Abstract

A leading cause for extension ladder fall incidents is a slide-out event usually related to suboptimal ladder inclination. An improved ladder positioning method or procedure could reduce the risk of ladder stability failure and the related fall injury. The objective of the study was to comparatively evaluate the effectiveness of a multimodal angle indicator with other existing methods for extension ladder angular positioning.

Twenty experienced and 20 inexperienced ladder users participated in the study. Four ladder positioning methods were tested in a controlled laboratory environment with 4.88 m (16 ft) and 7.32 m (24 ft) ladders in extended and retracted positions. The positioning methods included a no-instruction method, the current standard anthropometric method, and two instrumental methods – a bubble level indicator, and a multimodal indicator providing direct feedback with visual and sound signals. Performance measures included positioning angle and time.

The results indicated that the anthropometric method was effective in improving the extension ladder positioning angle (p < 0.001); however, it was associated with considerable variability and required 50% more time than no-instruction. The bubble level indicator was an accurate positioning method (with very low variability), but required more than double the time of the no-instruction method (p < 0.001). The multimodal indicator improved the ladder angle setting as compared to the no-instruction and anthropometry methods (p < 0.001) and required the least time for ladder positioning among the tested methods (p < 0.001).

An indicator with direct multimodal feedback is a viable approach for quick and accurate ladder positioning. The main advantage of the new multimodal method is that it provides continuous feedback on the angle of the device and hence does not require repositioning of the ladder. Furthermore, this indicator can be a valuable tool for training ladder users to correctly apply the current ANSI A14 standard anthropometric method in ladder angular positioning.

The multimodal indicator concept has been further developed to become a hand-held tool in the form of a smart phone application.

Keywords: Extension ladders, Ladder safety, Angular positioning, Anthropometric method, Angle indicators, Multimodal indicator

1. Introduction

Slipping of ladder base has been identified as a leading cause for ladder fall incidents (Hsiao et al., 2008). The likelihood of a straight ladder base slipping depends on the following factors: angle of ladder inclination, coefficient of friction (COF) between the ladder base and the supporting surface, magnitude of static and dynamic loads on the ladder, the location of the load on the ladder, and the COF between the top of the ladder and the supporting structure (Pesonen and Häkkinen, 1988). Earlier analytical considerations (Hepburn,1958) have shown that the angle of inclination is a critical factor affecting extension ladder stability. Consistently, more recent experimental studies (Chang et al., 2004) have demonstrated that a change in the angle from 75° to 65° nearly doubles the required COF at the ladder base for an extension ladder to remain in balance. Accordingly, the setup angle of inclination has been specifically addressed in the ladder safety standards, both by establishing a recommended angle value and suggesting procedures for achieving the recommended angle value.

The current ANSI A14 standard (ALI, 2000) defines the requirement for angle of inclination as follows: “Portable non-self-supporting ladders should be erected at a pitch of 75.5° from the horizontal for optimum resistance to sliding, strength of the ladder, and balance of the climber. A simple rule for setting up a ladder at the proper angle is to place the base a distance from the wall or upper support equal to one-quarter the effective working length of the ladder (the “quarter length rule”)”. The value of 75.5° has been suggested by earlier practical recommendations (ILO, 1949) and analytical studies (Hepburn, 1958). More recently, Irvine and Vejvoda (1977) studied the preferred angle of inclination for the use of extension ladders and suggested using the “anthropometric method” instead of the “quarter length rule”. The “anthropometric” method instructs the climber to stand at the base of the ladder with toes against the rails and arms outstretched horizontally – the proper angle is achieved when the palms of the hands touch the top of the rung at shoulder level. Since 1990, the anthropometric method has been adopted by the ANSI A14 standard as another practical method for ladder setup and a corresponding anthropometric sticker is provided on the side rail of extension ladders.

Earlier work by Dewar (1977), Häkkinen et al. (1988) and Irvine and Vejvoda (1977) demonstrated that without any instruction on how to set up a ladder or what is the recommended angle, ladder users generally tend to setup ladders at shallower angles than 75.5°. Furthermore, Irvine and Vejvoda (1977) indicated that the application of the anthropometric method would also result on average in shallower angles than the recommended by the standard 75.5°. The limited experimental studies of the anthropometric method indicated relatively large variability in the ladder positioning angle (Young and Wogalter, 2000). A recent comprehensive laboratory evaluation revealed that when correctly performed, the anthropometric method provides improvement in the ladder angular positioning (Simeonov et al., 2012a); the study also suggested that the large variability in the ladder positioning angle was associated with ladder effective length and variability in human anthropometry. With this in mind, development and use of instrumental methods (i.e., angle indicators) should improve compliance with the standard recommendations and thus reduce the risk of ladder slide-out incidents.

