Abstract

Introduction: Resin cements are generally preferred for cementation of zirconia ceramics. Resin bonding of zirconia ceramics cannot be done with the same methods of traditional ceramics because zirconia is a silica-free material. In recent years, many methods have been reported in the literature to provide the resin bonding of zirconia ceramics. The purpose of this in vitro study is to evaluate effects of different surface treatments and 10-metacryloxydecyl dihydrogen phosphate (MDP) monomer on shear bond strength between zirconia and resin cement.

Methods: 120 zirconia specimens were treated as follows: Group I: sandblasting, group II: sandblasting + tribochemical silica coating + silane, group III: sandblasting + Nd:YAG (neodymium: yttrium-aluminum-garnet) laser. One specimen from each group was evaluated under scanning electron microscope (SEM). Specimens in each group were bonded either with conventional resin cement Variolink II or with a MDP containing resin cement Panavia F2.0. Subgroups of bonded specimens were stored in distilled water (37°C) for 24 hours or 14 days. Following water storage shear bond strength test was performed at a crosshead speed of 1 mm/min in a universal test machine. Then statistical analyses were performed.

Results: Highest shear bond strength values were observed in group II. No significant difference between group I and III was found when Panavia F2.0 resin cement was used. When Variolink II resin cement was used group III showed significantly higher bond strength than group I. In group I, Panavia F2.0 resin cement showed statistically higher shear bond strength than Variolink II resin cement. In group II no significant difference was found between resin cements. No significant difference was found between specimens stored in 37°C distilled water for 24 hours and 14 days. In group I surface irregularities with sharp edges and grooves were observed. In group II less roughened surface was observed with silica particles. In group III surface microcracks connecting each other were observed.

Conclusion: Tribochemical silica coating is an effective method for achieving an acceptable bond between zirconia and resin cement. Use of a MDP monomer containing resin cement increases the bond strength of sandblasted zirconia.

Keywords: Zirconia, Resin cement, Bond strength

Introduction

In recent years, zirconia ceramics have attracted great attention for use in oral rehabilitation.1 Its properties, such as high mechanical strength, flexural resistance, and long term stability make zirconia ceramics ideal for esthetic crowns, bridges, and frameworks in the anterior and posterior region.2 The mechanical properties of zirconia ceramics are considerably higher than other dental ceramics.3 Its flexural strength is 900-1200 MPa, fracture toughness is 9-10 MPa,4,5 compressive strength is 2000 MPa6 and young modulus is 210 GPa.4,5,7

The high strength and fracture toughness of zirconia arise from the partially stabilized structure of zirconia. When a crack is formed, tensile stresses at the crack tip induce transformation of tetragonal zirconium oxide form in to the monoclinic form. As a result of this transformation a local volume increase is observed. This volume increase leads to compressive stresses around the crack tip which counteract the external tensile stresses at the crack tip. This physical property of zirconia is transformation toughening.4

Although improved mechanical properties are important for the long-term performance of ceramic materials, the clinical success of the restoration also strongly depends on the cementation procedure.3,8 Zirconia restorations can be bonded to teeth structures by conventional cements and resin cements9 however resin cements are more preferred because they have the advantages of marginal seal, good retention and improvement of fracture resistance of ceramic materials.10 With certain resin bonding of ceramic materials, fewer tooth tissues would be removed, more tooth structure would be preserved and more durable restorations would be performed with short clinic crowns.11

There is a common thought that conventional methods of adhesive cementation, which include prior acid etching of the ceramic surface with hydrofluoric acid and further silanation, are not efficient for zirconia ceramics, because zirconia do not include silica and glass phase in its structure.3 Therefore in order to achieve an exceptional bonding between resin cements and zirconia surface, the bonding area of zirconia must be increased and an active surface must be produced. Sandblasting, tribochemical silica coating, acid etching, plasma spraying, low-fusing porcelain layers, application of a glaze layer, silane application, heat-induced maturation-selective etching techniques, and lasers have been evaluated on zirconia restorations as surface treatment methods.12

Sandblasting with Al2O3 particles is commonly used surface treatment method for achieving resin bonding of zirconia ceramics. The abrasive process of this method removes the contamination layers of the ceramic surface, increases the bonding area and improves flowing of resin cement to the ceramic surface.13 This method also increases the surface energy and wettability but can weaken the ceramic by creating microcracks on the zirconia surface. However it has been shown that resin luting agents heal the minor surface flaws created by sandblasting and strengthen the ceramic.14

To achieve a chemical bond between zirconia and silane agents silica coating techniques are developed. The most common used silica coating technique is tribochemical silica coating which can be used for coating of metal alloys, alumina and zirconia based ceramics with silica. In this technique silica coated alumina particles are driven in to zirconia surface under high pressure and silica is transferred on the ceramic surface. This results in both preparing the surface for silanation and creating micromechanical retention.15

A new treatment protocol to modify zirconia surface and develop roughness is laser etching. Er,Cr:YSGG (erbium, chromium: yttrium-scandium-gallium-garnet), Er:YAG (erbium yttrium aliminum garnet), CO2 (carbon dioxide) and Nd:Yag (neodymium yttrium aluminum garnet) lasers are used for roughening ceramic surfaces in studies.16-19

In recent years 10-metacryloxydecyl dihydrogen phosphate (MDP) monomer containing bonding agents are developed.9,20 MDP is an acidic phosphate monomer which is originally designed to bond to metal oxides and its use has been extended to zirconia.14 It has affinity to metal oxides. Zirconia surface is easily covered with a passive oxide layer which makes zirconia similar to metals. Therefore it can be used for increasing bond strength between zirconia and resin cements.8,21 It has been stated in various studies that use of primers or resin cements containing MDP monomer following sandblasting increases the bond strength of zirconia.22,23

There are various studies comparing different surface treatments and bonding agents but the best method for achieving the bond between zirconia and resin cements is still indefinite. The purpose of this in vitro study was to evaluate the effects of different surface treatment methods and MDP monomer on shear bond strength between zirconia and two different resin cements after 24 hours and 14 days water storage.

