Abstract

Objective

The study objectives were to identify factors affecting extension ladders’ angular positioning and evaluate the effectiveness of two anthropometric positioning methods.

Background

A leading cause for extension ladder fall incidents is a slide-out event, usually related to suboptimal ladder inclination. An improved ladder positioning method or procedure could reduce the risk of ladder stability failure and the related fall injury.

Method

Participants in the study were 20 experienced and 20 inexperienced ladder users. A series of ladder positioning tests was performed in a laboratory environment with 4.88-m (16-ft) and 7.32-m (24-ft) ladders in extended and retracted positions. The setup methods included a no-instruction condition and two anthropometric approaches: the American National Standards Institute A14 and “fireman” methods. Performance measures included positioning angle and time.

Results

The results indicated that ladder setup method and ladder effective length, defined by size and extended state, affected ladder positioning angle. On average, both anthropometric methods were effective in improving extension ladder positioning; however, they required 50% more time than did the no-instruction condition and had a 9.5% probability of setting the ladder at a less-than-70° angle. Shorter ladders were consistently positioned at shallower angles.

Conclusion

Anthropometric methods may lead to safer ladder positioning than does no instruction when accurately and correctly performed. Workers tended to underperform as compared with their theoretical anthropometric estimates. Specific training or use of an assistive device may be needed to improve ladder users’ performance.

Application

The results provide practical insights for employers and workers to correctly set up extension ladders.

Keywords: extension ladders, ladder safety, angular positioning, anthropometric methods

INTRODUCTION

In 2008, work-related falls from ladders resulted in 119 fatalities and an estimated 17,540 serious injuries in the United States (Bureau of Labor Statistics, 2010a, 2010b), which are a significant burden to the workers and to society. Slipping of ladder base was identified as a leading cause for ladder fall incidents (Hsiao et al., 2008). The likelihood of an extension ladder base slipping depends on the angle of ladder inclination, friction between ladder base and supporting surfaces, magnitude of static and dynamic loads on the ladder, and load location on the ladder (Pesonen & Häkkinen, 1988). Earlier analysis (Hepburn, 1958) has shown that the inclination angle is a very important factor affecting extension ladder stability. Consistently, recent experimental studies (Chang, Chang, Matz, & Son, 2004) demonstrated that an angle change from 75° to 65° nearly doubles the required friction for keeping an extension ladder in balance. Accordingly, the inclination angle has been specifically addressed in the ladder safety standards in both a recommended angle value and suggested procedures for achieving this angle value.

The current American National Standards Institute (ANSI) A14 standard (American Ladder Institute, 2007) defines the requirement for angle of inclination as follows:

Portable non-self-supporting ladders should be erected at a pitch of 75.5° from the horizontal for optimum resistance to sliding, strength of the ladder, and balance of the climber. A simple rule for setting up a ladder at the proper angle is to place the base a distance from the wall or upper support equal to one-quarter the effective working length of the ladder (the “quarter length rule”).

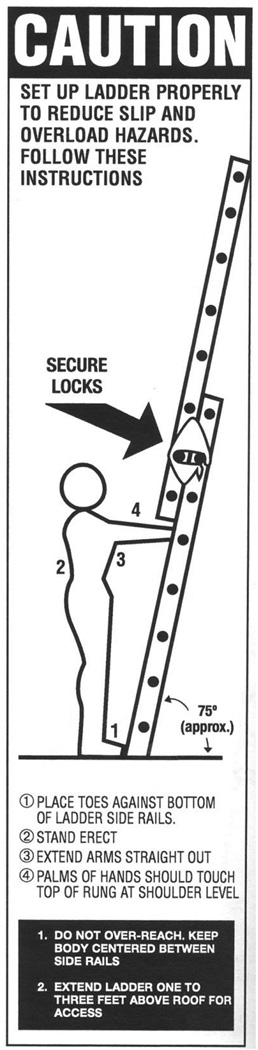

The value of 75.5° has been proposed in earlier guidelines (International Labor Office, 1949) and analytical studies (Hepburn, 1958). More recently, Irvine and Vejvoda (1977) studied the angle of inclination for extension ladders and suggested using the anthropometric method instead of the quarter length rule and the fixed angle of 75.5°. The anthropometric method instructs the climber to stand at the base of the ladder with toes against the rails and arms outstretched horizontally; the proper angle is achieved when the palms of the hands touch the top of the rung at shoulder level. Since 1990, the anthropometric method has been accepted by the ANSI A14 standard as a practical method for ladder setup, and a corresponding anthropometric sticker is provided on the side rail of extension ladders (Figure 1).

Figure 1.

Current American National Standards Institute (ANSI) A14 standard anthropometric sticker. From American National Standards Institute (ANSI) A14.2: American National Standard for Ladders–Portable Metal–Safety Requirements (p. 63), by American Ladder Institute, 2007, Chicago, IL: American Ladder Institute. Copyright 2007 by American Ladder Institute. Reprinted with permission.

In earlier research (Dewar, 1977; Häkkinen, Pesonen, & Rajamäki, 1988; Irvine & Vejvoda, 1977; Young & Wogalter, 2000), when not instructed or given any method or aid, ladder users tend to set up ladders at angles shallower than 75.5°, on average in the range of 66° to 69°. These studies also indicated that the anthropometric method resulted in, on average, a shallower-than-recommended angle with relatively large variability in the angle measurements (Irvine & Vejvoda, 1977; Young & Wogalter, 2000). The reasons for the discrepancy and variability of extension ladder positioning angles during the use of the current standard procedure have not been thoroughly explored.

It is understandable that the ratio difference in shoulder height, arm grab length, and foot and shoe length among individuals is a contributing factor to the variability in positioning angles. Furthermore, some variability and discrepancy may be attributed to worker postural behaviors, which result from ladder size (length and weight), ladder state (retracted or extended), and worker experience. Workers may unconsciously lean to or away from a ladder or extend their shoulder positions in different ladder conditions. An additional variation associated with the ANSI A14 anthropometric method is related to the differences in users’ shoulder height relative to the height of a corresponding ladder rung. To hold the fifth rung of an extension ladder positioned at a 75.5° angle while maintaining outstretched arms horizontally, the ladder user’s shoulder height has to be exactly 1.34 m; a shorter or a taller person who will end up with a steeper or shallower ladder angle. This additional variation can be eliminated by using a modified anthropometric method also known as the “fireman method,” in which the horizontal outstretched hands are to hold the side rails instead of the rung.

