Abstract:

Electrical failure during cardiopulmonary bypass (CPB) has previously been reported to occur in 1 of every 1500 cases. Most heart—lung machine pump consoles are equipped with built-in battery back-up units. Battery run times of these devices are variable and have not been reported. Different conditions of use can extend battery life in the event of electrical failure. This study was designed to examine the run time of a fully charged battery under various conditions of pump speed, pressure loads, pump boot material, multiple pump usage, and battery life. Battery life using a centrifugal pump also was examined. The results of this study show that battery life is affected by pump speed, circuit pressure, boot stiffness, and the number of pumps in service. Centrifugal pumps also show a reduced drain on battery when compared with roller pumps. These elements affect the longevity and performance of the battery. This information could be of value to the individual during power failure as these are variables that can affect the battery life during such a challenging scenario.

Keywords: electrical failure, battery life, heart lung machine

The pump console used at our institute is a Jostra HL20, (Jostra AB, Lund, Sweden), unit with four single modular roller pumps or a combination of three roller pumps with a centrifugal pump. The unit comes with a 24-volt inbuilt battery pack in the base of the console. The batteries consist of 2 dryfit 30-A/hour, 12-volt, gel-filled batteries. The main input voltage to the console control module is constantly monitored. Should the line voltage fall to less than 85% of the nominal voltage (220 volts), the unit automatically switches to battery operation. This battery system will run the complete system, all pumps, supervisory modules, monitoring, and data recording in the event of power failure.

The total length of battery operation time reported by the manufactures of a complete system, one arterial at 4 litres per minute (LPM) (156 rpm), three ancillary pumps (50 rpm), pump display and system monitoring is approximately 1.5 hours. Battery operation time depends on the conditions of the battery and the load powered by the batteries.

Electrical failure during CPB has previously been reported to occur 1 in every 1500 cases (1). Having suffered a number of electrical failures in our institute (2), we feel that battery back-up is essential for the bypass machine. However, knowledge of battery drain of these devices and factors affecting them is essential to decide how long to run the bypass machine and estimate how long CPB can continue or when, if possible, the procedure can be postponed.

METHOD

Fully discharged Jostra pump batteries were charged overnight before each test for a minimum of 12 hours. Closed system circuits were assembled for each of the trials. The system comprised a Jostra oxygenator (Jostra AG, Hirrlingen, Germany) and aterial—venous tubing and pumps. The circuit was primed with 1.2 L of Hartmann’s solution.

The Jostra console has a monitoring unit that records data to a memory card. This card can be read on a standard computer with appropriate software. The run time of the pump was recorded automatically, eliminating the need for the manual observations. Before each test, the memory card was initialized and the test noted on the memory card. Manual observation was necessary only during battery voltage drop monitoring versus time.

Test 1

Using the arterial pump, only the prime was circulated at 200 rpm at a pressure of 180 mmHg using a silastic boot. The arterial outlet pressure was achieved by partially clamping the arterial outlet using a gate clamp. Voltage was recorded ever 15 minutes until the pump stopped. Battery run time was noted.

Test 2

The prime was circulated at different speeds (100 rpm and 200 rpm) using the arterial pump. The arterial outlet pressure was 180 mmHg. Battery run time was recorded.

Test 3

Using the roller pump with silastic boot the prime was circulated at 156 rpm (4 LPM), nonpressurized, using an arterial pump and then using 1, 2, and then 3 additional pumps at 50 rpm. Battery life was recorded. This was repeated with an arterial outlet pressure of 180 mmHg.

Test 4

Test 3 was repeated with an arterial outlet pressure of 180 mmHg and repeated with a roller pump with a 3/8-inch PVC boot and an arterial outlet pressure of 180 mmHg.

Test 5

Using a different pump console with an older circuit, one that was 15 months old, the prime was circulated at 156 rpm (4 LPM) using the arterial pump.

Test 6

A comparison was made between different pump types. A Jostra centrifugal pump, (Jostra AB), was incorporated into the circuit. The prime was circulated at a speed of 4 LPM and a pressure of 180 mmHg. The battery run time was recorded.

It should be noted that the monitoring and data collection system on the Jostra system cannot be shut down to conserve battery life and will be draining current for the duration of the procedure irrespective of the number of pumps in use. Each test was run in triplicate and all data are presented as mean.

