Abstract

The purpose of this study was to assess red beet as a natural colorant in emulsified pork sausage and to investigate the effect of red beet on quality characteristics of emulsified pork sausage during 20 d of cold storage. Red beet was prepared as a powder and a substitute with sodium nitrite at 0.5% and 1.0% levels in emulsified pork sausage. Red beet significantly increased the moisture content and pH (p<0.0001) and affected color traits. Lightness of emulsified pork sausage decreased by the addition of red beet powder (p<0.01), whereas lightness with red beet treatments slightly increased during 20 d of cold storage at 4℃ (p<0.05). Redness dramatically increased with red beet powder (p<0.0001). Color by sensory evaluation also showed a significant effect from red beet addition (p<0.05), whereas the other sensory properties such as flavor, tenderness, juiciness, and overall acceptability were not affected by the addition of red beet powder (p>0.05). Texture and 2-thiobabituric acid reactive substance were also not affected by red beet addition (p>0.05). Therefore, red beet could be a good natural colorant in emulsified pork sausage but it needs additional processing, such as betalain concentration and extraction as a juice, to be used as an antioxidant in meat products.

Keywords: red beet, emulsified sausage, sodium nitrite, natural colorant, quality characteristics

Introduction

Nitrite is a useful ingredient in meat product manufacturing. It inhibits the growth of microorganisms, such as Clostridium botulinum and Listeria monocytogenes, and contributes to the cured meat color and flavor (Honikel, 2004; Pegg and Shahidi, 2000; Sebranek and Bacus, 2007; Tompkin, 2005). However, there is a growing concern about the use of nitrite in meat products because of the formation of N-nitroso carcinogens from amines and amides (Archer, 1989; Cammack et al., 1999; Santamaria, 2006). Excessive intake of nitrate is associated with gastric cancer from the N-nitroso compound synthesis promoted by stomach acid (Forman and Shuker, 1997; Hsu et al., 2009).

Recent reports have suggested natural ingredients as a substitute for nitrite. For example, sea salt, raw sugar, vegetable juices and powders, flavorings, spices, and starter culture (Staphylococcus carnosus ssp. utilis) are the most common natural ingredients in processed meat (Herrador et al., 2005; Sebranek and Bacus, 2007). A reddish-pink color of cured meat products is expected by substituting fruits and vegetables for nitrite (Hsu et al., 2009; Sebranek and Bacus, 2007). Although fruits and vegetables are good sources of natural colorants, most have a disadvantage in the long-term stability of food color, including in cured meat (Herbach et al., 2006).

Red beet is regarded as a good source of antioxidants and natural colorants because of the phenolic compounds and betalains that are present in red beet (Mattila and Hellstrom, 2007; Ravichandran et al., 2012, 2013). Betalains are water-soluble nitrogen-containing pigments and consist of two subgroups, betacyanins and betaxanthins(Delgado-Vargas et al., 2000; Stintzing and Carle, 2004). Moreover, betalains are more stable to pH than anthocyanins, which are mostly used as natural pigments to give foods a red-purple color (Mazza and Miniati, 1993; Pazmiño- Durán et al., 2001; Roy et al., 2004). Most studies have focused on developing purification and extraction technology and on analyzing betalains and phenolic compounds in red beet. Only a few studies have examined the application of red beet to food processing (Lee and Jin, 2012; Martinez et al., 2006).

Therefore, the objective of this study was to assess red beet as a natural colorant in emulsified pork sausage and to investigate the effect of red beet on quality characteristics of emulsified pork sausage during 20 d of cold storage.

Materials and Methods

Preparation of red beet powder

Red beet (Beta vulgaris L. var. conditiva) roots were bought at a local market in Korea. The red beet roots were washed, peeled, and chopped into small pieces. Chopped red beet was subsequently placed into a freeze dryer (PVTFD50A, Ilsin Co., Korea) and dried at −20℃ and 1.0±0.3 mmHg vacuum pressure. After 48 h of freeze drying, the dried product was ground using a hammer mill (GM 100, Youngjin Co., Korea). The final moisture content of the red beet powder (RBP) was 3.5±0.5%.

Emulsified pork sausage processing

Pork meat and back fat were purchased from a local retailer. Subcutaneous and excessive connective tissues were removed from the pork meat and minced through a 3-mm plate twice. Six batches (10 kg) were prepared for each treatment; the basic recipe consisted of 66.5% meat, 15.2% back fat, and 16.4% ice water. Minced meat was ground for 1 min using a bowl cutter (Talsa K30, DSL Food Machinery Ltd., Spain). Salt (1.3%), polyphosphate (0.2%), and half of the ice were subsequently added and mixed for 2 min. Different concentrations of sodium nitrite (NaNO2) and RBP for each treatment (C0, no added; CN, 75 ppm NaNO2; RN1, 75 ppm NaNO2 + 0.5% RBP; RN2, 75 ppm NaNO2 + 1.0% RBP; RB1, 0.5% RBP; RB 2, 1.0% RBP) were then added. After 1 min, fat and spices were added and emulsified for 1 min and the remaining ice was added to the batter. The final emulsified batter was obtained by applying an additional 3 min of mixing under high speed (bowl speed: 24 rpm, knife shaft speed: 2840 rpm). The temperature of the batter was maintained below 11.5℃. The batter was then stuffed into 70-mm diameter fibrous casings (Nalo Top, Kalle GmbH, Germany) using a stuffer (IS-8, Sirman, Italy). The stuffed samples were cooked in a heating chamber (Thematec Food Industry Co., Korea) to an internal temperature of 75℃. The emulsified sausages were then cooled and stored at 4℃ for 20 d. The formulation for the emulsified pork sausages is presented in Table 1.

Table 1. Formulation of emulsified pork sausage.

| Ingredients (%) | Treatments |

|||||

|---|---|---|---|---|---|---|

| C0 | CN | RB1 | RB2 | RN1 | RN2 | |

| Meat | 66.5 | 66.5 | 66.5 | 66.5 | 66.5 | 66.5 |

| Fat | 15.2 | 15.2 | 15.2 | 15.2 | 15.2 | 15.2 |

| Water | 16.4 | 16.4 | 16.4 | 16.4 | 16.4 | 16.4 |

| Salt | 1.3 | 1.3 | 1.3 | 1.3 | 1.3 | 1.3 |

| Spices | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Polyphosphate | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Red beet powder | 0.0 | 0.0 | 0.5 | 1.0 | 0.5 | 1.0 |

| Sodium nitrite | 0.0 | 0.0075 | 0.0 | 0.0 | 0.0075 | 0.0075 |

| Total | 100 | 100.0075 | 100.5 | 101 | 100.5075 | 101.0075 |

Proximate composition and pH

Moisture content (%), crude protein (%), and crude ash (%) were determined using the AOAC method (2000). Crude fat (%) was analyzed using the method described in Folch et al. (1957). The pH of 3.0 g samples in suspended in 27 mL of deionized water was measured using a pH meter (MP230, Mettler Toledo, Switzerland).