In this study, we evaluated the effect of ladder positioning method (ANSI A14 method and fireman method), ladder size and weight, ladder extended state, and user experience on ladder setup angle. Their effect on time required to complete ladder positioning was also studied.

METHOD

Participants

Participants in the study were 20 experienced (19 male, 1 female) and 20 inexperienced (13 male, 7 female) ladder users. The average age of the experienced group was 42.7 (SD = 10.0) years and of the inexperienced group was 37.2 (SD = 13.1) years. The average weight and height of the experienced group were 95.3 kg (SD = 26.6 kg) and 175.3 cm (SD = 8.1 cm) and of the inexperienced group were 88.2 kg (SD = 21.9 kg) and 172.8 cm (SD = 10.1 cm) correspondingly. The participants were recruited through newspaper advertisements from the local area (Morgantown, West Virginia). The requirements for study participation were normal or corrected vision in both eyes, absence of known musculoskeletal and balance problems, and no medication use or alcohol consumption in the past 24 hr. All participants gave informed consent prior to the study and were compensated for their time. The study protocol was approved by the Institutional Review Board of the National Institute for Occupational Safety and Health (NIOSH).

Geometrical Considerations and Estimated Angles

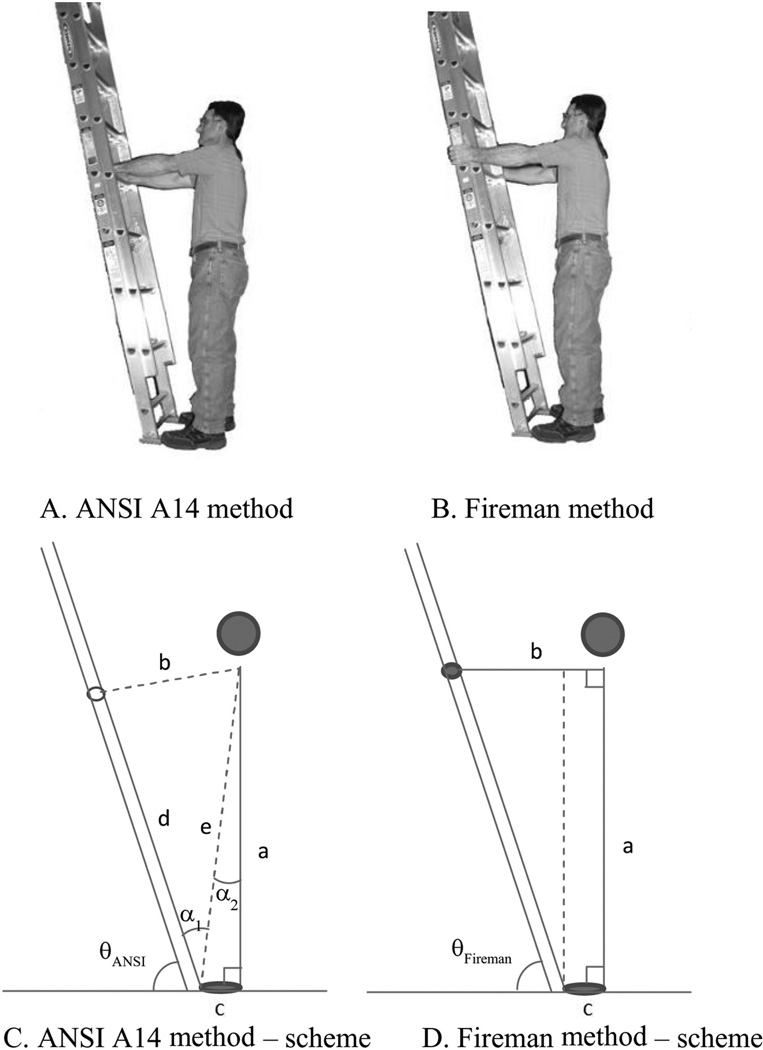

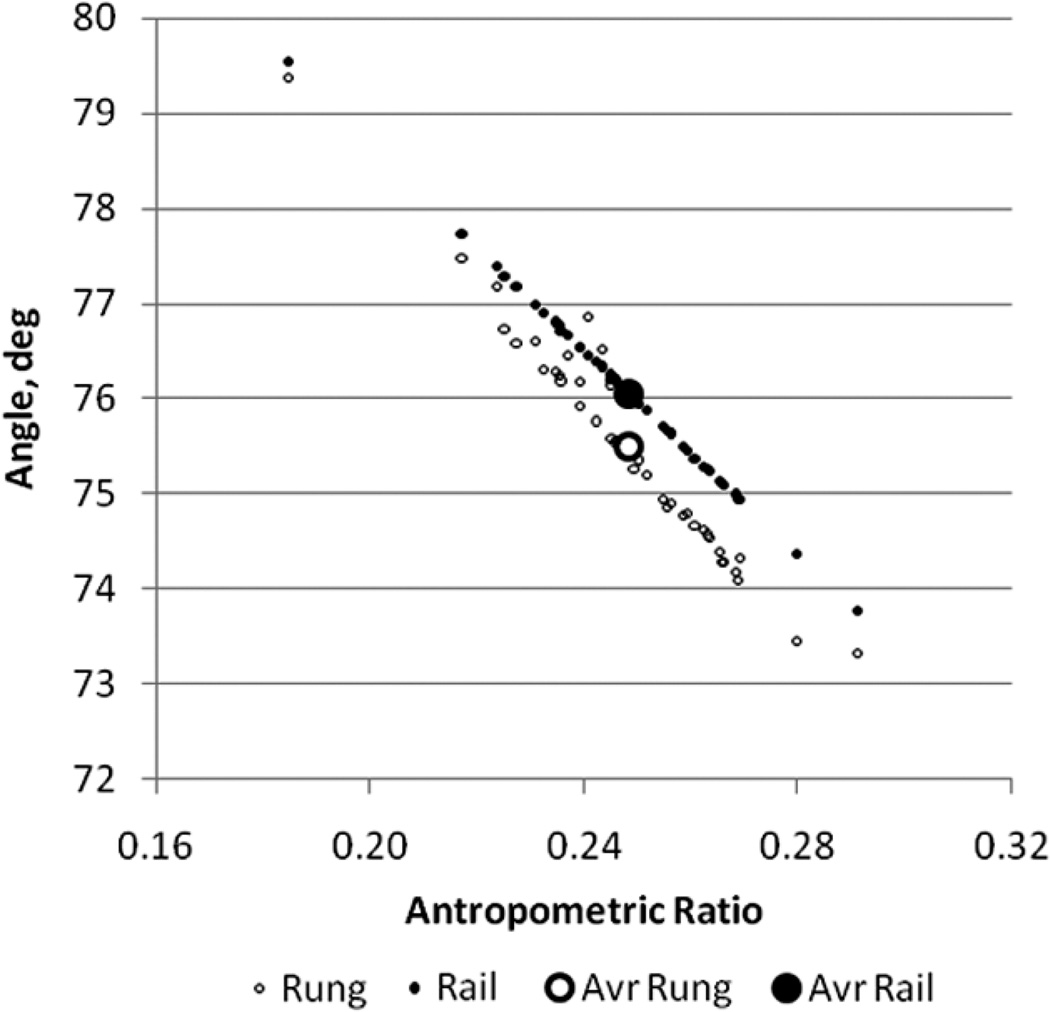

The two anthropometric methods, ANSI A14 and fireman method, are visualized by the pictures in Figure 2A and 2B. With the assumptions of a vertical body posture and linearly outstretched arms, the two methods are also schematically represented by the drawings in Figure 2C and 2D. Established geometrical relations were used to estimate the theoretical ladder inclination (estimated angle) for each participant. The estimated angle values for both anthropometric methods are displayed in Figure 3 as a function of participant’s anthropometry, represented by the summary value anthropometric ratio. The anthropometric ratio is defined as the grip reach minus ankle-to-toe length, divided by shoulder height, and thus directly represents the ladder slope for the fireman method. The estimated average angle values were 75.5° for the ANSI A14 method and 76.1° for the fireman method.

Figure 2.

The two anthropometric methods for ladder positioning and their schematic geometrical representation. (A) ANSI A14 method. (B) Fireman method. (C) ANSI A14 method scheme. (D) Fireman method scheme. θANSI = 90° − α1 + α2 = 90° − arcos[(d2 + e2 − b2)/(2*d*e)] + arctan(c/a), and θFireman = 90° − arctan[(b − c)/a)], where a = shoulder (acromial) height in standing (with shoes), b = grip reach from shoulder (reduced by half of the ladder rail width), c = ankle-to-toe length (average of medial and lateral measurements with shoes), d = length from ladder bottom to fifth rung, and e = (a2 + c2)0.5.