Methods

120 (13 × 7.5 × 2.5 mm) zirconia specimens were milled from presintered zirconium oxide blocks (Ice Zirkon, Zirkon-Zahn, Bruneck, Italy [ZrO3; specifications, Y2O3 % 4-6, Al2O3 % 1, SiO2 % max. 0.02, Fe2O3 % max. 0.01, Na2O % max. 0.04]) by using Zirkograph 025 ECO (Zirkonzahn, Bruneck, Italy). The specimens were sintered at 1500°C for 8 hours in a high-temperature sintering furnace for zirconia (Zirkonofen 600/V2, Zirkonzahn, Bruneck, Italy). The final dimensions of the specimens were 10±0.4 mm x 5±0.4 mm x 2±0.3 mm following 20% volumetric shrinkage associated with the sintering. Each specimen was embedded in an autopolymerizing acrylic resin block (Meliodent; Heraeus Kulzer, Armonk, NY) and ground-finished with 600-800-1000-1200 grit silicon carbide abrasives (3M ESPE, St. Paul, MN) under running water on a polishing machine(Metkon Gripo 2V, Bursa, Turkey). All specimens were ultrasonically cleaned in distilled water for 15 minutes before application of surface treatments and then air dried.

Specimens were divided into 3 groups according to the surface treatment performed:

Group I: Specimens in this group were sandblasted with 50 µm Al2O3 particles from a distance of 10 mm perpendicular to the specimen surface at a pressure of 2.5 bar for 15 seconds.

Group II: Specimens in this group were sandblasted with 50 µm Al2O3 particles with the same procedure in group I. Then specimens were tribochemical silica coated by using 30 μm Al2O3 particles coated with silica (Cojet Sand; 3M ESPE AG, Seefeld, Germany). Tribochemical silica coating was performed from a distance of approximately 10 mm and at a pressure of 2.8 bar for 15 seconds. After silica coating a thin layer of silan coupling agent (Monobond S, Ivocalar Vivadent, Schaan, Liechtenstein) was applied to the surfaces of the specimens.

Group III: Specimens in this group were sandblasted with 50 µm Al2O3 particles with the same procedure in group I. Then specimens were coated with graphite and surface of the each specimen was laser irradiated with Nd:YAG laser (Fidelis Plus III Fotona, Ljublgana, Slovenia) by using 300 µm diameter optical fiber tip during 2 minutes. The energy intensity was set at 100 mJ. The output power was 2 W, the repetition rate was 20 Hz and pulse duration was 100 μs. No air or water cooling was used.

Surface characteristics of one specimen in each group was evaluated under a scanning electron microscope (SEM) (JEOL JSM-5600 Scanning Electron Microscope, JEOL Ltd, Tokyo, Japan) with magnification of ×100, ×250, ×500, ×1000, ×2000 and ×5000. Before SEM evaluation specimens were gold sputter coated (Polaron SC 7610 Sputter coater, VG Microtech, East Sussex, England).

After application of surface treatments each group was divided in to two subgroups depending on the luting system applied. Two resin cements were used as follows; MDP containing resin cement Panavia F2.0 (Kuraray, Osaka, Japan) and conventional resin cement Variolink II (Ivoclar, Vivadent AG, Schaan Liechtenstein). Adhesion procedures were performed according to the manufacturer’s recommendations.

Plexiglas tubes were placed in the center of the specimens and resin cements were filled in the tubes with the help of a hand instrument. Then resin cements were light cured from two opposite sides for 40 seconds (Blue Lex LD-105, Monitex Industrial CO, Taipei, Taiwan).

Each resin cement group was divided in two subgroups of ten specimens and stored in in 37°C distilled water either for 24 hours or for 14 days. Following water storage shear bond strength test was performed at a crosshead speed of 1mm/min in a universal test machine (Lloyd-LRX; Lloyd Instruments, Fareham, UK).

Data analysis was performed by using SPSS for Windows, version 11.5 (SPSS Inc., Chicago, IL, United States). Whether the distributions of continious variables were normally or not was determined by Kolmogorov Smirnov test. Levene test was used for the evaluation of homogenity of variances. Data were shown as median (IQR). While, the differences in median shear bond strength levels among surface treatments were compared by Kruskal Wallis test, otherwise, Mann-Whitney U test was applied for comparisons regarding for both resin cements and water storage times. When the p value from Kruskal Wallis test statistics are statistically significant Conover’s non-parametric multiple comparison test was used to know which group differ from which others. A P value less than 0.5 was considered statistically significant. But, for all possible multiple comparisons, the Bonferroni Correction was applied for controlling type 1 error.

Results

Two specimens in group I cemented with Variolink II resin cement was debonded during two weeks water storage and not incorporated in to statistical analyses.