RESULTS

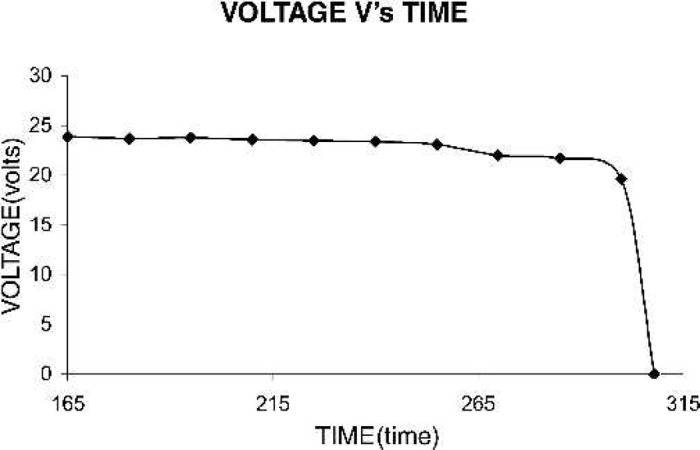

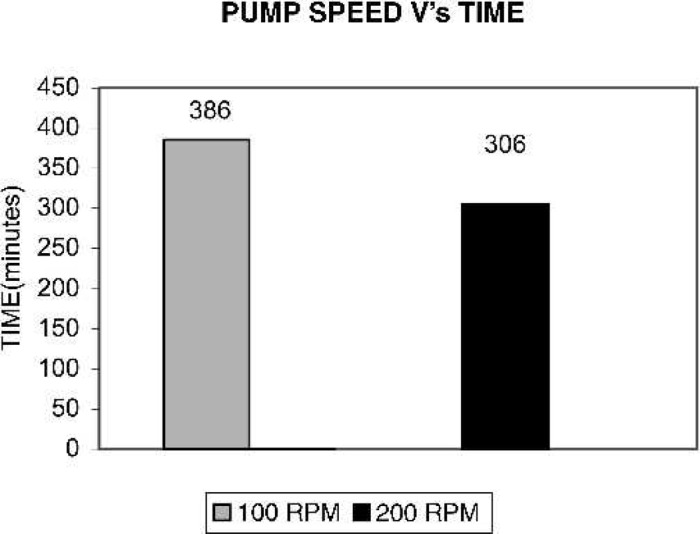

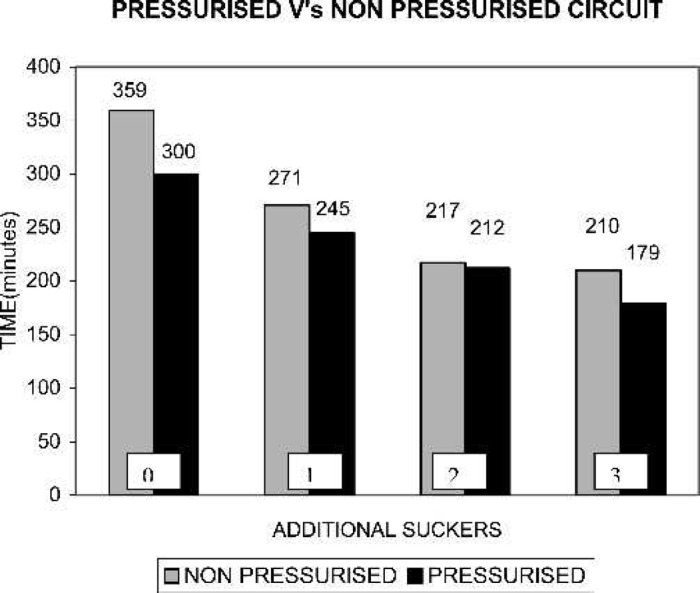

Figure 1 illustrates battery run time versus voltage drop of a roller pump at 200 rpm using no additional pumps with arterial outlet pressure of 180 mmHg. The run time of the battery was 308 minutes. Figure 2 is a comparison of the run time in minutes of a roller pump with silastic boot at 100 and 200 rpm, pressurized to 180 mmHg using no additional pumps. Figure 3 shows the battery run time of a roller pump at 156 rpm (4 LPM) using additional pumps in a pressurized and nonpressurized circuit.

Figure 1.

Battery run time versus voltage drop of a roller pump at 200 rpm using no additional pumps with arterial outlet pressure of 180 mmHg. The run time of the battery was 308 minutes.

Figure 2.

Comparison of the run time in minutes of a roller pump with silastic boot at 100 and 200 rpm, pressurized to 180 mmHg using no additional pumps.

Figure 3.

Battery run time of a roller pump at 156 rpm (4 LPM) using additional pumps in a pressurized and nonpressurized circuit.

