), 5.00 (m, 1H, H-4-Fucp), 4.74 (dd, J = 9.6, 8.0 Hz, 1H, H-2-Glup), 4.62 – 4.47 (m, 2H, CH2=CH-CH2-O-), 4.30 (d, J = 7.6 Hz, 1H, H-1-Fucp), 4.01 (dd, J = 10.8, 5.2 Hz, 1H, H-6-Glup), 3.92 (dd, J = 9.2, 8.0 Hz, 1H, H-2-Fucp), 3.80 – 3.67 (m, 3H, H-3-Fucp, H-4-Glup, H-6-Glup), 3.66 – 3.57 (m 2H), 3.31 (m, 1H, H-5-Glup), 2.35 (br, 2H), 2.11 (s, 3H, CH3-C=O), 1.82 – 1.72 (m, 6H, CH3-CH-C(CH3)-C=O), 1.62 – 1.48 (m, 2H), 1.43 (s, 3H, (CH3)2C), 1.41 – 1.25 (m, 9H), 1.13 (d, J = 6.4 Hz, 3H, H-6-Fucp), 0.98 – 0.82 (m, 12H), 0.12 (s, 3H, CH3-Si), 0.09 (s, 3H, CH3-Si). 13C NMR (100 MHz, CDCl3) δ 170.8, 166.8, 154.3, 137.9, 135.0, 131.4, 128.0, 118.3, 116.7, 101.6, 99.6, 99.5, 81.0, 77.1, 75.2, 73.5, 73.4, 72.2, 72.0, 68.9, 68.4, 67.2, 62.3, 39.4, 33.7, 32.3, 28.9, 25.8 (x3), 24.9, 22.9, 20.9, 18.8, 17.7, 16.6, 14.4, 14.2, 12.0, −4.2, −5.0. IR (film): v = 2932, 2859, 1759, 1655, 1269, 1115, 1096, 839, 760. HRMS (ESI) m/z calcd for C41H68NaO14Si [M+Na]+ 835.4276, found: 835.4273.

Disaccharide 26a

To a cooled (−10 °C) solution of compound 7a (5.52 g, 6.79 mmol) in 1:1 MeOH–THF (160 mL) was added CH3COONH4 (5.23 g, 67.9 mmol). With vigorous stirring, NaBH4 (51 mg, 1.4 mmol), Pd[P(C6H5)3]4 (314 mg, 0.27 mmol), and NaBH416,31–33 (462 mg, 12.2 mmol) was added in 3 portions immediately one after another. Four minutes after the addition of the second portion of NaBH4, TLC (EtOAc–hexanes, 1: 6) indicated that the reaction was complete. The reaction mixture was concentrated under diminished pressure, the residue was dissolved in CH2Cl2 (200 mL) and washed with water (100 mL), then the organic layer was dried over Na2SO4. Evaporation and purification by column chromatography (silica, EtOAc–hexanes, 1:10) to afford compound 26a (4.71 g, 95%) as a colorless syrup. [α]D25 −8.6 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 6.90 – 6.81 (m, 1H, Me-CH=C(Me)-C=O), 5.92 – 5.79 (m, 1H, CH2=CH-CH2-), 5.16 (t, J = 9.6 Hz, 1H, H-3-Glup), 5.11 – 5.00 (m, 3H, CH2=CH-CH2-, H-4-Fucp), 4.72 (d, J = 8.0 Hz, 1H, H-1-Glup), 4.39 (d, J = 7.6 Hz, 1H, H-1-Fucp), 3.98 – 3.85 (m, 2H, H-6-Glup, H-2-Fucp), 3.82 – 3.74 (m, 2H, H-6-Glup, H-3-Fucp), 3.73 – 3.65 (m, 2H, H-4-Glup), 3.64 – 3.56 (m, 1H, H-5-Fucp), 3.55 – 3.46 (m, 2H, H-2-Glup, OH), 3.42 – 3.37 (m, 1H, H-5-Glup), 2.37 – 2.24 (m, 2H), 2.10 (s, 3H, CH3-C=O), 1.88 – 1.74 (m, 6H, CH3-CH-C(CH3)-C=O), 1.60 – 1.49 (m, 2H), 1.45 (s, 3H, (CH3)2C), 1.40 – 1.21 (m, 9H), 1.13 (d, J = 6.4 Hz, 3H, H-6-Fucp), 0.91 – 0.83 (m, 12H), 0.17 (s, 3H, CH3-Si), 0.14 (s, 3H, CH3-Si). 13C NMR (100 MHz, CDCl3) δ 170.8, 167.5, 137.3, 134.6, 128.4, 116.9, 104.6, 101.4, 99.6, 79.1, 79.0, 75.4, 72.8, 72.7, 72.6, 71.6, 68.8, 68.3, 62.2, 38.1, 34.0, 31.8, 28.9, 25.8 (x3), 24.3, 22.6, 20.9, 18.9, 17.8, 16.4, 14.3, 14.0, 12.1, −4.5, −4.6. IR (film): v = 3447, 2930, 2859, 1744, 1719, 1653, 1252, 1233, 1066, 837, 754. HRMS (ESI) m/z calcd for C37H64NaO12Si [M+Na]+ 751.4065, found: 751.4060.