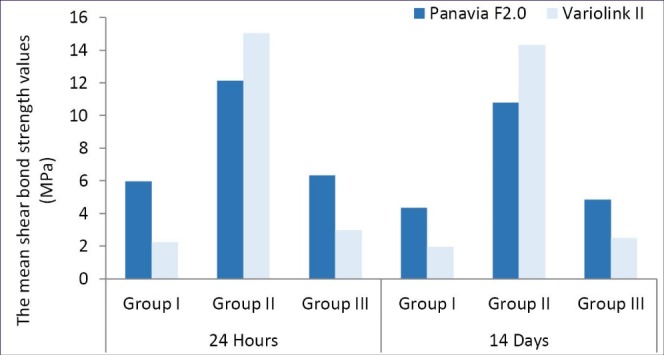

The mean shear bond strength values in MPa is summarized in Table 1 and Figure 1. A significant difference between surface treatments was detected (P < .001).

Table 1 . The Mean Shear Bond Strength Values in MPa .

| 24 Hours | 14 Days | |||

| Panavia F2.0 | Variolink II | Panavia F2.0 | Variolink II | |

| Group I | 5.97 (2.27) A,a | 2.24 (1.05) A,b | 4.35 (3.11) A,a | 1.98 (1.54) A,b |

| Group II | 12.13 (4.69) B,a | 15.05 (11.53) B,a | 10.77 (4.20) B,a | 14.30 (5.56) B,a |

| Group III | 6.32 (3.34) A,a | 2.97 (0.80) C,b | 4.85 (1.90) A,a | 2.51 (1.65) A,a |

Same capital letters in the columns are statistically similar for Bonferroni Correction (P >.0125), Same small letters shows statistically similar resin cements for Bonferroni Correction when water storage times are fixed (P >.0083).

Figure 1 .

The Mean Shear Bond Strength Values in MPa.

Shear bond strengths in group II were statistically higher than both group I and III. No significant difference between group I and III was found when Panavia F2.0 resin cement was used. When Variolink II resin cement was used group III showed significantly higher bond strengths than group I.

In group I, Panavia F2.0 resin cement showed statistically higher shear bond strengths than Variolink II. In group II no significant difference was found between resin cements. In all groups water storage times did not showed statistically significant difference.