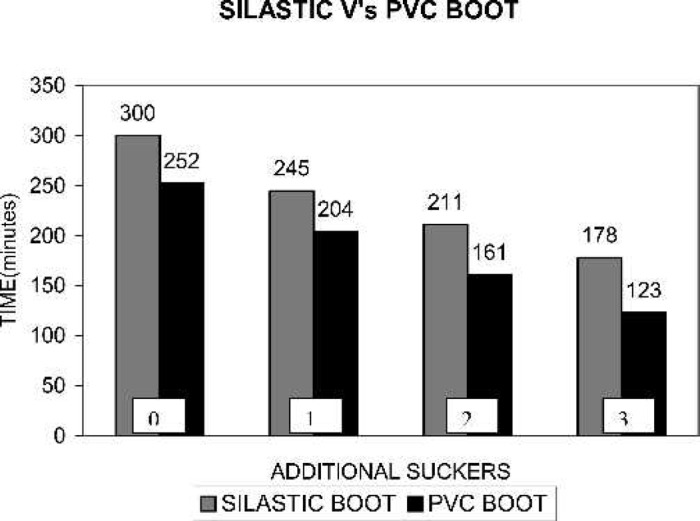

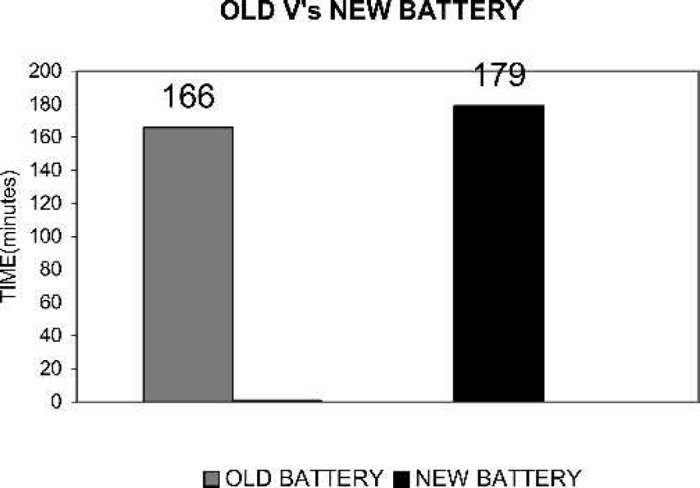

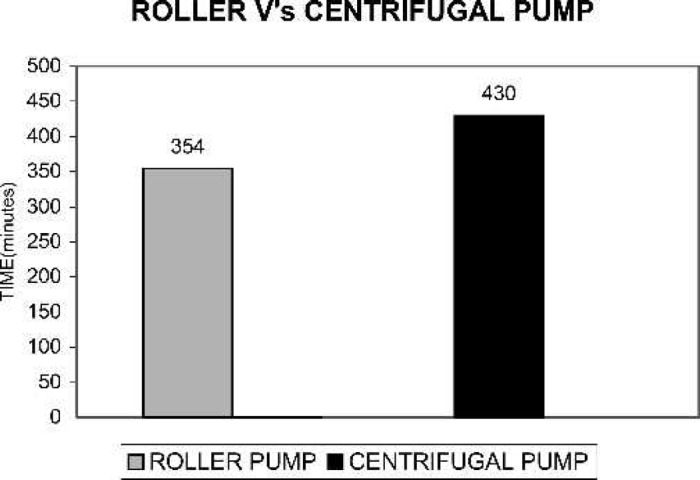

Figure 4 shows the life of a battery powering a roller pump with silastic boot pressurised to 180 mmHg using 0, 1, 2, and 3 additional pumps compared to the battery life of a roller pump with PVC boot using 0, 1, 2, and 3 additional pump also pressurized to 180 mmHg. Figure 5 shows the run times of a new and old battery pack powering a roller pump using 3 additional pumps and pressurized to 180 mmHg. Figure 6 is a comparison of the run time of a battery powering a centrifugal pump and a roller pump at a speed of 156 rpm, pressurised to 180 mmHg and using no additional pumps.

Figure 4.

Life of a battery powering a roller pump with silastic boot pressurized to 180 mmHg using 0, 1, 2, and 3 additional pumps compared with the battery life of a roller pump with PVC boot using 0, 1, 2, and 3 additional pumps also pressurized to 180 mmHg.

Figure 5.

The run times of a new and old battery pack powering a roller pump using 3 additional pumps and pressurized to 180 mmHg.

Figure 6.

Comparison of the run time of a battery powering a centrifugal pump and a roller pump at a speed of 156 rpm, pressurized to 180 mmHg and using no additional pumps.