Figure 3.

Estimated angles for the two anthropometric methods. Anthropometric ratio = (b − c)/a, where a = shoulder (acromial) height in standing (with shoes), b = grip reach from shoulder (reduced by half of the ladder rail width), and c = ankle-to-toe length (average of medial and lateral measurements with shoes).

Independent Variables

Methods for ladder positioning (method): Three levels

The methods for extension ladder positioning, comparatively evaluated in this study, included a no-instruction method and two anthropometric methods (ANSI A14 and fireman). The no-instruction method was used as a baseline; the participants were told to position the ladder “as if they are going to climb it” without any additional instructions on how to do so. The labels on the ladder remained visible throughout all trials. For the ANSI A14 anthropometric method, the participants were guided to make iterative corrections to the ladder angular position by adjusting the toes of their feet against the bottom of ladder side rails, standing straight with outstretched arms and referencing the palms of their hands against a ladder rung (Figure 2A). For the fireman method, the participants were instructed to make iterative corrections to the ladder angular position by adjusting the toes of their feet against the bottom of ladder side rails, standing straight with horizontally extended arms and referencing the palms of their hands to the ladder rails (Figure 2B).

Ladder size and type (ladder): Two levels

Two extension ladders were selected for the tests to represent some of the most frequently purchased extension ladder types at a local home improvement store: a 4.88-m (16-ft) aluminum ladder (Warner, D1100 Series, Type III) weighing 8.4 kg and a 7.32-m (24-ft) aluminum ladder (Warner, D1200 Series, Type II) weighing 15.2 kg.

Ladder extended state (state): Two levels

The ladders were tested in a partially retracted and in a fully extended state. In the partially retracted state, the ladders were extended by one rung, and their effective length was 2.75 m (9 ft) and 3.97 m (13 ft) for the 4.88-m (16-ft) and the 7.32-m (24-ft) ladders, respectively. In the extended state, the ladders were extended to the maximum length allowable by the standard (with three rungs overlapping), and their effective length was 3.97 m (13 ft) and 6.41 m (21 ft) for the 4.88-m (16-ft) and the 7.32-m (24-ft) ladders, respectively.

Work experience: Two levels

Both experienced construction workers (with more than 1 year of job-related extension ladder use) and inexperienced ladder users participated in the study.

