Abstract

Background

The lactic acid bacterium Lactobacillus rhamnosus GG is the most studied probiotic bacterium with proven health benefits upon oral intake, including the alleviation of diarrhea. The mission of the Yoba for Life foundation is to provide impoverished communities in Africa increased access to Lactobacillus rhamnosus GG under the name Lactobacillus rhamnosus yoba 2012, world’s first generic probiotic strain. We have been able to overcome the strain’s limitations to grow in food matrices like milk, by formulating a dried starter consortium with Streptococcus thermophilus that enables the propagation of both strains in milk and other food matrices. The affordable seed culture is used by people in resource-poor communities.

Results

We used S. thermophilus C106 as an adjuvant culture for the propagation of L. rhamnosus yoba 2012 in a variety of fermented foods up to concentrations, because of its endogenous proteolytic activity, ability to degrade lactose and other synergistic effects. Subsequently, L. rhamnosus could reach final titers of 1E+09 CFU ml−1, which is sufficient to comply with the recommended daily dose for probiotics. The specific metabolic interactions between the two strains were derived from the full genome sequences of L. rhamnosus GG and S. thermophilus C106. The piliation of the L. rhamnosus yoba 2012, required for epithelial adhesion and inflammatory signaling in the human host, was stable during growth in milk for two rounds of fermentation. Sachets prepared with the two strains, yoba 2012 and C106, retained viability for at least 2 years.

Conclusions

A stable dried seed culture has been developed which facilitates local and low-cost production of a wide range of fermented foods that subsequently act as delivery vehicles for beneficial bacteria to communities in east Africa.

Electronic supplementary material

The online version of this article (doi:10.1186/s12934-015-0370-x) contains supplementary material, which is available to authorized users.

Keywords: Enrichment, Lactobacillus rhamnosus GG, Lactobacillus rhamnosus yoba 2012, Streptococcus thermophilus C106, Bacterial fermentation, Consortium, Yoghurt, Functional foods, Fermented foods

Background

Diarrheal diseases and associated malnutrition remain a leading cause of mortality and morbidity of children in low-income countries in sub-Saharan Africa [1]. Beneficial bacteria, such as Lactobacillus rhamnosus GG are known to contribute to the reduction of the overall incidence of symptomatic rotavirus associated diarrhea, as reported in a recent meta-analysis [2]. At present, such effective probiotics are not available in sub-Saharan Africa or not affordable to the poor. Other means of ingesting beneficial microbes include fermented foods, of which various forms have a long history in Africa and are broadly acknowledged to contribute to a healthy life style and gastrointestinal wellbeing [3, 4]. Unfortunately, traditional food processing is often hampered by spoilage; in Uganda alone, 27 % of the produced milk is lost due to spillage and spoilage at different stages of the chain [5]. An additional concern is the decline of the consumption of fermented food due to westernization of diets [6, 7].

We reason that access to probiotic cultures for fermentation can contribute to improving health and wealth of people in resource poor countries in multiple ways: (1) increase of shelf life and microbial food safety, (2) reduce spoilage by controlled fermentations, (3) increase the nutritional properties of the fermented foods by delivery of beneficial bacteria, bioactive compounds such as vitamins, and sequestering toxic components, (4) prevent and reduce episodes of diarrhea resulting from the intake of a probiotic strain, and (5) provide incomes for local producers who sell the foods.

The ability to propagate probiotics in fermented foods is limited due to legal and biological constraints. On one hand, ownership of intellectual property and a for-profit business model limits sales to premium products. On the other hand, probiotics originating from niches in the intestinal tract often lack the metabolic capabilities to propagate well in food matrices. In addition, the continuous propagation of intestinal isolates in a dairy environment may lead to the selection of mutants with genetic rearrangements, potentially coinciding with a reduction of their probiotic functionality [8]. Recently, we reported on the concept of “generic probiotics”, as a practical solution to create increased access to probiotics for people in resource poor countries [9]. Analogous to generic drugs, we reasoned that patent-expired probiotics are free to be used by other suppliers. We applied this concept of generic probiotics, and after isolating L. rhamnosus GG from a commercially available product [9] we renamed it L. rhamnosus yoba 2012.

The failure of the probiotic L. rhamnosus GG strain to grow in milk, results from its inability to degrade casein and lactose [10]. In order to enable propagation of the strain, food matrices should be enriched with either degradable sugars such as glucose, proteolytic enzymes, or partially hydrolyzed nitrogen sources such as yeast extract. All three solutions lead to higher cost and technical complexity. As an alternative low-cost solution we identified a proteolytic strain of S. thermophilus able to degrade casein and lactose that would allow L. rhamnosus yoba 2012 to propagate.

In the present work, we aimed at creating a novel bacterial consortium that can be easily distributed and used for local production of fermented foods with increased food safety and nutritional values, including a genetically stable probiotic strain. The newly formulated S. thermophilus C106 and L. rhamnosus yoba 2012 consortium was shown to be sufficiently stable. Under the applied conditions, the probiotic strain L. rhamnosus yoba 2012 appeared to retain its pili, which are important for adhesion to the intestinal epithelium and related health effects [11–13].

Results

Isolation, characterization and genome sequence of S. thermophilus C106

Streptococcus thermophilus C106 was isolated from an artisanal cheese produced in Ireland, and classified on the basis of its 16S rRNA sequence (data not shown). The draft genome sequence of S. thermophilus C106 has been deposited at GenBank, BioProject ID PRJNA288538. The full genome sequence with a GC content of 39.0 %, comprises 1.77 Mbp assembled into 87 contigs and a total number of 1416 functional proteins have been annotated. The predicted functions of the proteins in COG categories [14] showed a rather equal distribution into cellular processes and signalling (18 %), information storage and processing (25 %) and metabolism (37 %) functions. Approximately 20 % of the predicted proteins have not been assigned a specific function (Additional file 1: Figure S1).

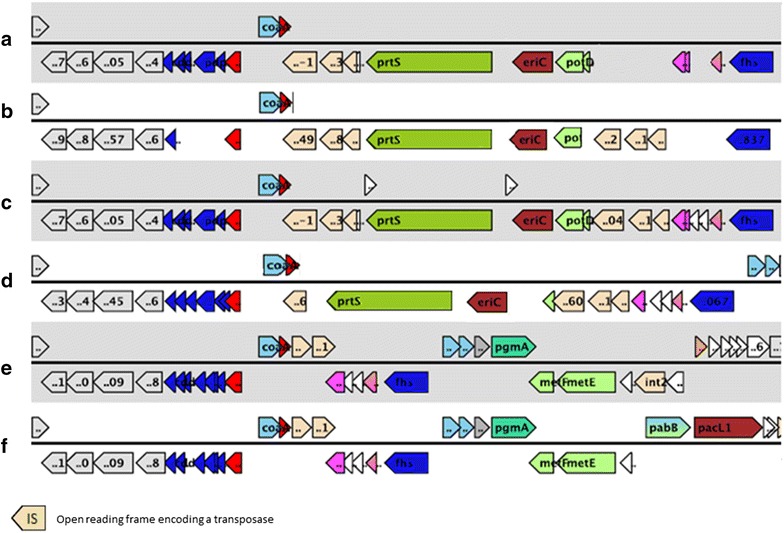

The annotated genome sequence confirms the ability of S. thermophilus C106 strain to grow in milk by its endogenous metabolic capacity. A functional annotation of the genome reveals the presence of genes required for lactose catabolism (lacAYZ) operon, casein degradation (prtS) and transporters for peptides and dipeptides (oppABCDF, dtpABCDF). The genomic organization of the cell wall proteinase encoding gene (prtS) in S. thermophilus C106 is comparable to the one reported by Delorme et al. for S. thermophilus LM9-D and JIM8232 [15]. In the latter strains the proteinase gene is located in a 15 kb intergenic genomic island, between the pseudo gene ciaH and the gene rpst, as indicated in Fig. 1. Different from the findings of Delorme et al. [15], we were not able to confirm the presence—in silico—of mobile elements on both flanking regions of the prtS gene in S. thermophilus C106, but only in the upstream region. This is likely because mobile elements are repetitive sequences easily missed during the assembly and annotation process.