Residual nitrite analysis

Residual nitrite analysis was performed using AOAC method no. 973.31 (AOAC, 2000). All residual nitrite was analyzed in triplicate.

Color measurements

The color of the sausage samples was measured using a Minolta Chromameter CR-300 (Minolta Co., Japan) that was standardized with a white plate (Y=93.5, X =0.3132, y=0.3198) and expressed as Commission Internationale de l’Eclairage (CIE) lightness (L*), redness (a*), and yellowness (b*).

Texture property analysis

Three cylindrical (1.0 cm diameter and 2.0 cm length) samples from each treatment were prepared for texture property analysis. An Instron Universal Testing Machine (Model 3343, Instron Corp., USA) was used and force versus time curves were obtained with 10 kg load cell applied at a crosshead speed of 200 mm/min. Hardness, cohesiveness, springiness and gumminess were calculated from the curves (Bourne, 1978).

2-Thiobabituric acid reactive substance (TBARS)

Five grams of sample was weighed into a 50 mL test tube and homogenized with 15 mL of deionized distilled water using homogenizer (T25, IKA Werke GmbH & Co., Germany) for 10 sec at 3,000 rpm. One milliliter of homogenate was transferred to a disposable test tube (3×100 mm), and butylated hydroxyanisole (50 μL, 10%) and thiobarbituric acid / tricholoroacetic acid (TBA/ TCA) (2 mL) were added. The mixture was vortexed and then incubated in a boiling water bath for 15 min to develop color. The sample was cooled in cold water for 10 min, vortexed again, and centrifuged for 15 min at 2,000 g. The absorbance of the resulting supernatant solution was determined at 531 nm against a blank containing 1 mL of distilled water and 2 mL of TBA/TCA solution. The amounts of TBARS were expressed as milligrams of malondialdehyde per kilogram of sample. To avoid interruption of RBP, the absorbance of RBP at 531 nm was checked and the linear standard curve was calculated. TBARS of sausage samples were calculated and their absorbance was determined at 531 nm along the RBP standard curve.

Sensory property analysis

Sensory property analysis was performed by ten panelists from Gyeongnam National University of Science and Technology, South Korea. The panelists were selected based on their frequency of consumption of pork sausage and experience in sensory property analysis of various meat products. The panelists evaluated each treatment in triplicate. Color, flavor, tenderness, juiciness and overall acceptability of emulsified pork sausage samples were evaluated using a nine-point scale in which a score of 1 was bad or slightly extreme and 9 was good or much extreme.

Statistical analysis

The effect of nitrite substitution with red beet in emulsified pork sausage was analyzed using the SAS program (SAS, 2002). Analysis of variance (ANOVA) and t-test were used to analyze the effect of red beet on the physicochemical properties of emulsified pork sausage. The two-way ANOVA was adopted to analyze the substitution effect of nitrite with red beet and the difference between storage days. The t-test analysis was adopted to analyze the effects of nitrite and red beet addition on the physicochemical properties of emulsified pork sausages. Duncan’s multiple range tests were used to determine the statistical significance among the means at the 95% significant level.

Results and Discussion

Proximate composition and pH

The results for the proximate composition of moisture, crude fat, crude ash, and crude protein are presented in Table 2. The interaction of nitrite and nitrite × red beet was not found to affect the proximate composition (p>0.05). However, there was a significant effect from red beet substitution for nitrite in moisture (p<0.0001), crude fat (p<0.0001), and crude ash (p<0.05). The moisture of emulsified pork sausage increased with the addition of RBP regardless of the added levels (0.5% vs. 1.0%). In contrast, crude fat of the control samples (C0 and CN) was lower than that of samples with red beet (RB1, RB2, RN1, and RN2). The crude ash results showed the same trend as that for moisture. Analysis by t-test showed a significant effect for the percentage of added red beet (p<0.01). Treatments with 1.0% red beet (RB2 and RN2) had a higher moisture content than those with 0.5% red beet (RB1 and RN1; p<0.01). Although only a small amount of RBP was added (0.5 or 1.0%), the dietary fiber of RBP is assumed to have resulted in the higher moisture content. The total dietary fiber of freeze-dried red beet is 17.2-21.8% (Zemzer et al., 2011), and its addition improves water retention in meat products (Grossi et al., 2012; Moller et al., 2011). Puolanne (1999) reported that the water-binding capacity affected the content of the ingredient and the interactions of the ingredient to each other, in particular, non-meat ingredients. Similar trends in the proximate composition were observed in reducedfat sausage supplemented with brown rice fiber (Choi et al., 2011); in dry fermented sausage supplemented with wheat, oat, and fruit fiber (García et al., 2002); and in emulsified sausage added with goldenrod leaf and stem powder (Choe et al., 2011). Therefore, red beet powder contributed the moisture and fat content by the emulsion stability.

Table 2. Proximate composition and pH of emulsified pork sausage substituted nitrite with red beet.

| Traits | Treatments1) | ANOVA2) | t-test3) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C0 | CN | RB1 | RB2 | RN1 | RN2 | N | RB | N×RB | N | RB | |

| Moisture (%) | 67.24 | 67.01 | 68.00 | 68.71 | 68.80 | 69.21 | ns4) | *** | ns | ns | ** |

| (0.07) | (0.13) | (0.04) | (0.08) | (0.04) | (0.04) | ||||||

| Crude fat (%) | 13.77 | 13.84 | 12.28 | 12.13 | 11.88 | 11.63 | ns | *** | ns | ns | ns |

| (0.54) | (0.51) | (0.11) | (0.43) | (0.25) | (0.62) | ||||||

| Crude ash (%) | 1.55 | 1.48 | 1.70 | 1.64 | 1.68 | 1.68 | ns | * | ns | ns | ns |

| (0.12) | (0.13) | (0.16) | (0.07) | (0.03) | (0.18) | ||||||

| Crude protein (%) | 17.45 | 17.26 | 17.58 | 17.51 | 17.45 | 17.13 | ns | ns | ns | ns | ns |

| (0.09) | (0.14) | (0.30) | (0.18) | (0.16) | (0.16) | ||||||

| PH | 6.03 | 6.06 | 6.21 | 6.30 | 6.23 | 6.22 | ns | *** | ns | ns | ** |

| (0.01) | (0.01) | (0.01) | (0.01) | (0.01) | (0.02) | ||||||

Data are means (SE).