Experimental Setup

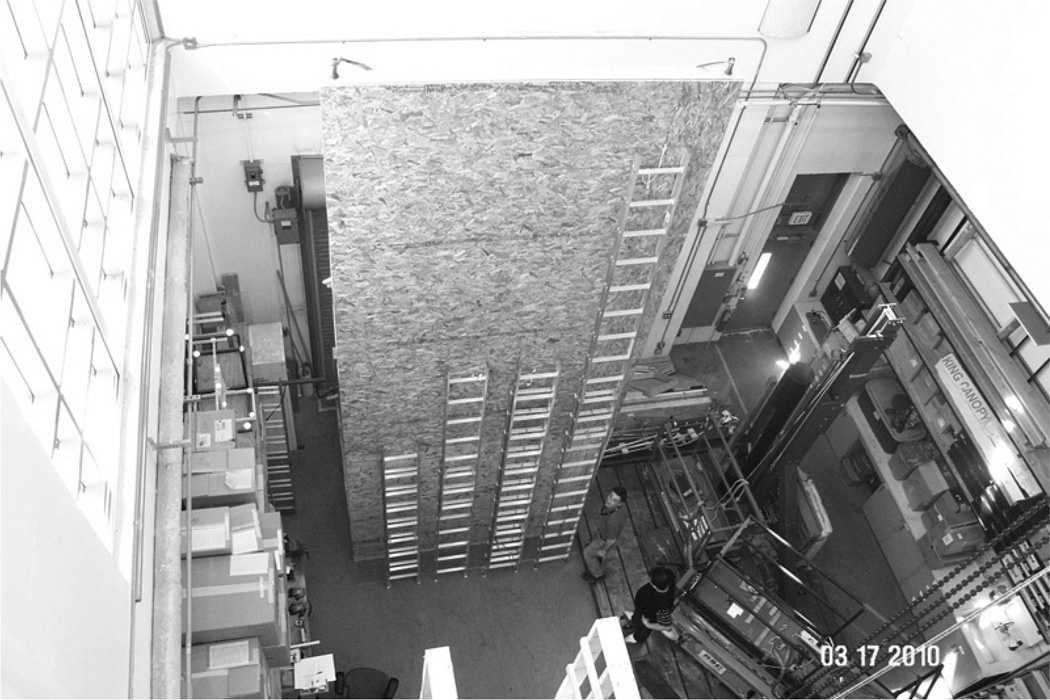

The study was conducted in the NIOSH High Bay laboratory. The extension ladder positioning was evaluated in an environment of simple geometry: on a level concrete floor and against a vertical wall free of obstructions. The vertical wall was constructed from wood particle boards and was 7.32 m (24 ft) high (Figure 4) and 2.9 m wide, allowing the four test ladders to be equally spaced at 0.24 m. The starting position for all the ladders was set nearly vertical: Ladder feet were 0.1 m away from the wall base to allow the ladders to be freestanding. This starting ladder position allowed comparative evaluation of the time used for ladder angular adjustment. The ladders were returned to the initial position before the next trial. For safety, the ladder tops were tethered to the wall with a loose cord loop allowing free vertical movement.

Figure 4.

Experimental setup with the four ladders in the High Bay lab.

Experimental Procedure

On the day of the experiment, the participants were briefed on the study objectives, methods, procedures, and potential risks. Anthropometric measurements were taken before the tests while participants were wearing their own shoes. For the entire study, each participant performed 36 trials of ladder angular positioning (12 experimental conditions, 3 methods × 2 ladders × 2 states, with each condition repeated in three consecutive trials). The ladder positioning task required lifting the lower part of the ladder and moving it away from the vertical wall until a desired angular position was achieved. Depending on the method used, the ladder positioning task could require a series of iterative checks and readjustments.

The experiments were balanced across conditions within each of two blocks: no-instruction method block (1 method × 4 ladder tasks) and anthropometric methods block (2 methods × 4 ladder tasks). The no-instruction method block of tasks was performed first to eliminate possible transfer of learning effects from the anthropometric methods. Before the first trial of each new method, the researchers gave specific instructions and brief demonstration of the task, after which the participants were allowed several trials to familiarize themselves with the procedure. The participants followed an instruction to start a trial and indicated the end of the trial verbally and by letting their hands off the ladder. There was a 3-min rest interval between each experimental condition. The participants completed the test session in approximately 1.5 hr and were compensated for their time.

Dependent Variables

Estimated angle

The theoretical angle values for the anthropometric methods were calculated on the basis of participants’ anthropometric measurements defined in the “Geometrical Considerations and Estimated Angles” section and the equations presented in Figure 2.

Performance angle (angle)

The ladder angle to the horizontal was measured after each setup task with the use of a digital inclinometer (Angle/Level V, Dejon Tools & Design, Inc., Covington, OH) with accuracy of 0.1°. The inclinometer was positioned and aligned with one of the ladder rails at the level between the fourth and fifth rung.

Time required for ladder setup (time)

The time for ladder setup was measured with a digital stop watch with accuracy of 0.01 s. The time required for ladder setup was measured from the moment of first touching the ladder after a verbal instruction to the moment of final release of the ladder after completing the task (indicated also by a verbal report).

Statistical Analysis

For the dependent variables angle (in degrees) and time (in seconds), a mixed model with repeated-measures ANOVA was used to evaluate the effects of different experimental conditions. The mixed model included both fixed and random effects. The fixed effects included all the independent variables. The random effects included the correlation within each individual participant. The only between-subject factor in this study was the participant’s work experience. Various models were used to find the appropriate covariance structure of observations within each participant. A model that provided the best fit was selected for final analysis; statistical significance was set at p ≤ .05. For post hoc tests, Tukey-Kramer procedure was used subsequently for pairwise comparisons. All analyses were performed with SAS/STAT® software.

RESULTS

Estimated Angle

The estimated angle average values were 75.6° for the ANSI A14 method and 76.2° for the fireman method with standard deviations of 1.2° and 1.0°, respectively; the 95% confidence interval (CI) for the mean was [73.3°, 78.0°] for the ANSI A14 method and [74.1°, 78.2°] for the fireman method.

Performance Angle

The 2 × 3 × 2 × 2 (Experience × Method × Ladder × State) ANOVA on the angle variable revealed significant effects of method, ladder, and state as well as significant interactions of method and experience, method and ladder, and ladder and state (p < .05).