Fig. 1.

Chromosomal regions of different streptococci genome sequences. a S. thermophilus C106; b S. thermophilus LMD-9; c S. thermophilus JIM8232; d S. thermophilus MN-ZLW-002; e S. thermophilus CNRZ1066 and f S. thermophilus LMG 1831 depicting the genomic island flanked by mobile elements of four open reading frames: potC (truncated), potD, eriC, prtS. Other genes in this figure are coaA (pantothenate kinase), ciaH (sensor protein), fhs (formate-tetrahydrofolate), pgmA (phosphoglucomutase), metF (methylenetetrahydrofolate reductase), metE (5-methyltetrahyropteroltriglutamate-homocysteine S-methyl transferase), pabB (para-amino benzoate synthase component I), pacL1 (Ca2+, Mn2+, P-ATPase)

In addition, the annotated genome sequence indicates that S. thermophilus C106 is able to synthesize all essential amino acids, including histidine, methionine and glutamate, which is considered to be an indispensable metabolic property for growth in milk, as glutamate and methionine are scarce in milk with concentrations of approximately 45 mg and <1 mg l−1 [16], which are below the minimally required levels of 200 and 60 mg l−1, respectively [17]. It should be noted that auxotrophy for histidine and methionine is common among streptococci, see e.g. S. thermophilus LMG18311 [18].

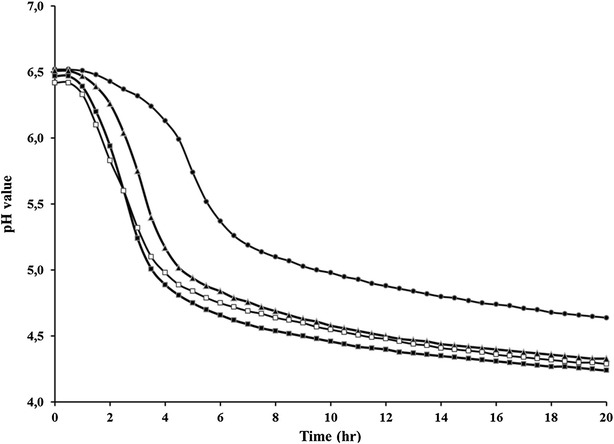

The growth of S. thermophilus C106 in milk as sole carbon and nitrogen source was measured at temperatures of 32, 37, 42 and 45 °C (Fig. 2). Above 32 °C the strain was able to produce enough lactate to acidify the milk from pH 6.2 until pH 4.2 within 24 h. The production of lactate (as expressed in the difference in pH as a function of time) by S. thermophilus C106 increased at higher temperatures, reinforcing the thermophilic character of S. thermophilus C106. The highest delta pH/time (0.80), and thus the optimal growth temperature was found at 42 °C. Cell count analysis at t = 0 h and t = 24 h, at the optimal temperature, indicated that the propagation in milk resulted in a 4 log CFU increase during this cultivation time.

Fig. 2.

Fermentation profile of S. thermophilus C106 in milk at different temperatures. (filled circle) 32 °C; (filled triangle) 37 °C; (filled square) 42 °C; (unfilled square) 45 °C

Metabolic interactions between S. thermophilus C106 and L. rhamnosus GG

A combined analysis of the genomes of S. thermophilus C106 and L. rhamnosus GG [12, 19], and its generic variant Lactobacillus rhamnosus yoba 2012 used for this study [8], revealed potential interactions between the Streptococcus and Lactobacillus strains during growth in milk (Table 1). The interactions were compared to those of the classical yoghurt consortium S. thermophilus and L. bulgaricus [20], and references therein. While L. bulgaricus is proteolytic, S. thermophilus is usually non-proteolytic and therefore growth of most S. thermophilus strains can be highly improved when co-cultured with L. bulgaricus, as they profit from released peptides and amino acids. L. bulgaricus lacks a pyruvate-formate lyase and might be supplied with formate by S. thermophilus as well as with folic acid, which is required for purine and amino acid biosynthesis. Furthermore, L. bulgaricus benefits from the carbon dioxide released by S. thermophilus, which is used for amino acid and nucleotide biosynthesis. Since L. bulgaricus misses parts of the biosynthetic pathway needed for the biosynthesis of long chain unsaturated fatty acids, which can promote growth, one can speculate that S. thermophilus also would also supply long chain unsaturated fatty acids to L. bulgaricus. It is further suggested that both organisms exchange ornithine and putrescine in order to increase their resistance to oxidative stress.

Table 1.

Potential interactions between S. thermophilus and Lactobacillus species

| Classical yoghurt consortium | Novel consortium | ||||

|---|---|---|---|---|---|

| Compound | S. thermophilus | L. bulgaricus | Compound | S. thermophilus C106 | L. rhamnosus yoba 2012 |

| Amino acids | Consumes | Provides | Folic acid | Provides | Consumes |

| Carbon dioxide | Provides | Consumes | Galactose | Provides | Consumes |

| Fatty acids | Provides | Consumes | Glycerol | Provides | Consumes |

| Folic acid | Provides | Consumes | Peptides | Provides | Consumes |

| Formic acid | Provides | Consumes | Succinate | Provides | Consumes |

| Ornithine | Provides | Consumes | Xanthine/Guanine | Provides | Consumes |

| Peptides | Consumes | Provides | |||

| Putrescine | Consumes | Provides | |||

| Pyruvatic acid | Provides | Consumes | |||

Metabolic interactions include those in the classical yoghurt consortium of L. bulgaricus and S. thermophilus and between S.thermophilus C106 and Lactobacillus rhamnosus yoba 2012

The potential interactions between S. thermophilus C106 and L. rhamnosus yoba 2012 were determined by using genome-scale models (see Methods for details). The models suggest that L. rhamnosus yoba 2012 is not capable of producing folic acid, which therefore needs to be provided by C106 (Table 1). Moreover, C106 needs to provide either xanthine or guanine to L. rhamnosus yoba 2012, both of which are involved in purine metabolism. We also observed an excretion of succinate and glycerol by C106, which can both be metabolized by L. rhamnosus yoba 2012. The L. rhamnosus strain cannot grow on lactose, however on galactose [21], which is released by C106, as concluded from HPLC analysis of milk fermented by the consortium (data not shown). While this interaction is revealed by our stoichiometric model, the uptake of galactose by L. rhamnosus yoba 2012 may not be essential for growth since in silico it could also utilize succinate or glycerol made by C106 as described above. In the experimental set-up, however, an accumulation of galactose in the media would be disadvantageous for C106 because of product inhibition. Hence, the removal of galactose by L. rhamnosus yoba 2012 might be beneficial for the C106 strain.