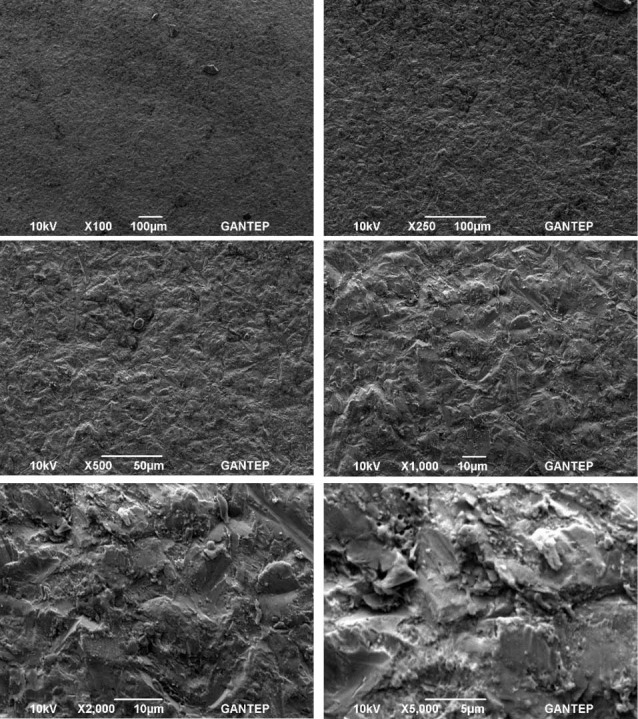

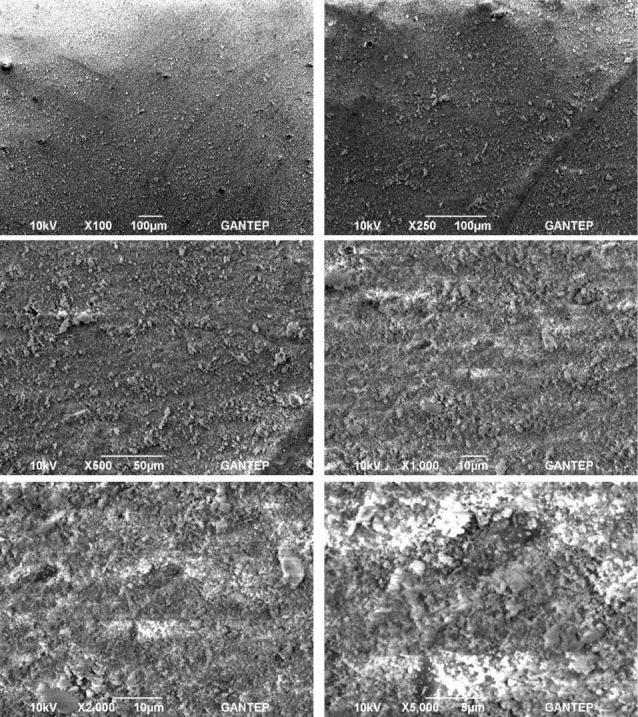

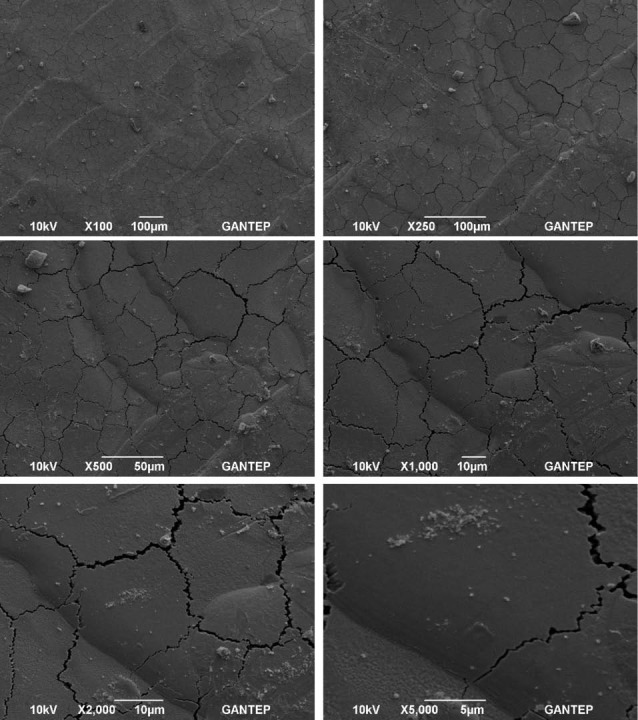

SEM analyses showed that sandblasting caused surface irregularities with sharp edges and grooves (Figure 2). Tribochemical silica coating following sandblasting caused less roughened surface than sandblasting with rounded irregularities and silica particles were observed on the zirconia surface (Figure 3). Nd:YAG laser treatment following sandblasting did not increase surface roughness and caused microcracks connecting each other like a network on the zirconia surface (Figure 4).

Figure 2 .

SEM Images of Group I.

Figure 3 .

SEM Images of Group II.

Figure 4 .

SEM Images of Group III.

Discussion

This study evaluated the effects of three different surface treatment methods and MDP monomer on shear bond strength of zirconia and two resin cements after 24 hours and 14 days water storage. According to the results of this study it can be said that surface treatment method is an effective factor on resin cementation of zirconia ceramics.

Bond strength between two materials can be defined by different test methods. Most common test methods used to evaluate adhesive bonding between two materials are tensile, microtensile and shear bond strength tests.24 Shear bond strength test has easy application procedure because no additional process is required once bonding procedure is completed.25 But this test method has disadvantage of in-homogenous stress distribution.24,26 Microtensile test shows less standard deviation than shear test because small adhesive interface used in microtensile test contains less defects compared larger specimens used in shear test.27 One limitation of this study is shear bond strength test was used because of easy application procedure.

Sandblasting is the most preferred surface treatment method to modify surface of zirconia ceramics14,28 so sandblasting method was used as control group in this study. There are various studies reporting that sandblasting increases the bond strength between zirconia and resin cement.29,30 The increase of bond strength is due to increase in microroughness of sandblasted zirconia surface.13 With a rougher surface, surface area, surface energy, surface wettability and flowing of resin cement in to microretention areas increases so a stronger micromechanical interlock can be achieved.24

In this study tribochemical silica coating group showed higher shear bond strength values than sandblasting group in consistent with previous studies.31-34 Clinically acceptable bond strength is 10-13 MPa.9,35,36 According to the results of this study tribochemical silica coating following sandblasting is an effective method for resin cementation of zirconia ceramics.

There are many disadvantages of existing silica coating methods like forming a too thick silica layer, non-homogenous silica layer or non-stable silica layer.9 It is reported in studies including water aging and thermal cycles that, tribochemical silica coating with silanation increased the initial bond strength between zirconia and resin cement but in long time period a decrease in bond strength values was observed.37 A study which evaluated long term bond strength between zirconia and resin cement after tribochemical silica coating showed that a stable bond was not achieved and this was explained with the fact that the silica particles was not strongly hanged on the zirconia surface.38 Silica is probably deposited on the zirconia surface by physical forces such as Vander-Waals forces which are not stable enough in oral environment.39 The results of Subaşı et al1 and Akyıl et al40 studies support this opinion. They reported that there was no significant difference between bond strength of tribochemical silica coated and sandblasted groups after thermal cycles and water storage.

Surface treatments used for achieving micromechanical retention on the ceramic surface can affect the mechanical properties of ceramics.13 Sandblasting zirconia surface causes phase transformation and can reduce fatigue strength of zirconia.41 Özcan et al42 found that sandblasting with 50 µm Al2O3 decreased fracture strength and Weibull modulus of zirconia and caused increase in monoclinic phase. Tribochemical silica coating technique is based on a sandblasting procedure. In this technique zirconia surface is air abraded with 100 µm or 30 µm silica coated aluminium particles and silica is embedded on to the ceramic surface.41 This procedure can decrease the fracture strength of zirconia,43 however, there are studies reporting that sandblasting and tribochemical silica coating techniques strengthen zirconia ceramics.37,44-46

In previous studies evaluating bond strength between zirconia and resin cement it was observed that Nd:YAG laser treatment combined with sandblasting shows higher shear bond strength values than only Nd:YAG laser treatment40,43 so Nd:YAG laser treatment was applied following sandblasting in this study. Surface conditioning with Nd:YAG laser following sandblasting improved bond strength between zirconia and resin cement compared to only sandblasting when conventional resin cement Variolink II was used. However no significant difference was found between Nd:YAG laser treatment and sandblasting when MDP containing resin cement Panavia F2.0 was used. This result is not in agreement with Üşümez et al47 who evaluated effect of Nd:YAG laser treatment on bond strength of zirconia and resin cement which contains MDP monomer in its application procedure. They found that Nd:YAG laser treatment increased bond strength compared to sandblasting. It can be explained by the higher laser power used in Üşümez et al study. Liu et al2 reported that, it can be concluded that increasing the laser energy can improve bond strength between zirconia and resin cement but high laser energy can lead to surface defects and effect the mechanical properties of zirconia.2

In this study surface of one specimen from each surface treatment group was evaluated under SEM. SEM analysis of sandblasted and tribochemical silica coated groups were in agreement with previous studies.1,13,14, 21 ,29,30,32,48-50, Sandblasting caused surface irregularities with sharp edges and grooves. Tribochemical silica coating caused less roughened surface with rounded irregularities and silica particles were observed on the surface. Nd:YAG laser treatment following sandblasting did not increased surface roughness and caused microcracks on zirconia surface. Liu et al2 reported similar results but Kırmalı et al51 found Nd:YAG laser treatment following sandblasting increased surface roughness and did not cause microcracks. Increase of surface roughness can be due to larger Al2O3 particles and longer application time of Nd:YAG laser treatment in study of Kırmalı et al. No microcrack formation can be explained by application of laser energy under water cooling.