Disaccharide 26b

Compound 26b (343 mg, 85%, colorless syrup) was prepared by treating 7b (450 mg, 0.55 mmol) with CH3COONH4 (427 mg, 5.53 mmol), Pd[P(C6H5)3]4 (26 mg, 0.02 mmol) and NaBH4 (31 mg, 0.82 mmol) in 1:1 MeOH–THF (15 mL) under the same conditions as described for the synthesis of 26a. [α]D25 −1.5 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 6.90 – 6.80 (m, 1H, Me-CH=C(Me)-C=O), 5.93 – 5.79 (m, 1H, CH2=CH-CH2-), 5.15 (t, J = 9.6 Hz, 1H, H-3-Glup), 5.10 – 5.00 (m, 3H, CH2=CH-CH2-, H-4-Fucp), 4.70 (d, J = 8.0 Hz, 1H, H-1-Glup), 4.39 (d, J = 7.6 Hz, 1H, H-1-Fucp), 3.99 – 3.85 (m, 2H, H-6-Glup, H-2-Fucp), 3.83 – 3.72 (m, 2H, H-6-Glup, H-3-Fucp), 3.72 – 3.69 (m, 2H, H-4-Glup), 3.62 – 3.58 (m, 1H, H-5-Fucp), 3.57 – 3.43 (m, 2H, H-2-Glup, OH), 3.40 – 3.35 (m, 1H, H-5-Glup), 2.49 – 2.30 (m, 2H), 2.10 (s, 3H, CH3-C=O), 1.90 – 1.73 (m, 6H, CH3-CH-C(CH3)-C=O), 1.60 – 1.50 (m, 2H), 1.46 (s, 3H, (CH3)2C), 1.41 – 1.21 (m, 9H), 1.15 (d, J = 6.4 Hz, 3H, H-6-Fucp), 0.94 – 0.80 (m, 12H), 0.18 (s, 3H, CH3-Si), 0.15 (s, 3H, CH3-Si). 13C NMR (75 MHz, CDCl3) δ 170.9, 167.6, 137.4, 134.6, 128.4, 117.0, 104.5, 101.5, 99.6, 79.5, 78.8, 75.4, 72.8, 72.8, 72.7, 71.7, 68.8, 68.3, 62.3, 38.7, 32.9, 32.1, 29.0, 25.8 (x3), 24.7, 22.6, 20.9, 18.9, 17.8, 16.5, 14.4, 14.1, 12.1, −4.5, −4.5. HRMS (ESI) m/z calcd for C37H64NaO12Si [M+Na]+ 751.4065, found: 751.4058.

Disaccharide 27a

TBSOTf (5.94 mL, 25.8 mmol) was added to a solution of compound 26a (4.71 g, 6.46 mmol) and 2,6-lutidine (7.48 mL, 64.6 mmol) in distilled CH2Cl2 (100 mL) at 0 °C The reaction was allowed to warm to ambient temperature and stirred for 24 h. At this point, TLC (silica, 1:6 EtOAc–hexanes) showed the reaction was complete. Evaporation of the solvent followed by purification of the residue by flash chromatography (silica, EtOAc–hexanes, 1:20 → 1:10) gave compound 27a (3.61 g, 66%) as a colorless syrup and 28a (1.45 g, 27 %) as a white foam.

27a

[α]D −7.8 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 6.88 – 6.75 (m, 1H, Me-CH=C(Me)-C=O), 6.16 – 5.99 (m, 1H, CH2=CH-CH2-), 5.15 – 5.02 (m, 3H, H-3-Glup, CH2=CH-CH2-), 4.99 – 4.92 (m, 2H, H-1-Glup, H-4-Fucp), 4.32 (d, J = 7.6 Hz, 1H, H-1-Fucp), 4.03 (dd, J = 9.2, 7.6 Hz, 1H, H-2-Fucp), 3.95 (dd, J = 10.8, 5.2 Hz, 1H, H-6-Glup), 3.85 (dd, J = 9.2, 4.0 Hz, 1H, H-3-Fucp), 3.71 (t, J = 10.4 Hz, 1H, H-6-Glup), 3.67 – 3.58 (m, 2H, H-5-Fucp, -CH2-CH-CH2-), 3.57 – 3.50 (m, 2H, H-2-Glup, H-4-Glup), 3.30 – 3.21 (m, 1H, H-5-Glup), 2.32 (t, J = 6.4 Hz, 2H), 2.11 (s, 3H, CH3-C=O), 1.82 – 1.75 (m, 6H, CH3-CH-C(CH3)-C=O), 1.66 – 1.45 (m, 2H), 1.41 (s, 3H, (CH3)2C), 1.39 – 1.22 (m, 9H), 1.12 (d, J = 6.4 Hz, 3H, H-6-Fucp), 0.91 – 0.83 (m, 12H), 0.78 (s, 9H), 0.14 (s, 3H, CH3-Si), 0.09 (s, 3H, CH3-Si), 0.08 (s, 3H, CH3-Si), −0.01 (s, 3H, CH3-Si). 13C NMR (100 MHz, CDCl3) δ 170.9, 166.8, 136.9, 135.9, 128.7, 116.1, 101.0, 100.5, 99.3, 80.6, 74.9, 74.3, 74.2, 73.8, 73.3, 72.5, 68.8, 66.9, 62.5, 38.5, 34.3, 31.8, 28.9, 25.8 (x3), 25.8 (x3), 24.5, 22.6, 21.0, 18.8, 18.1, 17.6, 16.7, 14.3, 14.0, 12.1, −3.2, −4.0, −4.3, −5.3.IR (film): v = 2930, 2859, 1743, 1728, 1653, 1200, 1066, 835, 777. HRMS (ESI) m/z calcd for C43H78NaO12Si2 [M+Na]+ 865.4930, found: 865.4929.

28a

[α]D25 −19.3 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 6.92 – 6.75 (m, 1H, Me-CH=C(Me)-C=O), 6.09 – 5.93 (m, 1H, CH2=CH-CH2-), 5.15 – 5.03 (m, 2H, CH2=CH-CH2-), 5.02 (d, J = 7.6 Hz, 1H, H-1-Glup), 4.98 – 4.91 (m, 2H, H-2-Glup, H-4-Fucp), 4.32 (d, J = 7.6 Hz, 1H, H-1-Fucp), 3.95 (dd, J = 10.8, 5.2 Hz, 1H, H-6-Glup), 3.86 (dd, J = 9.2, 7.6 Hz, 1H, H-2-Fucp), 3.77 (t, J = 10.4 Hz, 1H, H-6-Glup), 3.72 (d, J = 9.6, 3.6 Hz, 1H, H-3-Fucp), 3.72 – 3.63 (m, 2H, H-5-Fucp, -CH2-CH-CH2-), 3.61 – 3.51 (m, 2H, H-3-Glup, H-4-Glup), 3.25 – 3.16 (m, 1H, H-5-Glup), 2.36 (t, J = 6.4 Hz, 2H), 2.09 (s, 3H, CH3-C=O), 1.85 – 1.76 (m, 6H, CH3-CH-C(CH3)-C=O), 1.61 – 1.50 (m, 2H), 1.47 (s, 3H, (CH3)2C), 1.40 (s, 3H, (CH3)2C), 1.38 – 1.21 (m, 6H), 1.11 (d, J = 6.4 Hz, 3H, H-6-Fucp), 0.88 (t, J = 6.8 Hz, 3H), 0.85 (s, 9H), 0.79 (s, 9H), 0.07 (s, 3H, CH3-Si), 0.05 (s, 3H, CH3-Si), 0.03 (s, 3H, CH3-Si), −0.04 (s, 3H, CH3-Si). 13C NMR (100 MHz, CDCl3) δ 170.8, 166.0, 137.5, 135.5, 128.6, 116.4, 101.3, 99.7, 99.3, 80.0, 75.7, 75.3, 73.9, 73.8, 73.6, 73.4, 68.8, 67.2, 62.4, 38.3, 34.2, 31.9, 29.0, 25.8 (x3), 25.6 (x3), 24.6, 22.6, 20.9, 18.9, 18.1, 17.8, 16.5, 14.2, 14.1, 12.3, −4.2, −4.5, −4.6, −5.1. IR (film): v = 2930, 2857, 1744, 1728, 1653, 1246, 1066, 835, 777.