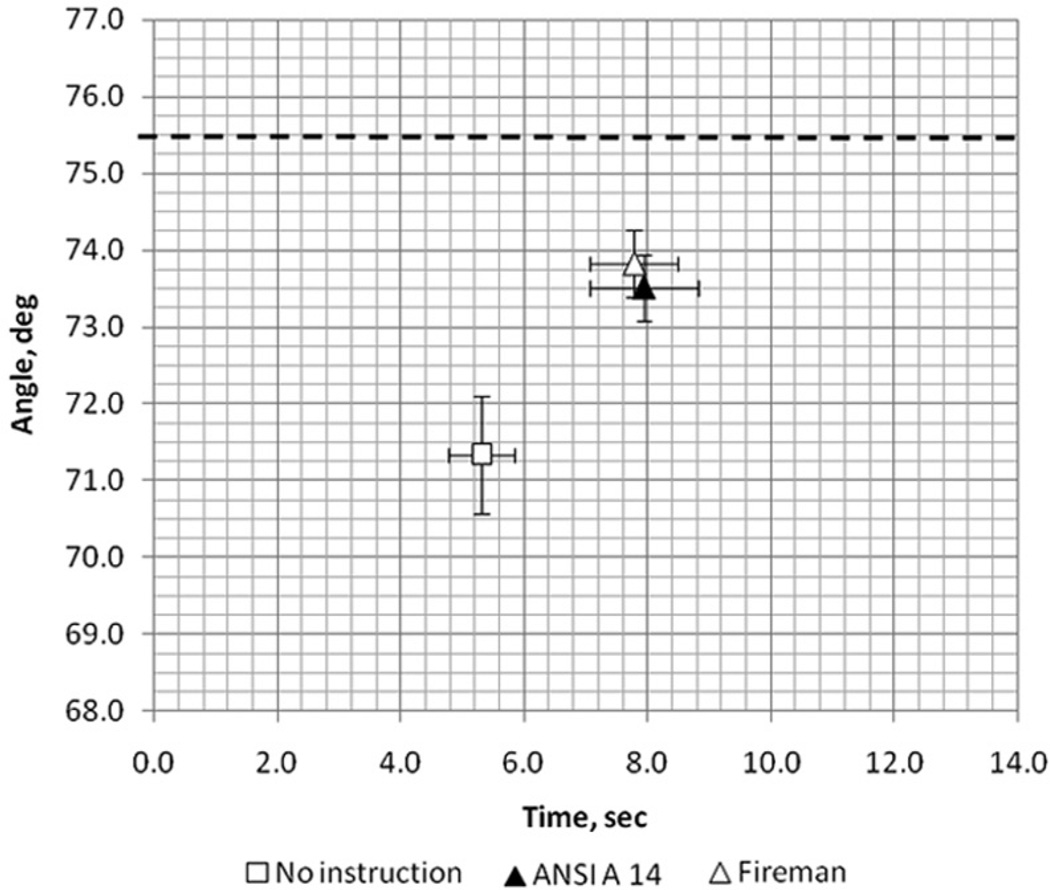

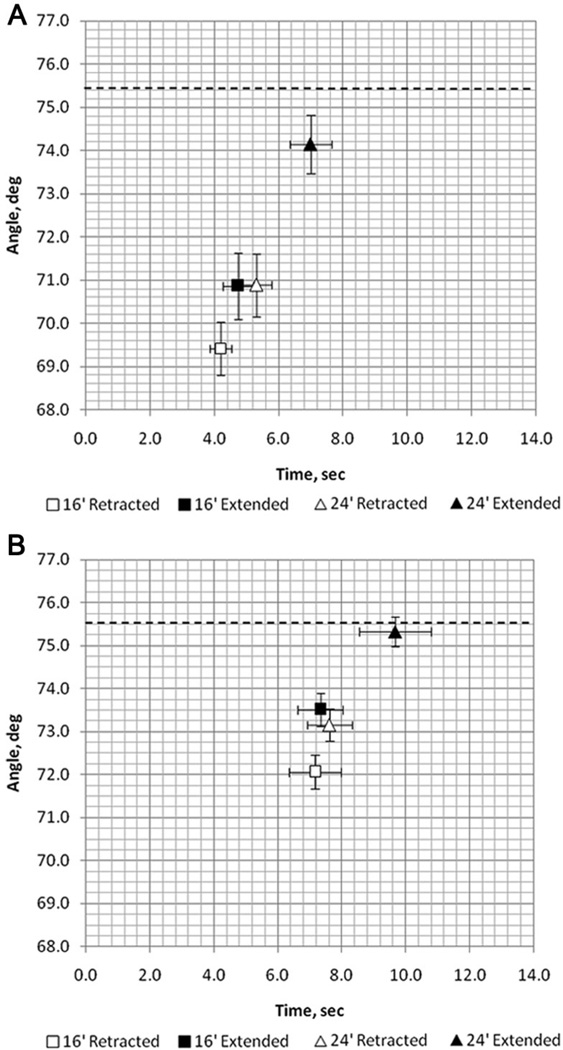

Method had a strong effect on angle (Figure 5). The no-instruction method resulted in a relatively shallow angle: an average of 71.3°. The ANSI A14 and fireman methods improved significantly (p < .001) the ladder angle with similar averages of 73.5° and 73.8°, respectively, but still underperformed as compared with the recommended angle (75.5°; p < .001). The Method × Ladder interaction further indicated that the effects of the anthropometric methods were significantly (p = .0033) larger for the 4.88-m (16-ft) as compared with the 7.32-m (24-ft) ladder (2.8° vs. 1.9° increase from no instruction). For the no-instruction method, the range between the average angle values for the shortest, 4.88-m (16-ft) retracted, and the longest, 7.32-m (24-ft) extended, ladder conditions was 69.4° to 74.1° (Figure 6A). Of the anthropometric approaches, the average ranges were 72.0° to 75.3° for the ANSI A14 method (Figure 6B) and 72.5° to 75.7° for the fireman method.

Figure 5.

Summarized effect of method on ladder positioning performance in ladder angle and execution time. Error bars represent standard error. Dashed line indicates the standard recommended angle of 75.5°.

Figure 6.

Interaction of ladder type and extended state on ladder positioning performance. (A) No-instruction method. (B) Standard anthropometric method. Error bars represent standard error. Dashed line indicates the standard recommended angle of 75.5°.

Post hoc tests for the Method × Experience interaction indicated significant (p = .0209) advantage (0.71° increase) of the fireman method compared with the ANSI A14 method only for the inexperienced ladder users.

The variability in the ladder positioning angle, expressed as 95% CI, was [62.4°, 81.8°] for the no-instruction method, [67.6°, 79.2°] for the ANSI A14, and [67.9°, 80.1°] for the fireman method. The probability of positioning a ladder at an angle of less than 70° was 35.6% for the no-instruction method, 9.5% for the ANSI A14 method, and 9.2% for the fireman method.

The ladder and state variables had significant (p < .001) main and interaction effects on angle: Shorter ladders and retracted ladders were consistently positioned at shallower angles than were longer ladders and extended ladders, with a larger state effect for the 7.32-m (24-ft) as compared with the 4.88-m (16-ft) ladder (Figure 6A). Post hoc tests revealed no significant difference in setup angles between the two ladder conditions with equal length (13 ft), that is, between the 4.88-m (16-ft) extended and the 7.32-m (24-ft) retracted ladders.