Several forms of angle indicators as a ladder positioning assistance tool have been reported in the literature. A bubble level indicator was proposed and patented more than 50 years ago (Thomiszer, 1958) and different variations and technical solutions are still being proposed and developed (Scallo, 2004; Rivers et al., 2008; Marby, 2008), and some products are available on the market both in US and abroad. Work by Young and Wogalter (2000) on the bubble indicator and work by Bloswick and Crookston (1992) on the plumb bob indicator demonstrated excellent accuracy and precision, but also a number of limitations. Most of the known indicators provide indirect feedback of ladder angles since they are attached to the side rail of the ladder. They require iterative adjustments of the ladder and thus most likely longer adjustment time. Recently, a prototype indicator based on solid state electronics with direct multimodal feedback, enclosed in a rung or attached to a rail of an extension ladder, was developed at the National Institute for Occupational Safety and Health (NIOSH) (Simeonov et al., 2012b). The multimodal indicator provides visual and auditory signals as direct feedback indication of proximity to and exact position at the recommended ladder angle during ladder positioning. It is expected that the multimodal indicator will allow for a one-step (non-iterative) setup of the ladder and thus reduce the ladder setup time and increase angle accuracy.

This study comparatively evaluated the effectiveness of four ladder positioning approaches with the hypothesis that an indicator with direct multimodal feedback will improve both the accuracy (angle) and efficiency (time) of ladder setup.

2. Method

2.1. Participants

Twenty experienced ladder users (including 19 male and 1 female) with average age 42.7 (S.D. = 10.0) years, average weight 95.3 kg (S.D. = 26.6 kg), and average height 175.3 cm (S.D. = 8.1 cm); and twenty inexperienced participants (including 13 male and 7 female) with average age 37.2 (S.D. = 13.1) years, average weight 88.2 kg (S.D. = 21.9 kg), and average height 172.8 cm (S.D. = 10.1 cm) were recruited from the Morgantown, WV area. All participants were free of known musculoskeletal problems or balance disorders and had normal vision. All participants gave informed consent and were compensated as approved by the Institutional Review Board of NIOSH.

2.2. Independent variables

2.2.1. Methods for ladder positioning (“Method”) – four levels

Four different methods for extension ladder positioning were compared, including a base-line no-instruction method, the standard anthropometric method, and two instrumental methods using indicators – a bubble level indicator and a multimodal indicator.

For the no-instruction method (“no-instruction”) the participants were told to position the ladder “as if they are going to climb it” without any additional instructions on the recommended ladder angle and ladder setup method.

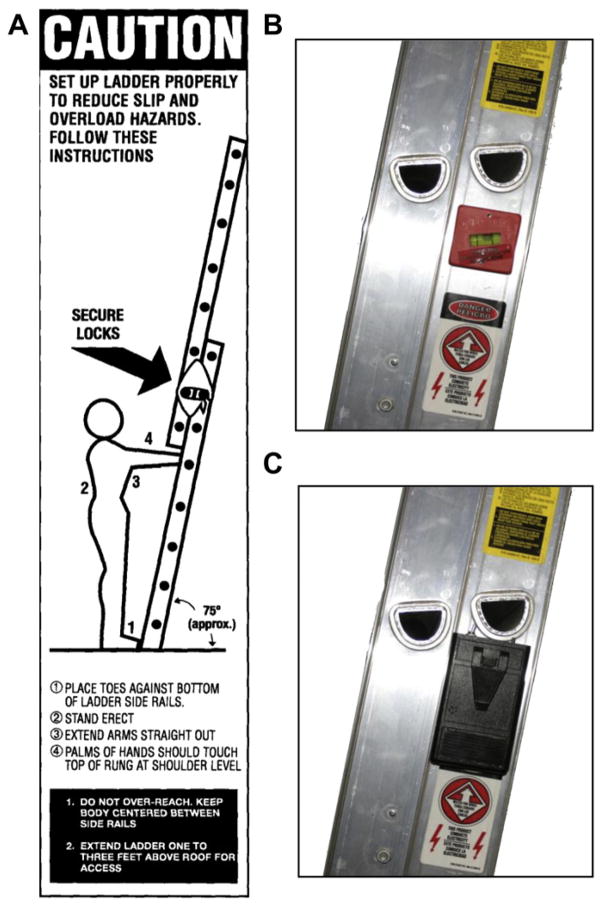

The anthropometric method (“anthropometric”) followed the instructions in the current standard anthropometric label – the participants were guided to make iterative corrections to the ladder angular position by placing the toes of their feet against the ladder rails, standing straight with horizontally extended arms and positioning the palms of their hands against a ladder rung (Fig. 1a).