Disaccharide 27b

27b (298 mg crude product) was prepared by treating 26b (343 mg, 0.47 mmol) with TBSOTf (0.43 mL, 1.9 mmol) and 2,6-lutidine (0.55 mL, 4.7 mmol) in distilled CH2Cl2 (5 mL) under the same conditions as described for the synthesis of 27a. Attempt to get pure 27b using column chromatography (silica, EtOAc–hexanes) was not successful. The crude product was used in the next step to get 29b.

Diol 29a

CSA (199 mg, 0.86mmol) was added in one portion to a solution of 27a (3.61 g, 4.28 mmol) in MeOH (100 mL) at room temperature. The reaction mixture was stirred for 3 h at which point TLC (silica, 1:3 EtOAc–hexanes) showed it was complete. The reaction was quenched with Et3N (240 µL, 1.72 mmol) and concentrated. The residue was purified by column chromatography (silica, EtOAc–hexanes, 1:3 → 1:2) gave compound 29a (3.26 g, 95%) as a white foam. [α]D25 +19.1 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 7.00 – 6.85 (m, 1H, Me-CH=C(Me)-C=O), 6.07 – 5.94 (m, 1H, CH2=CH-CH2-), 5.16 – 5.02 (m, 2H, CH2=CH-CH2-), 5.01 – 4.88 (m, 3H, H-1-Glup, H-3-Glup, H-4-Fucp), 4.31 (d, J = 7.6 Hz, 1H, H-1-Fucp), 4.06 (t, J = 8.4 Hz, 1H, H-2-Fucp), 3.91 (dd, J = 12.0, 3.6 Hz, 1H, H-6-Glup), 3.85 (dd, J = 9.2, 3.6 Hz, 1H, H-3-Fucp), 3.78 (dd, J = 12.0, 4.4 Hz, 1H, H-6-Glup), 3.70 – 3.59 (m, 3H, H-4-Glup, H-5-Fucp, -CH2-CH-CH2-), 3.58 – 3.52 (m, 1H, H-2-Glup), 3.41 – 3.33 (m, 1H, H-5-Glup), 235 – 2.29 (m, 4H), 2.14 (s, 3H, CH3-C=O), 1.88 – 1.77 (m, 6H, CH3-CH-C(CH3)-C=O), 1.69 – 1.50 (m, 2H), 1.43 – 1.21 (m, 6H), 1.14 (d, J = 6.4 Hz, 3H, H-6-Fucp), 0.92 – 0.82 (m, 12H), 0.80 (s, 9H), 0.15 (s, 3H, CH3-Si), 0.11 (s, 6H, 2 × CH3-Si), 0.06 (d, J = 11.9 Hz, 3H, CH3-Si). 13C NMR (100 MHz, CDCl3) δ 170.9, 169.2, 138.7, 135.4, 128.2, 116.5, 101.2, 100.0, 80.7, 79.2, 75.2, 74.4, 73.8, 73.5, 73.3, 70.7, 68.9, 62.2, 38.5, 34.3, 31.8, 25.9 (x3), 25.8 (x3), 24.6, 22.6, 21.1, 18.1, 17.6, 16.7, 14.5, 14.1, 12.1, −3.0, −3.9, −4.2, −5.3. IR (film): v = 3446, 2930, 2857, 1740, 1718, 1653, 1256, 1076, 839, 762. HRMS (ESI) m/z calcd for C40H74NaO12Si2 [M+Na]+ 825.4617, found: 825.4614.

Diol 29b

27b (298 mg, crude product) was dissolved in a 70% solution of acetic acid and water (10 mL). The reaction mixture was stirred at 70 °C for 1 h at which point TLC (silica, 1:3 EtOAc–hexanes) showed it was complete. The reaction was concentrated and then coevaporated with toluene (3 × 5 mL). The residue was purified by column chromatography (silica, EtOAc– hexanes, 1:3 → 1:2) and gave compound 29b (165 mg, 44% over 2 steps) as a white foam. [α]D25 +15.4 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 6.96 – 6.85 (m, 1H, Me-CH=C(Me)-C=O), 5.90 – 5.79 (m, 1H, CH2=CH-CH2-), 5.11 – 5.01 (m, 2H, CH2=CH-CH2-), 5.01 – 4.90 (m, 3H, H-1-Glup, H-3-Glup, H-4-Fucp), 4.31 (d, J = 7.6 Hz, 1H, H-1-Fucp), 4.08 (t, J = 8.4 Hz, 1H, H-2-Fucp), 3.88 (dd, J = 12.0, 3.6 Hz, 1H, H-6-Glup), 3.85 (dd, J = 9.2, 3.6 Hz, 1H, H-3-Fucp), 3.77 (dd, J = 12.0, 4.4 Hz, 1H, H-6-Glup), 3.69 – 3.56 (m, 3H, H-4-Glup, H-5-Fucp, -CH2-CH-CH2-), 3.55 – 3.49 (m, 1H, H-2-Glup), 3.40 – 3.31 (m, 1H, H-5-Glup), 2.50 – 2.28 (m, 4H), 2.13 (s, 3H, CH3-C=O), 1.88 – 1.78 (m, 6H, CH3-CH-C(CH3)-C=O), 1.60 – 1.46 (m, 2H), 1.40 – 1.22 (m, 6H), 1.14 (d, J = 6.4 Hz, 3H, H-6-Fucp), 0.97 – 0.83 (m, 12H), 0.80 (s, 9H), 0.15 (s, 3H, CH3-Si), 0.11 (s, 6H, 2 × CH3-Si), 0.05 (d, J = 11.9 Hz, 3H, CH3-Si). 13C NMR (100 MHz, CDCl3) δ 170.9, 169.1, 138.6, 134.8 128.2, 116.9, 101.6, 100.0, 81.5, 79.2, 75.3, 74.4, 73.9, 73.4, 73.3, 70.8, 68.8, 62.1, 39.6, 33.9 32.1, 25.8 (x3), 25.8 (x3), 25.3, 22.7, 21.0, 18.1, 17.6, 16.7, 14.4, 14.0, 12.0, −3.0, −3.9, −4.2, −5.2.