There is a reaction between phosphate ester monomers and zirconia. This reaction improves resin bonding of zirconia restorations.9 Wegner and Kern38 reported that MDP – a phosphate ester monomer – monomer obtains a durable and water resistant chemical bonding. In studies it is shown that using MDP monomer containing bonding agents increase the bond strength between sandblasted zirconia and resin cement.14,52-57 , So two resin cements were used in this study to evaluate efficiency of MDP monomer and obtained results in sandblasting group are agreement with pervious studies. Use of MDP monomer containing resin cement Panavia F2.0 increased the bond strength with sandblasting. However in the tribochemical silica coated groups use of Panavia F2.0 did not increase the bond strength. According to the results of this study it can be said that when tribochemical silica coating is used as surface treatment technique, use of a MDP monomer containing resin cement is an ineffective factor to improve resin bonding of zirconia so both adhesive and conventional resin cements can be used. In contrast Erdem et al12 reported MDP monomer increased the bond strength of zirconia and resin cement. This can be explained additional sandblasting procedure was applied before tribochemical silica coating in this study and water storage time is longer in study of Erdem et al.

Nothdurft et al58 reported that when adhesive phosphate monomer containing resin cement was used, tribochemical silica coating after sandblasting did not provide increased bond strengths compared to sandblasting. In contrast, when conventional cement was used they found that tribochemical silica coating following sandblasting increased bond strength compared to only sandblasting. So they indicated that additive silica coating of sandblasted zirconia is not necessary with phosphate monomer containing resin cements. In this study application of tribochemical silica coating following sandblasting resulted higher bond strength values both with phosphate monomer containing resin cement and conventional resin cement than only sandblasting.

Restorations are subjected to repeated thermal stresses and mechanical fatigue due to masticatory forces.35 Artificial aging is an important factor to predict intraoral bond strengths.24 One limitation of this study is no thermal cyclic or mechanic fatigue was performed. Specimens were stored in water during 24 hours and 14 days. In studies it is reported that bond strengths generally decreased after aging.23,52,59 In this study no significant difference was observed between water storage times. Water storage times in this study might be too short to allow water saturation of luting cements.

In the limitations of this study, it can be said that use of MDP containing resin cements increase the bond strength of sandblasted zirconia and tribochemical silica coating following sandblasting is an effective method for achieving resin bonding of zirconia ceramics. But long-term performance of tribochemical silica coating method is questionable. Studies including thermal cyclic and long period water storage are needed to observe more objective results. Still there is no consensus on resin bonding of zirconia ceramics. Further studies are needed.

Acknowledgments

The authors wish to express their gratitude to Gazi University for financial support and Gaziantep University for SEM evaluations.

Conflict of Interest

The authors have no conflict of interest to declare.

Please cite this article as follows: Taniş MÇ, Akçaboy C. Effects of different surface treatment methods and MDP monomer on resin cementation of zirconia ceramics an in vitro study. J Lasers Med Sci. 2015;6(4):174-181. doi:10.15171/jlms.2015.15.

References

- 1.Subaşı G, İnan Ö. Evaluation of topographical surface changes and roughness of zirconia after different surface treatments. Lasers Med Sci. 2012;27:735–742. doi: 10.1007/s10103-011-0965-3. [DOI] [PubMed] [Google Scholar]

- 2.Liu L, Liu S, Song X, Zhu Q, Zhang W. Effect of Nd:YAG laser irradiation on surface properties and bond strength of zirconia ceramics. Lasers Med Sci. 2013;7:1381–1387. doi: 10.1007/s10103-013-1381-7. [DOI] [PubMed] [Google Scholar]

- 3.Calvalcanti AN, Foxton RM, Watson TF, Oliveira MT, Giannini M, Marchi GM. Bond strength of resin cements to a zirconia ceramic with different surface treatments. Oper Dent. 2009;34(3):280–287. doi: 10.2341/08-80. [DOI] [PubMed] [Google Scholar]

- 4.Raigrodski AJ. Contemporary materials and technologies for all- ceramic fixed partial dentures: a review of the literature. J Prosthet Dent. 2004;92:557–562. doi: 10.1016/j.prosdent.2004.09.015. [DOI] [PubMed] [Google Scholar]

- 5.Komine F, Blatz MB, Matsumura H. Current status of zirconia-based fixed restorations. J Oral Sci. 2010;52(4):531–539. doi: 10.2334/josnusd.52.531. [DOI] [PubMed] [Google Scholar]

- 6.Manicone PF, Lommetti PR, Raffaelli L. An overview of zirconia ceramics: Basic properties and clinical aplications. J Dent. 2007;35:819–826. doi: 10.1016/j.jdent.2007.07.008. [DOI] [PubMed] [Google Scholar]