Fig. 1.

Ladder angular positioning methods: (A) Anthropometric label; (B) Bubble level indicator; (C) Multimodal indicator.

For the bubble level method (“bubble”) the indicator was attached to the ladder rail (Fig. 1b) per manufacturer’s recommendation (Angle-Rite, Safe-T-Climb, Inc., Acton, CA).

The multimodal indicator (“multimodal”) is a ladder accessory which provides visual and auditory signals as direct feedback indication of proximity to and exact position at the recommended ladder angle during ladder positioning (Simeonov et al., 2012b). The proof-of-concept prototype of the multimodal indicator tested in this study was attached to the side of the ladder (Fig. 1c). The prototype consists of a dual axis MEMS-based inclinometer, a 16-bit microcontroller, voltage regulators, vibratory motor, speaker, and LEDs. The microcontroller monitors the output of the inclinometer and provides multimodal feedback (a constant audible and visual signal) to the user while the ladder approaches (i.e., within ±1.5°) the optimal positioning angle of 75.5°.

2.2.2. Ladder size and type (“Ladder”)

Two extension ladders were selected for the tests to represent some of the most frequently purchased extension ladder types at a local home improvement store: a 4.88 m (16 ft) aluminum ladder (Warner, D1100 Series, Type III Duty Rating) weighing 8.4 kg and a 7.32 m (24 ft) aluminum ladder (Warner, D1200 Series, Type II Duty Rating) weighing 15.2 kg. The lower section width and side-rail dimensions were 407 mm and 24 × 70 mm respectively for the shorter ladder and 443 mm and 27 × 77 mm for the longer ladder.

2.2.3. Ladder extended state (“State”)

The ladders were tested in partially retracted (“retracted”) and fully extended (“extended”) states. The partially retracted ladders were extended by only one rung and their effective length was 2.75 m and 3.97 m for the 4.88 m and the 7.32 m ladders respectively. In the extended state the ladders were extended to the maximum length allowable by the standard (with three rungs overlap) and their effective length was 3.97 m and 6.41 for the 4.88 m and the 7.32 m ladders respectively.

2.2.4. Work experience (“Experience”)

The experienced construction workers had more than one year of job-related extension ladder use and the inexperienced participants had no job-related experience with extension ladders.

2.3. Experimental setup

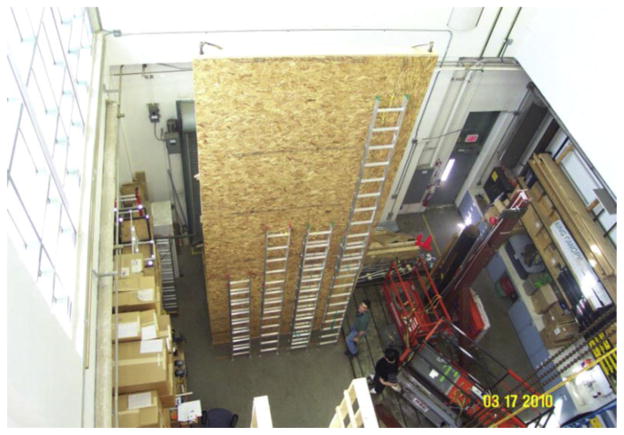

The extension ladder positioning was evaluated in an environment of simple geometry – on a smooth and level concrete floor and a vertical wall free of obstructions in the laboratory. The wall was 7.32 m (24 ft) high and was constructed from wood particle boards (Fig. 2). It was 2.9 m wide allowing the four test ladders to be equally spaced at 0.24 m. The starting position for the ladders was nearly vertical – ladder feet were 0.1 m away from the wall base to allow the ladders to be free standing. To prevent ladder from tipping during the experiment, the ladder tops were tethered to the wall with a loose cord loop. The setting allowed free vertical movement of the ladder top within a required range for unobstructed ladder angular positioning.