Diene 9a

DCC (853 mg, 4.14 mmol) was added in one portion to a 0°C CH2Cl2 (200 mL) solution of 29a (3.02 g, 3.76 mmol), 4-oxonon-8-eneoic acid 819 (703 mg, 4.14 mmol) and 4-dimethylaminopyridine (46 mg, 0.38 mmol). The reaction was allowed to warm to ambient temperature and stirred overnight. At this point, TLC (silica, 1:3 EtOAc–hexanes) showed the reaction was complete. The reaction mixture was diluted with ether (100 mL) and hexanes (40 mL), stirred for 20 minutes then filtered thru a pad of celite using ether (50 mL) as the eluent and the filtrate concentrated in vacuo. The residue was purified by column chromatography (silica, EtOAc–hexanes, 1:6) gave diene 9a (2.51 g, 70%) as a colorless syrup. [α]D25 +9.2 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 6.97 – 6.90 (m, 1H, Me-CH-C(Me)-C=O), 6.24 – 6.04 (m, 1H, CH2=CH-CH2-), 5.82 – 5.70 (m, 1H, CH2=CH-CH2-), 5.20 – 4.88 (m, 7H, 2 × CH2=CH-CH2-, H-1-Glup, H-3-Glup, H-4-Fucp), 4.43 (dd, J = 12.0, 4.4 Hz, 1H, H-6-Glup), 4.37 (d, J = 8.0 Hz, 1H, H-1-Fucp), 4.34 – 4.28 (dd, J = 12.0, 2.0 Hz, 1H, H-6-Glup), 4.06 (t, J = 9.2, 7.6 Hz, 1H, H-2-Fucp), 3.89 (dd, J = 9.2, 3.6 Hz, 1H, H-3-Fucp), 3.68 – 3.47 (m, 4H, H-2-Glup, H-4-Glup, H-5-Fucp, -CH2-CH-CH2-), 3.46 – 3.39 (m, 1H, H-5-Glup), 2.94 (d, J = 4.8 Hz, 1H, OH), 2.87 – 2.49 (m, 4H), 2.49 – 2.42 (m, 2H), 2.31 (t, J = 6.0 Hz, 2H), 2.13 (s, 3H, CH3-C=O), 2.09 – 2.00 (m, 2H), 1.88 – 1.77 (m, 6H, CH3-CH-C(CH3)-C=O), 1.74 – 1.47 (m, 4H), 1.42 – 1.19 (m, 6H), 1.14 (d, J = 6.4 Hz, 3H, H-6-Fucp), 0.92 – 0.82 (m, 12H), 0.80 (s, 9H), 0.13 (s, 3H, CH3-Si), 0.08 (s, 6H, 2 × CH3-Si), 0.02 (s, 3H, CH3-Si). 13C NMR (101 MHz, CDCl3) δ 208.6, 173.2, 170.9, 168.9, 138.5, 137.8, 136.1, 128.2, 116.2, 115.3, 100.8, 99.9, 80.8, 78.6, 74.1, 74.0, 73.8, 73.7, 73.4, 70.1, 68.9, 63.3, 41.8, 38.6, 37.1, 34.4, 33.0, 31.9, 27.7, 25.8 (x3), 25.8 (x3), 24.5, 22.7, 22.6, 21.0, 18.1, 17.6, 16.7, 14.4, 14.1, 12.0, −3.2, −4.0, −4.3, −5.3. IR (film): v = 3482, 2930, 2857, 1736, 1717, 1653, 1641, 1257, 1074, 839, 762. HRMS (ESI) m/z calcd for C49H86NaO14Si2 [M+Na]+ 977.5454, found: 977.5444.

Diene 9b

9b (110 mg, 55%, colorless syrup) was prepared by treating 29b (176 mg, 0.22 mmol) with 4-oxonon-8-eneoic acid 819 (41.0 mg, 0.241 mmol) and 4-dimethylaminopyridine (2.5 mg, 0.022 mmol) in distilled CH2Cl2 (10 mL) under the same conditions as described for the synthesis of 9a. [α]D25 +4.2 (c 1 CHCl3). 1H NMR (300 MHz, CDCl3) δ 7.00 – 6.89 (m, 1H, Me-CH-C(Me)-C=O), 5.95 – 5.69 (m, 2H, 2 × CH2=CH-CH2-), 5.12 – 4.89 (m, 7H, 2 × CH2=CH-CH2-, H-1-Glup, H-3-Glup, H-4-Fucp), 4.41 (dd, J = 12.0, 4.4 Hz, 1H, H-6-Glup), 4.39 (d, J = 8.0 Hz, 1H, H-1-Fucp), 4.35 – 4.33 (dd, J = 12.0, 2.0 Hz, 1H, H-6-Glup), 4.08 (t, J = 9.2, 7.6 Hz, 1H, H-2-Fucp), 3.90 (dd, J = 9.2, 3.6 Hz, 1H, H-3-Fucp), 3.70 – 3.49 (m, 4H, H-2-Glup, H-4-Glup, H-5-Fucp, -CH2-CH-CH2-), 3.48 – 3.40 (m, 1H, H-5-Glup), 2.94 (d, J = 4.8 Hz, 1H, OH), 2.82 – 2.55 (m, 4H), 2.52 – 2.41 (m, 2H), 2.38 (t, J = 6.0 Hz, 2H), 2.13 (s, 3H, CH3-C=O), 2.11 – 2.01 (m, 2H), 1.89 – 1.77 (m, 6H, CH3-CH-C(CH3)-C=O), 1.76 – 1.65 (m, 4H), 1.42 – 1.21 (m, 6H), 1.14 (d, J = 6.4 Hz, 3H, H-6-Fucp), 0.97 – 0.85 (m, 12H), 0.80 (s, 9H), 0.15 (s, 3H, CH3-Si), 0.11 (s, 6H, 2 × CH3-Si), 0.04 (s, 3H, CH3-Si). 13C NMR (75 MHz, CDCl3) δ 208.7, 173.1, 171.0, 169.1, 138.7, 137.9, 135.0, 128.2, 116.9, 115.3, 101.1, 100.0, 81.0, 79.0, 74.3, 73.9, 73.8, 73.4, 70.4, 68.8, 63.6, 41.8, 39.6, 37.1, 33.8, 33.0, 32.3, 27.7, 25.8 (x3), 25.8 (x3), 25.3, 22.9, 22.7, 21.1, 18.1, 17.6, 16.7, 14.5, 14.3, 12.0, −3.1, −3.9, −4.2, −5.1.