Performance Time

The 2 × 3 × 2 × 2 (Experience × Method × Ladder × State) ANOVA on the time variable revealed significant effects of method, ladder, and state as well as a significant interaction of ladder and state (p < .05).

Method had a strong effect (p < .001) on time (Figure 5). Positioning a ladder by the no-instruction method required, on average, 5.3 s. Both anthropometric methods required, on average, approximately 7.9 s, which was 50% longer than with the no-instruction method. Positioning time was also significantly affected by the ladder and state variables (p < .001) as well as their interaction (p < .001). Shorter ladders and retracted ladders required less time for positioning than did longer ladders and extended ladders, with a larger state effect for the 7.32-m (24-ft) as compared with the 4.88-m (16-ft) ladder. Post hoc tests revealed no significant difference in setup time between the two ladder conditions with equal length (13 ft), that is, between the 4.88-m (16-ft) extended and the 7.32-m (24-ft) retracted ladders. With the no-instruction method, the range between the setup time for the 4.88-m (16-ft) retracted ladder (the fastest) and the setup time for the 7.32-m (24-ft) extended ladder (the slowest) was 4.19 s to 6.99 s (Figure 6A). The overall slower anthropometric methods resulted in a similar time range of 7.16 s to 9.66 s between the different ladders and ladder extended positions (Figure 6B).

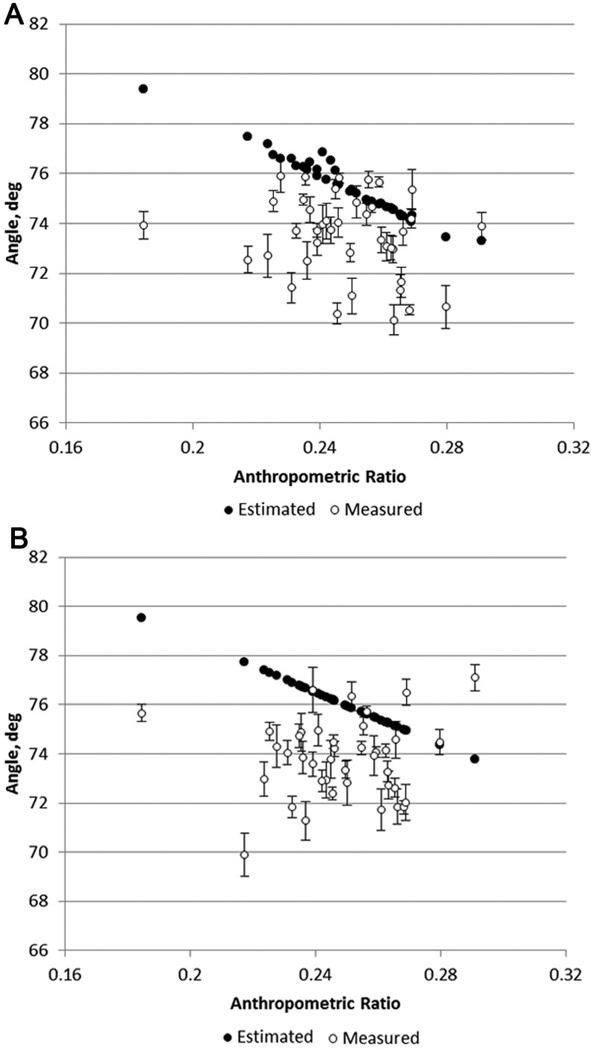

Comparison of Estimated and Performance Angles

The estimated and performance (measured) angle values for the anthropometric methods are displayed as a function of anthropometric ratio in Figure 7. The anthropometric ratio (grip reach – ankle to toe length / shoulder height) captures all major anthropometric variables and allows for good visualization of the associated variation in ladder setup angles. A comparison between the performance angle data and the estimated angle data for the anthropometric methods revealed that the anthropometric differences accounted for less than half of the total variability for both the ANSI A14 and fireman methods: For estimated angle, SD = 1.2° and 1.0°; for angle, SD = 2.4° and 2.5°, respectively. Furthermore, the large variability related to ladder effective length was persistent throughout the results for participants within the whole range of anthropometric ratios (Figures 7A and 7B).

Figure 7.

Estimated and measured angles as related to participants’ anthropometric ratio. (A) ANSI A14. (B) Fireman. Error bars represent standard error.

DISCUSSION

The results of this study provided valuable insight into the factors defining the positioning angle for extension ladders and the efficiency of the current ANSI A14 method and the fireman method.

No-Instruction Method

Without any instruction, ladder users positioned the ladders at a considerably shallower angle than the standard recommended angle, and there was a 35.6% probability for positioning ladders at an angle of less than 70°. The average angle of 71.3° found in this study is consistent with the average angle (71.9°) found by Irvine and Vejvoda (1977) and with the observations of Dewar (1977) that straight and extension ladders are most commonly used at roughly 1:3 (71.6°) slope. Other experimental and field studies have reported even lower ladder positioning angles, with averages in the range of 66° to 68° (Häkkinen et al., 1988; Morse, Ryan, & Henrikson, 1999; Young & Wogalter, 2000).

With steeper ladder angles (75° vs. 70°), there is an increase in the feeling of insecurity from falling backward, increased awkwardness in climbing the ladder, and a greater risk of stumbling during the climbing cycle, which drive workers to the tendency of setting shallow positioning angles (Dewar, 1977). In addition, with steeper ladder angles, the required moments and forces of hands and feet are increased (Bloswick & Chaffin, 1990), and it is more difficult to maintain balance (Dewar, 1977). The findings from this study along with the literature demonstrate the need for effective and reliable methods to help ladder users overcome their inherent tendency for setting ladders at a shallower-than-recommended angle.

The significant ladder and state effects on angle in the no-instruction condition imply a considerable influence of the ladder effective length on the setup angle. Consistently, Irvine and Vejvoda (1977) and Young and Wogalter (2000) found similar effects of ladder length on the ladder positioning angle. These effects may reflect ladder users’ perceptions in the initial climbing phase that it is easier to tip over a shorter and lighter ladder than a longer and heavier ladder.

From the perspective of psychophysics, it is more likely that the ladder center-of-mass (COM) location is the real influencing factor on ladder angle positioning. When setting up the ladder, users may estimate the relative location of the COM of the ladder-worker system during the initial climbing phase and may subconsciously try to minimize the perceived risk of the ladder’s tipping backward. For shorter and lighter ladders, a shallower angle will increase the ladder COM arm and the corresponding momentum, counteracting any ladder tipping force.