- 7.Özkurt Z, Kazazoğlu E. Clinical success of zirconia in dental applications. J Prosthodont. 2010;19:64–68. doi: 10.1111/j.1532-849X.2009.00513.x. [DOI] [PubMed] [Google Scholar]

- 8.Gomes AL, Ramos JC, Reigo SS, Montero J, Albaladejo A. Thermocycling effect on microshear bond strength to zirconia ceramic using Er:YAG and tribochemical silica coating as surface conditioning. Lasers Med Sci. 2015;30(2):787–795. doi: 10.1007/s10103-013-1433-z. [DOI] [PubMed] [Google Scholar]

- 9.Chen C, Kleverlaan C, Feilzer AJ. Effect of an experimental zirconia-silica coating technique on microtensile bond strength of zirconia in different priming conditions. Dent Mater. 2012;28:127–134. doi: 10.1016/j.dental.2012.04.020. [DOI] [PubMed] [Google Scholar]

- 10.Oba Y, Koizumi H, Nakayama D, Ishii T, Akazawa N, Matsumura H. Effect of silane and phosphate primers on the adhesive performance of a tri-n-butylborane initiated luting agent bonded to zirconia. Dent Mater J. 2014;33(2):226–232. doi: 10.4012/dmj.2013-346. [DOI] [PubMed] [Google Scholar]

- 11.Akın H, Özkurt Z, Kırmalı Ö, Kazazoglu E, Ozdemir AK. Shear bond strength of resin cement to zirconia ceramic after aluminum oxide sandblasting and various laser treatments. Photomed Laser Surg. 2011;29(12):797–802. doi: 10.1089/pho.2011.3039. [DOI] [PubMed] [Google Scholar]

- 12.Erdem A, Akar GC, Erdem A, Kose T. Effect of different surface treatments on bond strength between resin cements and zirconia ceramics. Oper Dent. 2014;39(3):118–127. doi: 10.2341/12-420-l. [DOI] [PubMed] [Google Scholar]

- 13.Demir N, Subaşı MG, Öztürk N. Surface roughness and morphological changes of zirconia following different surface treatments. Photomed Laser Surg. 2012;30(6):339–345. doi: 10.1089/pho.2011.3213. [DOI] [PubMed] [Google Scholar]

- 14.Blatz MB, Sadan A, Martin J, Lang B. In vitro evaluation of shear bond strengths of resin to densly-sintered high purity zirconium oxide ceramic after long term storage and termal cycling. J Proshet Dent. 2004;91:356–62. doi: 10.1016/j.prosdent.2004.02.001. [DOI] [PubMed] [Google Scholar]

- 15.Thompson JY, Stoner BR, Piascik JR, Smith R. Adhesion/cementation to zirconia and other non-silicate ceramics: where are we now? Dent Mater. 2011;27:71–82. doi: 10.1016/j.dental.2010.10.022. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 16.Cvikl B, Moser G, Wernish J, Raabe M, Gruber R, Moritz A. The impact of Er,Cr:YSGG laser on the shear strength of the bond between dentin and ceramic dependent on the adhesive material. Lasers Med Sci. 2011;27:717–722. doi: 10.1007/s10103-011-0963-5. [DOI] [PubMed] [Google Scholar]

- 17.Ural Ç, Külünk T, Külünk Ş, Kurt M. The effect of laser treatment on bonding between zirconia ceramic surface and resin cement. Acta Odon Scan. 2010;68:354–359. doi: 10.3109/00016357.2010.514720. [DOI] [PubMed] [Google Scholar]

- 18.Akin H, Tugut F, Akin GE, Guney U, Mutaf B. Effect of Er:YAG laser application on the shear bond strength and microleakage between resin cements and Y-TZP cermic. Lasers Med Sci. 2012;27:333–338. doi: 10.1007/s10103-011-0883-4. [DOI] [PubMed] [Google Scholar]

- 19.Öztoprak MO, Tozlu M, İşeri U, Ulkur F, Arun T. Effects of different application durations of scanning laser method on debonding strength of laminate veneers. Lasers Med Sci. 2012;27(4):713–716. doi: 10.1007/s10103-011-0959-1. [DOI] [PubMed] [Google Scholar]

- 20.Tanaka R, Fujishima A, Shibata Y, Manabe A, Miyazaki T. Cooperation of phosphate monomer and silica modification on Zirconia. J Dent Res. 2008;87:666–670. doi: 10.1177/154405910808700705. [DOI] [PubMed] [Google Scholar]

- 21.Yun JY, Ha SR, Lee JB, Kim SH. Effect of sanblasting and various metal primers on the shear bond strength of resin cement to Y-TZP ceramic. Dent Mater. 2010;26:650–8. doi: 10.1016/j.dental.2010.03.008. [DOI] [PubMed] [Google Scholar]

- 22.Shin YJ, Shin Y, Yi YA. et al. Evaluation of the shear bond strength of resin cement to Y-TZP ceramic after different surface treatments. Scanning. 2014;36(5):479–486. doi: 10.1002/sca.21142. [DOI] [PubMed] [Google Scholar]

- 23.Wolfart M, Lehmann F, Wolfart S, Kern M. Durability of resin bond strength to zirconia ceramic after using different surface conditioning methods. Dent Mater. 2007;23:45–50. doi: 10.1016/j.dental.2005.11.040. [DOI] [PubMed] [Google Scholar]

- 24.Papia E, Larsson C, Toit M, Steyern PV. Bonding between oxide ceramics and adhesive cement systems: a systematic review. J Biomed Mater Res B: Appl Biomater. 2013;102(2):395–413. doi: 10.1002/jbm.b.33013. [DOI] [PubMed] [Google Scholar]