Preparation, fermenting capacity and technical properties of L. rhamnosus yoba 2012 and S. thermophilus C106 seed culture

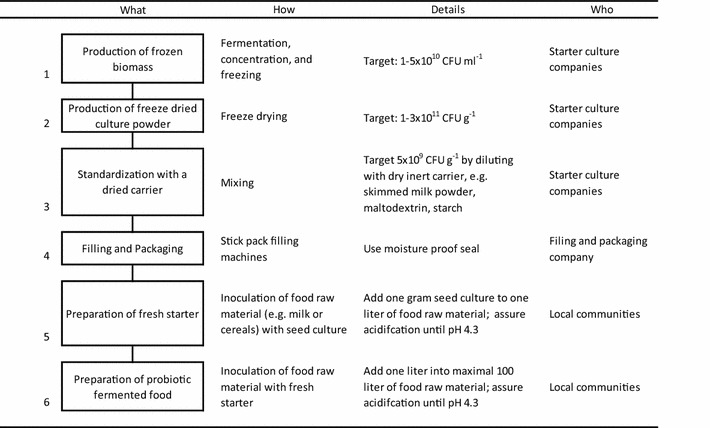

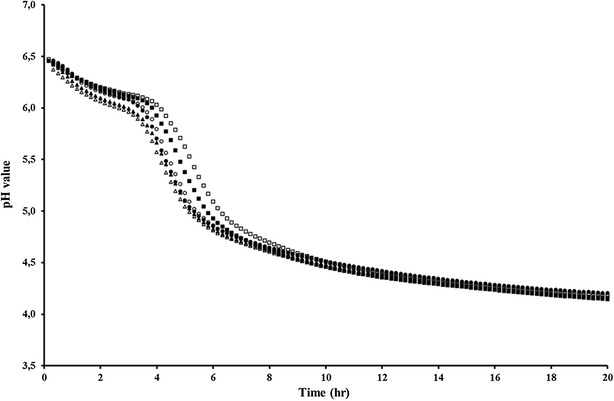

The production process for the dried seed cultures and its subsequent application for the preparation of fermented foods are depicted in Table 2 and Additional file 2: Figure S2. In a typical experiment, one gram of seed culture containing L. rhamnosus yoba 2012 and S. thermophilus C106 in concentrations of 5E+09 CFU g−1 each, was used as inoculum for one l of semi-skimmed milk. Growth temperature can vary between 37 and 45 °C. After a short lag phase, the milk acidified until pH 4.3, while both the L. rhamnosus and S. thermophilus strains propagated and reached titers of 7.8E+08 and 1E+09 CFU ml−1, respectively (Table 3, rows 3 and 4). The fermentation profile (pH decrease as a function of time) is depicted in Fig. 3. For the so-called main fermentation, 1 % (v/v) of fermented milk produced by the first round of fermentation was used as an inoculum. The final pH and cell titers were similar to those observed after the first fermentation (Table 3 rows 4 and 5). In addition to pH and CFU analyses, HPLC analyses indicated a consumption of lactose and production of galactose and lactic acid (data not shown).

Table 2.

Seed culture production and application protocol

In order to assure food safety of the produced steed cultures, the seed cultures were checked for absence of pathogen and spoilage organisms after step 4

Table 3.

Propagation of Lactobacillus rhamnosus yoba 2012 in a variety of fermented foods

| Product | Origin/site | Raw materials/Composition | After fermentation (CFU/ml) | |||||

|---|---|---|---|---|---|---|---|---|

| L. rhamnosus | S. thermophilus | S. th/L.rha | t (h) | T (°C) | pH | |||

| Yoba | Uganda | Semi-skimmed milka,d | 2.1E+07 | 7.8E+08 | 37 | 16 | 45 | 4.3 |

| Yoba | Uganda | Semi-skimmed milka,d | 1.8E+07 | 9.0E+08 | 50 | 16 | 45 | 4.3 |

| Yoba | Uganda | Semi-skimmed milkb,d | 1.3E+07 | 1.60E+09 | 123 | 16 | 45 | 4.3 |

| Yoba | Uganda | Semi-skimmed milkb,d | 9.5E+06 | 1.90E+09 | 200 | 16 | 45 | 4.3 |

| Yoba | Kenya | 1000 ml of milkc | 4.0E+07 | ND | – | 16 | 45 | ND |

| Yoba | Kenya | 1000 ml of milkc | 2.2E+07 | ND | – | 16 | 45 | ND |

| Yoba | Uganda | 1000 ml of milkc | 6.2E+07 | 1.6E+09 | 26 | 16 | 37 | 4.4 |

| Yoba | Uganda | 1000 ml of milkc | 7.9E+07 | 1.5E+09 | 19 | 16 | 37 | 4.4 |

| Yoba | Uganda | 1000 ml of milkb | 6.5E+07 | 2.4E+09 | 37 | 16 | 37 | 4.3 |

| Yoba | Uganda | 1000 ml of milkb | 5.6E+07 | 2.3E+09 | 41 | 16 | 37 | 4.3 |

| Yoba | Uganda | 1000 ml of milkc,d | 2.6E+07 | 5.1E+08 | 20 | 16 | 45 | 4.4 |

| Yoba | Uganda | 1000 ml of milkc,d | 3.5E+07 | 8.0E+08 | 23 | 16 | 45 | 4.4 |

| Yoba | Uganda | 1000 ml of milkb,d | 1.7E+07 | 1.7E+09 | 100 | 16 | 45 | 4.3 |

| Yoba | Uganda | 1000 ml of milkb,d | 1.6E+07 | 8.0E+08 | 50 | 16 | 45 | 4.3 |

| Zomkom | Burkina Faso | 100 g wheat, 1000 ml waterb | 3.4E+08 | 3.3E+06 | 0.01 | 15 | 37 | <4.3 |

| Zomkom | Burkina Faso | 75 g wheat, 250 ml milk, 750 ml waterb | 2.5E+08 | 5.7E+08 | 2 | 15 | 37 | <4.3 |

| Zomkom | Burkina Faso | 50 g wheat, 500 ml milk, 500 ml waterb | 6.6E+08 | 2.7E+09 | 4 | 15 | 37 | <4.3 |

| Zomkom | Burkina Faso | 25 g wheat, 750 ml milk, 250 ml waterb | 2.6E+08 | 2.8E+09 | 11 | 15 | 37 | <4.3 |

| Zomkom | Burkina Faso | 0 g wheat, 1000 ml milk, 0 ml waterb | 3.8E+07 | 2.4E+09 | 63 | 15 | 37 | <4.3 |

| Obushera | Uganda | 50 g sorghum in 400 ml waterc | 2.8E+08 | ND | – | 24 | 25 | 4.0 |

| Obushera | Uganda | 50 g sorghum in 400 ml waterc | 1.3E+08 | ND | – | 24 | 25 | 4.1 |

| Uji | Kenya | Maizeb,e | 8.9E+09 | ND | – | 16 | 45 | ND |

| Uji | Kenya | Sorghumb,e | 7.5E+09 | ND | – | 16 | 45 | ND |

| Uji | Kenya | Sorghum and maize (1:1)b,e | 3.7E+09 | ND | – | 16 | 45 | ND |

| Mutandabota | Zimbabwe | Pulp of the baobab fruit and milkf | 6.3E+08 | 0 | – | 24 | 30 | 3.5 |

Fermentations were carried out at 37 °C unless stated otherwise. The cell count of L. rhmanosus GG and S. thermophilus C106 after inoculation varied between 1E+06 and 1E+07 CFU ml−1

ND not determined

aFirst passage, one gram seed culture used as inoculum

bSecond passage, freshly prepared liquid starter used as inoculum

cTwo year old seed culture

dIncubation at 45 °C

eAverage of three independent CFU counts per product over a period of 2 weeks

fStarter with exclusively L. rhamnosus yoba 2012 as reported by Mpofu et al. [40]

Fig. 3.

Fermentation capacity of seed cultures in pasteurized semi-skimmed milk inoculated after different storage time and at different growth temperatures. 45 °C, 2 years old (filled circle, unfilled circle); 45 °C fresh (filled triangle, unfilled triangle); 37 °C 2 years old (filled square, unfilled square)

In order to test the stability and fermentation activity of the seed cultures over time, the growth experiments were repeated 2 years later using seed cultures from the same production batch stored at −20 °C. Table 4 shows the cell concentration of the two strains determined in 8 different seed cultures, and indicates a non-significant loss of viability for S. thermophilus (from 2.5 to 2.3E+09 CFU g−1) and a minor decrease in the average cell count of L. rhamnosus yoba 2012 (from 4.9 to 1.5E+09 CFU g−1). The latter decrease is acceptable as it does not significantly affect the fermentation profiles and final CFU’s of L. rhamnosus strain in fermented food products. Accordingly, the fermentation profile shown in Fig. 3 and the measured pH and cell count in Table 3 (rows 13–16) confirmed that the cultures had kept their fermentation capacity at 37 and 45 °C.