RCM/Hydrogenation Product 10a

To a solution of diene 9a (2.25 g, 2.36 mmol) in CH2Cl2 (500 mL) was added Hoveyda-Grubbs catalyst 2nd generation26,27 (148 mg, 0.24 mmol) in one portion at room temperature. The reaction mixture was refluxed for 4 h. At this point, TLC (silica, 1:2 EtOAc–hexanes) showed the reaction was complete. The reaction was cooled to ambient temperature and then concentrated. Flash chromatography (silica, EtOAc–hexanes, 1:4 → 1:2) gave isomer 30a (1.92 g, 88%) as a white foam which was not fully characterized. To a solution of 30a (715 mg, 0.771 mmol) in EtOH (4 mL) was added Wilkinson’s catalyst (143 mg, 0.154 mmol) in one portion at room temperature. The reaction was then stirred under an atmosphere of hydrogen (1 atm) overnight. At this point, TLC (silica, 1:2 EtOAc–hexanes) showed the reaction was complete. The reaction mixture was filtered thru a pad of celite using EtOAc (5 mL) as the eluent and the resulting filtrate concentrated. Flash chromatography (silica, EtOAc–hexanes, 1:5 → 1:3) gave 10a (565 mg, 79%) as a colorless syrup. [α]D25 +17.3 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 6.98 – 6.90 (m, 1H, Me-CH-C(Me)-C=O), 5.08 – 4.92 (m, 3H, H-1-Glup, H-3-Glup, H-4-Fucp), 4.75 (m, 1H, H-6-Glup), 4.38 (br, 1H, H-1-Fucp), 4.04 – 4.34 (m, 2H, H-6-Glup, H-2-Fucp), 3.99 – 3.89 (m, 1H, H-3-Fucp), 3.73 – 3.65 (m, 1H, H-5-Fucp), 3.57 (br, 1H, H-5-Glup), 3.51 – 3.33 (m, 3H, H-2-Glup, H-4-Glup, -CH2-CH-CH2-), 3.13 –3.06 (m, 1H, OH), 3.01 – 2.84 (m, 1H), 2.75 – 2.56 (m, 3H), 2.52 – 2.41 (m, 1H), 2.36 – 2.24 (m, 1H), 2.11 (s, 3H, CH3-C=O), 1.87 – 1.80 (m, 6H, CH3-CH-C(CH3)-C=O), 1.78 – 1.49 (m, 6H), 1.47 – 1.20 (m, 12H), 1.13 (d, J = 6.4 Hz, 3H, H-6-Fucp), 0.91 – 0.84 (m, 12H), 0.82 (s, 9H), 0.16 (s, 3H, CH3-Si), 0.11 (s, 3H, CH3-Si), 0.10 (s, 3H, CH3-Si), 0.01 (s, 3H, CH3-Si). 13C NMR (100 MHz, CDCl3) δ 210.3, 172.4, 170.9, 168.0, 137.8, 128.5, 100.7, 100.2, 78.0, 74.5, 74.0, 73.9, 73.7, 69.0, 68.7, 63.3, 41.8, 37.1, 34.9, 33.5, 32.0, 29.6, 29.1, 28.5, 28.3, 25.9, 25.8 (x6), 25.2, 24.5, 23.4, 22.6, 20.9, 18.0, 17.6, 16.6, 14.4, 14.0, 12.0, −3.3, −4.0, −4.3, −5.1. IR (film): v = 3476, 2928, 2857, 1740, 1717, 1246, 1070, 837, 777. HRMS (ESI) m/z calcd for C47H84NaO14Si2 [M+Na]+ 951.5297, found: 951.5288.

RCM/Hydrogenation Product 10b

30b (93 mg, 87%, white foam) was prepared by treating 9b (110 mg, 0.12 mmol) with Hoveyda-Grubbs catalyst 2nd generation26,27 , (7.2 mg, 0.011 mmol) in distilled CH2Cl2 (40 mL) under the same conditions as described for the synthesis of 30a. 10b (36.1 mg, 70%, colorless syrup) was prepared by treating 30b (51.4 mg, 0.055 mmol) with Wilkinson’s catalyst (22 mg, 0.024 mmol) in EtOH (2 mL) under the same conditions as described for the synthesis of 10a. [α]D25 +18.0 (c 1 CHCl3). 1H NMR (300 MHz, CDCl3) δ 7.00 – 6.89 (m, 1H, Me-CH-C(Me)-C=O), 5.03 – 4.85 (m, 3H, H-1-Glup, H-3-Glup, H-4-Fucp), 4.51 (m, 1H, H-6-Glup), 4.47 (br, 1H, H-1-Fucp), 4.35 – 4.21 (m, 2H, H-6-Glup, H-2-Fucp), 3.99 – 3.89 (m, 1H, H-3-Fucp), 3.72 – 3.61 (m, 1H, H-5-Fucp), 3.59 (br, 1H, H-5-Glup), 3.51 – 3.40 (m, 3H, H-2-Glup, H-4-Glup, -CH2-CH-CH2-), 3.08 – 2.95 (m, 1H, OH), 2.95 – 2.89 (m, 1H), 2.78 – 2.60 (m, 3H), 2.60 – 2.48 (m, 1H), 2.38 – 2.27 (m, 1H), 2.12 (s, 3H, CH3-C=O), 1.89 – 1.78 (m, 6H, CH3-CH-C(CH3)-C=O), 1.75 – 1.51 (m, 6H), 1.49 – 1.21 (m, 12H), 1.12 (d, J = 6.4 Hz, 3H, H-6-Fucp), 0.95 – 0.86 (m, 12H), 0.79 (s, 9H), 0.16 (s, 3H, CH3-Si), 0.12 (s, 3H, CH3-Si), 0.11 (s, 3H, CH3-Si), 0.05 (s, 3H, CH3-Si). 13C NMR (75 MHz, CDCl3) δ 210.1, 172.5, 170.9, 169.4, 138.9, 128.1, 99.8, 100.2, 79.4, 74.3, 74.1, 73.8, 73.5, 61.1, 68.7, 63.8, 41.7, 37.2, 33.3, 32.8, 32.3, 28.8, 27.0, 26.7, 26.0, 25.9 (x6), 24.9, 23.0, 22.7, 22.6, 21.1, 18.1, 17.7, 16.6, 14.5, 14.2, 12.0, −3.3, −3.9, −4.3, −5.2.