1)Treatments: C0, no added; CN, 75 ppm NaNO2; RB1, 0.5% red beet; RB2, 1.0% red beet; RN1, 75 ppm NaNO2 + 0.5% red beet; RN2, 75 ppm NaNO2 + 1.0% red beet.

2)ANOVA, two-way ANOVA analysis among the treatments; N, nitrite; RB, red beet.

3)t-test: N, t-test analysis between nitrite treatments (RN1 and RN2) and the others (RB1 and RB2) except for control (C0 and CN); RB, ttest analysis between 0.5% red beet treatments (RB1 and RN2) and 1.0% red beet treatments (RB2 and RN2); ns, not significant.

4)ns, not significant; *p<0.05; **p<0.01; ***p<0.0001.

The pH range of emulsified pork sausage with red beet substituted for nitrite was 6.03-6.30, as presented in Table 2. Red beet significantly affected the pH of emulsified pork sausage (p<0.0001); all red beet treatments had higher pH values than controls (C0 and CN). The treatment groups with 1.0% red beet added (RB2 and RN2) showed a higher moisture content than treatment groups with 0.5% red beet (RB1 and RN1; p<0.05). It seems that the high pH (6.31±0.14) of red beet increased the pH of emulsified sausage and the reactions with meat proteins during processing. More specific studies are needed on the chemical reaction between betalains and meat components and on physical changes in meat product during processing.

Residual nitrite

The results of the residual nitrite analysis are presented in Table 3. Treatments with added red beet had higher residual nitrite values at 0 and 20 d of storage compared to C0 (p<0.0001). As expected, all nitrite-added treatments showed high values of residual nitrite, ranging from 13.35 to 18.93 ppm at 0 d of storage. Although these values decreased to 11.64-16.68 ppm, they remained higher than those of C0, RB1, and RB2. ANOVA results showed a combined effect of nitrite and red beet (p<0.0001), indicating that red beet contains nitrite. It is well-known that vegetables, including red beet, are good sources of natural flavorings, spices and other ingredients (Sebranek and Bacus, 2007). Further, beet as well as celery, carrot, and lettuce can be used as a source of nitrate because of their nitrate content (171 ppm, 2114 ppm, 2273 ppm and 3227 ppm for carrot, celery, beet and spinach juice, respectively) (Sebranek and Bacus, 2007). In this study, the addition of 0.5% and 1.0% red beet increased levels of residual nitrite in emulsified sausage. However, declining residual nitrite levels were observed in CN, RN1, and RN2, which are sodium nitrite-added treatments. The same declining residual nitrite, as presented by Sindelar et al. (2007), was observed in this study; however, red beet-added treatments (RB1 and RB2) did not show the same trend. In this case, the levels of nitrite may have been too low (4.91 ppm and 5.09 ppm for RB1 and RB2, respectively).

Table 3. Residual nitrite (ppm) of emulsified pork sausage substituted nitrite with red beet during cold storage at 4℃ for 20 d.

| Treatments1) | Storage time |

Storage effect | ||

|---|---|---|---|---|

| Day 0 | Day 20 | |||

| C0 | 4.31C (1.16) | 3.72C (0.63) | ns4) | |

| CN | 13.35B (0.62) | 11.64B (0.45) | ** | |

| RB1 | 4.91C (0.64) | 4.96C (0.20) | ns | |

| RB2 | 5.09C (0.72) | 4.44C (0.50) | ns | |

| RN1 | 18.26A (0.34) | 15.80A (0.13) | ** | |

| RN2 | 18.93A (0.27) | 16.68A (0.49) | ** | |

| ANOVA2) | N | *** | *** | ns |

| RB | *** | *** | ns | |

| N×RB | *** | *** | ns | |

| t-test3) | N | *** | *** | ns |

| RB | ns | ns | ns | |

A-CMeans with different superscript in the same column are significantly different in nitrite × red beet interaction (p<0.0001).

1)Treatments: C0, no added; CN, 75 ppm NaNO2; RB1, 0.5% red beet; RB2, 1.0% red beet; RN1, 75 ppm NaNO2 + 0.5% red beet; RN2, 75 ppm NaNO2 + 1.0% red beet.

2)ANOVA, two-way ANOVA analysis among the treatments; N, nitrite; RB, red beet.

3)t-test: N, t-test analysis between nitrite treatments (RN1 and RN2) and the others (RB1 and RB2) except for control (C0 and CN); RB, t-test analysis between 0.5% red beet treatments (RB1 and RN2) and 1.0% red beet treatments (RB2 and RN2); ns, not significant.

4)ns, not significant; **p<0.01; ***p<0.0001.

Instrumental color

Lightness (CIE L*), redness (CIE a*), and yellowness (CIE b*) were measured to investigate the effect of red beet on the color of emulsified sausage (Table 4). A clear effect on all color traits from the addition of red beet to emulsified sausage was observed during cold storage. Red beet decreased lightness (p<0.01) and increased redness and yellowness (p<0.05). Redness, in particular, dramatically increased with red beet regardless of whether sodium nitrate was added (p<0.0001). The redness value of C0 was 1.7-2.7; however, redness values of red beet added treatments were approximately 10 times higher (17.8-29.2). The amount of red beet addition also influenced lightness (p<0.01) and redness (p<0.01) but not yellowness (p>0.05). Lightness decreased with an increase in red beet addition, but higher redness was observed with 1.0% red beet addition (RB2 and RN2) compared to 0.5% (RB1 and RN1) during storage (p<0.01). Yellowness was not affected by the level of red beet added (p>0.05). Sodium nitrite increased redness (p<0.05) and decreased yellowness (p<0.05), but it did not influence lightness (p>0.05). Results of the t-test analysis of nitrite plus red beet addition indicated an effect only on redness throughout the storage period (p<0.05). Storage effects were found in all color measurements of all treatments except for lightness in the C0 and CN groups (p<0.05). Redness decreased but yellowness increased over storage time. Lightness values for red beet-added treatments increased slightly during storage (p<0.05); however C0 and CN did not show a storage effect on lightness (p>0.05).