Fig. 2.

Experimental setup with the four ladders in the laboratory.

2.4. Experimental procedure

Participants were briefed on the study objectives, methods, procedures and potential risks and completed a questionnaire on extension ladder safety knowledge and experience. Each participant performed a total of 48 trials of ladder angular positioning (16 experimental tasks repeated in 3 consecutive trials). To reduce the potential of learning effects transfer, the participants completed first the no-instruction block of tests, then continued with the anthropometric block, and finished with the instrumental block of tests. In addition, the tests were balanced across conditions within each one of the three blocks: no-instruction method block (1 method × 4 ladder tasks), anthropometric methods block (1 method × 4 ladder tasks), and instrumental methods block (2 methods × 4 ladder tasks). There were 3-min rest intervals between experimental conditions. The participants completed the test session in approximately 2 h.

2.5. Dependent variables

2.5.1. Ladder safety knowledge and experience (“Knowledge and Experience”)

The participants rated their formal and on-the-job knowledge on ladder safety, as well as their experience in lifting, extending, setting up, climbing, working from, and transitioning from/to an extension ladder at height, using the following scale: “none” = 0, “a little” = 1, “some” = 2, and “a lot” = 3. The participants rated their knowledge of 1) the recommended ladder angle-setting method, 2) the minimum required ladder extension above a supporting edge, and 3) the ladder tie-off requirements while using it for transitioning at height using a binary ranking – “knows” or “correct” = 1 and “does not know” or “incorrect” = 0.

2.5.2. Angle of ladder inclination (“Angle”)

The angle of the extension ladder inclination (to the horizontal) was measured after each set up task using a digital inclinometer (Angle/Level V, Dejon Tools & Design, Inc., Covington, OH) with accuracy of 0.1°. The measurements were taken while the inclinometer was positioned on and aligned with one of the ladder rails at the level between the fourth and fifth rung.

2.5.3. Time required for ladder setup (“Time”)

The time required to complete ladder setup was measured using a digital stop watch. The time required for ladder setup was defined and measured in this study from the moment of first touching the ladder after a verbal instruction to start the trial to the moment when finally releasing the ladder after completing the task, as also indicated by a verbal report from the subject.

2.6. Statistical analysis

The effects of participant’s work experience on the self-rated perceptions of education, training, knowledge, and experience was assessed using an exact Wilcoxon two-sample test. The effects of ladder positioning methods, ladder size, ladder extended state, and participant’s work experience on angle and time, were evaluated separately using a mixed model with repeated measures analysis of variance. In the mixed model, the fixed effects included the four independent variables (Method, Ladder, State, and Experience) and the random effects included the correlation within each individual participant. Various models were used to find the appropriate covariance structure of observations within each participant. A model that provided the best fit was selected for final analysis. For post-hoc tests, Tukey–Kramer procedure was used for multiple comparisons. All analyses were performed using SAS/STAT® software.

3. Results

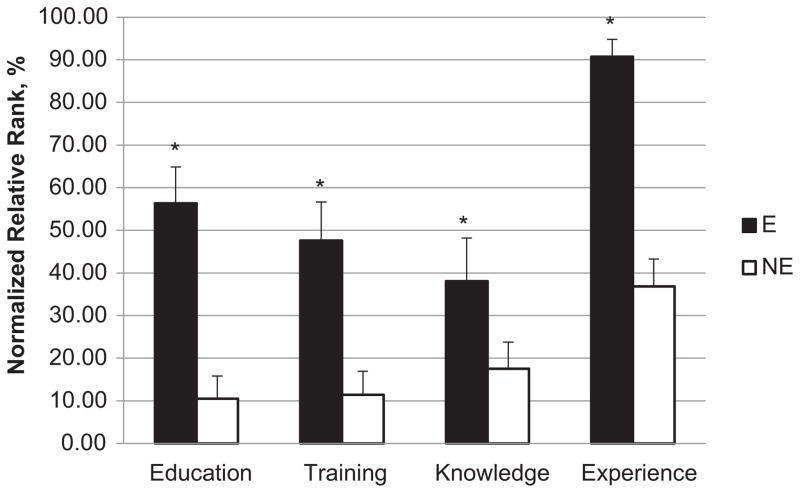

3.1. Knowledge and Experience

Experienced ladder users demonstrated significantly more formal and on the job education (p < 0.001) and training (p < 0.001), and significantly more knowledge (p < 0.05) and experience (p < 0.001) in setting up and using extension ladders than the inexperienced participants group (Fig. 3). However, the knowledge of standard requirements for safe ladder positioning (i.e., the 75.5° angle, min 3 ft. extension above edge, and tie-off requirements) was low for both the experienced (38%) and inexperienced (18%) groups.