From the perspective of biomechanics, a lighter ladder requires less effort and work to lift and handle than does a heavier ladder, and thus its base could be easily pulled relatively farther during positioning, leading to a shallower angle. However, post hoc tests revealed no significant difference in setup angles between the two ladder conditions with different weight and equal length (13 ft), that is, between the 4.88-m (16-ft) extended and the 7.32-m (24-ft) retracted ladders, which implied the dominant influence of ladder length (and COM location) versus ladder weight.

It is important to note, however, that from the aspect of statics, the risk for ladder base slide-out during the final portion of the climbing phase is considerably higher for the shorter and lighter ladders as compared with the tall and heavy ladders—a risk that is not immediately and easily perceived and that puts the ladder user in a more dangerous situation with shorter ladders, since they are consistently positioned at shallower angles.

Anthropometric Methods

Estimated angles

The estimated ladder angles based on participants’ anthropometry indicate that both the ANSI A14 and the fireman method lead theoretically to very accurate (close to 75.5°) average angle values with relatively small variability. This finding is in contrast with some of the earlier estimates, based on published and experimental anthropometric data, of lower average ladder angles (Irvine & Vejvoda, 1977; Young & Wogalter, 2000). It should be noted that the current study accounted for the effects of shoes (as opposed to the barefoot condition used in the traditional anthropometric charts), which increase both the effective shoulder height and the distance from ladder base to ankles and thus can lead to more than 1° increase of the estimated ladder angles.

Performance data

As demonstrated by the significant effect of method on angle, the ANSI A14 method considerably improved the ladder positioning angle (2.2° increase) as compared with the no-instruction method. However, the average result (73.5°) for the standard method in this study was still lower than the recommended angle (75.5°) and was associated with relatively large variability. Although the method (when followed correctly) remains a viable approach for improving the extension ladder positioning angle, there was a 9.5% probability of setting the ladder at a less-than-70° angle. Further enhancements in the ladder positioning methodology may be needed to reduce the associated large variability.

As indicated by the significant effect of method on time, the ANSI A14 method required longer time (by 2.46 s) than did the no-instruction method. This finding should be expected since the anthropometric method involves an iterative check-and-correct procedure that could take more than one adjustment trial. Although the increase in time was relatively small, it may still be a contributing factor for potentially lower user acceptance and application rates for the method, likely because of perceived reduced productivity.

The estimated variability attributed to anthropometric differences for the participants in this study was less than half of the performance variability associated with the anthropometric methods: For estimated angle, SD = 1.2° and 1.0°, and for angle, SD = 2.4° and 2.5°, for the ANSI A14 and the fireman method, respectively. The larger performance variability of anthropometric methods could be explained in part by the significant effects of ladder and state (i.e., ladder COM or effective length). Even with the anthropometric methods, ladders with shorter working lengths were generally positioned at shallower angles. Enhanced instructions and specific training procedures for the anthropometric methods may be needed to improve their positioning accuracy.

The lack of a main effect of experience on ladder positioning performance is likely related to the fact that the anthropometric methods rely on geometrical relations, such as human dimensions ratios, and thus may remain less sensitive to the skills developed during work experience. However, the significant effect of method only for the inexperienced group suggests that the experienced participants may have developed a more stable body posture–ladder model, which could not be affected by the difference in the two anthropometric methods.

The large discrepancy between the estimated and measured ladder angles both in averages and in variability indicates that participants’ body posture diverged considerably from the theoretical assumptions of posture verticality and linear arms alignment. Although some of these deviations may be random, the results suggest the strong association of body posture variations with ladder COM or effective length. Actual observations during the tests revealed that most ladder users first positioned their ladder according to their perception or physical estimation (close to the no-instruction method) and then made some minor corrections; in many cases, they adjusted their posture to the ladder position to confirm an imperfect anthropometric method.

The fireman method tested in this study did not show statistically significant advantage to the standard method in either angle (0.3° increase) or time (0.2-s decrease) and therefore should be considered similar to the ANSI A14 standard method. Given that the estimated ladder angle values revealed that the fireman method reduced the variability of angles as compared with that of the ANSI A14 method, the fireman method can be a good alternative to the current ANSI A14 method.

Limitations

Some of the results of this study may not be directly applicable to every work situation, since the tests were done in a laboratory environment with simple geometry. In real work environments, the nature of the support surface, terrain slope, and profile may affect ladder user safety perceptions and ladder setup decisions. An improper ladder positioning angle may also be a consequence of a confined work area or of using a ladder that is too short or too long for the job; in such cases, other equipment, such as scaffolds or work platforms, may be a better choice than ladders (Cohen & Lin, 1991).

The test setup in this study may have influenced to some extent the ladder positioning performance results. Specifically, the wall section edges and the presence of other ladders in the vicinity, leaning in a near-vertical position on the wall, may have provided additional vertical cues to the participants and thus modified their performance, mostly in the no-instruction method. Some visual factors may alter perceptions and have been shown to affect the ladder setup angle (Bloswick & Crookston, 1992).

The smaller number of female participants in the experienced as compared with the inexperienced group in this study may be a good representation of the ladder user population in the real world; however, it may have influenced to some extent the results for the effects of experience. Earlier studies reported generally higher estimates for ladder setting angles for female versus male ladder users (Irvine & Vejvoda, 1977).

CONCLUSION

Ladder users tend to position extension ladders at shallower angles than recommended by the current standard. This tendency is especially strong for shorter ladders, which would be at increased risk for slide-out fall incidents.

The current ANSI A14 anthropometric method for extension ladder setup remains a valid approach for safe ladder positioning when accurately and correctly performed. An alternative to the method, with similar performance, is the fireman anthropometric method. Both anthropometric methods underperform as compared with the theoretical estimates from users’ anthropometry.

The variability in ladder angle setting was affected by ladder COM (or effective length) along with individual anthropometry differences. Enhanced instructions and training procedures for the anthropometric methods, with specific emphasis on shorter ladders, may be needed to improve their positioning accuracy.

Key Points.

Users have a natural tendency to position extension ladders at suboptimal angles; without instruction, there was a 35.6% probability for positioning ladders even at a less-than-70° angle.