Table 4. Instrumental color of emulsified pork sausage substituted nitrite with red beet during cold storage at 4℃ for 20 d.

| Storage time (d) | Treatments1) | ANOVA2) | t-test3) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C0 | CN | RB1 | RB2 | RN1 | RN2 | N | RB | N×RB | N | RB | |

| Lightness (CIE L*) | |||||||||||

| 0 | 79.9 | 79.2 | 63.7c | 57.4d | 64.6c | 58.0b | ns4) | *** | ns | ns | ** |

| (0.1) | (0.2) | (0.7) | (0.5) | (0.4) | (1.0) | ||||||

| 5 | 79.5 | 79.0 | 66.0ab | 59.6b | 65.8b | 59.3ab | ns | ** | ns | ns | *** |

| (0.8) | (0.1) | (0.4) | (0.1) | (0.9) | (1.6) | ||||||

| 10 | 80.1 | 78.7 | 66.1ab | 59.5b | 66.2b | 58.7b | ns | *** | ns | ns | *** |

| (0.3) | (0.3) | (0.1) | (0.4) | (0.3) | (0.3) | ||||||

| 15 | 80.1 | 79.0 | 65.3b | 58.8c | 65.9b | 60.7a | ns | *** | ns | ns | *** |

| (0.2) | (0.3) | (0.4) | (0.4) | (0.5) | (0.5) | ||||||

| 20 | 79.1 | 78.7 | 66.4a | 60.5a | 67.3a | 60.5a | ns | *** | ns | ns | ** |

| (1.1) | (0.7) | (0.4) | (0.4) | (0.6) | (0.2) | ||||||

| Storage effect | ns | ns | ** | *** | ** | * | |||||

| Redness (CIE a*) | |||||||||||

| 0 | 2.7a | 7.1c | 21.0a | 27.4a | 23.0a | 29.2a | * | *** | ns | ** | ** |

| (0.2) | (0.0) | (0.2) | (0.7) | (0.5) | (1.3) | ||||||

| 5 | 2.3b | 7.3b | 18.7b | 25.7bc | 22.1ab | 28.2abc | * | *** | ns | * | ** |

| (0.1) | (0.1) | (0.7) | (0.2) | (1.1) | (2.2) | ||||||

| 10 | 2.0bc | 6.9d | 18.4bc | 25.4bc | 21.4b | 28.7ab | * | *** | ns | *** | ** |

| (0.3) | (0.1) | (0.2) | (0.9) | (0.7) | (0.2) | ||||||

| 15 | 1.7a | 7.7a | 18.9b | 25.8c | 21.3b | 26.0a | * | *** | ns | ** | *** |

| (0.1) | (0.1) | (0.4) | (0.4) | (0.2) | (0.3) | ||||||

| 20 | 1.8cd | 7.3b | 17.8c | 24.5c | 19.4c | 26.6bc | * | *** | ns | *** | ** |

| (0.2) | (0.1) | (0.7) | (0.8) | (0.3) | (0.2) | ||||||

| Storage effect | ** | *** | *** | ** | ** | * | |||||

| Yellowness (CIE b*) | |||||||||||

| 0 | 10.4Ac | 8.2Bb | 9.2Bb | 10.4Ab | 9.0ABc | 10.3Ac | * | * | * | ns | ns |

| (0.1) | (0.0) | (0.4) | (0.6) | (0.7) | (1.5) | ||||||

| 5 | 10.6ABbc | 8.2Cb | 11.3Aa | 11.4Aab | 9.8Bbc | 11.3Abc | ** | ** | * | ns | ns |

| (0.2) | (0.1) | (0.5) | (0.2) | (0.9) | (0.8) | ||||||

| 10 | 10.8Bb | 8.7Ca | 11.3ABa | 11.7Aa | 10.6Bb | 10.8Bc | *** | *** | * | ns | ns |

| (0.3) | (0.2) | (0.4) | (0.4) | (0.3) | (0.1) | ||||||

| 15 | 11.3Ca | 8.1Eb | 11.5Ca | 11.8Ba | 10.4Db | 12.7Aa | ** | ** | ** | ns | ns |

| (0.0) | (0.1) | (0.1) | (0.3) | (0.3) | (0.2) | ||||||

| 20 | 11.1Ba | 8.2Cb | 12.4Aa | 11.9ABa | 12.0Aa | 12.3Aab | *** | *** | *** | ns | ns |

| (0.1) | (0.0) | (1.0) | (0.5) | (0.2) | (0.2) | ||||||

| Storage effect | ** | ** | ** | ** | ** | * | |||||

A-EMeans with different superscript in the same row are significantly different in nitrite × red beet interaction (p<0.05).

a-dMeans with different superscript in the same column are significantly different between storage time (p<0.05).

1)Treatments: C0, no added; CN, 75 ppm NaNO2; RB1, 0.5% red beet; RB2, 1.0% red beet; RN1, 75 ppm NaNO2 + 0.5% red beet; RN2, 75 ppm NaNO2 + 1.0% red beet.

2)ANOVA, two-way ANOVA analysis among the treatments; N, nitrite; RB, red beet.

3)t-test: N, t-test analysis between nitrite treatments (RN1 and RN2) and the others (RB1 and RB2) except for control (C0 and CN); RB, ttest analysis between 0.5% red beet treatments (RB1 and RN2) and 1.0% red beet treatments (RB2 and RN2); ns, not significant.

4)ns, not significant; *p<0.05; **p<0.01; ***p<0.0001.

These results indicate that red beet is very effective in increasing the redness of emulsified sausage because of the betalains contained in red beet (Mattila and Hellstrom, 2007; Mazza and Miniati, 1993; Ravichandran et al., 2012; Roy et al., 2004). Although redness decreased over storage time, this is probably caused by pigment degradation as noted by Fernandez-Gines et al. (2003). Jeong et al. (2010) also reported a decrease in redness of low-fat sausage, which added RB homogenate during storage, but the smoked low-fat sausage with 75 ppm sodium nitrite and 0.5% RB homogenate showed stable redness during storage. This report did not agree with the present study, because of the differences in RB type (powder vs. homogenate) and sausage type (emulsified sausage vs. smoked low-fat sausage). The addition of red beet decreases lightness and increases yellowness of emulsified pork sausage; thus, the added level of red beet needs to be adjusted to control desirable properties. It seems that the powder type of RB is better than the RB homogenates in adjusting the addition level of RB, because of the lower effect and higher moisture of RB.