Fig. 3.

Participants self-rated extension ladder safety education, training, knowledge and experience. Experienced (E), Not Experienced (NE); * indicates significantly different (α < 0.05).

3.2. Angle

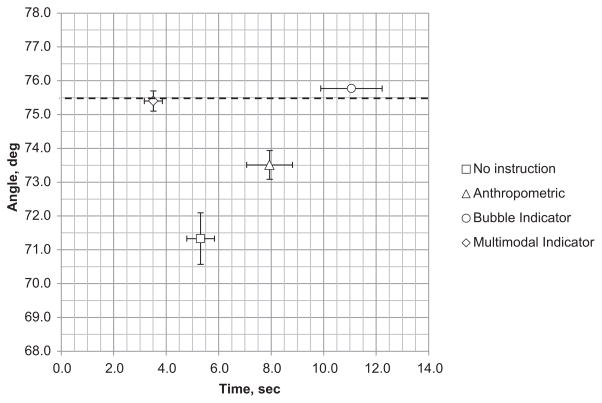

Significant effects on angle (p < 0.001) were observed for Method, Ladder, and Extended State, and for the interactions of Method and Ladder, Method and State, and Ladder and State (Table 1). The “no-instruction” method resulted in a relatively shallow angle – an average of 71.3° (Fig. 4). The anthropometric method improved the ladder angle significantly (p < 0.001) with an average of 73.5°, but still underperformed as compared to the recommended angle (75.5°). The instrumental methods were the most accurate, with not significantly different results (p > 0.05), and averages of 75.4° for the multimodal indicator and 75.8° for the bubble indicator.

Table 1.

ANOVA table for dependent variables Angle and Time.

| Effect | Num DF | Den DF | Angle (deg)

|

Time (sec)

|

||

|---|---|---|---|---|---|---|

| F-value | Pr > F | F-value | Pr > F | |||

| Experience (Experienced, Inexperienced) | 1 | 38 | 0.73 | 0.3987 | 0.09 | 0.7686 |

| Method (Control, Anthro, Bubble, Mutimodal) | 3 | 114 | 451.56 | <0.0001 | 416.47 | <0.0001 |