Table 4.

Stability and bacterial content variability of dried seed cultures

| Sachet # | 2013 | 2015 | ||

|---|---|---|---|---|

| L. rha (CFU g−1) | S. the (CFU g−1) | L. rha (CFU g−1) | S. the (CFU g−1) | |

| 1 | 4.0E+09 | 2.7E+09 | 1.4E+09 | 2.0E+09 |

| 2 | 3.1E+09 | 1.4E+09 | 1.5E+09 | 2.7E+09 |

| 3 | 6.3E+09 | 3.0E+09 | 1.4E+09 | 2.2E+09 |

| 4 | 3.9E+09 | 2.0E+09 | 1.4E+09 | 2.2E+09 |

| 5 | 3.9E+09 | 2.2E+09 | 1.2E+09 | 1.8E+09 |

| 6 | 7.7E+09 | 2.9E+09 | 1.5E+09 | 2.5E+09 |

| 7 | 5.5E+09 | 2.9E+09 | 1.1E+09 | 2.1E+09 |

| 8 | 5.1E+09 | 2.7E+09 | 2.2E+09 | 3.0E+09 |

| Average | 4.9 ± 1.5E+09 | 2.5 ± 0.6E+09 | 1.5 ± 0.3E+09 | 2.3 ± 0.4E+09 |

The values indicate the CFU ml−1 of Lactobacillus rhamnosus yoba 2012 (L. rha) and Streptoccoccus thermophilus C106 (S. the) produced on 18/01/2013 and tested on 12/07/2013 and 13/02/2015

Robustness of piliation of L. rhamnosus yoba 2012 during milk fermentation

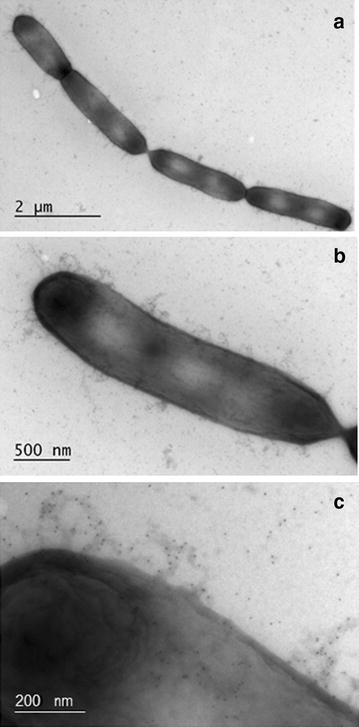

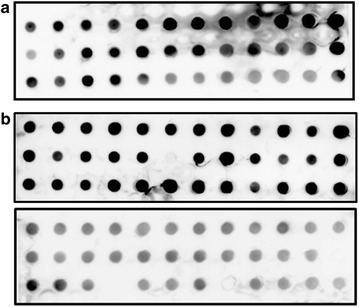

Previously, we reported that the genome of L. rhamnosus GG is prone to genetic rearrangements, especially around the insertion sequence flanked genomic islands containing the spaCBA-srtC1 pili encoding genes [8]. Therefore, we checked for the presence of pili after the first and second fermentation of the milk. The generic variant of L. rhamnosus GG used in this study, L. rhamnosus yoba 2012, harbored pilus structures, as observed by immunogold-staining TEM (Fig. 4). Immunoblotting with anti-spaA antiserum on 36 L. rhamnosus colonies isolated from the first passage were all piliated, whereas immunoblotting on 72 L. rhamnosus colonies isolated after the second passage indicated that 4 colonies were pilus negative (Fig. 5). The observed pilus phenotypes were confirmed by LGG-specific and pilus-specific (the srtC1 gene) PCRs for a selected number of colonies. Quantitative PCRs performed on fermented milk samples after the first and the second passage did not show a detectable loss of pilus-specific genes (data not shown), confirming that the loss of these genes was a marginal in terms of its impact on probiotic functionality.

Fig. 4.

Transmission electron microscopy observations of piliated Lactobacillus rhamnosus strain yoba 2012. Cells were isolated from fermented milk and immuno-gold labeled with anti-SpaA antibodies and gold particule-conjugated protein A. Gold particules (5 nm) co-localize with pilus structures (black dots on pictures)

Fig. 5.

Immunoblotting analysis of fermented milk after first (a) and second passage (b) using anti-SpaA serum. Single L. rhamnosus colonies were randomly picked from 2-day old MRS agar plates and analyzed by immunoblotting using anti-SpaA polyclonal antibodies. In a 70 out of 72 colonies tested were pilus positive (97.2 %). In b 101 out of 108 colonies tested were pilus positive (93.5 %). Note: a third immunoblotting (not shown in Fig. 5) was performed for sample 2b and included in the piliation percentage calculation above. Piliation phenotype of some colonies tested was further confirmed by PCR analysis as described in the “Methods”

Application of L. rhamnosus yoba 2012 and S. thermophilus C106 seed culture on other food raw materials

In order to further investigate the potential of using L. rhamnosus yoba 2012 and S. thermophilus C106 seed cultures for preparation other traditionally fermented foods, we tested production of zomkom (Burkina Faso, wheat and milk), obushera (Uganda, sorghum), uji (Kenya, maize or sorghum) and mutandabota (Zimbabwe, fruits of the baobab tree and milk). Table 3 shows that all ingredients were well-fermented down to a pH of approximately 4.3. Depending on the specific food matrix, the titer of L. rhamnosus yoba 2012 and S. thermophilus C106 increased up to a factor of 1000 resulting in a final titer of >1E109 CFU ml−1. Furthermore, L. rhamnosus propagated well in wheat, sorghum and maize. In contrast, S. thermophilus did not multiply without the presence of milk in wheat, despite the growth of L. rhamnosus in this food matrix.

Food safety and sensory evaluation

In addition to the technical evaluation, the fermented products were subjected to food safety tests, as required for human consumption, prior to sensory evaluation by local Ugandan panel members. In a total of 10 sachets each containing 1 g of seed culture, the following results were obtained: no detectable levels of Enterobacteriaceae, less than 100 CFU g−1 of non-lactic acid bacteria, less than 10 CFU g−1 of yeasts and moulds, no detectable levels of Listeria monocytogenes and no detectable levels of Salmonella.

Typical sensory aspects such as texture, viscosity, creaminess, taste, sourness, sweetness and mouthfeel were evaluated. Whitening ability and whey separation were also evaluated for the fermented milk products. Despite the large variation of the scores, likely as a results of different raw materials and not always perfectly controlled processing conditions in the African setting, the overall liking and general acceptability of all fermented products were positive (data not shown).

Discussion

Africa has an extensive history of production and a rich variety of traditionally fermented foods. These type of foods have a large impact on the nutrition, health and socio-economy of the people of a continent that is often challenged by war, drought, famine and disease. So far the use of indigenous foods as potential vehicles for delivering beneficial bacteria received little attention, notwithstanding their great potential for prophylactic and therapeutic use in resource poor countries [4].

Here we describe the development and the characterization of a stable dried seed culture that induces the propagation of probiotic L. rhamnosus yoba 2012 in milk, fruit and cereal-based food matrices. Through the addition of S. thermophilus C106 to the seed culture, we were able to overcome the metabolic limitations of L. rhamnosus to grow in milk, a widely-available raw material in rural regions of sub-saharan Africa: Degradation of casein and lactose was carried out by S. thermophilus, which provided peptides and monosaccharides, including galactose, that could be subsequently be used by the L. rhamnosus strain.