Texture property

Hardness, cohesiveness, springiness, and gumminess were analyzed to investigate the effect of red beet addition on the texture of emulsified pork sausage. Results are shown in Table 5. There were no significant effects from the addition of red beet on the texture of emulsified pork sausage (p>0.05). Improved texture was expected because red beet addition affected moisture content, but no effect was observed for any texture property trait. This could be a positive factor in the quality of emulsified pork sausage from the point of view of substitutes. The effects of nitrite, storage, and interaction between red beet and nitrite were also not significant ((p>0.05). Jeong et al. (2010) also reported no effect of RB addition on textural properties in low-fat sausage. Nitrite addition at levels of 0-1,000 ppm was not found to affect the texture of canned chopped ham (Randall and Voisey, 1977), whereas Calvo et al. (2008) and Hayes et al. (2013) found effects of tomato peel and powder on the texture of meat products. In the present study, nitrite did not affect the texture of emulsified sausages, suggesting that 1.0% RBP could be added to emulsified pork sausage without property changes in texture.

Table 5. Texture property of emulsified pork sausage substituted nitrite with red beet during cold storage at 4℃ for 20 d.

| Storage time (d) | Treatments1) | ANOVA2) | t-test3) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C0 | CN | RB1 | RB2 | RN1 | RN2 | N | RB | N×RB | N | RB | |

| Hardness (N) | |||||||||||

| 0 | 29.40 | 30.38 | 31.36 | 33.32 | 31.36 | 32.34 | ns4) | ns | ns | ns | ns |

| (0.98) | (1.96) | (2.88) | (1.96) | (1.96) | (2.94) | ||||||

| 5 | 32.34 | 31.36 | 33.32 | 35.28 | 30.38 | 33.32 | ns | ns | ns | ns | ns |

| (3.92) | (1.96) | (2.90) | (2.94) | (2.94) | (1.96) | ||||||

| 10 | 34.30 | 31.36 | 31.36 | 29.40 | 33.32 | 34.30 | ns | ns | ns | ns | ns |

| (1.96) | (1.96) | (2.94) | (3.92) | (3.92) | (3.92) | ||||||

| 15 | 29.40 | 30.38 | 28.42 | 33.32 | 32.34 | 30.38 | ns | ns | ns | ns | ns |

| (1.96) | (1.96) | (0.98) | (2.94) | (2.90) | (0.98) | ||||||

| 20 | 30.38 | 30.38 | 28.42 | 28.42 | 33.32 | 29.40 | ns | ns | ns | ns | ns |

| (2.94) | (2.86) | (3.92) | (2.80) | (2.90) | (2.94) | ||||||

| Storage effect | ns | ns | ns | ns | ns | ns | |||||

| Cohesiveness | |||||||||||

| 0 | 0.58 | 0.60 | 0.56 | 0.59 | 0.60 | 0.53 | ns | ns | ns | ns | ns |

| (0.02) | (0.05) | (0.07) | (0.04) | (0.05) | (0.02) | ||||||

| 5 | 0.59 | 0.58 | 0.57 | 0.57 | 0.58 | 0.59 | ns | ns | ns | ns | ns |

| (0.01) | (0.02) | (0.02) | (0.02) | (0.02) | (0.02) | ||||||

| 10 | 0.55 | 0.57 | 0.59 | 0.55 | 0.55 | 0.54 | ns | ns | ns | ns | ns |

| (0.01) | (0.04) | (0.03) | (0.04) | (0.05) | (0.01) | ||||||

| 15 | 0.57 | 0.60 | 0.61 | 0.59 | 0.53 | 0.53 | ns | ns | ns | ns | ns |

| (0.01) | (0.04) | (0.05) | (0.03) | (0.01) | (0.07) | ||||||

| 20 | 0.57 | 0.60 | 0.56 | 0.56 | 0.56 | 0.54 | ns | ns | ns | ns | ns |

| (0.06) | (0.03) | (0.03) | (0.07) | (0.02) | (0.05) | ||||||

| Storage effect | ns | ns | ns | ns | ns | ns | |||||

| Springiness (mm) | |||||||||||

| 0 | 9.90 | 10.19 | 10.00 | 10.19 | 10.49 | 9.80 | ns | ns | ns | ns | ns |

| (0.10) | (0.49) | (0.20) | (0.20) | (0.59) | (0.10) | ||||||

| 5 | 10.39 | 10.09 | 10.29 | 10.09 | 10.09 | 10.09 | ns | ns | ns | ns | ns |

| (0.39) | (0.59) | (0.20) | (0.29) | (0.49) | (0.29) | ||||||

| 10 | 9.80 | 10.09 | 10.00 | 9.90 | 10.09 | 10.09 | ns | ns | ns | ns | ns |

| (0.00) | (0.20) | (0.29) | (0.10) | (0.39) | (0.39) | ||||||

| 15 | 10.00 | 10.00 | 10.39 | 10.00 | 9.80 | 10.19 | ns | ns | ns | ns | ns |

| (0.29) | (0.29) | (0.49) | (0.20) | (0.10) | (0.49) | ||||||

| 20 | 10.09 | 10.19 | 9.80 | 10.39 | 9.80 | 10.09 | ns | ns | ns | ns | ns |

| (0.49) | (0.78) | (0.00) | (0.39) | (0.00) | (0.49) | ||||||

| Storage effect | ns | ns | ns | ns | ns | ns | |||||

| Gumminess (N) | |||||||||||

| 0 | 10.01 | 10.02 | 10.00 | 10.01 | 10.03 | 10.00 | ns | ns | ns | ns | ns |

| (0.20) | (0.20) | (0.39) | (0.20) | (0.29) | (0.10) | ||||||

| 5 | 10.02 | 10.01 | 10.02 | 10.01 | 10.00 | 10.01 | ns | ns | ns | ns | ns |

| (0.10) | (0.10) | (0.10) | (0.29) | (0.10) | (0.20) | ||||||

| 10 | 10.01 | 10.02 | 10.01 | 10.00 | 10.01 | 10.01 | ns | ns | ns | ns | ns |

| (0.29) | (0.10) | (0.10) | (0.20) | (0.39) | (0.39) | ||||||

| 15 | 10.01 | 10.02 | 10.00 | 10.03 | 10.00 | 9.98 | ns | ns | ns | ns | ns |

| (0.20) | (0.10) | (0.49) | (0.20) | (0.20) | (0.10) | ||||||

| 20 | 10.02 | 10.00 | 10.01 | 10.01 | 10.01 | 9.99 | ns | ns | ns | ns | ns |

| (0.20) | (0.29) | (0.10) | (0.29) | (0.00) | (0.20) | ||||||

| Storage effect | ns | ns | ns | ns | ns | ns | |||||

Data are means (SE).