| Ladder (16′, 24′) | 1 | 38 | 156.98 | <0.0001 | 124.52 | <0.0001 |

| State (Retracted, Extended) | 1 | 38 | 209.07 | <0.0001 | 49.12 | <0.0001 |

| Experience*Method | 3 | 114 | 0.56 | 0.6448 | 2.31 | 0.0799 |

| Experience*Ladder | 1 | 38 | 1.86 | 0.1807 | 0.47 | 0.4956 |

| Experience*State | 1 | 38 | 1.54 | 0.2226 | 0.02 | 0.8912 |

| Method*Ladder | 3 | 117 | 28.57 | <0.0001 | 8.32 | <0.0001 |

| Method*State | 3 | 117 | 26.65 | <0.0001 | 0.62 | 0.6004 |

| Ladder*State | 1 | 39 | 23.85 | <0.0001 | 27.34 | <0.0001 |

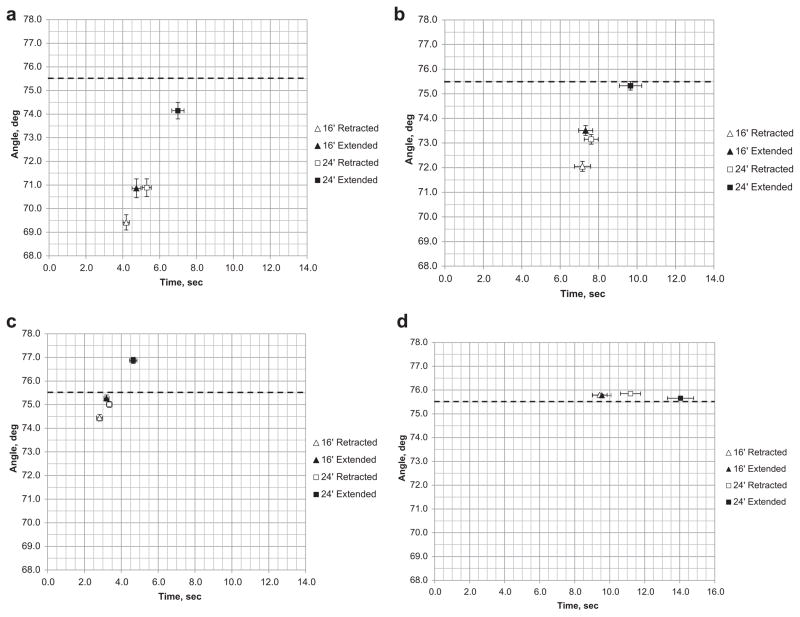

Fig. 4.

Average effects of Method on Angle and Time. Dashed line represents the standard recommended value of ladder inclination (75.5°); error bars indicate standard error.

Shorter and retracted ladders were consistently positioned at shallower angles as compared to longer and extended ladders. The effects of the Ladder and State variables and the corresponding angle ranges were different among the different methods. The “no instruction” method was the most strongly affected by Ladder and State variables – the range between the average angle values for the shortest (16 ft retracted) and the longest (24 ft extended) ladder condition was 69.4°–74.1° (Fig. 5a). The anthropometric method was also strongly affected by these variables – with averages range of 72.0°–75.3° (Fig. 5b). The application of the multimodal indicator resulted in a considerably reduced average range of 74.4°–76.8°, while the bubble indicator was extremely accurate with an average range of 75.7°–75.9° (Fig. 5c, d).

Fig. 5.

Effects of Ladder and State variables on Angle and Time. a. No-instruction method. b. Anthropometric method. c. Multimodal indicator. d. Bubble indicator. Dashed line represents the standard recommended value of ladder inclination (75.5°); error bars indicate standard error.

Overall, there was no significant difference in positioning angle accuracy between experienced and inexperienced ladder users (p = 0.3987), nor the interaction effects of experience with method (p = 0.6448), ladder (p = 0.1807), and state (p = 0.2226) (Table 1).

3.3. Time

The factors Method, Ladder, and State, as well as, the interactions of Method and Ladder, and Ladder and State were all significant (p < 0.001) with respect to time (Table 1). Positioning a ladder by the “no-instruction” method required on average 5.3 s (Fig. 4). The anthropometric method required on average about 7.9 s, i.e., 50% longer than the no-instruction. The bubble indicator was the slowest method with an average of 11.1 s, more than double the time of the no-instruction. The multimodal indicator was the fastest method with an average time of 3.5 s – a 33% reduction from the time of the no-instruction method.

Overall, shorter ladders and retracted ladders required less time for positioning as compared to longer ladders and extended ladders. The effects of the Ladder and State variables and the corresponding positioning time ranges were different among the different methods. The time range between the fastest (16 ft retracted) and the slowest (24 ft extended) was 4.2–7.0 s when using the “no instruction” method (Fig. 5a). The overall slower anthropometric method had a time range of 7.2–9.7 s between the different ladders and ladder extended positions (Fig. 5b). The bubble indicator method, in addition to being on average the slowest, had the largest time range 9.5–14.1 s (Fig. 5c), while the multimodal indicator method, in addition to being on average the fastest, had the lowest time range 2.8–4.7 s between the average time for 16 ft retracted and the 24 ft extended conditions (Fig. 5d).

Finally, there was no significant difference in positioning performance time between experienced and inexperienced ladder users (p = 0.7686), nor the interaction effects of experience with method (p = 0.0799), ladder (p = 0.4956), and state (p = 0.8912) for all of the tested conditions (Table 1).

4. Discussion

The comparative evaluation of the ladder positioning methods supported the study hypothesis that the multimodal ladder angle indicator significantly improved both the accuracy and the efficiency of the ladder angular positioning task, as compared to the “no instruction” method and the standard anthropometric method, and that it was also significantly faster than the bubble indicator method.

With the no-instruction method, the participants positioned the ladders at an average of 3–4° less than the 75.5° recommended in the ladder-safety standards. These findings are consistent with those of Irvine and Vejvoda (1977), and Dewar (1977). Other studies have reported values 7–9° less than the recommended (Hakkinen et al., 1988; Morse et al., 1999; Young and Wogalter, 2000). These results demonstrate the consistent ladder user positioning tendency for shallower-than – recommended ladder angles. Dewer (1977) reasoned that at steeper ladder angles (75° vs. 65°), there is an increased feeling of insecurity from falling backwards, increased awkwardness in climbing the ladder, and a greater risk of stumbling. To overcome these behavioral deterrents to achieving the recommended ladder angle, a training, strategy, or assistance device may be needed.