In traditional yoghurt fermentations, S. thermophilus stimulates L. bulgaricus via lipolysis and by supplying formic acid, folic acid and CO2, which are all involved in purine metabolism. In turn, L. bulgaricus provides S. thermophilus with peptides and amino acids released from milk casein by its exoprotease PrtB. Exopolysaccharides are reported to potentially facilitate these nutritional exchanges [22]. Contrary to the proto-cooperation of the usual yoghurt strains, the S. thermophilus C106 is able to grow in milk without the metabolic activity of a Lactobacillus strain. Although the removal of galactose by L. rhamnosus yoba 2012 might increase the final titres of S. thermophilus C106, detailed evidence for mutual metabolic dependencies and benefits for both the S. thermophilus C106 and L. rhamnosus yoba 2012 consortium should be gained from longitudinal transcriptome analysis during fermentation [22].

The use of two strains provides an affordable way of delivering dried seed cultures at an affordable price for people living in resource poor settings. To reach 100 l production, the strains are first grown in 1 l followed by passage to the larger milk volume (Table 3; Fig. 3). Multiple analyses of the final titre of L. rhamnosus yoba 2012 in the fermented milk indicated a concentration of approximately 8E+07 CFU ml−1, which would result in a daily dose of at least 1E+10 CFU upon consumption of 200–250 ml of the fermented drink.

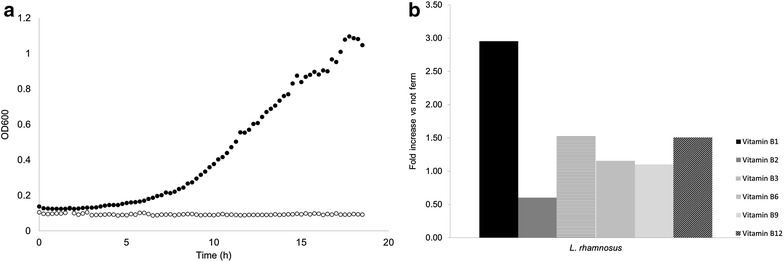

A well-accepted aspect of fermented food is its food preservation capacity and increased nutritional value compared to the non-fermented raw material. The use of the present combination of lactic acid bacteria will help to avoid spoilage, enhance food safety and increase the nutritional value by delivery of vitamins [23]. Examples of such characteristics are shown by the prevention of outgrowth of the food pathogen Cronobacter sakazakii in a sorghum matrix as a result of the acidification by lactic acid produced by L. rhamnosus GG and potentially other antagonistic effects induced by specific antimicrobial peptides (Fig. 6a). This finding of enhanced microbial food safety is further supported in a recent study indicating the efficient suppression of five food pathogens in an African dairy product fermented with Lactobacillus rhamnosus yoba 2012 [24]. In addition, we evaluated the change in concentration of B vitamins as a result of the fermentation process. We observed a 3-fold increase of vitamin B1 or thiamine, while the other B vitamins remained at similar concentrations to those found prior to fermentation (Fig. 6b).

Fig. 6.

Additional benefits of foods fermented with Lactobacillus rhamnosus. a Growth of the pathogen Cronobacter sakazakii in sorghum in presence (unfilled circle) and absence (filled circle) of fermenting Lactobacillus rhamnosus. b Change in vitamin B content of soy after and before fermentation

In addition, detoxification is a well-accepted benefit of some food fermentations [25]. Although not tested here, L. rhamnosus GG has been shown to bind and neutralize toxins known to contaminate foods, leading to a reduction of their uptake in the gastro-intestinal tract as they are secreted with L rhamnosus GG during defecation. [26, 27]. In addition, probiotic L. rhamnosus GR-1 supplemented yogurt has been shown to lower mercury and arsenic uptake in children and pregnant women [28].

Another probiotic functionality of L. rhamnosus GG relates to adhesion. Recent studies indicated that the pilus encoding spaCBA-srtC1 genes are responsible for epithelial adhesion and subsequent induction of cellular responses [11, 13]. In the present consortium and its subsequent use for yoghurt production, we could show that only minor depiliation was observed with the L. rhamnosus strain. On this basis, we conclude that the new fermented milk product described here did not significantly lose probiotic activity related to adherence capacity during two passages in the yoghurt production process.

In a more clinical context, a number of studies have shown that oral administration of L. rhamnosus GG bacteria results in in a reduction of the duration of diarrhoea [29]. Meta-analyses of clinical studies led to scientific consensus for Lactobacillus rhamnosus GG as a probiotic that upon oral intake is able to consistently shorten the diarrheal phase of rotavirus infection by one day with no reported adverse events, see e.g. [30, 31]. Notably, this diarrheal disease is a major concern among children in sub-Saharan Africa, including Uganda [32]. We plan to further substantiate the health benefits of affordable generic probiotics by intervention studies among local communities in Uganda. The outcome of these studies could provide more insights in specific health benefits brought by fermented foods produced by controlled fermentation, including so-called locally sourced probiotics [33], in addition to the generic use of a globally sourced probiotics as described here.

It should be noted that the current practices of traditional fermentation are mostly restricted to the house-hold level and are not suitable for commercialization as a result of poor and inconsistent quality of final products. The distribution of the Yoba seed cultures allows small entrepreneurs and cooperatives to produce fermented food in a controlled manner, which renders these products suitable for consumer acceptance and local commercialisation. Apart from the improved quality, the use of seed cultures for controlled fermentation prevents spoilage and results in reduced food losses. According to our observations, the introduction of the seed cultures in rural Uganda does not affect traditional fermented food practices at the house-hold level. People who rely on rural homesteads for their meals including traditional fermented foods will continue to do so, since this often concerns own farm produce whereby no costs are involved. However, people who have budget to take food in villages and trading centres tend to switch to yoghurt instead of other, often unhealthy and less nutritious types of food and soft drinks. To date, seed cultures containing the two strains described in this paper have been implemented by 46 dairy cooperatives and local producers in Uganda, resulting in sales of over 8000 l of probiotic fermented milk per week in mostly rural areas. This has benefitted over 25,000 people, including producers and consumers (Additional file 3: Figure S3) with the potential to reach hundreds of thousands in the near future.

Conclusions

We have described the creation of a novel probiotic formulation of two lactic acid bacteria that is affordable and practical for use in resource-challenged communities in Africa. An essential feature of the formulation is strain S. thermophilus C106 which complements the disability of L. rhamnosus yoba 2012 to grow in milk by degrading casein and lactose. The entire production process has been validated and is carried out in rural areas and only requires the sachet, milk, a sauce pan and a source of heat. The freeze-dried strains stored in moisture-proof sachets remain active over a period of at least 2 years. This initiative provides a means to bring highly nutritious, health-promoting food to people around the world who currently have no access to probiotic benefits.

Methods

Genome-scale metabolic model of L. rhamnosus yoba 2012 and S. thermophilus C106

Genome scale models for S. thermophilus C106 and L. rhamnosus yoba 2012 have been created based on the NCBI reference sequences NC_013198.1 and NC_006448.1, respectively, using FiJo: in-house developed software based on the Autograph method [34] using L. plantarum WCFS1 and S. thermophilus LMG18311 as reference models. Non-gene associated reactions from L. plantarum and S. thermophilus were added to the models of L. rhamnosus yoba 2012 and S. thermophilus C106, respectively. Details in cell wall components and fatty acid biosynthesis were copied from the reference models as they were not considered to affect the metabolic interactions and would require more detailed scrutiny outside of the scope of this paper. Potential interactions have been revealed by forcing equal growth rate to both organisms which would be required for balanced growth of the consortium [35] and subsequently disabling transport reactions for shared metabolites. Through flux balance analysis (FBA) with growth rate as objective function, we scored which reactions abolished growth. The media consists of biotine, lactose, milk peptides, nicotinate, pantothenate, phosphate, pyridoxamine, riboflavin, thiamin and water. All simulations have been performed using CBMPy associated to PySCeS [36].

Preparation of the dried seed culture

The strain Lactobacillus rhamnosus yoba 2012 [9]; strain LMG 27229 was isolated from a powder dairy formula by Sybesma et al. [8]. The Streptococcus thermophilus C106 strain (CSK Food Enrichment culture collection, Ede, The Netherlands) was isolated from an artisanal cheese in Ireland. LMG 27229 and S. thermophilus C106 were cultivated in 100 and 12,000 l batch fermentations, respectively, harvested by centrifugation, supplemented with lactose as a cryoprotectant, frozen in pellets using liquid nitrogen and stored at −55 °C, following CSK food enrichment fermentation recipes.