Estimates from human anthropometry indicated that the current American National Standards Institute (ANSI) A14 method for ladder positioning can be useful; results from ladder positioning trials, however, showed that on average, workers set their ladders below the recommended angle, and 9.5% of workers set the ladder at even less than 70° when using the anthropometric method.

The variability in ladder positioning angles was largely attributed to ladder center-of-mass location (or effective length), aside from differences in human anthropometry.

Although the fireman method did not show a statistically significant advantage to the current ANSI A14 method in angle (0.3° increase) or time (0.2-s decrease), it demonstrated a smaller variability in estimated ladder setup angle as compared with that of the standard ANSI A14 method and thus can be a good alternative to the current ANSI A14 method.

Biographies

Peter Simeonov is a safety engineer in the Protective Technology Branch, Division of Safety Research, at the National Institute for Occupational Safety and Health (NIOSH) in Morgantown, West Virginia. He received his PhD in technical sciences and civil engineering materials from the Bulgarian Academy of Science in Sofia, Bulgaria, in 1987.

Hongwei Hsiao is the chief of the Protective Technology Branch, Division of Safety Research, at NIOSH and an adjunct professor at West Virginia University in Morgantown. He received his PhD in industrial engineering from the University of Michigan in Ann Arbor in 1990.

In-Ju Kim is a visiting fellow in the Protective Technology Branch, Division of Safety Research, at NIOSH in Morgantown, West Virginia. He received his PhD in applied biomechanics and ergonomics from the University of Sydney in Sydney, Australia, in 2001.

John R. Powers, Jr., is an electrical engineer and team chief with the Protective Technology Branch, Division of Safety Research, at NIOSH in Morgantown, West Virginia. He received a BS in electrical engineering from the Pennsylvania State University in 1988.

Tsui-Ying Kau is the clinical information analyst staff specialist-statistician of Clinical Information and Decision Support Services, Office of Clinical Affairs, Hospitals and Health Centers, at the University of Michigan, where she received her MPH in biostatistics in 1981.

Footnotes

The author(s) of this article are U.S. government employees and created the article within the scope of their employment. As a work of the U.S. federal government, the content of the article is in the public domain.

The findings and conclusions in this report are those of the authors and do not necessarily represent the views of the National Institute for Occupational Safety and Health. Mention of the name of any company or product, or inclusion of any reference, does not constitute endorsement by the National Institute for Occupational Safety and Health.

Contributor Information

Peter Simeonov, National Institute for Occupational Safety and Health, Morgantown, West Virginia.

Hongwei Hsiao, National Institute for Occupational Safety and Health, Morgantown, West Virginia.

In-Ju Kim, National Institute for Occupational Safety and Health, Morgantown, West Virginia.

John R. Powers, National Institute for Occupational Safety and Health, Morgantown, West Virginia

Tsui-Ying Kau, University of Michigan, Ann Arbor, Michigan.

REFERENCES

- American Ladder Institute. American National Standards Institute (ANSI) A14.2: American national standard for ladders–Portable metal–Safety requirements. Chicago, IL: Author; 2007. [Google Scholar]

- Bloswick DS, Chaffin DB. An ergonomic analysis of ladder climbing activity. International Journal of Industrial Ergonomics. 1990;6:17–27. [Google Scholar]

- Bloswick DS, Crookston G. The effect of personal, environmental and equipment variables on preferred ladder slant. In: Kumar S, editor. Advances in industrial ergonomics and safety. Vol. 4. New York, NY: Taylor and Francis; 1992. pp. 1015–1020. [Google Scholar]

- Bureau of Labor Statistics. National census of fatal occupational injuries in 2008: Table A-9. Washington, DC: U.S. Department of Labor; 2010a. Retrieved from http://www.bls.gov/iif/oshwc/cfoi/cftb0240.pdf. [Google Scholar]

- Bureau of Labor Statistics. 2008 survey of occupational injuries and illnesses: Table R31. Number of nonfatal occupational injuries and illnesses involving days away from work. Washington, DC: U.S. Department of Labor.; 2010b. Retrieved from http://www.bls.gov/iif/oshwc/osh/case/ostb2113.pdf. [Google Scholar]

- Chang WR, Chang CC, Matz S, Son DH. Friction requirements for different climbing conditions in straight ladder ascending. Safety Science. 2004;42:791–805. [Google Scholar]

- Cohen HH, Lin LJ. A scenario analysis of ladder fall accidents. Journal of Safety Research. 1991;22:31–39. [Google Scholar]

- Dewar ME. Body movements in climbing a ladder. Ergonomics. 1977;20:67–86. doi: 10.1080/00140137708931602. [DOI] [PubMed] [Google Scholar]

- Häkkinen KK, Pesonen JP, Rajamäki E. Experiments on safety in the use of portable ladders. Journal of Occupational Accidents. 1988;10:1–9. [Google Scholar]

- Hepburn HA. Portable ladders: The quarter length rule. British Journal of Industrial Safety. 1958;4(46):155–158. [Google Scholar]

- Hsiao H, Simeonov P, Pizatella T, Stout N, McDougall V, Weeks J. Extension-ladder safety: Solutions and knowledge gaps. International Journal of Industrial Ergonomics. 2008;38:959–965. [Google Scholar]

- International Labor Office. Model code of safety regulations for industrial establishments for the governance of governments and industry. Geneva, Switzerland: Author; 1949. Regulation 211: Equipment and tools; p. 403. [Google Scholar]

- Irvine CH, Vejvoda MV. An investigation of the angle of inclination for setting non-self-supporting ladders. Professional Safety. 1977 Jul;:34–39. [Google Scholar]

- Morse JS, Ryan LD, Henrikson E. Minimizing extension ladder slide-out accidents; Paper presented at the ASAE/CSAE Annual International Meeting; Toronto, Canada. 1999. Jul, [Google Scholar]

- Pesonen JP, Häkkinen KK. Evaluation of safety margin against slipping in a straight aluminum ladder. Hazard Prevention. 1988;24:6–13. [Google Scholar]

- Young SL, Wogalter MS. On improving set-up angle accuracy for extension ladders; Paper presented at the IEA 2000/HFES 2000 Congress; San Diego, CA. 2000. Jul-Aug. [Google Scholar]