1)Treatments: C0, no added; CN, 75 ppm NaNO2; RB1, 0.5% red beet; RB2, 1.0% red beet; RN1, 75 ppm NaNO2 + 0.5% red beet; RN2, 75 ppm NaNO2 + 1.0% red beet.

2)ANOVA, two-way ANOVA analysis among the treatments; N, nitrite; RB, red beet.

3)t-test: N, t-test analysis between nitrite treatments (RN1 and RN2) and the others (RB1 and RB2) except for control (C0 and CN); RB, ttest analysis between 0.5% red beet treatments (RB1 and RN2) and 1.0% red beet treatments (RB2 and RN2); ns, not significant.

4)ns, not significant.

TBARS

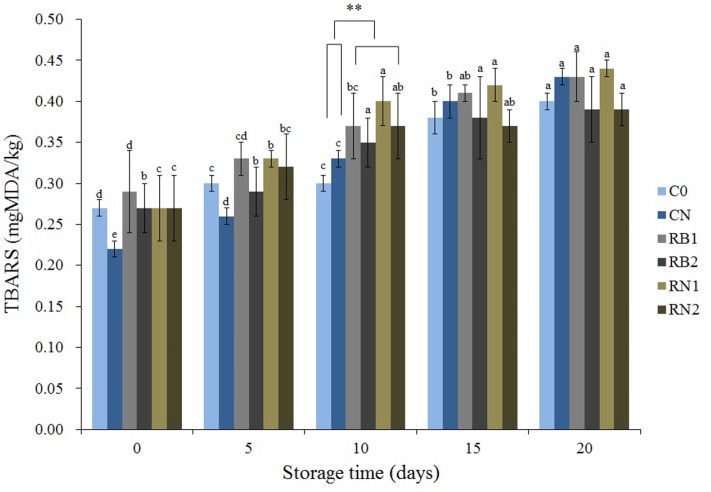

The results of TBARS are presented in Fig. 1. All treatments showed significant increases following increased storage time (p<0.05). An effect from red beet was not found among treatments during the storage period except for 10 d (p>0.05) when the addition of red beet increased TBARS values (p<0.01). This effect of red beet addition on TBARS of emulsified sausage was expected, since red beet contains betalains, which exhibit antioxidant and radical-scavenging activities (Escribano et al. 1998; Georgiev et al., 2010). Approximately 62.04-118.92 mg of betalains exist in 100 g of red beet (Stagnari et al., 2014). However, the addition of 0.5% and 1.0% of red beet would be too small to affect lipid oxidation of emulsified sausage.

Fig. 1. 2-thiobabituric acid reactive substance analysis of emulsified pork sausage substituted nitrite with red beet during cold storage at 4℃ for 20 d. Treatments: C0, no added; CN, 75 ppm NaNO2; RB1, 0.5% red beet; RB2, 1.0% red beet; RN1, 75 ppm NaNO2 + 0.5% red beet; RN2, 75 ppm NaNO2 + 1.0% red beet. a-eDifferent superscripts on the bar indicate significant differences among the storage time (p<0.05). **indicates significant effect of red beet among the treatments (p<0.01).

Sensory properties

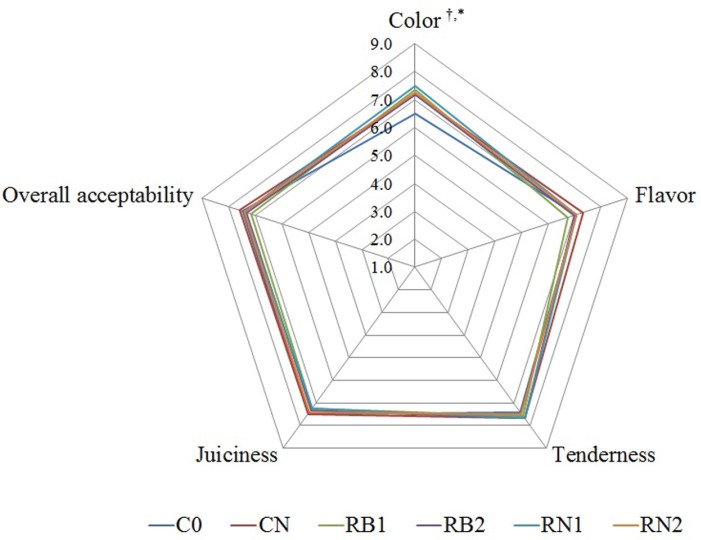

As shown in Fig. 2, color, flavor, tenderness, juiciness, and overall acceptability were selected for sensory property analysis. Color showed significant effects from red beet addition and nitrite in emulsified sausages (p<0.05), whereas no significance was found among the treatments for the other sensory traits (p>0.05). Color showed the same trend as instrumental color, which showed an effect from red beet addition. However, in the sensory property evaluation, panelists did not note an influence from the addition of red beet. Although C0 had the lowest color value among the treatments, there was no significant difference in overall acceptability from flavor, tenderness, or juiciness among the treatments (p>0.05).

Fig. 2. Sensory property analysis of emulsified pork sausage substituted nitrite with red beet. Treatments: C0, no added; CN, 75 ppm NaNO2; RB1, 0.5% red beet; RB2, 1.0% red beet; RN1, 75 ppm NaNO2 + 0.5% red beet; RN2, 75 ppm NaNO2 + 1.0% red beet. † and * indicate significant effects of nitrite and red beet among the treatments, respectively (p<0.05).