Compound 31a

Method 1

To a cold (0 °C) solution of compound 10a (47.4 mg, 0.051 mmol) and DMAP (12.5 mg, 0.102 mmol) in pyridine (3 mL) was added cinnamoyl chloride (34.0 mg, 0.204 mmol). The reaction mixture was allowed to warm to ambient temperature and stirred for 24 h. At the end of this time TLC (silica, 1:2 EtOAc–hexanes) indicated that the reaction was complete. The reaction was quenched with MeOH (20 µL) and diluted with CH2Cl2 (20 mL), washed with 1 M HCl (20 mL), saturated aqueous NaHCO3 (20 mL), and dried (Na2SO4). The solvent was evaporated under vacuum and the residue was purified by column chromatography (silica, EtOAc–hexanes, 1:6) to afford compound 31a (43 mg, 80%) as a white foam.

Method 2

Cinnamic acid (14.3 mg, 0.097 mmol) was added in one portion to a solution of compound 10a (60 mg, 0.065 mmol), DCC (20.0 mg, 0.097 mmol) and DMAP (1.6 mg, 0.013 mmol) in CH2Cl2 (2 mL). The reaction mixture was stirred at room temperature overnight. At this point, TLC (silica, 1:3 EtOAc–hexanes) showed the reaction was complete. The reaction mixture was diluted with ether (2 mL) and hexanes (1 mL), stirred for 20 minutes and then filtered through a pad of Celite using ether (3 mL) as the eluent and the filtrate concentrated in vacuo. The residue was purified by column chromatography (silica, EtOAc–hexanes, 1: 4) gave compound 31a (60.2 mg, 88%) as a colorless syrup. 31a: [α]D25 −40.6 (c 1 CHCl3). 1H NMR (400 MHz, CDCl3) δ 7.63 (d, J = 16.0 Hz, 1H, Ph-CH=C-), 7.55 – 7.46 (m, 2H, 2 × ArH), 7.41 – 7.33 (m, 3H, 3 × ArH), 6.87 – 6.72 (m, 1H, Me-CH-C(Me)-C=O), 6.35 (d, J = 16.0 Hz, 1H, Ph-CH=CH-), 5.25 (t, J = 9.2 Hz, 1H, H-3-Glup), 5.13 – 4.95 (m, 3H, H-1-Glup, H-4-Glup, H-4-Fucp), 4.61 (br, 1H, H-1-Fucp), 4.30 – 4.22 (m, 1H, H-6-Glup), 4.21 – 4.14 (m, 1H, H-6-Glup), 4.10 – 4.01 (m, 1H, H-3-Fucp), 4.00 – 3.91 (m, 1H, H-2-Fucp), 3.80 – 3.66 (m, 3H, H-5-Glup, H-5-Fucp, -CH2-CH-CH2-), 3.60 (dd, J = 8.8, 7.6 Hz, 1H, H-2-Glup), 2.84 – 2.70 (m, 2H), 2.65 – 2.34 (m, 4H), 2.13 (s, 3H, CH3-C=O), 1.80 – 1.61 (m, 9H), 1.60 – 1.49 (m, 3H), 1.47 – 1.20 (m, 12H), 1.13 (d, J = 6.4 Hz, 3H, H-6-Fucp), 0.94 – 0.84 (m, 12H), 0.81 (s, 9H), 0.20 (s, 3H, CH3- Si), 0.12 (s, 3H, CH3-Si), 0.11 (s, 3H, CH3-Si), 0.01 (s, 3H, CH3-Si). 13C NMR (100 MHz, CDCl3) δ 209.1, 172.0, 171.0, 166.9, 165.6, 146.0, 138.0, 134.1, 130.5, 128.8 (x2), 128.2 (x2), 128.1, 116.8, 99.8, 99.8, 75.2, 73.9, 73.8, 71.2, 69.7, 68.8, 41.7, 36.9, 34.3, 32.0, 28.5, 27.9, 27.4, 25.8 (x3), 25.7 (x3), 24.5, 24.4, 23.3, 22.6, 21.0, 18.0, 17.8, 16.5, 14.4, 14.1, 12.0, −3.7, −3.9, −4.5, −5.2. IR (film): v = 2928, 2857, 1736, 1719, 1638, 1248, 1067, 837, 777. HRMS (FTMS) m/z calcd for C56H90NaO15Si2 [M+Na]+ 1081.5716, found: 1081.5717.