The anthropometric method considerably improved ladder positioning angle (2.2° increase) as compared to the no-instruction method. It should be pointed out, however, that the use of the anthropometric method in this study (Fig. 4) was associated with relatively large variability (SD = 2.41°) with 95% confidence interval of 67.6°–79.2°. The larger variability and underperformance of the anthropometric method may be explained in part by anthropometric differences and by the significant effect of ladder effective length, as defined by ladder size and ladder extended state (Simeonov et al., 2012a). Smaller ladders with shorter working lengths were generally positioned at shallower angles. In addition, some ladder users seemed to first position the ladder according to their perceptions (close to the shallower angle in the no-instruction method) and then instead of making corrections tried to adjust their posture to the ladder position (Simeonov et al., 2012a). Enhanced instructions and improved training procedures for the anthropometric method, i.e., to avoid body leaning and ensure correct posture, may improve its positioning accuracy.

The anthropometric method also required longer time (by 2.5 s on average) for positioning than the “no-instruction” method. This should be expected since the anthropometric method involves an iterative check-and-correct procedure that could take more than one adjustment trial.

The angular positioning accuracy and the low variability (SD = 0.35°) associated with the bubble indicator method in this study (Fig. 4) are consistent with the findings of previous studies using a bubble level (Young and Wogalter, 2000) and a plumb bob device (Bloswick and Crookston, 1992). As demonstrated in this study, the bubble indicator method, involving several iterative adjustments, required considerably longer (by 6.3 s on average) adjustment times, which was more than twice longer than the no-instruction method. The longer adjustment times, perceived as a reduction of productivity can be a barrier for implementation. It also has been reported that bubble devices could be damaged under the harsh treatments that ladders often receive during their lifecycle (Young and Wogalter, 2000).

The multimodal indicator method improved both the accuracy and the efficiency of the ladder positioning task. The average positioning angle of 75.4° nearly perfectly matched the standard recommended angle while the average positioning time of 3.5 s was significantly faster than that of the no-instruction method (5.3 s) and the anthropometric method (7.9 s). In addition, the multimodal indicator method was less affected by ladder size and ladder extended state, with a corresponding small average range of 74.4°–76.8° (Fig. 5c).

The variability in positioning angle associated with the multimodal prototype device (SD = 1.69°) was larger than that for the bubble indicator method (Fig. 4). In this study the participants were instructed to position the ladder after the very first indication (periodic signal) and not try to achieve a 75.5° angular adjustment (constant signal). For shorter and retracted ladders the participants tended to overshoot (move beyond) the signal which resulted in a shallower angles, while for the longer and extended ladders, which deflected during the adjustments, the signal came slightly earlier and thus lead to steeper angles. Additional refinement of the multimodal device could address these minor technical issues and further improve its overall performance. Possible barriers to a wider implementation and acceptance of such indicator device embedded in the ladder may be the additional upfront cost and the required periodic maintenance (i.e., battery replacement). One promising alternative to a ladder-embedded indicator device, which avoids these barriers, is a hand-held tool in the form of a smart phone application. Finally, the current “proof-of-concept” prototype of the multimodal indicator involves only two modalities – visual and auditory. It could be housed in the ladder rung or in an ergonomically designed grip-handle, allowing the inclusion of the tactile modality, i.e., vibration signals, which may be especially beneficial during ladder positioning involving visual tasks and noisy construction environments.

The lack of significant main effect for Experience in this study is consistent with the findings of Irvine and Vejvoda (1977). It should be noted, however, that in this study both experienced and inexperienced ladder user groups showed relatively low levels of ladder safety standard knowledge.

5. Conclusions

Ladder users typically demonstrate a preference for positioning an extension ladder at a shallower angle than the angle recommended by the current ladder safety standard. This preference is especially pronounced when positioning smaller and lighter ladders, which are significantly more likely to have slide out fall incidents. The current standard anthropometric method for extension-ladder setup remains a valid method for safe ladder positioning when accurately and correctly performed, but is associated with large variability and longer positioning time.