- 25.Inokoshi M, Kameyema A, Munck JD, Minakuchi S, Meerbeek BV. Durable bonding to mechanically and/or chemically pre-treated dental zirconia. J Dent. 2013;41:170–9. doi: 10.1016/j.jdent.2012.10.017. [DOI] [PubMed] [Google Scholar]

- 26.Amaral M, Beli R, Cesar PF. et al. The potential of novel primers and universal adhesives to bond to zirconia. J Dent. 2014;42:90–98. doi: 10.1016/j.jdent.2013.11.004. [DOI] [PubMed] [Google Scholar]

- 27.Sano H, Shono T, Sonoda H. et al. Relationship between surface area for adhesion and tensile bond strength — Evaluation of a micro-tensile bond test. Dent Mater. 1994;10(4):236–240. doi: 10.1016/0109-5641(94)90067-1. [DOI] [PubMed] [Google Scholar]

- 28.Zandsparsa R, Talua NA, Finkelman MD, Schaus SE. An in vitro comparison of shear bond strength of zirconia to enamel using different surface treatments. J Prosthodont. 2013;23(2):117–123. doi: 10.1111/jopr.12075. [DOI] [PubMed] [Google Scholar]

- 29.Oyagüe RC, Monticelli F, Toledano M, Osorio E, Ferrari M, Osorio R. Influence of surface treatments and resin cement selection on bonding to densely-sintered zirconium-oxide ceramic. Dent Mater. 2009;25:172–179. doi: 10.1016/j.dental.2008.05.012. [DOI] [PubMed] [Google Scholar]

- 30.Torres SMP, Borges GA, Spohr AM, Cury AA, Yadav S, Platt JA. The effect of surface treatments on the microshear bond strength of a resin luting agent and four all-ceramic systems. Oper Dent. 2009;34(4):399–407. doi: 10.2341/08-87. [DOI] [PubMed] [Google Scholar]

- 31.Xible AA, Tavarez RRJ, Araujo CR, Bonachela WC. Effect of silica coating and silanization on flexural strengths of zirconia posts: an in vitro study. J Prosthet Dent. 2006;95:224–229. doi: 10.1016/j.prosdent.2005.12.010. [DOI] [PubMed] [Google Scholar]

- 32.Tsukakoshi M, Shinya A, Gomi H, Lassila LVJ, Vallittu PK, Shinya A. Effects of dental adhesive cement and surface treatment on bond strength and leakage of zirconium oxide ceramics. Dent Mater J. 2008;27(2):159–171. doi: 10.4012/dmj.27.159. [DOI] [PubMed] [Google Scholar]

- 33.Della Bona A, Borba M, Benetti P, Cecchetti D. Effect of surface treatments on the bond strength of a zirconia-reinforced ceramic to composite resin. Braz Oral Res. 2007;21(1):10–15. doi: 10.4012/dmj.27.159. [DOI] [PubMed] [Google Scholar]

- 34.Atsu SS, Kiliçarslan MA, Kucukesmen HC, Aka PS, Sema P. Effect of zirconium-oxide ceramic surface treatments on the bond strength to adhesive resin. J Prosthet Dent. 2006;95:430–436. doi: 10.1016/j.prosdent.2006.03.016. [DOI] [PubMed] [Google Scholar]

- 35.Attia A. Bond strength of three luting agents to zirconia ceramic-influence of surface treatment and termocycling. J App Oral Sci. 2011;19:388–395. doi: 10.1590/S1678-77572011005000015. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 36.Derand P, Derand T. Bond strength of luting cements to zirconium oxide ceramics. Int J Prosthodont. 2000;13(2):131–135. [PubMed] [Google Scholar]

- 37.Queblawi DM, Munoz CA, Brewer JD, Monaco EA Jr. The effect of zirconia surface treatment on flexural strength and shear bond strength to a resin cement. J Prosthet Dent. 2010;103:210–220. doi: 10.1016/S0022-3913(10)60033-9. [DOI] [PubMed] [Google Scholar]

- 38.Kern M, Wegner SM. Bonding to zirconia ceramic: adhesion methods and their durability. Dent Mater. 1998;14:64–71. doi: 10.1016/s0109-5641(98)00011-6. [DOI] [PubMed] [Google Scholar]

- 39.Chen L, Suh BI. Bonding of resin materials to all-ceramics: a review. Curr Res Dent. 2012;3(1):7–17. [Google Scholar]

- 40.Akyıl MŞ, Uzun İH, Bayındır F. Bond strength of resin cement to yttrium-stabilized tetragonal zirconia ceramic treated with air abrasion, silica coating, and laser irradiation. Photomed Laser Surg. 2010;28(6):801–808. doi: 10.1089/pho.2009.2697. [DOI] [PubMed] [Google Scholar]

- 41.Monaco C, Cardelli P, Scotti R, Valandro LF. Pilot evaluation of four experimental conditioning treatments to improve the bond strength between resin cement and Y-TZP ceremic. J Prosthodont. 2011;20:97–100. doi: 10.1111/j.1532-849X.2010.00677.x. [DOI] [PubMed] [Google Scholar]

- 42.Özcan M, Melo RM, Souza RO, Machado JPB, Valandro LF, Botttino MA. Effect of air-particle abrasion protocols on the biaxial flexural strength, surface characteristics and phase transformation of zirconia after cyclic loading. Journal of the Mech Behav Biomed Mater. 2013;20:19–28. doi: 10.1016/j.jmbbm.2013.01.005. [DOI] [PubMed] [Google Scholar]