Compound 31b

31b (27.5 mg, 86%, white foam) was prepared by treating 10b (28.1 mg, 0.030 mmol) with DMAP (9.0 mg, 0.060 mmol) and cinnamoyl chloride (20.1 mg, 0.120 mmol) in pyridine (2 mL) under the same conditions as described for the synthesis of 31a (method 1). [α]D25 −1.8 (c 0.5 CHCl3). 1H NMR (400 MHz, CDCl3) δ 7.62 (d, J = 16.0 Hz, 1H, Ph-CH=C-), 7.54 – 7.47 (m, 2H, 2 × ArH), 7.44 – 7.35 (m, 3H, 3 × ArH), 6.85 – 6.75 (m, 1H, Me-CH-C(Me)-C=O), 6.33 (d, J = 16.0 Hz, 1H, Ph-CH=CH-), 5.25 (t, J = 9.2 Hz, 1H, H-3-Glup), 5.09 – 4.93 (m, 3H, H-1-Glup, H-4-Glup, H-4-Fucp), 4.51 (br, 1H, H-1-Fucp), 4.34 – 4.27 (m, 1H, H-6-Glup), 4.20 – 4.11 (m, 1H, H-6-Glup), 4.06 – 4.00 (m, 1H, H-3-Fucp), 3.99 – 3.92 (m, 1H, H-2-Fucp), 3.78 – 3.70 (m, 3H, H-5-Glup, H-5-Fucp, -CH2-CH-CH2-), 3.66 (dd, J = 8.8, 7.6 Hz, 1H, H-2-Glup), 3.01 – 2.70 (m, 2H), 2.78 – 2.46 (m, 4H), 2.12 (s, 3H, CH3-C=O), 1.76 – 1.70 (m, 9H), 1.70 – 1.55 (m, 3H), 1.46 – 1.22 (m, 12H), 1.12 (d, J = 6.4 Hz, 3H, H-6-Fucp), 0.99 – 0.84 (m, 12H), 0.80 (s, 9H), 0.20 (s, 3H, CH3-Si), 0.13 (s, 3H, CH3-Si), 0.12 (s, 3H, CH3-Si), 0.03 (s, 3H, CH3-Si). 13C NMR (100 MHz, CDCl3) δ 210.1, 172.1, 170.9, 167.0, 165.8, 146.3, 138.0, 134.1, 130.6, 128.9 (x2), 128.3 (x2), 128.2, 116.7, 100.1, 100.0, 75.0, 74.0, 73.8, 71.6, 70.1, 68.6, 41.7, 37.1, 33.8, 31.9, 28.8, 27.9, 27.4, 25.9 (x3), 25.8 (x3), 24.9, 24.7, 23.0, 22.7, 21.1, 18.1, 17.7, 16.6, 14.4, 14.1, 11.9, −3.5, −3.9, −4.3, −5.3.

Ipomoeassin F. 7,10,11

Method 1

To a solution of 31a (34 mg, 0.032 mmol) in THF (3 mL) and MeOH (1 mL) was added AcOH (367 µL, 6.42 mmol) and TBAF (1M solution in THF, 3.21 mL, 3.21 mmol) at 0 °C The reaction was allowed to warm to ambient temperature and stirred for 48 h. At this point, TLC (silica, 1:1 EtOAc–hexanes) showed the reaction was complete. The reaction mixture was diluted with Et2O (30 mL), washed with 1M HCl (15 mL), saturated aqueous NaHCO3 (15 mL), brine (15 mL). The aqueous layer was extracted with Et2O (30 mL). The combined organic layer was dried over Na2SO4 and concentrated under reduced pressure. The residue was purified by column chromatography (silica, EtOAc–hexanes, 1:2 → 1:1) gave Ipomoeassin F (23.3 mg, 88%) as a white film.

Method 2

To a solution of 31a (58 mg, 0.055 mmol) in THF (4 mL) was added TBAF (1M solution in THF, 0.27 mL, 0.27 mmol) at −10 °C. The reaction mixture was stirred at the same temperature for 4 h at which point TLC (silica, 1:1 EtOAc–hexanes) showed the reaction was complete. The reaction mixture was diluted with Et2O (40 mL), washed with 1M HCl (20 mL), saturated NaHCO3 (20 mL), and brine (10 mL). The aqueous layer was extracted with Et2O (40 mL). The combined organic layer was dried over Na2SO4 and concentrated under reduced pressure. The residue was purified by column chromatography (silica, EtOAc–hexanes, 1:2 → 1:1) gave compound Ipomoeassin F (37.3 mg, 82%) as a white foam. [α]D25 −62.4 (c 0.5 CHCl3). 1H NMR (400 MHz, CDCl3). 1H NMR (400 MHz, CDCl3) δ 7.64 (d, J = 16.0 Hz, 1H, Ph-CH=C-), 7.53 – 7.47 (m, 2H, 2 × ArH), 7.43 – 7.34 (m, 3H, 3 × ArH), 6.93 – 6.85 (m, 1H, Me-CH-C(Me)-C=O), 6.35 (d, J = 16.0 Hz, 1H, Ph-CH=CH-), 5.32 (t, J = 9.6 Hz, 1H, H-4-Glup), 5.18 – 5.10 (m, 2H, H-3-Glup, H-4-Fucp), 4.62 (d, J = 8.0 Hz, 1H, H-1-Glup), 4.58 (br, 1H, OH), 4.47 (dd, J = 12.4, 3.6 Hz, 1H, H-6-Glup), 4.41 (d, J = 7.6 Hz, 1H, H-1-Fucp), 4.15 (dd, J = 12.4, 2.4 Hz, 1H, H-6-Glup), 3.96 – 3.87 (m, 2H, OH, H-3-Fucp), 3.80 – 3.74 (m, 1H, H-5-Glup), 3.73 – 3.57 (m, 4H, H-2-Glup, H-2-Fucp, H-5-Fucp, -CH2-CH-CH2-), 2.85 – 2.38 (m, 6H), 2.18 (s, 3H, CH3-C=O), 1.80 – 1.72 (m, 6H, CH3-CH-C(CH3)-C=O), 1.71 – 1.61 (m, 2H), 1.58 – 1.46 (m, 4H), 1.41 – 1.21 (m, 12H), 1.20 (t, J = 6.4 Hz, 3H, H-6-Fucp), 0.90 (t, J = 6.8 Hz, 3H). 13C NMR (100 MHz, CDCl3) δ 210.0, 171.8, 171.7, 168.8, 165.4, 146.1, 139.8, 134.0, 130.6, 128.9 (x2), 128.3 (x2), 127.5, 116.7, 105.7, 100.2, 82.8, 79.7, 75.8, 73.9, 72.7, 72.6, 72.4, 68.8, 67.4, 61.8, 41.8, 37.6, 34.3, 33.1, 31.9, 29.1, 29.0, 28.3, 24.7, 24.5, 23.5, 22.6, 20.9, 16.3, 14.6, 14.1, 12.0. HRMS (FTMS) m/z calcd for C44H62NaO15 [M+Na]+ 853.3986, found: 853.3984. The 1H, 13C NMR data were in accordance with the literature.11 HPLC (96.7%; MeCN/H2O 1:9, 0–5 min; increase to 9:1 over 20 min, 5–25 min; 9:1, 25–35 min; finally return to 1:9 in a minute, 35–36 min; 1 mL/min, tR = 30.4 min).