The cell concentration of L. rhamnosus yoba 2012 and S. thermophilus C106 in the frozen pellets was determined by using plate assays of MRS (Biotrading, article K511F200GV) or M17 (Biotrading, K464F200GV) supplemented with 0.5 % lactose, respectively. The frozen pellets were also checked for the presence of Enterobacteriaceae (absent in 10 ml), non-lactic acid bacteria (<100 CFU ml−1), yeasts and moulds (<10 CFU ml−1), Listeria monocytogenes (absent in 1 ml) and Salmonella (absent in 1 ml). Two kg of liquid frozen pellets were freeze dried (GR Instruments; Wijk bij Duurstede, Netherlands) for 48 h at −40 °C. Next, the freeze dried residue was grinded into a homogenous powder, followed by cell count analysis of the two strains. The bacterial powders were blended with an inert maltodextrin up to a target concentration between 5E+09 and 1E+10 CFU g−1. Finally, the bacterial powder was filled under humidity-controlled conditions in water-tight sachets with total dried powder content of one gram per sachet. The entire seed culture production process is shown in Table 2.

Acidification profiles of seed cultures

Milk was pre-treated by a heating step of 30 min at 102 °C and aliquoted into four 250 ml glass bottles. The temperature of each bottle was adjusted to 32, 37, 42 or 45 °C using different water baths. Frozen pellets of S. thermophilus C106 with known starting viability were dosed (0.25 g l−1) into 200 ml milk. For each cultivation the pH was monitored every 30 min for a total of 240 h.

Immunoblotting analysis

From 48 h MRS plates, two distinct colony morphologies could be observed: large white colonies and very small white colonies, corresponding, respectively, to L. rhamnosus and S. thermophilus cells. L. rhamnosus colonies were randomly picked from seed culture sachets, first and second passages of fermented milk for further analysis. Expression of SpaA pilin subunits in L. rhamnosus cells was assessed using a immunoblotting approach where single colonies were transferred into 96-well plates and analyzed by immunoblotting using polyclonal anti-SpaA antibodies, as primary antibody and goat anti-rabbit antibodies conjugated to horse radish peroxidase, as secondary antibody (Biorad Laboratories Inc., Hercules, CA, USA). The overall method has been described previously [10].

Colony PCR-screening

Lactobacillus rhamnosus colonies were picked from MRS agar plates, re-suspended in 20 µl double distilled water and microwaved for 3 min to break down the bacteria cells. Next, 2 µl of each picked colony was added to Green Dream Taq Master Mix (Thermo Scientific) as per manufacturer’s instructions using one of the two different sets of primers, as described below. Amplicons were analyzed by 1 % (w/v) agarose gel electrophoresis. The sequences of the LGG-specific primers were based on a previous study [37], the srtC1-specific primers include the forward primer 5′-AAACCGCCCAACTTGAAGCCTC-3′ and the reverse primer 5′AAAGTTAATAAGATAAATGAG-3′.

Immuno-staining transmission microscopy

Samples were observed by transmission electron microscopy (JEOL 1400, Jeol Ltd., Japan), as previously described [38]. Gold particles with a diameter of 5 nm were conjugated to protein A and polyclonal anti-SpaA antibodies were employed to visualize pilus structures on the cell surface of L. rhamnosus.

Preparation of probiotic fermented foods

In a typical experiment, the content of a sachets (one gram) was used to inoculate 1 l of semi-skimmed and pasteurized milk (1.5 % fat, 3.5 % protein), and incubated at 37 or 45 °C for approximately 12 h, until pH 4.3 (first passage). The fermented milk was subsequently used as inoculum for the production of maximal 100 l fermented milk or other fermented food (second passage).

Fermentations in milk were carried out for pilot experiments in the laboratory of CSK Food Enrichment, Ede, The Netherlands as well as for yoghurt1 production in African countries, including Uganda, Kenya, Tanzania, Zambia, Zimbabwe, and Burkina Faso (Table 3). Obushera—a sorghum-based beverage [39]—was fermented with the Yoba seed culture in the Department of Food Technology and Nutrition, Makerere University, Kampala, Uganda for a period of 24 h at 25–27 °C.

Uji was prepared at the Jomo Kenyatta University of Agriculture and Technology in Kenya. Sorghum, maize flour or a mixture of both was added to water to a final concentration of approximately 6 % (w/v), boiled to obtain a thick porridge and cooled down to 45 °C prior to inoculation with the Yoba seed culture. Zomkom, a sorghum-based beverage from Burkina Faso, was prepared in The Netherlands by boiling one l of water with sorghum or wheat flour, full fat milk, 5 % ginger syrup (v/v) and 3 % dark brown sugar (w/v), as specified in Table 3. After pasteurization and continuous stirring, the mixture was cooled down to 43 °C and a freshly prepared fermented milk starter (1–2 %) was added. The mixture was incubated at 37 °C for 15 h.

The preparation of fermented mutandabota—a product from the fruits of the baobab tree and milk—in Zimbabwe has been reported previously [40].

Cell counts for L. rhamnosus and S. thermophilus were determined on MRS agar medium (Difco Laboratories, Detroit, MI, USA) and LM17 (Difco Laboratories), respectively, by using commonly applied microbiological plating methods.

Food safety of seed cultures and sensory evaluation of dairy and cereal-based fermentations

The content of the seed cultures were routinely tested by selective enumeration methods: Listeria monocytogenes according to ISO 11290-2, Enterobacteriaceae yeast and moulds according to ISO 7954 (1987) and non-lactic-acid bacteria according to a validated in-house colony count technique from Eurofins Food Testing BV, Heerenveen, The Netherlands. Typical sensory aspects such as color, structure, firmness, sweetness, sourness and taste were evaluated by a panel in Uganda in agreement with local practices. Whitening ability and whey separation were also evaluated for the fermented milk products.

Availability of supporting data

The genome sequence of S. thermophilus C106 has been deposited in GenBank with accession number LGRS00000000, BioProject ID PRJNA288538. The genome sequence of L. rhamnosus yoba 2012 has been reported previously [8] and deposited at the NCBI BioSample database, Sequence Read Archive, project SRP017797.

Authors’ contributions

RK and WS coordinated the study and wrote the manuscript. MS, WM, LB, BH developed, characterized, and produced the mixed seed cultures and provided the genome sequence of S. thermophilus C106. FD and WdV carried out the immunoblotting and TEM. WG and BT constructed genome-scale models and determined the metabolic potential of the consortium. NW and CT tested feasibility of the use of seed cultures by field work in Uganda. IMM coordinated the Obushera fermentation and CFU counts in Uganda. GR provided input into the studies and the manuscript. All authors read and approved the final manuscript.

Acknowledgements

The authors gratefully acknowledge Eddy Smid for utilization of the freeze-drying facility at the Laboratory of Food Microbiology, WUR, The Netherlands and Thomas Lautischer from Lactosan GmbH & Co, Austria, for technical support. Hajo van Otterloo for Zomkom production in The Netherlands. Karin Overkamp, TNO Microbiology and Systems Biology for HPLC analysis. Rehema Meeme from the Department of Food Technology and Nutrition, Makerere University, Kampala, Uganda for colony enumeration experiments with fermented Obushera. Kathleen Walsh from Western Heads East for Uji and Yoba production and characterization in Kenya. The team of the East Africa Dairy Development project under Heifer International in Uganda for their support in the field testing. The personnel from the Electron Microscopy Unit (Institute of Biotechnology, Helsinki) for providing excellent technical assistance. We thank Brett G. Olivier for his help with the construction of the genome-scale models. Edwin Ananta from the Nestlé Research Center, Lausanne, Switzerland, is greatly acknowledged for the analysis of pathogen inhibition and vitamin production in fermented foods.