DISCUSSION

Adequate knowledge of the battery life during electrical failure in the heart lung pump consoles by the perfusionists is necessary to conserve battery life. The consequence of power failure can be catastrophic. In a recent study to identify incidents occurring in centers performing CPB showed that during a 2-year period 267 incidents of 4882 required hand cranking of the machine or the machine that had power interrupted (3). In this study, we demonstrate a variety of factors that affect power consumption of batteries of a heart lung pump console during simulated electrical failure.

As stated by the manufacture’s guidelines and as seen in Figure 1, the voltage of a battery during electrical failure drops relatively slowly at the beginning of use. As the battery becomes exhausted, the voltage drops more rapidly. When the voltage has dropped to 22 volts, there is only enough for a few more minutes of operation. The system warns the operator of an impending halt by sounding a double bleep that cannot be silenced, and the battery operation lamp on the console flashes. When the battery drops to 19.2 volts, operation of the pump motor becomes unpredictable and the system halts. The life of a battery powering a roller pump using no additional pumps at 200 rpm was 308 minutes.

The effects of the main arterial pump speed on battery life were examined. From Figure 2, it can be seen by doubling the pump speed from 100 rpm to 200 rpm, battery life is reduced by 20%. It would indicate that by using larger tubing in the roller raceway would help to reduce the revolution thus reducing battery drain.

The difference in the life of a battery, powering a roller pump in a pressurized circuit and nonpressurized using additional pumps was examined. Figure 3 shows the life of a battery in minutes using a pump at 156 rpm (4 LPM), nonpressurized and then pressurized, using 1, 2, and 3 additional pumps at 50 rpm. The average difference in battery life between the pressurized and the nonpressurized circuit was 10%. Taking account of the cumulative effects of the number of pumps in service the results indicate that the average decrease in battery life for each additional pump used was 14%.

In test 4, we examined the effects of increased boot stiffness. Increased boot stiffness decreases battery life. At 156 rpm (4 LPM), the average difference in battery life between the circuit with a silastic boot and PVC boot was 20%.

The effects of battery age on battery run times can be seen in Figure 5. We examined the effects of age by comparing the run times of a pump utilizing a new and old pump console. The run times of both batteries in the consoles were similar. Powering a roller pump at 156 rpm using 3 additional pumps battery life of the new and old batteries were 167 minutes and 179 minutes, respectively. The life of properly maintained batteries is not altered noticeably with age. In our unit, batteries are changed every 2 years as part of the routine maintenance of the heart—lung machine.

The results in Figure 6 also show that the use of a centrifugal is less draining on battery power than a roller pump. The life of a battery powering a roller pump and centrifugal pump was 354 minutes and 430 minutes, respectively, a difference of 18%.

On the basis of results, one is encouraged to take account of the factors affecting battery life during electrical failure. Knowledge of these results will alert the perfusionist to necessary termination of systems to conserve battery life.

CONCLUSION

This study was conducted as an investigation into heart—lung machine battery life under a variety of conditions. The result of the study demonstrates that the run time of a battery pack may far exceed manufactures guidelines. The manufacture state that the total length of battery operation of a complete system (one arterial pump at 156 rpm, 3 sucker pumps [50 rpm], pump displays and monitoring systems) is approximately 90 minutes. Our study demonstrates that the battery life actually lasts longer, i.e., 179 minutes for the same system. These results show that the run time of a battery back-up pack is affected by the number of pumps in use, pressure load on the circuit, boot material, and type of pump used. These factors affect the longevity and performance of the battery. This information could be of value to the individual who encounters catastrophic institutional power failure or who is transporting a patient on battery power. Perhaps, perfusion teams can use the methods mentioned as a model to test and appreciate the limitations of their own battery power systems.

REFERENCES

- 1.Kurusz M, Conti VR, Arens JF, Bowene TP, Faulkner SC, Manning JV.. Perfusion accident survey. Proc Am Acad Cardiovasc Perfusion. 1986;7:57–65. [Google Scholar]

- 2.Hargrove M, Ramish BD, O’Donnell A, Aherne A.. Electrical failure during cardiopulmonary bypass: An evaluation of incidence, cause, management and guidelines for preventive measure. Perfusion. 2002;17:369–72. [DOI] [PubMed] [Google Scholar]

- 3.Stammers AH, Mejak BL, Rauch E, et al. An update on perfusion safety: Does the type pf perfusion pratice affect the rate of incidents related to cardiopulmonary bypass. Perfusion. 2001;16:189–98. [DOI] [PubMed] [Google Scholar]