Conclusions

Red beet slightly increased the moisture content in emulsified pork sausage; however, texture and sensory properties, except for color, were not significantly affected by the addition of red beet. Color traits, including instrumental measurement and sensory property, were affected by red beet addition because red beet has both natural nitrite levels and pigments (betalains). Therefore, red beet could be a good natural colorant in emulsified pork sausage and other meat products. However, an antioxidant effect was not identified at added levels of 0.5% and 1.0%. If red beet is concentrated after betalain extraction or juice types, it could be an appropriate colorant as well as additive or water (ice) substitute in meat products.

Acknowledgments

This study was carried out with the support of “Cooperative Research Program for Agriculture Science & Technology Development (Project title: Development of Manuals for Manufacturing and Hygienic Management of Meat Products for the Revitalization of Meat and Meat Product Selling Business, Project No. PJ009848)”, Rural Development Administration, Republic of Korea.

References

- 1.AOAC. Official methods of analysis. (17th ed.) Association of Official Analytical Chemists; Gaithersburg, MD: (2000). [Google Scholar]

- 2.Archer M. C. Mechanisms of action of N-nitroso compounds. Cancer Surv. (1989);8:241–250. [PubMed] [Google Scholar]

- 3.Bourne M. C. Texture profile analysis. Food Technol. (1978);32:62–72. [Google Scholar]

- 4.Calvo M. M., Garcia M. L., Selgas M. D. Dry fermented sausages enriched with lycopene from tomato peel. Meat Sci. (2008);80:167–172. doi: 10.1016/j.meatsci.2007.11.016. [DOI] [PubMed] [Google Scholar]

- 5.Cammack R., Joannou C. L., Cui X. Y., Martinez C. T., Maraj S. R., Hughes M. N. Nitrite and nitrosyl compounds in food preservation. Acta Biochim. Biophys. Sin. (1999);1411:475–488. doi: 10.1016/S0005-2728(99)00033-X. [DOI] [PubMed] [Google Scholar]

- 6.Choe J.H., Kim H.Y., Han D. J., Kim Y. J., Park J. H., Ham Y.K., Kim C.J. Effect of goldenrod (solidago virgaurea) leaf and stem powder on physical and sensory characteristics of emulsion-type sausages. Korean J. Food Sci. Ani. Resour. (2011);31:668–675. doi: 10.5851/kosfa.2011.31.5.668. [DOI] [Google Scholar]

- 7.Choi Y. S., Kim H.W., Song D. H., Cho J. H., Park J. H., Kim M. Y., Lim C. S., Kim C. J. Quality characteristics and sensory properties of reduced-fat emulsion sausages with brown rice fiber. Korean J. Food Sci. Ani. Resour. (2011);31:521–529. doi: 10.5851/kosfa.2011.31.4.521. [DOI] [Google Scholar]

- 8.Delgado-Vargas F., Jiménez A. R., Paredes-López O. Natural pigments: Carotenoids, anthocyanins, and betalains - characteristics, biosynthesis, processing, and stability. Crit. Rev. Food Sci. Nutr. (2000);40:173–289. doi: 10.1080/10408690091189257. [DOI] [PubMed] [Google Scholar]

- 9.Escribano J., Pedreño M. A., García-Carmona F., Muñoz R. Characterization of the antiradical activity of betalains from Beta vulgaris L. roots. Phytochem. Anal. (1998);9:124–127. doi: 10.1002/(SICI)1099-1565(199805/06)9:3<124::AID-PCA401>3.0.CO;2-0. [DOI] [Google Scholar]

- 10.Fernandez-Gines J. M., Fernandez-Lopez J., Sayas-Barbera E., Sendra E., Perez-Alvarez J. A. Effect of storage conditions on quality characteristics of bologna sausages made with citrus fiber. J. Food Sci. (2003);68:710–715. doi: 10.1111/j.1365-2621.2003.tb05737.x. [DOI] [Google Scholar]

- 11.Folch J., Lees M., Sloane-Stanley G. H. A simple method for the isolation and purification of total lipids from animal tissues. J. Biol. Chem. (1957);226:497–509. [PubMed] [Google Scholar]

- 12.Forman D., Shuker D. Helicobacter pylori and gastric cancer - A case study in molecular epidemiology. Mutat. Res.-Fundam. Mol. Mech. Mutagen. (1997);379:S159. [Google Scholar]

- 13.García M. L., Dominguez R., Galvez M. D., Casas C., Selgas M. D. Utilization of cereal and fruit fibers in low fat dry fermented sausages. Meat Sci. (2002);60:227–236. doi: 10.1016/S0309-1740(01)00125-5. [DOI] [PubMed] [Google Scholar]

- 14.Georgiev V. G., Weber J., Kneschke E. M., Nedyalkov Denev P., Bley T., Pavlov A. I. Antioxidant activity and phenolic content of betalain extracts from intact plants and hairy root cultures of the red beetroot Beta vulgaris cv. detroit dark red. Plant Food Hum. Nutr. (2010);65:105–111. doi: 10.1007/s11130-010-0156-6. [DOI] [PubMed] [Google Scholar]

- 15.Grossi A., Søltoft-Jensen J., Christian Knudsen J., Christensen M., Orlien V. Reduction of salt in pork sausages by the addition of carrot fibre or potato starch and high pressure treatment. Meat Sci. (2012);92:481–489. doi: 10.1016/j.meatsci.2012.05.015. [DOI] [PubMed] [Google Scholar]

- 16.Hayes J. E., Canonico I., Allen P. Effects of organic tomato pulp powder and nitrite level on the physicochemical, textural and sensory properties of pork luncheon roll. Meat Sci. (2013);95:755–762. doi: 10.1016/j.meatsci.2013.04.049. [DOI] [PubMed] [Google Scholar]

- 17.Herbach K. M., Stintzing F. C., Carle R. Betalain stability and degradation-Structural and chromatic aspects. J. Food Sci. (2006);71:R41–R50. doi: 10.1111/j.1750-3841.2006.00022.x. [DOI] [Google Scholar]

- 18.Herrador M. A., Sayago A., Rosales D., Asuero A. G. Analysis of a sea salt from the Mediterranean Sea. Acta Aliment. (2005);360:85–90. [Google Scholar]

- 19.Honikel K. O. Minced meats. In: Devine C., Dikeman M., Jensen. W. K., editors. Encyclopedia of meat sciences. Elsevier; Oxford: (2004). pp. 854–856. [Google Scholar]