Ladder angle indicators could provide accurate ladder positioning with low variability among tasks and users. However, most often ladder angle indicators require multiple incremental adjustments and thus require considerably longer positioning times, i.e., reduced efficiency. The innovative inclination indicator tested in this study, can improve the accuracy and reduce the time for ladder positioning. The main advantage of this new method is that it provides continuous multimodal feedback on the angle of the device and hence does not require repositioning of the ladder. One potential application of the multimodal device is to train ladder users in setting extension ladders at the correct angle, especially in practicing the current standard anthropometric approach.

A known drawback of most instrumental methods is their durability and reliability, i.e., in surviving the harsh field conditions. Field or laboratory testing on the survivability and reliability of the new and existing ladder angle indicators would provide further insight for safe use with extension ladders. A promising alternative to a ladder-embedded indicator device, which can sustain these barriers, is a hand-held tool in the form of a smart phone application.

Footnotes

Disclaimer

The findings and conclusions in this report are those of the authors and do not necessarily represent the views of the National Institute for Occupational Safety and Health. Mention of the name of any company or product, or inclusion of any reference, does not constitute endorsement by the National Institute for Occupational Safety and Health.

References

- American Ladder Institute (ALI) American National Standards Institute (ANSI) A14.2: American National Standard for Ladders – Portable Metal – Safety Requirements. American Ladder Institute; Chicago, IL: 2000. [Google Scholar]

- Bloswick DS, Crookston G. The effect of personal, environmental and equipment variables on preferred ladder slant. In: Kumar S, editor. Advances in Industrial Ergonomics and Safety IV. Taylor and Francis; 1992. pp. 1015–1020. [Google Scholar]

- Chang WR, Chang CC, Matz S, Son DH. Friction requirements for different climbing conditions in straight ladder ascending. Safety Science. 2004;42:791–805. [Google Scholar]

- Dewar ME. Body movements in climbing a ladder. Ergonomics. 1977;20(1):67–86. doi: 10.1080/00140137708931602. [DOI] [PubMed] [Google Scholar]

- Häkkinen KK, Pesonen JP, Rajamäki E. Experiments on safety in the use of portable ladders. Journal of Occupational Accidents. 1988;10:1–9. [Google Scholar]

- Hepburn HA. Portable ladders: the quarter length rule. The British Journal of Industrial Safety. 1958;4(46):155–158. [Google Scholar]

- Hsiao H, Simeonov P, Pizatella T, Stout N, McDougall V, Weeks J. Extension-ladder safety: solutions and knowledge gaps. International Journal of Industrial Ergonomics. 2008;38(11–12):959–965. [Google Scholar]

- International Labor Office (ILO) Model Code of Safety Regulations for Industrial Establishments for the Governance of Governments and Industry, Regulation 211: “Equipment and tools”. International Labor Office; Geneva, Switzerland: 1949. p. 403. [Google Scholar]

- Irvine CH, Vejvoda MV. An investigation of the angle of inclination for setting non-self-supporting ladders. Professional Safety. 1977 Jul 34–39 [Google Scholar]

- Marby EL. Ladder Level Indicator. 2008/0006479. US Patent Application. 2008

- Morse JS, Ryan LD, Henrikson E. Minimizing Extension Ladder Slide-out Accidents. ASAE/CSAE Annual International Meeting; 1999, July 18–21; Toronto, Canada. 1999. [Google Scholar]

- Pesonen JP, Häkkinen KK. Evaluation of safety margin against slipping in a straight aluminum ladder. Hazard Prevention. 1988;24:6–13. [Google Scholar]

- Rivers P, Diggle F., III Angle Meter and Spirit Level. 7392593. US Patent. 2008

- Scallo JP. Angle Indicator for a Ladder. 2004/0158998 A1. US Patent Application. 2004

- Simeonov P, Hsiao H, Kim IJ, Powers J, Kau TY. Factors affecting extension ladder angular positioning. Human Factors. 2012a;54:334–345. doi: 10.1177/0018720812445805. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Simeonov P, Hsiao H, Powers J. Multimodal Indicator Safety Device for Ladder Positioning. 8167087. US Patent. 2012b

- Thomiszer HJ. Indicating Device for Ladders. 2845719. US Patent. 1958

- Young SL, Wogalter MS. On improving set-up angle accuracy for extension ladders. Proceedings of the IEA 2000/HFES 2000 Congress; San Diego, CA. 2000. [Google Scholar]