Competing interests

Wilbert Sybesma and Remco Kort are the founders of the Yoba for Life foundation, a not-for-profit organization, accredited by the Dutch Tax Authorities as a Public Benevolent Institution (PBI), which aims to promote local production and consumption of fermented products in Africa. Fermented products made with the Yoba seed culture, including yoghurt, zomkom, obushera and mutandabota are not marketed by the foundation as such, but the Yoba for Life foundation stimulates local production and ownership, allowing income-generating activities for African entrepreneurs in the food sector. The Yoba for Life foundation distributes and sells ready-to-use sachets with dried bacterial seed cultures through a network of partners and volunteers to facilitate the local production of dairy and cereal-based products by controlled bacterial fermentation [41].

Additional files

10.1186/s12934-015-0370-x Predictive distribution of all functional encoded proteins of S. thermophilus C106 into COG Functional Categories: CELLULAR PROCESSES AND SIGNALING: [D] Cell cycle control, cell division, chromosome partitioning; [M] Cell wall/membrane/envelope biogenesis; [N] Cell motility; [O] Post-translational modification, protein turnover, and chaperones; [T] Signal transduction mechanisms; [U] Intracellular trafficking, secretion, and vesicular transport; [V] Defense mechanisms. INFORMATION STORAGE AND PROCESSING (355): [J] Translation, ribosomal structure and biogenesis; [K] Transcription; [L] Replication, recombination and repair. METABOLISM (529): [C] Energy production and conversion; [E] Amino acid transport and metabolism; [F] Nucleotide transport and metabolism; [G] Carbohydrate transport and metabolism; [H] Coenzyme transport and metabolism; [I] Lipid transport and metabolism; [P] Inorganic ion transport and metabolism; [Q] Secondary metabolites biosynthesis, transport, and catabolism and unknown function: [R] Function does not belong to COG categories [S] Function unknown.

10.1186/s12934-015-0370-x Protocol for the production of fermented milk from the seed culture. Front and backside of the sachets designed for African dairy producers. The protocol on the backside indicates two rounds of fermentation: round 1 from the dried bacterial powder (1 g per l) to fermented milk. round 2: from 1 l fermented milk to 50-100 l fermented milk.

10.1186/s12934-015-0370-x Geographical placement of Yoba yoghurt producing groups in Uganda and their weekly volumes as of October 2015. Cities are indicated by blue circles, Yoba producing cooperatives by red circles, and starter culture distribution points by yellow triangles.

Footnotes

The final product of milk fermented by Lactobacillus rhamnosus yoba 2012 and S. thermophilus C106 as described in this paper is referred to as fermented milk, yoghurt or Yoba.

Contributor Information

Remco Kort, Phone: +31 20 7715299, Email: remco.kort@yoba4life.com.

Nieke Westerik, Email: nieke.westerik@telfort.nl.

L. Mariela Serrano, Email: m.serrano@cskfood.com

François P. Douillard, Email: francois.douillard@helsinki.fi

Willi Gottstein, Email: w.g.gottstein@vu.nl.

Ivan M. Mukisa, Email: ivanmukisa@caes.mak.ac.ug

Coosje J. Tuijn, Email: c.tuijn@gmail.com

Lisa Basten, Email: l.basten@cskfood.com.

Bert Hafkamp, Email: b.hafkamp@cskfood.com.

Wilco C. Meijer, Email: w.meijer@cskfood.com

Bas Teusink, Email: b.teusink@vu.nl.

Willem M. de Vos, Email: willem.devos@wur.nl

Gregor Reid, Email: gregor@uwo.ca.

Wilbert Sybesma, Email: wilbert.sybesma@yoba4life.com.

References

- 1.Collaborators GBoDS. Global, regional, and national incidence, prevalence, and years lived with disability for 301 acute and chronic diseases and injuries in 188 countries, 1990–2013: a systematic analysis for the Global Burden of Disease Study 2013. Lancet. 2015. [DOI] [PMC free article] [PubMed]

- 2.Szajewska H, Wanke M, Patro B. Meta-analysis: the effects of Lactobacillus rhamnosus GG supplementation for the prevention of healthcare-associated diarrhoea in children. Aliment Pharmacol Ther. 2011;34:1079–1087. doi: 10.1111/j.1365-2036.2011.04837.x. [DOI] [PubMed] [Google Scholar]

- 3.Chilton SN, Burton JP, Reid G. Inclusion of fermented foods in food guides around the world. Nutrients. 2015;7:390–404. doi: 10.3390/nu7010390. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 4.Franz CM, Huch M, Mathara JM, Abriouel H, Benomar N, Reid G, Galvez A, Holzapfel WH. African fermented foods and probiotics. Int J Food Microbiol. 2014;190:84–96. doi: 10.1016/j.ijfoodmicro.2014.08.033. [DOI] [PubMed] [Google Scholar]

- 5.Balikowa D. A review of Uganda’s dairy industry. Retrieved from the Dairy Development Authority. 2011. http://www.fao.org/3/a-aq292e.pdf.

- 6.Monachese M, Cunningham-Rundles S, Diaz MA, Guerrant R, Hummelen R, Kemperman R, Kerac M, Kort R, Merenstein D, Panigrahi P, et al. Probiotics and prebiotics to combat enteric infections and HIV in the developing world: a consensus report. Gut Microbes. 2011;2:198–207. doi: 10.4161/gmic.2.3.16106. [DOI] [PubMed] [Google Scholar]

- 7.Reid G, Nduti N, Sybesma W, Kort R, Kollmann TR, Adam R, Boga H, Brown EM, Einerhand A, El-Nezami H, et al. Harnessing microbiome and probiotic research in sub-Saharan Africa: recommendations from an African workshop. Microbiome. 2014;2:12. doi: 10.1186/2049-2618-2-12. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 8.Sybesma W, Molenaar D. van IW, Venema K, Kort R: genome instability in Lactobacillus rhamnosus GG. Appl Environ Microbiol. 2013;79:2233–2239. doi: 10.1128/AEM.03566-12. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 9.Kort R, Sybesma W. Probiotics for every body. Trends Biotechnol. 2012;30:613–615. doi: 10.1016/j.tibtech.2012.09.002. [DOI] [PubMed] [Google Scholar]

- 10.Douillard FP, Ribbera A, Kant R, Pietila TE, Jarvinen HM, Messing M, Randazzo CL, Paulin L, Laine P, Ritari J, et al. Comparative genomic and functional analysis of 100 Lactobacillus rhamnosus strains and their comparison with strain GG. PLoS Genet. 2013;9:e1003683. doi: 10.1371/journal.pgen.1003683. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 11.Ardita CS, Mercante JW, Kwon YM, Luo L, Crawford ME, Powell DN, Jones RM, Neish AS. Epithelial adhesion mediated by pilin SpaC is required for Lactobacillus rhamnosus GG-induced cellular responses. Appl Environ Microbiol. 2014;80:5068–5077. doi: 10.1128/AEM.01039-14. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 12.Kankainen M, Paulin L, Tynkkynen S, von Ossowski I, Reunanen J, Partanen P, Satokari R, Vesterlund S, Hendrickx AP, Lebeer S, et al. Comparative genomic analysis of Lactobacillus rhamnosus GG reveals pili containing a human-mucus binding protein. Proc Natl Acad Sci USA. 2009;106:17193–17198. doi: 10.1073/pnas.0908876106. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 13.Reunanen J, von Ossowski I, Hendrickx AP, Palva A, de Vos WM. Characterization of the SpaCBA pilus fibers in the probiotic Lactobacillus rhamnosus GG. Appl Environ Microbiol. 2012;78:2337–2344. doi: 10.1128/AEM.07047-11. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 14.Tatusov RL, Galperin MY, Natale DA, Koonin EV. The COG database: a tool for genome-scale analysis of protein functions and evolution. Nucleic Acids Res. 2000;28:33–36. doi: 10.1093/nar/28.1.33. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 15.Delorme C, Bartholini C, Bolotine A, Ehrlich SD, Renault P. Emergence of a cell wall protease in the Streptococcus thermophilus population. Appl Environ Microbiol. 2010;76:451–460. doi: 10.1128/AEM.01018-09. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Letort C, Nardi M, Garault P, Monnet V, Juillard V. Casein utilization by Streptococcus thermophilus results in a diauxic growth in milk. Appl Environ Microbiol. 2002;68:3162–3165. doi: 10.1128/AEM.68.6.3162-3165.2002. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 17.Letort C, Juillard V. Development of a minimal chemically-defined medium for the exponential growth of Streptococcus thermophilus. J Appl Microbiol. 2001;91:1023–1029. doi: 10.1046/j.1365-2672.2001.01469.x. [DOI] [PubMed] [Google Scholar]