- 43.Spohr AM, Borges GA, Burnett Junior LH, Mota EG, Oshima HM. Surface modification of In-Ceram Zirconia ceramic by Nd:YAG laser, Rocatec system, or Aluminum oxide sandblasting and its bond strength to aresin cement. Photomed Laser Surg. 2008;26(3):203–208. doi: 10.1089/pho.2007.2130. [DOI] [PubMed] [Google Scholar]

- 44.Aboushelib MN, Wang H. Effect of surface treatment on flexural strength of zirconia bars. J Prosthet Dent. 2010;104:98–104. doi: 10.1016/s0022-3913(10)60100-x. [DOI] [PubMed] [Google Scholar]

- 45.Kosmac T, Oblak C Jevnikar P, Funduk N, Marion L. The effect of surface grinding and sandblasting on flexural strength and reliability of Y-TZP zirconia ceramic. Dent Mater. 1999;15:426–433. doi: 10.1016/s0109-5641(99)00070-6. [DOI] [PubMed] [Google Scholar]

- 46.Scherrer SS, Cattani-Laronte M, Vittecoq E, Mestral F, Griggs A, Wiskott HW. Fatigue behavior in water of Y-TZP zirconia ceramics after abrasion with 30 µm silica-coated alümina particles. Dent Mater. 2011;27:28–42. doi: 10.1016/j.dental.2010.10.003. [DOI] [PMC free article] [PubMed] [Google Scholar]

- 47.Üşümez A, Hamdemirci N, Köroğlu BY. et al. Bond strength of resin cement to zirconia ceramic with different surface treatments. Lasers Med Sci. 2013;28(1):259–266. doi: 10.1007/s10103-012-1136-x. [DOI] [PubMed] [Google Scholar]

- 48.Moon J, Kim S, Lee J, Ha S, Choi Y. The effect of preparation order on the crystal structure of yitria-stabilized tetragonal zirconia polycrystals and shear bond strength of dental resin cements. Dent Mater. 2011;27:651–663. doi: 10.1016/j.dental.2011.03.005. [DOI] [PubMed] [Google Scholar]

- 49.Phark J, Duarte S, Blatz M, Sadan A. An in vitro evaluation of the long-term resin bond to a new densely sintered high purity zirconium-oxide ceramic surface. J Prosthet Dent. 2009;101:29–38. doi: 10.1016/s0022-3913(08)60286-3. [DOI] [PubMed] [Google Scholar]

- 50.Subaşı G, İnan Ö. Influence of surface treatments and resin cement selection on bonding to zirconia. Lasers Med Sci. 2014;29:19–27. doi: 10.1007/s10103-012-1221-1. [DOI] [PubMed] [Google Scholar]

- 51.Kırmalı Ö, Akın H, Kapdan A. Evaluation of the surface roughness of zirconia ceramics after different surface treatments. Acta Odon Scan. 2014;72(6):432–439. doi: 10.3109/00016357.2013.853320. [DOI] [PubMed] [Google Scholar]

- 52.Shahin R, Ker Ker, M M. Effect of air abrasion on the retention of zirconia ceramic crowns luted with different cements before and after artificial aging. Dent Mater. 2010;26:922–928. doi: 10.1016/j.dental.2010.06.006. [DOI] [PubMed] [Google Scholar]

- 53.Akgüngör G, Şen D, Aydın M. Influence of different surface treatments on the short term bond strength and durability between zirconia post and a composite resin core material. J Prosthet Dent. 2008;99:388–399. doi: 10.1016/s0022-3913(08)60088-8. [DOI] [PubMed] [Google Scholar]

- 54.Yang B, Barloi A, Kern M. Influence of air-abrasion on zirconia ceramic bonding using an adhesive composite resin. Dent Mater. 2010;26:44–50. doi: 10.1016/j.dental.2009.08.008. [DOI] [PubMed] [Google Scholar]

- 55.Gomes AL, Oyagüe RC, Lynch CD. et al. Influence of sandblasting granulometry end resin cement composition on microtensile bond strength to zirconia ceramic for dental prosthetic frameworks. J Dent. 2013;41:31–41. doi: 10.1016/j.jdent.2012.09.013. [DOI] [PubMed] [Google Scholar]

- 56.Kim M, Kim YK, Kim K, Kwon T. Shear bond strength of various luting cements to zirconia ceramic: surface chemical aspects. J Dent. 2011;39:795–803. doi: 10.1016/j.jdent.2011.08.012. [DOI] [PubMed] [Google Scholar]

- 57.Kitayama S, Nikaido T, Ikeda M, Alireza S, Miura H, Tagami J. Internal coating of zirconia restoration with silica-based ceramic improves bonding of resin cement to dental zirconia ceramic. Biomed Mater Eng. 2010;20:77–87. doi: 10.3233/BME-2010-0617. [DOI] [PubMed] [Google Scholar]

- 58.Nothdurft EP, Motter PJ, Pospiech PR. Effect of surface treatment on the initial bond strength of different luting cements to zirconium oxide ceramic. Clin Oral Invest. 2009;13:229–235. doi: 10.1007/s00784-008-0222-8. [DOI] [PubMed] [Google Scholar]

- 59.Lung CY, Botelho MG, Heinonen M, Matinlinna JP. Resin zirconia bonding promotion with some novel coupling agents. Dent Mater. 2012;28:863–872. doi: 10.1016/j.dental.2012.04.023. [DOI] [PubMed] [Google Scholar]