- 20.Hsu J., Arcot J., Lee N. A. Nitrate and nitrite quantification from cured meat and vegetables and their estimated dietary intake in Australians. Food Chem. (2009);115:334–339. doi: 10.1016/j.foodchem.2008.11.081. [DOI] [Google Scholar]

- 21.Jeong H. J., Lee H. C., Chin K. B. Effect of red beet on quality and color stability of low-fat sausages during refrigerated storage. Korean J. Food Sci. Anim. Resour. (2010);30:1014–1023. doi: 10.5851/kosfa.2010.30.6.1014. [DOI] [Google Scholar]

- 22.Lee J. H., Chin K. B. Evaluation of antioxidant activities of red beet extracts, and physicochemical and microbial changes of ground pork patties containing red beet extracts during refrigerated storage. Korean J. Food Sci. Anim. Resour. (2012);32:497–503. doi: 10.5851/kosfa.2012.32.4.497. [DOI] [Google Scholar]

- 23.Martinez L., Cilla I., Beltran J. A., Roncales P. Combined effect of modified atmosphere pachaging and addition of rosemary (Rosmarinus officinalis), ascorbic acid, red beet root (Beta vulgaris), and sodium lactate and their mixtures on the stability of fresh pork sausages. J. Agric. Food Chem. (2006);54:4674–4680. doi: 10.1021/jf060060+. [DOI] [PubMed] [Google Scholar]

- 24.Mattila P., Hellstrom J. Phenolic acids in potatoes, vegetables, and some of their products. J. Food Compos. Anal. (2007);20:152–160. doi: 10.1016/j.jfca.2006.05.007. [DOI] [Google Scholar]

- 25.Mazza G., Miniati E. Anthocyanins in fruits, vegetables and grains. CRC Press; Boca Raton, FL: (1993). pp. 1–87. [Google Scholar]

- 26.Moller S. M., Grossi A., Christensen M., Orlien V., Soltoft-Jensen J., Straadt I. K. Water properties and structure of pork sausages as affected by high-pressure processing and addition of carrot fibre. Meat Sci. (2011);87:387–393. doi: 10.1016/j.meatsci.2010.11.016. [DOI] [PubMed] [Google Scholar]

- 27.Pazmiño-Durán E. A., Giusti M. M., Wrolstad R. E., Glória M. B. A. Anthocyanins from banana bracts (Musa X paradisiacal) as potential food colorants. Food Chem. (2001);73:327–332. doi: 10.1016/S0308-8146(00)00305-8. [DOI] [Google Scholar]

- 28.Pegg R. B., Shahidi F. Nitrite curing of meat. The n-nitrosamine problem and nitrite alternatives. Food and Nutrition Press, Inc.; Trumbull, CT: (2000). [Google Scholar]

- 29.Puolanne E. Cooked meat products. Review; Proceedings 45th International Congress of Meat Science and Technology; Yokohama, Japan. (1999). pp. 116–120. [Google Scholar]

- 30.Randall C. J., Voisey P. W. method for measuring the texture of meat and the effect of nitrite and salt addition on the texture of cured meats. J. Texture Stud. (1977);8:49–60. doi: 10.1111/j.1745-4603.1977.tb01165.x. [DOI] [Google Scholar]

- 31.Ravichandran K., Ahmed A. R., Knorr D., Smetanska I. The effect of different processing methods on phenolic acid content and antioxidant activity of red beet. Food Res. Int. (2012);48:16–20. doi: 10.1016/j.foodres.2012.01.011. [DOI] [Google Scholar]

- 32.Ravichandran K., Saw N. M. M. T., Mohdaly A. A. A., Gabr A. M. M., Kastell A., Riedel H., Cai Z., Knorr D., Smetanska I. Impact of processing of red beet on betalain content and antioxidant activity. Food Res. Int. (2013);50:670–675. doi: 10.1016/j.foodres.2011.07.002. [DOI] [Google Scholar]

- 33.Roy K., Gullapalli S., Chaudhuri U. R., Chakraborthy R. The use of a natural colorant based on betalain in the manufacture of sweet products in India. Int. J. Food Sci. Technol. (2004);39:1087–1091. doi: 10.1111/j.1365-2621.2004.00879.x. [DOI] [Google Scholar]

- 34.Santamaria P. Nitrate in vegetables: Toxicity, content, intake and EC regulation (review) J. Sci. Food Agric. (2006);86:10–17. doi: 10.1002/jsfa.2351. [DOI] [Google Scholar]

- 35.SAS. SAS/STAT Software for PC. SAS Institute Inc.; Cary, NC: (2002). [Google Scholar]

- 36.Sebranek J., Bacus J. Natural and organic cured meat products: regulatory, manufacturing, marketing, quality and safety issues. American Meat Science Association White Paper Series. (2007);(1):115. [Google Scholar]

- 37.Sindelar J. J., Cordray J. C., Sebranek J. G., Love J. A., Ahn D. U. Effects of varying levels of vegetable juice powder and incubation time on color, residual nitrate and nitrite, pigment, pH, and trained sensory attributes of ready-to-eat uncured ham. J. Food Sci. (2007);72:S388–S395. doi: 10.1111/j.1750-3841.2007.00404.x. [DOI] [PubMed] [Google Scholar]

- 38.Stagnari F., Galieni A., Speca S., Pisante M. Water stress effects on growth, yield and quality traits of red beet. Sci. Hortic. (2014);165:13–22. doi: 10.1016/j.scienta.2013.10.026. [DOI] [Google Scholar]

- 39.Stintzing F. C., Carle R. Functional properties of anthocyanins and betalains in plants, food and in human nutrition. Trends Food Sci. Technol. (2004);15:19–38. doi: 10.1016/j.tifs.2003.07.004. [DOI] [Google Scholar]

- 40.Tompkin R. B. Nitrite. In: Davidson P. M., Sofos J. N., Branen A. L., editors. Antimicrobials in food. (3rd ed.) CRC Press, Taylor & Frances Group; Boca Raton, FL: (2005). [Google Scholar]

- 41.Zemzer B., Pietrzkowski Z., Spórna A., Stalica P., Thresher W., Michałowski T., Wybraniec S. Betalainic and nutritional profiles of pigment-enriched red beet root (Beta vulgaris L.) dried extracts. Food Chem. (2011);127:42–53. doi: 10.1016/j.foodchem.2010.12.081. [DOI] [Google Scholar]