11R-Epimer

11R-Epimer (12.0 mg, 77%, white foam) was prepared by treating 31b (20.0 mg, 0.019 mmol) with TBAF (1M solution in THF, 0.11 mL, 0.113 mmol) in THF (2 mL) under the same conditions as described for the synthesis of Ipomoeassin F (method 2). [α]D25 −17.0 (c 1.0 CHCl3). 1H NMR (400 MHz, CDCl3). 1H NMR (400 MHz, CDCl3) δ 7.68 (d, J = 16.0 Hz, 1H, Ph-CH=C-), 7.55 – 7.48 (m, 2H, 2 × ArH), 7.43 – 7.35 (m, 3H, 3 × ArH), 6.93 – 6.84 (m, 1H, Me-CH-C(Me)-C=O), 6.38 (d, J = 16.0 Hz, 1H, Ph-CH=CH-), 5.23 (t, J = 9.6 Hz, 1H, H-4-Glup), 5.20 – 5.16 (m, 2H, H-3-Glup, H-4-Fucp), 4.67 (d, J = 8.0 Hz, 1H, H-1-Glup), 4.22 (br, 1H, OH), 4.49 (dd, J = 12.4, 3.6 Hz, 1H, H-6-Glup), 4.46 (d, J = 7.6 Hz, 1H, H-1-Fucp), 4.16 (dd, J = 12.4, 2.4 Hz, 1H, H-6-Glup), 3.95 – 3.86 (m, 2H, OH, H-3-Fucp), 3.85 – 3.81 (m, 1H, H-5-Glup), 3.81 – 3.66 (m, 4H, H-2-Glup, H-2-Fucp, H-5-Fucp, -CH2-CH-CH2-), 3.00 – 2.91 (m, 1H), 2.75 – 2.42 (m, 5H) 2.20 (s, 3H, CH3-C=O), 1.80 – 1.75 (m, 6H, CH3-CH-C(CH3)-C=O), 1.75 – 1.70 (m, 2H), 1.70 – 1.52 (m, 4H), 1.51 – 1.20 (m, 12H), 1.19 (t, J = 6.4 Hz, 3H, H-6-Fucp), 0.88 (t, J = 6.8 Hz, 3H). 13C NMR (100 MHz, CDCl3) δ 209.4, 171.8, 171.5, 168.2, 165.6, 146.2, 139.1, 134.0, 130.7, 129.0 (x2), 128.3 (x2), 127.8, 116.7, 103.1, 98.0, 78.5, 77.5, 76.0, 74.6, 72.7, 72.2, 71.8, 69.2, 68.6, 62.5, 42.0, 37.4, 33.2, 32.6, 32.1, 29.7, 28.8, 28.1, 27.4, 24.7, 23.5, 23.1, 22.6, 21.0, 16.3, 14.5, 14.1, 12.0. IR (film): v = 3422, 2930, 2859, 1736, 1717, 1653, 1636, 1248, 1155, 1072. HRMS (ESI) m/z calcd for C44H62NaO15 [M+Na]+ 853.3986, found: 853.3986. HPLC (95.3%; MeCN/H2O 3:1; 1 mL/min, tR = 17.1 min).

Biology

MTT Cytotoxicity Assay

Ipomoeassin F and its analogs were tested for cytotoxicity by using the MTT assay. The compounds were dissolved in DMSO to make drug stocks. The stock solutions were diluted with a DMEM or RPMI medium (according to the cell type) to make fresh working solutions at varying concentrations right before each test. Experiments were done in triplicate. First, 100 µL of cell suspension at the density of 50,000 cells/mL was seeded in a 96-well plate (5,000 cells/well), which was incubated at 37 °C in 5% CO2 for 24 h. Subsequently, the cells were treated with a compound at various concentrations in the total volume of 200 µL/well for 72 h. After 72 h, the media were discarded and 200 µL of fresh medium containing 10% of MTT stock solution (5 mg/mL) was added to each well. The plate was then incubated at 37 °C in 5% CO2 for another 3 h. Next, 180 µL of the medium was discarded from each well. The formed formazan crystals were dissolved with 180 µL of DMSO. An absorbance of formazan was detected by a microplate reader (BioTek Synergy H1) at 570 nm with 650 nm as the reference wavelength. The percentage of viability compared to the negative control (DMSO-treated cells) was determined. The GraphPad Prism 6 software was used to make a plot of % viability versus sample concentration and to calculate the concentration at which a compound exhibited 50% cytotoxicity (IC50).

Cell Cycle

Cell cycle analysis was performed with flow cytometry. Briefly, ipomoeassin F in DMSO was added to the exponentially growing U937 cells (cultured in RPMI-1640 medium with 10% fetal bovine serum) at a final concentration of 90 nM. For control, the cells were treated with equivalent amount of DMSO. After 48 h of incubation of the cells with ipomoeassin F (or DMSO for control) at 37 °C in a CO2-incubator, the cells were harvested, washed twice with PBS, and fixed with 70% ice-cold ethanol at 4 °C overnight. The fixed cells were washed twice with PBS and incubated with 100 µg/ml of DNase-free RNase in PBS at 37 °C for 30 minutes. The cells were then stained with PI at a final concentration of 50 µg/mL, and the stained cells were kept at 4 °C before analysis. The fluorescence of the cells was measured with flow cytometry (Guava easyCyte HT system; EMD Millipore, Billerica, MA). Ten thousand events were recorded for each measurement. The cell cycle data were analyzed with software WinMDI (Version 2.8).

Cell Apoptosis Analysis

Cell apoptosis was analyzed by flow cytometry using annexin V-CF488A conjugate according to the procedures described by the manufacturer (Biotium, Hayward, CA). Briefly, U937 cells were treated with ipomoeassin F or DMSO as described for the cell cycle analysis. Forty eight hours after the treatment, the cells were harvested, washed twice with PBS, and resuspended in a binding buffer (10 mM Hepes, pH 7.4, 140 mM NaCl, and 2.5 mM CaCl2) at a concentration of 2 × 106 cells/mL. An aliquot of 100 µL of the resuspended cells was incubated with annexin V-CF488 conjugate at a final concentration of 0.25 µg/mL at room temperature for 15 minutes in the dark, followed by addition of 400 µL of the binding buffer to each sample. The cells were further stained with PI at a final concentration of 0.5 µg/mL and immediately analyzed by flow cytometry (Guava easyCyte HT system; EMD Millipore, Billerica, MA). The apoptosis data were analyzed with software GuavaSoft 2.6.