- 18.Pastink MI, Teusink B, Hols P, Visser S, de Vos WM, Hugenholtz J. Genome-scale model of Streptococcus thermophilus LMG18311 for metabolic comparison of lactic acid bacteria. Appl Environ Microbiol. 2009;75:3627–3633. doi: 10.1128/AEM.00138-09. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 19.Morita H, Toh H, Oshima K, Murakami M, Taylor TD, Igimi S, Hattori M. Complete genome sequence of the probiotic Lactobacillus rhamnosus ATCC 53103. J Bacteriol. 2009;191:7630–7631. doi: 10.1128/JB.01287-09. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 20.Sieuwerts S, de Bok FA, Hugenholtz J. van Hylckama Vlieg JE: Unraveling microbial interactions in food fermentations: from classical to genomics approaches. Appl Environ Microbiol. 2008;74:4997–5007. doi: 10.1128/AEM.00113-08. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 21.Douillard FP, Ribbera A, Jarvinen HM, Kant R, Pietila TE, Randazzo C, Paulin L, Laine PK, Caggia C, von Ossowski I, et al. Comparative genomic and functional analysis of Lactobacillus casei and Lactobacillus rhamnosus strains marketed as probiotics. Appl Environ Microbiol. 2013;79:1923–1933. doi: 10.1128/AEM.03467-12. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 22.Sieuwerts S. Analysis of molecular interactions between yoghurt bacteria by an integrated genomics approach. 2009.

- 23.Sybesma W, Kort R. Benefits of and access to locally produced functional fermented foods in Africa. In: The International Scientific Conference on Probiotics and Prebiotics. Budapest; 2015.

- 24.Mpofu A, Linnemann AR, Nout MJ, Zwietering MH, Smid EJ, den Besten HM. Inactivation of bacterial pathogens in yoba mutandabota, a dairy product fermented with the probiotic Lactobacillus rhamnosus yoba. Int J Food Microbiol. 2015;217:42–48. doi: 10.1016/j.ijfoodmicro.2015.09.016. [DOI] [PubMed] [Google Scholar]

- 25.Holzapfel WH. Appropriate starter culture technologies for small-scale fermentation in developing countries. Int J Food Microbiol. 2002;75:197–212. doi: 10.1016/S0168-1605(01)00707-3. [DOI] [PubMed] [Google Scholar]

- 26.Lahtinen SJ, Haskard CA, Ouwehand AC, Salminen SJ, Ahokas JT. Binding of aflatoxin B1 to cell wall components of Lactobacillus rhamnosus strain GG. Food Addit Contam. 2004;21:158–164. doi: 10.1080/02652030310001639521. [DOI] [PubMed] [Google Scholar]

- 27.Zoghi A, Khosravi-Darani K, Sohrabvandi S. Surface binding of toxins and heavy metals by probiotics. Mini Rev Med Chem. 2014;14:84–98. doi: 10.2174/1389557513666131211105554. [DOI] [PubMed] [Google Scholar]

- 28.Bisanz JE, Enos MK, Mwanga JR, Changalucha J, Burton JP, Gloor GB, Reid G. Randomized open-label pilot study of the influence of probiotics and the gut microbiome on toxic metal levels in Tanzanian pregnant women and school children. MBio. 2014;5:e01580. doi: 10.1128/mBio.01580-14. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 29.Guarino A, Guandalini S, Lo Vecchio A. Probiotics for Prevention and Treatment of Diarrhea. J Clin Gastroenterol. 2015;49(Suppl 1):S37–S45. doi: 10.1097/MCG.0000000000000349. [DOI] [PubMed] [Google Scholar]

- 30.Allen SJ, Martinez EG, Gregorio GV, Dans LF. Probiotics for treating acute infectious diarrhoea. Cochrane Database Syst Rev. 2010:CD003048. [DOI] [PMC free article] [PubMed]

- 31.de Roos NM, Katan MB. Effects of probiotic bacteria on diarrhea, lipid metabolism, and carcinogenesis: a review of papers published between 1988 and 1998. Am J Clin Nutr. 2000;71:405–411. doi: 10.1093/ajcn/71.2.405. [DOI] [PubMed] [Google Scholar]

- 32.Nakawesi JS, Wobudeya E, Ndeezi G, Mworozi EA, Tumwine JK. Prevalence and factors associated with rotavirus infection among children admitted with acute diarrhea in Uganda. BMC Pediatr. 2010;10:69. doi: 10.1186/1471-2431-10-69. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 33.Sybesma W, Kort R, Lee YK. Locally sourced probiotics, the next opportunity for developing countries? Trends Biotechnol. 2015;33:197–200. doi: 10.1016/j.tibtech.2015.01.002. [DOI] [PubMed] [Google Scholar]

- 34.Notebaart RA, van Enckevort FH, Francke C, Siezen RJ, Teusink B. Accelerating the reconstruction of genome-scale metabolic networks. BMC Bioinformatics. 2006;7:296. doi: 10.1186/1471-2105-7-296. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 35.Khandelwal RA, Olivier BG, Roling WF, Teusink B, Bruggeman FJ. Community flux balance analysis for microbial consortia at balanced growth. PLoS One. 2013;8:e64567. doi: 10.1371/journal.pone.0064567. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Olivier BG, Rohwer JM, Hofmeyr JH. Modelling cellular systems with PySCeS. Bioinformatics. 2005;21:560–561. doi: 10.1093/bioinformatics/bti046. [DOI] [PubMed] [Google Scholar]

- 37.Ahlroos T, Tynkkynen S. Quantitative strain-specific detection of Lactobacillus rhamnosus GG in human faecal samples by real-time PCR. J Appl Microbiol. 2009;106:506–514. doi: 10.1111/j.1365-2672.2008.04018.x. [DOI] [PubMed] [Google Scholar]

- 38.Douillard FP, Rasinkangas P, von Ossowski I, Reunanen J, Palva A, de Vos WM. Functional identification of conserved residues involved in Lactobacillus rhamnosus strain GG sortase specificity and pilus biogenesis. J Biol Chem. 2014;289:15764–15775. doi: 10.1074/jbc.M113.542332. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 39.Mukisa IM, Porcellato D, Byaruhanga YB, Muyanja CM, Rudi K, Langsrud T, Narvhus JA. The dominant microbial community associated with fermentation of Obushera (sorghum and millet beverages) determined by culture-dependent and culture-independent methods. Int J Food Microbiol. 2012;160:1–10. doi: 10.1016/j.ijfoodmicro.2012.09.023. [DOI] [PubMed] [Google Scholar]

- 40.Mpofu A, Linnemann AR, Sybesma W, Kort R, Nout MJ, Smid EJ. Development of a locally sustainable functional food based on mutandabota, a traditional food in southern Africa. J Dairy Sci. 2014;97:2591–2599. doi: 10.3168/jds.2013-7593. [DOI] [PubMed] [Google Scholar]

- 41.Kort R, Sybesma W. The Yoba for Life foundation. 2015. http://www.yoba4life.com. Accessed 25 October 2015.